Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

108results about How to "Reliably removed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

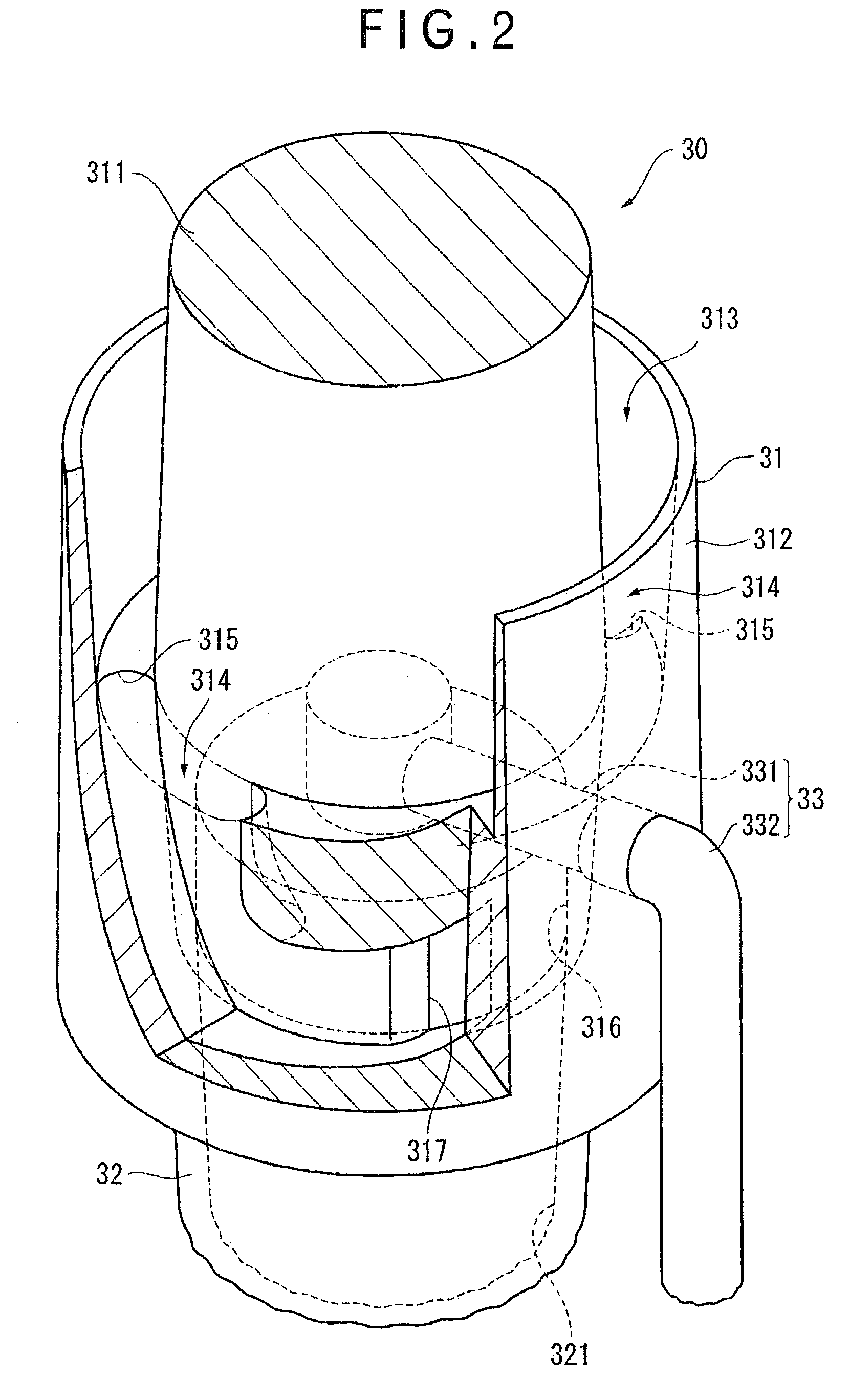

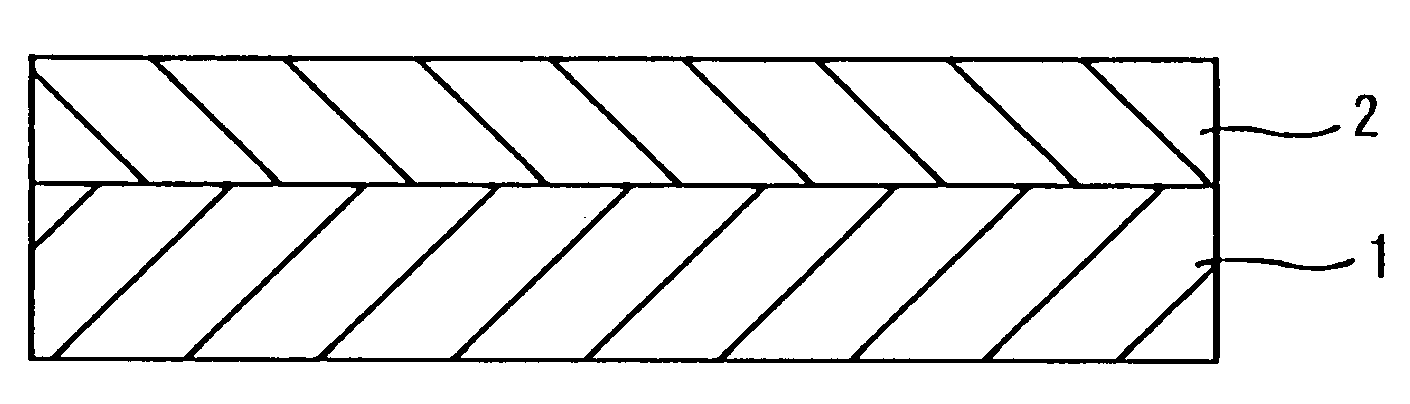

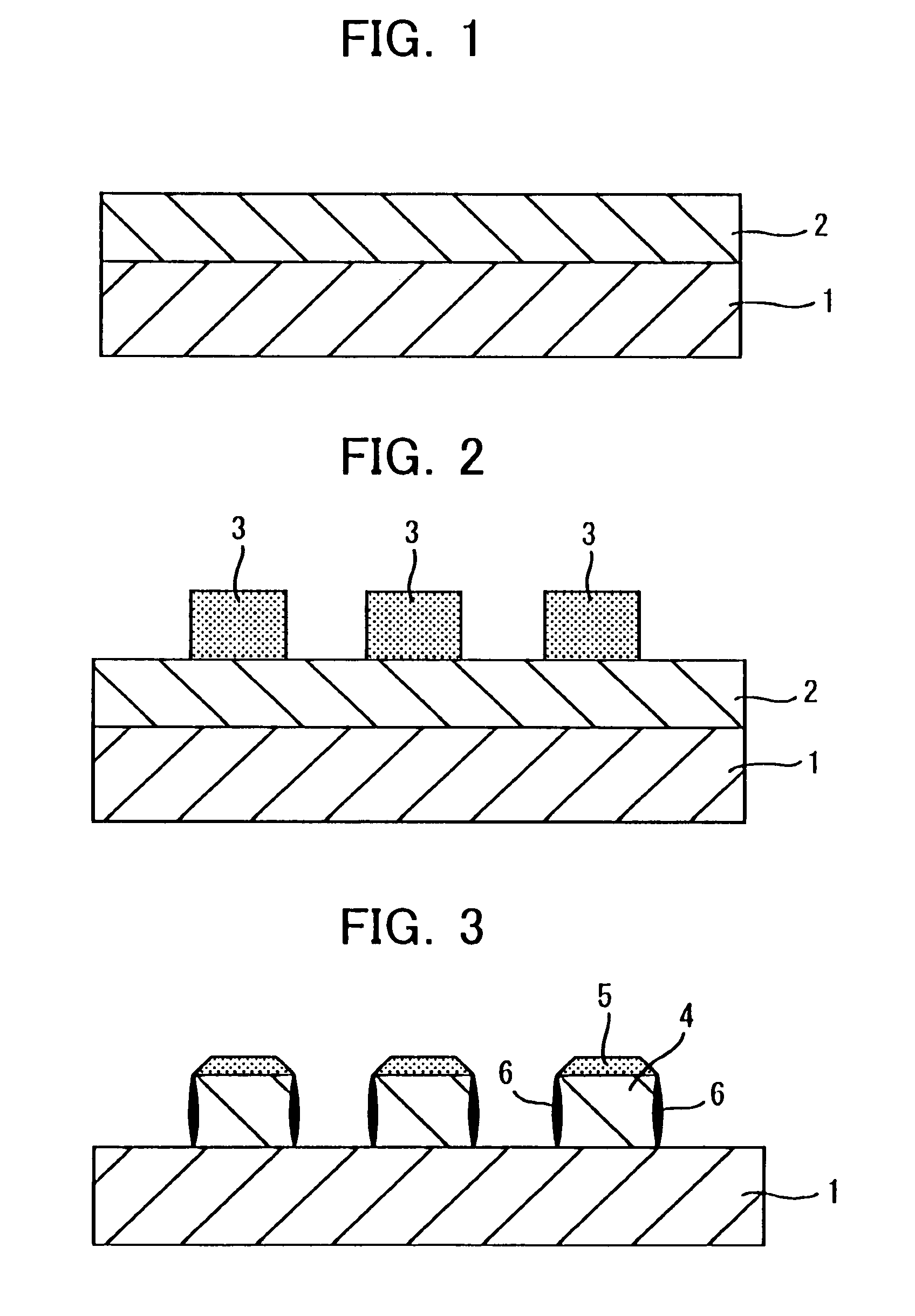

