Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

135results about How to "Improve technical and economic indicators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

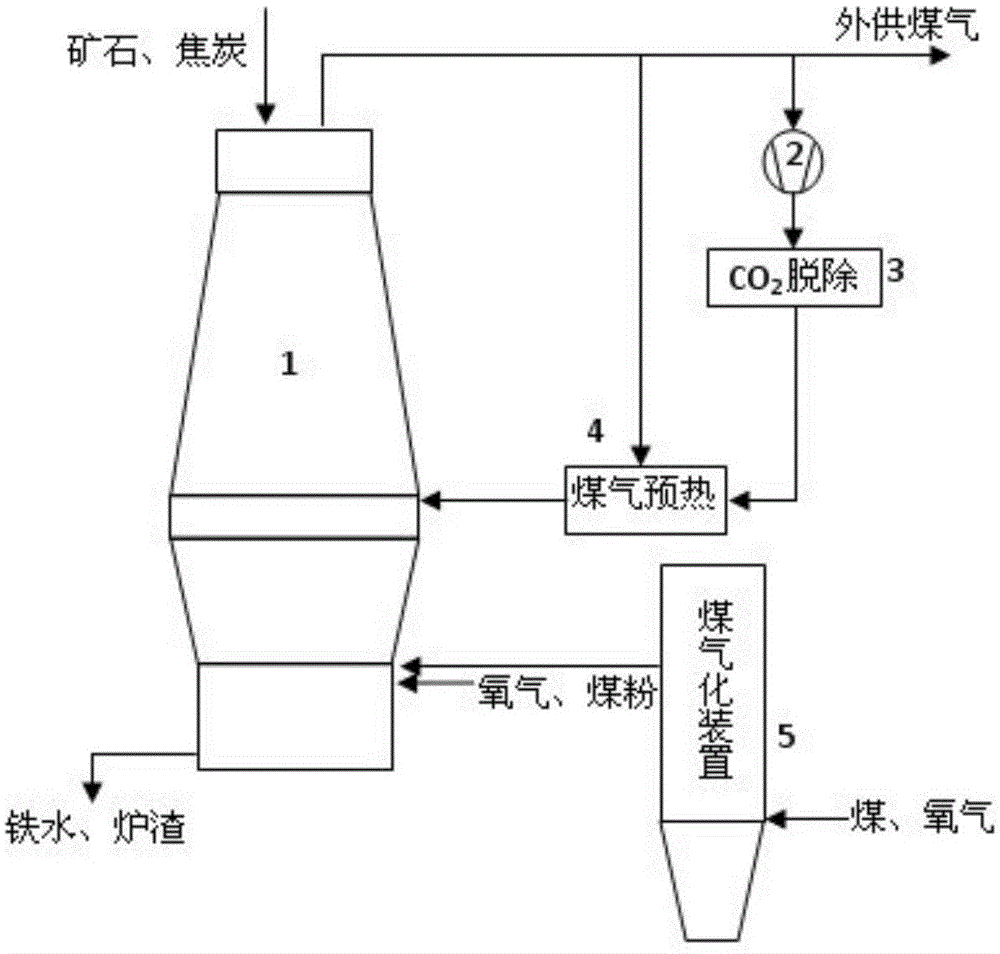

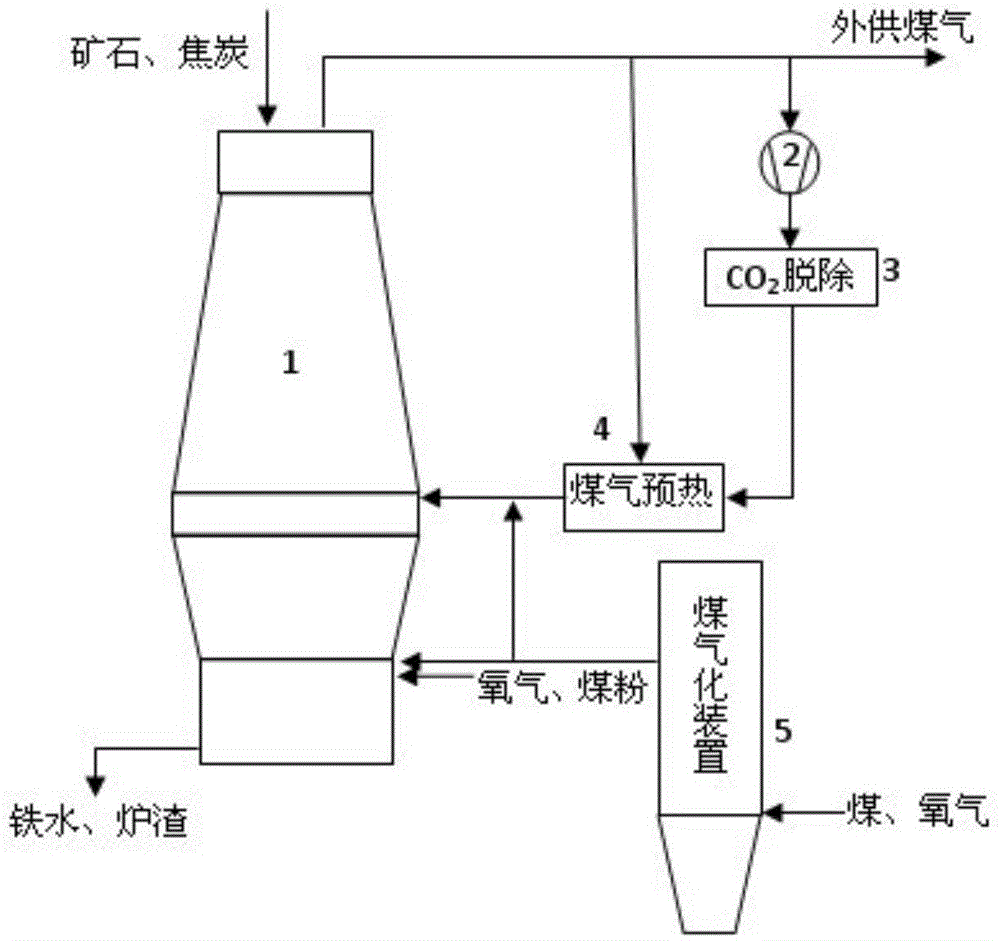

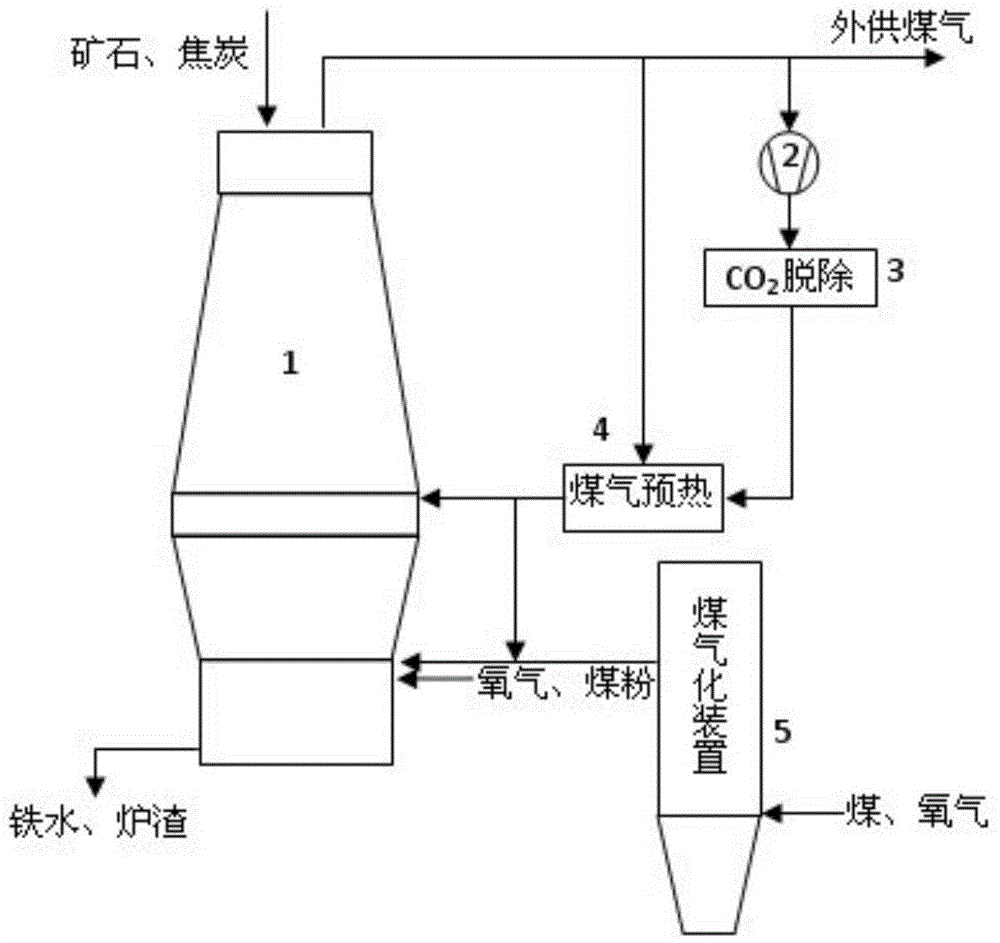

High-temperature gas injection-based iron-making technology

InactiveCN104131122ALower quality requirementsLow priceBlast furnace detailsGas emission reductionCo2 removalCapacity factor

The invention discloses a high-temperature gas injection-based iron-making technology and belongs to the field of black metallurgy. The high-temperature gas injection-based iron-making technology utilizes oxygen-rich normal-temperature air blasting to replace hot air operation, and high-temperature gas produced by a coal gasification device and CO2-free furnace top recycled gas are mixed and are respectively pumped into a blast furnace from the furnace body and the hearth so that furnace top recycled gas CO2 removal is realized. The high-temperature gas injection-based iron-making technology has a coal ratio of 240-350kg / tHM, a coal gasification unit coal-use amount of 50-250kg / tHM and a coke ratio of 180-260kg / tHM and a blast furnace capacity factor of 6.0-7.5, reduces operation costs of oxygen-containing blast furnace top gas CO2 removal and recycled gas pre-heating to a temperature of 900-1300 DEG C, realizes coke reduction and coal use increasing in blast furnace production, improves an iron-making technology energy structure and stabilizes gas balance of a steel enterprise.

Owner:UNIV OF SCI & TECH BEIJING

Sintering method for high-chromic vanadium-titanium ferroferrite

The invention discloses a sintering method of high-chromine typed V-Ti-bearing iron ore, which comprises the following steps: 1) allocating limestone and fined ferric ore to make grain; 2) adding water to wet; 3) putting wet and grained materials into sintering material in the mixer to ball; adding B2O3 in the composite material; 4) adding MgO in the composite material; 5) loading the composite material into sintering cup or sintering machine to sinter over 50 deg.c; increasing the content of calcium ferrite in the sintering ore by 5% and production by 4.2-5.0%.

Owner:PANZHIHUA IRON AND STEEL

Acidic full-vanadium-titanium pellets and preparation method thereof

Owner:PANZHIHUA IRON AND STEEL +1

Lignite drying system and technology with superheated steam capable of recycling waste steam heat

ActiveCN102967121AImprove energy saving and reduce consumptionImprove energy savingDrying solid materials with heatDrying gas arrangementsFluidized bed dryingWater vapor

The invention discloses a lignite drying technology with superheated steam capable of recycling waste steam heat. The lignite drying technology comprises the steps that (1) after raw lignite is fed to an internal-heating fluid bed dryer after being crushed and sieved; (2) saturated steam from a backpressure unit of a factory enters a built-in heat exchanger in the internal-heating fluid bed dryer; the moisture the pulverized lignite is removed through indirect heat exchange; the pulverized lignite that is dried till the moisture content is qualified is discharged from the bottom end of the internal-heating fluid bed dryer; and (3) the saturated steam generates condensate water through the indirect heat exchange; a part of the condensate water is sent to a boiler feed water system; the rest of the condensate water is sent to an evaporator; the steam generated by removing the moisture from the pulverized lignite and fluidized carrier gas are in superheated steam states and are discharged from the top of the internal-heating fluid bed dryer; after the steam and the fluidized carrier gas are dedusted by multiple stages, the steam and the fluidized carrier gas partially return to the internal-heating fluid bed dryer again; and the rest is recycled. Meanwhile, the invention further discloses a system implementing the technology.

