Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31 results about "Monocalcium aluminate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

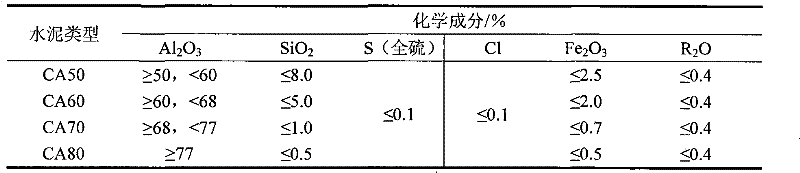

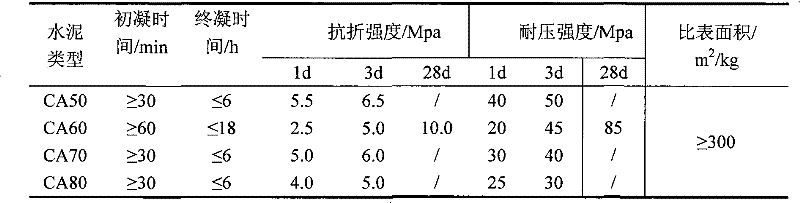

Monocalcium aluminate (CaAl₂O₄) is one of the series of calcium aluminates. It does occur in nature, although only very rarely, as two polymorphs known as krotite and dmitryivanovite, both from meteorites. It is important in the composition of calcium aluminate cements.

Aluminate cement and preparation thereof

InactiveCN101475327ARealize pollution-free treatmentHigh value-added utilizationCement productionMolten stateSlag

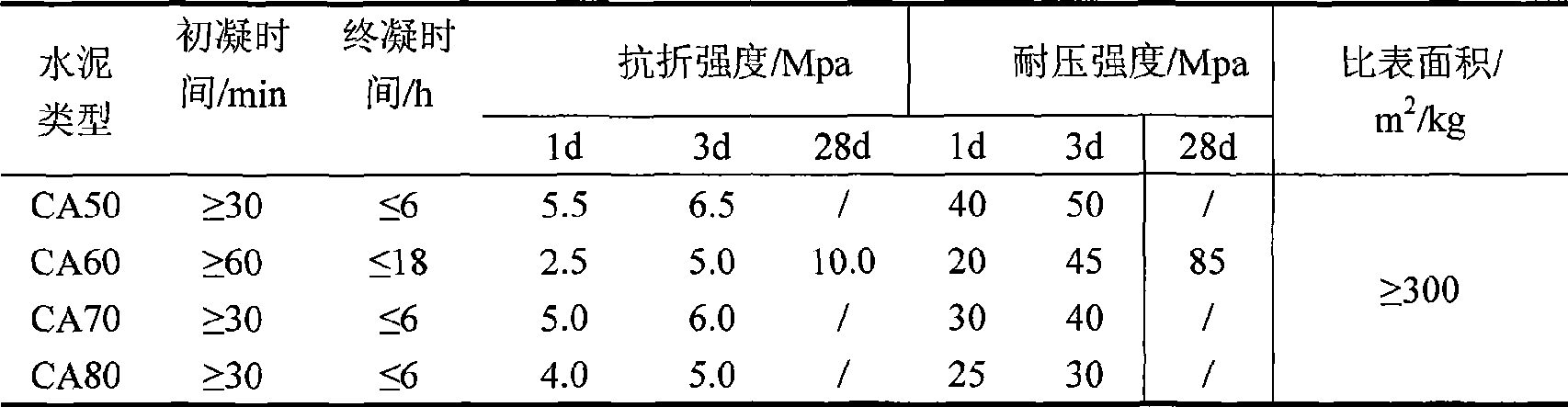

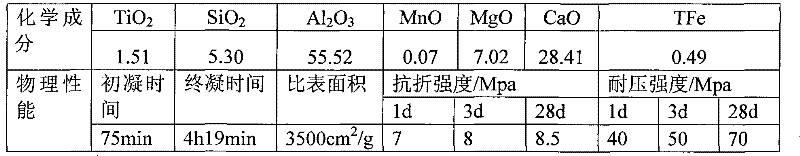

The invention in particular relates to an aluminate cement and a method for preparing the same. The invention adopts the following technical proposal: according to patent technology (ZL200510019664.3) of a method for preparing titanium and titanium alloy through utilization of titaniferous slag, after the titanium and titanium alloy are extracted by the patent method, the slag in a molten state is added with bauxite or industrial alumina of 5 to 40 weight percent of the slag, is melted, is subjected to cold quenching or slow cooling and is broken and pulverized till the specific surface area is more than 3,000cm / g, thereby preparing the aluminate cement. The chemical compositions of a produced product mainly comprise CaO, Al2O3, MgO and little SiO2; and the main crystal phases of the product are monocalcium aluminate (CA), dicalcium aluminate (CA2) and magnalium spinel (MgAl2O4) and sometimes contain little C12A7 and C2AS (gehlenite). The aluminate cement and the method can effectively utilize titanium resource of the slag, realize high added value utilization of the slag, realize harmless treatment of the titaniferous blast furnace slag and have better industrialized prospect.

Owner:WUHAN UNIV OF SCI & TECH

Super-early-strength and super-high-strength inorganic grouting material based on ordinary Portland cement and preparation method of grouting material

ActiveCN112939503AImprove early strengthSatisfy workabilitySolid waste managementMonocalcium aluminateWater reducer

The invention discloses a super-early-strength and super-high-strength inorganic grouting material based on ordinary Portland cement and a preparation method of the grouting material. The grouting material comprises the following components in parts by weight: 300-500 parts of ordinary Portland cement, 10-50 parts of silica fume, 400-600 parts of fine aggregate, 50-200 parts of a rapid hardening agent, 3-15 parts of a water reducing agent, 0.1-5 parts of a water-retaining agent and 0.1-5 parts of a defoaming agent. The rapid hardening agent comprises the following components in parts by weight: 20-100 parts of calcium aluminate mineral, 5-50 parts of anhydrous gypsum and 1-50 parts of light calcined magnesia. The calcium aluminate mineral is selected from one or more of anhydrous calcium sulphoaluminate mineral, calcium fluoroaluminate mineral, calcium aluminoferrite mineral, monocalcium aluminate and dodecacalcium heptaaluminate. The super-early-strength inorganic grouting material provided by the invention has ultrahigh hour strength while meeting workability, and the early strength of the grouting material is greatly improved; and the ordinary Portland cement and the anhydrite are used as basic raw materials, so that the material cost is low, and production and popularization are easy.

Owner:四川省佳宇建设集团有限公司

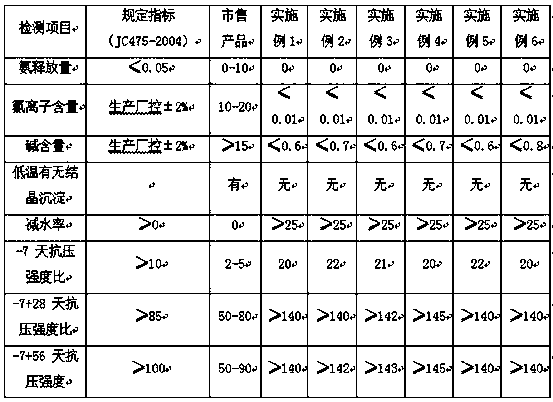

Cement early-strength admixture and preparation method thereof

The invention discloses a cement early-strength admixture which contains 34-58% of anhydrous calcium sulphoaluminate and 42-66% of monocalcium aluminate. The cement early-strength admixture is free of organic matters. The preparation method comprises the following steps: uniformly mixing calcic waste, bauxite and desulfurized gypsum, adding water (the water-to-cement ratio is 0.3-0.42), grinding for 4-7 hours, pouring the slurry into a mold, forming, and demolding to obtain a sample; and carrying out isothermal curing on the sample at 65-95 DEG C for 15-24 hours, cooling, crushing, calcining at 800-1000 DEG C for 60-120 minutes, taking out, quenching, and milling to obtain the cement early-strength admixture. The early-strength admixture prepared by the method provided by the invention has the advantages of early strength and setting acceleration, and does not need to add any organic matter which is harmful to the human body.

