Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

97 results about "Rebaudioside M" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

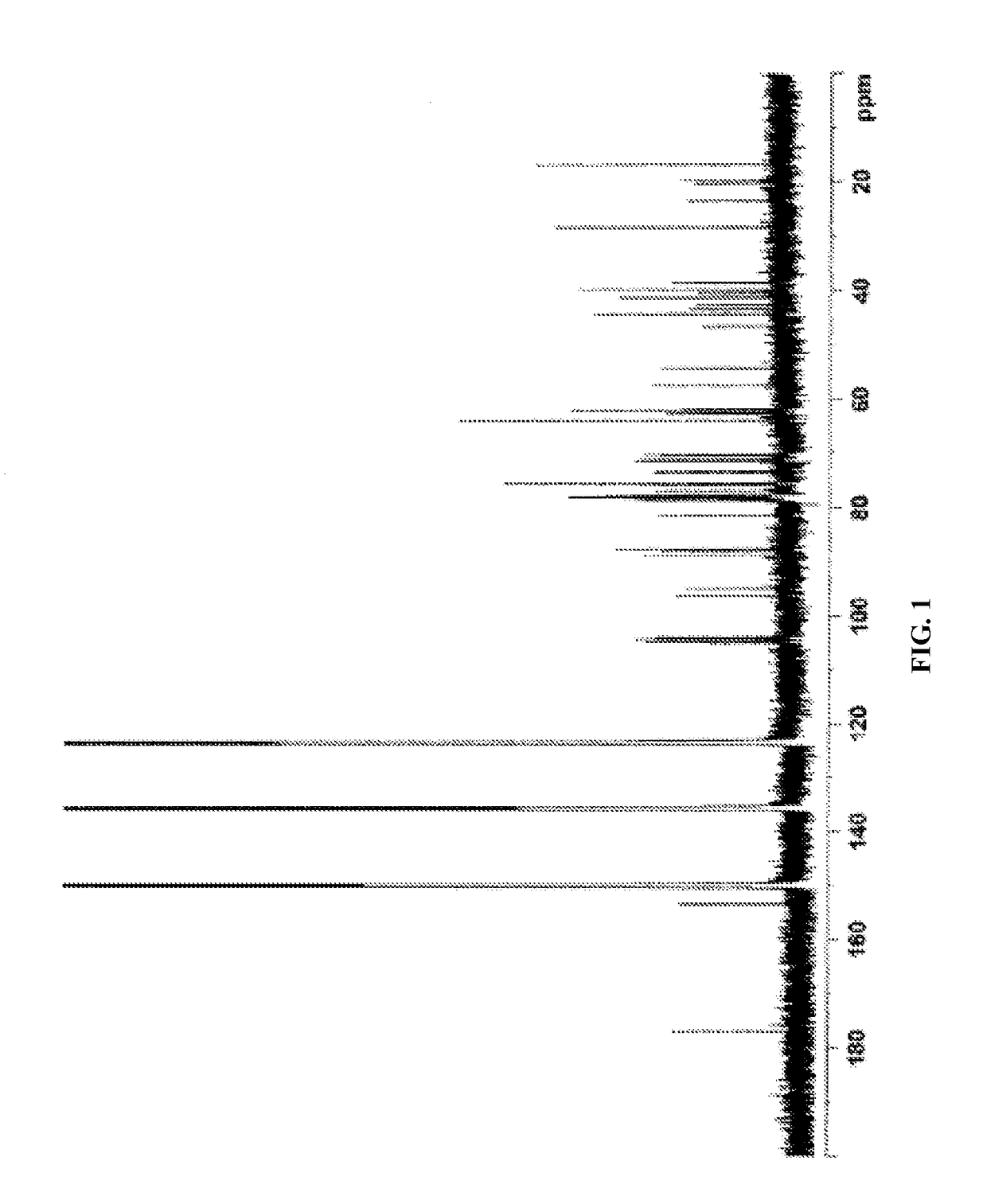

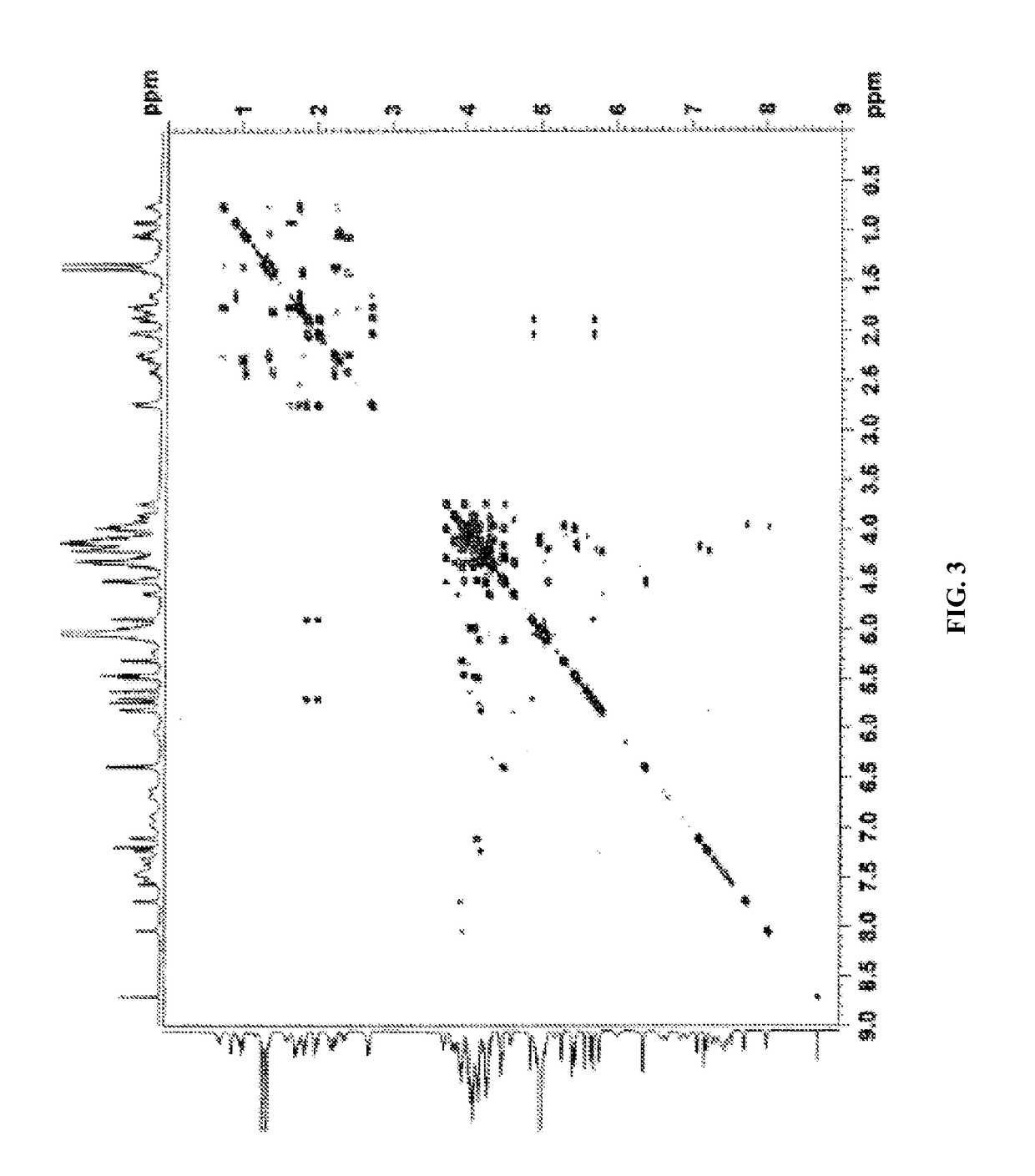

Compositions and Methods for Improving Rebaudioside M Solubility

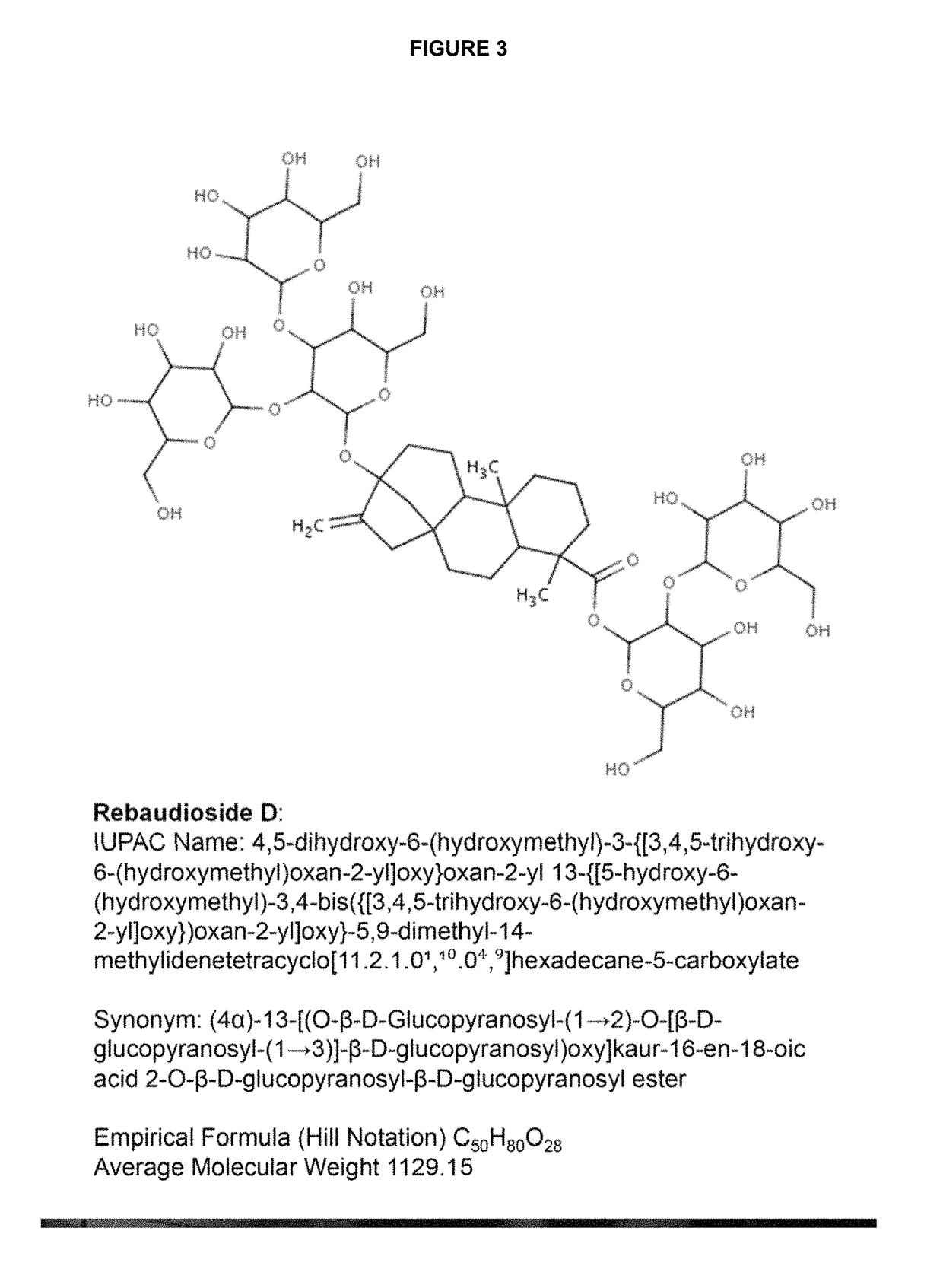

ActiveUS20150017284A1Good water solubilityReduce precipitationMilk preparationDough treatmentSolubilityRebaudioside D

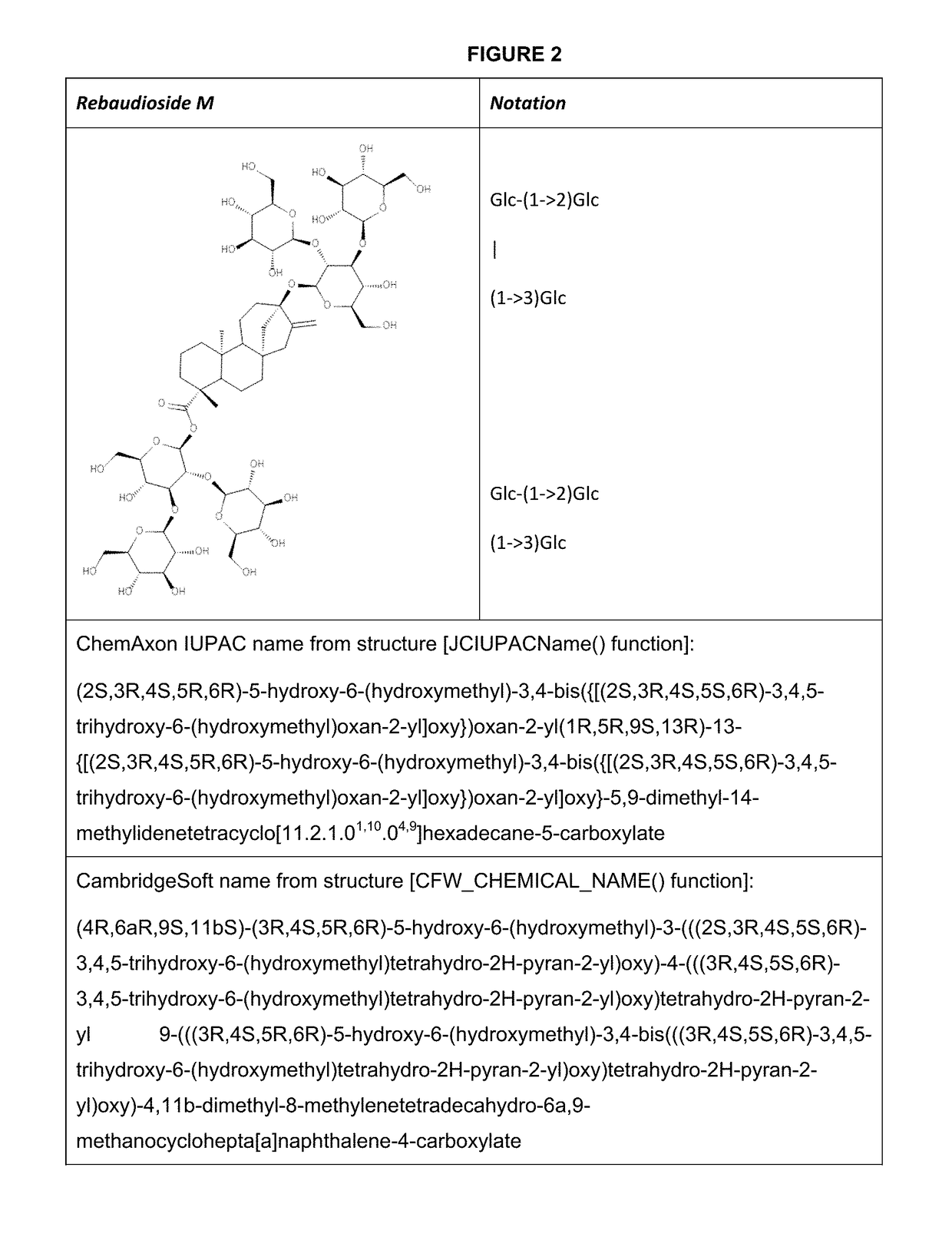

Rebaudioside M compositions with improved aqueous solubility and methods for preparing the same are provided herein. The rebaudioside M compositions include (i) disordered crystalline compositions comprising rebaudioside M and rebaudioside D, (ii) spray-dried compositions comprising rebaudioside M, rebaudioside D and steviol glycoside mixtures and / or rebaudioside B and / or NSF-02, (iii) spray-dried compositions comprising rebaudioside M, rebaudioside D and at least one surfactant, polymer, saponin, carbohydrate, polyol, preservative or a combination thereof. Sweetened compositions, such a beverages, containing the rebaudioside M compositions with improved water solubility are also provided herein.

Owner:THE COCA-COLA CO +1

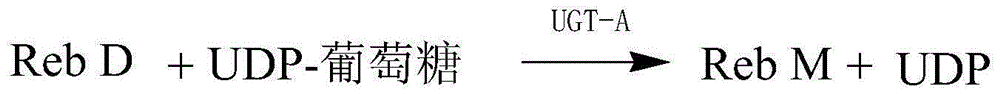

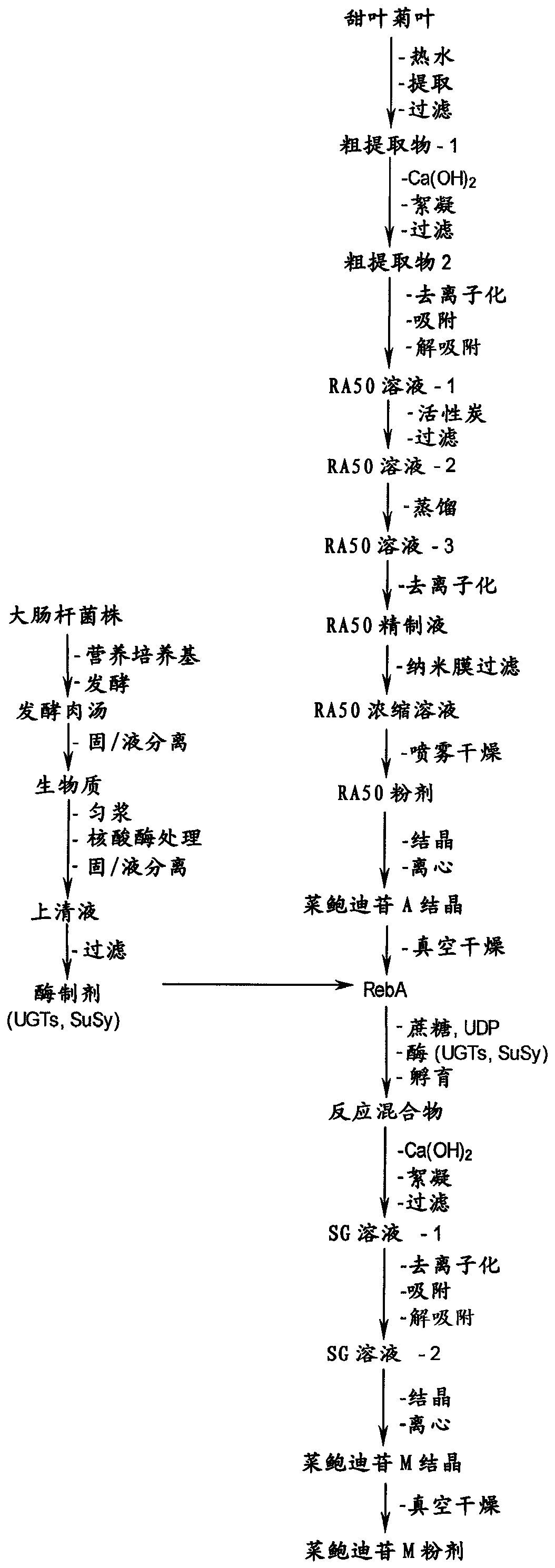

Method for preparing rebaudioside M through enzyme method

ActiveCN103757074AImprove conversion rateHigh purityFermentationSucrose synthetaseUdp glucosyltransferase