Owner:SHANDONG KEYUAN TIANLI ENERGY CONSERVATION ENG

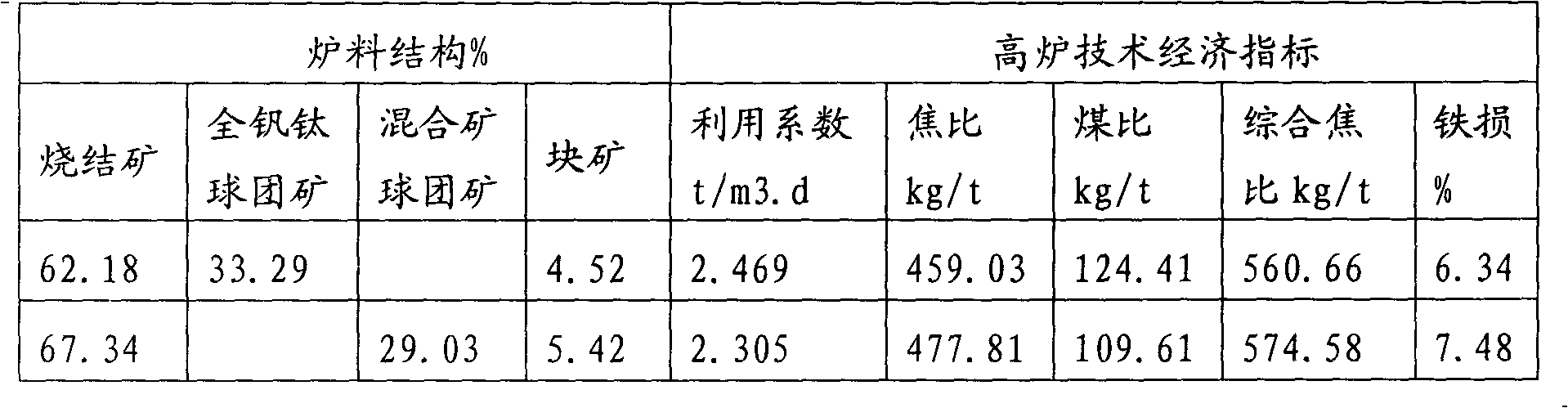

Blast furnace smelting method by using vanadium-titanium two-phase sintering ore

ActiveCN104673951AReduce ironmaking costsImprove utilization factorBlast furnace detailsIronstoneBlast furnace smelting

The invention belongs to the technical field of iron and steel metallurgy, in particular relates to a blast furnace smelting method by using a vanadium-titanium two-phase sintering ore. The blast furnace smelting method by using vanadium-titanium two-phase sintering ore is characterized in that the blast furnace burden structure is as follows: 70-100wt% of vanadium-titanium two-phase sintering ore, 0-30wt% of vanadium titanium magnetite pellet and 0-10wt% of common iron ore, wherein the common iron ore is an iron ore containing no vanadium or titanium. The invention provides the blast furnace smelting method by using vanadium-titanium two-phase sintering ore, and the method is low in cost; vanadium-titanium titanic magnetite for blast furnace smelting is provided by the vanadium-titanium two-phase sintering ore, so as to optimize the blast furnace burden structure, improve the breathability of the blast furnace burden structure and perfect the technical-economic indicator of blast furnace smelting.

Owner:攀钢集团西昌钢钒有限公司

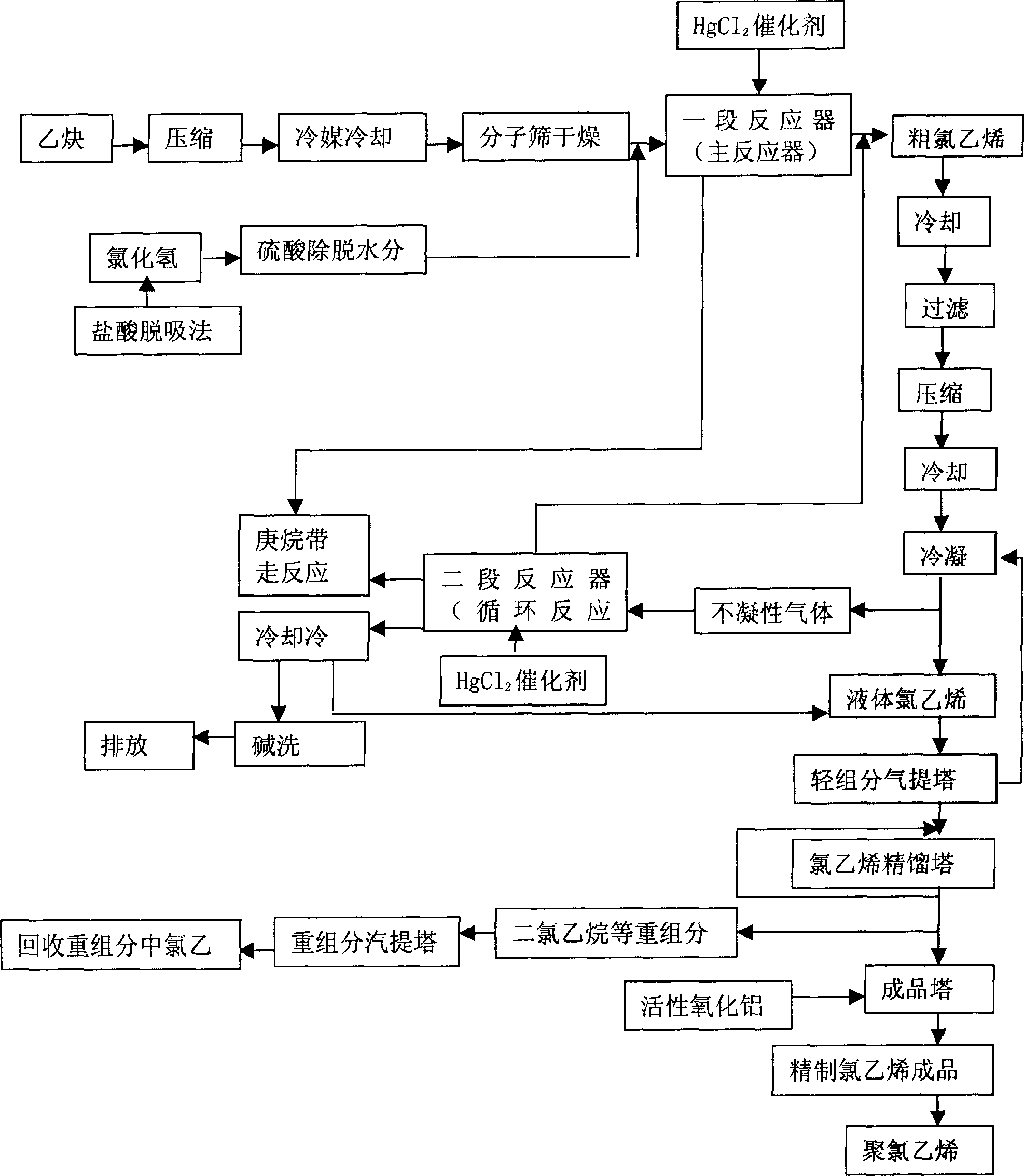

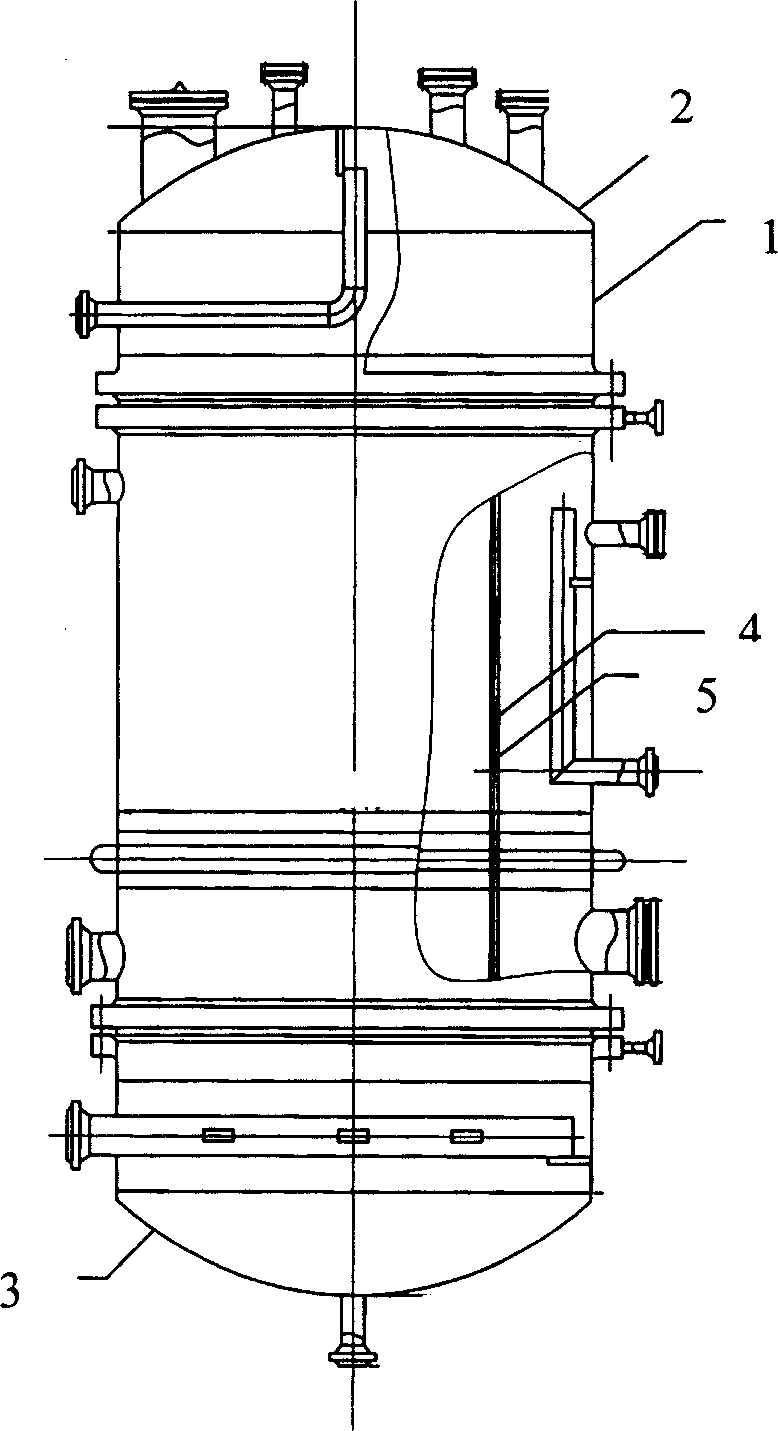

Process for producing vinyl chloride by acetylene method and dedicated device for realizing same

InactiveCN1884241ASmooth responseAvoid corrosionPreparation by halogen halide additionSewage treatmentUltimate tensile strength

The invention discloses a new method of chloroethylene through acetylene method and specific equipment, which comprises the following steps: disposing raw material gas strictly; reacting two-segment compensation; recycling heptane; cooling; radiating; providing specific catalyst and reactor to synthesize chloroethylene; disposing effluent with mercury to obtain high-purity chloroethylene monomer.

Owner:刘大军

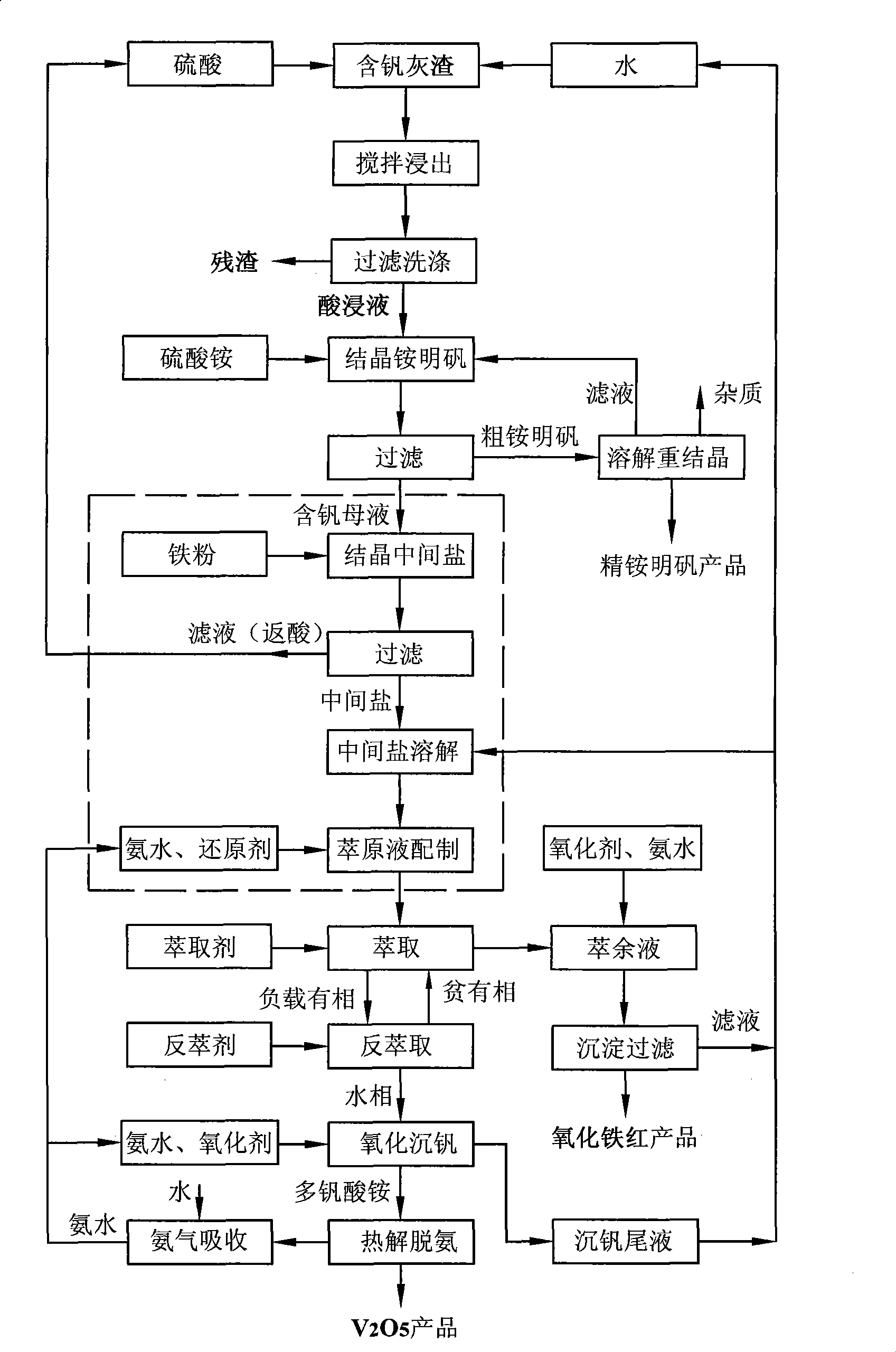

Vanadium pentoxide extraction method by direct acid dipping of stone coal ash containing vanadium