Owner:WASHI CEMENT GRP CO LTD

Concrete antifreezer and preparing method thereof

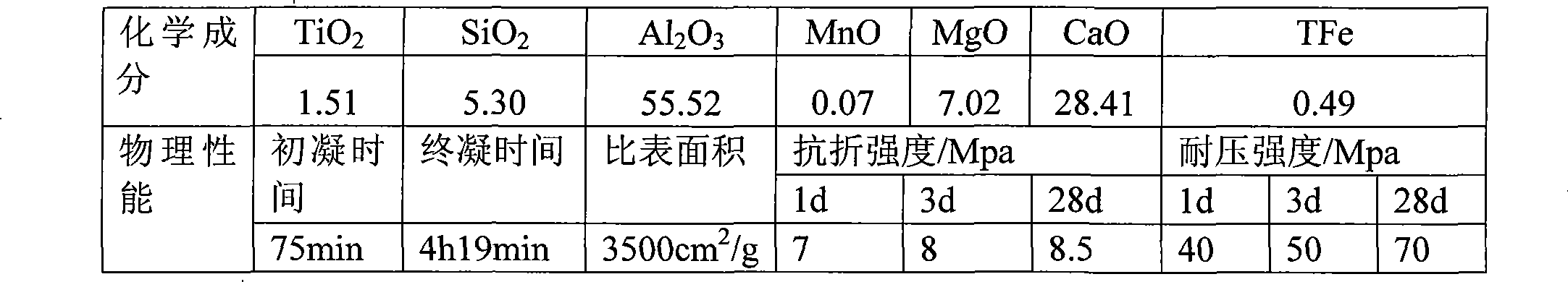

The invention relates to the technical field of concrete, in particular to concrete antifreezer.The concrete antifreezer is prepared from 15-25 parts of sodium oxide, 8-12 parts of aluminum potassium sulfate, 3-6 parts of triisopropanolamine, 10-12 parts of sodium lignosulphonate, 6-8 parts of sodium carbonate, 12-18 parts of monocalcium aluminate, 3-9 parts of sodium carboxymethylcellulose, 3-5 parts of paraffin, 1-4 parts of pimacol, 2-6 parts of cerous nitrate, 10-15 parts of tea saponin, 12-18 parts of melamine, 1.8-3.8 parts of SAF-I type superplasticizer, 0.8-2.4 parts of sulphonated acetone-formaldehyde resin, 1.2-3.8 parts of modified bentonite, 0.1-0.6 part of air entraining agent and 1.8-4.8 parts of antifoaming agent.The novel antifreezing components are adopted, the alkali content is greatly reduced, concrete alkali aggregate reaction can be avoided, and the antifreezer does not precipitate or crystallize when stored at the subzero temperature; the novel components do not contain ammonia and do not pollute the environment.

Owner:山东中粉建材科技有限公司

High temperature-resistant oil well cement, underground high temperature-resistant oil well cement paste and well cementation process method

InactiveCN102660241ALow elastic modulusDrilling compositionSealing/packingCementation processCement paste

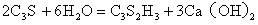

The invention discloses high temperature-resistant oil well cement, underground high temperature-resistant oil well cement paste and a well cementation process method. The high temperature-resistant oil well cement comprises 65 to 95 weight parts of monocalcium aluminate and 5 to 35 weight parts of dicalcium silicate which are used as main components and citric acid. The underground high temperature-resistant oil well cement paste comprises 50 to 56 weight parts of 50 to 56 weight parts of high temperature-resistant oil well cement, 44 to 50 weight parts of clear water, and 0.5 to 1.5 weight parts of retarder citric acid. The thickening time of the underground high temperature-resistant oil well cement paste is controlled to be 2 to 9 hours by the retarder citric acid. When the underground high temperature-resistant oil well cement paste is used for well cementation, a well can resist 800 DEG C and more than 60 MPa, and elastic modulus is less than 10 GPa; and the underground high temperature-resistant oil well cement paste can be applied to thickened oil thermal wells, extradeep wells, very deep wells and geothermal wells.

Owner:WUXI WEISHI TECH

Method for preparing high-purity monocalcium aluminate by solid-phase reaction

InactiveCN105859165AImproved mix mass ratioSimple production processCalcium aluminatesMonocalcium aluminateTableting

The invention relates to a method for preparing high-purity monocalcium aluminate by a solid-phase reaction. The monocalcium aluminate (CaO.Al2O3, CA) is prepared by the following steps: sufficiently and uniformly mixing 1 part of aluminum oxide (Al2O3) powder and 0.8-1 part of calcium carbonate (CaCO3) powder both by mass in an agate mortar in a closed environment; performing sufficient heat treatment with a platinum / rhodium crucible at 1000-1200 DEG C; heating to 1200-1400 DEG C and preserving heat for 4-6 hours; closing the heating furnace and slowly cooling to room temperature; grinding the mixture into fine-particle powder in the agate mortar in a closed environment; heating to 1200-1400 DEG C and preserving heat for 4-6 hours; closing the heating furnace and slowly cooling to room temperature; and levigating the powder in the agate mortar in a closed environment to obtain monocalcium aluminate. In the invention, the preparation technology is simple, the tabletting and granulating of raw materials are not needed, the reaction raw materials are nontoxic, and the product purity is very high.

