Visual system for testing cementation quality of specially-shaped well cementation interface II and intensity of specially-shaped body

A technology of strength testing and interface glue, applied in the direction of strength characteristics, using stable shear force to test the strength of materials, measuring devices, etc. Mechanical strength and other issues, to achieve the effect of rich performance, real test results, and reliable data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

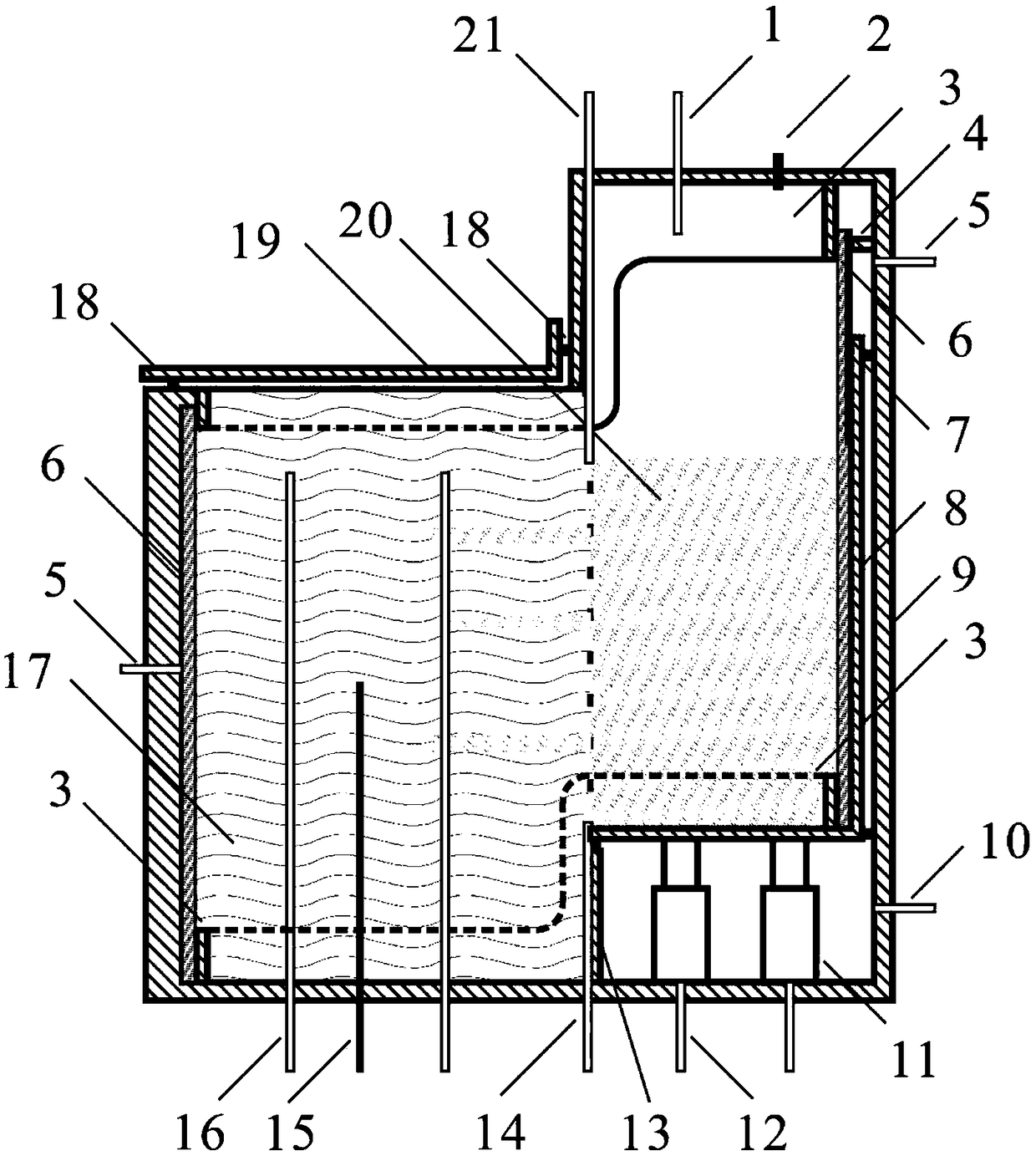

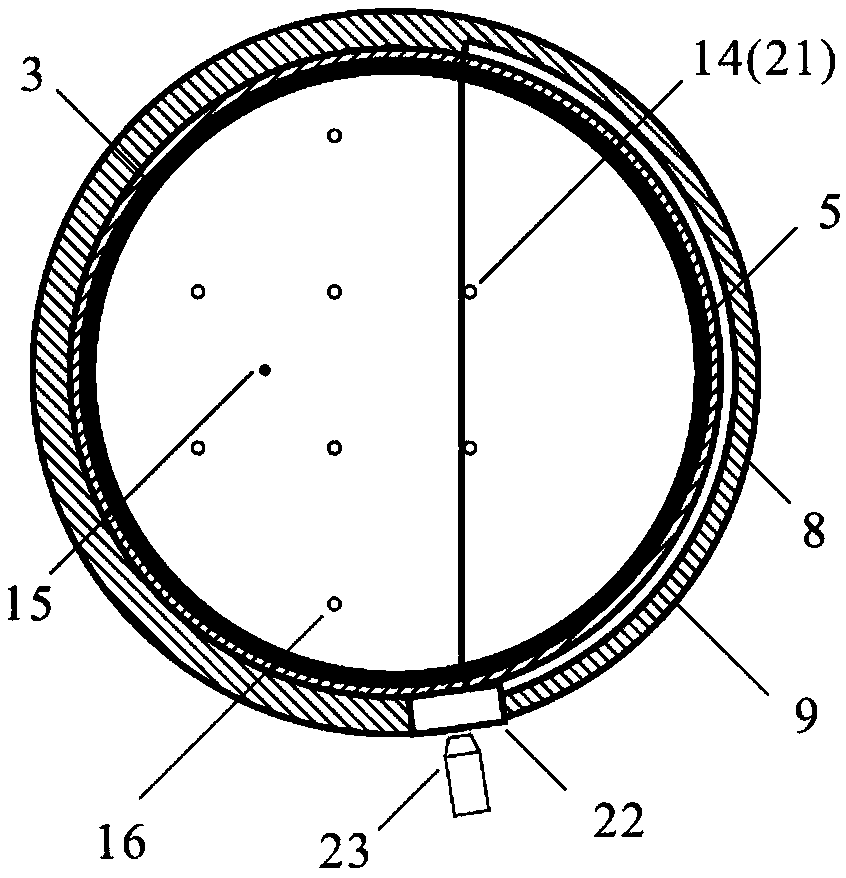

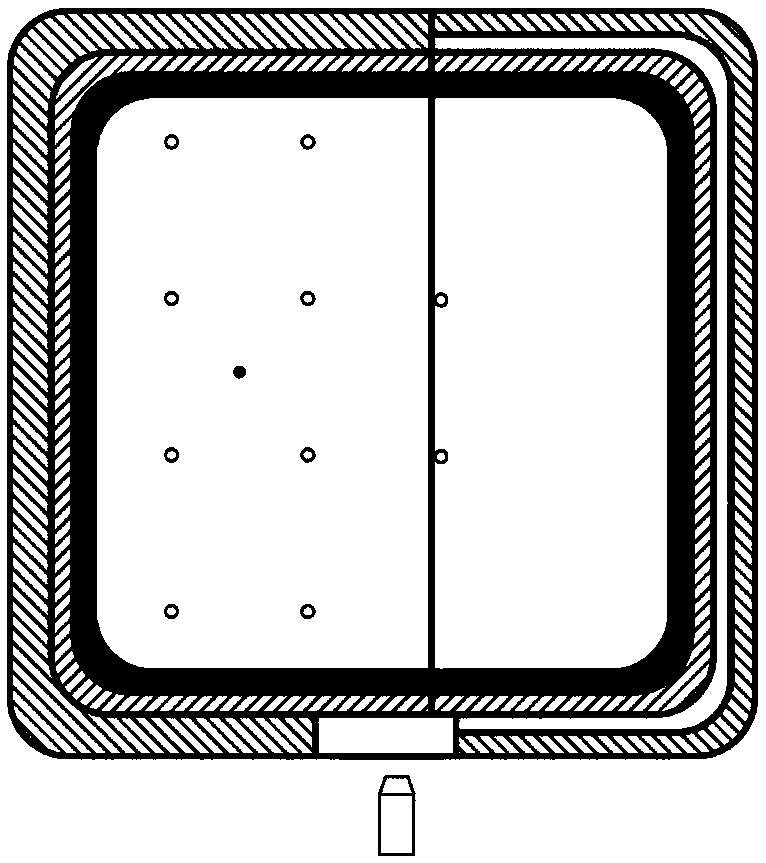

[0041] Such as figure 1 The visualized special-shaped cementing two-interface cementation quality and special-shaped body strength testing system shown mainly includes a high-pressure reactor body 9 and an observation instrument 23, such as figure 2 Shown, autoclave body 9 can be cylindrical, also can be as image 3 As shown, it is a rectangular parallelepiped. The high-pressure reactor body 9 includes a simulated formation cavity 17, a cement / cement stone cavity 20, and a hydraulic cylinder cavity, and one side wall of the hydraulic cylinder cavity is a cement stone lifting mold base 13; The hydraulic cylinder cavity is provided with a hydraulic cylinder chamber high-pressure gas-liquid inlet and outlet 10, a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com