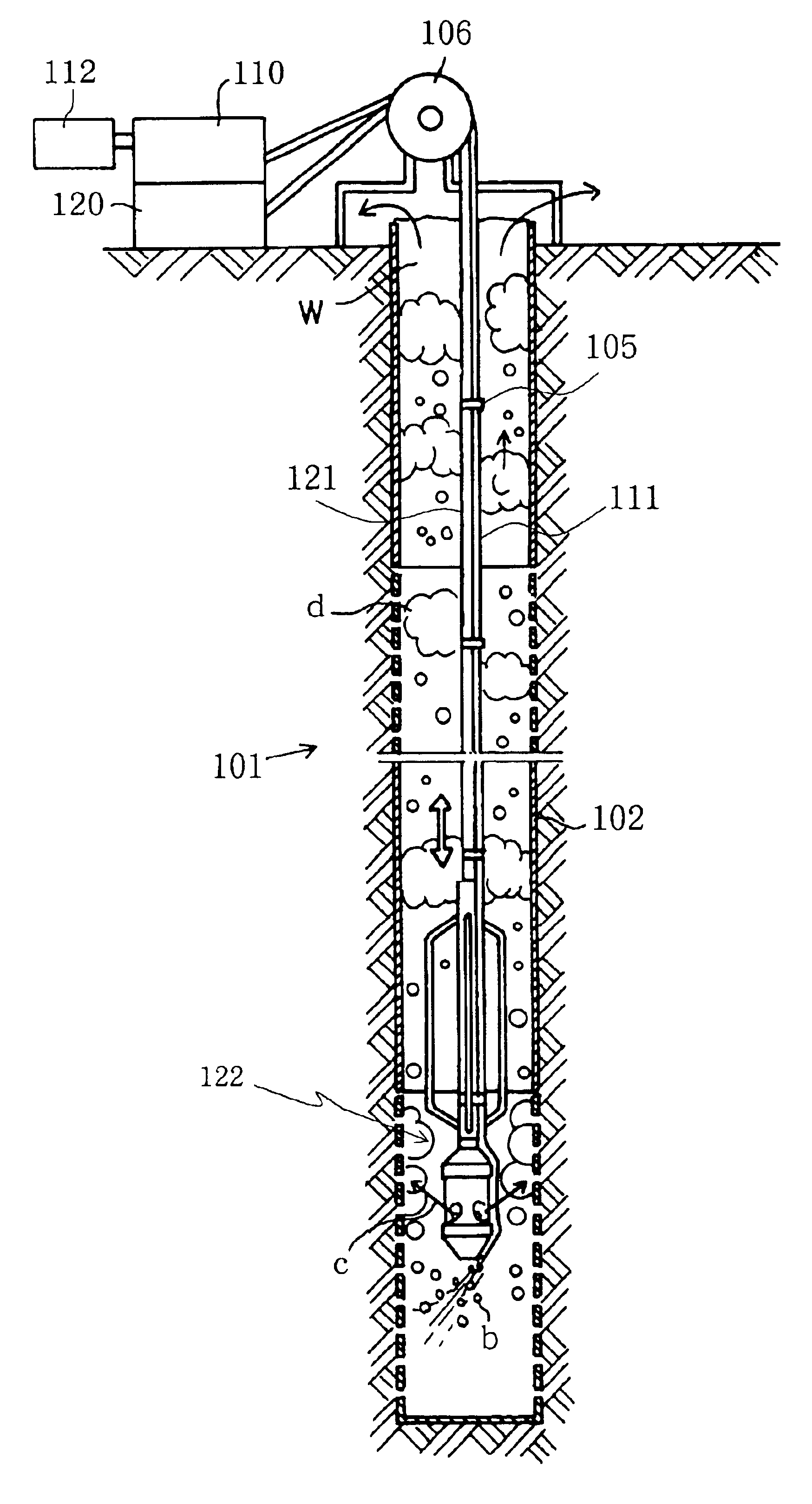

Method of fabricating an SOI wafer and SOI wafer fabricated thereby

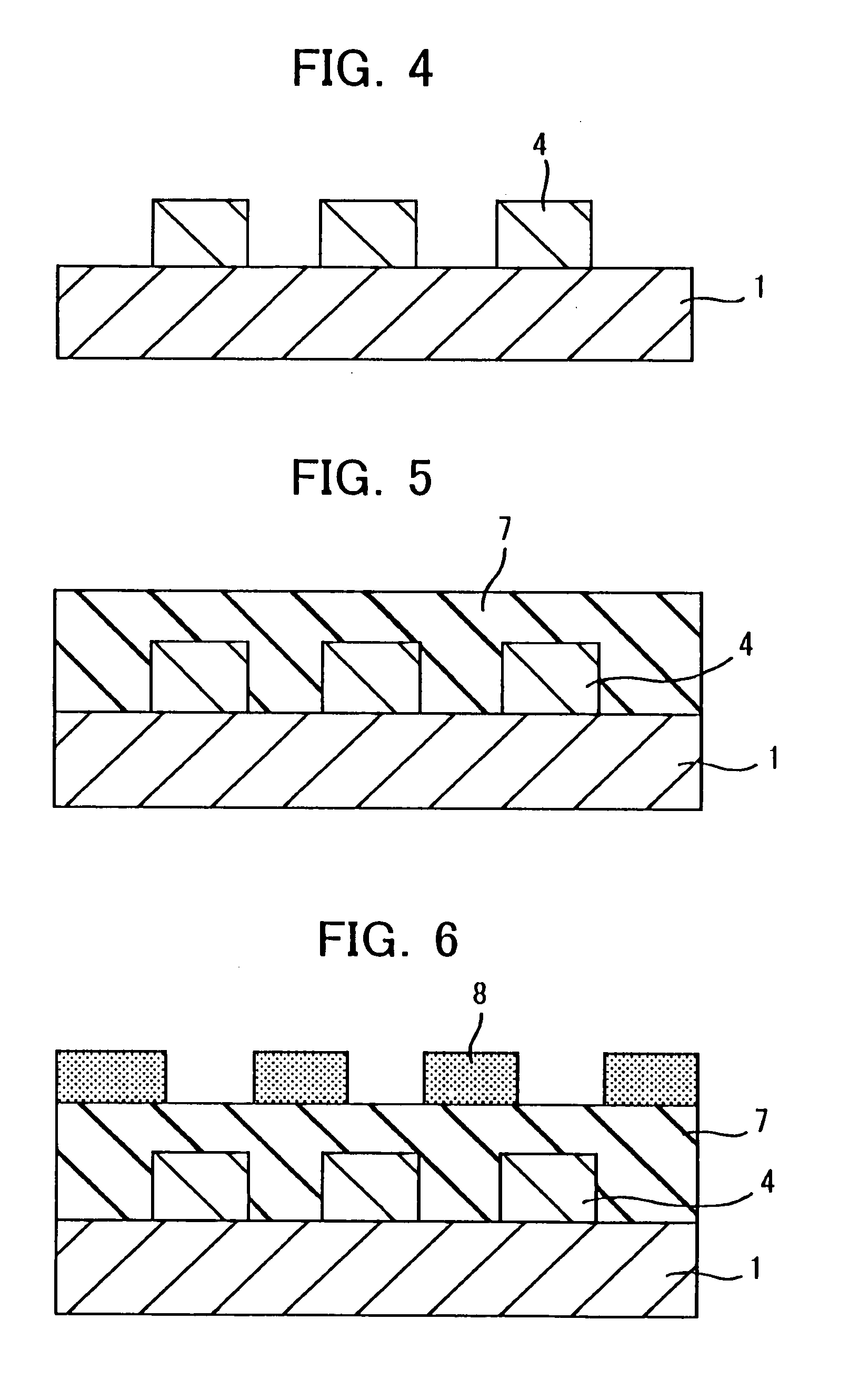

InactiveUS6140210AReliably removedUniform thicknessSolid-state devicesSemiconductor/solid-state device manufacturingNoble gasEtching

