Concrete antifreezer and preparing method thereof

An antifreeze and concrete technology, applied in the field of concrete, can solve the problems of high production and use cost, easy to produce rust, etc., and achieve the effects of reducing alkali content, avoiding reaction, and improving workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

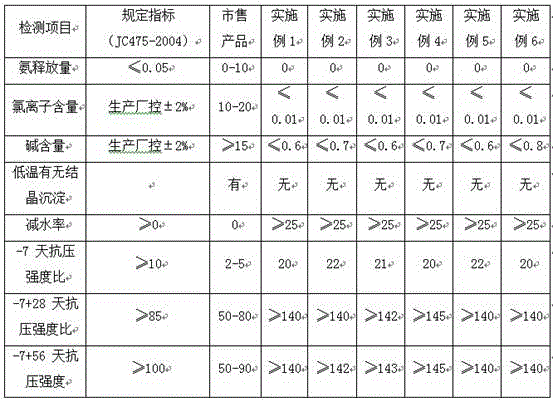

Examples

Embodiment 1

[0024] A kind of concrete antifreeze, its mass parts composition is as follows: 15 parts of sodium oxide, 8 parts of potassium aluminum sulfate, 3 parts of triisopropanolamine, 10 parts of sodium lignosulfonate, 6 parts of sodium carbonate, 12 parts of monocalcium aluminate, 3 parts of sodium carboxymethyl cellulose, 3 parts of paraffin, 1 part of sodium naphthalene acetate, 2 parts of cerium nitrate, 10 parts of tea saponin, 12 parts of p-melamine, 1.8 parts of SAF-I superplasticizer, sulfonated acetone- 0.8 parts of formaldehyde condensate, 1.2 parts of modified bentonite, 0.1 part of air-entraining agent, and 1.8 parts of defoamer.

[0025] Wherein, the modified bentonite is prepared by a microwave activation method, and the microwave activation method is as follows: the microwave frequency is 800 MHz, and the roasting activation time is 10 minutes.

[0026] Wherein, the mass parts of the air-entraining agent are composed as follows: 30 parts of camellia saponin aqueous sol...

Embodiment 2

[0030] A concrete antifreeze, its composition by mass is as follows: 16 parts of sodium oxide, 9 parts of potassium aluminum sulfate, 4 parts of triisopropanolamine, 11 parts of sodium lignosulfonate, 6.5 parts of sodium carbonate, 13 parts of monocalcium aluminate, 4 parts of sodium carboxymethyl cellulose, 3.5 parts of paraffin, 1.5 parts of sodium naphthalene acetate, 2.5 parts of cerium nitrate, 11 parts of tea saponin, 13 parts of p-melamine, 2 parts of SAF-I superplasticizer, sulfonated acetone- 1.2 parts of formaldehyde condensate, 1.5 parts of modified bentonite, 0.2 parts of air-entraining agent, and 2 parts of defoamer.

[0031] Wherein, the modified bentonite is prepared by a microwave activation method, and the microwave activation method is as follows: the microwave frequency is 800 MHz, and the roasting activation time is 10 minutes.

[0032] Wherein, the mass parts of the air-entraining agent are composed as follows: 32 parts of camellia saponin aqueous agent, 1...

Embodiment 3

[0036] A concrete antifreeze, its composition by mass is as follows: 20 parts of sodium oxide, 10 parts of potassium aluminum sulfate, 4.5 parts of triisopropanolamine, 11 parts of sodium lignosulfonate, 7 parts of sodium carbonate, 15 parts of monocalcium aluminate, 6 parts of sodium carboxymethyl cellulose, 4 parts of paraffin, 2.5 parts of sodium naphthalene acetate, 4 parts of cerium nitrate, 12 parts of tea saponin, 15 parts of p-melamine, 2.8 parts of SAF-I superplasticizer, sulfonated acetone- 1.6 parts of formaldehyde condensate, 2.5 parts of modified bentonite, 0.4 parts of air-entraining agent, and 3.2 parts of defoamer.

[0037] Wherein, the modified bentonite is prepared by a microwave activation method, and the microwave activation method is as follows: the microwave frequency is 800 MHz, and the roasting activation time is 10 minutes.

[0038] Wherein, the mass parts of the air-entraining agent are composed as follows: 35 parts of camellia saponin aqueous agent, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com