Method for preparing concrete waterproof material

A waterproof material and concrete technology, which is applied in the field of waterproof material preparation, can solve the problems of poor waterproof effect, insufficient impermeability and compressive strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The present invention provides a kind of preparation method of concrete waterproof material, and described preparation method comprises:

[0017] (1) Preparation of material A: cesium stearate, cesium chloride, sodium citrate, calcium carbonate, sodium carbonate, sodium silicate, beryllium carbonate, sodium bicarbonate, calcium metaaluminate and calcium chloride are mixed, through Material A is obtained after drying, sieving, roasting and grinding;

[0018] (2) Preparation of material B: D-malic acid, L-malic acid, cesium tartrate, tartaric acid, sodium malate and calcium metaaluminate are mixed, and material B is obtained after drying, sieving, roasting and grinding;

[0019] (3) Preparation of material C: mix petroleum resin, cesium carbonate and hydrochloric acid solution, undergo the first heat treatment and the second heat treatment in turn, and obtain material C after grinding;

[0020] (4) After mixing material A, material B and material C, the crystalline compo...

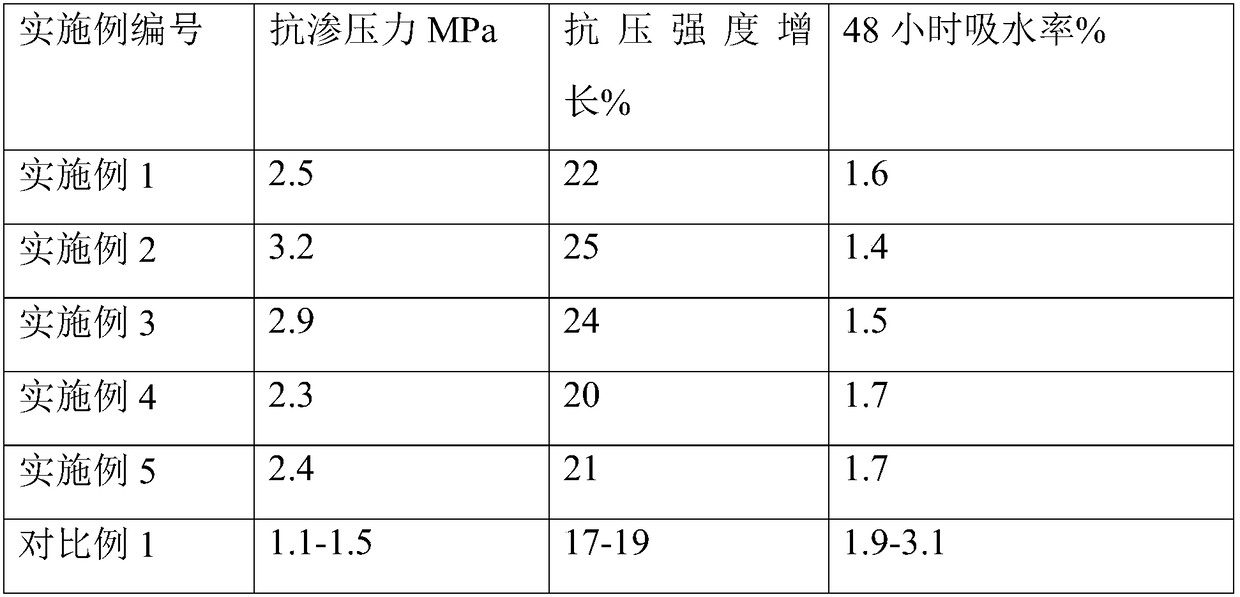

Embodiment 1

[0045] The waterproof material is prepared according to the above-mentioned preparation method, wherein, the crystalline composite material is compounded by material A, material B and material C according to a weight ratio of 10:1:0.1; the weight percentage content of each component in the material A is: Cesium Stearate 0.5%, Cesium Chloride 2%, Sodium Citrate 3%, Calcium Carbonate 2%, Sodium Carbonate 0.3%, Sodium Silicate 5%, Beryllium Carbonate 0.1%, Sodium Bicarbonate 0.3%, Calcium Metaaluminate 35% and the balance of calcium chloride; the weight percentage content of each component in the material B is: D-malic acid 1.8%, L-malic acid 2.5%, cesium tartrate 0.9%, tartaric acid 16%, sodium malate 2% and the balance of calcium metaaluminate; in material C, the weight ratio of stone resin and cesium carbonate is 1:0.08; relative to 100 parts by weight of Portland cement, the amount of the crystalline composite material is 0.3 parts by weight, so The consumption of the sodium ...

Embodiment 2

[0047] The waterproof material is prepared according to the above-mentioned preparation method, wherein, the crystalline composite material is compounded by material A, material B and material C according to a weight ratio of 10:2.5:0.3; the weight percentage content of each component in the material A is: Cesium Stearate 0.9%, Cesium Chloride 6%, Sodium Citrate 5%, Calcium Carbonate 4%, Sodium Carbonate 0.6%, Sodium Silicate 7%, Beryllium Carbonate 0.3%, Sodium Bicarbonate 0.6%, Calcium Metaaluminate 38% and the remainder calcium chloride; the weight percent content of each component in the material B is: D-malic acid 2.2%, L-malic acid 2.7%, cesium tartrate 1.2%, tartaric acid 17%, sodium malate 6% and the balance of calcium metaaluminate; in material C, the weight ratio of stone resin and cesium carbonate is 1:0.1; relative to 100 parts by weight of Portland cement, the amount of the crystalline composite material is 0.4 parts by weight, so The consumption of the sodium sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com