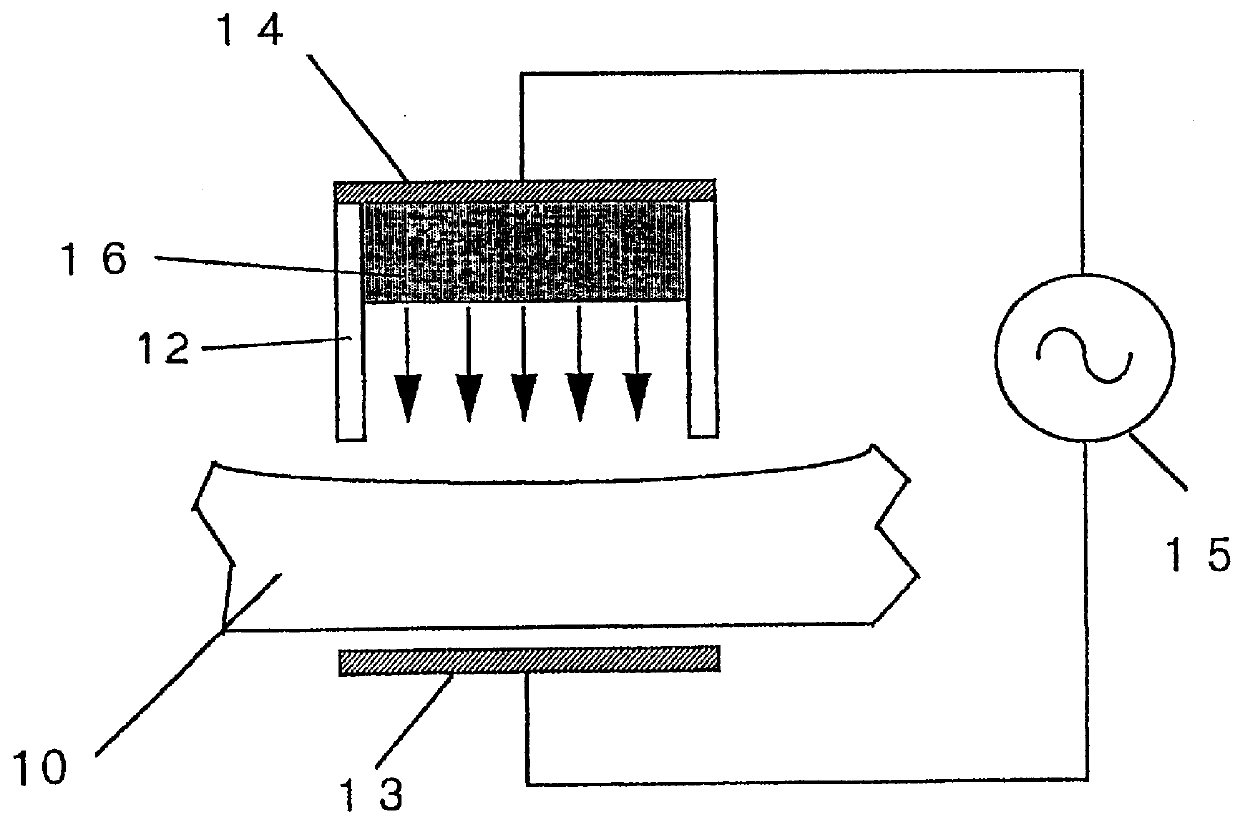

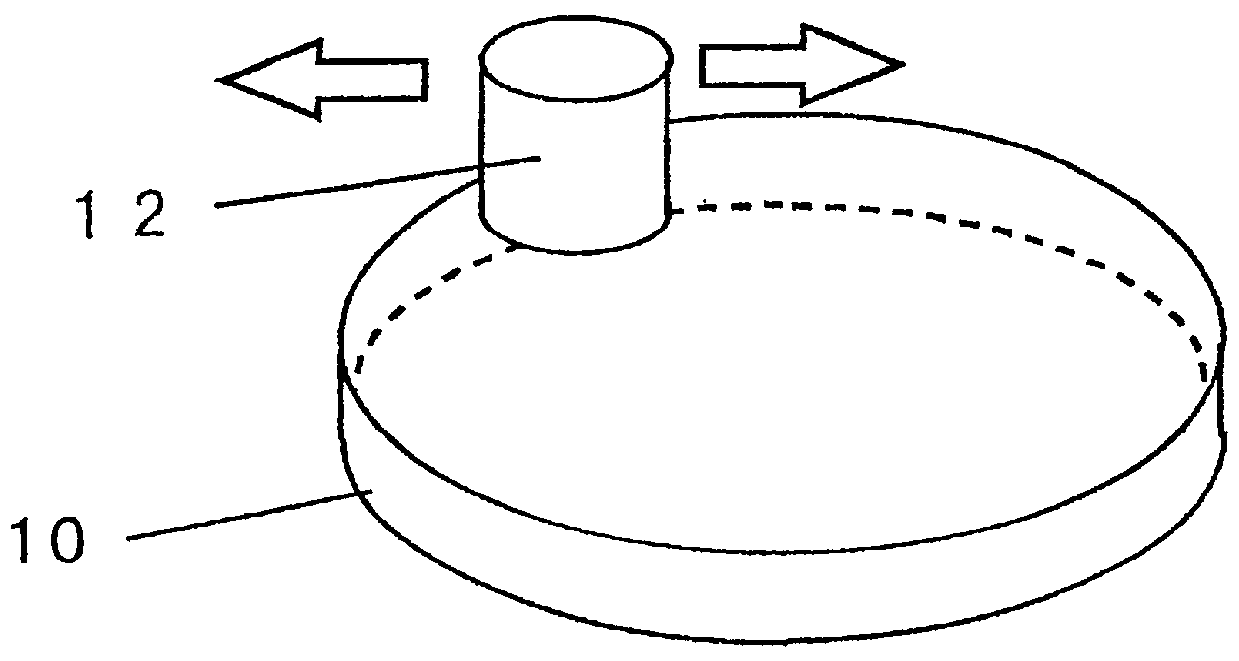

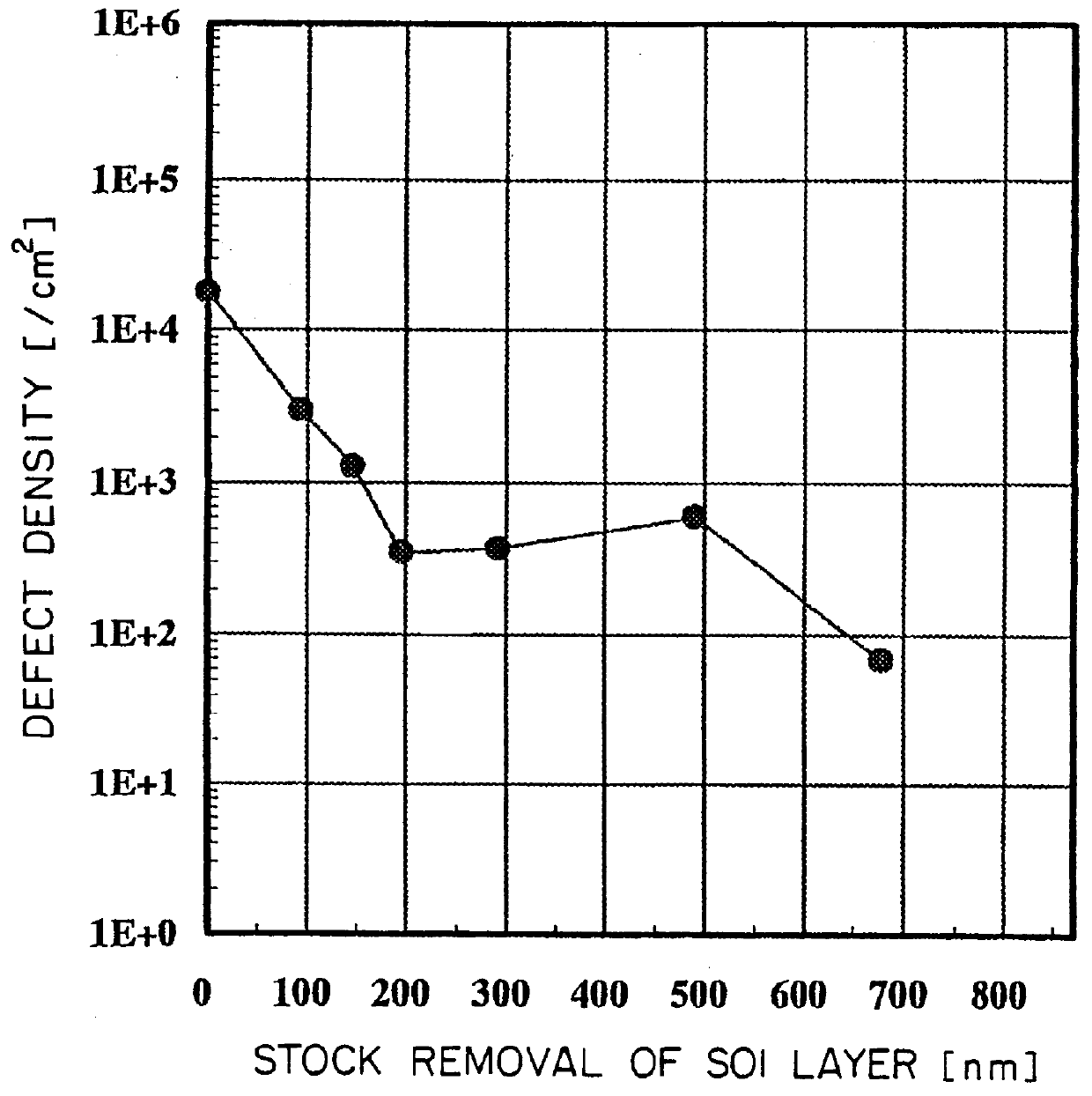

In a method of fabricating an SOI wafer, an oxide film is formed on the surface of at least one of two silicon wafers; hydrogen ions or rare gas ions are implanted into the upper surface of one of the two silicon wafers in order to form a fine bubble layer (enclosed layer) within the wafer; the ion-implanted silicon wafer is superposed on the other silicon wafer such that the ion-implanted surface comes into close contact with the surface of the other silicon wafer via the oxide film; heat treatment is performed in order to delaminate a portion of the ion-implanted wafer while the fine bubble layer is used as a delaminating plane, in order to form a thin film to thereby obtain an SOI wafer. In the method, a defect layer at the delaminated surface of the thus-obtained SOI wafer is removed to a depth of 200 nm or more through vapor-phase etching, and then mirror polishing is performed. Therefore, the obtained SOI wafer has an extremely low level of defects and a high thickness uniformity.