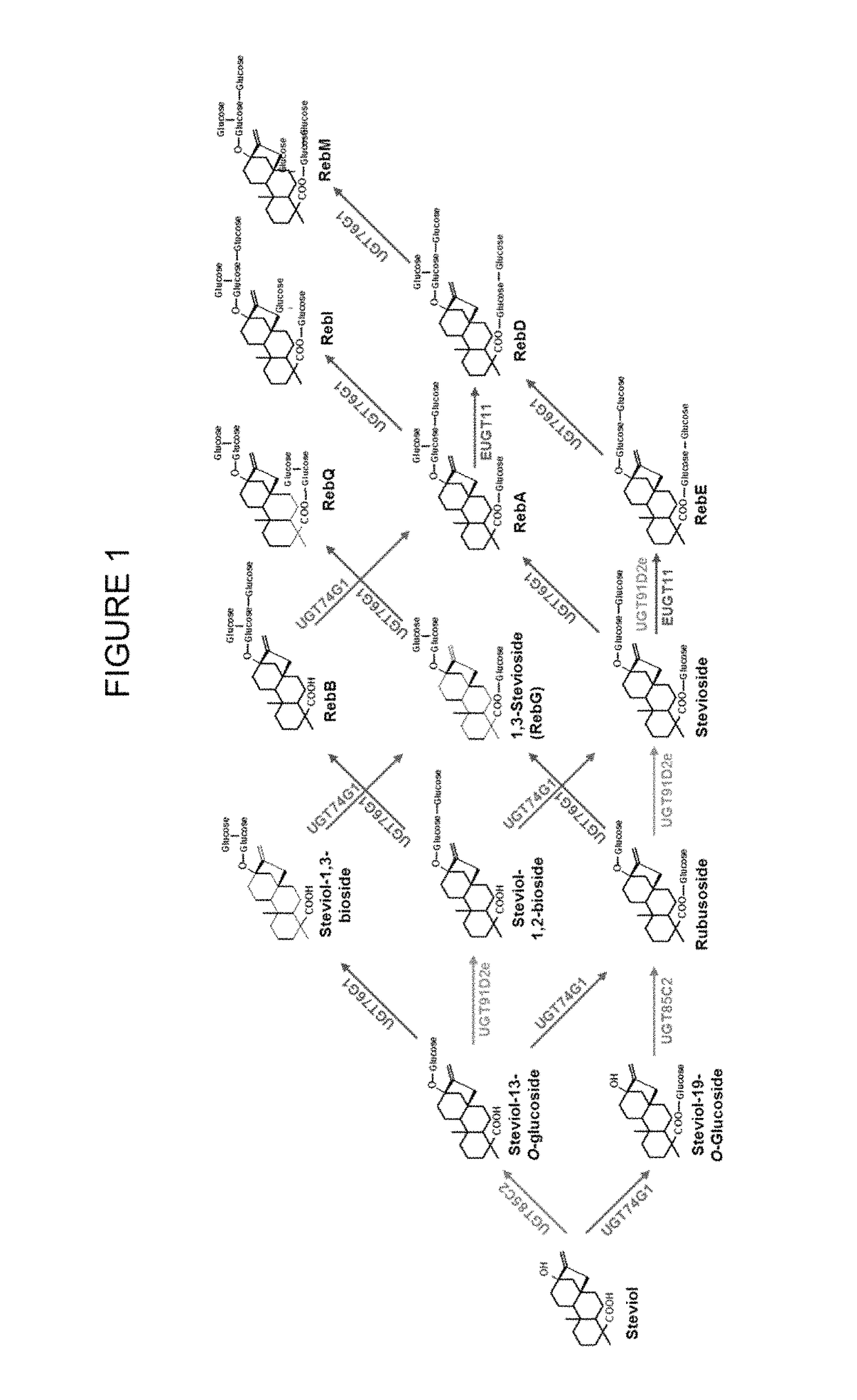

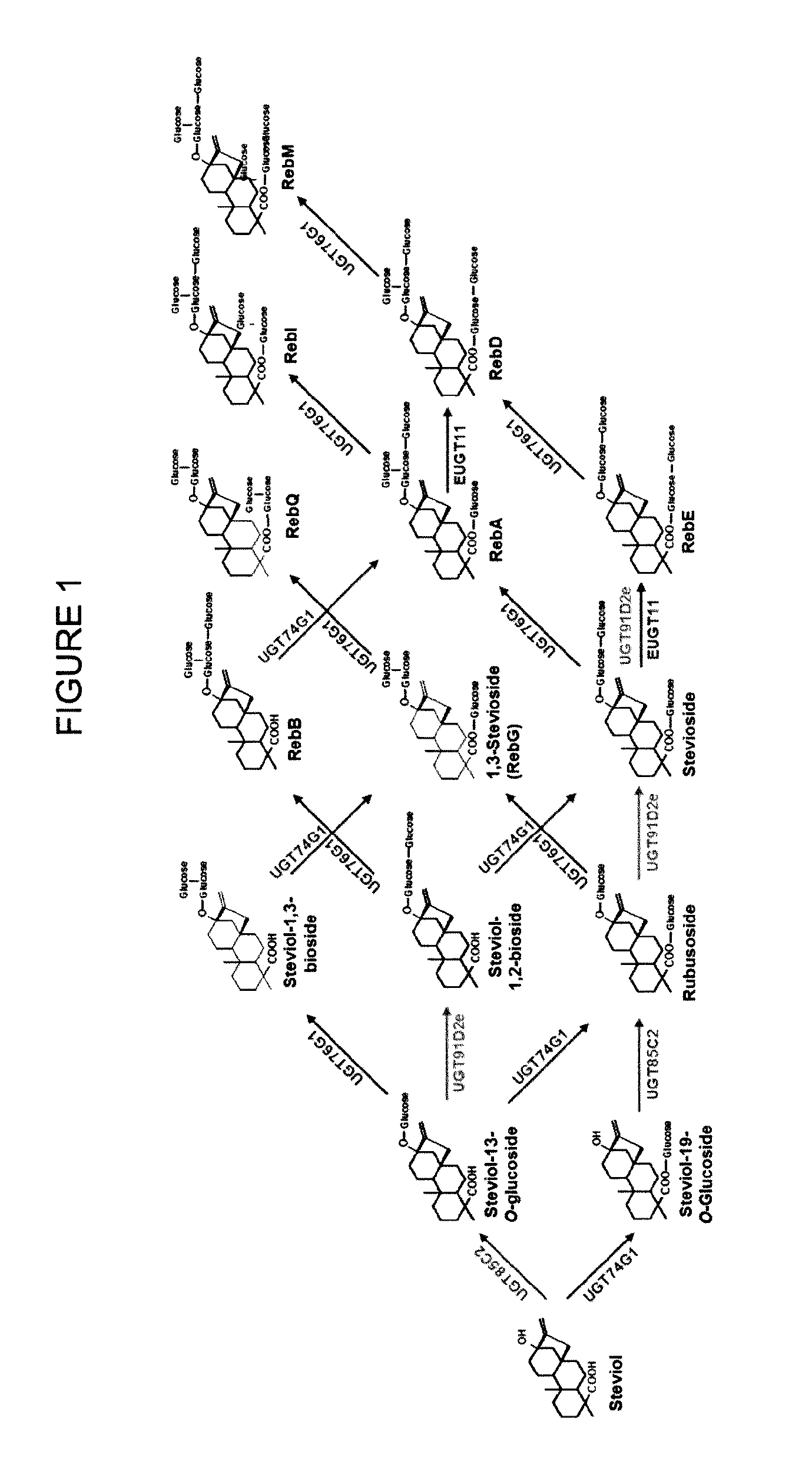

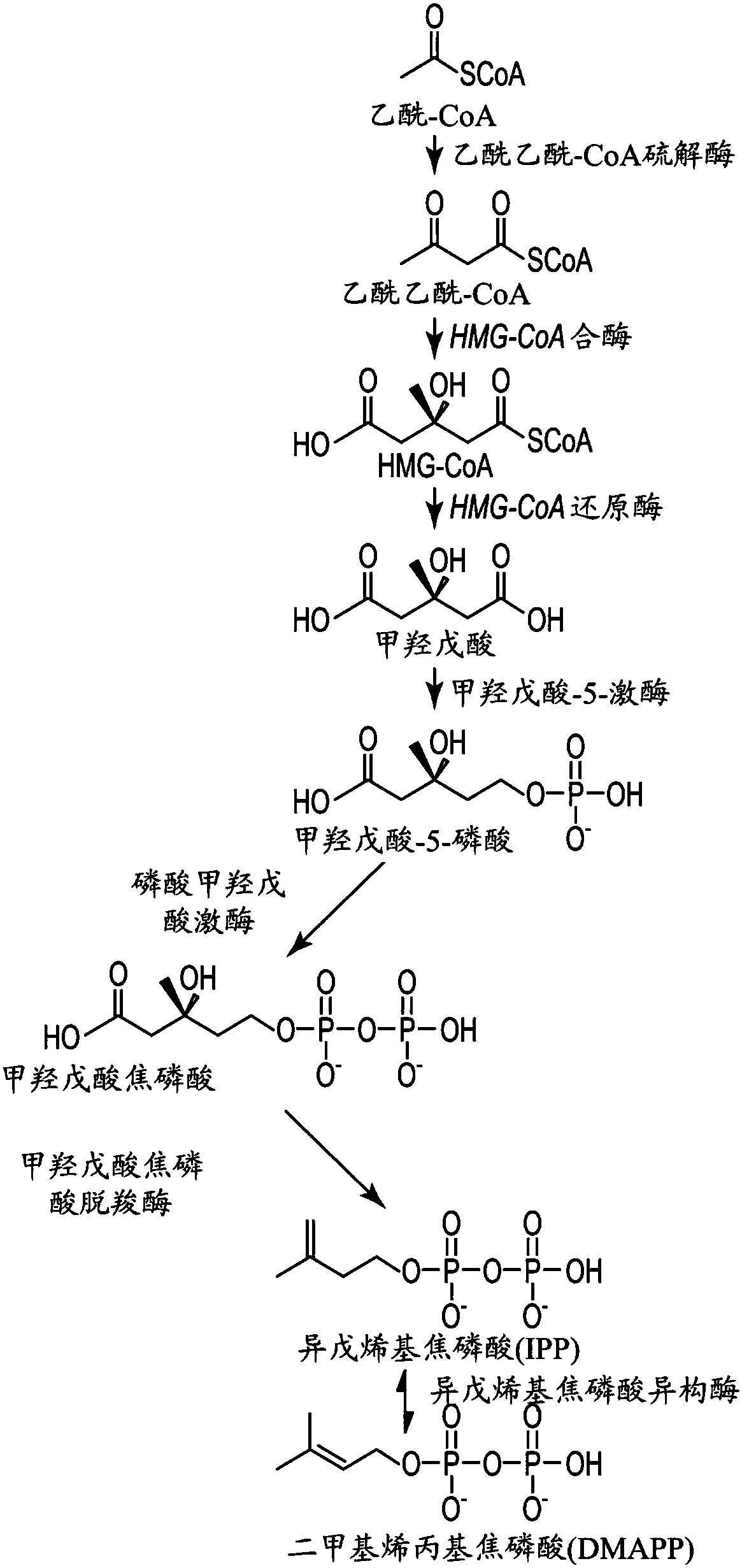

The invention relates to a method for preparing rebaudioside M through an enzyme method. According to the method, rebaudioside A or rebaudioside D is used as a substrate, and the substrate reacts to generate the rebaudioside M in the presence of sucrose and UDP under the catalytic action of a mixture of UDP-glucosyltransferase and sucrose synthetase or recombinant cells containing the UDP-glucosyltransferase and the sucrose synthetase, wherein the reaction is performed in a water-phase system having a pH value of 5.0-9.0 at 20-60 DEG C. The method for preparing rebaudioside M through an enzyme method has important application value; and compared with the existing technology of extracting rebaudioside M from stevia rebaudian leaves, the method provided by the invention obviously shortens the production cycle, improves the productivity and lowers the cost, and can provide products having higher purity. Thus, the method can be used in the food and beverage industry in a more economical manner.

Owner:PEPSICO INC

Methods for improved production of rebaudioside d and rebaudioside m

ActiveUS20160186225A1Increased specificity/activityIncrease ratingsBacteriaConfectioneryRebaudioside DBiochemistry

Owner:EVOLVA SA

Non-caloric sweeteners and methods for synthesizing

ActiveUS20160153018A1High sweetnessSugar derivativesAntibody mimetics/scaffoldsBiochemistrySteviol glycoside

Owner:CONAGEN INC

Non-caloric sweeteners and methods for synthesizing

ActiveUS20160097072A1High sweetnessSugar derivativesAntibody mimetics/scaffoldsBiochemistryRebaudioside E

