Process for preparing anti-bacteria stainless steel by double-layer glowing method

An antibacterial stainless steel, double glow technology, applied in coatings, manufacturing tools, heat treatment equipment, etc., can solve the problems of limited application scope, high rolling process requirements, increased labor intensity, etc., and achieve unlimited workpiece shape. , good antibacterial properties, avoid the effect of high copper content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

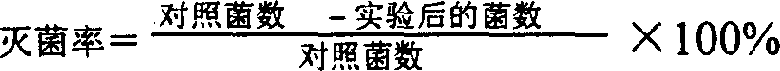

Examples

Embodiment

[0012] Embodiment (one) a kind of method for preparing martensitic antibacterial stainless steel with double-layer glow method

[0013] 1, a kind of concrete processing step that adopts double-layer glow method to prepare containing Cu martensitic antibacterial stainless steel is as follows:

[0014] (1) The matrix material is martensitic stainless steel, and its weight percentage is, C: 0.08~0.45wt%; Cr: 12~14wt%; Si: ≤0.6wt%; Mn: ≤0.8wt%; Cu: ≤ 0.1wt%; the rest is Fe.

[0015] (2) Put the above-mentioned martensitic stainless steel substrate into a double-layer glow metal infiltration furnace for surface copper infiltration, the pressure of argon gas is 20-80Pa, the source voltage is 1.2-1.4kV, and the workpiece voltage is 0.7-0.9 kV, the temperature is 900-1050°C, the pole spacing is 10-20mm, and the treatment time is 2-4 hours. The penetration amount of Cu element is 2.5-3.5wt%.

[0016] (3) Carry out vacuum aging treatment, the treatment time is 2-10 hours, and the tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com