InactiveCN101381103ASimple processImprove the operating environmentVanadium oxidesSlagResource utilization

The invention provides a method for extracting vanadic oxide from vanadiferous stone coal ash slag through direct acid leaching. The method comprises the following steps: an acid leaching solution obtained by the vanadiferous stone coal ash slag through direct acid leaching is added with ammonium sulphate to prepare tschermigite as a byproduct; a vanadiferous mother solution is added with an iron simple substance and is heated, evaporated, condensed and crystallized to form an intermediate salt crystal in order that vanadium is fully enriched in intermediate salt; the intermediate salt is dissolved to prepare an extractive stock solution; the extractive stock solution is subjected to extraction, back extraction, oxidation and vanadium precipitation to prepare ammonium ployvanadate; and the ammonium ployvanadate is subjected to pyrolysis and deamination to prepare a V2O5 product with purity of over 98 percent. The process is wholly operated in a liquid phase and has no pollution by exhaust gas; waste liquid is basically returned to a system for reclaiming and utilization; the discharged waste liquid is little and is easy to treat; the total reclaiming rate of vanadium can reach over 75 percent; simultaneously, aluminum resource in the ash slag can be reclaimed to form the tschermigite as the byproduct; and the yield of the byproduct can reach dozens to hundreds of times of the yield of the V2O5 product. The process has the advantages of good operating condition, high mechanization and automation degree, high resource utilization rate, low comprehensive cost, good benefit and light pollution.

Owner:ZHEJIANG UNIV +1

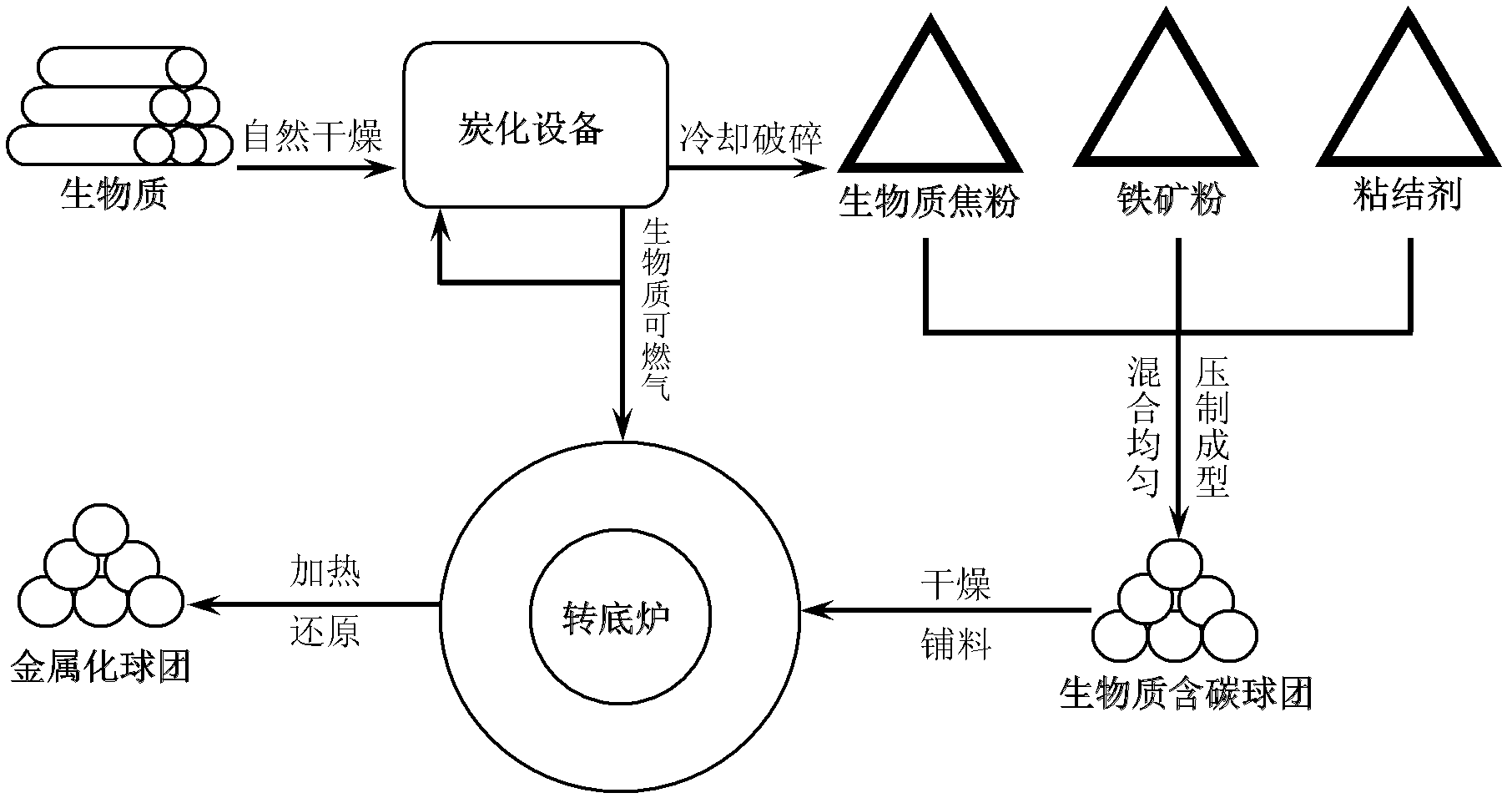

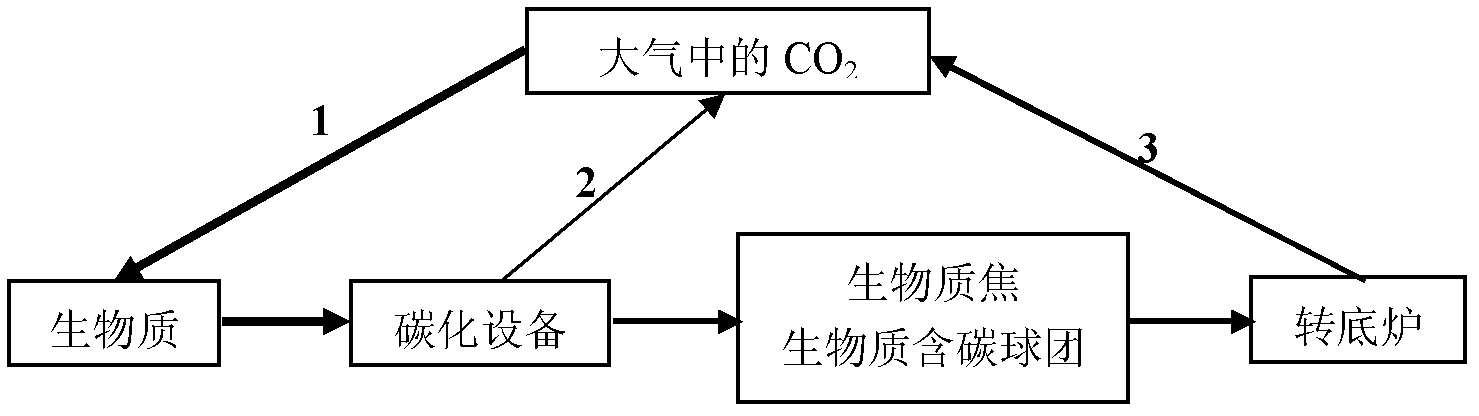

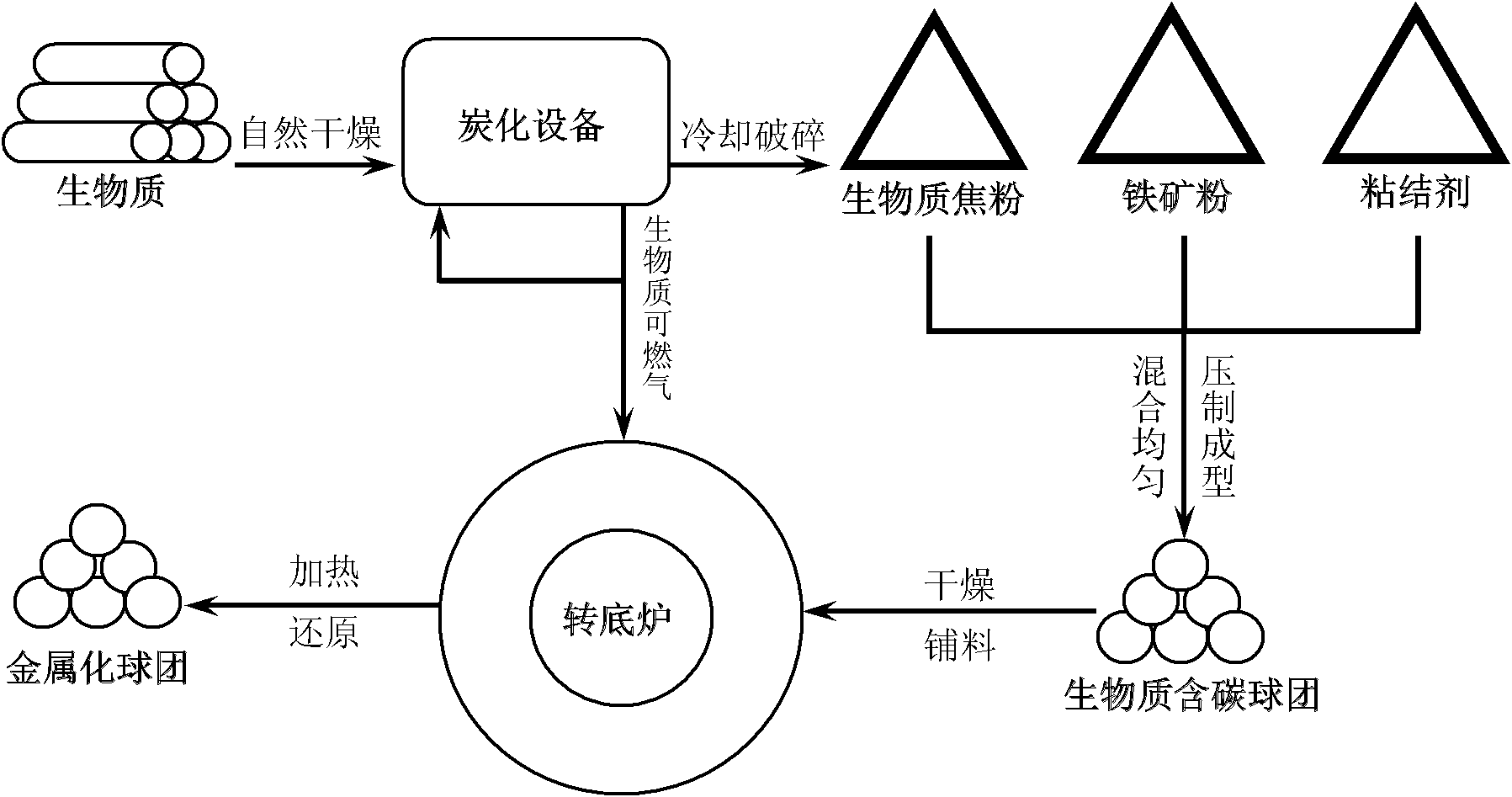

Rotary hearth furnace iron-making method utilizing biomass carbon-containing pellet to serve as raw material

InactiveCN102586529ARealize rational utilizationLarge reservesFluidised-bed furnacesBiomass carbonCoke

A rotary hearth furnace iron-making method utilizing biomass carbon-containing pellets to serve as a raw material belongs to the field of ferrous metallurgy and relates to a rotary hearth furnace iron-making process using the biomass to serve as iron-making fuel and a reducing agent. The process comprises the steps, utilizing reproducible carbon neutral biomass coke powder to replace pulverized coal, enabling the biomass coke powder and the iron ore powder to be matched with each other according to C / O=1.1-1.4, adding an appropriate binder, evenly mixing to make pellets, and enabling the pellets to enter a rotary hearth furnace to be heated and undergo reduction so that a metalized pellet is obtained. The biomass coke has carbon neutral and can fundamentally reduce discharge of pollutantssuch as CO2 caused by coal consumption. The impurity content of the biomass coke is little, the problem that sulphur content of products caused by coal using is too high is solved, and the comprehensive quality of the products is improved. The energy in the preparation process of the biomass coke can be supplied by biomass itself, and green circulating production is substantially achieved. The rotary hearth furnace iron-making method expands energy sources for rotary hearth furnace iron making, reduces production cost, improves product quality and production efficiency and reduces environmental pollution.