Owner:TONGJI UNIV

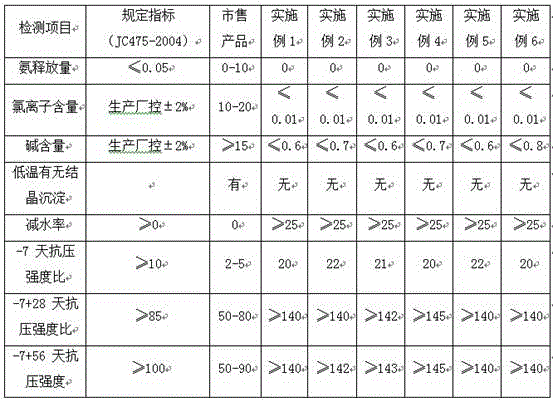

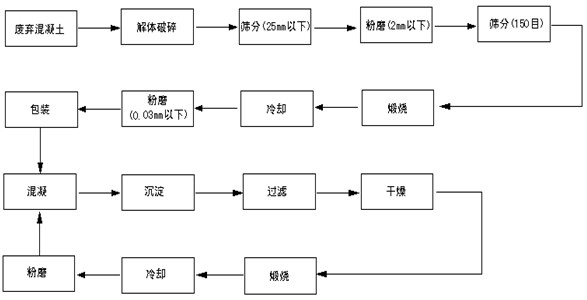

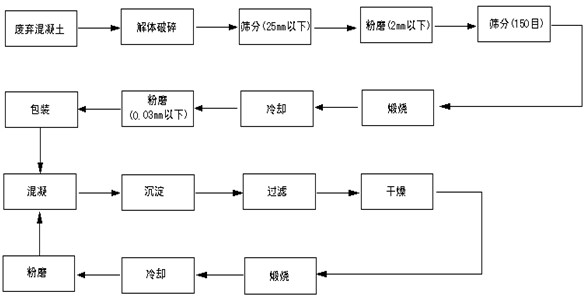

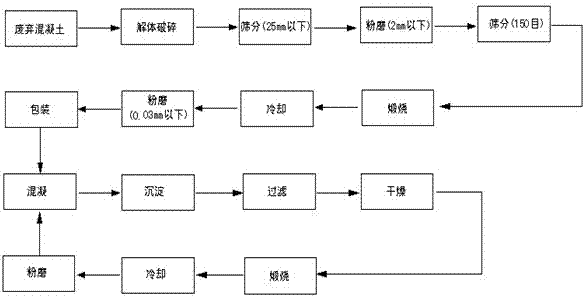

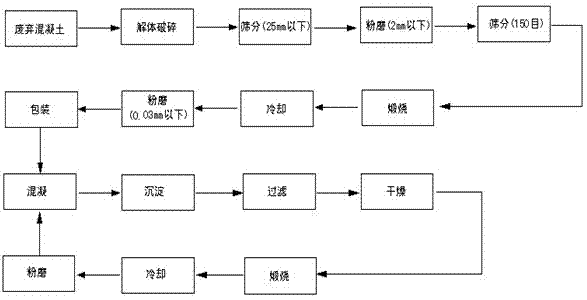

Regenerative coagulant, and preparation method and using method thereof

InactiveCN102079563ASolving Recycling ProblemsSolve processingSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningPhosphateSludge

The invention relates to a regenerative coagulant, and a preparation method and a using method thereof. The regenerative coagulant is characterized in that: the regenerative coagulant is prepared from waste concrete serving as a raw material. The preparation method comprises the following specific steps of: collecting the waste concrete, rejecting sands, crushing and grinding the waste concrete, sieving the ground concrete by using a 150-mesh sieve, calcinating the sieved concrete for 2h, cooling the calcinated concrete and levigating the cooled concrete to obtain the regenerative coagulant in form of powder with the particle sizes of less than 0.03mm and the specific surface area of 3,000 to 4,000 cm<2> / g. The regenerative coagulant and the preparation method ensure a good coagulation effect by fully utilizing the hydration of artificial minerals such as monocalcium aluminate, dicalcium phosphate, tricalcium silicate, tricalcium aluminate, tetracalcium aluminoferrite and the like, the electrical neutralization, absorption and enmeshment effects of hydrolyzate and the synergism of coagulation and precipitation; and in the using method, coagulant regeneration is realized by utilizing the high precipitation performance of coagulation sludge and adopting filtration, drying and calculation flows to recycle the coagulant for many times.

Owner:DONGHUA UNIV

Ceramic filter for continuous casting tundish and method for preparing the same

ActiveCN104944984AHigh strengthImprove corrosion resistanceMonocalcium aluminateUltimate tensile strength

The invention relates to a ceramic filter for a continuous casting tundish and a method for preparing the same. The technical scheme is that 50-70wt% of calcium carbonate particles, 2-15wt% of corundum particles and 2-10wt% of magnesia-alumina spinel particles serve as aggregate; 1-5wt% of prefused dodecacalcium hepta-aluminate particles, 10-15wt% of fine monocalcium aluminate powder and 4-10wt% of fine calcium dialuminate powder and 4-6wt% of prefused fine dodecacalcium hepta-aluminate powder serve as substrates; and silicone resin that accounts for 2-7wt% of the sum of the aggregate and the substrates serves as a binding agent. The binding agent and the aggregate are mixed and ground evenly, and the substrates are added to be mixed and ground for 3-7 min to obtain a mixture; vibrating pressure forming is performed, demolding is performed, and the mixture undergoes heat preservation for 6-36 h at 180-320 DEG C to obtain the ceramic filter for the continuous casting tundish. The ceramic filter for the continuous casting tundish has the advantages of wide impurity-removing particle size range, high efficiency, insusceptibility to blockage, high strength, washing resistance and long service life.

Owner:WUHAN UNIV OF SCI & TECH

Aluminate cement and preparation thereof

The present invention in particular relates to an aluminate cement and a method for preparing the same. The invention adopts the following technical proposal: according to patent technology (ZL200510019664.3) of a method for preparing titanium and titanium alloy through utilization of titaniferous slag, after the titanium and titanium alloy are extracted by the patent method, the slag in a molten state is added with bauxite or industrial alumina of 5 to 40 weight percent of the slag, is melted, is subjected to cold quenching or slow cooling and is broken and pulverized till the specific surface area is more than 3,000cm<2> / g, thereby preparing the aluminate cement. The chemical compositions of a produced product mainly comprise CaO, Al2O3, MgO and little SiO2; and the main crystal phases of the product are monocalcium aluminate (CA), dicalcium aluminate (CA2) and magnalium spinel (MgAl2O4) and sometimes contain little C12A7 and C2AS (gehlenite). The aluminate cement and the method can effectively utilize titanium resource of the slag, realize high added value utilization of the slag, realize harmless treatment of the titaniferous blast furnace slag and have better industrialized prospect.

