Sheradizing method and anti-corrosion metal part

A metal parts, anti-corrosion technology, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of high reaction activation energy, difficult reaction, slow reaction, etc., to achieve high economic benefits, A wide range of applications, the effect of improving the penetration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] This embodiment provides a method for sherardizing, including steps S1 to S3.

[0056] S1. Carry out degreasing and derusting treatment on the metal parts to be galvanized, and place the treated metal parts together with the zinc-seeding agent in a closed seepage tank, and the zinc-seeding agent includes the following components in parts by mass: metal powder 20-100 parts, 40-80 parts of dispersant, and 0.2-5 parts of decomposing agent, wherein the metal powder includes 60-97 parts of zinc powder and 3-40 parts of magnesium powder.

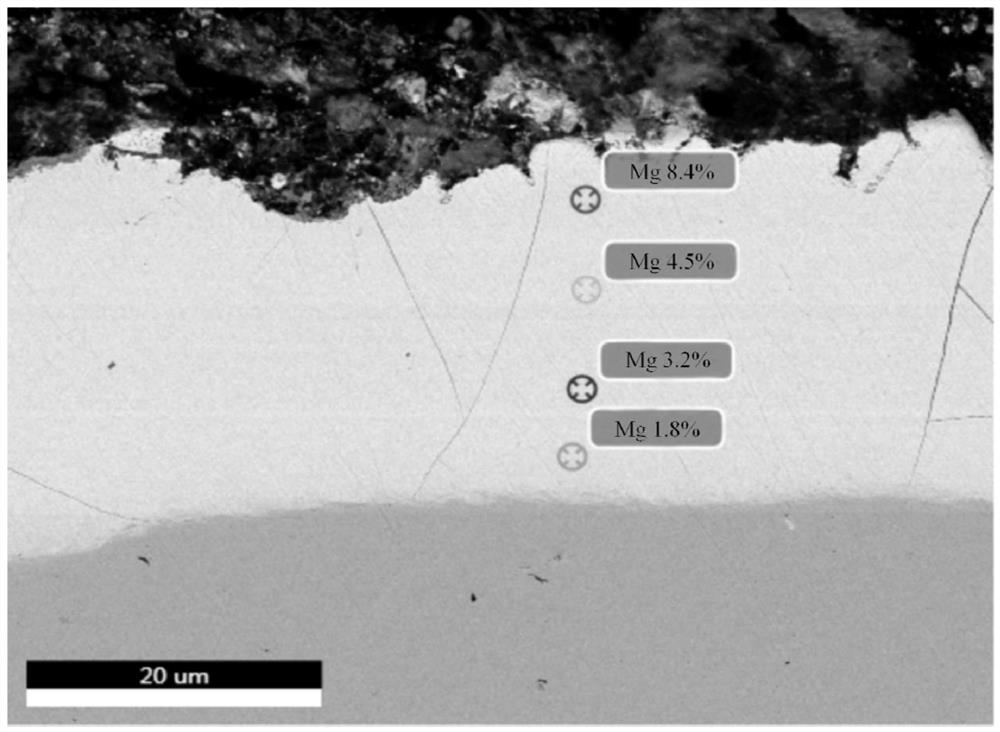

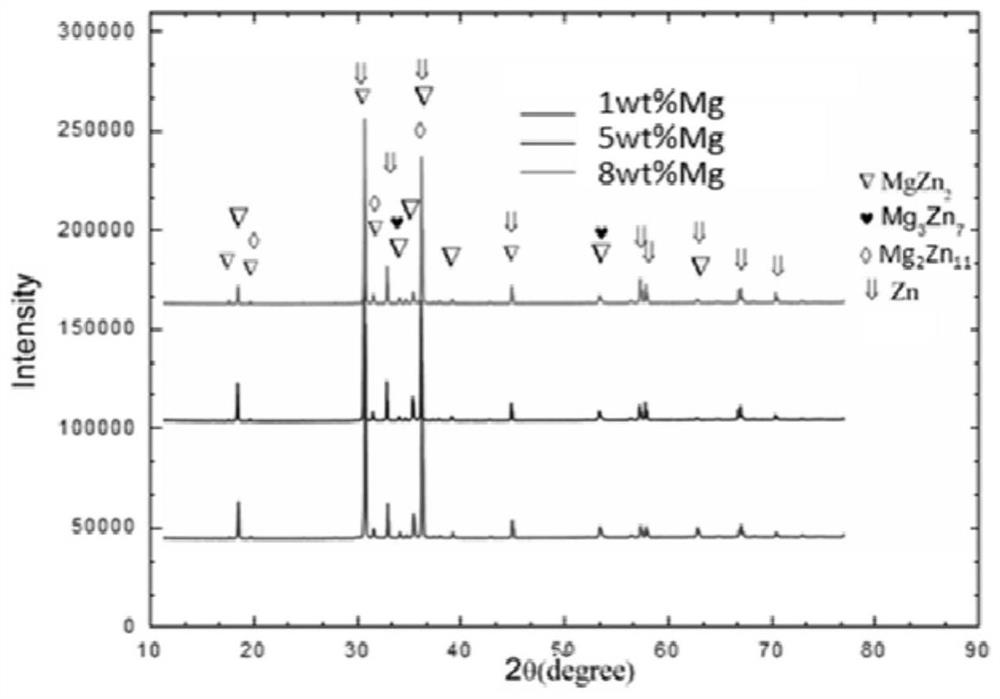

[0057] On the one hand, the atomic radius of zinc is 0.1332 nanometers, and the atomic half-valence of magnesium is 0.1598 nanometers. The difference between the atomic radii of the two is less than 15%. At the same time, both magnesium and zinc have a close-packed hexagonal structure, so the two can work together to form a seepage layer. Although magnesium itself is not resistant to corrosion, it can occupy some positions of zinc atoms in ...

Embodiment 2

[0087] On the basis of Example 1, this embodiment provides a zinc sherardizing method, the zinc sherardizing agent used in step S1 may also include 0.5-3 parts of an active agent capable of promoting magnesium infiltration into the infiltration layer, such as 0.5 part, 1 part , 1.5 copies, 2 copies, 2.5 copies, 3 copies, etc., this application does not limit this.

