Preparation method of waterproof material

A waterproof material and core material technology, applied in the field of composite materials, can solve the problems of insufficient performance of waterproof materials, achieve good stability and practicability, good waterproof performance, and improve the effect of impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The present invention provides a preparation method of a waterproof material, the preparation method comprising:

[0017] (1) Preparation of material A: mixing citric acid, beryllium tartrate, tartaric acid, maleic acid, ammonium formate and calcium metaaluminate, drying, sieving, roasting and grinding to obtain material A;

[0018] (2) Preparation of material B: adding calcium carbonate, sodium carbonate, sodium silicate, sodium stearate, alumina, sodium citrate pentahydrate, sodium metatitanate, sodium phosphate hydrate, calcium formate and calcium metaaluminate After mixing, drying, sieving, roasting and grinding to obtain material B;

[0019] (3) Preparation of material C: Mix kaolinite, sodium carbonate powder, and hydrochloric acid solution, and sequentially undergo the first heating treatment and the second heating treatment to obtain material C after grinding;

[0020] (4) After mixing material A, material B and material C, roasting and secondary tempering are performed...

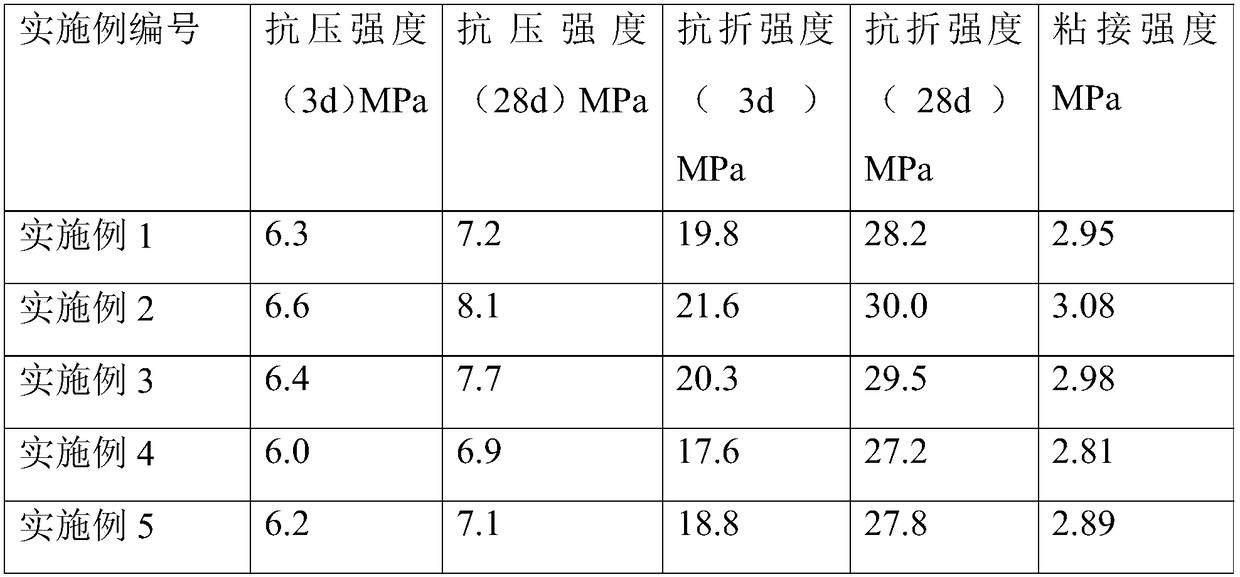

Embodiment 1

[0041] The waterproof material is prepared according to the above preparation method, wherein the waterproof material comprises the following raw material components in parts by weight: 10 parts by weight of Portland cement, 0.1 part of building core material, 1 part of sodium silicate, and 12 parts of water; The core material is composed of material A, material B and material C; the weight ratio of material A, material B and material C is: 0.1:10:0.1;

[0042] The weight percentage content of each component in the material A is: 0.28% of citric acid, 0.3% of beryllium tartrate, 24% of tartaric acid, 1.3% of maleic acid, 0.08% of ammonium formate and the balance of calcium metaaluminate;

[0043] The weight percentage content of each component in the material B is: calcium carbonate 3%, sodium carbonate 0.05%, sodium silicate 4%, sodium stearate 0.3%, alumina 11%, sodium citrate pentahydrate 3%, partial 0.1% of sodium titanate, 0.05% of sodium phosphate hydrate, 0.03% of calcium fo...

Embodiment 2

[0046] The waterproof material is prepared according to the above preparation method, wherein the waterproof material includes the following raw material components in parts by weight: 10 parts by weight of Portland cement, 0.12 parts of building core material, 3 parts of sodium silicate, and 14 parts of water; The core material is composed of material A, material B and material C; the weight ratio of material A, material B and material C is: 0.3:10:0.3;

[0047] The weight percentage content of each component in the material A is: 0.35% citric acid, 0.6% beryllium tartrate, 26% tartaric acid, 1.8% maleic acid, 0.15% ammonium formate and the balance of calcium metaaluminate;

[0048] The weight percentage content of each component in the material B is: calcium carbonate 4%, sodium carbonate 0.07%, sodium silicate 7%, sodium stearate 0.6%, alumina 14%, sodium citrate pentahydrate 5%, partial Sodium titanate 0.3%, sodium phosphate hydrate 0.09%, calcium formate 0.06% and the balance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com