Early strength agent composition and preparation method thereof, cement composition and uses of above

The technology of a composition and an early-strength agent, which is applied in the field of early-strength agent composition and its preparation, can solve the problems of slow hydration speed, shortened cement slurry thickening time, long waiting time and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

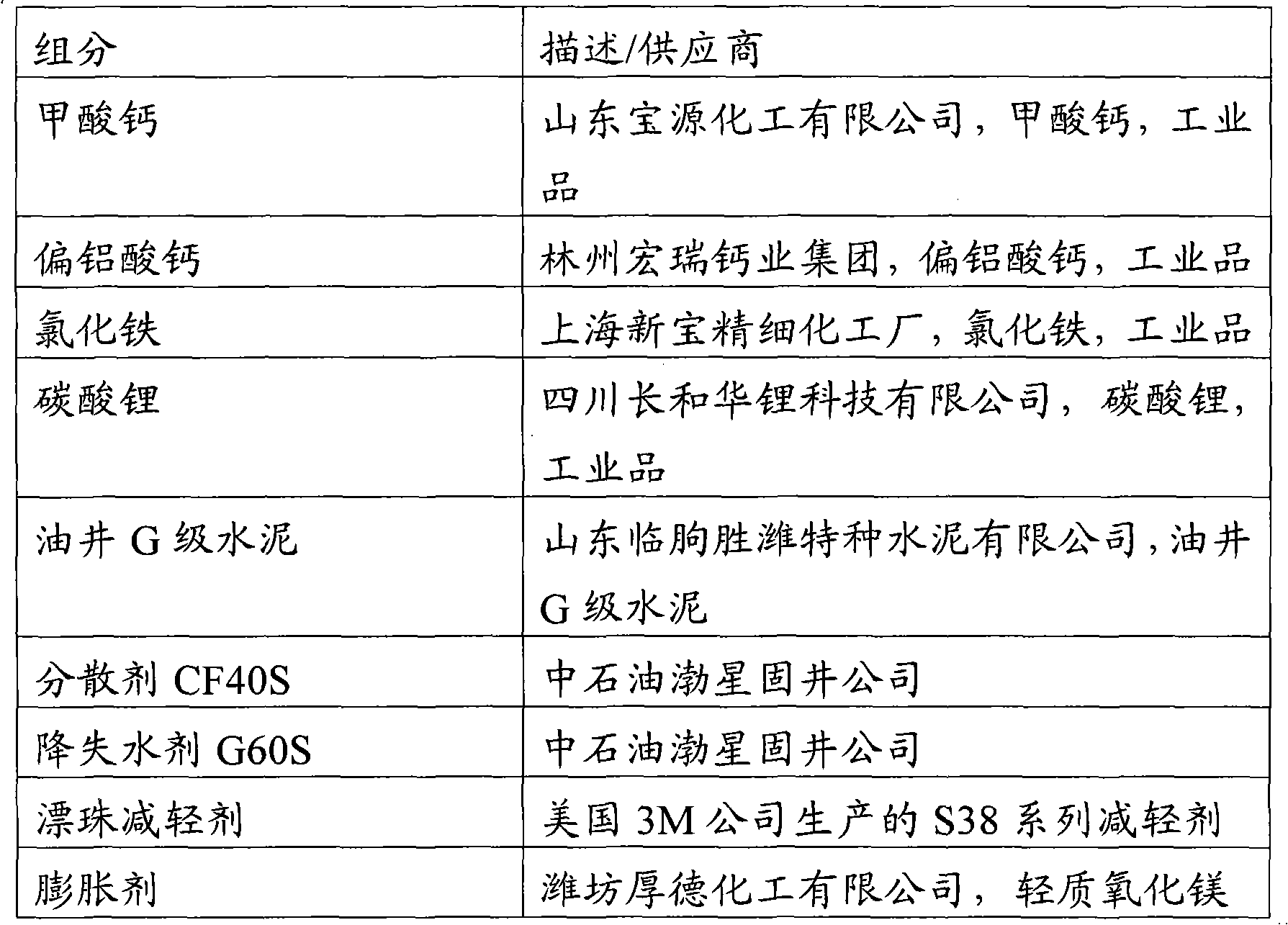

[0060] Embodiment 1 Accelerator composition A1

[0061] Prepare the accelerator composition A1 as follows: get 31 kilograms of calcium formate (Ca(HCOO) 2 ), 15 kg of calcium metaaluminate (Ca(AlO 2 ) 2 ), 45 kg of ferric chloride (FeCl 3), and 19 kg of lithium carbonate (Li 2 CO 3 ), these materials are mixed uniformly at normal temperature and pressure to obtain the accelerator composition A1 of the present invention.

Embodiment 2

[0062] Embodiment 2 early strengthening agent composition A2

[0063] Prepare the accelerator composition A2 as follows: get 25 kilograms of calcium formate (Ca(HCOO) 2 ), 13 kg of calcium metaaluminate (Ca(AlO 2 ) 2 ), 40 kg of ferric chloride (FeCl 3 ), and 22 kg of lithium carbonate (Li 2 CO 3 ), these materials are mixed homogeneously at normal temperature and pressure to obtain the accelerator composition A2 of the present invention.

Embodiment 3

[0064] Example 3 Cement Compositions B1 to B7

[0065] Taking accelerator composition A2 as an example, a cement composition was prepared. The cement compositions B1 to B7 were prepared as follows: Add a certain percentage of the accelerator composition A2 of the present invention to Shengwei G grade cement to obtain the cement compositions B1 to B7 of the present invention. The amounts of the accelerator composition A2 added in the cement compositions B1 to B7 are respectively: 1.0%, 1.5%, 2.0%, 2.5%, 3.0%, 3.5% and 4.0%.

[0066] Test 1: Compressive strength at 25°C for 24 hours

[0067] Prepare cement compositions B1 to B7 into cement pastes 1 to 7 according to the GB10238-88 standard, the water-cement ratio is 0.44, and the cement paste density is 1.92g / cm 3 . According to Chapter 7 of the standard GB / T 19139-2003 "Oil Well Cement Test Methods", the compressive strength of cement slurries 1 to 7 at different curing temperatures was measured, and the evaluation results a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com