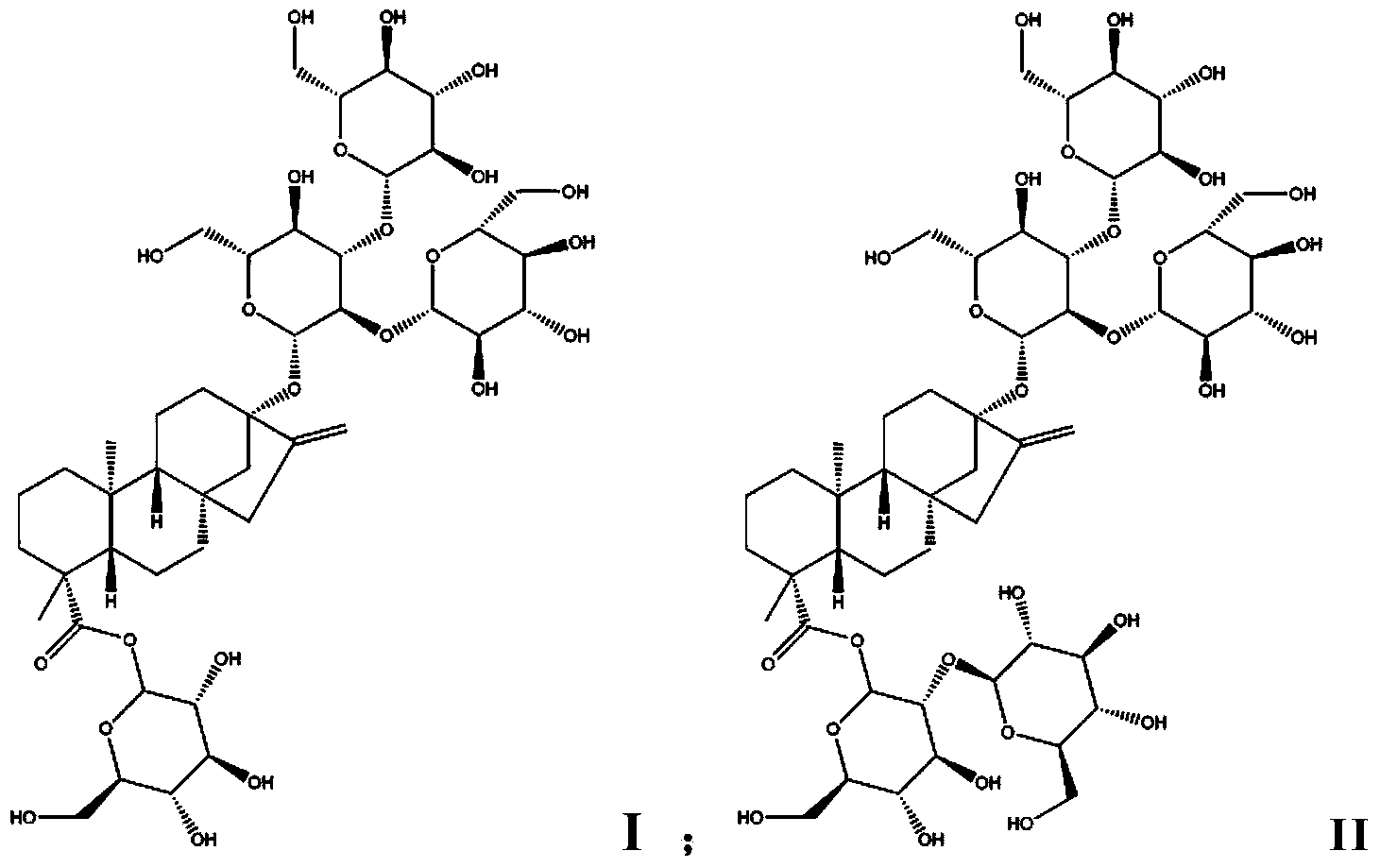

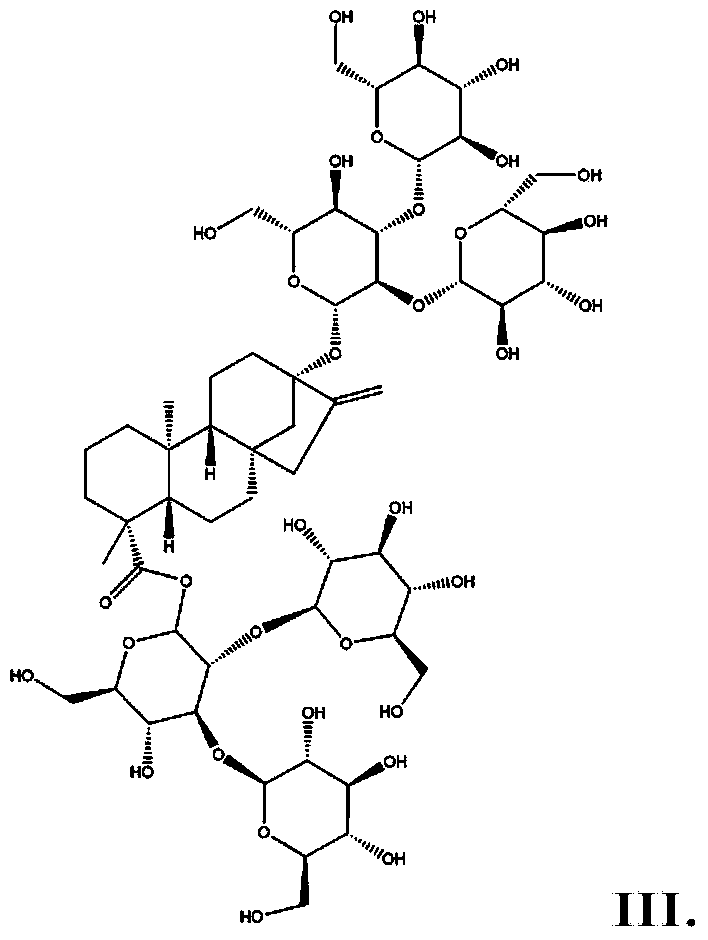

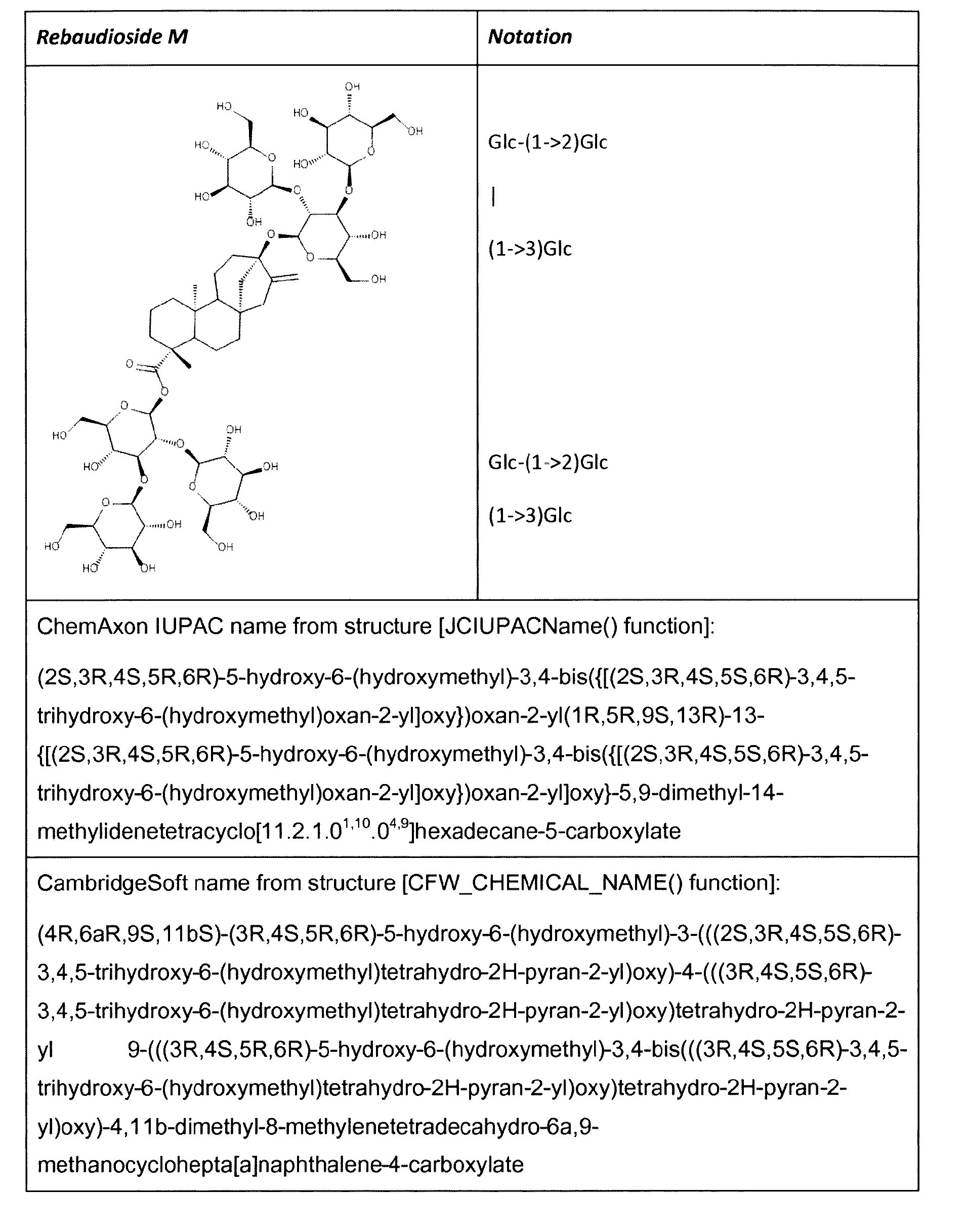

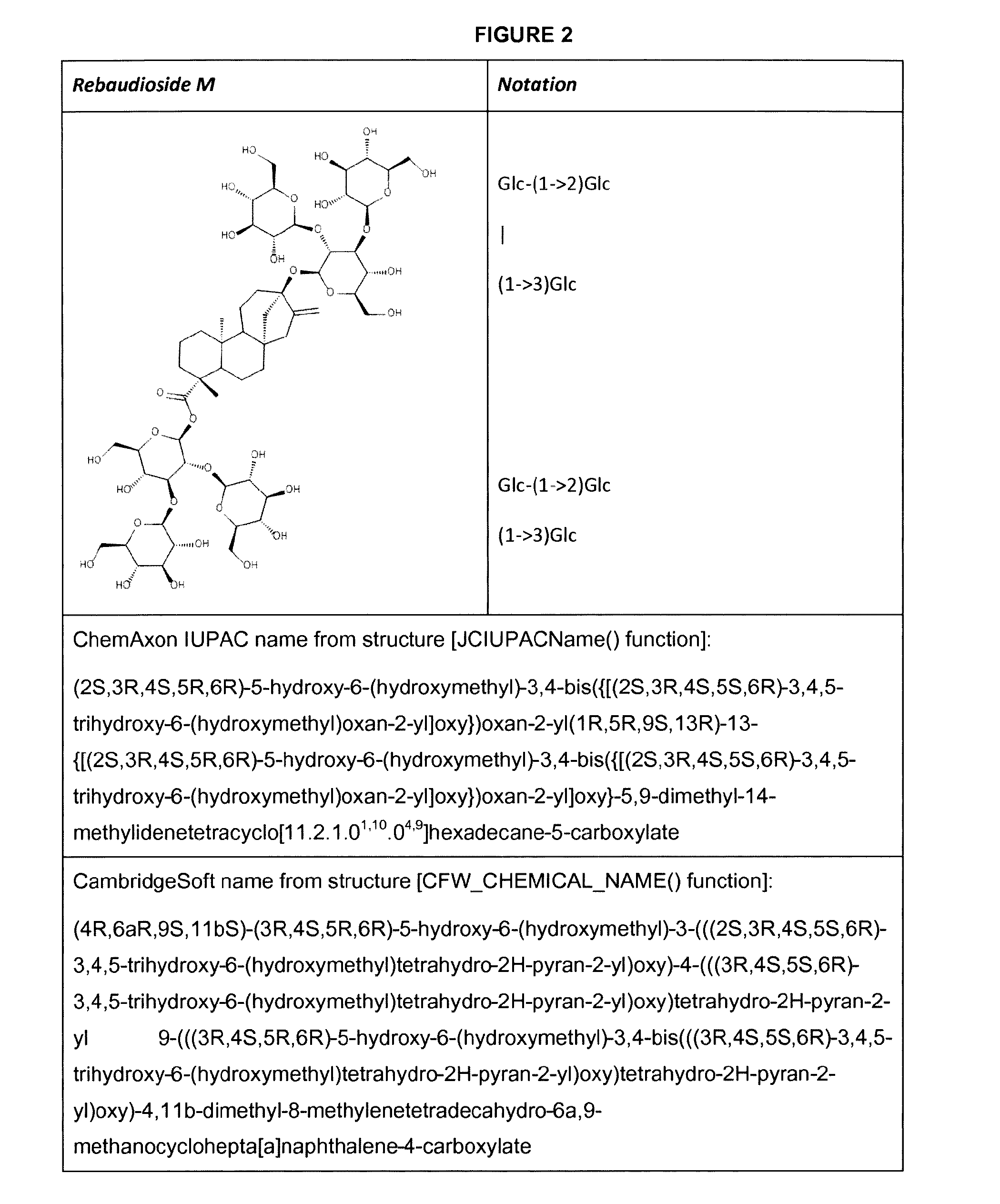

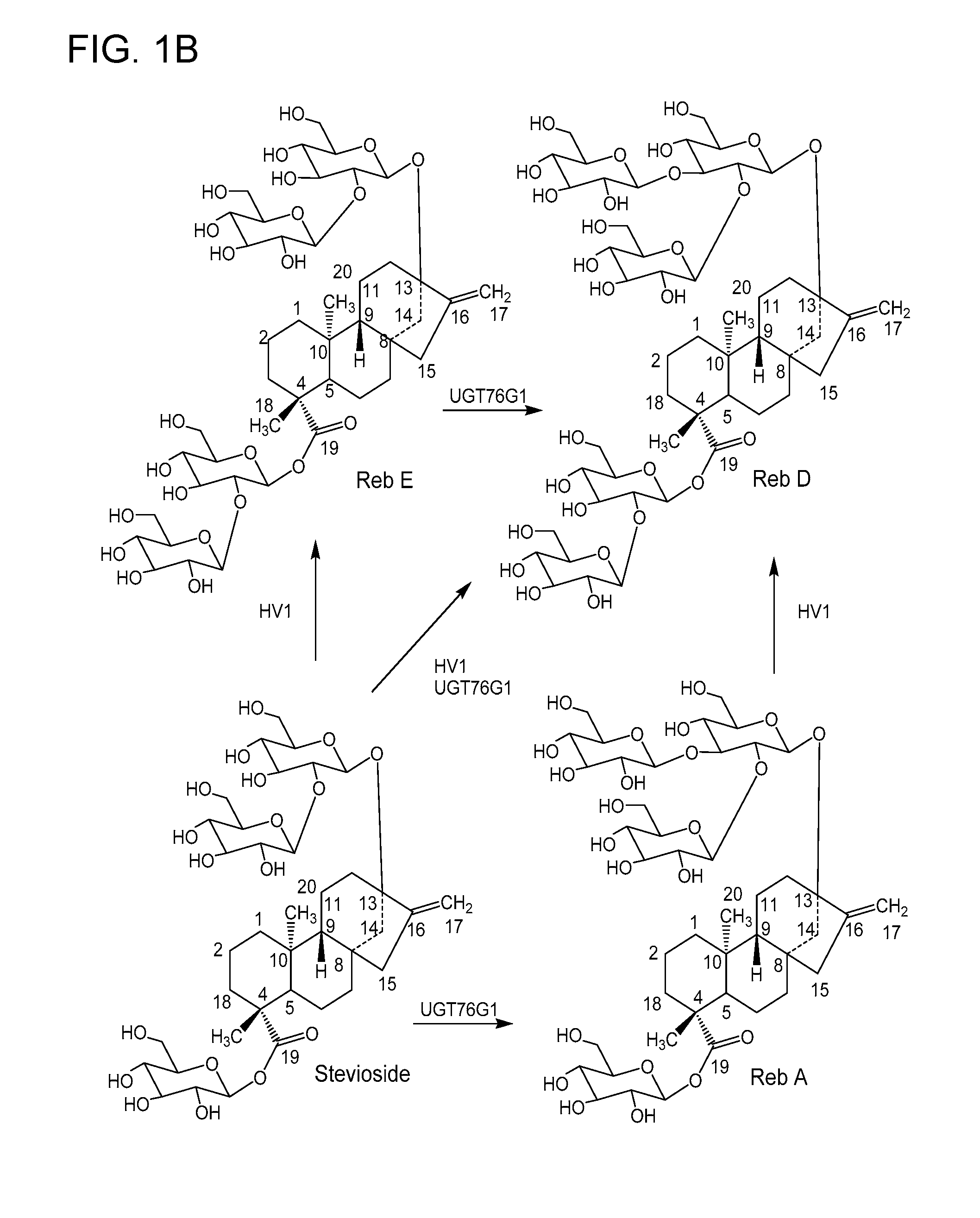

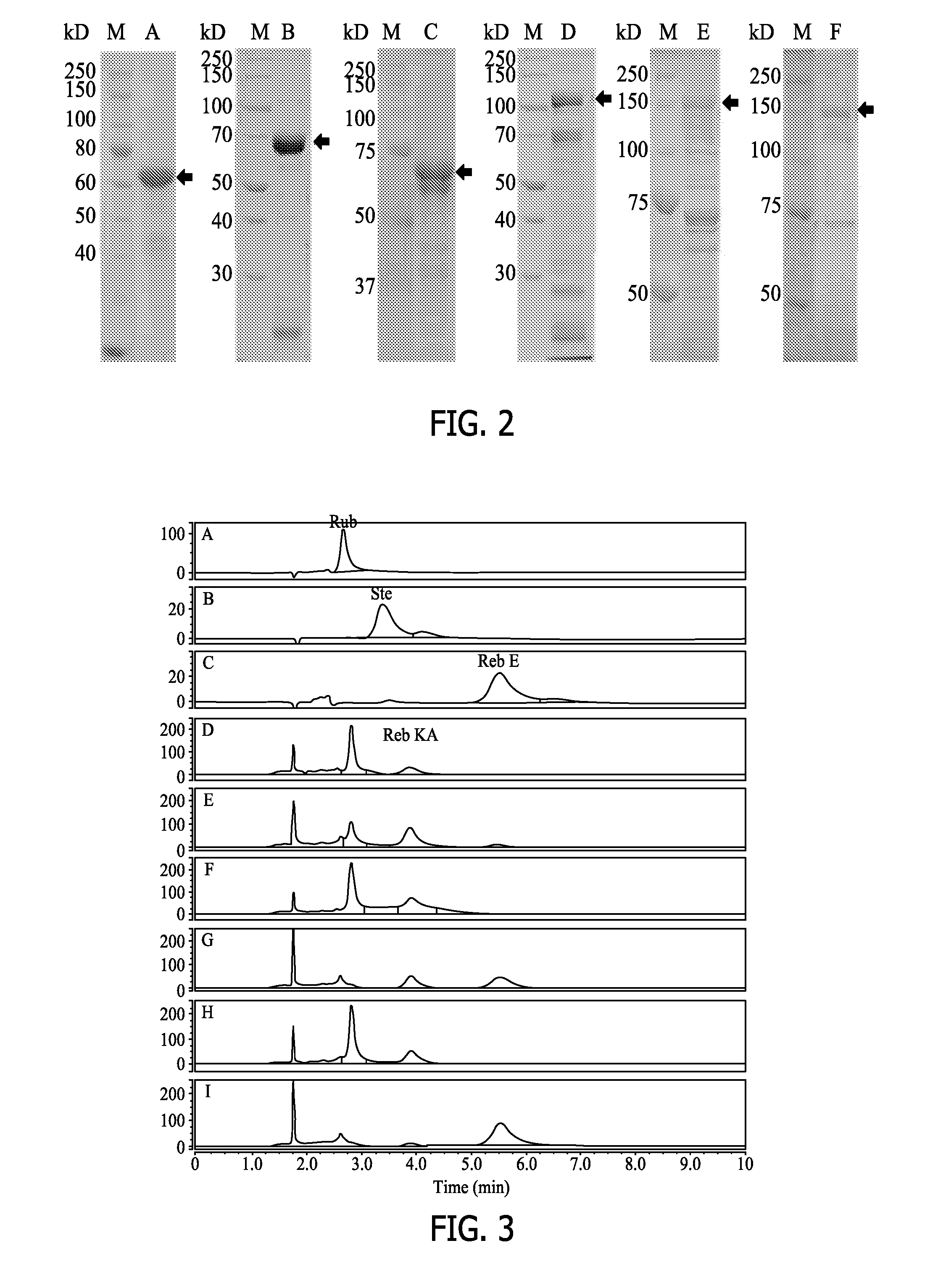

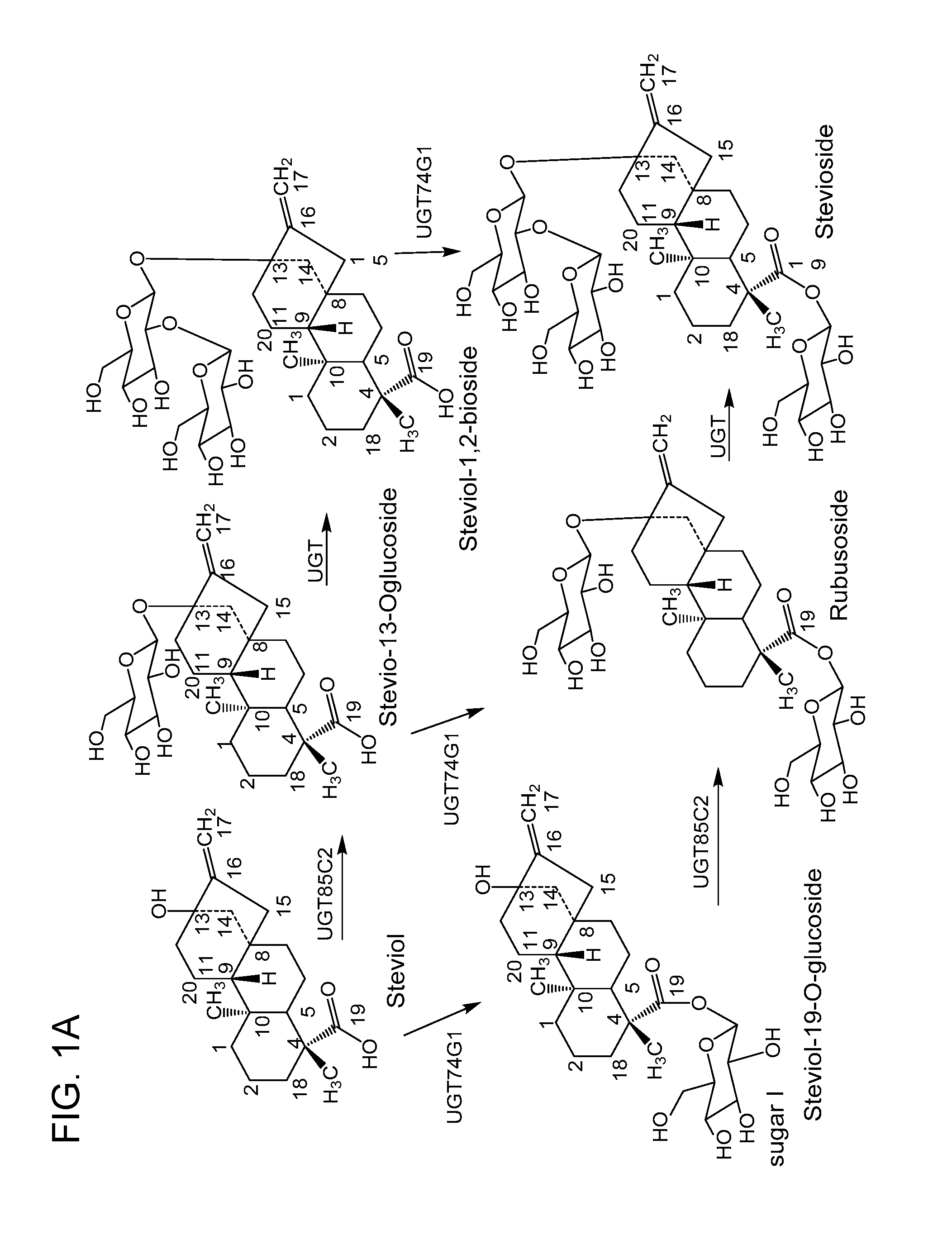

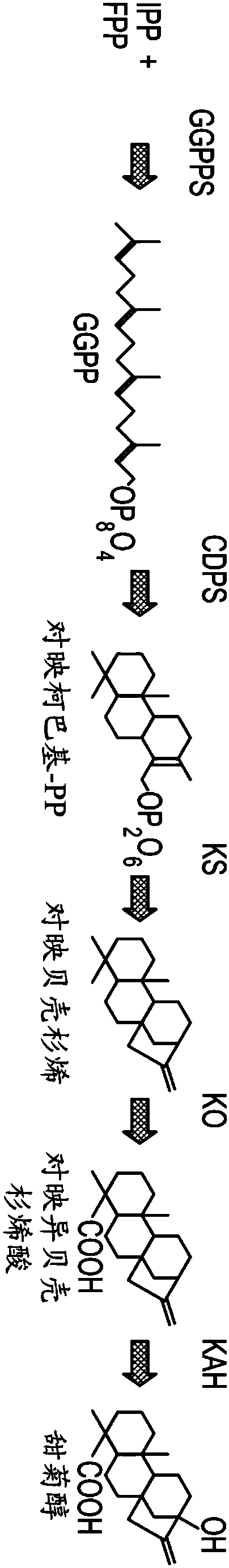

Disclosed are steviol glycosides referred to as rebaudioside V and rebaudioside W. Also disclosed are methods for producing rebaudioside M (Reb M), rebaudioside G (Reb G), rebaudioside KA (Reb KA), rebaudioside V (Reb V) and rebaudioside (Reb W).

Owner:CONAGEN INC

Non-caloric sweeteners and methods for synthesizing

ActiveUS20160097070A1High sweetnessSugar derivativesAntibody mimetics/scaffoldsBiochemistrySteviol glycoside

Disclosed are steviol glycosides referred to as rebaudioside V and rebaudioside W. Also disclosed are methods for producing rebaudioside M (Reb M), rebausoside G (Reb G), rebaudioside KA (Reb KA), rebaudioside V (Reb V) and rebaudioside (Reb W).

Owner:CONAGEN INC

Method for preparing rebaudioside-M by enzymic method

ActiveCN104726523AHigh reaction conversion rateReduce manufacturing costFermentationVector-based foreign material introductionUdp glycosyltransferaseSucrose synthetase

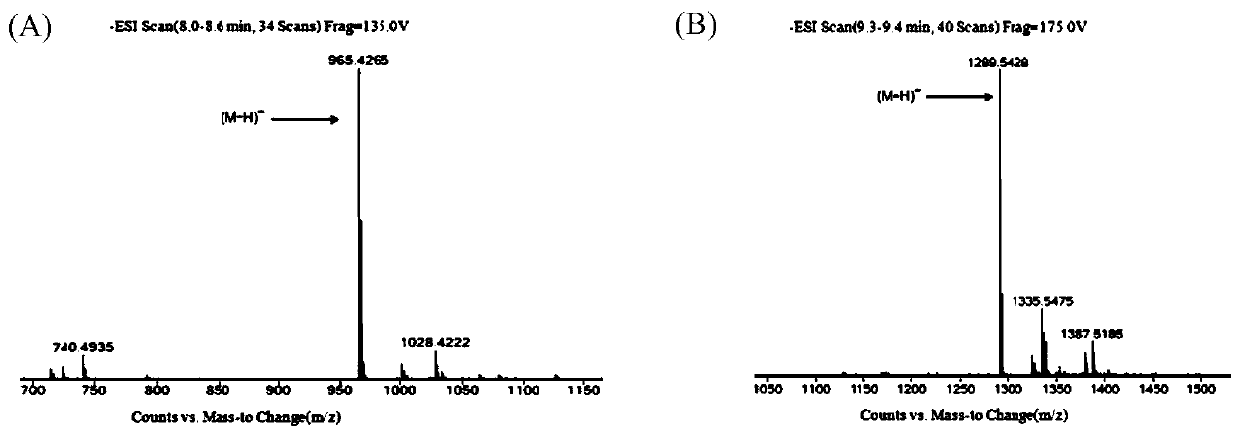

The invention discloses a method for preparing rebaudioside-M by an enzymic method. The method comprises the steps of utilizing tomato UDP-glycosyltransferase and potato sucrose synthetase, and using rebaudioside-A and sucrose as raw materials for producing rebaudioside-M. According to the method disclosed by the invention, the high-yield recombinant strain of UDP-glycosyltransferase and sucrose synthase is obtained by virtue of a genetic engineering technology at first, then a bio-enzyme crude product is collected, a catalytic reaction is directly carried out, UDP or UDP-glucose is not added in the reaction system, the rebaudioside-A and the sucrose are used as the raw materials, and the rebaudioside-A is catalyzed to generate the rebaudioside-M through the efficient circulation of catalyzing the UDP-glucose by the sucrose synthase, and through the action of the tomato UDP-glycosyltransferase. Compared with the existing preparation method for rebaudioside-M, the process is short in steps, low in cost, important in application value, and good in economical efficiency.