Owner:SHIN-ETSU HANDOTAI CO LTD

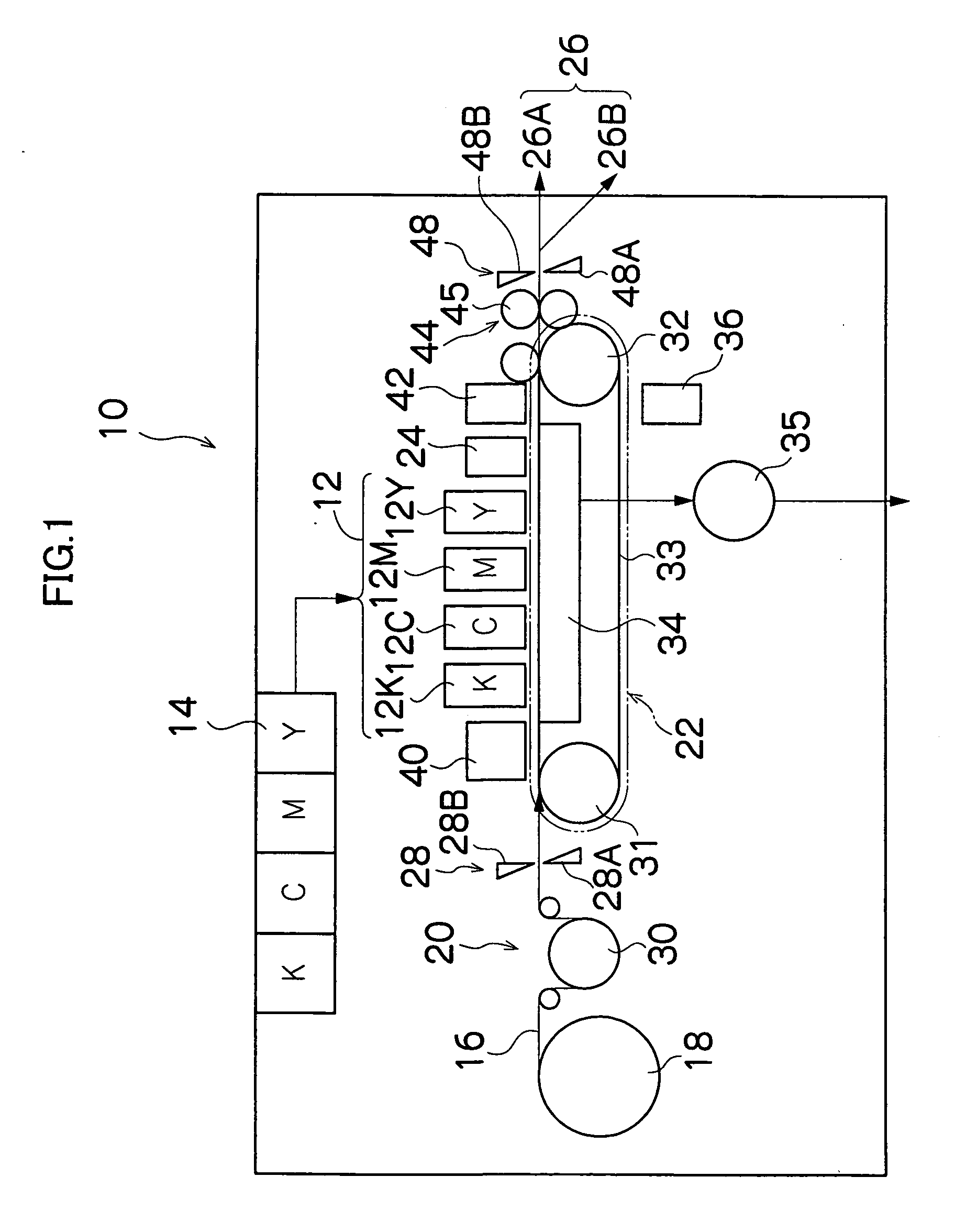

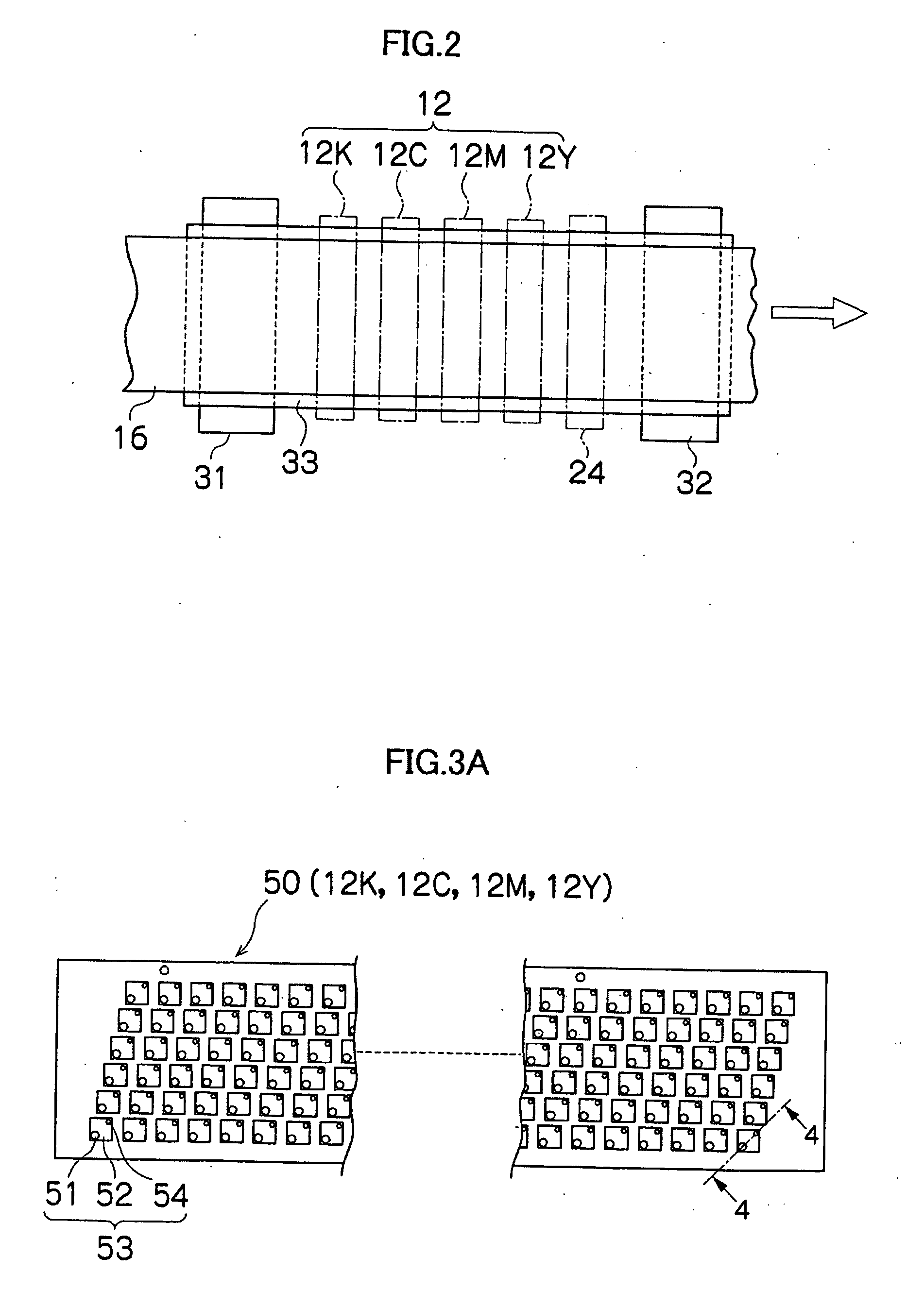

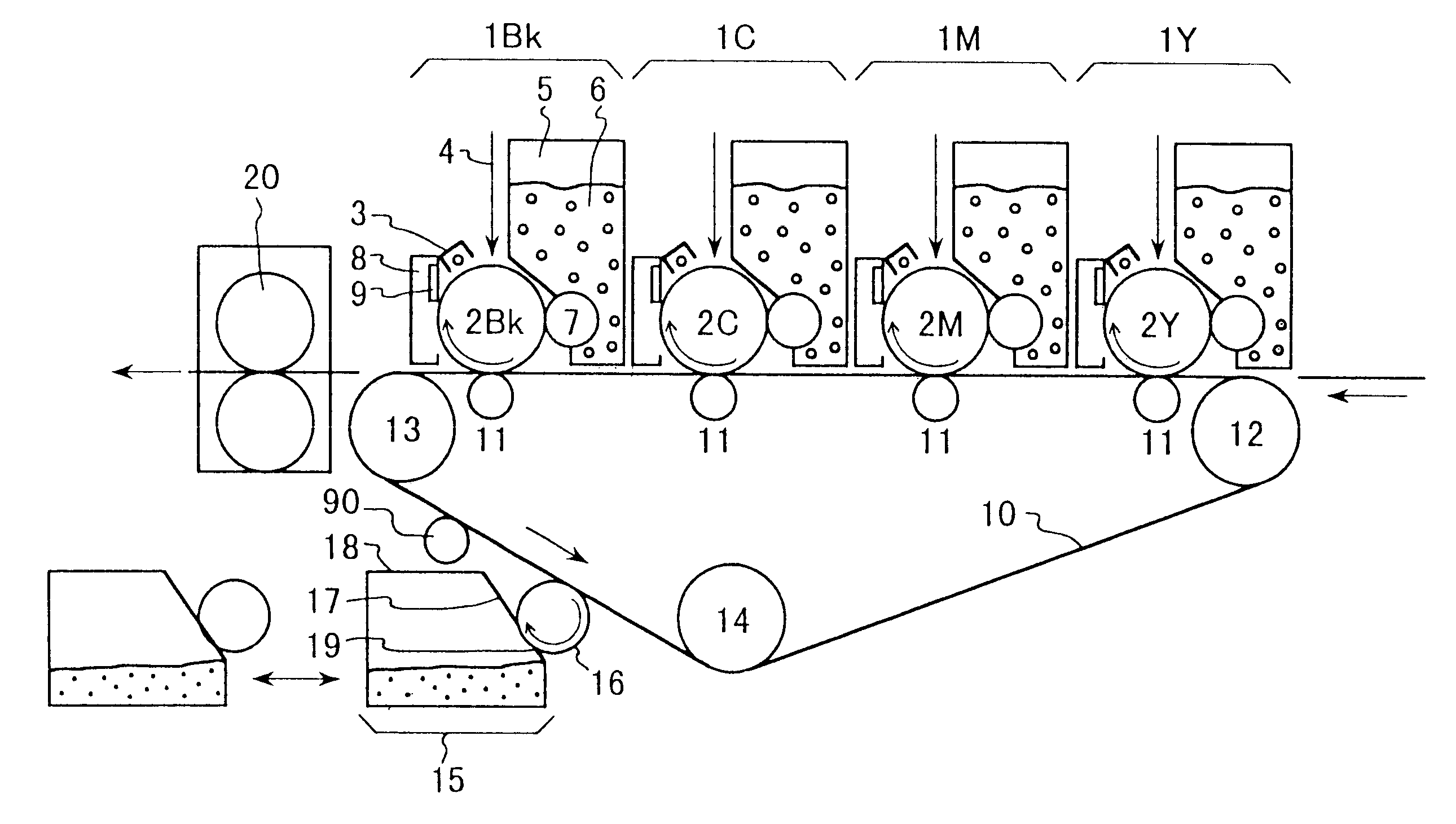