[0088] Specifically, the active agent is preferably a magnesium halide, and the magnesium halide includes at least one of magnesium chloride, magnesium fluoride, magnesium iodide, and magnesium bromide.

[0089] Since the magnesium halide is always in the solid state during the powder zinc sherardizing process, it can fully contact and react with the surface of the iron and steel parts and the seepage layer, so that the infiltration of magnesium is easier to achieve, and adding magnesium halide as an activator can promote the rapid and effective infiltration of magnesium. In the infiltrated layer, the interaction b...

Embodiment 3

[0092] On the basis of embodiment 1 or 2, this embodiment provides a kind of sherardizing method, and the sherardizing agent adopted in its step S1 can also include manganese dioxide, and the mass fraction of manganese dioxide is not greater than the mass fraction of decomposer Number, specifically, the mass fraction of manganese dioxide can be 0-3 parts, such as 0.01 part, 0.05 part, 0.1 part, 0.2 part, 0.3 part, 0.4 part, 0.5 part, 1 part, 1.5 part, 2 parts, 2.5 copies, 3 copies, etc., depending on the specific circumstances, this application does not limit this.

[0093] In practical applications, adding manganese dioxide to the zinc sherardizing agent can act as a catalyst for the infiltration reaction of magnesium, which promotes the diffusion of magnesium into the seepage layer by reacting with the ammonia halide as a decomposing agent. First, the ammonia halide is decomposed at high temperature to obtain ammonia and hydrogen halide gas, and then the hydrogen halide gas ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com