Owner:XINGHUA GL STEVIA CO LTD

Non-caloric sweeteners and methods for synthesizing

ActiveUS20160097071A1High sweetnessSugar derivativesAntibody mimetics/scaffoldsBiochemistrySteviol glycoside

Disclosed are steviol glycosides referred to as rebaudioside V and rebaudioside W. Also disclosed are methods for producing rebaudioside M (Reb M), rebausoside G (Reb G), rebaudioside KA (Reb KA), rebaudioside V (Reb V) and rebaudioside (Reb W).

Owner:CONAGEN INC

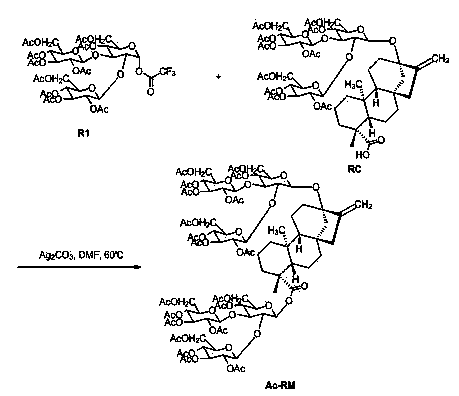

Process for preparing rebaudioside M

InactiveCN104163839ALow costMild reaction conditionsSugar derivativesSugar derivatives preparationChemical compoundHazardous substance

A process for preparing rebaudioside M is disclosed. The process includes: a step of subjecting rebaudioside C (RC) that is adopted as a substrate and a chemical compound R1 to a substitution reaction under the action of silver carbonate to obtain an intermediate Ac-RM; and a step of performing hydrolysis to obtain the product rebaudioside M (RM). By the manner, the process has characteristics of low raw material cost, mild reaction conditions, convenient purification, simple operation, good product quality, high yield, no generation of toxic harmful compounds in the whole process, and good environment protection effects, and is suitable for industrial production.

Owner:苏州景泓生物技术有限公司

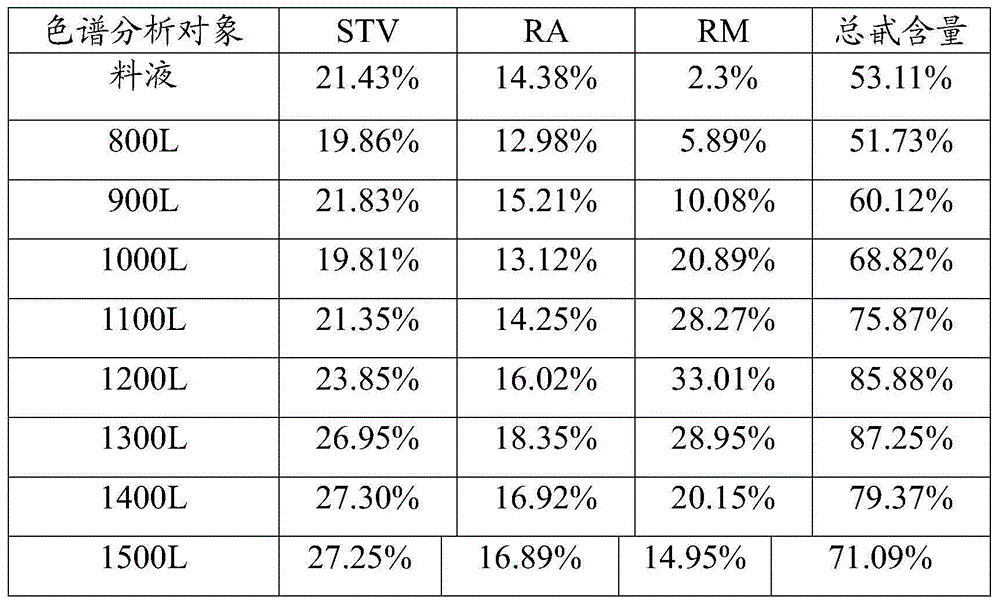

Rebaudioside M purification method

InactiveCN104151378AIncrease sweetnessBest mass concentrationSugar derivativesSolid sorbent liquid separationPurification methodsSucrose

The invention relates to a rebaudioside M purification method with the stages of crude extraction and subsequent refining treatment. The crude extraction stage comprises the following steps: a feed solution flows through eight macroporous absorption resin columns connected in series, and is absorbed sequentially; staged ethanol desorption is carried out, and analysis is carried out; an eluent is subjected to reduced-pressure concentration under high temperature; and an obtained solid is subjected to vacuum drying, such that crude rebaudioside M is obtained, wherein a crude rebaudioside M mass content reaches 25-35%. The subsequent refining treatment comprises the following steps: a mixed solvent is heated; the crude rebaudioside M is dissolved into the mixed solvent, such that a solution is formed; the temperature is reduced to normal temperature; standing and intermittent stirring is carried out; the product is allowed to stand for several hours, and solid-liquid separation is carried out; and the obtained solid is dried, such that refined rebaudioside M is obtained. The refined rebaudioside M content can be higher than 95%. The sweetness of the rebaudioside M is more than 300 times that of cane sugar. The sweetness is more long-lasting than that of cane sugar, and causes no bitter after-taste. The mouthfeel is closer to white sugar, and mouthfeel and taste quality are good. Rebaudioside M is an ideal natural sweet additive.

