Permeable crystallizing material and preparation method

A technology for infiltrating crystalline and waterproof materials, applied in the field of composite materials, can solve the problems of general waterproof and impermeability, reduce compressive strength, etc., and achieve the effects of improving impermeability, increasing compressive strength, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

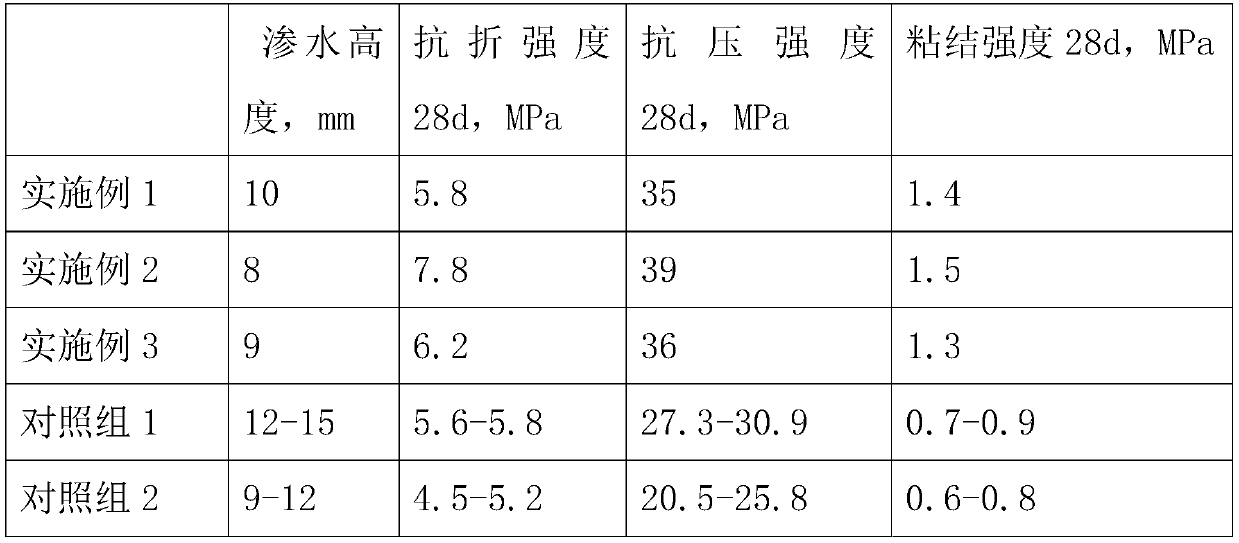

Embodiment 1

[0044] An infiltration crystalline material, which is prepared by mixing the following raw materials in weight percentage: 0.002% hydrochloric acid, 5.5% ferrous tartrate, 11% tartaric acid, 5% citric acid, 3% calcium chloride, 35% aluminum oxide composite powder material, Aluminum oxide and silicon oxide composite powder material is 21%, and the rest is aluminum oxide.

[0045] In this embodiment, the mass concentration of the hydrochloric acid is 25%.

[0046] In this embodiment, the weight percent content of each component in the alumina composite powder material is: aluminum sulfate 9%, aluminum nitrate 0.5%, aluminum potassium sulfate 0.5%, potassium chloride 0.6%, iron sulfate 2%, chlorine 6% aluminum oxide, 0.03% aluminum hypophosphite, 3% aluminum fluoride, and the rest aluminum oxide.

[0047] In this embodiment, in the aluminum oxide and silicon oxide composite powder material, aluminum oxide accounts for 25%, and the rest is silicon oxide.

[0048] A waterproof ma...

Embodiment 2

[0050] An infiltration crystalline material, which is prepared by mixing the following raw materials in weight percentage: 0.004% hydrochloric acid, 5.8% ferrous tartrate, 14% tartaric acid, 7% citric acid, 5% calcium chloride, 38% alumina composite powder material, Aluminum oxide and silicon oxide composite powder material is 24%, and the rest is aluminum oxide.

[0051] In this embodiment, the mass concentration of the hydrochloric acid is 25%.

[0052]In this embodiment, the weight percent content of each component in the alumina composite powder material is: aluminum sulfate 11%, aluminum nitrate 0.7%, aluminum potassium sulfate 0.7%, potassium chloride 0.8%, iron sulfate 6%, chlorine 7% aluminum oxide, 0.05% aluminum hypophosphite, 5% aluminum fluoride, and the rest aluminum oxide.

[0053] In this embodiment, in the alumina and silica composite powder material, alumina accounts for 27%, and the rest is silica.

[0054] A waterproof material, which is prepared by mixing...

Embodiment 3

[0056] An infiltration crystalline material, which is prepared by mixing the following raw materials in weight percentage: 0.006% hydrochloric acid, 6.1% ferrous tartrate, 16% tartaric acid, 9% citric acid, 8% calcium chloride, 40% alumina composite powder material, Aluminum oxide and silicon oxide composite powder material is 26%, and the rest is aluminum oxide.

[0057] In this embodiment, the mass concentration of the hydrochloric acid is 25%.

[0058] In this embodiment, the weight percent content of each component in the alumina composite powder material is: aluminum sulfate 14%, aluminum nitrate 0.9%, aluminum potassium sulfate 0.9%, potassium chloride 0.9%, iron sulfate 8%, chlorine Aluminum 9%, aluminum hypophosphite 0.08%, aluminum fluoride 8%, and the rest alumina.

[0059] In this embodiment, among the aluminum oxide and silicon oxide composite powder materials, aluminum oxide accounts for 29%, and the rest is silicon oxide.

[0060] A waterproof material, which i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com