Owner:WUHAN UNIV OF SCI & TECH

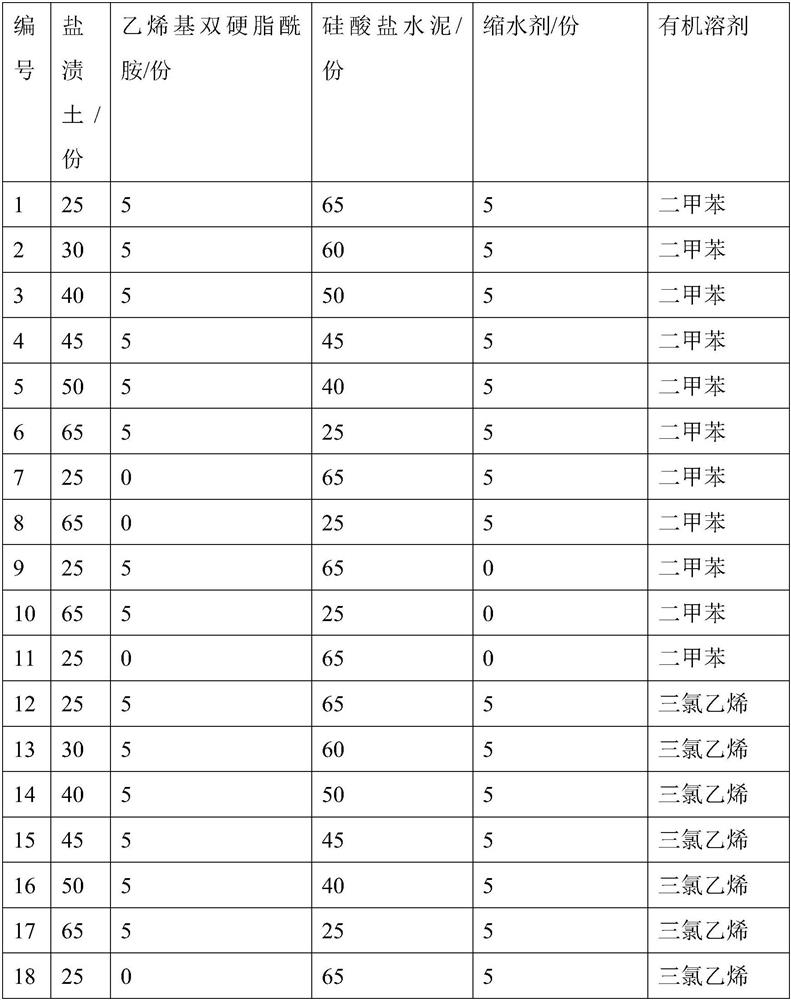

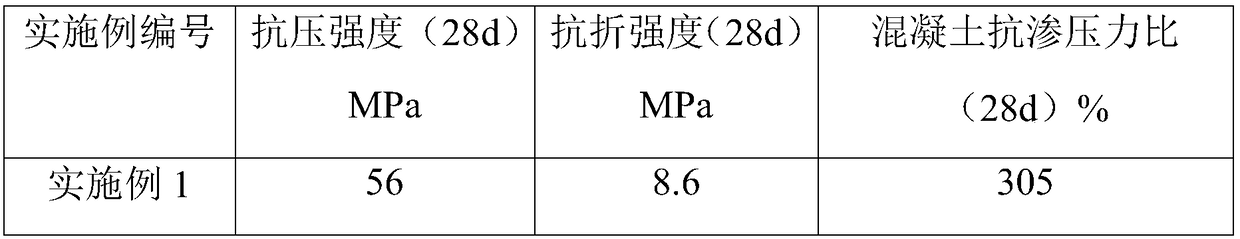

Cement modifier containing salinized soil and preparation method thereof

The invention relates to the field of cement modification, and particularly discloses a cement modifier containing salinized soil and a preparation method of the cement modifier. The cement modifier containing salinized soil comprises a component A and a component B, wherein the component A comprises the following raw materials in parts by weight: 25-65 parts of salinized soil, 0-5 parts of vinyl bis stearamide, 2-5 parts of Portland cement, 0-5 parts of a shrinking agent, and 0-5 parts of an organic solvent, and the component B is prepared from 5-8 parts of monocalcium aluminate. The preparation method comprises the following steps: pretreating salinized soil; dissolving vinyl bis stearamide; dispersing the salinized soil; solidifying the salinized soil; and finally mixing. According to the invention, the cement modifier containing the salinized soil has the advantages that the resistance of cement to thermal expansion and cold contraction is enhanced by utilizing soluble salt in the salinized soil; and the preparation method disclosed by the invention has the advantage that the cement with resistance to thermal expansion and cold contraction is prepared by simple and convenient steps.

Owner:包头市鼎鑫电杆有限公司

Concrete material containing active additive

The invention discloses a concrete material containing an active additive. The concrete material comprises Portland cement, the active additive, sodium silicate, quartz sand and water, wherein the active additive comprises material A, material B and material C; the material A is made with allophane and potassium carbonate; the material B is made with tartaric acid, maleic acid, ammonium formate, calcium metaaluminate, oxalic acid, sodium tartrate and calcium chloride; the material C is made with sodium silicate, sodium citrate, zinc formate, calcium carbonate, potassium carbonate, sodium acetate trihydrate, calcium formate, calcium metaaluminate and calcium chloride. The problem that traditional concrete material has insufficient overall mechanical strength and anti-permeability performance is solved.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Magnesium aluminate cement material containing C7A5M mineral

ActiveCN112645617AOutstanding early hardening and fast hardening performanceLower firing temperaturePhysical chemistryCem cement

The invention provides a magnesium aluminate cement material containing a C7A5M mineral, the weight percentage of a magnesium pentacalcium aluminate mineral in cement clinker is 40-60%, and the magnesium pentacalcium aluminate is 7CaO. 5Al2O3. MgO. And the cement clinker also contains monocalcium aluminate and magnesium aluminate. The aluminate cement material containing the C7A5M mineral has outstanding early strength and rapid hardening performance, and is low in firing temperature, good in hydration performance and energy-saving. The compressive strength of the cement mortar is 30-50 MPa in 3d and 60-80 MPa in 28d, the middle and later strength of the cement is remarkably improved, and the strength loss caused by air shrinkage is made up.

Owner:UNIV OF JINAN

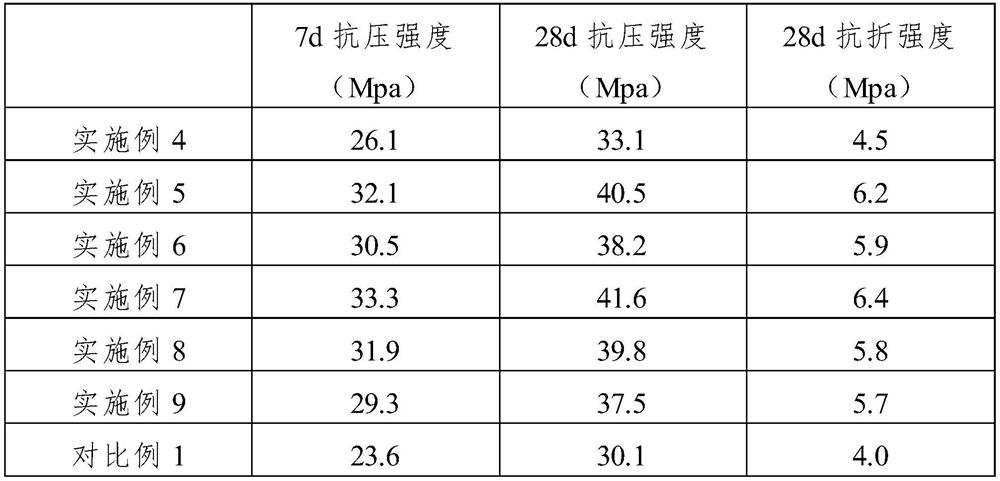

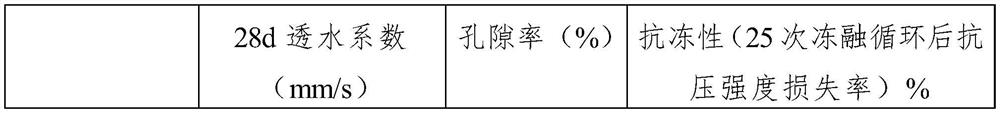

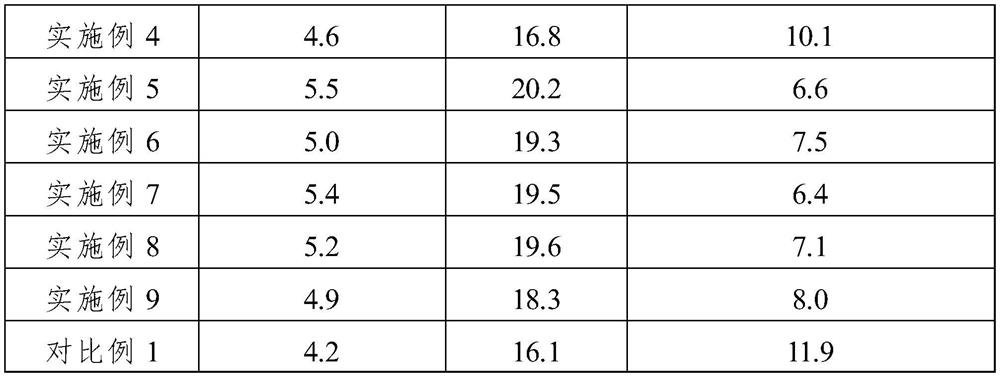

Water-permeable concrete early strength agent, water-permeable concrete and preparation method of water-permeable concrete early strength agent

ActiveCN114873942AImprove early strength performancePromote hydrationSolid waste managementMonocalcium aluminateUltimate tensile strength

The invention relates to the technical field of pervious concrete, in particular to a pervious concrete early strength agent, pervious concrete and a preparation method thereof.The pervious concrete early strength agent is prepared from, by weight, 15-20% of monocalcium aluminate, 0.5-1% of diethanolisopropanolamine and 79-84.5% of ettringite growth promoting agent; the ettringite growth promoting agent is prepared from the following raw materials in parts by weight: 45-55 parts of water-quenched superfine slag powder, 5-10 parts of gypsum, 3-6 parts of lime powder and 35-45 parts of water. The pervious concrete comprises the following raw materials in parts by weight: 1600-1800 parts of coarse aggregate, 370-420 parts of cement, 15-50 parts of an admixture, 3-6 parts of a water reducing agent, 135-155 parts of water and an early strength agent accounting for 1%-5% of the mass of the cement, the pervious concrete early strength agent endows pervious concrete with high early strength performance, and the pervious concrete is high in strength, strong in toughness and excellent in comprehensive performance.

