Composite plating process and equipment for magnetron sputtering-laser heating

A magnetron sputtering and laser heating technology, applied in sputtering coating, metal material coating process, ion implantation coating and other directions, can solve the problems of grain growth, poor bonding strength of film base, long time, etc. Achieve the effect of high power and high density thermal energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

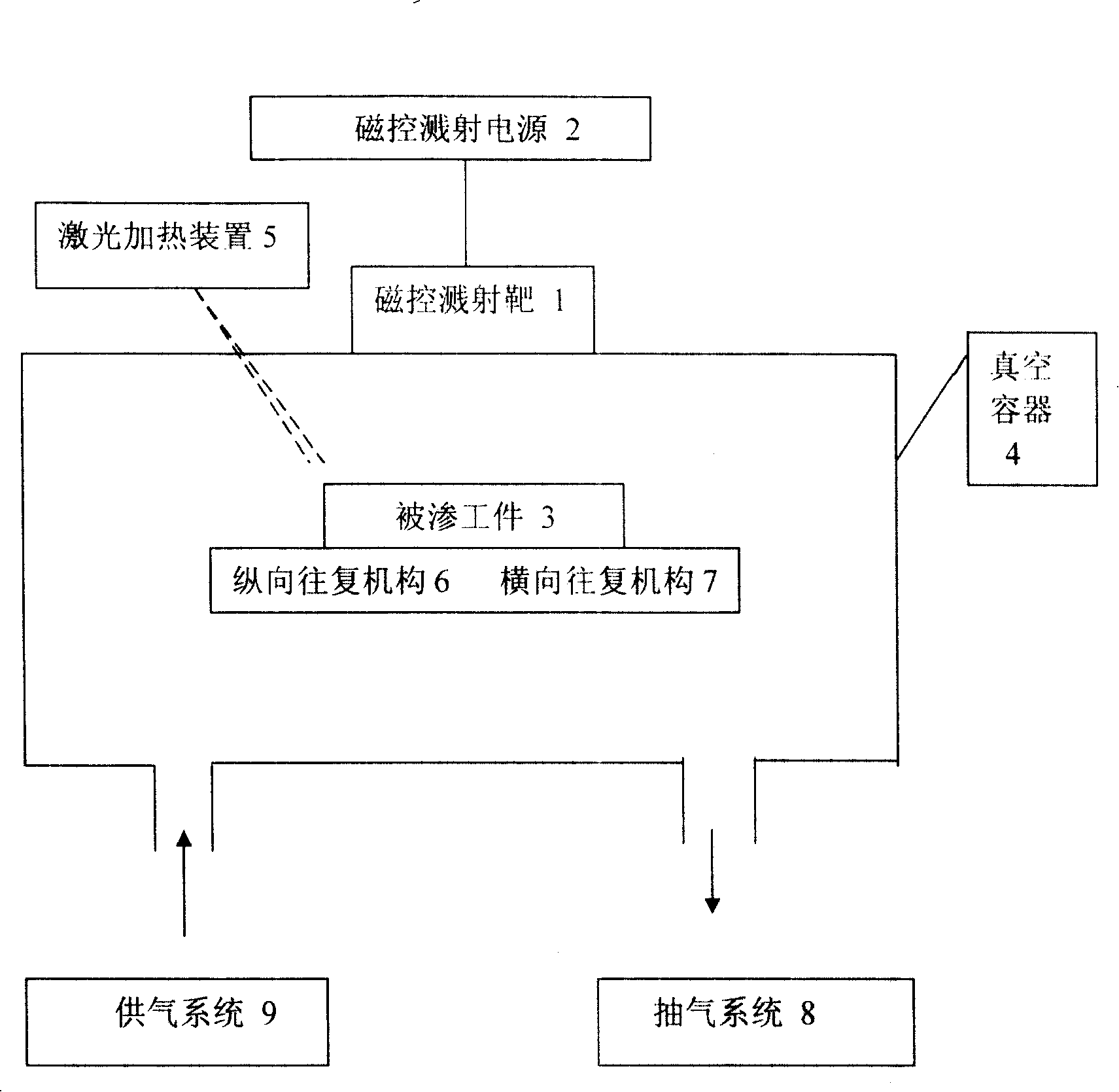

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0024] The size is 100mm * 100mm * 5mm, and the infiltrated workpiece 3 made of 20 steel is placed on the brackets of the longitudinal reciprocating mechanism 6 and the transverse reciprocating mechanism 7, and the size is selected to be φ100mm * 5mm (diameter * high) magnetic The magnetron sputtering target 1 is arranged above the workpiece to be infiltrated. The magnetron sputtering target is made of pure metal Mo, and the vacuum is evacuated to an ultimate vacuum degree of 3×10 -3 Above pa, fill the gas medium with argon gas to the working vacuum degree of 10Pa, first apply a high voltage DC voltage -500V to the magnetron sputtering target 1, and ion sputter the target for 20 minutes, stop sputtering, turn on the transverse reciprocating mechanism 7, and simultaneously laser The heating device 5 scans and heats the surface of the infiltrated workpiece 3 at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com