Owner:QINGDAO RUNDE BIOTECH

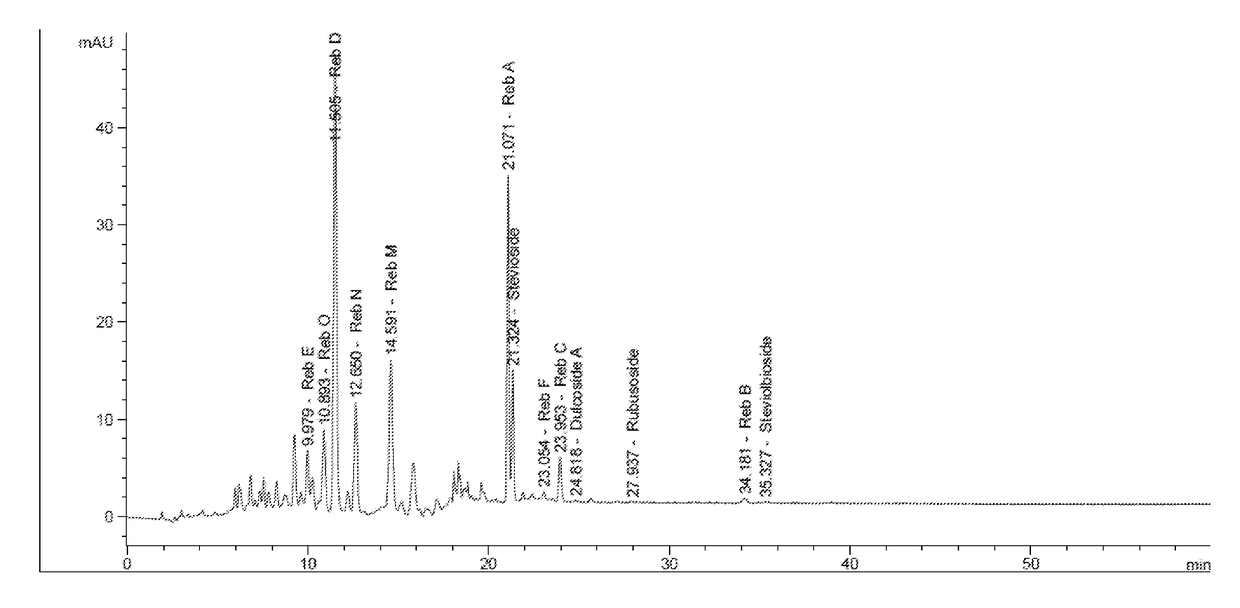

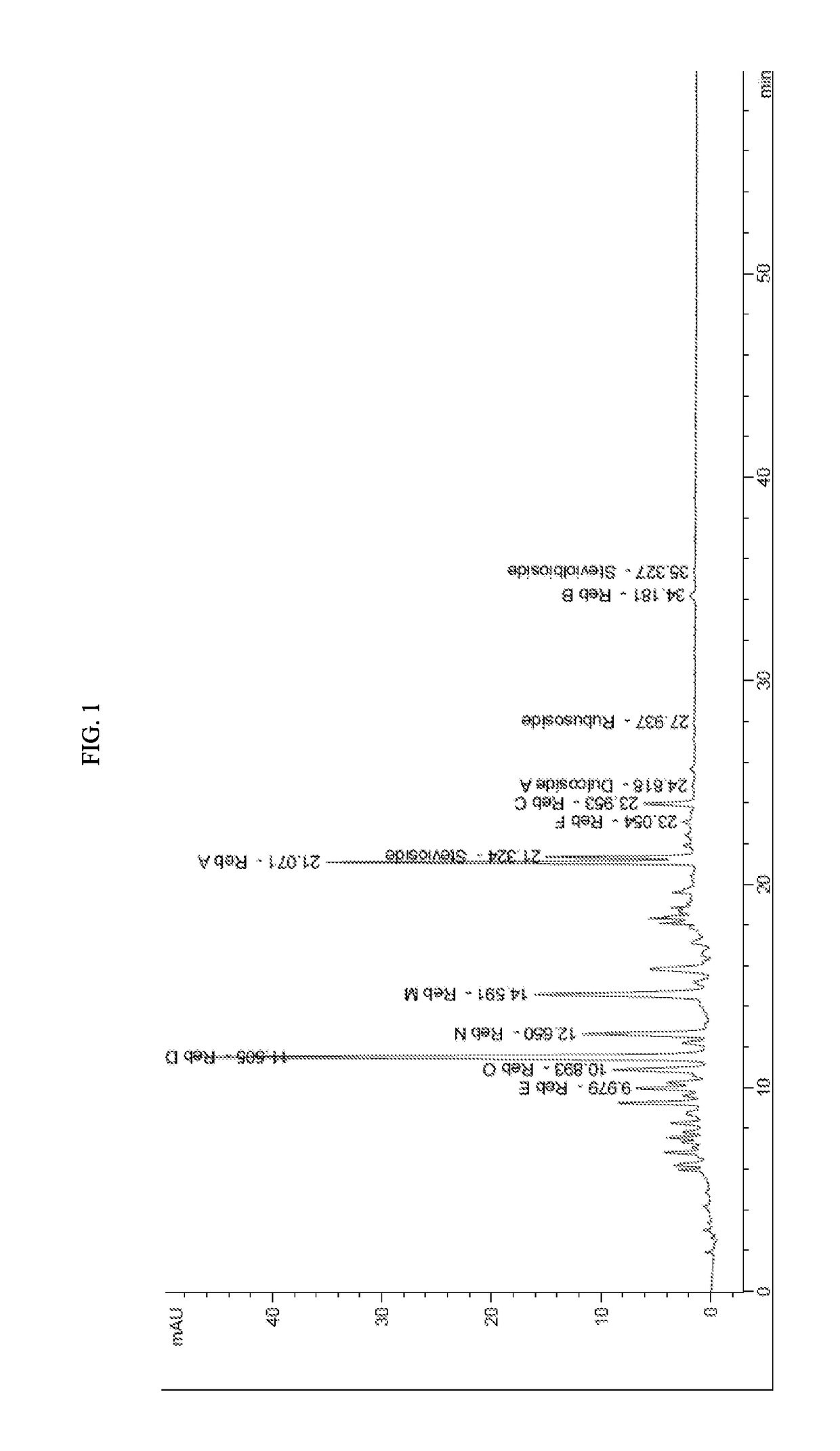

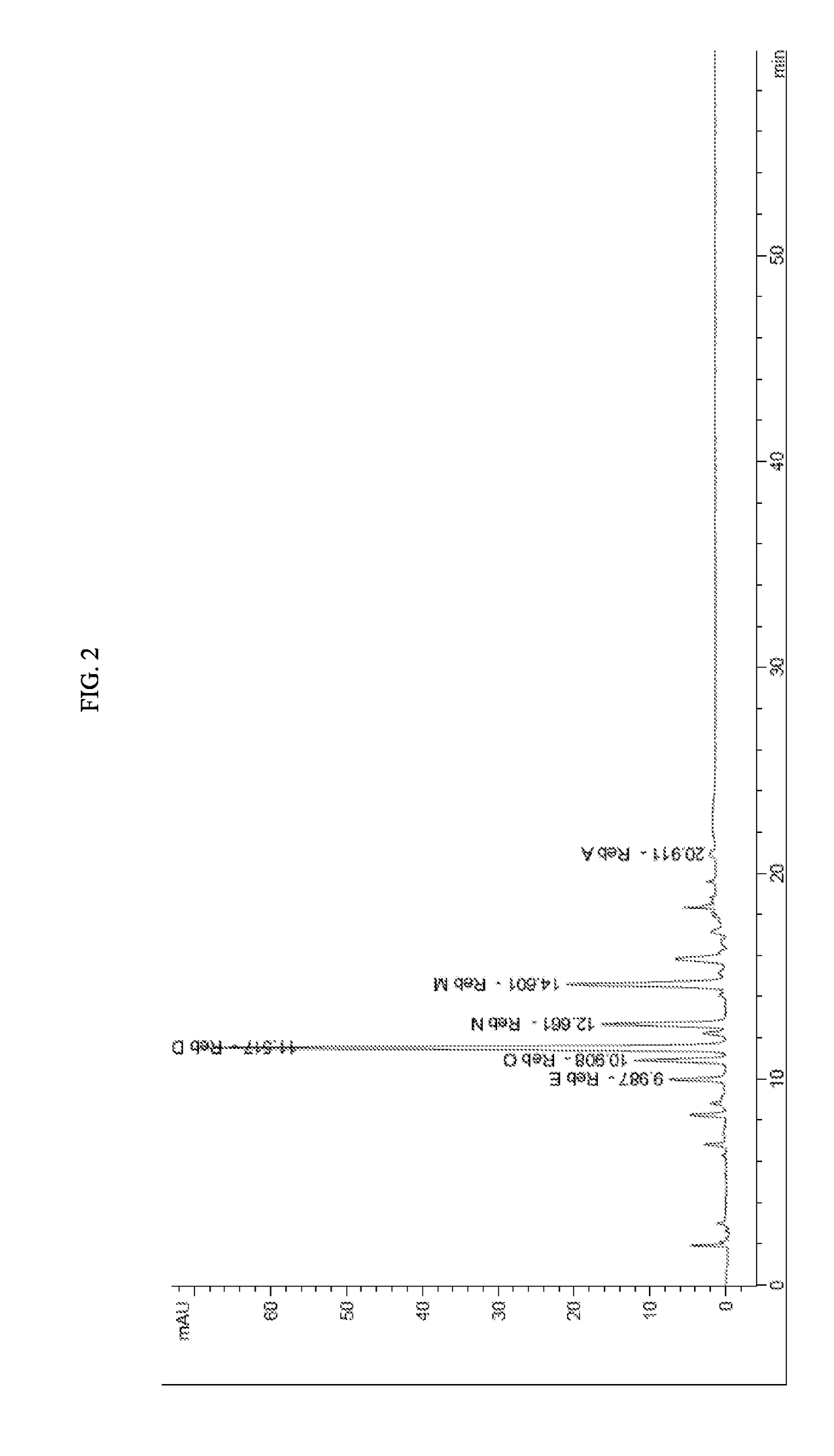

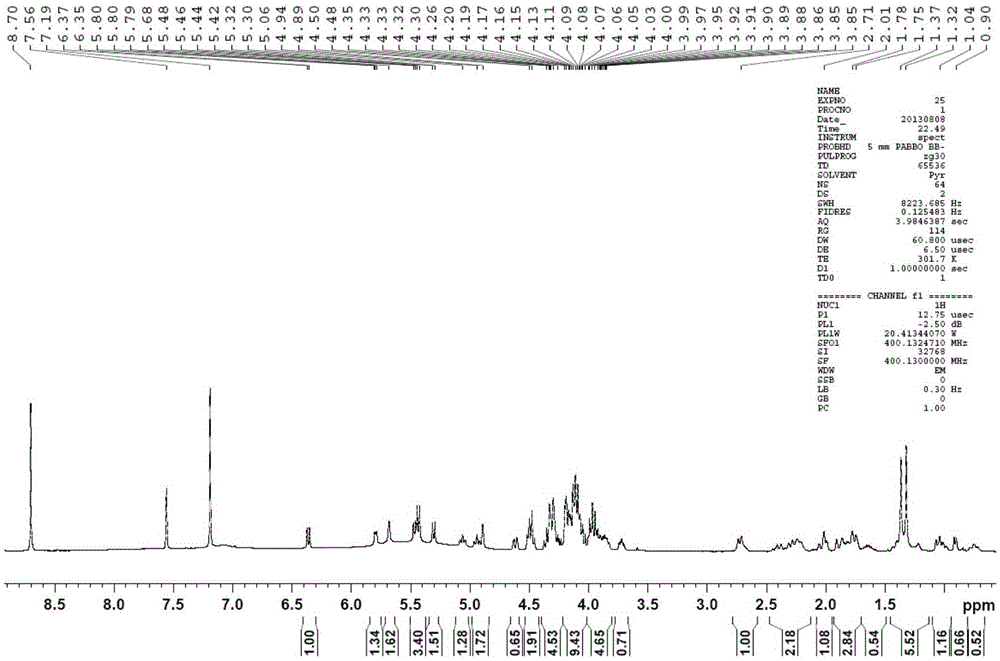

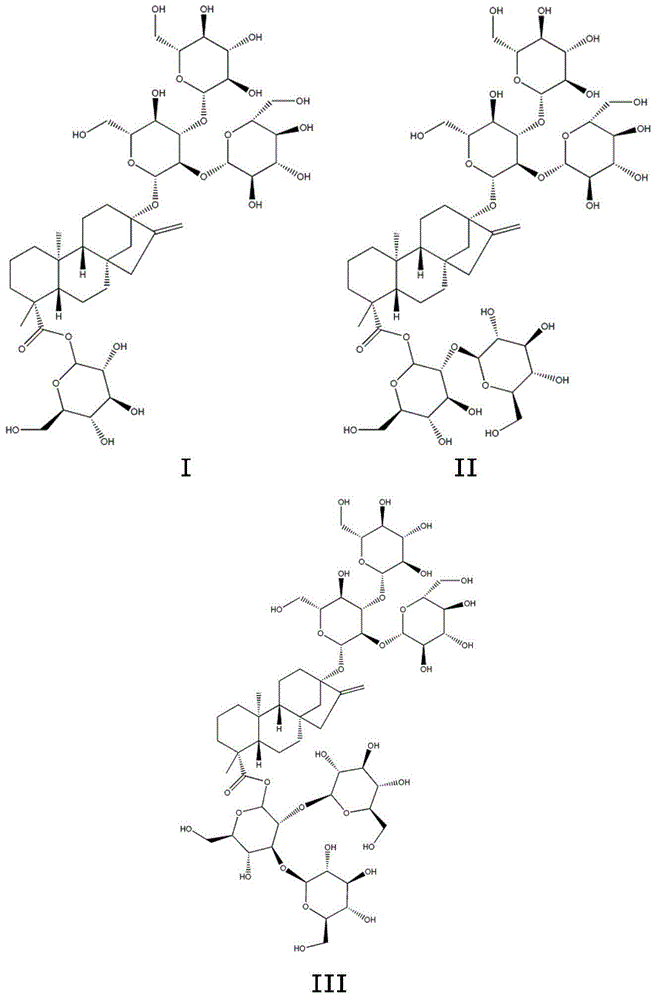

Methods of preparing steviol glycosides and uses of the same

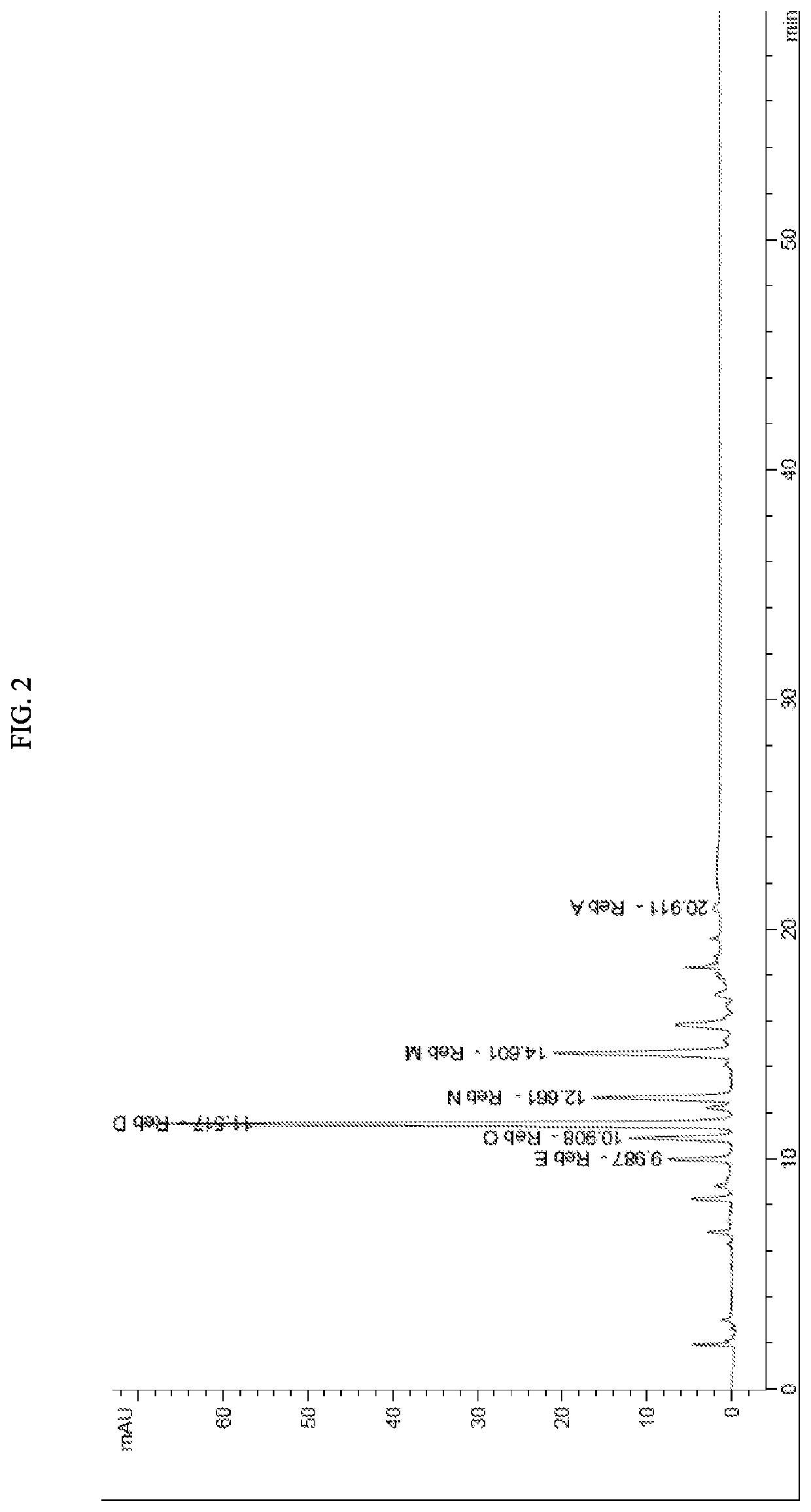

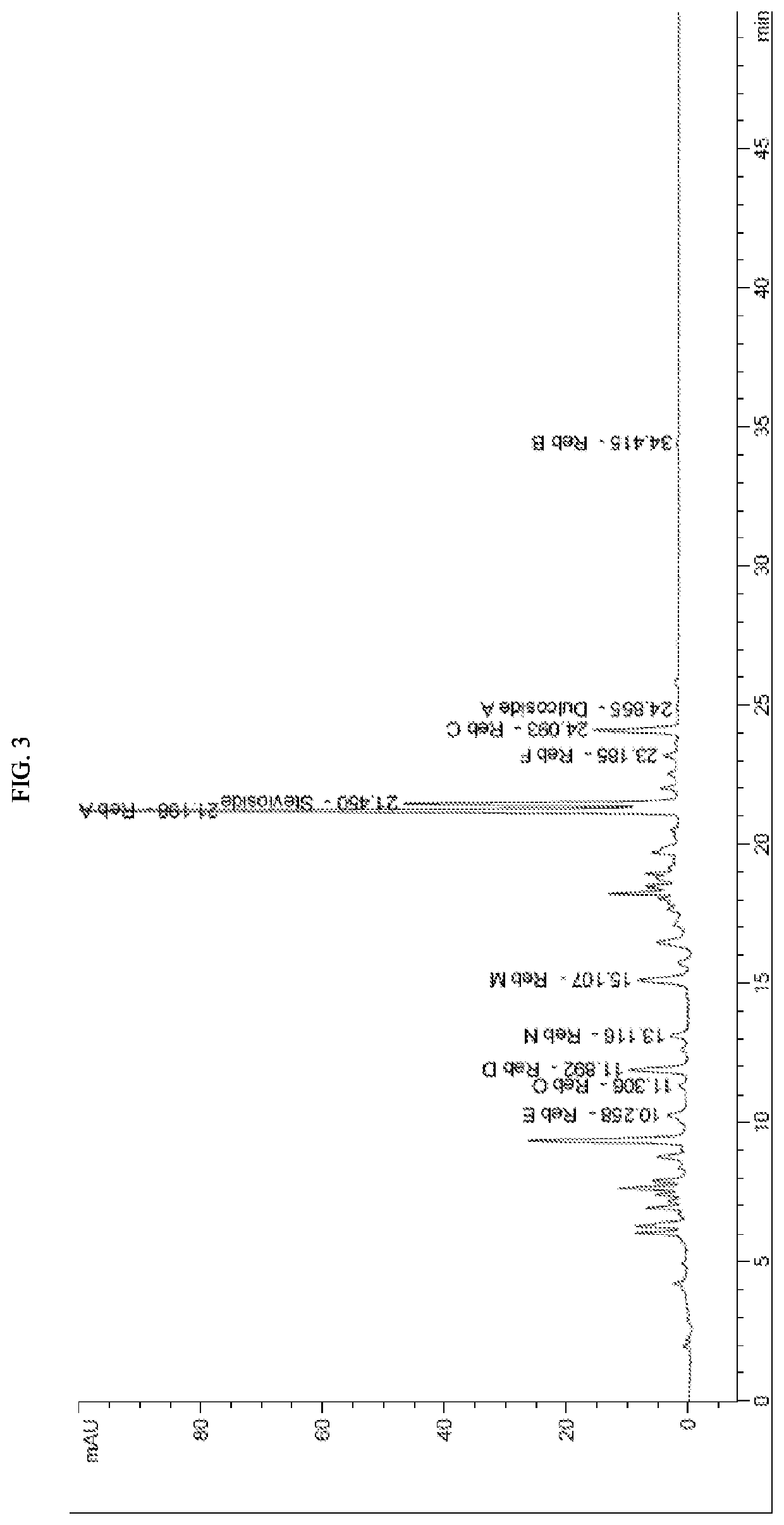

Methods of preparing steviol glycosides, including Rebaudioside D, Rebaudioside E, Rebaudioside M, Rebaudioside N and Rebaudioside O are provided herein. Sweetener and sweetened consumables containing Rebaudioside D, Rebaudioside E, Rebaudioside M, Rebaudioside N and Rebaudioside O are also provided herein.

Owner:PURECIRCLE USA

Method for preparing rebaudioside M according to saccharomyces cerevisiae enzymatic method

InactiveCN105200098AImprove securitySave fermentation timeMicroorganismsMicroorganism based processesFood additiveUdp glucosyltransferase

The invention discloses a method for preparing rebaudioside M according to a saccharomyces cerevisiae enzymatic method. The method for preparing rebaudioside M comprises the following steps: utilizing recombinant saccharomyces cerevisiae containing UDP-glucosyltransferase or UDP-glucosyltransferase prepared from the recombinant saccharomyces cerevisiae to catalyze rebaudioside A or rebaudioside D in the presence of a glucosyl group donor, so as to generate rebaudioside M. The recombinant saccharomyces cerevisiae is obtained by introducing a strong promoter into a plasmid to obtain a vector plasmid, inserting a UDP-glucosyltransferase gene into the vector plasmid through a restriction site to obtain an expression vector under the control the strong promoter, and carrying out saccharomyces cerevisiae transformation. The method for preparing rebaudioside M has the advantages that the high-safety recombinant saccharomyces cerevisiae is utilized for catalytic production; the produced UDP-glucosyltransferase is higher in expression level and activity; the produced rebaudioside M can be directly utilized as a food additive, and is short in production period, higher in yield, and relatively low in cost.

Owner:PEPSICO INC

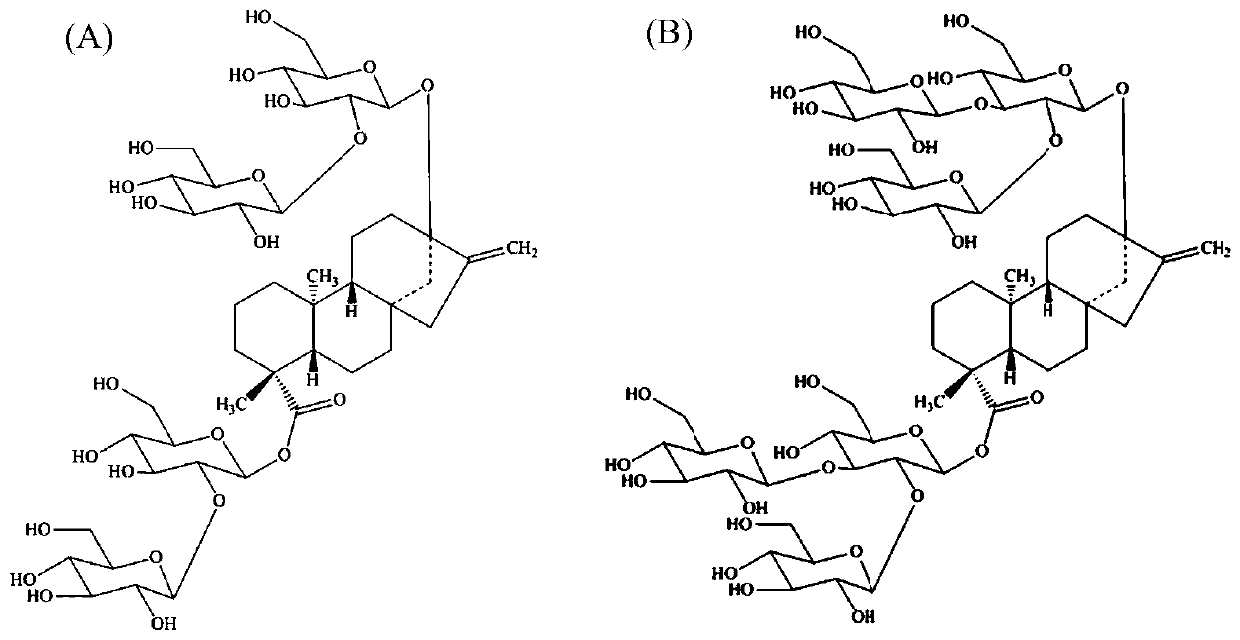

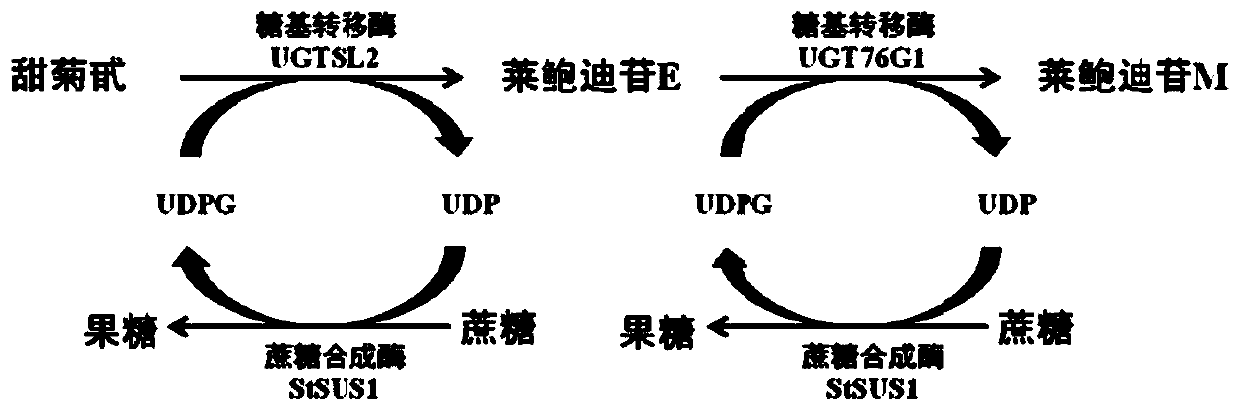

Biocatalytic method for synthesis of rebaudioside M

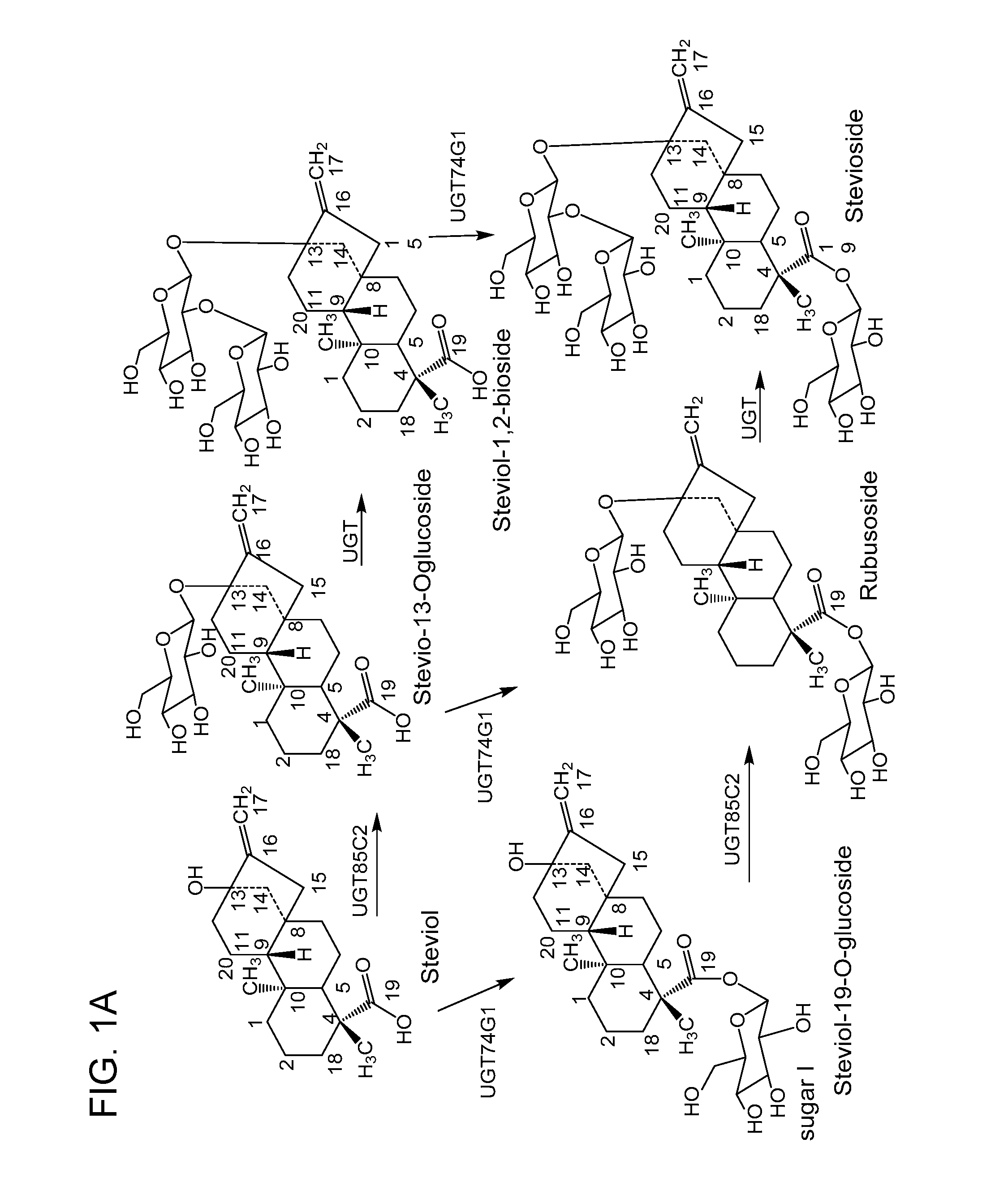

The invention discloses a biocatalytic method for synthesis of rebaudioside M. Firstly, rebaudioside E is synthesized by a glycosylation reaction of stevioside with UDP-glycosyltransferase from tomatos and sucrose synthetase from potatoes; then, rebaudioside M is synthesized by a glycosylation reaction of rebaudioside E with UDP-glycosyltransferase from stevia rebaudiana and sucrose synthetase from potatoes. The method uses a molecular cloning technique, escherichia coli genetically engineered bacteria for heterologous expression of UDP-glycosyltransferase and sucrose synthetase are obtained,after fermentation and enzyme production, crude extract of cells is directly used for a catalytic reaction, addditionally added saccharose is decomposed with sucrose synthetase to obtain UDP-glucose,UDP in the crude extract and the UDP-glucose serve as raw materials for the glycosylation reaction, a double-enzyme cycle reaction system is established, and the rebaudioside M is produced by effectively catalyzing stevioside. The cost of raw materials is lower, the processing steps are simple, and the method has an important application value.