Owner:江苏佳境生态工程技术有限公司

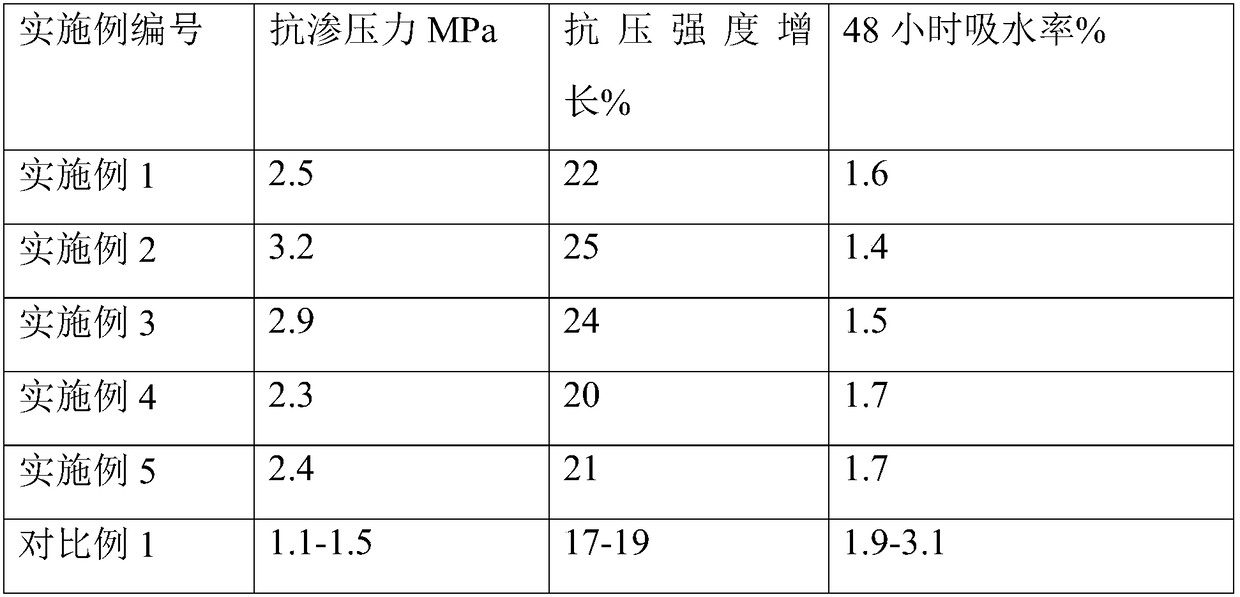

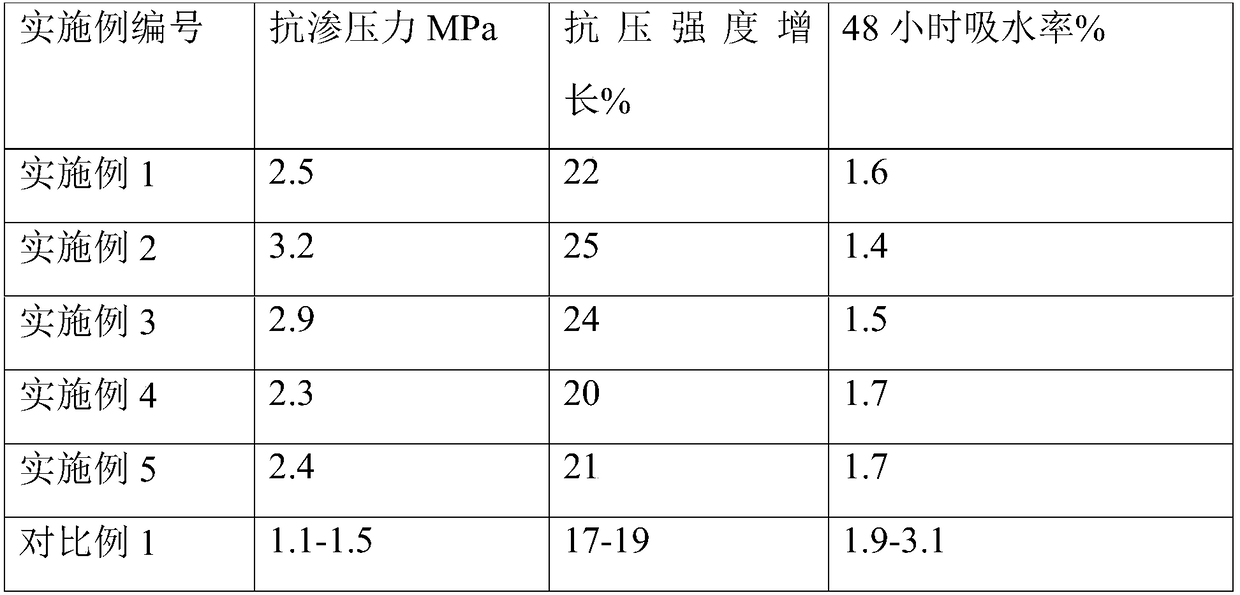

Method for preparing concrete waterproof material

The invention discloses a method for preparing concrete waterproof material, and the preparation method comprises: mixing cesium stearate, cesium chloride, sodium citrate, calcium carbonate, sodium carbonate, sodium silicate, beryllium carbonate, sodium hydrogen carbonate, calcium metaaluminate and calcium chloride, drying, sieving, roasting and grinding to obtain material A; mixing D-malic acid,L-malic acid, cesium tartrate, tartaric acid, sodium malate and calcium metaaluminate, drying, sieving, roasting and grinding to obtain material B; mixing gedanite, cesium carbonate and hydrochloric acid solution, performing heating treatment, and grinding to obtain material C; mixing the material A, the material B and the material C, roasting and carrying out secondary tempering treatment to obtain a crystalline composite material; mixing the silicate cement, the crystalline composite material, the sodium silicate, the quartz sand and the water to obtain a concrete waterproof material. The concrete waterproof material solves the problems that the traditional concrete waterproof material has insufficient impermeability and compressive strength, and bad waterproof effect.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Renewable ceramic filter for continuous casting tundish and preparation method thereof

ActiveCN104926331AHigh strengthImprove corrosion resistanceMelt-holding vesselsFiberSuperplasticizer

The invention relates to a renewable ceramic filter for continuous casting tundish and a preparation method thereof. According to the technical scheme, 40 to 60wt% of the calcium carbonate particles, 15 to 30wt% of corundum particles and 1 to 5wt% of pre-melting '12:7'calcium aluminate particles serve as aggregate, 10 to 15wt% of monocalcium aluminate fine powder, 4 to 10wt% of calcium dialuminate fine powder and 4 to 6wt% of pre-melting '12:7'calcium aluminate fine powder serve as substrate, and organic fiber accounting for 0.04 to 0.10wt% of the sum of the aggregate and the substrate and polycarboxylate superplasticizer accounting for 0.08 to 0.15wt% thereof as admixture. The method includes: grind-mixing evenly the binding agent and the substrate according to the content mentioned above, and adding the aggregate to grind-mix so as to obtain a mixed material; adding water accounting for 4 to 6wt% of the sum of the aggregate and the substrate, performing evenly mixing, forming, curing, demolding and drying, and holding the temperature at 1200 to 1700 DEG C for 0.5 to 6 hours to obtain the renewable ceramic filter for the continuous casting tundish. The renewable ceramic filter has the advantages of wide range of purified particle size, high efficiency, little possibility of plugging, erosion resistance and long service life.

