A selective sintering flue gas segmented comprehensive treatment process

A technology for sintering flue gas and comprehensive treatment, applied in waste heat treatment, furnace, lighting and heating equipment, etc., can solve the problems of equipment investment and operation, waste of site occupation, rising construction investment and operation cost, single function, etc., to reduce construction costs. The effect of investment and production operation costs, reduction of investment and operation costs, and improvement of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

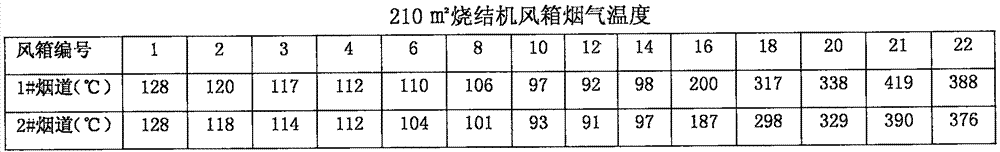

[0036] Take a certain 210m 2 Taking a sintering machine as an example, a detailed description of a selective sintering flue gas segmented comprehensive treatment process of the present invention is as follows:

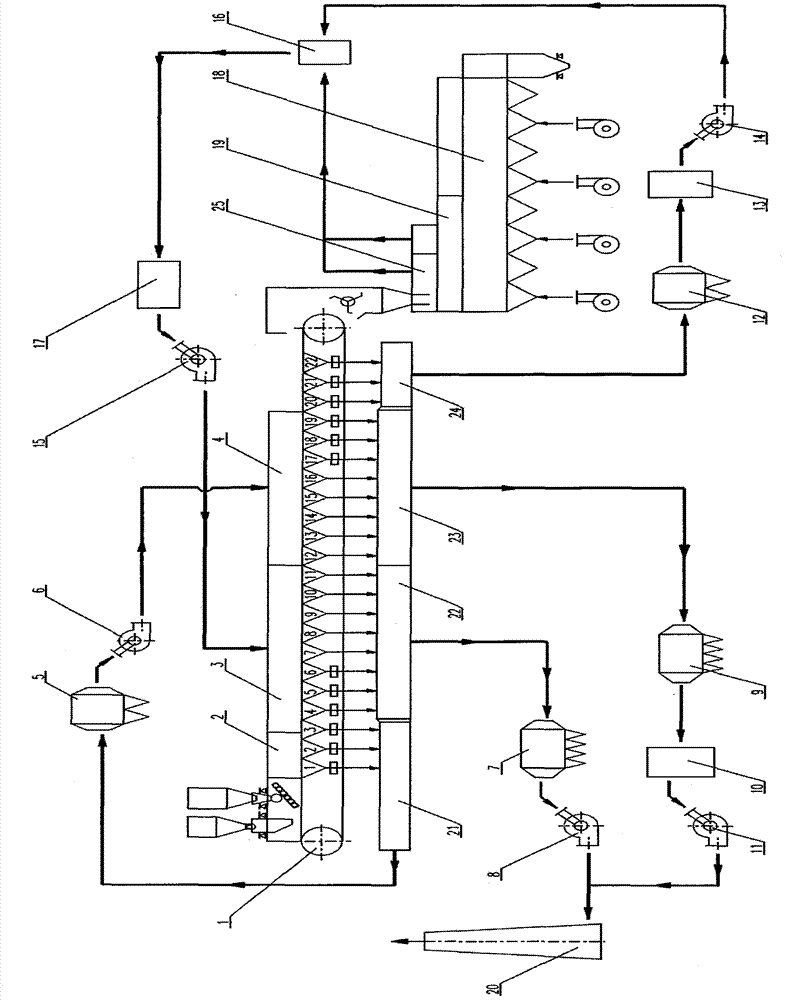

[0037] Such as figure 1 shown in a 210m 2 On the sintering machine 1, the sintering flue gas from the No.1-No.3 bellows in the ignition area of the sintering machine head in the area ① is collected into the flue gas pipeline of the machine head, and then passes through the multi-pipe dust collector 5 of the machine head and the circulating fan 6 of the machine head Lead to the flue gas circulation hood 4 of the sintering machine 1 for flue gas circulation and sintering; collect the sintering flue gas from No.4 to No.11 bellows in the area ② in the middle of the sintering machine where the flue gas is discharged directly into the direct flue gas pipeline The sintering electrostatic precipitator 7 is led by the sintering main exhaust fan 8 to the sintering main chimn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com