Owner:NANJING UNIV OF TECH

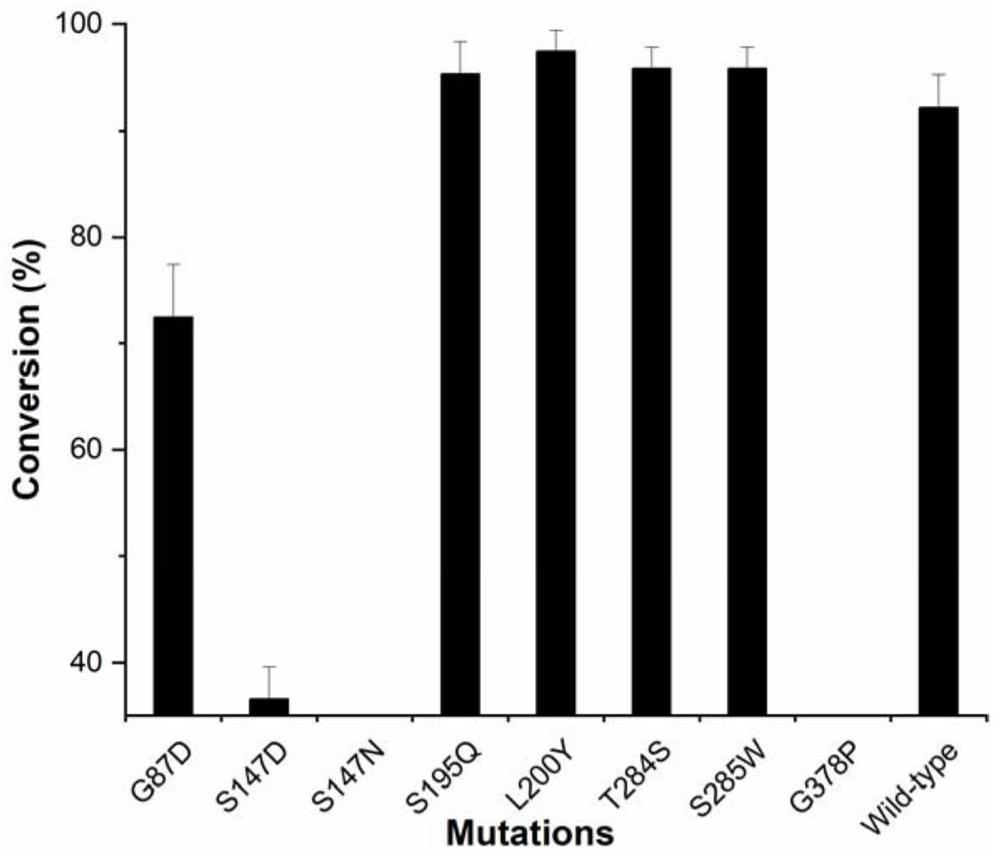

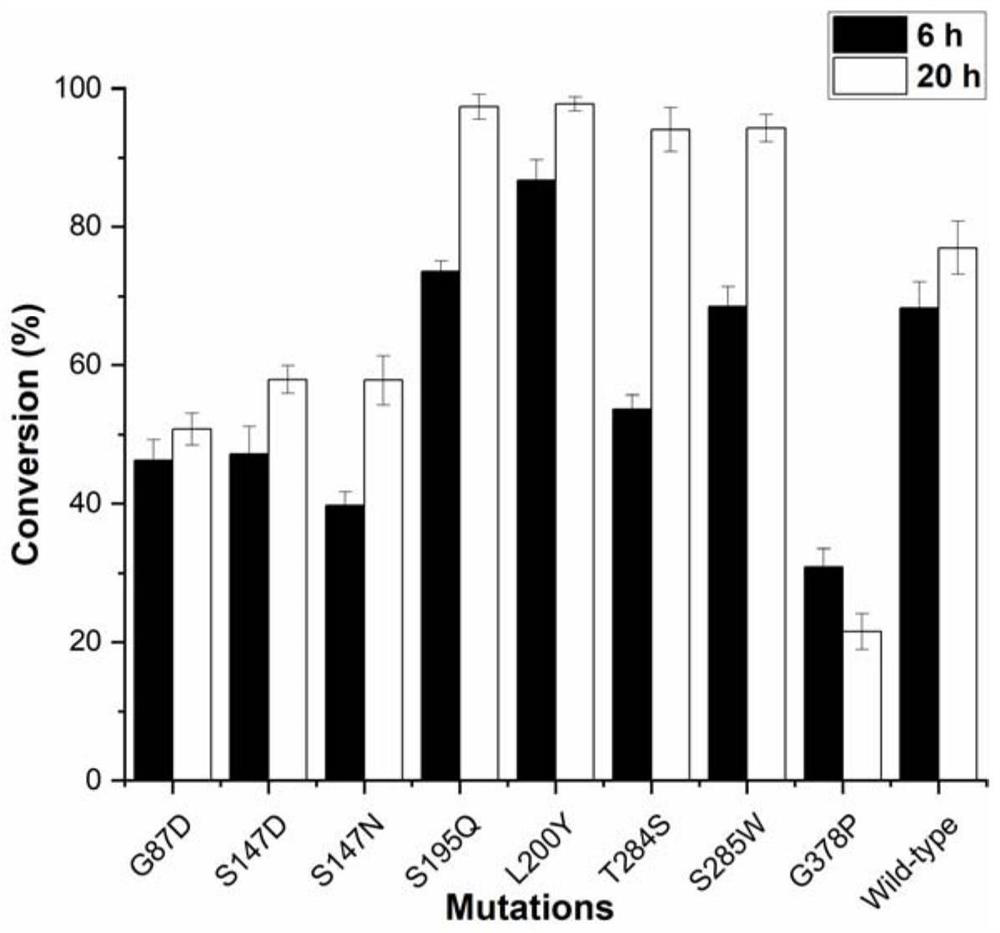

Glycosyl transferase mutant and method for catalytically synthesizing rebaudioside M by using glycosyl transferase mutant

ActiveCN113462670AIncrease productionHigh affinityBacteriaMicroorganism based processesSucrose synthetasePtru catalyst

The invention discloses a glycosyl transferase mutant and a method for catalytically synthesizing rebaudioside M by using the glycosyl transferase mutant. The mutant is obtained by performing mutation on the basis of a glycosyl transferase amino acid sequence shown as SEQ ID NO: 1, performing induced expression on a mutant strain to obtain a mutant enzyme, and catalyzing 20g / L RebE to synthesize 12.8 g / L RebM by using the mutant enzyme as a catalyst and the enzymic method. The kinetic parameters of the mutant S195Q on rebaudioside E and rebaudioside D and the Michaelis constant of the mutant are 56.34 + / -2.02 mu M and 214.48 + / -14.54 mu M respectively, and are 1 / 3 and 2 / 5 of those of a wild type. The glycosyl transferase mutant is coupled with sucrose synthase to realize efficient catalytic synthesis of rebaudioside M. According to the present invention, the recombinant strain of the glycosyl transferase UGT76G1 or the mutant thereof and the sucrose synthase is constructed so as to achieve the efficient catalytic synthesis of the rebaudioside M; the method has the optimal yield in the current enzymatic catalytic synthesis experiment of rebaudioside M, and is green, environment-friendly and pollution-free.

Owner:XINGHUA GL STEVIA CO LTD

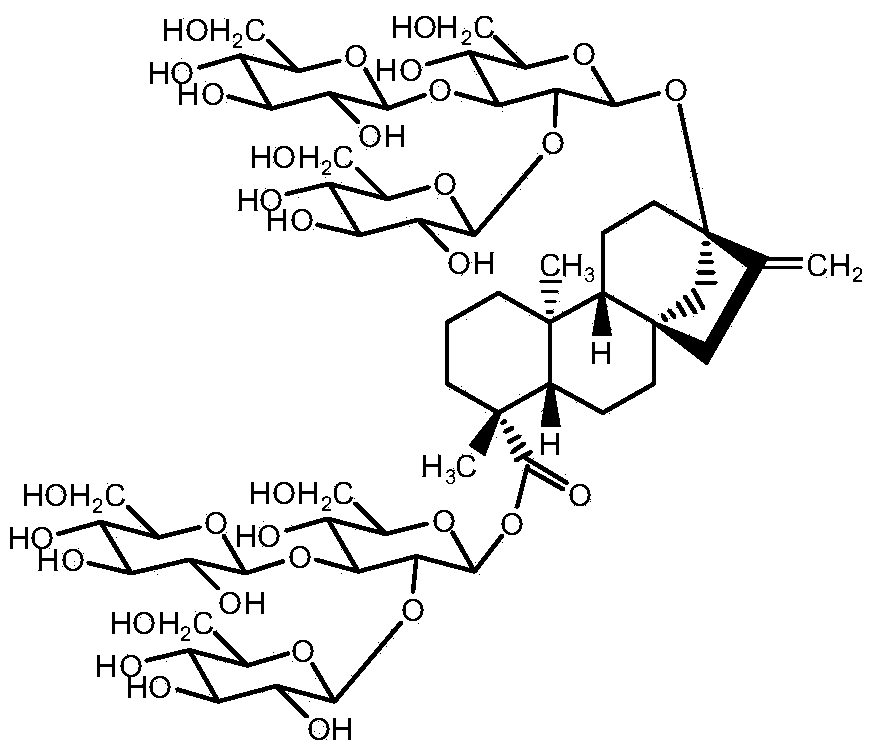

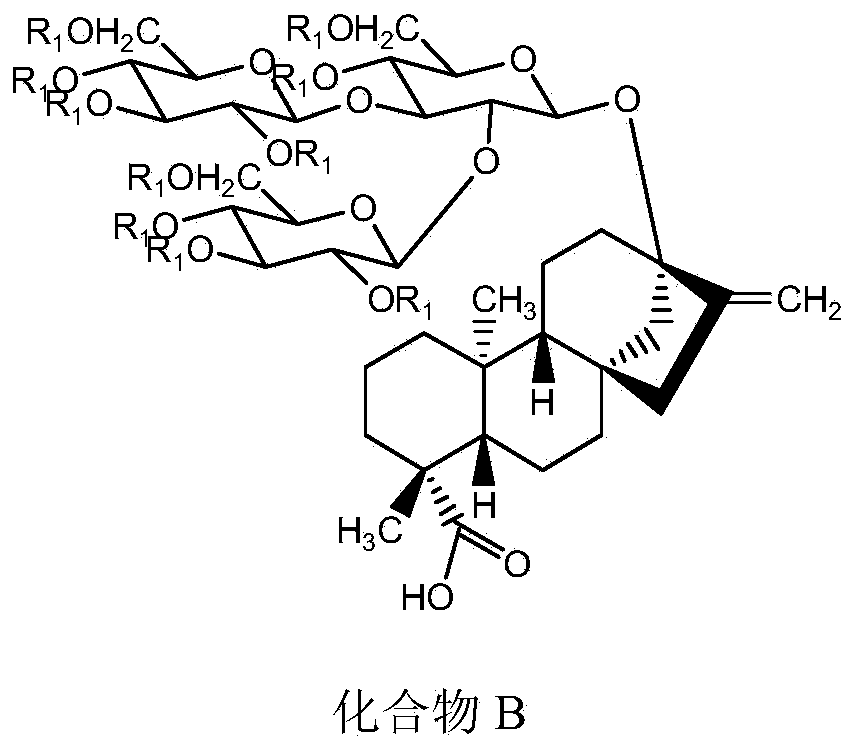

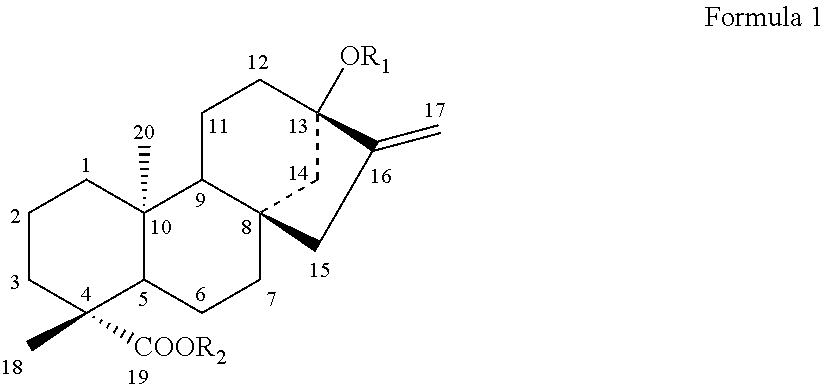

Synthesis method of rebaudioside M, intermediate product of rebaudioside M and synthesis method of intermediate product of rebaudioside M

InactiveCN104341470AHigh purityImprove conversion rateEsterified saccharide compoundsSugar derivativesChemical industryNatural product

The invention belongs to the field of food chemical industry, relates to a synthesis method of rebaudioside M, an intermediate product of the rebaudioside M and a synthesis method of the intermediate product of the rebaudioside M, and particularly relates to a process method which uses ready-made natural products and non-toxic reagents and is applicable to industrial production. The provided synthesis method of the rebaudioside M is bran-new. The synthesis method provided by the invention comprises the following routes: (1) protecting hydroxyl groups of a compound A, so as to obtain a compound B; (2) enabling the compound B and a compound C to react in the presence of a phase transition reagent and an inorganic base, so as to obtain a compound D; (3) removing protecting groups of R1 and R2 from the compound D, thereby obtaining the rebaudioside M. The method has the advantages that the preparation method is simple and is easy in operation, the purity of a product is high, and the conversion ratio is high.