Owner:WUHAN UNIV OF SCI & TECH +1

an elastic concrete

The invention belongs to the technical field of new materials and discloses elastic concrete. The elastic concrete comprises the following raw materials in parts by weight: 30-40 parts of cement, 10-20 parts of slag powder, 40-80 parts of rubber particles, 1-3 parts of a composite fiber, 0.01-0.05 part of polyoxyethylene sorbitan monostearate, 30-60 parts of emulsified asphalt, 10-30 parts of water-borne epoxy resin, 0.5-2 parts of a polycarboxylate superplasticizer, 0.01-0.05 part of a defoamer, 1-2 parts of calcium metaaluminate, 3-8 parts of modified zeolite powder, 50-60 parts of sand and10-30 parts of water. The elastic concrete is compounded by inorganic materials, is low in price, high in elasticity, good in flexibility and excellent in anti-freezing property, can be used for outdoor works, can effectively absorb an impact force brought by exercise, improves the degree of comfort during exercise and reduces injuries of the impact force on a body; and as the rubber particles arelow in heat conductivity coefficient and high in flexibility, an outdoor sport field can be prevented from free-thaw damages, and the service life of the field is prolonged.

Owner:建德市晶磊混凝土有限公司

High temperature-resistant oil well cement, underground high temperature-resistant oil well cement paste and well cementation process method

InactiveCN102660241BLow elastic modulusDrilling compositionSealing/packingCementation processCement paste

The invention discloses high temperature-resistant oil well cement, underground high temperature-resistant oil well cement paste and a well cementation process method. The high temperature-resistant oil well cement comprises 65 to 95 weight parts of monocalcium aluminate and 5 to 35 weight parts of dicalcium silicate which are used as main components and citric acid. The underground high temperature-resistant oil well cement paste comprises 50 to 56 weight parts of 50 to 56 weight parts of high temperature-resistant oil well cement, 44 to 50 weight parts of clear water, and 0.5 to 1.5 weight parts of retarder citric acid. The thickening time of the underground high temperature-resistant oil well cement paste is controlled to be 2 to 9 hours by the retarder citric acid. When the underground high temperature-resistant oil well cement paste is used for well cementation, a well can resist 800 DEG C and more than 60 MPa, and elastic modulus is less than 10 GPa; and the underground high temperature-resistant oil well cement paste can be applied to thickened oil thermal wells, extradeep wells, very deep wells and geothermal wells.

Owner:WUXI WEISHI TECH

A method for preparing high-purity monocalcium aluminate by solid-phase reaction

InactiveCN105859165BImproved mix mass ratioSimple production processCalcium aluminatesPlatinumRoom temperature

The invention relates to a method for preparing high-purity monocalcium aluminate by a solid-phase reaction. The monocalcium aluminate (CaO.Al2O3, CA) is prepared by the following steps: sufficiently and uniformly mixing 1 part of aluminum oxide (Al2O3) powder and 0.8-1 part of calcium carbonate (CaCO3) powder both by mass in an agate mortar in a closed environment; performing sufficient heat treatment with a platinum / rhodium crucible at 1000-1200 DEG C; heating to 1200-1400 DEG C and preserving heat for 4-6 hours; closing the heating furnace and slowly cooling to room temperature; grinding the mixture into fine-particle powder in the agate mortar in a closed environment; heating to 1200-1400 DEG C and preserving heat for 4-6 hours; closing the heating furnace and slowly cooling to room temperature; and levigating the powder in the agate mortar in a closed environment to obtain monocalcium aluminate. In the invention, the preparation technology is simple, the tabletting and granulating of raw materials are not needed, the reaction raw materials are nontoxic, and the product purity is very high.

Owner:TONGJI UNIV

A kind of cement accelerator and preparation method thereof

The invention discloses a cement early-strength admixture which contains 34-58% of anhydrous calcium sulphoaluminate and 42-66% of monocalcium aluminate. The cement early-strength admixture is free of organic matters. The preparation method comprises the following steps: uniformly mixing calcic waste, bauxite and desulfurized gypsum, adding water (the water-to-cement ratio is 0.3-0.42), grinding for 4-7 hours, pouring the slurry into a mold, forming, and demolding to obtain a sample; and carrying out isothermal curing on the sample at 65-95 DEG C for 15-24 hours, cooling, crushing, calcining at 800-1000 DEG C for 60-120 minutes, taking out, quenching, and milling to obtain the cement early-strength admixture. The early-strength admixture prepared by the method provided by the invention has the advantages of early strength and setting acceleration, and does not need to add any organic matter which is harmful to the human body.

Owner:WASHI CEMENT GRP CO LTD

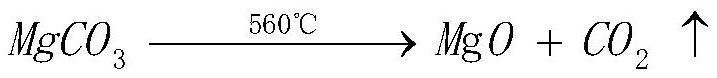

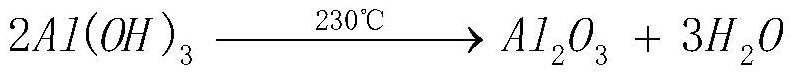

A kind of magnesia expansion agent prepared by using high-calcium magnesite tailings and its preparation method

ActiveCN110066128BRetains its own expansive propertiesImprove mechanical propertiesAluminium hydroxideEconomic benefits

The invention discloses a magnesia expansion agent and a method prepared by using high-calcium magnesite tailings. The magnesia expansion agent of the present invention uses high-calcium magnesite tailings as the main raw material, and uses aluminum hydroxide as the adjusting material. It was prepared by calcination at 1050°C. The present invention utilizes the Al produced by the decomposition of aluminum hydroxide 2 O 3 Absorb the f-CaO produced by the decomposition of high-calcium magnesite tailings to form the cementitious substances monocalcium aluminate and dodecalumina heptaaluminate, which significantly reduces the production of magnesite expansion agent from high-calcium magnesite tailings. The content of f-CaO solves the social problem of high-calcium magnesite tailings causing pollution to the ecological environment, expands the direction for the high value-added application of high-calcium magnesite tailings, and reduces the use of magnesite expansion agents. The production cost provides market competitiveness for the promotion and application of magnesium expansion agent in water conservancy and hydropower projects, and has significant social and economic benefits.

Owner:ZHENJIANG SOBUTE NEW MATERIAL CO LTD +1

a c 7 a 5 m mineral magnesium aluminate cement material

ActiveCN112645617BOutstanding early hardening and fast hardening performanceLower firing temperaturePhysical chemistryEngineering

The invention provides a C-containing 7 A 5 M mineral magnesium aluminate cement material, the weight percentage of magnesium pentaaluminate heptacalcium mineral in the cement clinker is 40~60%, and the magnesium pentaaluminate heptacalcium is 7CaO.5Al 2 o 3 .MgO. Cement clinker also contains monocalcium aluminate and magnesium aluminate. C containing in the present invention 7 A 5 The aluminate cement material of M mineral has outstanding early strength and rapid hardening performance, low firing temperature, good hydration performance, and energy saving. The compressive strength of cement mortar: 30~50MPa for 3d, 60~80Mpa for 28d, the strength of cement in the middle and late stages has been significantly improved to make up for the strength loss caused by drying shrinkage.

