Mo-Si-B coating on niobium-based alloy and preparation method of Mo-Si-B coating

A niobium-based alloy, mo-si-b technology, applied in the field of high-temperature oxidation-resistant coatings, can solve the problems of reduced strength of the base metal, high processing temperature, and long time, and achieve high-temperature oxidation resistance and flow improvement properties, viscosity-lowering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention relates to a method for preparing a Mo-Si-B coating on an Nb-based superalloy by combining plasma spraying and embedding infiltration technology. The coating preparation method has the following steps:

[0034] The first step: pretreatment of the substrate

[0035] (A) Nb-16Si-22Ti-17Cr-2Al-2Hf alloy matrix is carried out surface polishing treatment with SiC water abrasive paper of 800#, makes the first sample;

[0036] The surface roughness of the first sample is Ra=1.6~2.0;

[0037] (B) Put the first sample into absolute ethanol and perform ultrasonic cleaning for 10 to 20 minutes to obtain the second sample;

[0038] In the present invention, the purpose of grinding and cleaning the substrate is to obtain a clean surface with a certain roughness, and the surface of the substrate with a small roughness is conducive to the compact deposition of the Mo material.

[0039] The second step: plasma spraying Mo layer

[0040] The second sample was sprayed ...

Embodiment 1

[0058] The first step: pretreatment of the substrate

[0059] (A) Nb-16Si-22Ti-17Cr-2Al-2Hf alloy matrix is carried out surface polishing treatment with the SiC water abrasive paper of 800#, makes the first sample; The surface roughness of described first sample is Ra= 1.6;

[0060] (B) The first sample is put into absolute ethanol, and after ultrasonic cleaning is carried out for 15 minutes under the condition of ultrasonic frequency of 30 KHz, the second sample is obtained by natural air drying after cleaning;

[0061] The second step: plasma spraying Mo layer

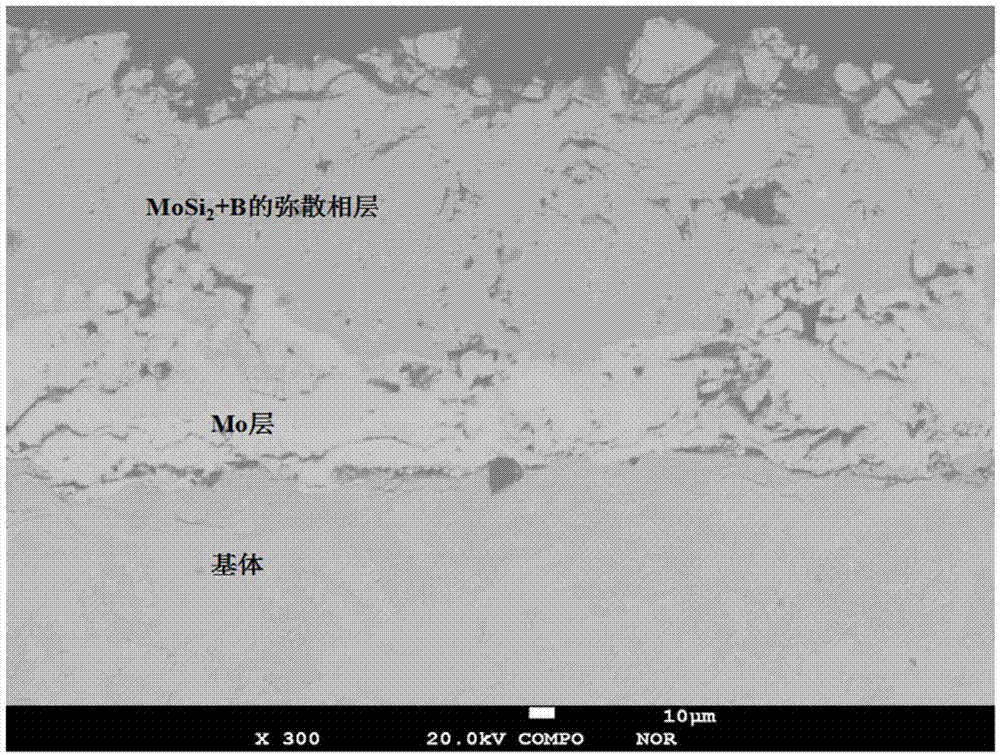

[0062] The second sample was sprayed with atmospheric plasma to form a Mo layer to obtain the third sample;