Owner:成都华高瑞甜科技有限公司

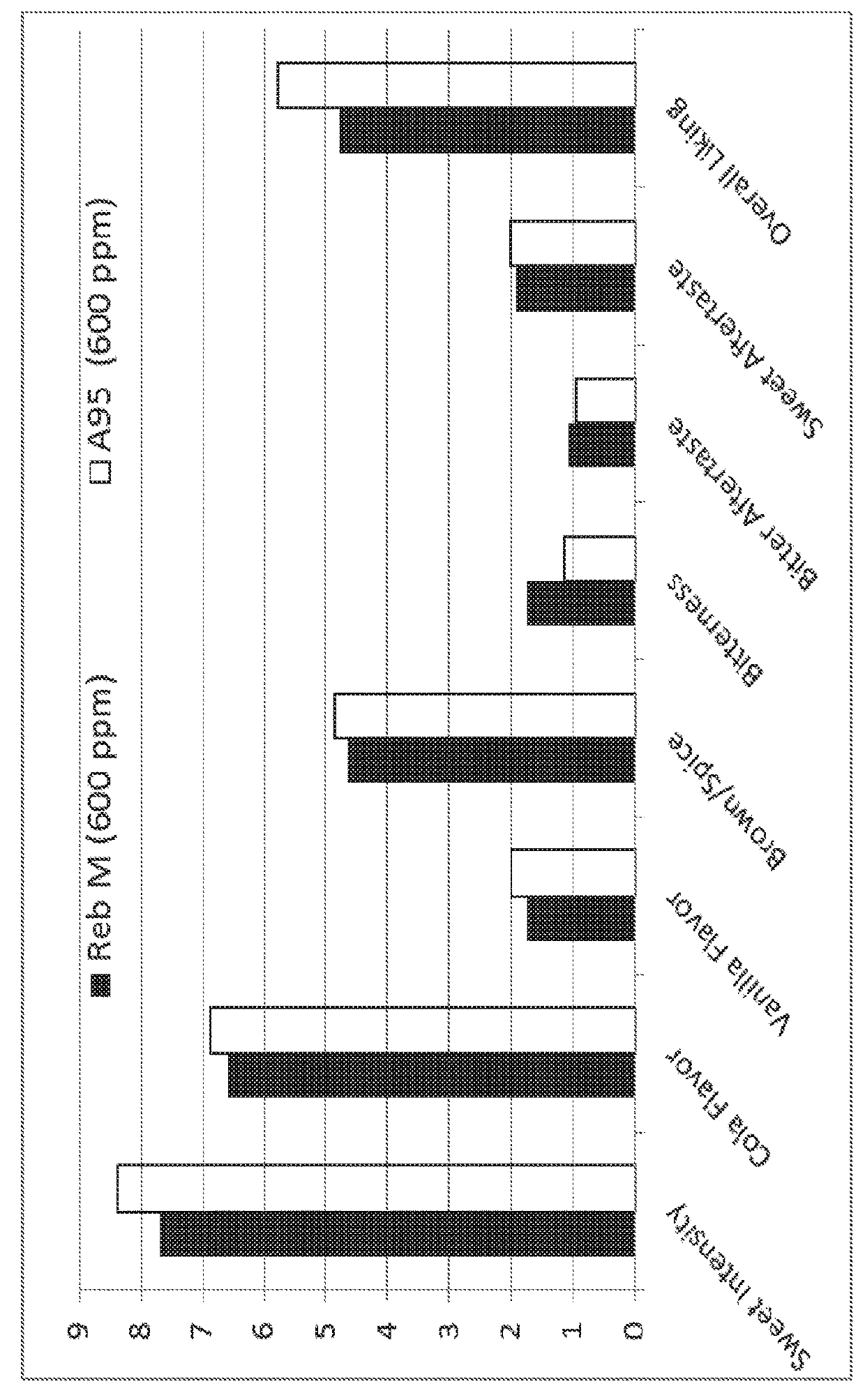

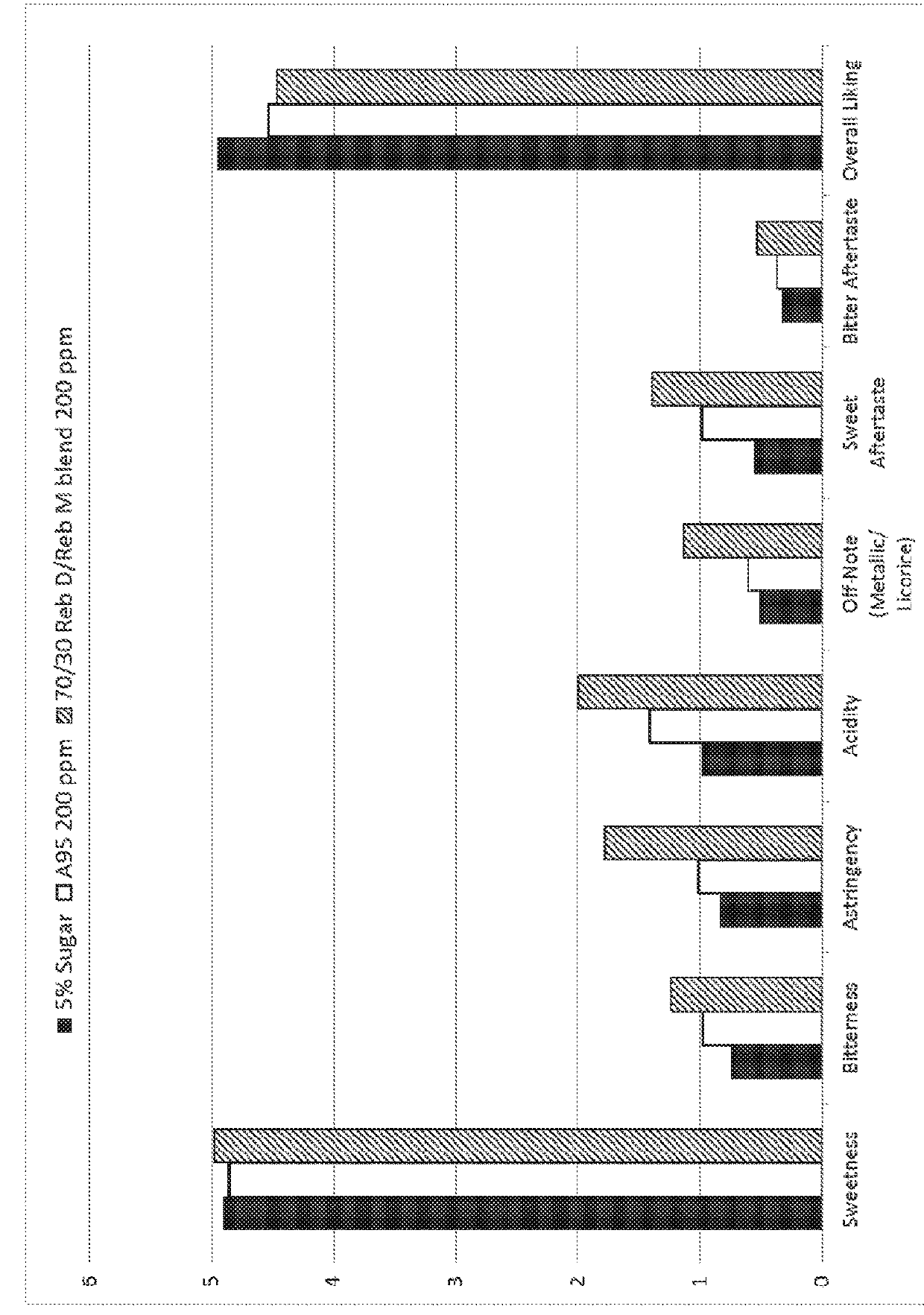

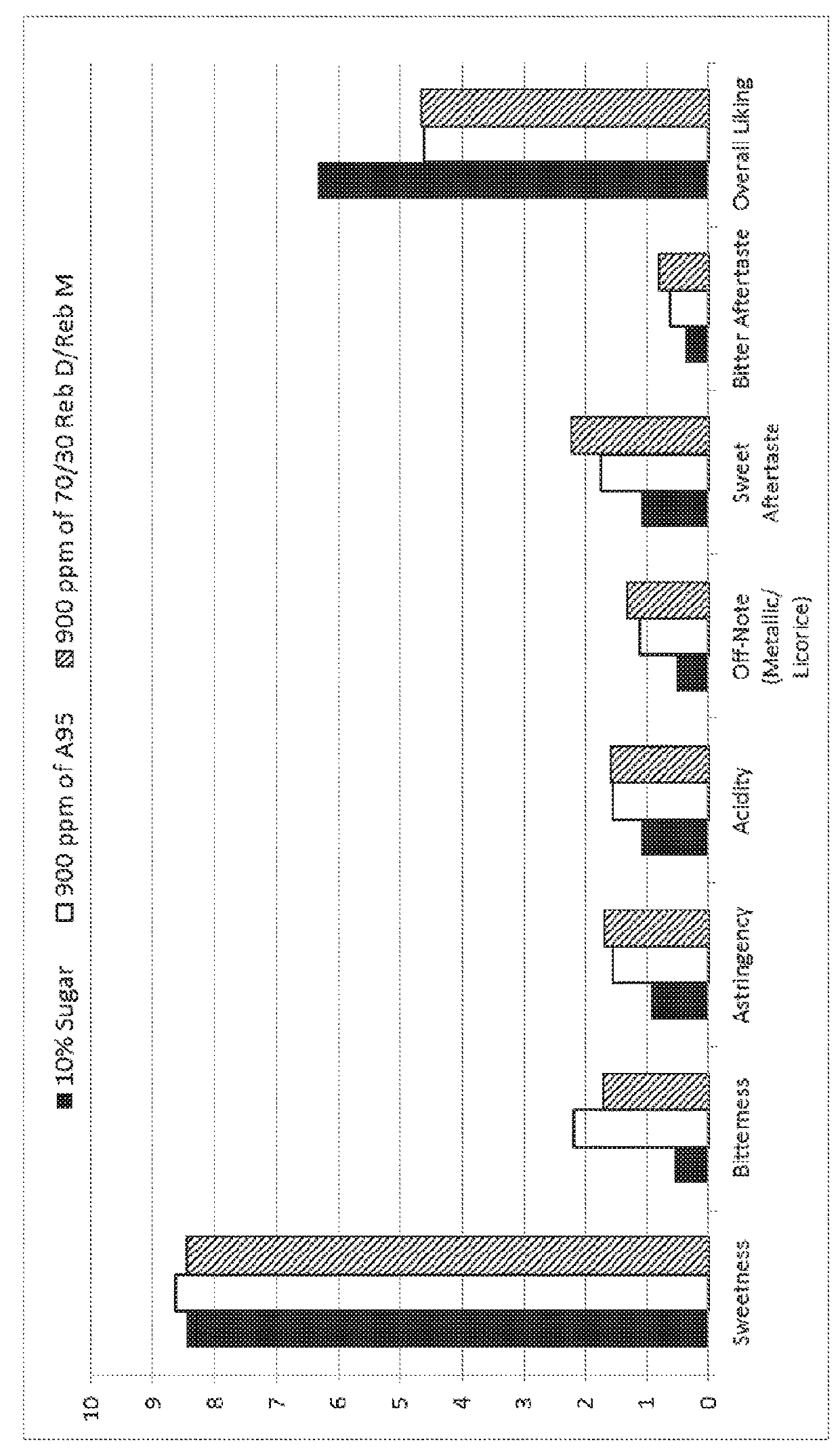

Steviol Glycoside Sweeteners with Improved Flavor Profiles

InactiveUS20180263269A1Improve sensory propertiesImprove the level ofDough treatmentSugar productsRebaudioside DFood flavor

Steviol glycoside compositions comprising certain proportions of rebaudioside D, rebaudioside M, rebaudioside A, rebaudioside N, rebaudioside O, and rebaudioside E are provided. Sweetener compositions comprising the steviol glycoside compositions and additional substances are also provided. Consumables, particularly beverages and beverage products containing said steviol glycoside compositions, and sweetener compositions comprising the same, are also provided. Methods of preparing the sweetener compositions and consumables are also detailed herein.

Owner:THE COCA-COLA CO +1

Compositions and Methods for Improving Rebaudioside M Solubility

InactiveUS20170172191A1Good water solubilityReduce the temperatureFood scienceSolubilityRebaudioside D

Owner:PURECIRCLE SDN BHD +1

Steviol Glycoside Blends, Compositions and Methods

PendingUS20180289051A1Superior to consumables sweetenedSugar food ingredientsFood ingredient functionsRebaudioside DSweetness

Ternary blends of rebaudioside B, rebaudioside D and rebaudioside M are provided. Quaternary blends of rebaudioside B, rebaudioside D, rebaudioside M and rebaudioside A are also provided. Sweetener compositions and consumables, particularly beverages and beverage products, comprising the ternary and quaternary blends are also provided. Methods of preparing consumables are also provided. The ternary and quaternary blends disclosed herein have improved sweetness profiles compared to certain blends of other steviol glycosides.

Owner:THE COCA-COLA CO

Methods for producing rebaudioside d and rebaudioside m and compositions thereof

The invention relates to methods for producing rebaudioside D and / or rebaudioside M, and compositions comprising the same. The invention provides a method for producing RD and / or RM compositions. The method comprises using rebaudioside A and / or stevioside as substrate and a recombinant microorganism or an enzyme produced by the recombinant microorganism or a metabolite of the recombinant microorganism to catalyze the reaction of the substrate in the presence of sucrose and trisodium citrate and produce a mixture of rebaudioside D and rebaudioside M, and then separates and purifies the mixture to obtain rebaudioside D or rebaudioside M.