Owner:UNIV OF JINAN

Ceramic filter for continuous casting tundish and preparation method thereof

ActiveCN104944984BHigh strengthImprove corrosion resistanceFiltration separationDodecacalcium hepta-aluminateSpinel

The invention relates to a ceramic filter for a continuous casting tundish and a method for preparing the same. The technical scheme is that 50-70wt% of calcium carbonate particles, 2-15wt% of corundum particles and 2-10wt% of magnesia-alumina spinel particles serve as aggregate; 1-5wt% of prefused dodecacalcium hepta-aluminate particles, 10-15wt% of fine monocalcium aluminate powder and 4-10wt% of fine calcium dialuminate powder and 4-6wt% of prefused fine dodecacalcium hepta-aluminate powder serve as substrates; and silicone resin that accounts for 2-7wt% of the sum of the aggregate and the substrates serves as a binding agent. The binding agent and the aggregate are mixed and ground evenly, and the substrates are added to be mixed and ground for 3-7 min to obtain a mixture; vibrating pressure forming is performed, demolding is performed, and the mixture undergoes heat preservation for 6-36 h at 180-320 DEG C to obtain the ceramic filter for the continuous casting tundish. The ceramic filter for the continuous casting tundish has the advantages of wide impurity-removing particle size range, high efficiency, insusceptibility to blockage, high strength, washing resistance and long service life.

Owner:WUHAN UNIV OF SCI & TECH

Regenerative coagulant, and preparation method and using method thereof

InactiveCN102079563BWith coagulation effectSolving Recycling ProblemsSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningPhosphateFiltration

The invention relates to a regenerative coagulant, and a preparation method and a using method thereof. The regenerative coagulant is characterized in that: the regenerative coagulant is prepared from waste concrete serving as a raw material. The preparation method comprises the following specific steps of: collecting the waste concrete, rejecting sands, crushing and grinding the waste concrete, sieving the ground concrete by using a 150-mesh sieve, calcinating the sieved concrete for 2h, cooling the calcinated concrete and levigating the cooled concrete to obtain the regenerative coagulant in form of powder with the particle sizes of less than 0.03mm and the specific surface area of 3,000 to 4,000 cm<2> / g. The regenerative coagulant and the preparation method ensure a good coagulation effect by fully utilizing the hydration of artificial minerals such as monocalcium aluminate, dicalcium phosphate, tricalcium silicate, tricalcium aluminate, tetracalcium aluminoferrite and the like, the electrical neutralization, absorption and enmeshment effects of hydrolyzate and the synergism of coagulation and precipitation; and in the using method, coagulant regeneration is realized by utilizing the high precipitation performance of coagulation sludge and adopting filtration, drying and calculation flows to recycle the coagulant for many times.

Owner:DONGHUA UNIV

Renewable ceramic filter for continuous casting tundish and preparation method thereof

ActiveCN104926331BHigh strengthImprove corrosion resistanceMelt-holding vesselsFiberSuperplasticizer

The invention relates to a renewable ceramic filter for continuous casting tundish and a preparation method thereof. According to the technical scheme, 40 to 60wt% of the calcium carbonate particles, 15 to 30wt% of corundum particles and 1 to 5wt% of pre-melting '12:7'calcium aluminate particles serve as aggregate, 10 to 15wt% of monocalcium aluminate fine powder, 4 to 10wt% of calcium dialuminate fine powder and 4 to 6wt% of pre-melting '12:7'calcium aluminate fine powder serve as substrate, and organic fiber accounting for 0.04 to 0.10wt% of the sum of the aggregate and the substrate and polycarboxylate superplasticizer accounting for 0.08 to 0.15wt% thereof as admixture. The method includes: grind-mixing evenly the binding agent and the substrate according to the content mentioned above, and adding the aggregate to grind-mix so as to obtain a mixed material; adding water accounting for 4 to 6wt% of the sum of the aggregate and the substrate, performing evenly mixing, forming, curing, demolding and drying, and holding the temperature at 1200 to 1700 DEG C for 0.5 to 6 hours to obtain the renewable ceramic filter for the continuous casting tundish. The renewable ceramic filter has the advantages of wide range of purified particle size, high efficiency, little possibility of plugging, erosion resistance and long service life.

Owner:WUHAN UNIV OF SCI & TECH +1

A kind of concrete antifreeze and preparation method thereof

Owner:山东中粉建材科技有限公司

Preparation method of concrete material containing active additives

ActiveCN109133836BSolve the mechanical strengthImprove waterproof performanceOXALIC ACID DIHYDRATECalcium formate

The invention discloses a preparation method of a concrete material containing active additives. The preparation method comprises: mixing allophane, potassium carbonate powder and hydrochloric acid solution, and performing the first heat treatment and the second heat treatment in sequence , to obtain material A after grinding; mix tartaric acid, maleic acid, ammonium formate, calcium metaaluminate, oxalic acid, sodium tartrate and calcium chloride, and obtain material B after drying, sieving, roasting and grinding; Sodium silicate, sodium citrate, zinc formate, calcium carbonate, potassium carbonate, sodium acetate trihydrate, calcium formate, calcium metaaluminate and calcium chloride are mixed, and material C is obtained after drying, sieving, roasting and grinding; After mixing material A, material B and material C, the active additive is obtained through roasting and secondary tempering treatment; the concrete material is obtained by mixing portland cement, active additive, sodium silicate, quartz sand and water. It solves the problem of insufficient overall mechanical strength and impermeability of traditional concrete materials.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Preparation method of waterproof material

InactiveCN109020458ASolve the problems of many deficiencies in performanceSodium stearateSodium phosphates

The invention discloses a preparation method of a waterproof material. The preparation method comprises the following steps: preparation of a material A: mixing citric acid, beryllium tartrate, tartaric acid, maleic acid, ammonium formate and calcium metaaluminate, drying, sieving, roasting and grinding to obtain the material A; preparation of a material B: mixing calcium carbonate, sodium carbonate, sodium silicate, sodium stearate, alumina, sodium citrate pentahydrate, sodium metatitantate, sodium phosphate hydrate, calcium formate and calcium metaaluminate, drying, sieving, roasting and grinding to obtain the material B; preparation of a material C: mixing kaolinite, sodium carbonate powder and a hydrochloric acid solution, successively carrying out first heating treatment and secondaryheating treatment, and grinding to obtain the material C; mixing the material A, the material B and the material C, roasting and carrying out secondary tempering treatment to obtain a building core material; mixing Portland cement, the building core material, sodium silicate and water so as to obtain the waterproof material. Many deficiencies in performance of traditional waterproof materials aresolved.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