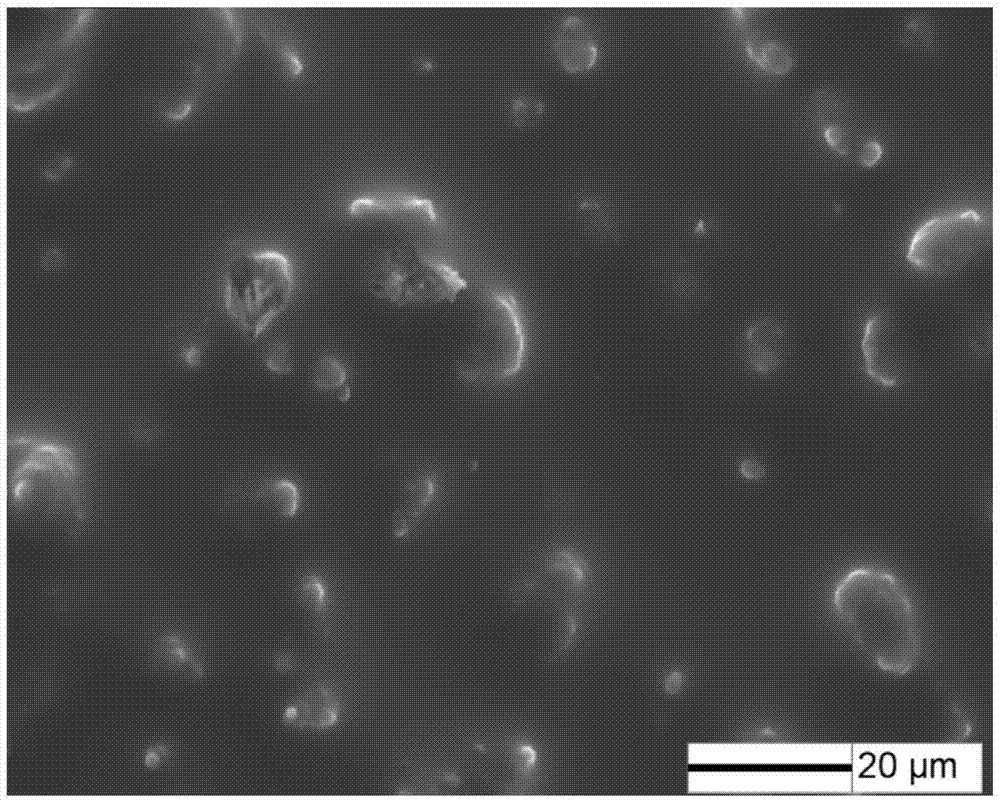

[0063] The particle size of Mo powder is 100μm;

[0064] Atmospheric plasma spraying process parameters: the current of atmospheric plasma spraying is 450 A, the voltage is 65 V, the flow rate of argon gas is 60 l / min, and the flow rate of hydrogen gas is 20 l / min; the average temperature of the substrat...

Embodiment 2

[0083] The first step: pretreatment of the substrate

[0084] (A) Nb-16Si-22Ti-17Cr-2Al-2Hf alloy matrix is carried out surface polishing treatment with the SiC water abrasive paper of 800#, makes the first sample; The surface roughness of described first sample is Ra= 1.8;

[0085] (B) After the first sample was put into absolute ethanol and ultrasonically cleaned for 15 minutes, the second sample was obtained;

[0086] The second step: plasma spraying Mo layer

[0087] The second sample was sprayed with atmospheric plasma to form a Mo layer to obtain a third sample;

[0088] The particle size of Mo powder is 75μm;

[0089] Atmospheric plasma spraying process parameters: the current of atmospheric plasma spraying is 450 A, the voltage is 65 V, the flow rate of argon gas is 60 l / min, and the flow rate of hydrogen gas is 20 l / min; the average temperature of the substrate surface during the deposition process is 300 °C; the spraying distance is 100 mm, and the powder feedi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com