Owner:UNIV OF SCI & TECH BEIJING

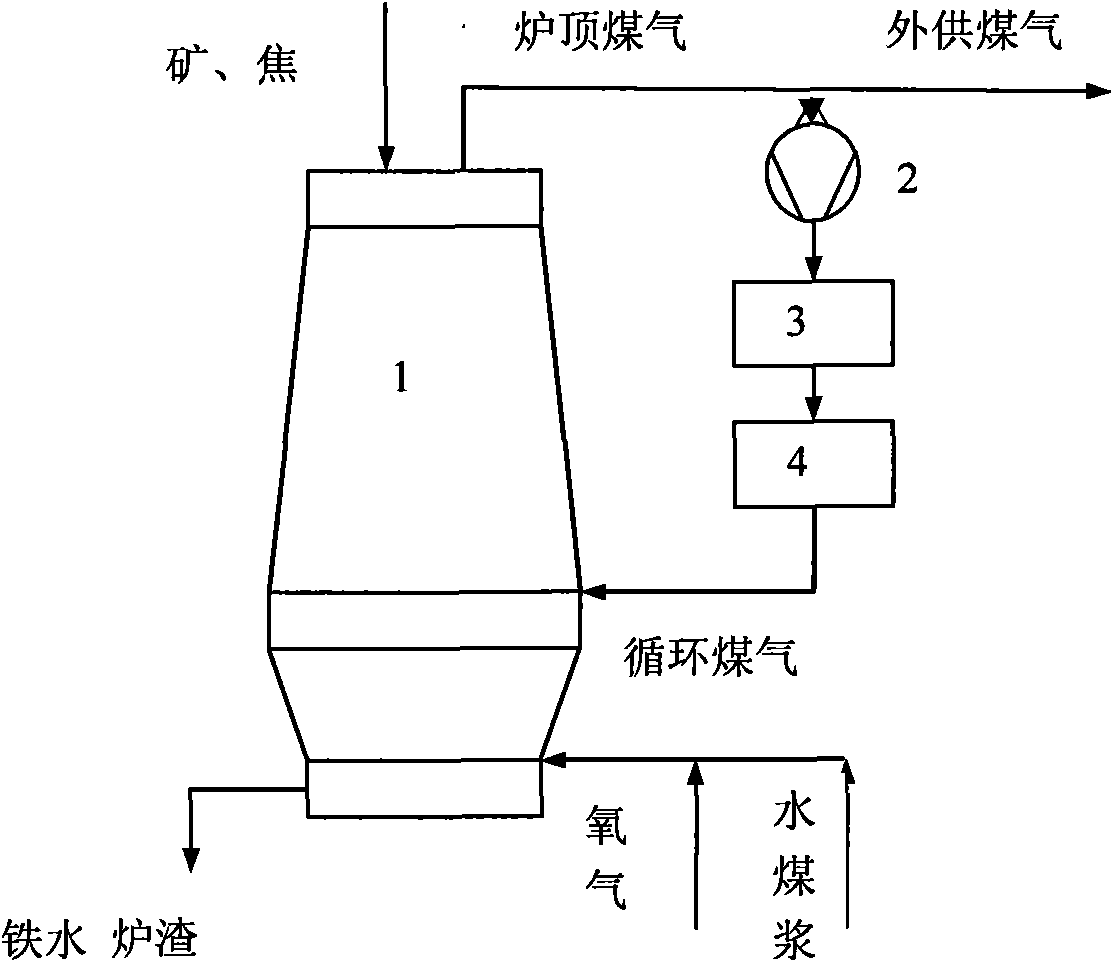

Oxygen blast furnace iron-making process adopting water-coal-slurry as fuel

InactiveCN101555533AImprove productivityReduce adverse effectsBlast furnace detailsDecompositionCoal dust

The invention belongs to the field of ferrous metallurgy and relates to a blast furnace iron-making process using water-coal-slurry as fuel and reducer for iron-making. The process using water-coal-slurry is simple and safe, and the injecting process of water-coal-slurry provides convenience for accurate control and precise measurement. A water-coal-slurry oxygen blast furnace utilizes normal-temperature oxygen and water-coal-slurry as fuel which is injected into the blast furnace so as to partially displace coke and coal dust; the injected amount of oxygen is 200 to 500 Nmt HM, the injected amount of water-coal-slurry is 200 to 400 Nm / t HM, the required weight ratio between coal and water in the water-coal-slurry is 7:3, and the required thermal value of the water-coal-slurry is larger than 20 MJ / kg. The water-coal-slurry is decomposed and burnt to generate water-gas reaction in a circulation zone of a blast-furnace tuyere, the absorbed heat can be adopted to solve the problem of 'lower hot' caused by smelting with prior oxygen blast furnaces, and a large amount of gas generated by the decomposition and burning of the water-coal-slurry raises and can relieve the problem of 'upper cold' caused by the full-oxygen injection of the blast furnace; and the water-coal-slurry oxygen blast furnace contains rich H2 so as to enhance the penetrating power and reduction performance of blast-furnace coal gas, raise the indirect reduction degree of the blast furnace and reduce the emission amount of CO2 by 200 to 500 Nm / t HM. The process reduces both manufacturing cost and pollution to environment.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing intermediate salt during acid leaching and extraction of vanadium pentoxide from vanadium-containing stone coal ash

InactiveCN101381818ASimple methodImprove the operating environmentVanadium oxidesProcess efficiency improvementFiltrationToxic material

The invention provides a preparation dissolution method for intermediate salt during the process of acid leaching extraction of vanadium pentoxide from vanadium-containing stone coal clinker. The method comprises the following steps: the vanadium-containing stone coal clinker undergoes acid leaching, so as to obtain an acid leaching solution; ammonium sulfate is added into the acid leaching solution to separate out tschermigite, so as to obtain a vanadium-bearing mother liquor as a raw material; the vanadium-containing mother liquor and iron elementary substance are added into a reaction vessel, wherein the mass of the iron elementary substance is 1 to 60 percent of that of the vanadium pentoxide in the vanadium-containing mother liquor; the mixture is stirred for full reaction, and is heated, evaporated and concentrated until the concentration of H<+> in the solution is between 18 and 22 mol per liter; after complete crystallization, the solution is cooled to the room temperature, and filtrate and filter residue are obtained through filtration; and the filter residue is taken, and intermediate salt solid is obtained. The method has the advantages that the method is simple; the operating environment is good; the whole process undergoes full-liquid phase operation; no pollution of toxic waste gas exists; more than 98 percent of vanadium in the mother liquor is enriched into the intermediate salt, thereby greatly simplifying the subsequent extraction operation; and a residual acid after preparation of the intermediate salt can be recovered, thereby greatly reducing the cost.

Owner:ZHEJIANG UNIV +1

Method for smelting vanadium-titanium magnetite in blast furnace

ActiveCN102041331AImprove technical and economic indicatorsReduced stabilityBlast furnace detailsFurnace temperatureSlag

The invention provides a method for smelting vanadium-titanium magnetite in a blast furnace, which comprises the following steps of: controlling blast kinetic energy, air quantity and air speed of the blast furnace with different furnace volume in different ranges respectively, and forming an air inlet with the length of 450 to 480mm on the two sides of an iron notch of the blast furnace respectively; controlling the blast oxygen enrichment rate in the range of 2.6 to 3.0 percent; controlling the blast temperature in the range of 1,150 to 1,200 DEGC; and controlling the furnace temperature of the blast furnace in the range of 1,450 to 1,500 DEG C. By methods of adjusting the blast kinetic energy, blast volume and the blast temperature, controlling feeding rate, the reaction temperature of the blast furnace and slag basicity, and the like, the strengthened smelting of the vanadium-titanium magnetite in the blast furnace is realized, the utilization factor of the blast furnace is improved, and iron loss is reduced.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

Sintering method for high-grade vanadium titanium iron ore concentrate

ActiveCN103014323AImproved particle size compositionImprove breathabilityBlast furnace detailsGranularityBlast furnace smelting

The invention discloses a sintering method for a high-grade vanadium titanium iron ore concentrate. The method comprises the steps which are sequentially performed as follows: fuel pretreatment, burdening, water adding and mixing, pelletizing, ignition sintering, CaCl2 solution spraying and blast furnace smelting, wherein, in percentage by mass, the particle size of coke powder in the fuel after the pretreatment is 0-3 mm, 20%-29% of the coke powder is provided with the particle size smaller than 0.5 mm, quick lime is added twice, the proportion of a second addition is 25%-75%, a mixture which is formed by adding water and mixing contains 7.3%-7.6% of water, the carbon content of the mixture is 4.6%-4.75%, the material layer height during ignition sintering is 660-740 mm, and the mass concentration of the sprayed CaCl2 solution is 1%-3%. According to the sintering method for the high-grade vanadium titanium iron ore concentrate, the processing steps of optimizing sintering processing parameters, comprehensively applying fuel pretreatment, increasing water of the sintering mixture, appropriately reducing the carbon content of the sintering mixture, increasing the material layer height, separately adding fluxing agents, spraying the CaCl2 solution to a sintering ore and the like are adopted, so that the production quality and the low-temperature reduction degradation performance of the sintering ore are substantially improved, and the fuel consumption is reduced.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

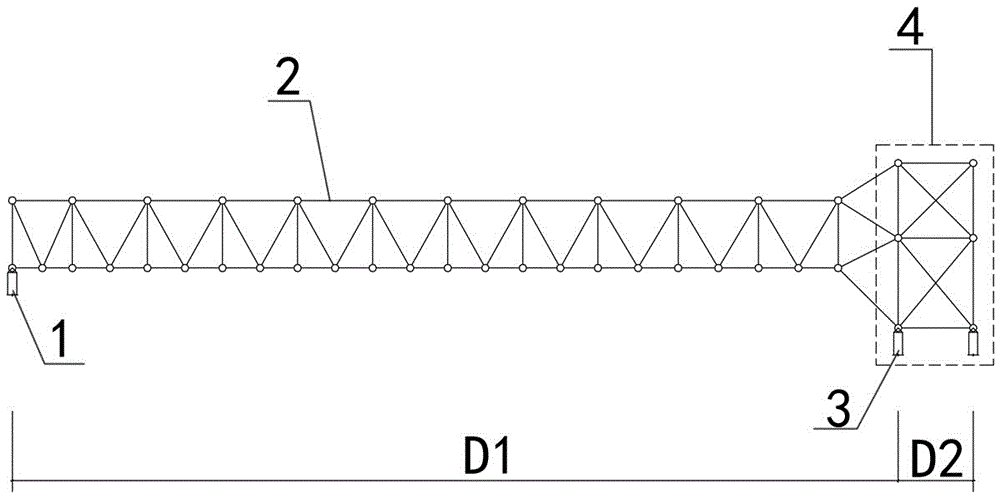

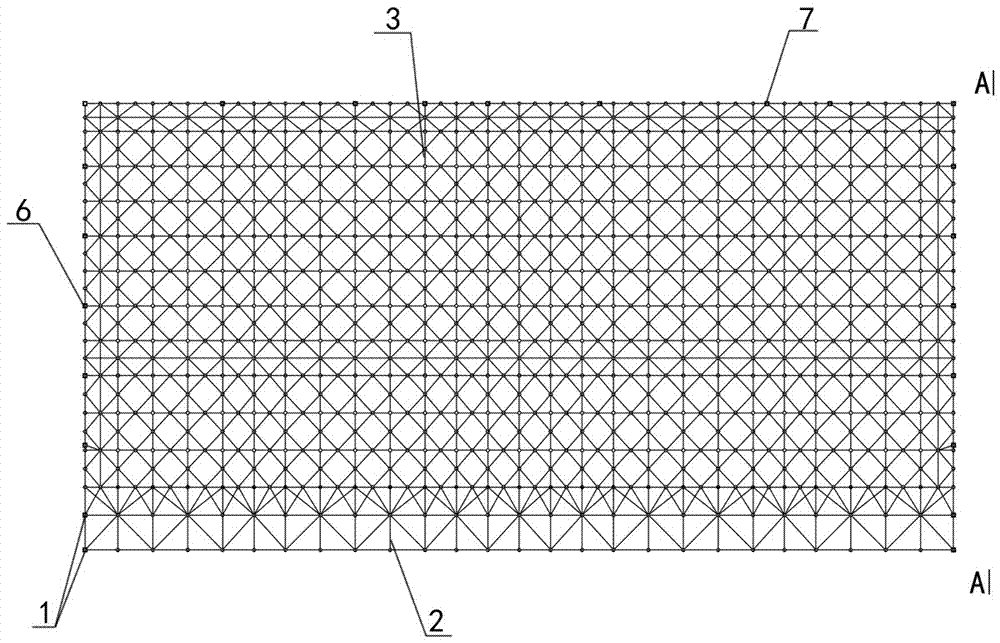

Large-span hangar fringe truss prestressed structure system and construction method thereof

ActiveCN106193306AImprove mechanical performanceImprove vertical support stiffnessBuilding roofsPre stressEngineering

The invention discloses a large-span hangar fringe truss prestressed structure system and a construction method of the large-span hangar fringe truss prestressed structure system. The structure system comprises roof supporting columns, a roof steel structure, gate truss supporting columns and a gate truss, wherein the roof supporting columns are arranged along the three edges of a hangar at intervals, the roof steel structure is fixed to the tops of the roof supporting columns and is in a flat plate shape, the gate truss supporting columns are located on the sides of the opening edges of the root supporting columns and arranged in the depth direction of the hangar at intervals, and the gate truss is fixed to the tops of the gate truss supporting columns. The root steel structure is directly connected with the gate truss. A body interior prestressed steel strand cable is arranged in a lower chord of the gate truss and completes pretension through an anchoring end joint and a tension end joint at the two ends of the lower chord correspondingly. The two ends of the lower chord and adhesive sections on the outer sides of the two ends of the prestressed steel strand cable are filled with concrete. By the adoption of the body interior prestressed technology, a ball or pipe truss can be adopted to successfully span a single-span hangar with the span larger than 140 m, and the technical and economical index of the structure is greatly improved.

