Method for extracting amber acid in fermentation liquor by cationic resin exchange

A cationic resin, fermentation broth technology, applied in fermentation, separation/purification of ammonium sulfate, carboxylic acid compounds, etc., to achieve the effects of short process route, high yield and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

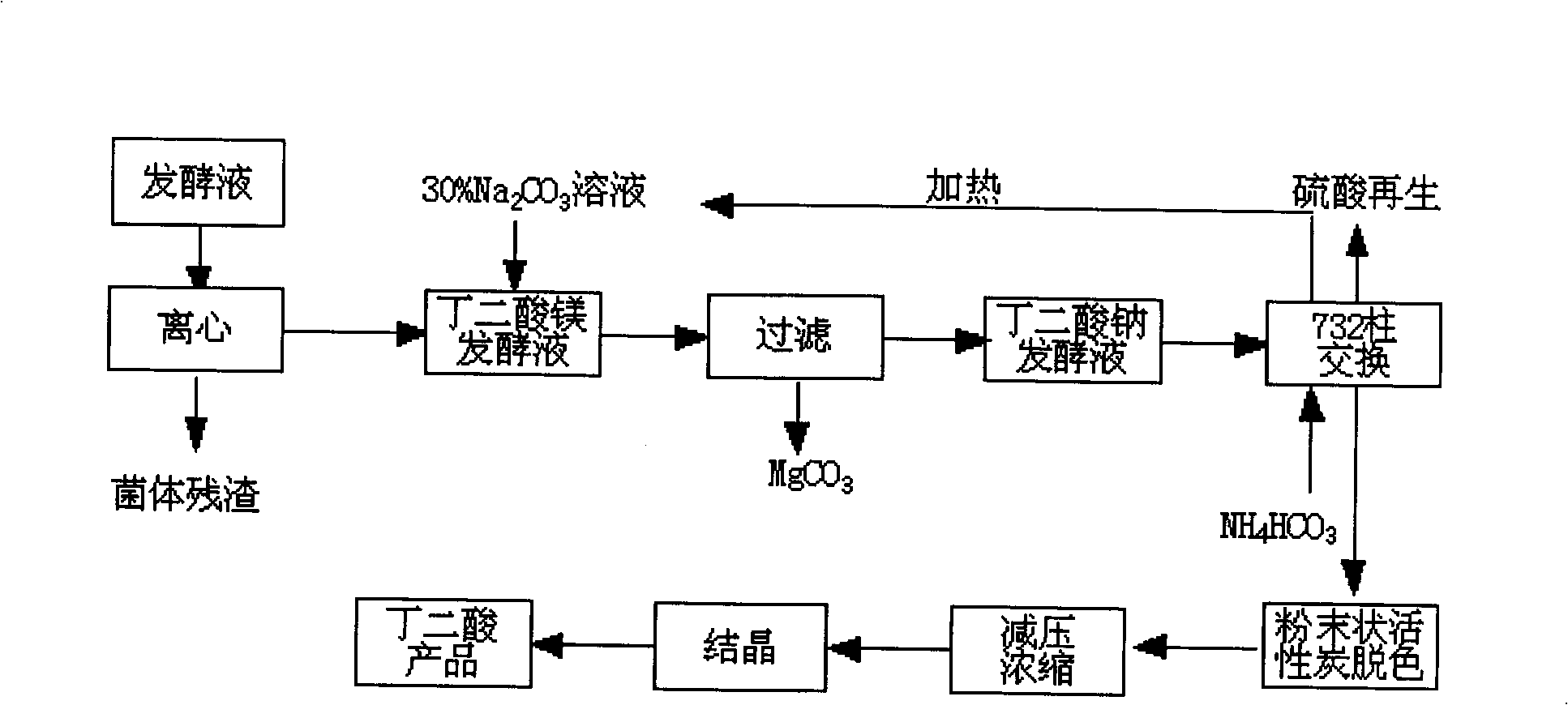

[0024] Cationic resin exchange extraction process of succinic acid by recovery of magnesium salt and sodium salt

[0025] Experimental conditions: The fermentation broth used in this experiment was fermented with corn hydrolyzed syrup, cassava starch hydrolyzed syrup, industrial sugar waste molasses (such as sugarcane molasses), corn straw hydrolyzed syrup, Jerusalem artichoke syrup, and sweet sorghum straw syrup. MgCO 3 Adjust pH.

[0026] The magnesium succinate fermentation liquid fermented with the above-mentioned corn syrup, sugarcane molasses, etc. as raw materials was heated to 85° C., centrifuged at 8000 r / min for 10 min, and bacteria were removed to obtain the magnesium succinate fermentation serum.

[0027] 30% concentration of Na 2 CO 3 The solution was heated to 65°C, and slowly added to the above-mentioned fermentation broth with stirring, and 45-60 ml of Na was added to each liter of fermentation broth. 2 CO 3 The solution, after reacting for 40 minutes, was...

Embodiment 7

[0035] Experimental conditions: The fermentation liquid used in this experiment was fermented with corn syrup and sugarcane molasses respectively, and Na 2 CO 3 Adjust pH.

[0036] The sodium succinate fermentation liquid fermented with corn syrup and sugarcane molasses respectively as raw materials is heated to 85° C. and filtered with a 0.45 μ microfiltration membrane to obtain the sodium succinate-containing fermentation serum.

[0037] Pass the fermented liquid containing sodium succinate through a 732 column equipped with treated strong acidic hydrogen, and the column flow rate is 1.5h -1 . Then wash with water in an amount 1 to 2 times the weight of the fermentation broth, and collect the effluent. Then the effluent was decolorized at 75° C. for 30 minutes, and the dosage of activated carbon for decolorizing the fermentation broth of the two raw materials was 3-5 g / L and 10-12 g / L respectively. Concentrate and crystallize the obtained solution to obtain succinic acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com