Biocatalytic method for synthesis of rebaudioside M

A technology of biocatalysis and catalytic reaction, applied in the field of bioengineering, can solve the problems of low economic efficiency of rebaudioside M

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

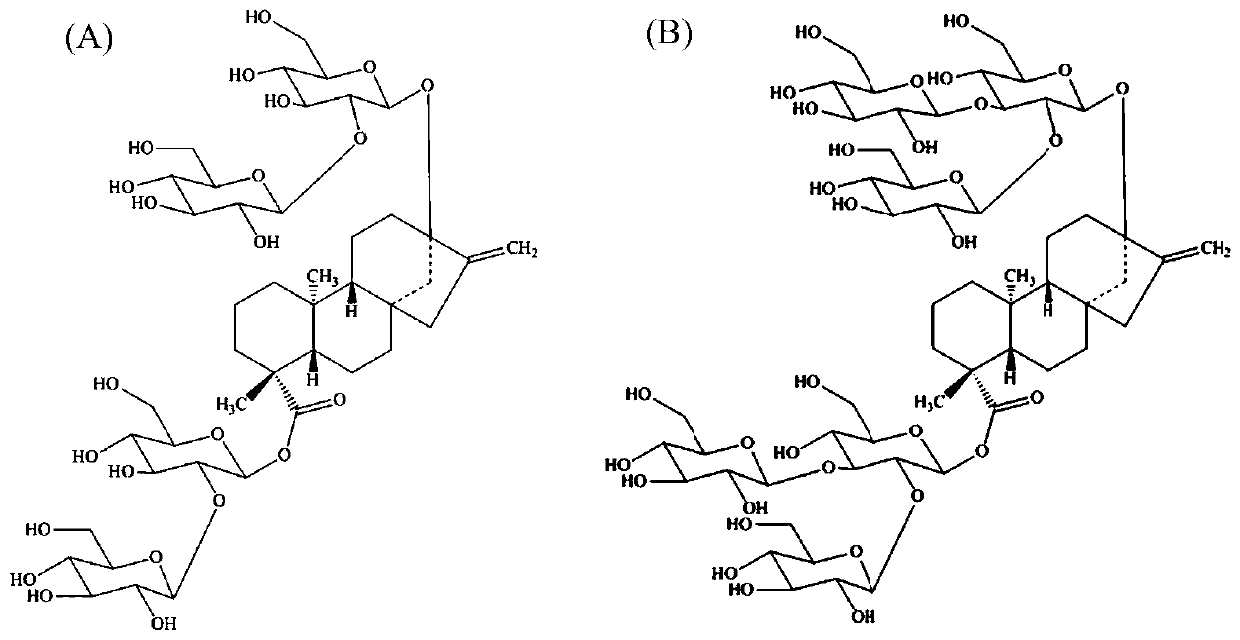

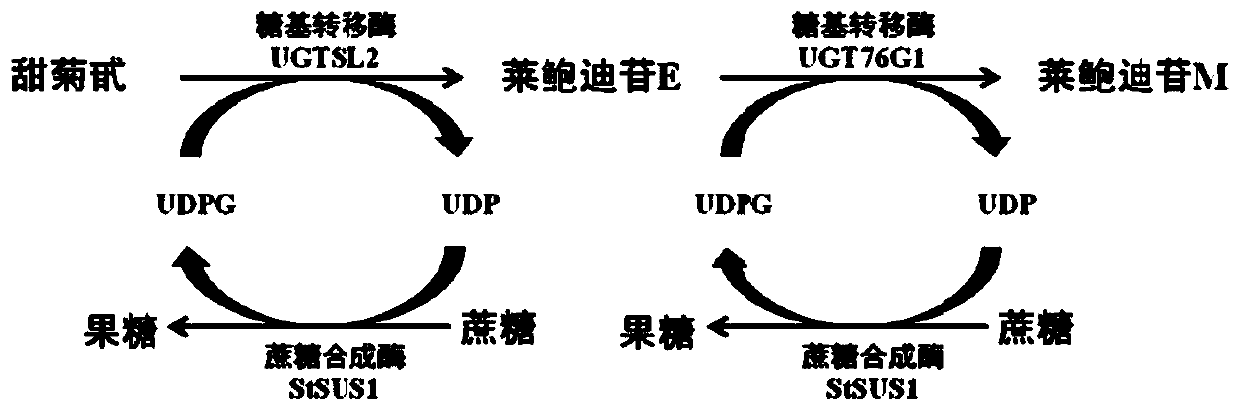

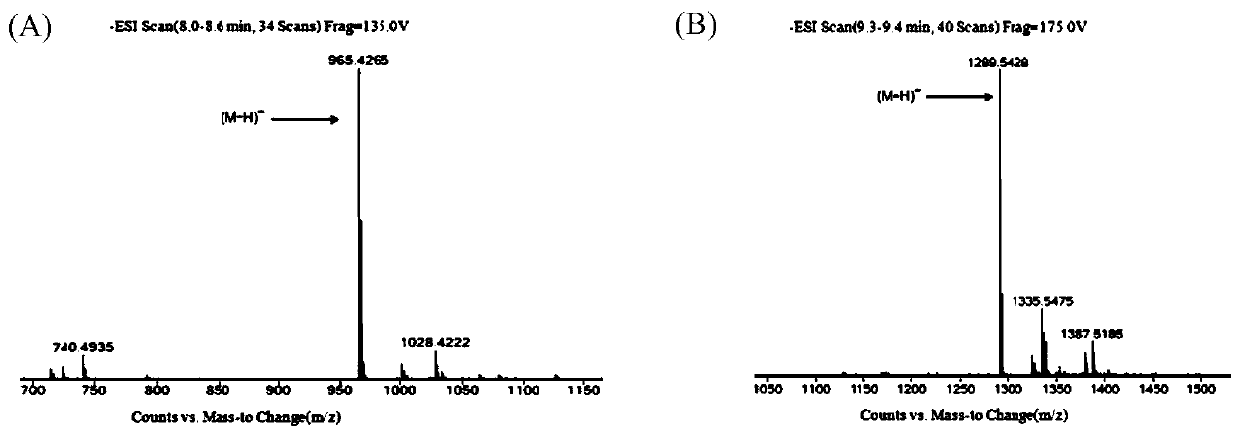

Image

Examples

Embodiment 1

[0032] Embodiment 1: the construction of recombinant escherichia coli genetically engineered bacteria

[0033] 1) Obtaining recombinant Escherichia coli genetically engineered bacteria co-expressing UGTSL2 and StSUS1

[0034] The full sequence of UGTSL2 and StSUS1 genes was synthesized by Nanjing GenScript Company and constructed on the plasmid pRSFDuet-1, wherein the UGTSL2 gene fragment was inserted into the plasmid vector RSFDuet-1 (Novagen Company) Nde I and xho Between the I restriction sites, the StSUS1 gene fragment was inserted into the plasmid vector pRSFDuet-1 (Novagen) Nco I and Eco Between the R I restriction sites, a recombinant plasmid, pRSFDuet-UGTSL2-StSUS1, which can exogenously co-express glycosyltransferase UGTSL2 and sucrose synthase StSUS1 was provided.

[0035] Add 40 uL ddH 2 O into the recombinant plasmid pRSFDuet-UGTSL2-StSUS1 dry powder, fully dissolved, take 5 ul of heat shock and transform into E. coli BL21 (DE3) competent cells, and the ...

Embodiment 2

[0039] Embodiment 2: the co-expression of genetically engineered bacteria double enzyme