Owner:CHINA AVIATION INT CONSTR & INVESTMENT CO LTD

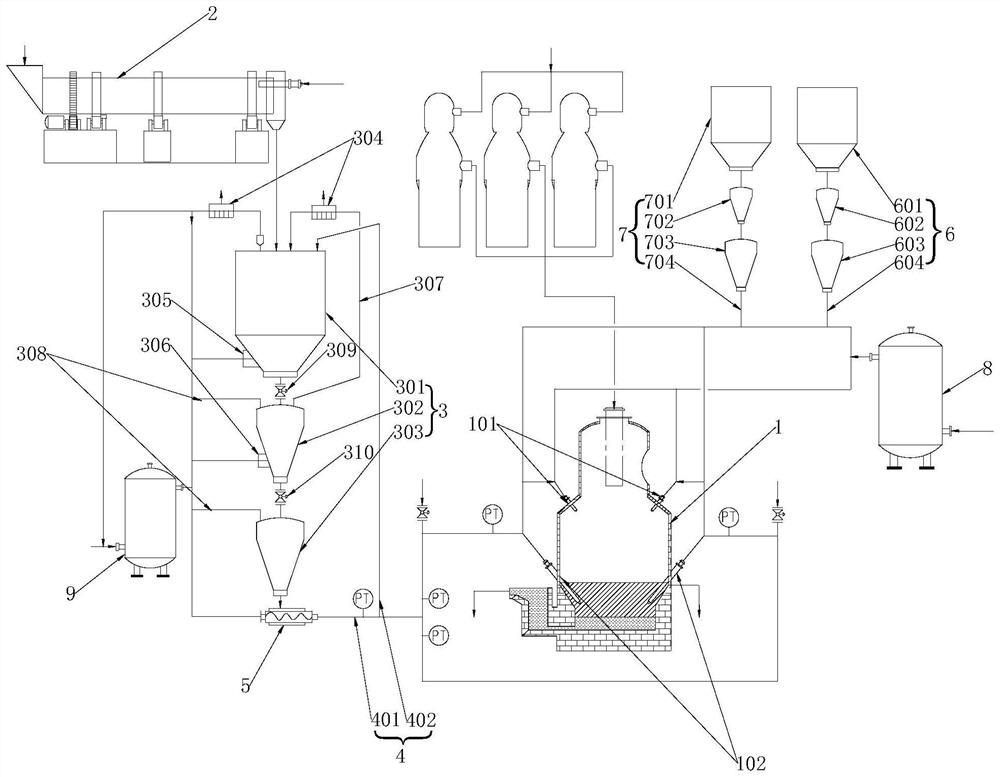

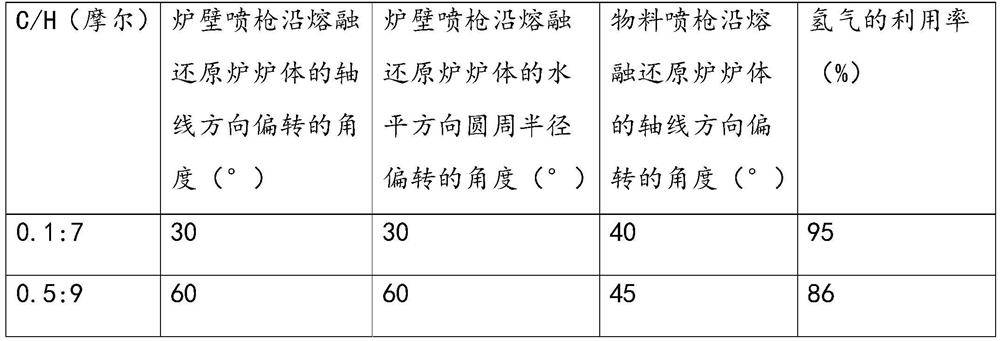

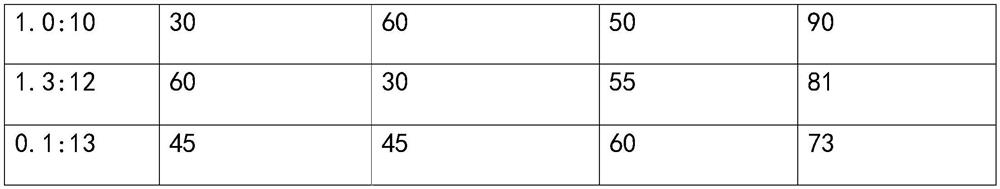

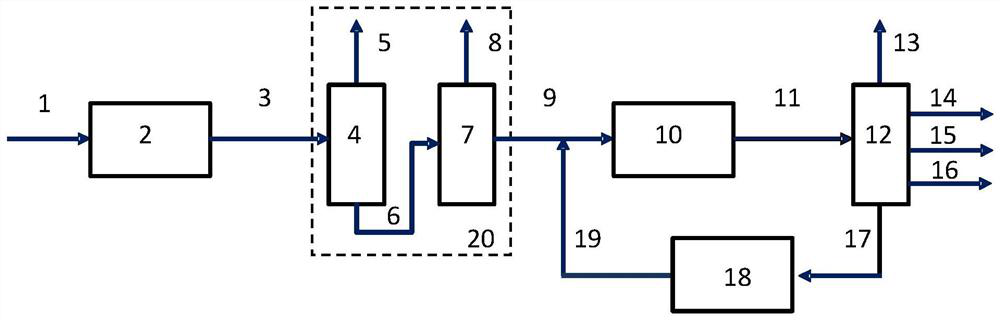

Smelting reduction hydrogen metallurgy process and device

The invention discloses a smelting reduction hydrogen metallurgy process and device. The smelting reduction hydrogen metallurgy process includes the steps that hydrogen is injected into a combustion area of a smelting reduction furnace to form high-pressure rotational flow in the combustion area; and a mixture of an iron-containing material and a magnesium-containing flux, a first carburant and first lime are blown into an iron bath area of the smelting reduction furnace by taking the hydrogen as a carrier gas. According to the smelting reduction hydrogen metallurgy process, the high-pressurerotational flow is formed in the combustion area, so that the retention time of the hydrogen in the smelting reduction furnace and the contact time of the hydrogen and iron-containing materials are prolonged, the amount of the hydrogen entering the combustion area discharged out of the smelting reduction furnace along with flue gas is reduced, the reduction reaction of the iron bath area is enhanced, the content of FeO in slag is reduced, the refractory material erosion speed is reduced, and the hydrogen utilization rate is increased; and the hydrogen is used as the carrier gas, so that the injection depth of a reducing agent can be effectively increased, the fountain effect in the smelting reduction furnace is enhanced, the reduction efficiency in the smelting reduction furnace is improved, and carbon emission in the metallurgical process is reduced.

Owner:SHANDONG MOLONG PETROLEUM MACHINERY

Method for calculating optimum preparing and adding proportion of iron ore sintering

The invention discloses a method for calculating the optimum preparing and adding proportion of iron ore sintering. According to the method, according to the uniformly mixed ore chemical ingredient requirements and raw material physical and chemical properties and proportioning constraints, a method of combining linear planning and a genetic algorithm is adopted for calculating an initial ore proportioning scheme group; sintering process parameters, production quality indexes and ore proportioning costs of each ore proportioning scheme are calculated; the technical economic integral evaluation index of the ore proportioning scheme is calculated according to the ore proportioning cost, the sintering solid fuel mixture ratio and the sintering ore rotating drum intensity by using the coefficient, and the highest integral evaluation index is used as the selection basis of the best ore proportioning scheme; the iron ore purchase and the sintering production are guided; the technical support is provided for the popularization and the application of new ore types.

Owner:CENT SOUTH UNIV

Method for smelting qualified pig iron from low-grade dilution ores containing high quantities of harmful elements

ActiveCN103205514AReduce adverse effectsExpand the range of available resourcesBlast furnace detailsCokeSilicon

The invention provides a method for manufacturing qualified pig iron from low-grade dilution ores containing high quantities of harmful elements. The method includes feeding, by mass, 60-75% of dilution sintering ores, 10-15% of dilution pellet ores, 10-20% of conventional pellet ores, 0-7% of lump ores and coke containing 80% of fixed carbon into a blast furnace according to conventional quantities; and smelting the ores and the coke to obtain the low-cost qualified pig iron. The sum of the mass proportions of the dilution sintering ores, the dilution pellet ores, the conventional pellet ores and the lump ores is 100%. The method has the advantages that certain smelting intensity is kept under the condition of the blast furnace, the blast furnace can stably and smoothly run for long cycles, the content of silicon is stably controlled, the yield keeps unchanged, the fuel ratio is stable, and local low-grade ore resources are sufficiently utilized.

Owner:WUKUN STEEL +1

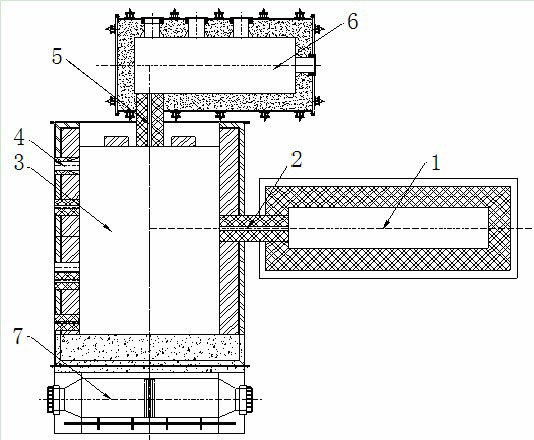

Stibium blast furnace for generating antimony matte, device of coarse stibium blowing furnace and direct converting method

InactiveCN102534256AImprove technical and economic indicatorsReduced focusProcess efficiency improvementSlagContinuous production

Provided are a stibium blast furnace for generating antimony matte, a device of a coarse stibium blowing furnace and a direct converting method. The device comprises the stibium blast furnace, a stibium blast furnace front bed arranged above a front bed furnace head and a blowing furnace and is characterized in that a slag through channel is arranged between the stibium blast furnace and the stibium blast furnace front bed, the blowing furnace is arranged at the tail portion of the stibium blast furnace front bed, and a stibium through channel is arranged between the blowing furnace and the stibium blast furnace front bed. The stibium blast furnace, the stibium blast furnace front bed and the blowing furnace are optimized, and the antimony matte and coarse stibium directly enter the blowing furnace through the stibium through channel, the thermal energy of the stibium blast furnace front bed is fully utilized, the antimony matte and the coarse stibium which enter the blowing furnace for converting are hot melt, and continuous production can be achieved without external heating. A technical economic index of the stibium blast furnace is optimized, the treatment performance of the stibium blast furnace bed is improved by 10% or more, and coke rate is >=5%, stibium comprehensive recovery rate is improved by 0.2% or more, and the comprehensive recovery rate of precious metal is improved by 3.0% or more.

Owner:锡矿山闪星锑业有限责任公司

66kV burst short circuit transformer

ActiveCN103500632ASimple insulation structureImproved ampere-turn balanceTransformers/inductances coils/windings/connectionsLow voltageStress level

The invention relates to a 66kV burst short circuit transformer. A three-phase three-limb iron core is arranged in a lower fuel-saving box of the transformer. The iron core is sleeved with a low-voltage coil and a high-voltage coil. Wires are led out from the head end of the high-voltage coil and the head end and tail end of the low-voltage coil in the axial direction, and are led into a sleeve through cables. The high-voltage coil is of a fully continuous structure, wherein every two of three composite conductors are wound in parallel in the radial direction. A subsidiary pressing plate on the high voltage side and a subsidiary pressing plate on the low voltage side are respectively of a fan shape as a whole, and the fan-shaped subsidiary pressing plate on the high voltage side and the fan-shaped subsidiary pressing plate on the low voltage side share the same center of a circle and are placed in a symmetric mode. The subsidiary pressing plates and a pressing plate are provided with positioning holes and are connected through an insulating screw rod. According to the 66kV burst short circuit transformer, the insulation structures of the coils are optimized, ampere-turn balance of the coils is improved, horizontal eddy current loss of the coils is lowered on the premise that insulation reliability is guaranteed, the stress level of the coils is lowered substantially at the time of a short circuit, the capability in resistance to the short circuit of a product is enhanced, and a basis is provided for further optimization of a product design.

