Waterproof material

A technology of waterproof material and core material, applied in the field of composite materials, can solve problems such as insufficient performance of waterproof materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

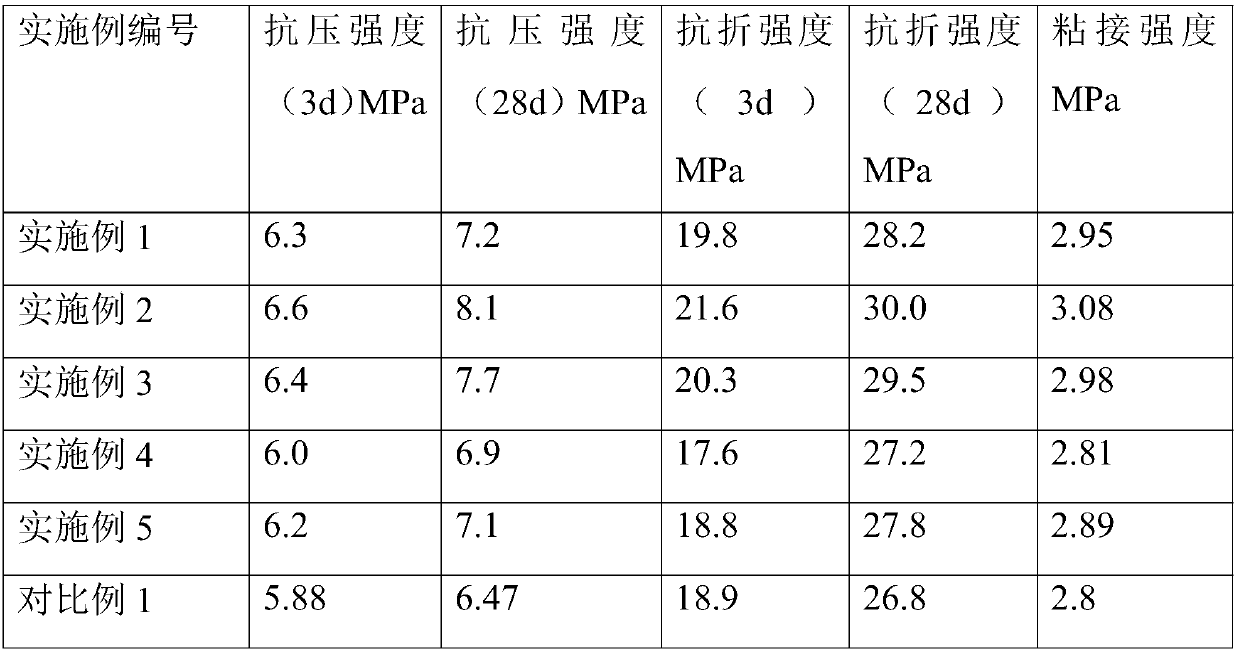

Embodiment 1

[0027] The waterproof material is prepared according to the above preparation method, wherein the waterproof material includes the following raw material components in parts by weight: 10 parts of Portland cement, 0.1 part of building core material, 1 part of sodium silicate and 12 parts of water; The core material is composed of material A, material B and material C; the weight ratio of material A, material B and material C is: 0.1:10:0.1;

[0028] The weight percentage content of each component in the material A is: 0.28% of citric acid, 0.3% of beryllium tartrate, 24% of tartaric acid, 1.3% of maleic acid, 0.08% of ammonium formate and the balance of calcium metaaluminate;

[0029] The weight percent content of each component in the material B is: calcium carbonate 3%, sodium carbonate 0.05%, sodium silicate 4%, sodium stearate 0.3%, aluminum oxide 11%, sodium citrate pentahydrate 3%, meta 0.1% of sodium titanate, 0.05% of sodium phosphate hydrate, 0.03% of calcium formate ...

Embodiment 2

[0032] The waterproof material is prepared according to the above preparation method, wherein the waterproof material includes the following raw material components in parts by weight: 10 parts of Portland cement, 0.12 parts of building core material, 3 parts of sodium silicate and 14 parts of water; The core material is composed of material A, material B and material C; the weight ratio of material A, material B and material C is: 0.3:10:0.3;

[0033] The weight percentage content of each component in the material A is: 0.35% of citric acid, 0.6% of beryllium tartrate, 26% of tartaric acid, 1.8% of maleic acid, 0.15% of ammonium formate and the balance of calcium metaaluminate;

[0034] The weight percent content of each component in the material B is: calcium carbonate 4%, sodium carbonate 0.07%, sodium silicate 7%, sodium stearate 0.6%, aluminum oxide 14%, sodium citrate pentahydrate 5%, meta 0.3% of sodium titanate, 0.09% of sodium phosphate hydrate, 0.06% of calcium forma...

Embodiment 3

[0037] The waterproof material is prepared according to the above preparation method, wherein the waterproof material includes the following raw material components in parts by weight: 10 parts of Portland cement, 0.13 parts of building core material, 4 parts of sodium silicate and 15 parts of water; The core material is composed of material A, material B and material C; the weight ratio of material A, material B and material C is: 0.5:10:0.5;

[0038] The weight percentage content of each component in the material A is: 0.39% of citric acid, 0.9% of beryllium tartrate, 29% of tartaric acid, 2.1% of maleic acid, 0.28% of ammonium formate and the balance of calcium metaaluminate;

[0039] The weight percent content of each component in the material B is: 7% calcium carbonate, 0.09% sodium carbonate, 10% sodium silicate, 0.9% sodium stearate, 17% aluminum oxide, 8% sodium citrate pentahydrate, meta 0.5% of sodium titanate, 0.11% of sodium phosphate hydrate, 0.08% of calcium form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com