[0040] Inoculate recombinant genetically engineered bacteria containing plasmid pRSFDuet-UGTSL2-StSUS1 (or pRSFDuet-UGT76G1-StSUS1) into LB medium containing 50 mg / L kanamycin resistance (0.5 g / L yeast powder, 1 g / L Sodium chloride, 1 g / L tryptone), shake overnight at 37°C and 200 rpm, then transfer the cultured bacteria into 100 mL of TB medium (2.5 g / L yeast powder, 1 g / L sodium chloride, 1.5 g / L tryptone, 0.2 g / L glucose, 0.05 g / L lactose) in a 500 mL shake flask, at 200 rpm, 37°C for 2 h, then transferred to 25°C for 24 h, Bacteria were collected by centrifugation. The cells were disrupted by ultrasonication, and the supernatant obtained by centrifugation was the crude cell extract, which was stored at 4°C until use.

Embodiment 3

[0041] Example 3: Synthesis of rebaudioside E from stevioside by enzymatic method

[0042] 1) Catalytic reaction system

[0043] Add 20 g / L stevioside, 60 g / L sucrose, 3 mM Mg 2+ And an appropriate amount of crude cell extract (~6 mg / mL total protein) co-expressing UGTSL2 and StSUS1 in 50 mM potassium phosphate buffer (pH 7.2), the total volume was quantified to 20 mL. React at 30°C and 200 rpm for 24 h, sample 500 uL at regular intervals, heat in a water bath at 95°C for 15 min, centrifuge at room temperature at 12,000 rpm for 1 min, separate the supernatant into a new 1.5 mL EP tube, store at 4°C, and wait for HPCL detection. According to the results (Table 1), it is feasible to catalyze the synthesis of rebaudioside E from stevioside by glycosyltransferase UGTSL2 coupled with sucrose synthase StSUS1, and the conversion rate of stevioside reached 94.12% after 24 hours of reaction. The yield of rebaudioside E was 66.32%.

[0044] 2), PHLC detection method

[0045] Chromat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com