Owner:TBEA SHENYANG TRANSFORMER GRP CO LTD

Aluminium electrolyzing process

InactiveCN1974863ASolve the problems of easy formation of precipitation crusts and easy melting of the side furnace sideThe furnace is regular and stableElectrolysisAluminium oxides

The aluminum electrolyzing process with alumina as material to produce aluminum features the electrolyte comprising LiF 2-5 wt%, CaF2 2-5 wt%, Al2O3 1.5-3.0 wt%, and cryolite with NaF / AlF3 molar ratio not higher than 2.3 for the rest. The process has initial crystallizing temperature of the electrolyte not higher than 920 deg.c, superheating degree of 5-12 deg.c, and electrolysis temperature no higher than 935 deg.c. The present invention has no encrusting and melting-off of the electrolytic furnace, high current efficiency, low power consumption and improved economic and technological indexes.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

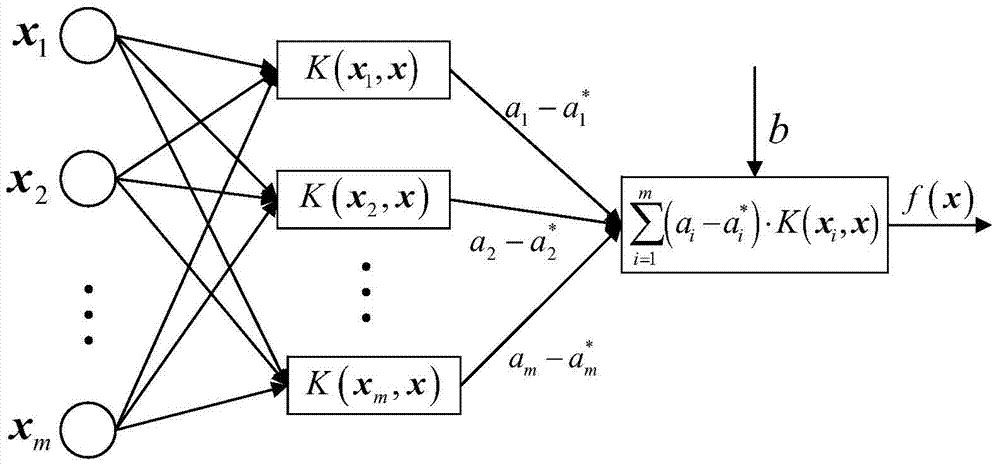

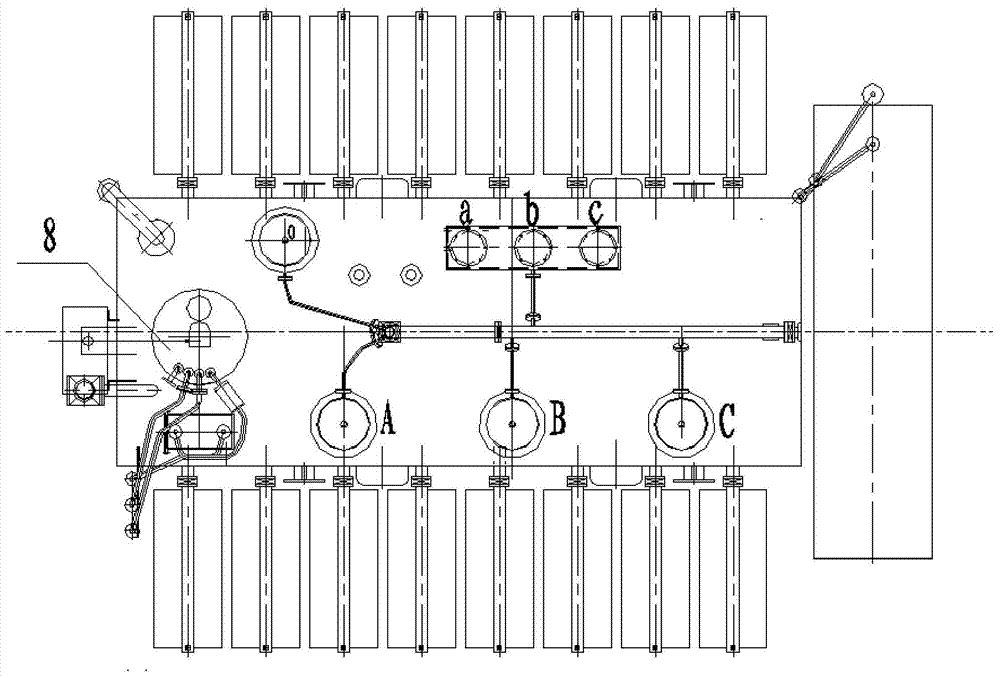

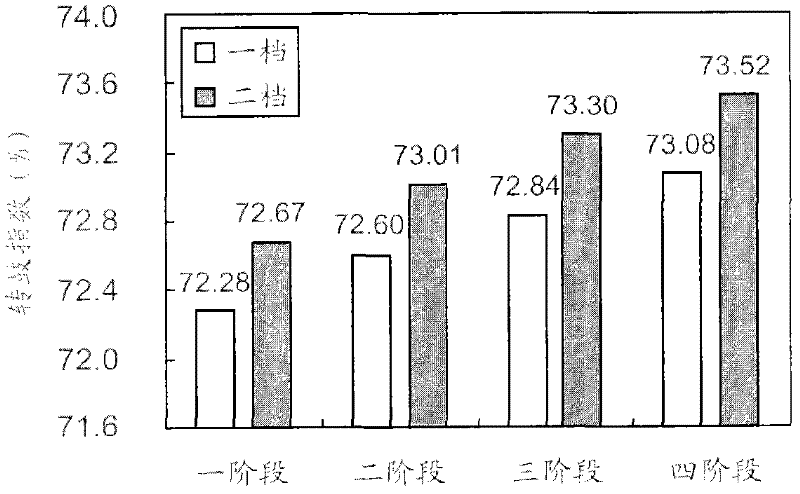

Process optimization method for sintering vanadium-titanium magnetite concentrate by large-scale sintering machine

ActiveCN102269993AGood technical and economic indicatorsImprove technical and economic indicatorsTotal factory controlProgramme total factory controlProcess optimizationSolid fuel

The invention provides a process optimization method for sintering a vanadium-titanium magnetite concentrate by a large-scale sintering machine. According to the invention, the method comprises the following steps that: a sintering process is constructed into a sintering system that includes input, an intermediate link and output; ore return quantity, feeding quantity, material layer thickness, machine speed, and material temperature and the like are selected and are taken as adjustable parameters; index parameters of a sintering system are improved by a plurality of phases that are connectedsequentially, wherein each phase among the plurality of phases comprises multi-group records that record adjustable parameters and the index parameters that are corresponding to the adjustable parameters during sintering production and a record in which index parameters satisfy a target range of the present phase is selected from the multi-group records; adjustable parameters at the next phase are controlled on the basis of a mean value of adjustable parameters of the last phase among the plurality phases, wherein the adjustable parameters of the last phase are in a record and satisfy a target range of the last phase and the target range of the next phase is not inferior to that of the last phase. According to the invention, index parameters including a utilization coefficient, a drum index and low solid fuel consumption and the like in the sintering process are improved.

Owner:PANZHIHUA IRON AND STEEL +1

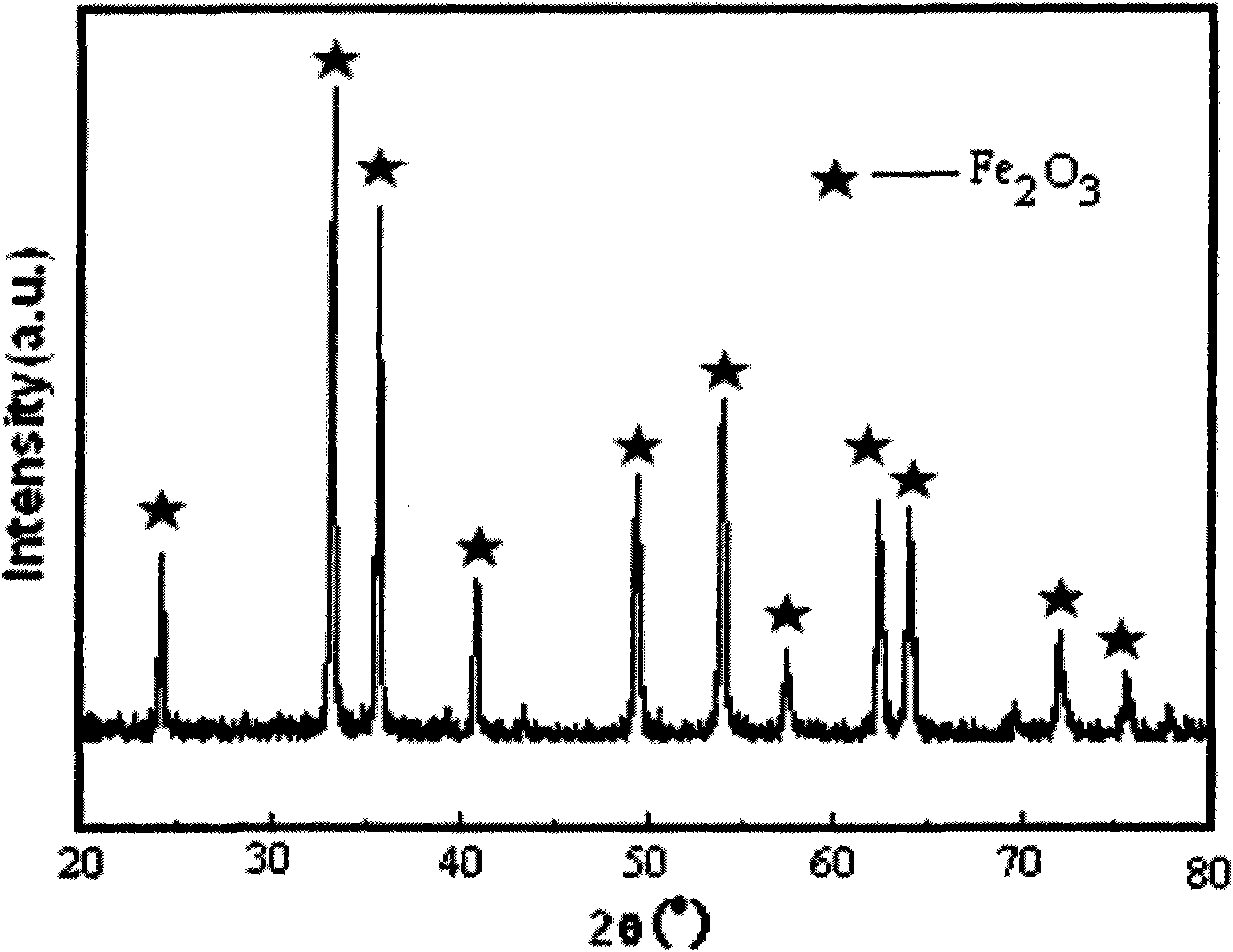

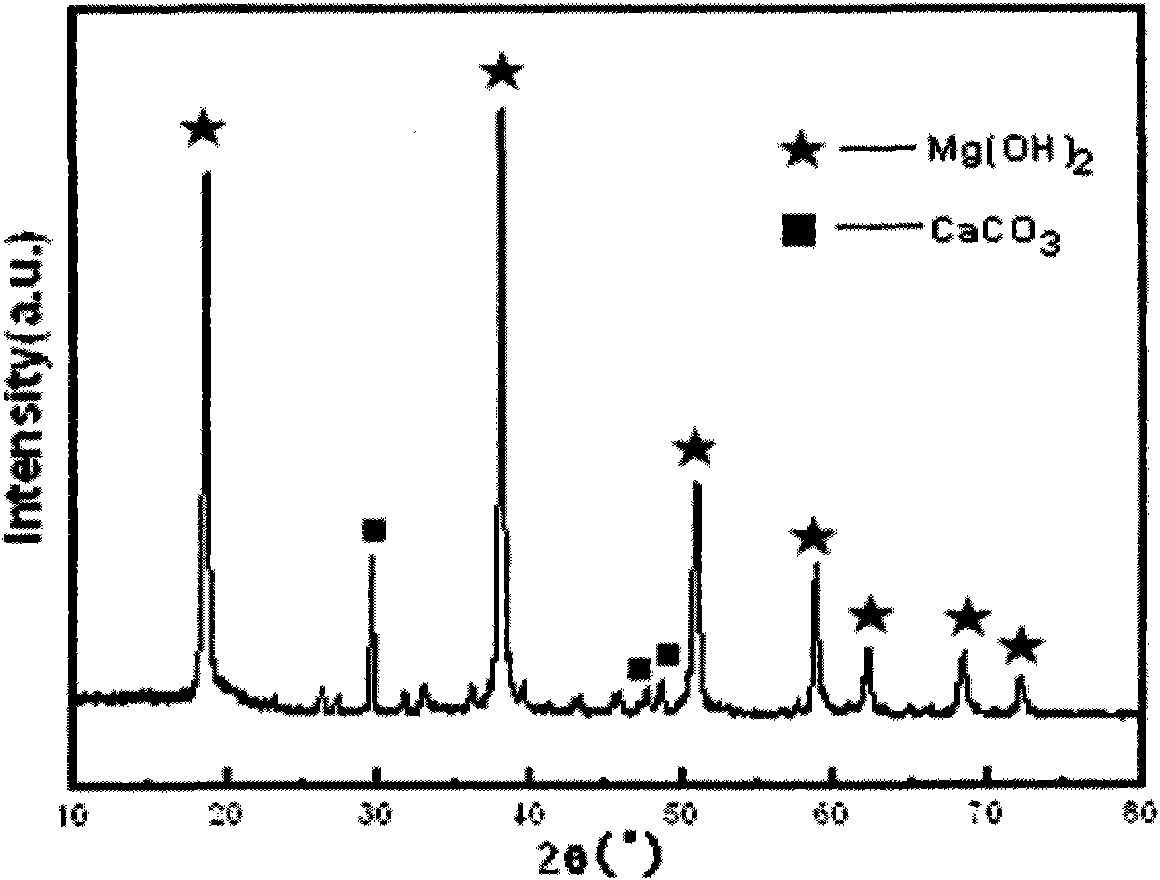

Method for extracting metallic elements of ferrum, magnesium and calcium from molybdenum milltailings

InactiveCN101831542AImprove technical and economic indicatorsImprove resource recoveryProcess efficiency improvementHydrometallurgyImpurity

The invention relates to a method for extracting metallic elements of ferrum, magnesium and calcium from molybdenum milltailings, belonging to the technical field of wet-process metallurgy and comprehensive utilization of tailings. The method comprises the following steps of: treating the molybdenum milltailings by using a hydrochloric acid solution to obtain pickle liquor and adding hydrogen peroxide to the pickle liquor to oxidize Fe<2+> totally into Fe<3+>; dropping ammonia water into the solution and controlling the pH value to prepare a crude Fe(OH)3 precipitate; dissolving the crude Fe(OH)3 in acid, filtering and then dropping the ammonia water to carry out a precipitation reaction; filtering and calcining at a high temperature of 750 DEG C to obtain a Fe2O3 product with a purity larger than 98 weight percent; dropping NaOH to ferrum precipitate filter liquor and controlling the pH value to remove impurity elements; continuing to dropping NaOH and controlling the pH value to obtain a Mg(OH)2 product with a purity larger than 83 weight percent; and dropping Na2CO3 into magnesium precipitate filter liquor to obtain a CaCO3 product with a purity larger than 97 weight percent. The process adopts full liquid-phase operations and has no waste gas pollution, and a tail solution is mainly a NaCl and NaOH mixture solution which is easy to treat. The recovery rates of the ferrum, the magnesium and the calcium all reach higher than 80 percent, and meanwhile, the enrichment of trace elements such as molybdenum, tungsten, copper, and the like in the tailings is also realized.

