Water-permeable concrete early strength agent, water-permeable concrete and preparation method of water-permeable concrete early strength agent

A technology of permeable concrete and early strength agent, applied in the field of permeable concrete early strength agent, permeable concrete and its preparation, to achieve the effects of improving flexural strength, compressive strength and late strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

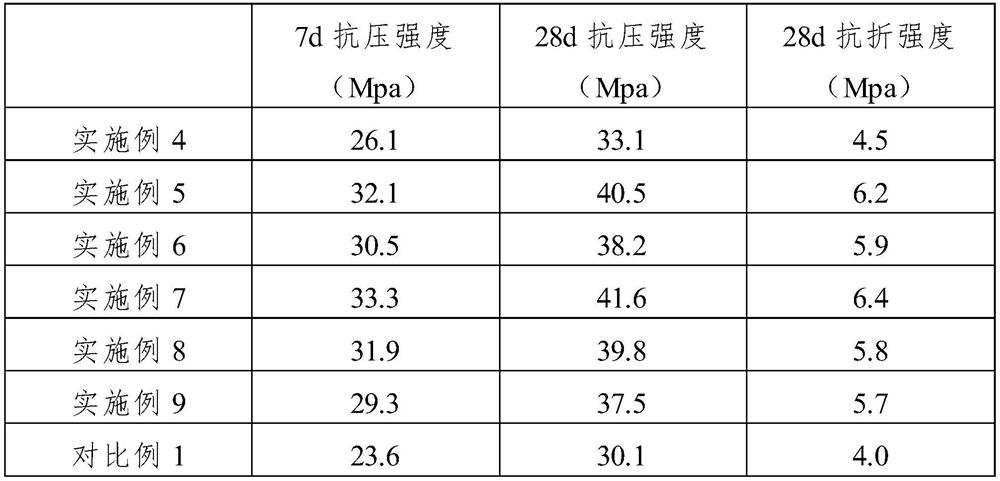

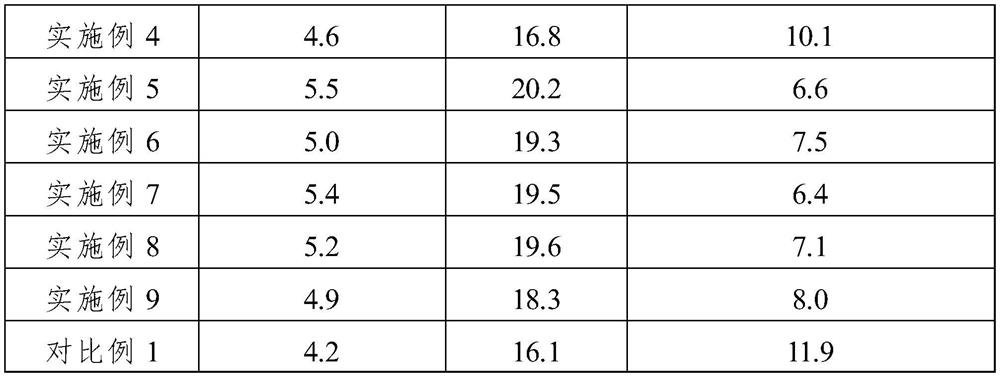

Examples

Embodiment 1

[0037] An early strength agent for permeable concrete comprises the following raw materials by weight percentage: 18% of monocalcium aluminate, 0.8% of diethanol monoisopropanolamine, and 81.2% of ettringite growth promoter.

[0038] The ettringite growth promoter is made from the following raw materials by weight: 50 parts of water-quenched slag micropowder, 10 parts of hemihydrate gypsum, 5 parts of lime powder, and 45 parts of water.

[0039] The preparation method of above-mentioned ettringite growth promoter comprises the following steps:

[0040] (1) Add water-quenched slag micropowder, hemihydrate gypsum, lime powder and water into the mixer according to the proportion, and after stirring evenly, use a ball-forming equipment to form a sphere with a diameter of 5-20mm;

[0041] (2) The sphere is placed at 100°C for steam curing for 13 hours;

[0042] (3) The spheres after steam curing continued to undergo natural curing for 7 days.

[0043] The preparation method of th...

Embodiment 2

[0045] An early strength agent for permeable concrete comprises the following raw materials by weight percentage: 20% of monocalcium aluminate, 1% of diethanol monoisopropanolamine, and 79% of ettringite growth promoter.

[0046]The ettringite growth promoter is made from the following raw materials by weight: 45 parts of water-quenched slag micropowder, 8 parts of hemihydrate gypsum, 6 parts of lime powder, and 42 parts of water.

[0047] The preparation method of above-mentioned ettringite growth promoter comprises the following steps:

[0048] (1) Add water-quenched slag micropowder, hemihydrate gypsum, lime powder and water into the mixer according to the proportion, and after stirring evenly, use a ball-forming equipment to form a sphere with a diameter of 5-20mm;

[0049] (2) The sphere is placed at 100°C for steam curing for 15 hours;

[0050] (3) The spheres after steam curing continued to undergo natural curing for 5 days.

[0051] The preparation method of the abov...

Embodiment 3

[0053] An early strength agent for permeable concrete comprises the following raw materials by weight percentage: 15% of monocalcium aluminate, 0.5% of diethanol monoisopropanolamine, and 84.5% of ettringite growth promoter.

[0054] The ettringite growth promoter is made from the following raw materials by weight: 55 parts of water-quenched slag micropowder, 5 parts of natural dihydrate gypsum, 3 parts of lime powder, and 35 parts of water.

[0055] The preparation method of above-mentioned ettringite growth promoter comprises the following steps:

[0056] (1) Add water-quenched slag micropowder, natural dihydrate gypsum, lime powder and water to the mixer according to the proportion, and after stirring evenly, use a ball-forming equipment to form a sphere with a diameter of 5-20mm;

[0057] (2) The sphere is placed at 90°C for steam curing for 10 hours;

[0058] (3) The spheres after steam curing continued to undergo natural curing for 8d.

[0059] The preparation method o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com