Owner:SICHUAN INGIA BIOSYNTHETIC CO LTD

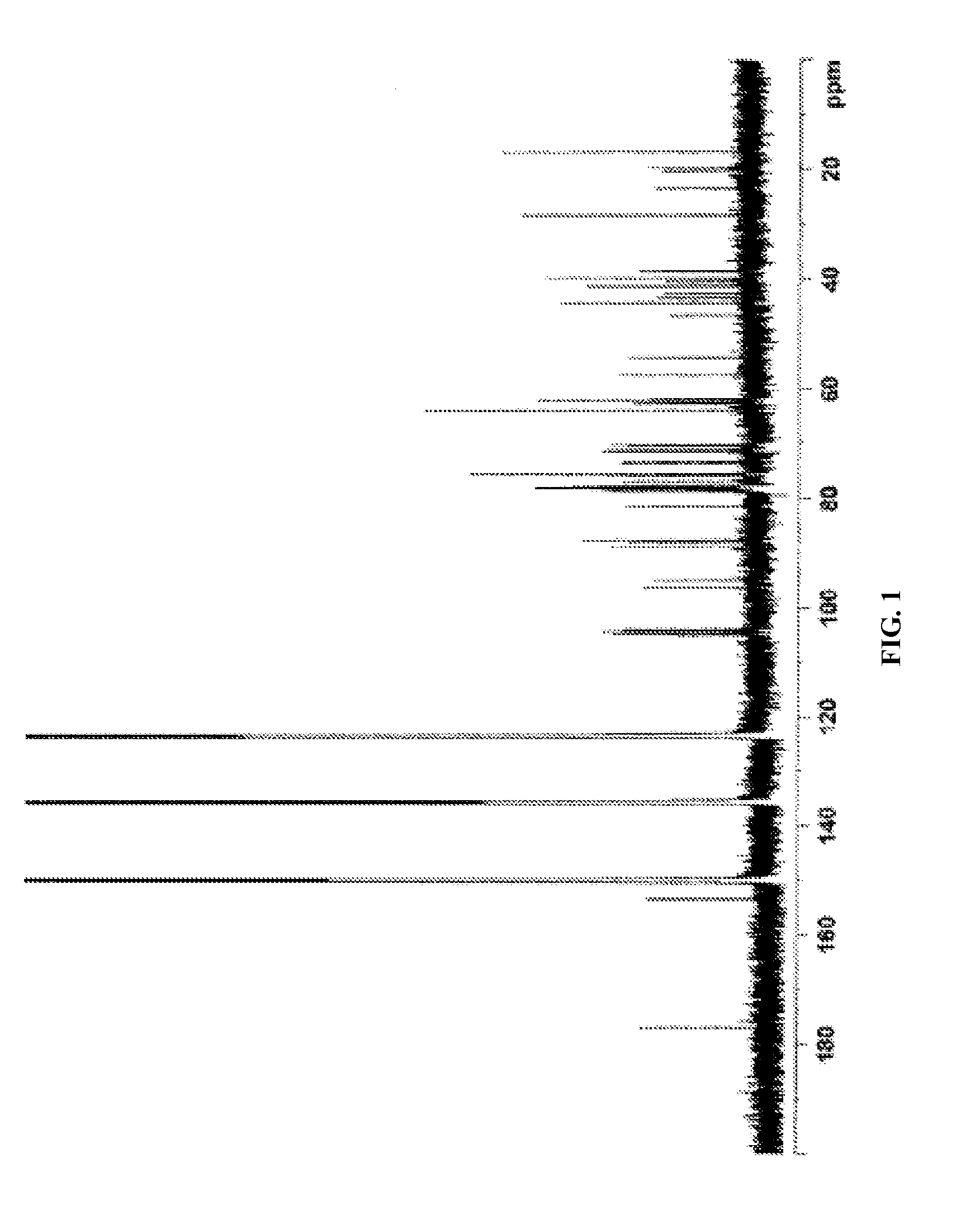

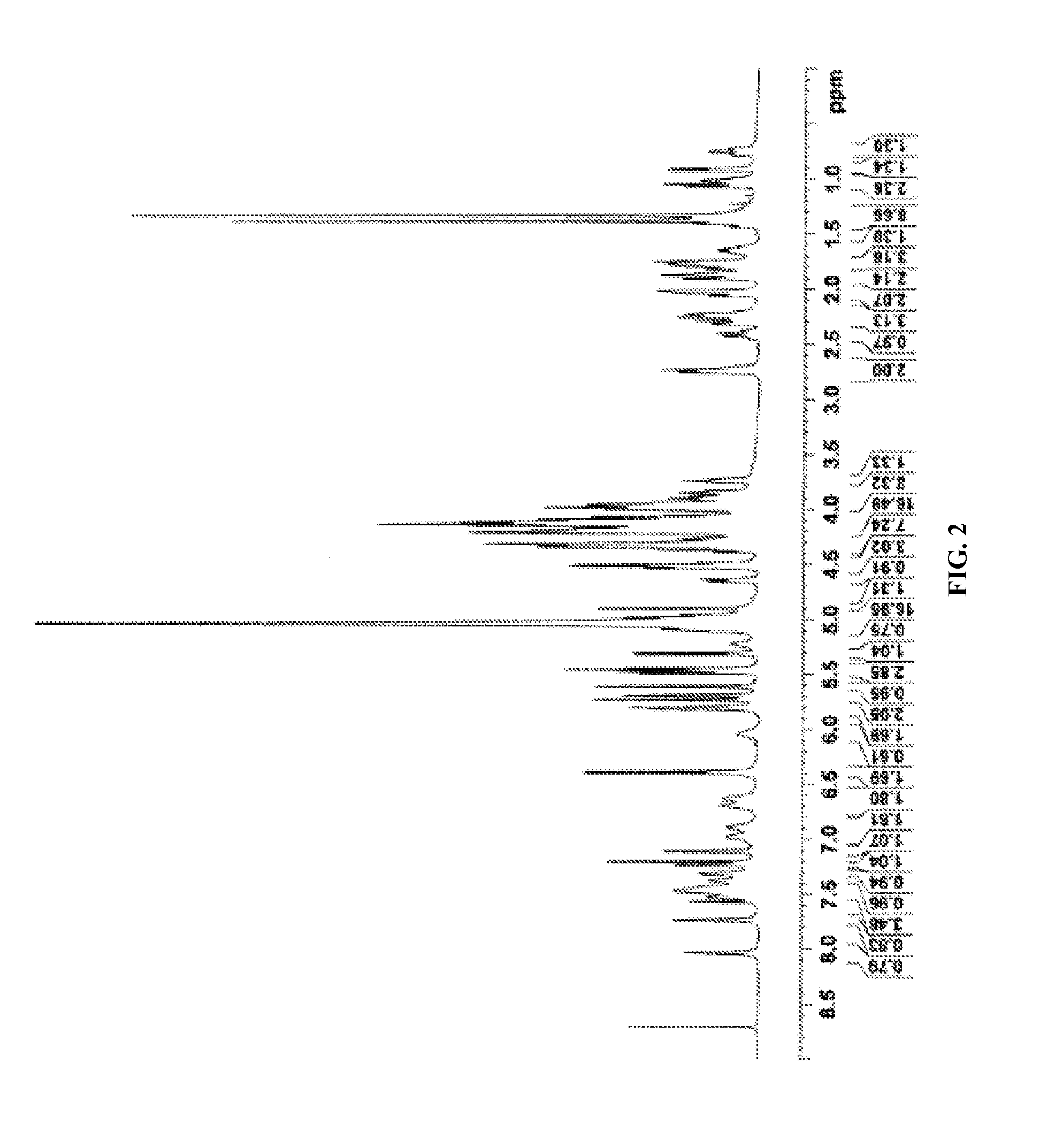

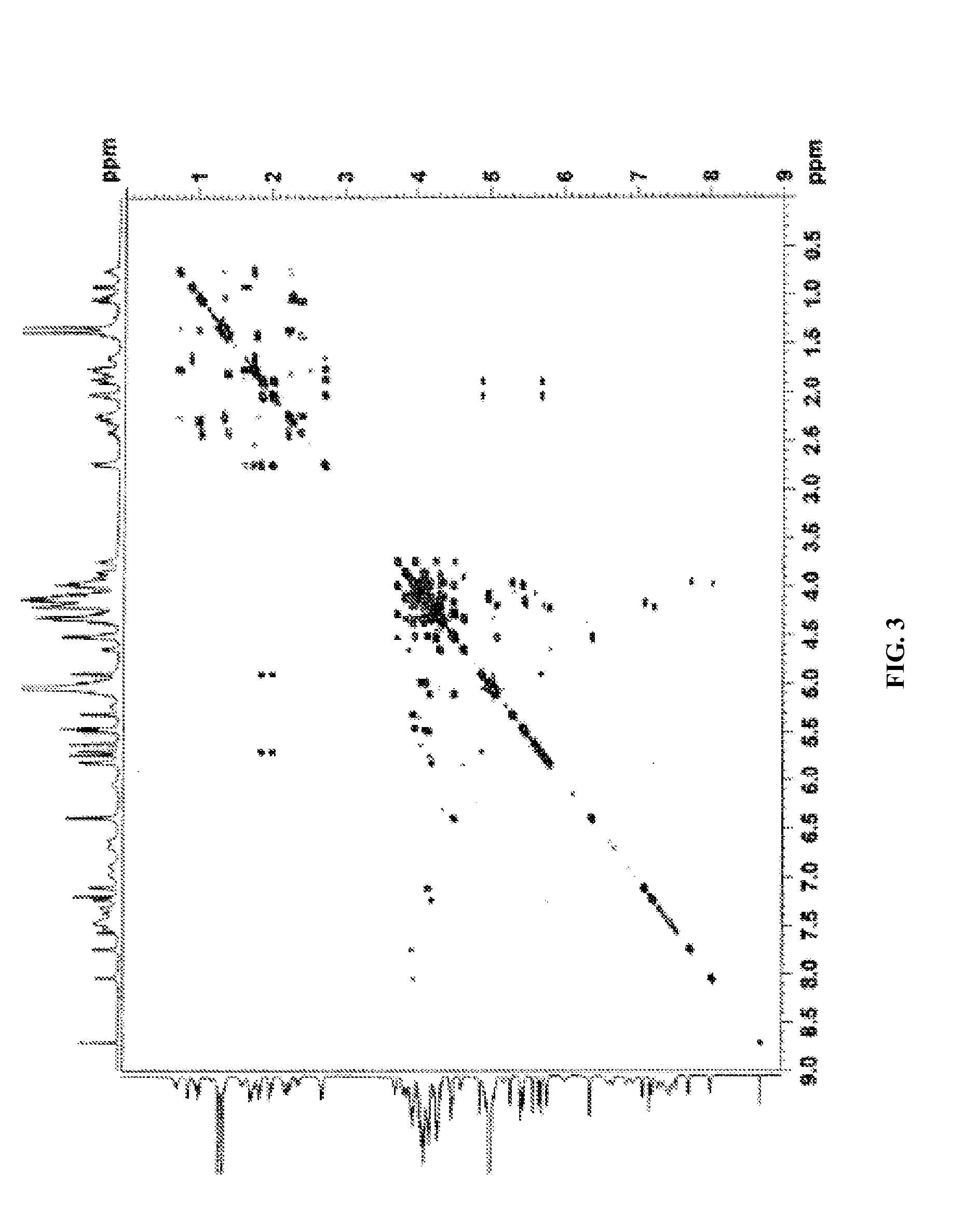

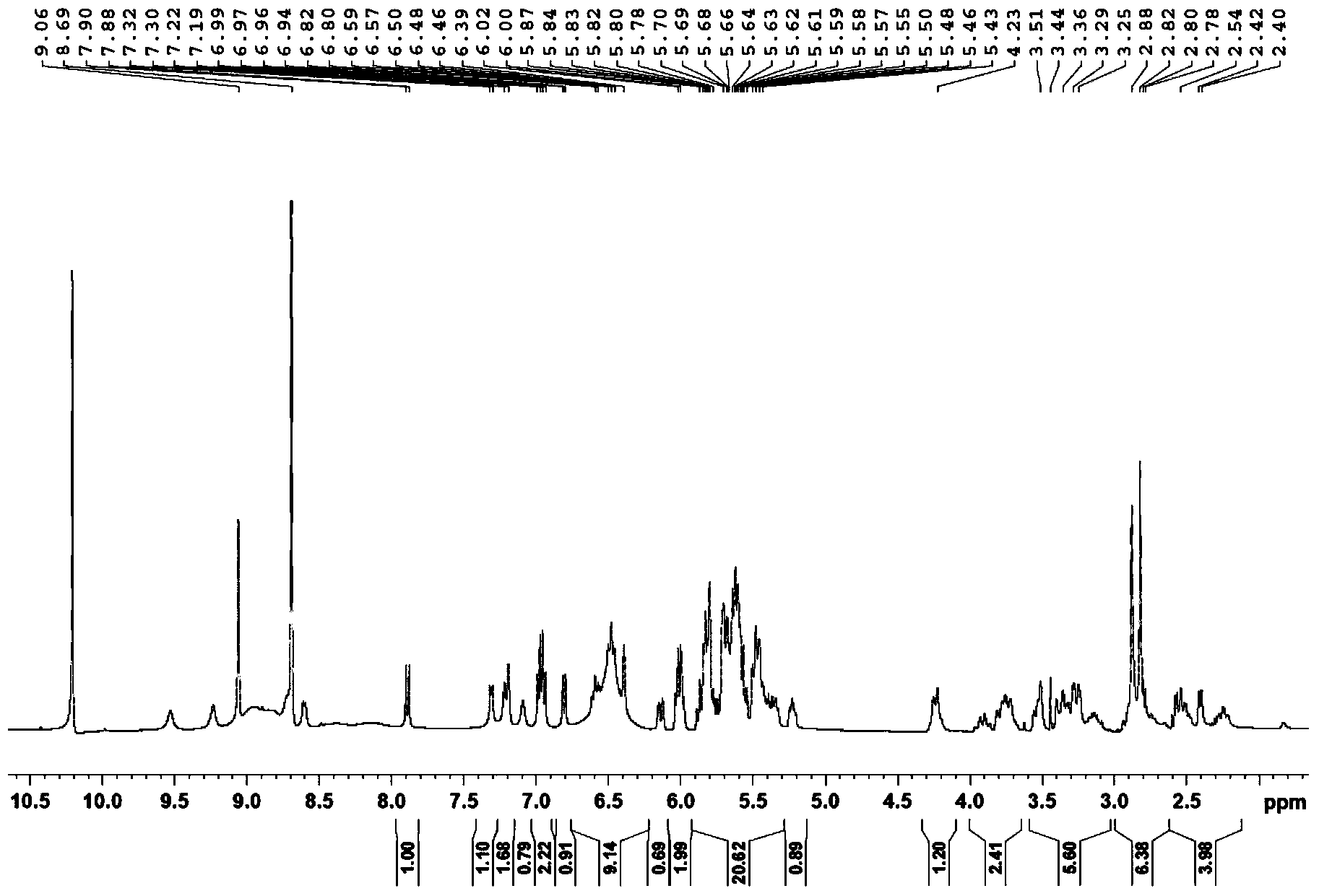

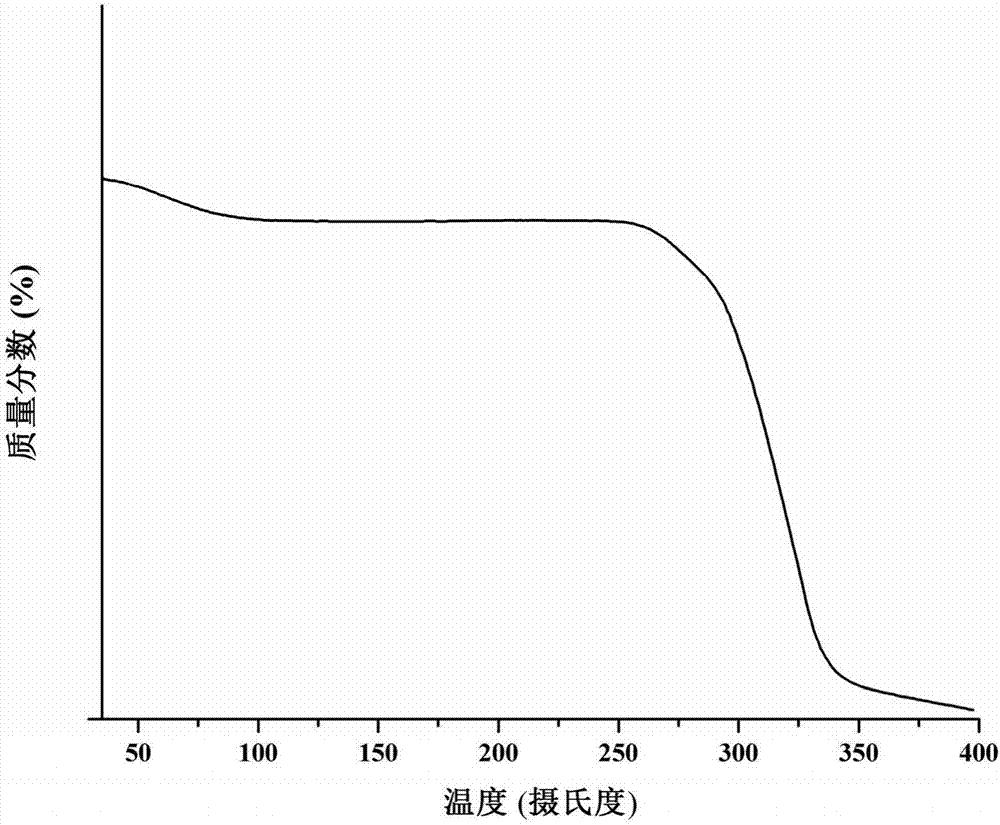

A rebaudioside M crystal form, and a preparing method and uses thereof

The invention relates to a rebaudioside M crystal form, and a preparing method and uses thereof, and particularly relates to a rebaudioside M crystal form A that is extracted from natural compounds and which is a high-power sweetener, and a preparing method and applications thereof. Through comprehensive representation of the novel crystal form, the novel crystal form shows advantages of a high degree of crystallization, good stability, low hygroscopicity, and the like, and is suitable for wider application fields. The method is simple, easy to operate, good in selectivity, good in reappearance and capable of preparing the target crystal form stably.

Owner:ZHUCHENG HAOTIAN PHARMA

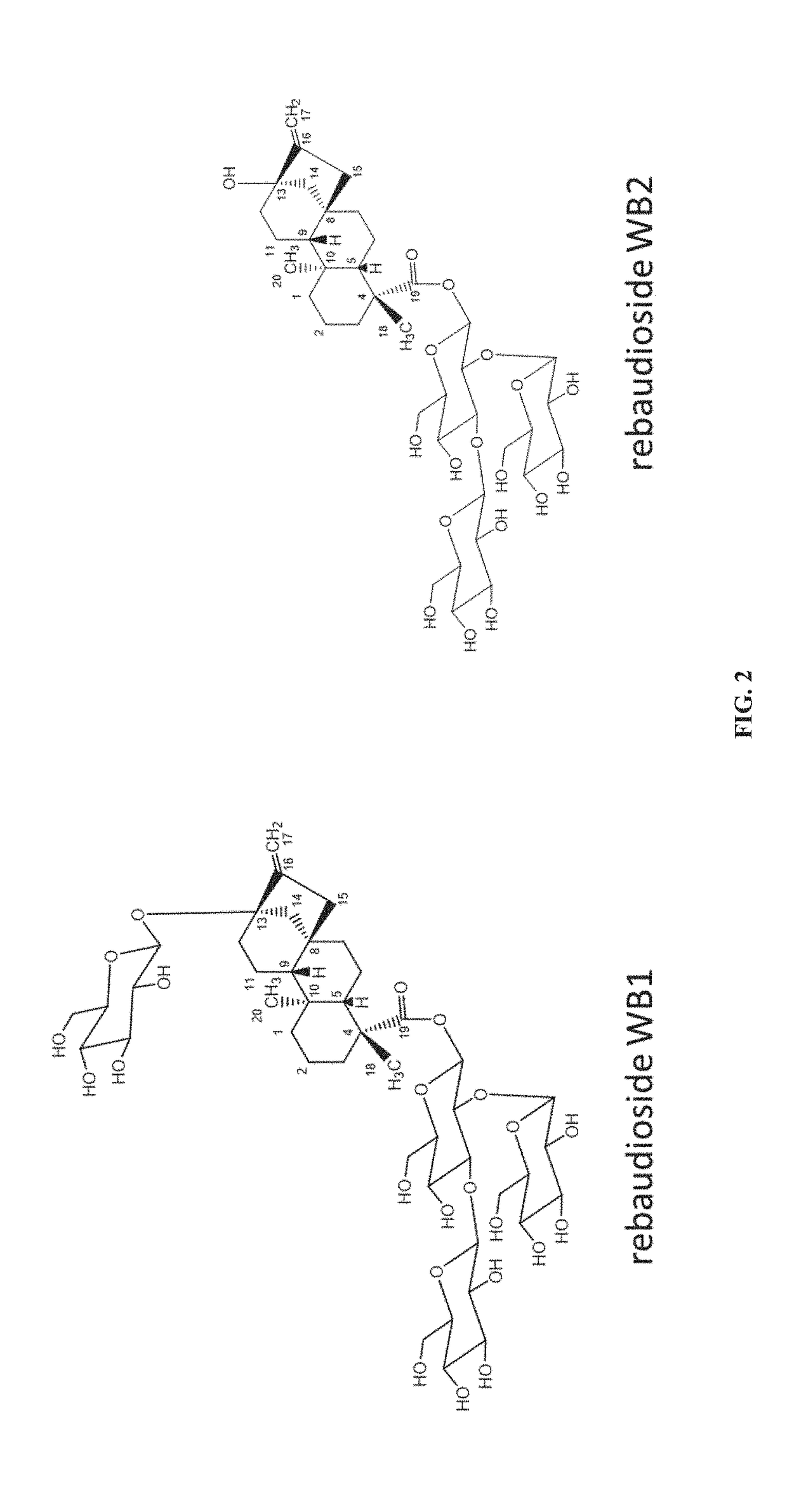

Biosynthetic production of steviol glycosides and processes therefore

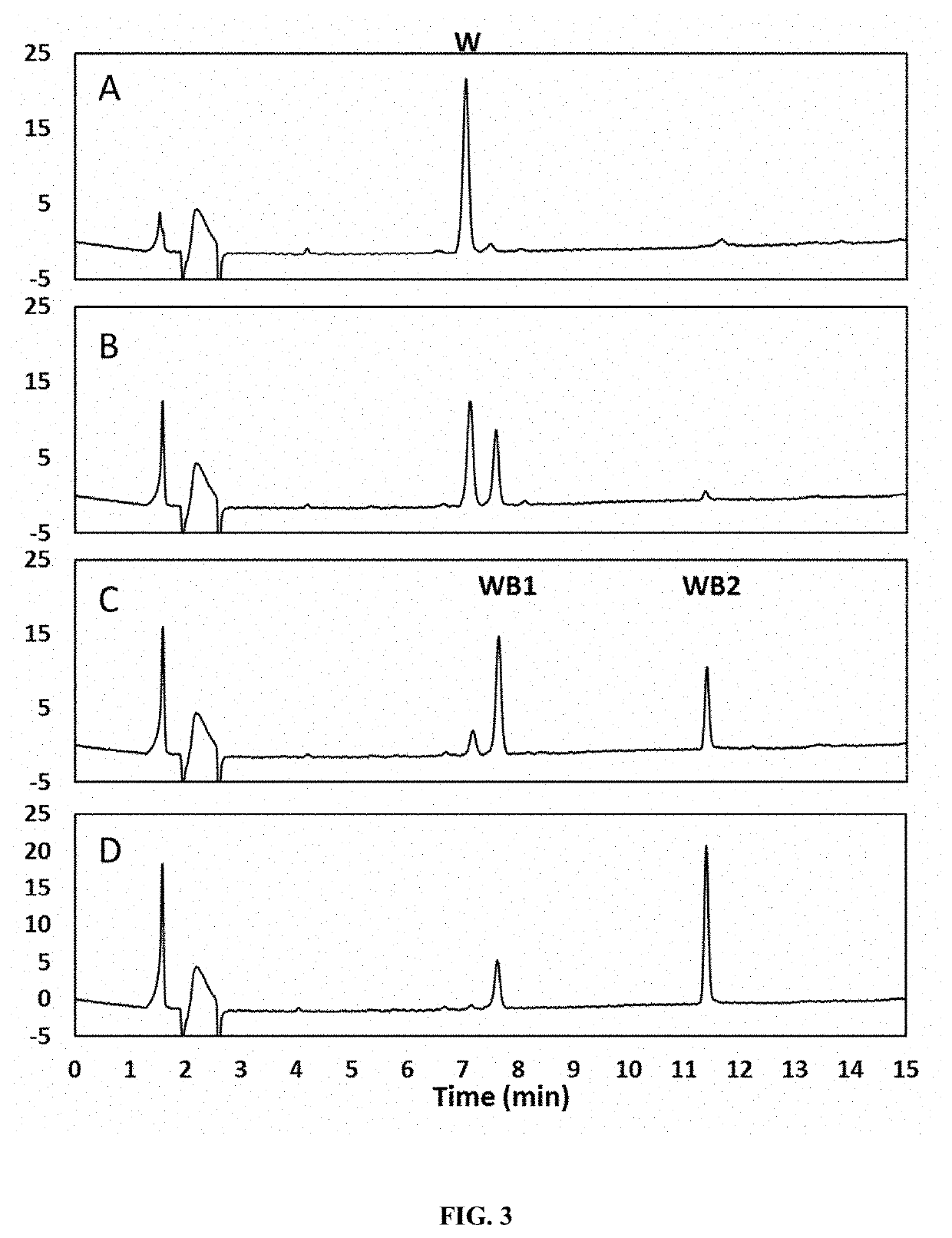

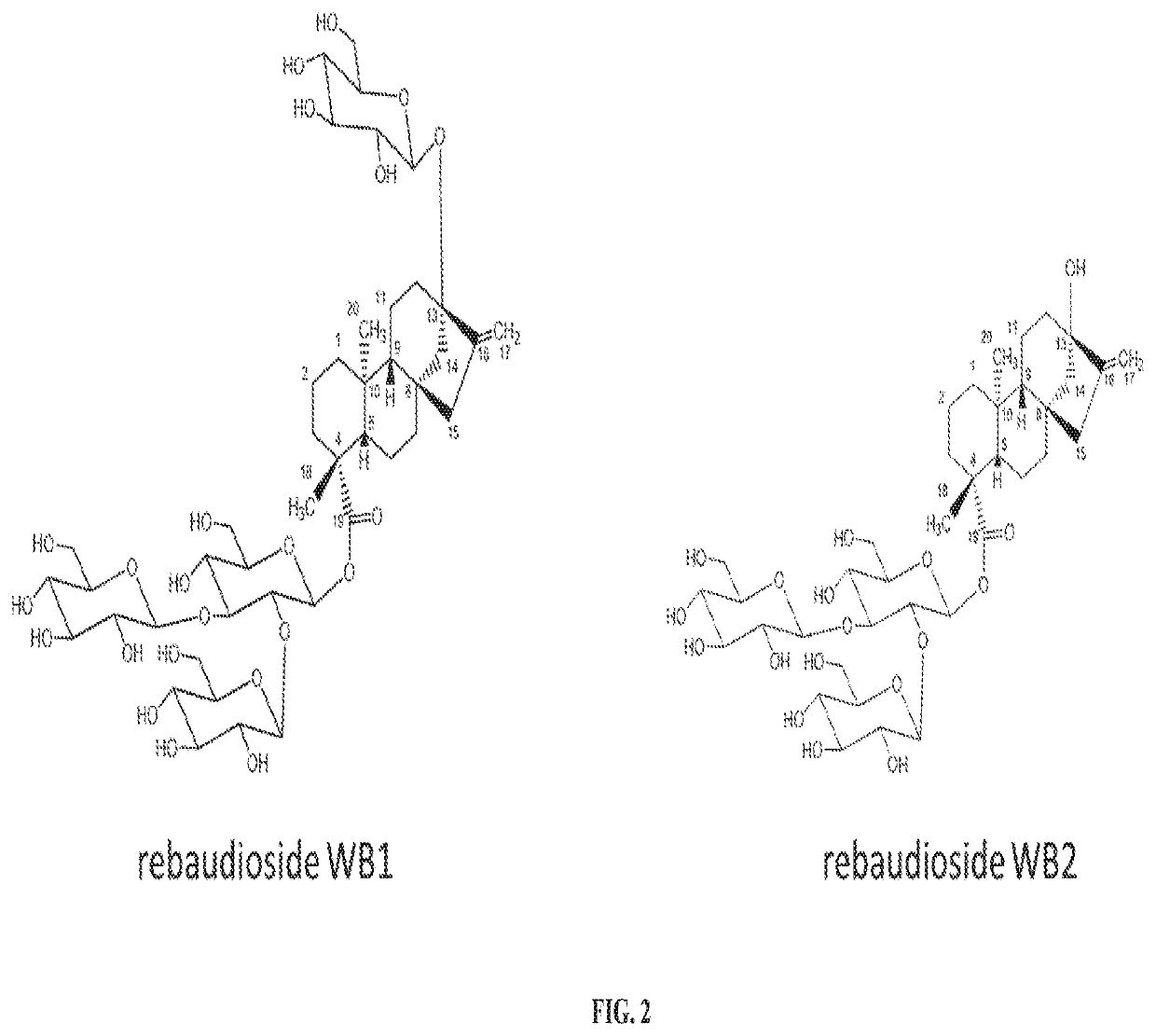

The present invention relates to the production of steviol glycoside rebaudiosides D4, WB1 and WB2 and the production of rebaudioside M from Reb D4.

Owner:CONAGEN INC

Stevia-containing beverage

ActiveUS20190183148A1Improve continuityTea extractionFood ingredient as taste affecting agentRebaudioside DMethods of production

Beverages having an improvement in continuity of aftertaste caused by Rebaudioside D (RebD) and Rebaudioside M (RebM) and methods of production thereof. A content (A) of catechin compound(s) in beverages is adjusted to within a certain range, a total content (B) of RebM and / or RebD in beverages is adjusted to within a certain range, and B / A is adjusted to within a certain range.

Owner:SUNTORY HLDG LTD

Compositions

PendingUS20200345049A1High sweetnessWeakens astringent tasteMilk preparationFood scienceSteviolmonosideSweetness

A composition includes (i) rebaudioside M, (ii) a glucosylated steviol glycoside and (iii) an effective amount of a taste modifier. A sweetened composition includes the composition and at least one other sweetener, and a sweetened consumable containing the composition or the sweetened composition. Methods of making the composition, sweetened compositions and sweetened consumables are also provided. Methods of using the compositions to reduce the amount of sugar present in a sweetened consumable, to enhance the sweetness of sweetened compositions and sweetened consumables, and / or to modify a characteristic of a sweetened consumable is further provided.

Owner:GIVAUDAN SA

High-purity steviol glycosides

Owner:PURECIRCLE USA

Biosynthetic production of steviol glycosides and processes therefore

The present invention relates to the production of steviol glycoside rebaudiosides D4, WB1 and WB2 and the production of rebaudioside M from Reb D4.

Owner:CONAGEN INC

Biosynthesis production of steviol glycosides and processes therefore

The present invention relates to the production of steviol glycoside rebaudiosides D4, WB1 and WB2 and the production of rebaudioside M from Reb D4.

Owner:CONAGEN INC

Sweetness and Taste Improvement of Steviol Glycoside or Mogroside Sweeteners

ActiveUS20190142043A1Eliminate bitternessEnhance the sucrose equivalence (SE)Organic chemistryFood ingredient as flavour affecting agentSucroseSaccharum

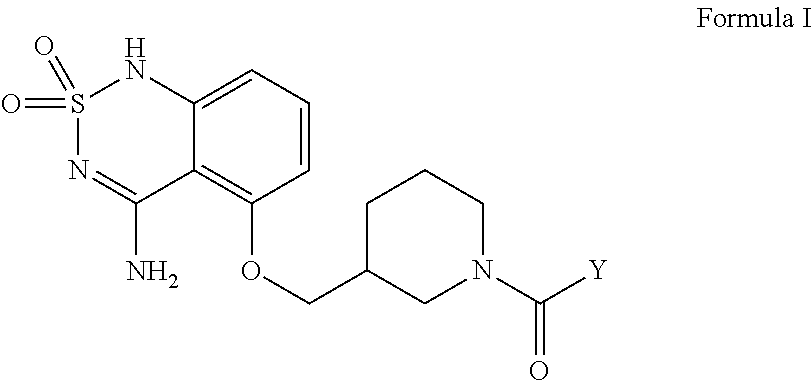

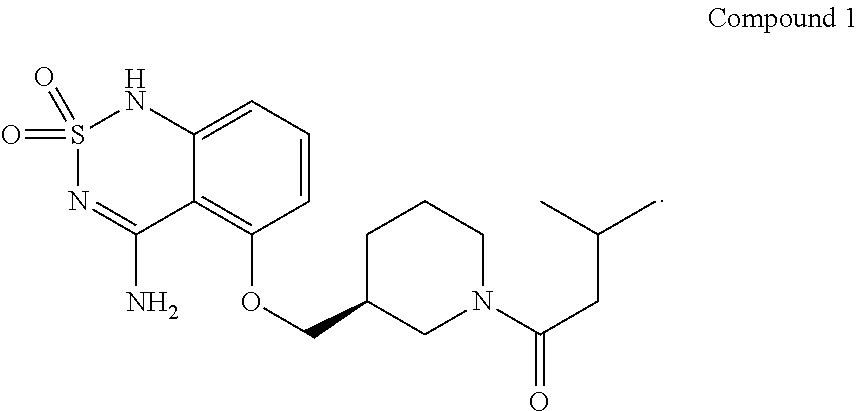

Consumables comprising a sweetener and at least one compound of the formulae described are provided herein, wherein the sweetener comprises a sweetening amount of rebaudioside M and / or a sweetening amount of at least one mogroside. The at least one compound of the formulae described herein enhances the sweetness of the consumable and / or modulates one or more taste attributes to make the consumable taste more like a sucrose-sweetened consumable. Methods of enhancing the sweetness of a consumable, methods of making a consumable taste more like a sucrose-sweetened consumable and methods of preparing consumables are also detailed herein.

Owner:THE COCA-COLA CO

Methods of preparing steviol glycosides and uses of the same

Owner:PURECIRCLE USA

Fermentation methods for producing steviol glycosides with multi-phase feeding

Disclosed are methods for producing steviol glycosides, such as rebaudioside D and rebaudioside M, using engineered yeast. The methods include at least two phases: first and second phases where a glucose-containing feed composition is provided to the medium in different modes of feeding in each phase, such as variable feeding and then constant feeding. The two phase feeding can result in a growthrate that is slower in the second phase than in the first phase, and consequently increased steviol glycoside production rates, reduced fermentation times, and reduced biomass concentrations.

Owner:CARGILL INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com