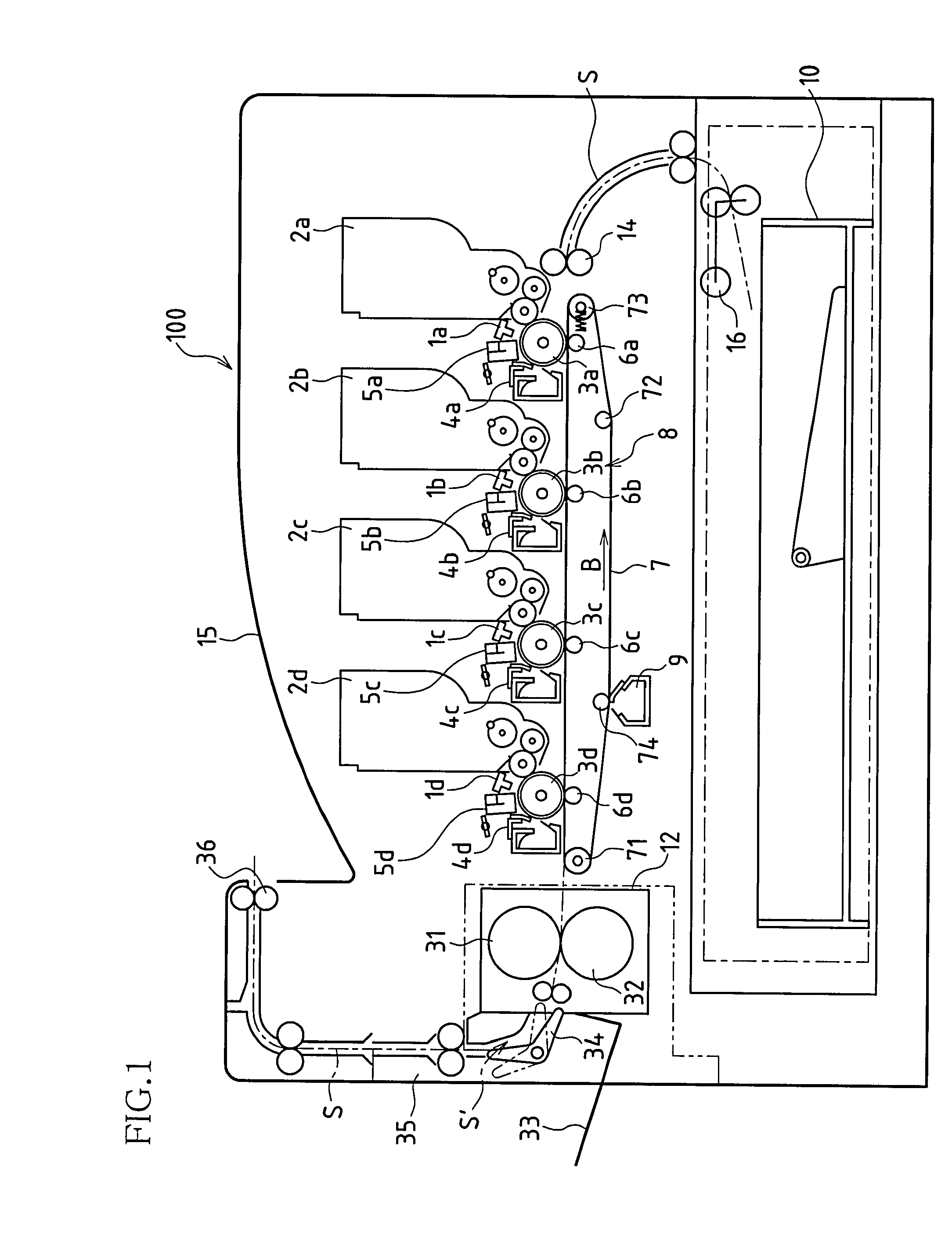

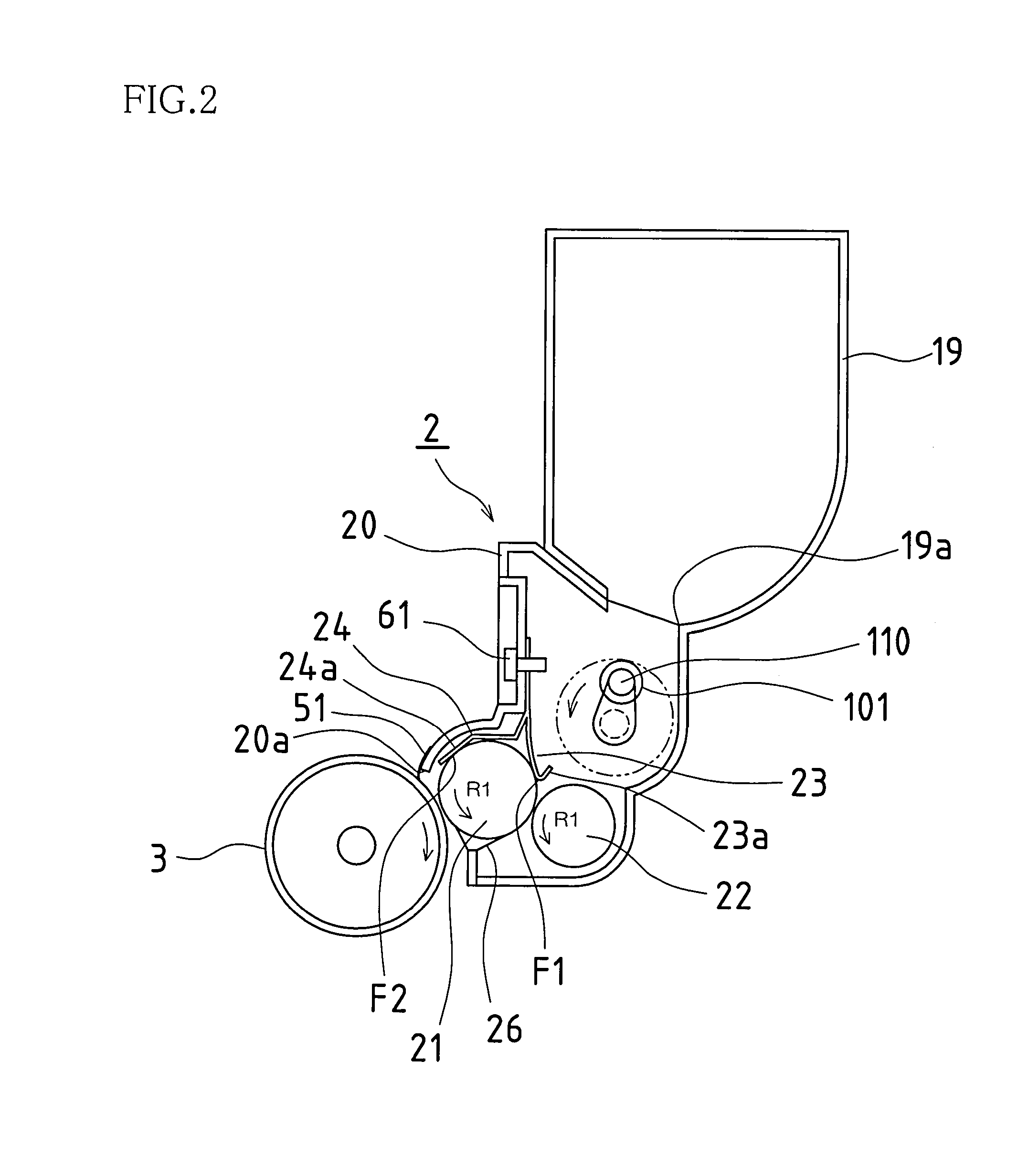

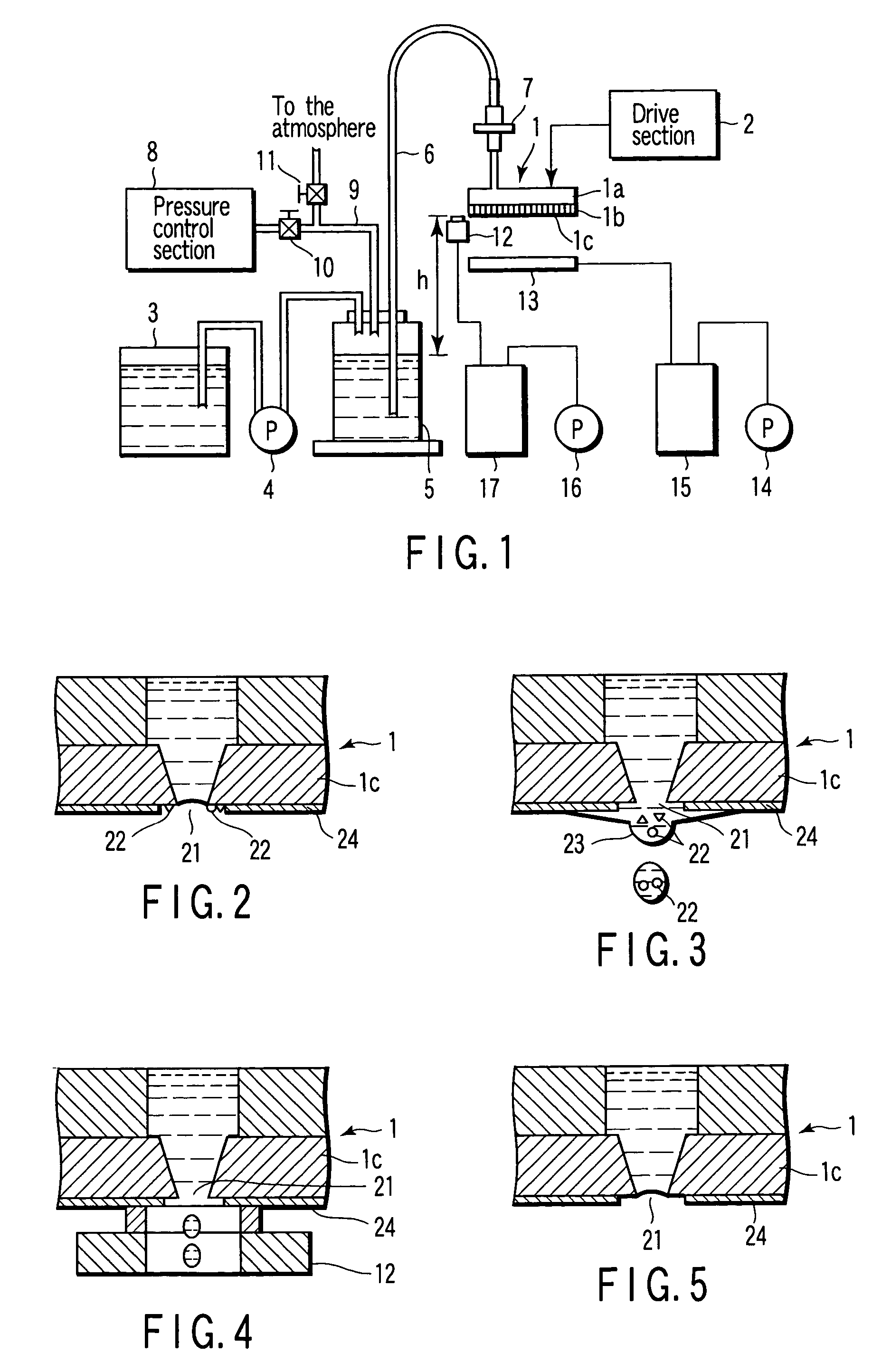

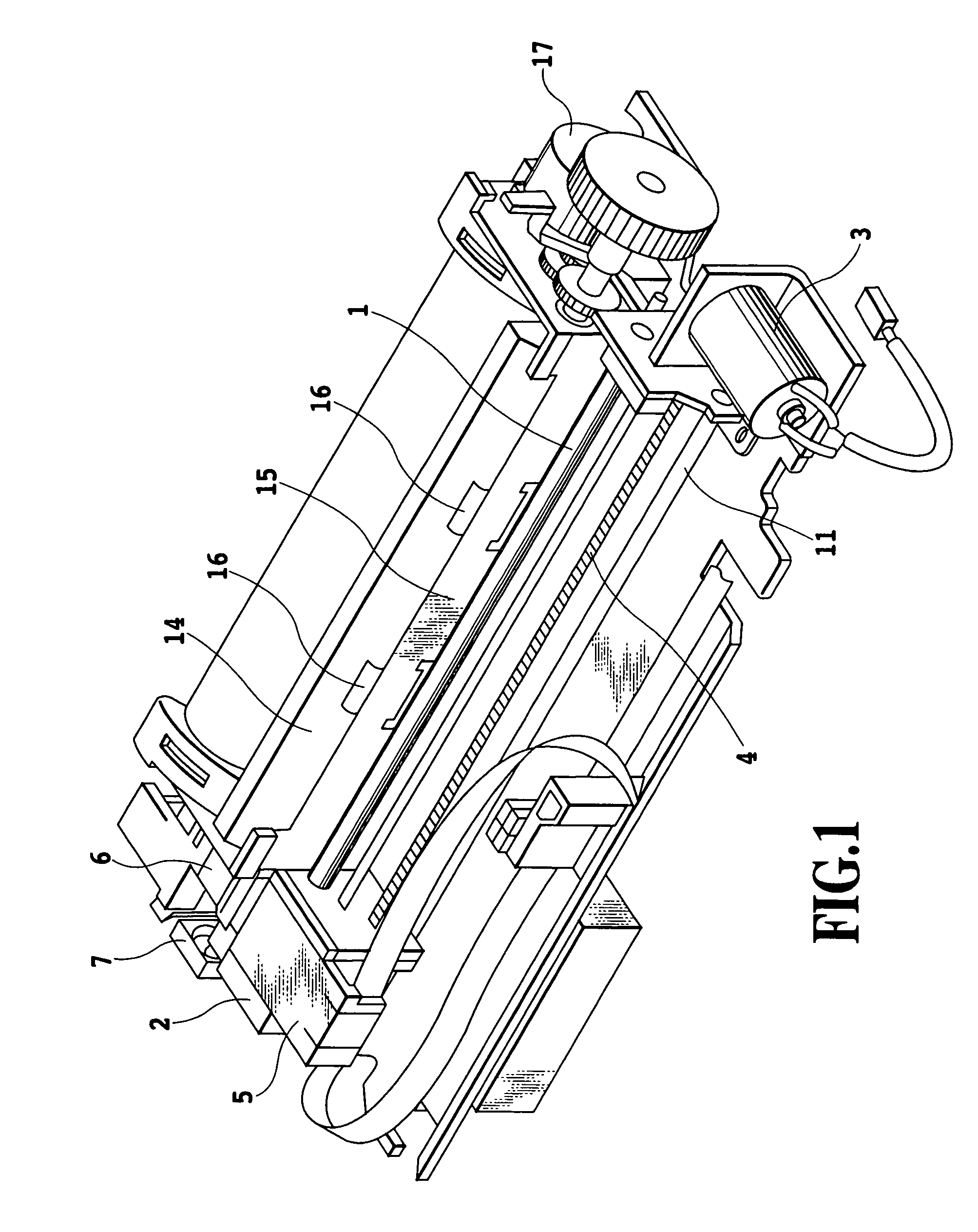

Inkjet recording apparatus, and ink discharge surface cleaning method and device

InactiveUS20050062797A1Reliable removalReducing durable lifespanPrintingSurface cleaningRecording media

