Concrete material containing active additive

An active additive and concrete technology, which is applied in the field of concrete materials, can solve the problems of insufficient mechanical strength and impermeability, achieve good water blocking effect, enhance impermeability, and improve the effect of cracking and seepage again

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

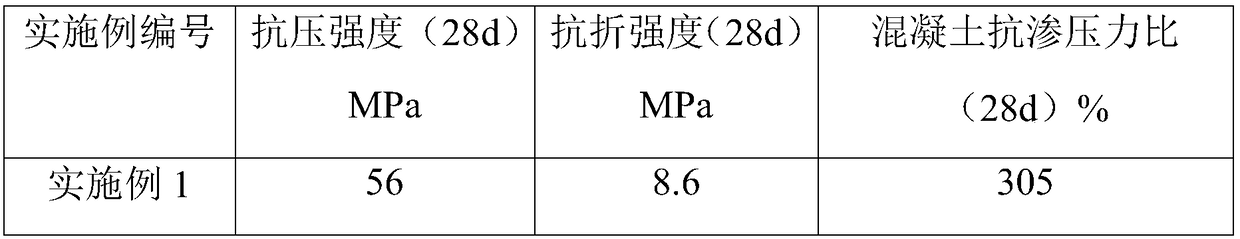

Examples

Embodiment 1

[0031] The waterproof material is prepared according to the above preparation method, wherein the concrete material includes the following raw material components by weight: 100 parts of Portland cement, 0.4 parts of active additives, 15 parts of sodium silicate, 50 parts of quartz sand and 110 parts of water The weight ratio of material A, material B and material C is: 0.2:2:10; in material A, the weight ratio of allophane and potassium carbonate is 1:0.11; the weight percent content of each component in the material B are: 10% of tartaric acid, 0.5% of maleic acid, 0.3% of ammonium formate, 40% of calcium metaaluminate, 0.4% of oxalic acid, 4% of sodium tartrate and the balance of calcium chloride; the weight of each component in the material C The percentage content is: sodium silicate 4%, sodium citrate 3%, zinc formate 0.5%, calcium carbonate 2%, potassium carbonate 5%, sodium acetate trihydrate 2%, calcium formate 0.2%, calcium metaaluminate 32% and balance calcium chlor...

Embodiment 2

[0033]The waterproof material is prepared according to the above-mentioned preparation method, wherein the concrete material comprises the following raw material components in parts by weight: 100 parts of Portland cement, 0.6 parts of active additives, 22 parts of sodium silicate, 55 parts of quartz sand and 120 parts of water The weight ratio of material A, material B and material C is: 0.6:4:10; in material A, the weight ratio of allophane and potassium carbonate is 1:0.13; the weight percent content of each component in the material B are: 13% of tartaric acid, 0.7% of maleic acid, 0.5% of ammonium formate, 49% of calcium metaaluminate, 0.6% of oxalic acid, 7% of sodium tartrate and the balance of calcium chloride; the weight of each component in the material C The percentage content is: sodium silicate 7%, sodium citrate 6%, zinc formate 0.7%, calcium carbonate 6%, potassium carbonate 7%, sodium acetate trihydrate 6%, calcium formate 0.5%, calcium metaaluminate 35% and ba...

Embodiment 3

[0035] The waterproof material is prepared according to the above preparation method, wherein the concrete material includes the following raw material components by weight: 100 parts of Portland cement, 0.8 parts of active additives, 30 parts of sodium silicate, 60 parts of quartz sand and 130 parts of water ; The weight ratio of material A, material B and material C is: 0.8:5:10; in material A, the weight ratio of allophane and potassium carbonate is 1:0.14; the weight percent content of each component in the material B It is: 15% of tartaric acid, 0.9% of maleic acid, 0.8% of ammonium formate, 55% of calcium metaaluminate, 0.8% of oxalic acid, 9% of sodium tartrate and the balance of calcium chloride; the weight of each component in the material C The percentage content is: sodium silicate 10%, sodium citrate 8%, zinc formate 0.9%, calcium carbonate 8%, potassium carbonate 9%, sodium acetate trihydrate 8%, calcium formate 0.8%, calcium metaaluminate 38% and balance calcium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com