Owner:UNIV OF SCI & TECH BEIJING

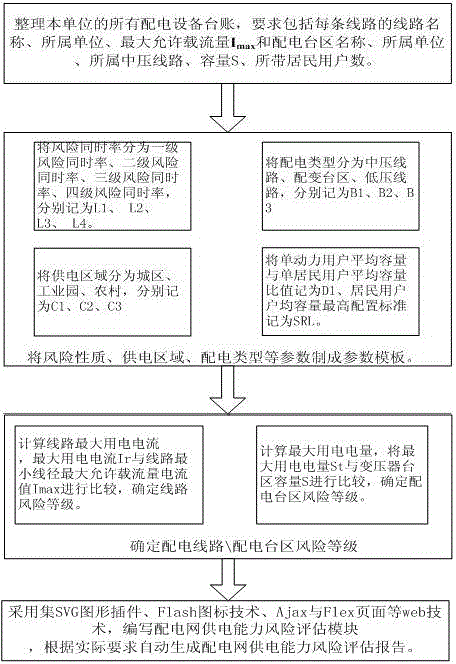

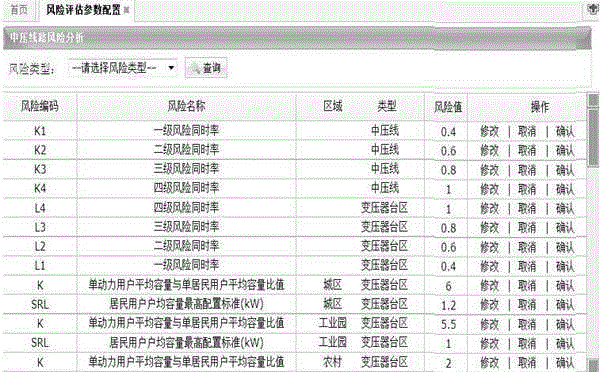

Power distribution network power supply capacity risk assessment method

InactiveCN104091202AImprove operation and maintenance management levelEffectively formulate corrective measuresData processing applicationsLow voltageComputer science

A power distribution network power supply capacity risk assessment method includes the steps that standing books of power distribution equipment of a unit are obtained through a power distribution equipment monitoring system; essential information of the power distribution equipment is obtained; power distribution network power supply capacity risk parameters are set; on the basis, a power distribution network power supply capacity program is written, essential parameters such as the run-unit, the equipment class and counting time are input, and finally a power distribution network power supply capacity risk assessment report is automatically generated. The method is suitable for dividing power distribution network power supply capacity risk key areas and technical and economic indexes of transformation work of medium and low voltages of a power distribution network are optimized.

Owner:STATE GRID CORP OF CHINA +1

Self-adaptive surface treatment device and rolling method

The invention discloses a self-adaptive surface treatment device and rolling method. The device comprises a rolling head body and a rolling head secondary disk, first piston chambers are formed in the rolling head body, an eccentric piston block is installed in each first piston chamber, the part, outside the first piston chambers, of the rolling head body is provided with first oil ducts, second oil ducts are formed in the part, outside the first oil ducts, of the surface of the rolling head body, and the second oil ducts are arranged to be in a T shape; seal rings are arranged between the rolling head body and the rolling head secondary disk, and the seal rings isolate the second oil ducts to form six independent sealed annular sections; multiple second piston chambers are formed in the rolling head secondary disk, a cylindrical piston is arranged in each second piston chamber, and five second piston chambers are formed in the position corresponding to each second oil duct; an alloy column pin is arranged on the lower half portion of each second piston chamber. In the self-adaptive surface treatment device, the alloy column pins have a certain floating function and certain flexibility, so that the device is applicable to surface treatment of a work piece which is provided with a certain radian.

Owner:JINAN VOCATIONAL COLLEGE

Large wide airliner multi-position maintenance hangar roof diagonal truss structural system

ActiveCN106968382ARelieve stressThe maximum internal force is reducedBuilding roofsStructural systemEngineering

A large wide airliner multi-position maintenance hangar roof diagonal truss structural system comprises roof bearing columns arranged along three edges of a hangar at intervals and a roof steel structure fixed to the tops of the roof bearing columns and further comprises gate truss bearing columns arranged along the open edge of the hangar and a gate truss fixed to the tops of the gate truss bearing columns. The roof steel structure is connected with the gate truss, the hangar comprises a single-span hangar body and a multi-span hangar body, the roof steel structure comprises a main structural frame covering the hangar and further comprises a diagonal truss and a linear truss which are arranged in the main structure frame, and the linear truss intersects with the diagonal truss. Based on the shortest transfer path theory of force, the diagonal truss and the linear truss are arranged in the hangar, a roof is divided and surrounded, the pressure of the gate truss is effectively relieved, and it is possible to implement the ultralow-airspace height-limited-place ultra-large-span multi-position maintenance hangar.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

Method for smelting low-silicon pig iron by using iron ore with complex mineral structure

ActiveCN111748666AGuaranteed continuityOptimize the mine structureBlast furnace detailsIronstoneBlast furnace smelting

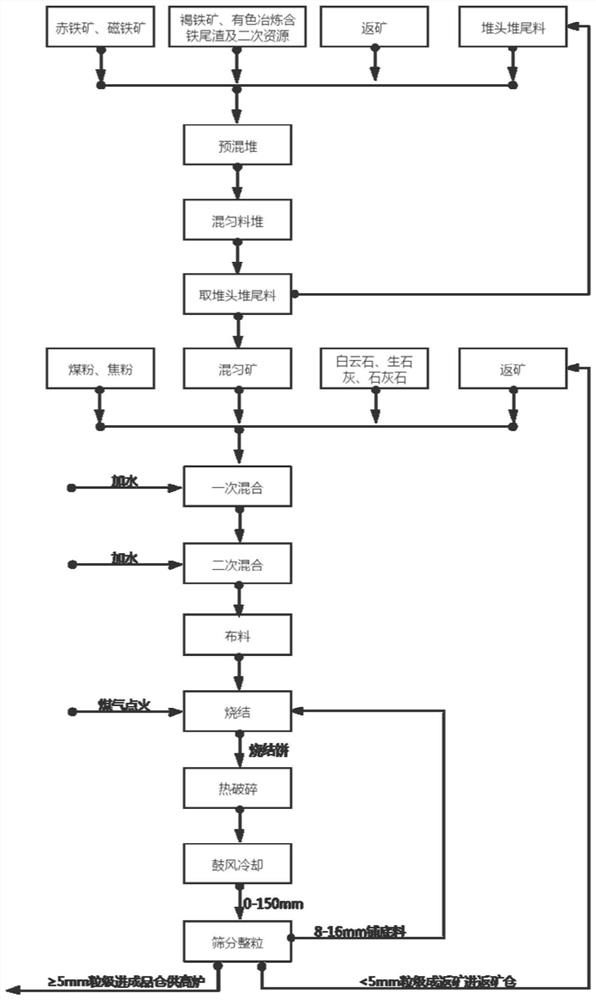

The invention relates to a method for smelting low-silicon pig iron by using iron ore with a complex mineral structure, and belongs to the technical field of ironmaking. The method comprises the following steps of uniformly mixing limonite, nonferrous smelting iron-containing tailings, secondary resources, fine-grained magnetite concentrate, fine-grained vanadium-titanium magnetite concentrate andhematite, piling, taking the uniformly mixed ore in the middle of a material pile, mixing the uniformly mixed ore with SYP synergist, dolomite, limestone, quicklime and coke powder, pelletizing, sintering the obtained pellets to obtain a finished product sinter, crushing, spraying a CaCl2 solution, screening, and blending the sintered ore with the particle size of more than 5mm, the pellet ore and the lump brown iron ore into a blast furnace for blast furnace smelting to obtain a low-silicon qualified pig iron. According to the method, secondary resource reutilization is achieved, on one hand, environmental pollution is reduced, meanwhile, the production cost can be saved, and application and popularization are easy.

Owner:红河钢铁有限公司

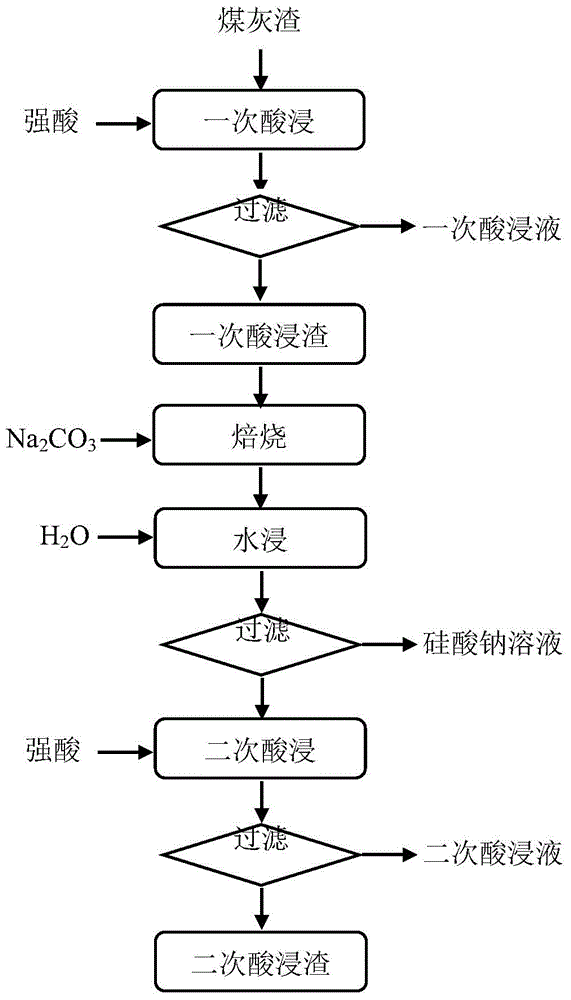

Method for secondary acid leaching of alumina in coal ash residues

InactiveCN103952557ASimple processAdvanced technologyAlkali metal silicatesProcess efficiency improvementAluminum IonResource utilization

The invention provides a method for secondary acid leaching of alumina in coal ash residues. The method comprises the following steps of carrying out direct acid leaching on coal ash residues to obtain an aluminum ion-containing primary acid leaching liquid and aluminum crystal-containing primary acid leaching residues, carrying out calcination on the aluminum crystal-containing primary acid leaching residues added with sodium carbonate so that aluminum-containing crystals in the aluminum crystal-containing primary acid leaching residues are destroyed, carrying out water leaching on the calcined clinker to obtain a sodium silicate solution and aluminum-containing water leaching residues, carrying out secondary acid leaching treatment on the aluminum-containing water leaching residues and feeding the residual aluminum into the secondary acid leaching liquid. The total leaching efficiency of the two aluminum acid-leaching processes is more than 98%. The method has the advantages of good operation conditions, wide coal ash residue application range, no waste residue, high resource utilization rate, low comprehensive cost, good benefits and less pollution.