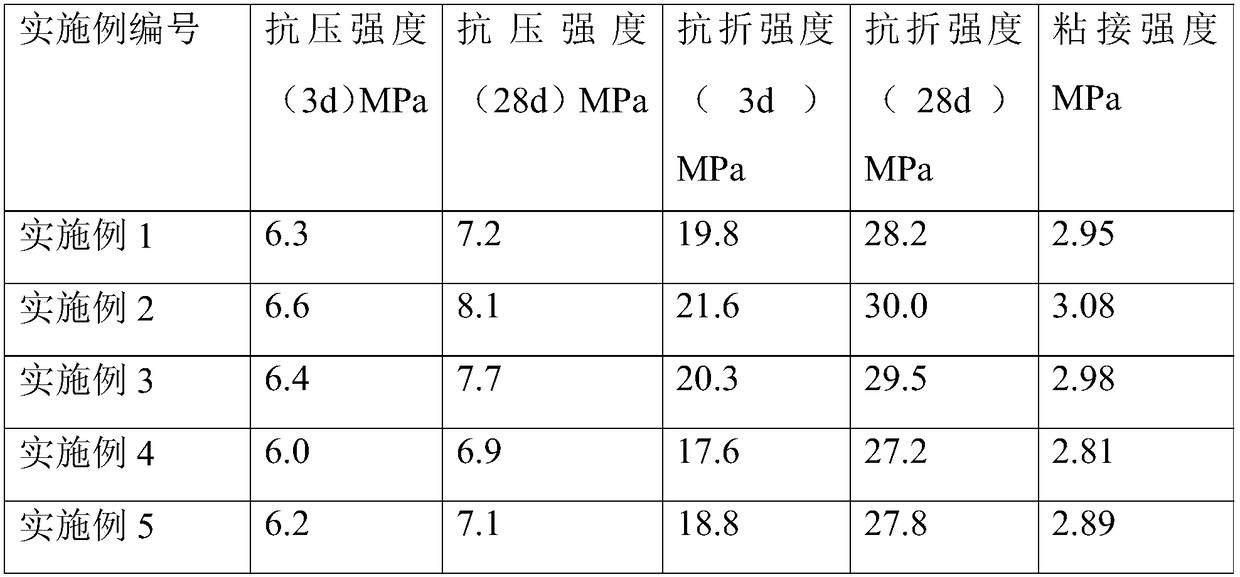

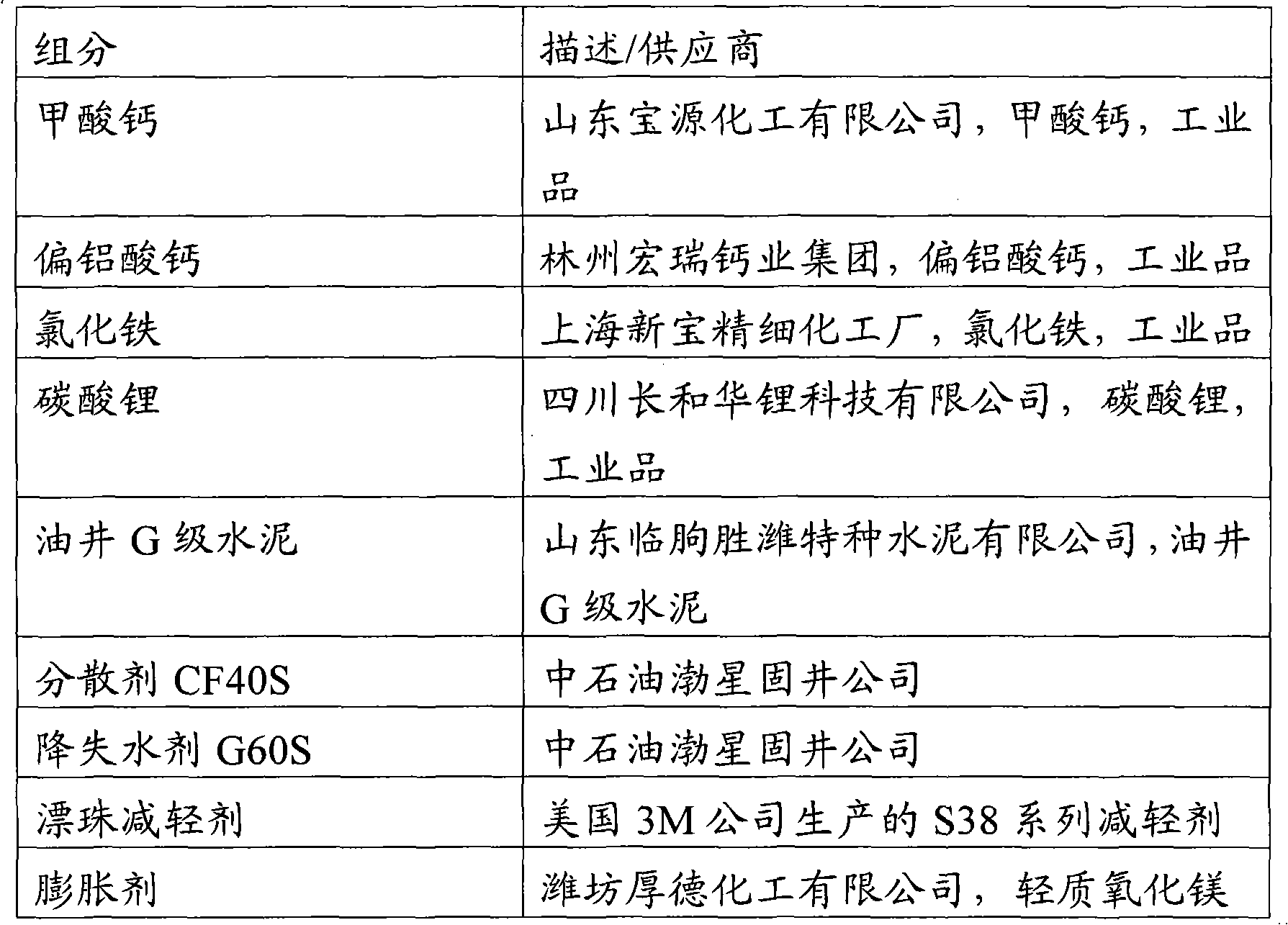

Early strength agent composition and preparation method thereof, cement composition and uses of above

The present invention relates to an early strength agent composition, which comprises the following materials, by weight, 15-40 parts of a soluble organic calcium compound, 5-25 parts of calcium metaaluminate (Ca(AlO2)2), 25-55 parts of a metal chloride, and 10-28 parts of an alkali metal carbonate (M2CO3), wherein M is an alkali metal. The present invention further relates to a preparation method for the early strength agent composition, a cement composition containing the early strength agent composition. The present invention further relates to uses of the compositions in cementing application.

Owner:CHINA UNITED COALBED METHANE +1

Crystalline composite material and concrete waterproof material

The invention discloses a crystalline composite material and a concrete waterproof material. The crystalline composite material is composed of a material A, a material B and a material C; wherein rawmaterials of the material A include cesium stearate, cesium chloride, sodium citrate, calcium carbonate, sodium carbonate, sodium silicate, beryllium carbonate, sodium hydrogencarbonate, calcium metaaluminate and calcium chloride. Raw materials of the material B include D-malic acid, L-malic acid, cesium tartrate, tartaric acid, sodium malate and calcium metaaluminate. Raw materials of the material C include gedanite and cesium carbonate. The crystalline composite material and the concrete waterproof material solve the problem that the traditional waterproof material has insufficient impermeability and compressive strength and poor waterproof effect.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Method for recycling discharged water through carbon neutralization

PendingCN114014458ALow costReduce conductivityCalcium/strontium/barium sulfatesDispersed particle separationSodium aluminateEnvironmental engineering

The invention relates to the technical field of chloride ion removal and carbon neutralization recycling, in particular to a method for recycling discharged water through carbon neutralization. According to the method, sodium metaaluminate is replaced by calcium metaaluminate, so that the treatment cost is reduced, and a support is provided for later carbon neutralization. The reaction mechanism of an ultrahigh calcium aluminum precipitation method is that Ca(OH)2, Al(OH)3 and Cl<-> react to form a Freund's salt precipitate, and the added aluminate is hydrolyzed to form Al(OH)3. Besides, CO2 is adopted as a carbon neutralizer to replace traditional acid carbonate, the pH value of the solution can be regulated and controlled, the CO2 and the added calcium salt can form sediment, and the purpose of reducing the conductivity of the solution is achieved.

Owner:LANZHOU PETROCHEM COLLEGE OF VOCATIONAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com