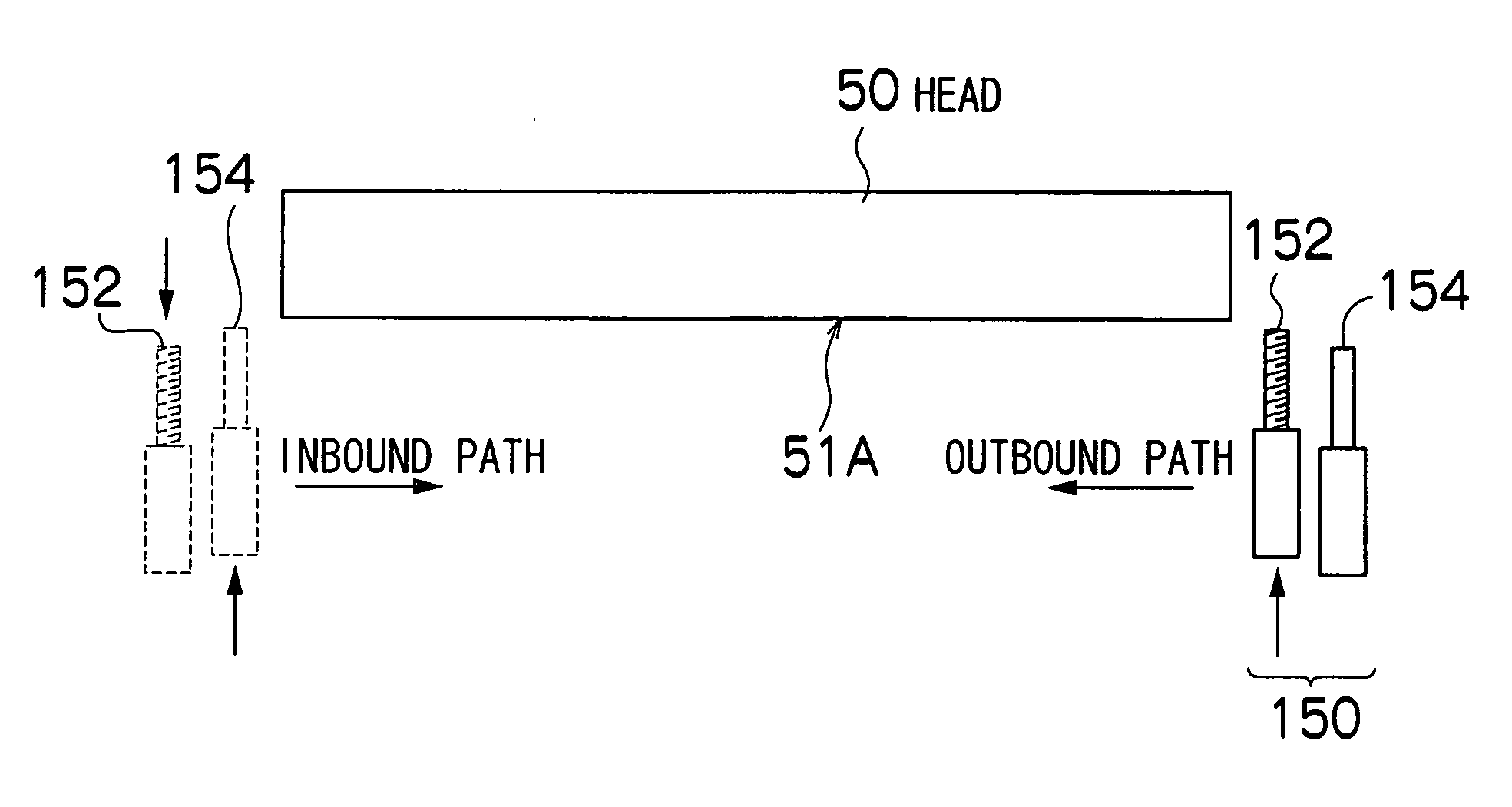

The inkjet recording apparatus comprises: a printing device including a print head which discharges ink droplets onto a recording medium to perform printing, the print head having discharge ports through which the ink droplets are discharged; a liquid removal device which absorbs droplets deposited on an ink discharge surface of the print head in which the ink discharge ports are formed; and a deposit removal device which wipes away matter deposited on the ink discharge surface.