Owner:ZHEJIANG UNIV

Full conversion method and device for producing light aromatic hydrocarbon from catalytic diesel oil

ActiveCN112322349AHigh selectivityHigh yieldHydrocarbon oil crackingTreatment with hydrotreatment processesAromatic hydrocarbonPhotochemistry

The invention relates to a full conversion method and device for producing light aromatic hydrocarbon from catalytic diesel oil. According to the technical scheme, the method comprises the steps thatcatalytic diesel oil flow undergoes a selective conversion reaction after being subjected to hydrofining and impurity separation, and light aromatic hydrocarbon such as benzene toluene and xylene, C9Aaromatic hydrocarbon, C10A aromatic hydrocarbon and tower bottom heavy tail oil are sequentially separated from generated mixed aromatic hydrocarbon through separation, heavy tail oil at the bottom of the tower enters a post-selective saturation reactor, is subjected to high-selectivity hydrogenation saturation under the conditions of low temperature and low pressure to obtain a benzene ring product, and then is sent back to the selective conversion reactor. The method realizes full-fraction conversion of light aromatic hydrocarbons produced from catalytic diesel oil, and has the technical effect of high yield of monocyclic aromatic hydrocarbons such as benzene toluene, xylene, C9A aromatic hydrocarbons and C10A aromatic hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

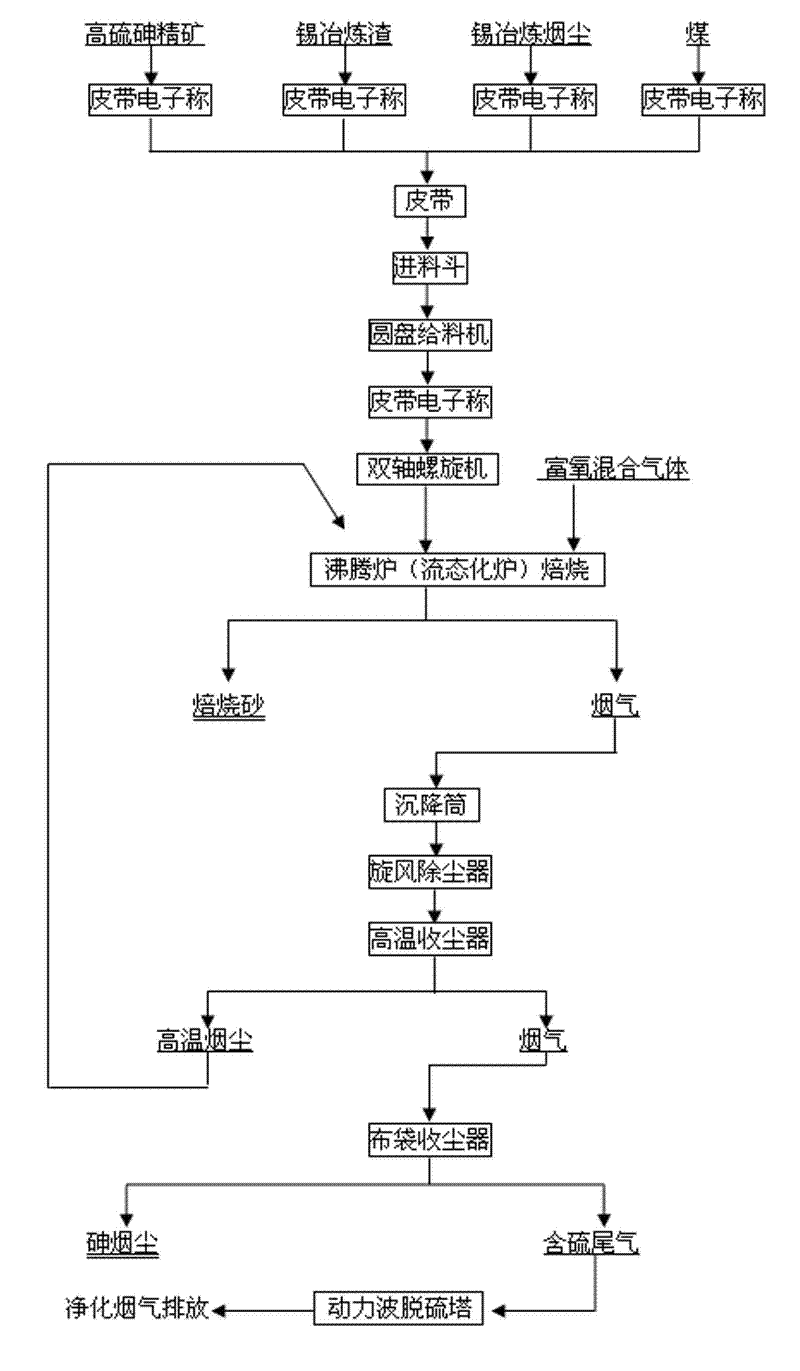

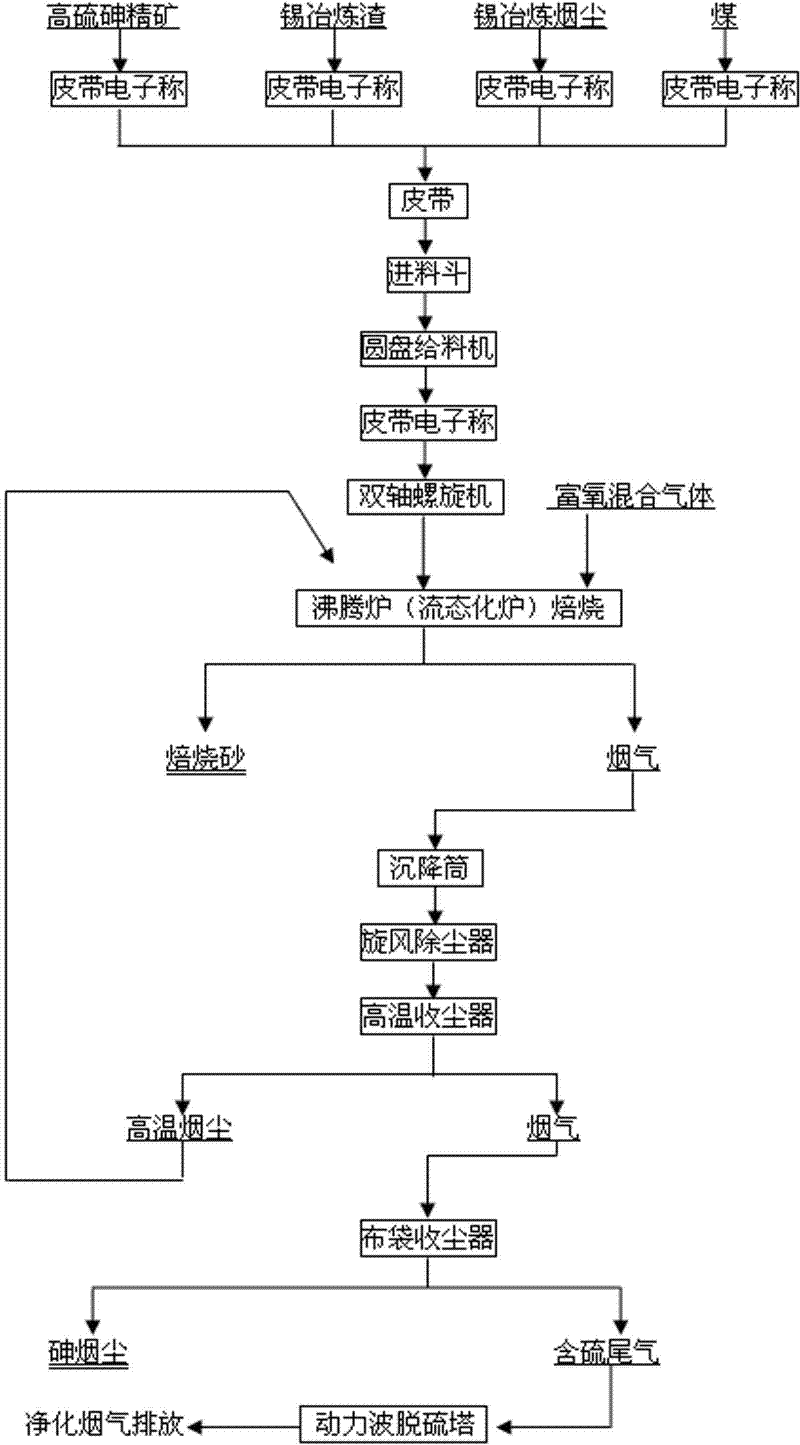

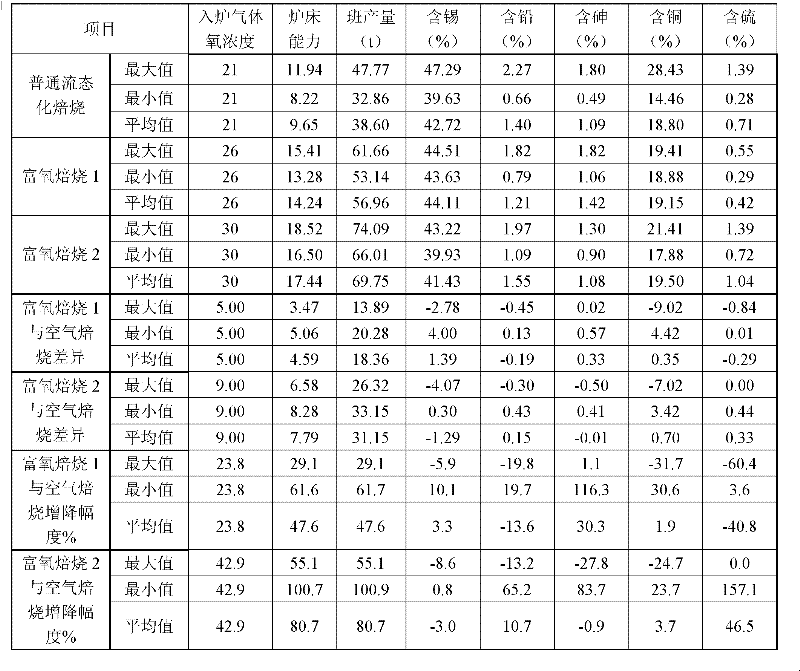

Method for roasting tin-containing high-arsenic and high-sulfur material by fluidized rich oxygen

InactiveCN102230074AIncrease the furnace concentrationReduce the amount of furnaceProcess efficiency improvementExhaust gasArsenic

The invention belongs to the technical field of tin metallurgy, in particular relates to a novel method for roasting a tin-containing high-arsenic and high-sulfur material by fluidized rich oxygen. The method comprises the following steps of: mixing oxygen into a charged gas of a fluidized furnace; controlling the oxygen quantity to reach 22-45 wt% of the total charged gas; carrying out oxygen-enriched fluidized roasting on the material at 600-1000 DEG C; and adding the oxygen in such a way that the quantity of the charged air is gradually reduced and the oxygen quantity is gradually increased so that the total charged gas is invariable and the oxygen concentration satisfies the process parameters while a charging system is started for charging. According to the invention, the arsenic and sulfur removing rate can be effectively increased, the roasting quality can be improved, the smoke gas quantity generated by treatment of the unit material can be reduced, the heat loss can be reduced, the heat utilization rate can be increased, the furnace hearth capacity can be improved without increasing the area of the furnace hearth, the treatment quantity can be increased and the production efficiency can be enhanced; meanwhile, the concentration of SO2 in the smoke gas can be increased so that the problems of low SO2 concentration in the tail gas, unfavorable acid making and environment pollution can be solved to change the harm into the treasure in the tail gas acid making.

Owner:YUNNAN TIN GROUP HLDG

Sintering method of fine Baima vanadium-titanium magnetite concentrate

The invention discloses a sintering method of fine Baima vanadium-titanium magnetite concentrate. The sintering method comprises the sequential steps of burdening, mixing with water, pelletizing, igniting and sintering, spraying CaCl2 solution and blast furnace processing, wherein based on mass, the water content in the mixed material in the water mixing step is 7.2-7.5%; the carbon content in the mixed material is 4.8-5.0%; the material layer height when igniting and sintering is 640-700 mm; and the mass concentration of the sprayed CaCl2 solution is 1.5-3%. Through optimizing of the sintering technical parameters, comprehensively improving of the water content of the sintering mixed material, the carbon content in the mixed material and the height of the material layer, the grain composition and the sinter components of the mixed material when the fine Baima vanadium-titanium magnetite concentrate is sintered are greatly improved; the sintering atmosphere, flux mineralization, sintering heat system and mineral crystallization in the sintering process are effectively strengthened, so as to improve the sinter product yield and quality, and enable the yield and the quality of the sinter and the metallurgical performance to be greatly improved.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

Method for recycling byproducts generated in aluminum electrolysis

InactiveCN102140651AImprove technical and economic indicatorsGood technical and economic indicatorsProgramme control in sequence/logic controllersZero emissionAluminium

The invention discloses a method for recycling byproducts generated in aluminum electrolysis, and relates to a method for recycling byproducts such as shell surface materials, recycled aluminum dirty materials, aluminum ash and the like in the aluminum electrolysis production process. The method is characterized by comprising the following steps of: collecting the byproducts generated in the process of electrolyzing aluminum, screening, mixing and crushing, and gathering in a storage silo; and when an anode is replaced during aluminum electrolysis, lifting materials in the silo on the ground, conveying into a feeding bin of an electrolyzer through a pipe, and automatically feeding to cover the surface of the anode. In the method for recycling the byproducts generated in aluminum electrolysis, the byproducts such as the shell surface materials, recycled aluminum dirty materials, aluminum ash and the like generated in the aluminum electrolysis process are all recycled, and problems of high cost, high labor intensity, long working hours, high thermal loss of the electrolyzer, low environmental sanitation and the like in the adding process are solved. The technical economical indexes of the system are obviously improved, and the aims of zero emission of the byproducts of the aluminum electrolysis and energy conservation and consumption reduction are fulfilled.

Owner:陕西铜川铝业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com