Owner:FUJIFILM CORP

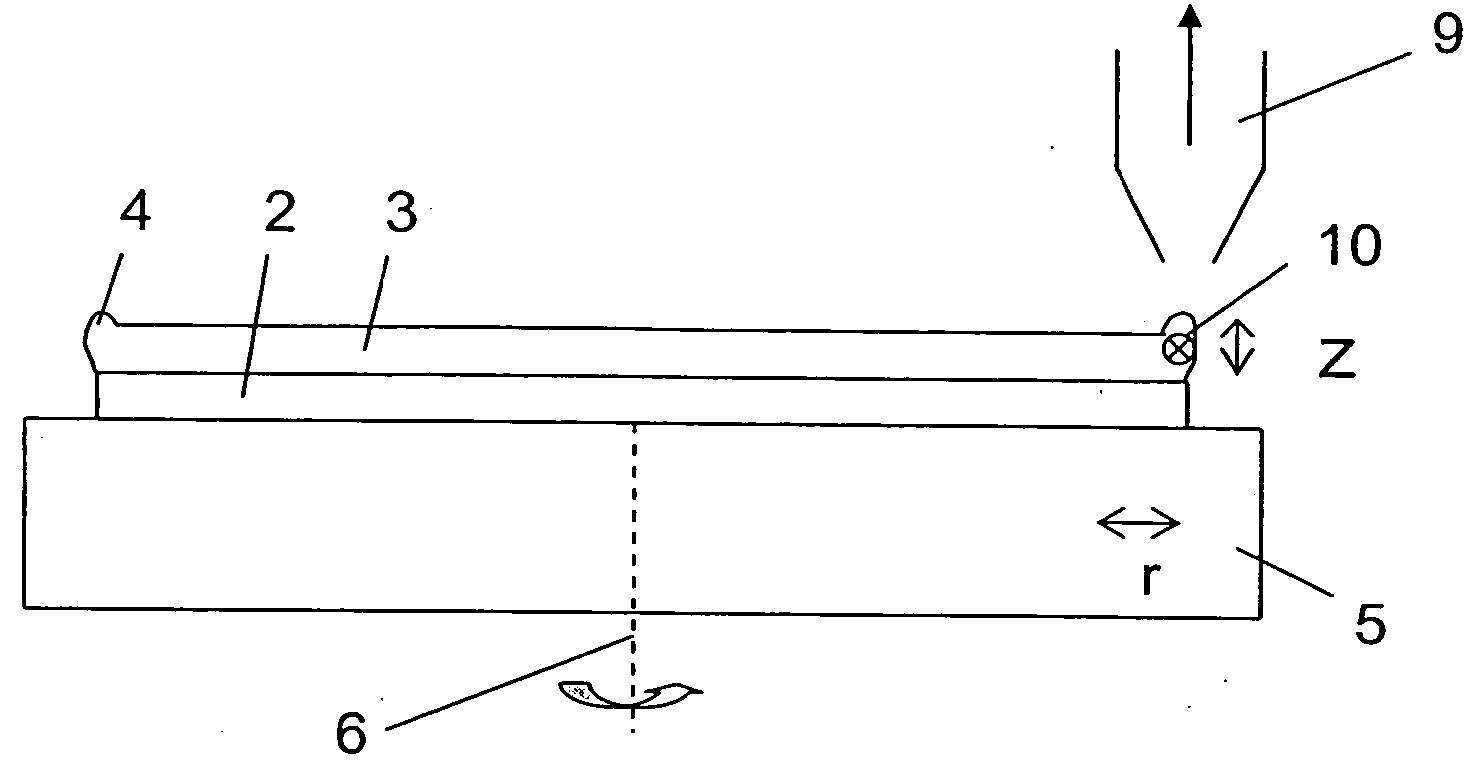

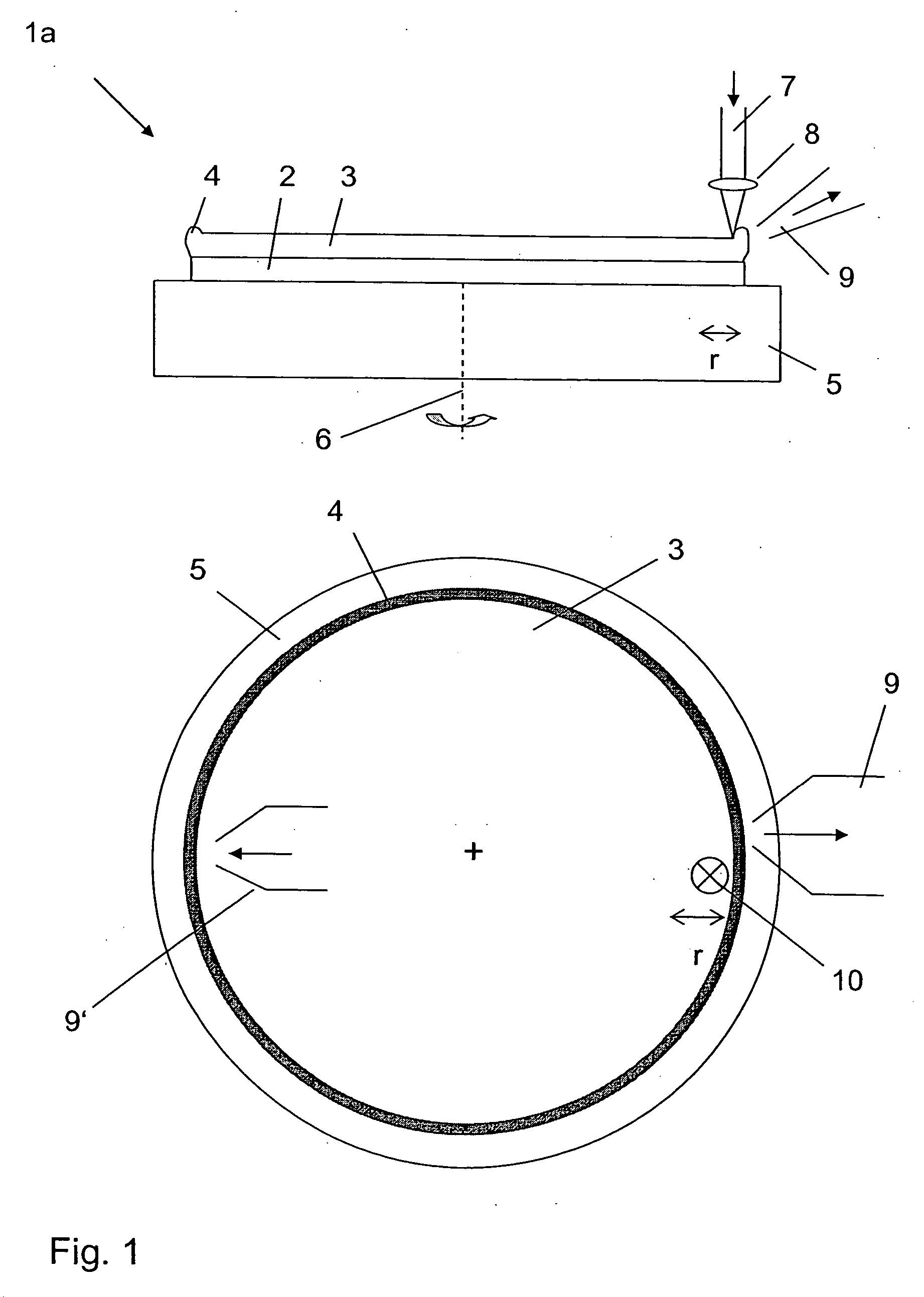

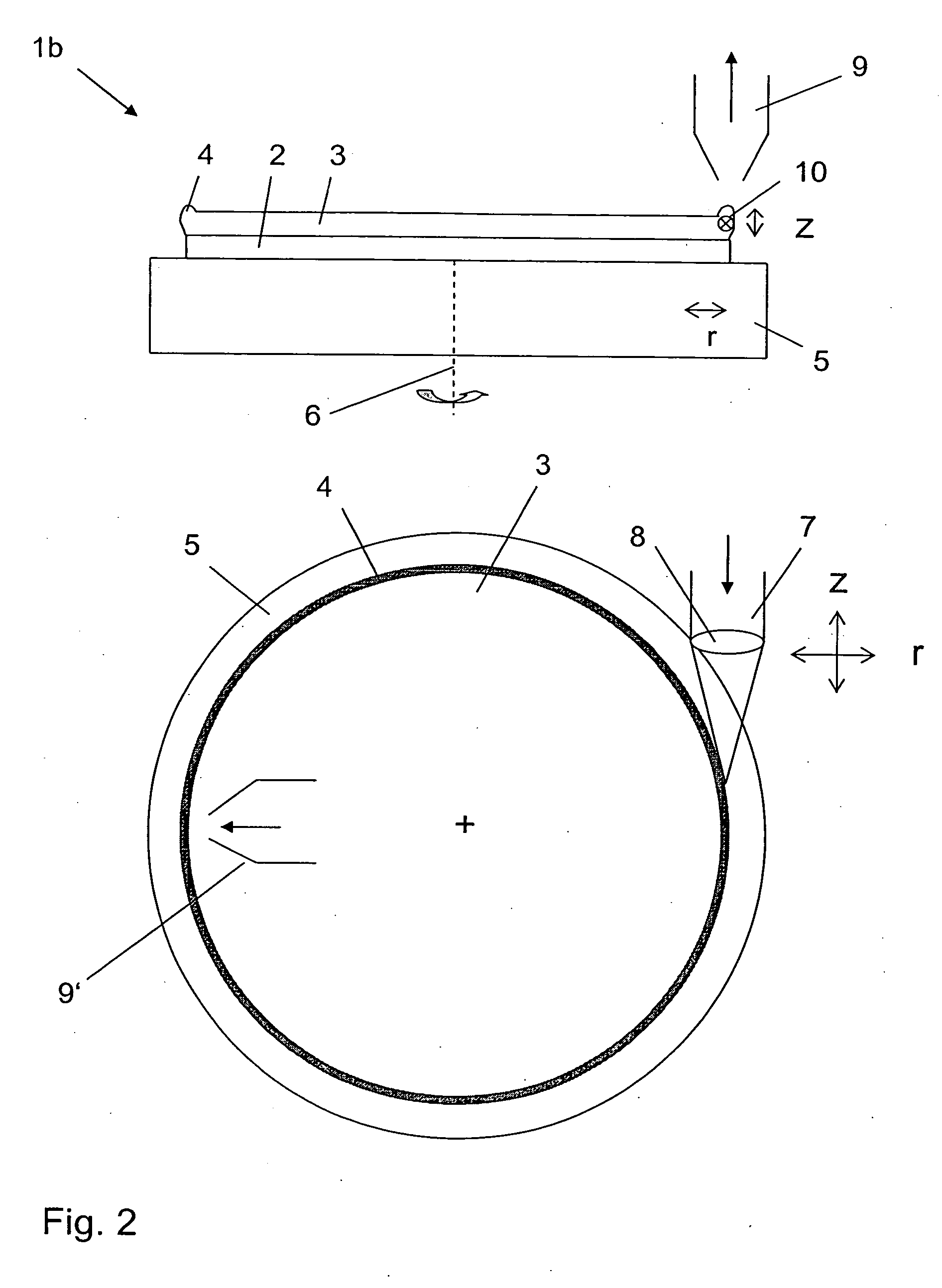

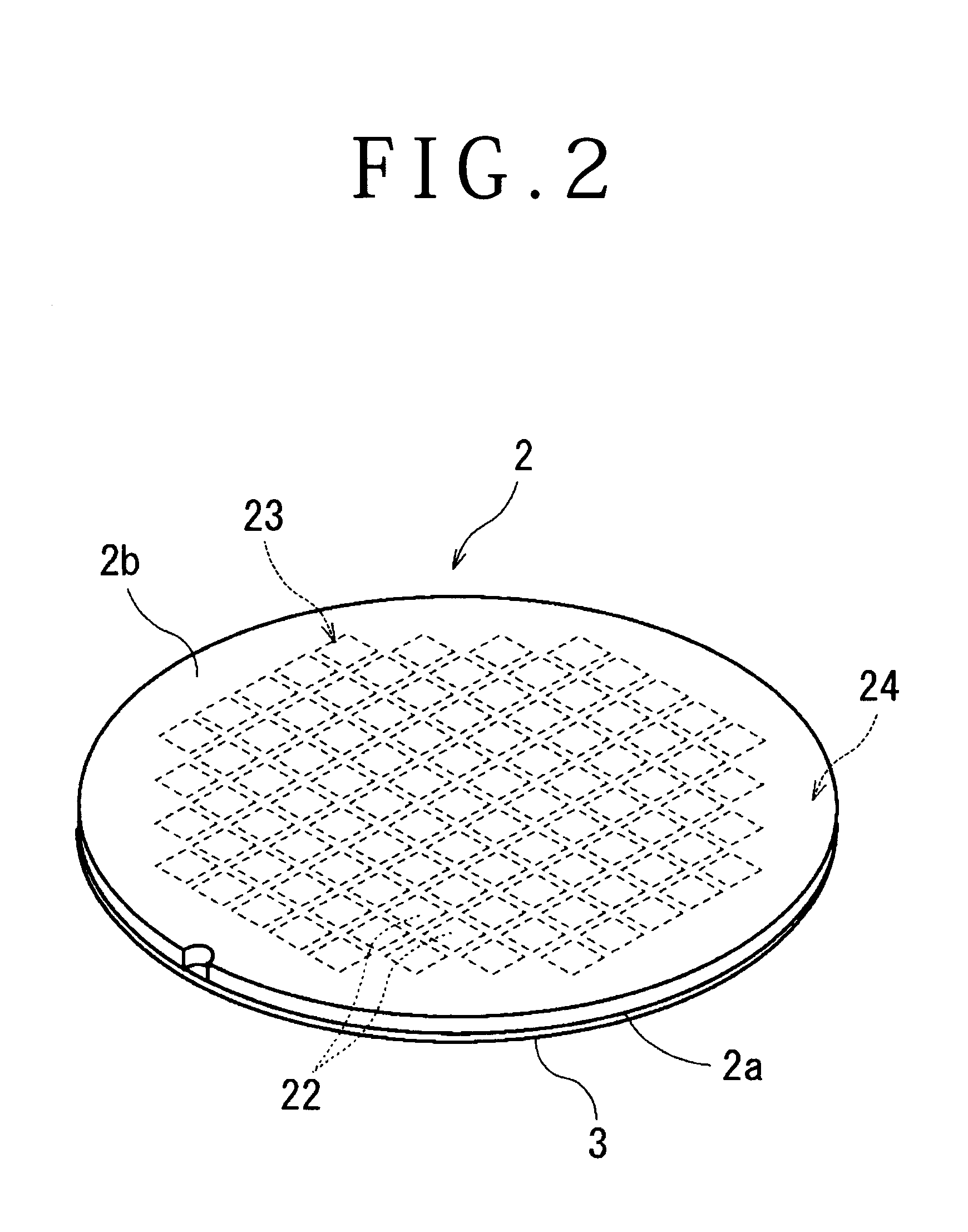

Method and apparatus for removing an edge region of a layer applied to a substrate and for coating a substrate and a substrate

InactiveUS20050020087A1Reliable removalSimple and reliable processSemiconductor/solid-state device manufacturingOptical resonator shape and constructionOptoelectronicsLaser beams

The invention relates to a method and an apparatus for removing an edge region of a layer applied to a substrate and for coating a substrate, in particular, with a photoresist layer. Furthermore, the present invention relates to a substrate, onto which a layer, in particular, a photoresist layer for use in a microlithographic process, is applied, wherein an edge region of the layer is removed according to the invention. In the method, a laser beam is imaged onto the edge region, and the edge region is removed by the laser beam. In this manner, the edge region can be removed reliably and precisely, without damage to or contamination of regions of the layer which are not to be removed.

Owner:SCHOTT AG

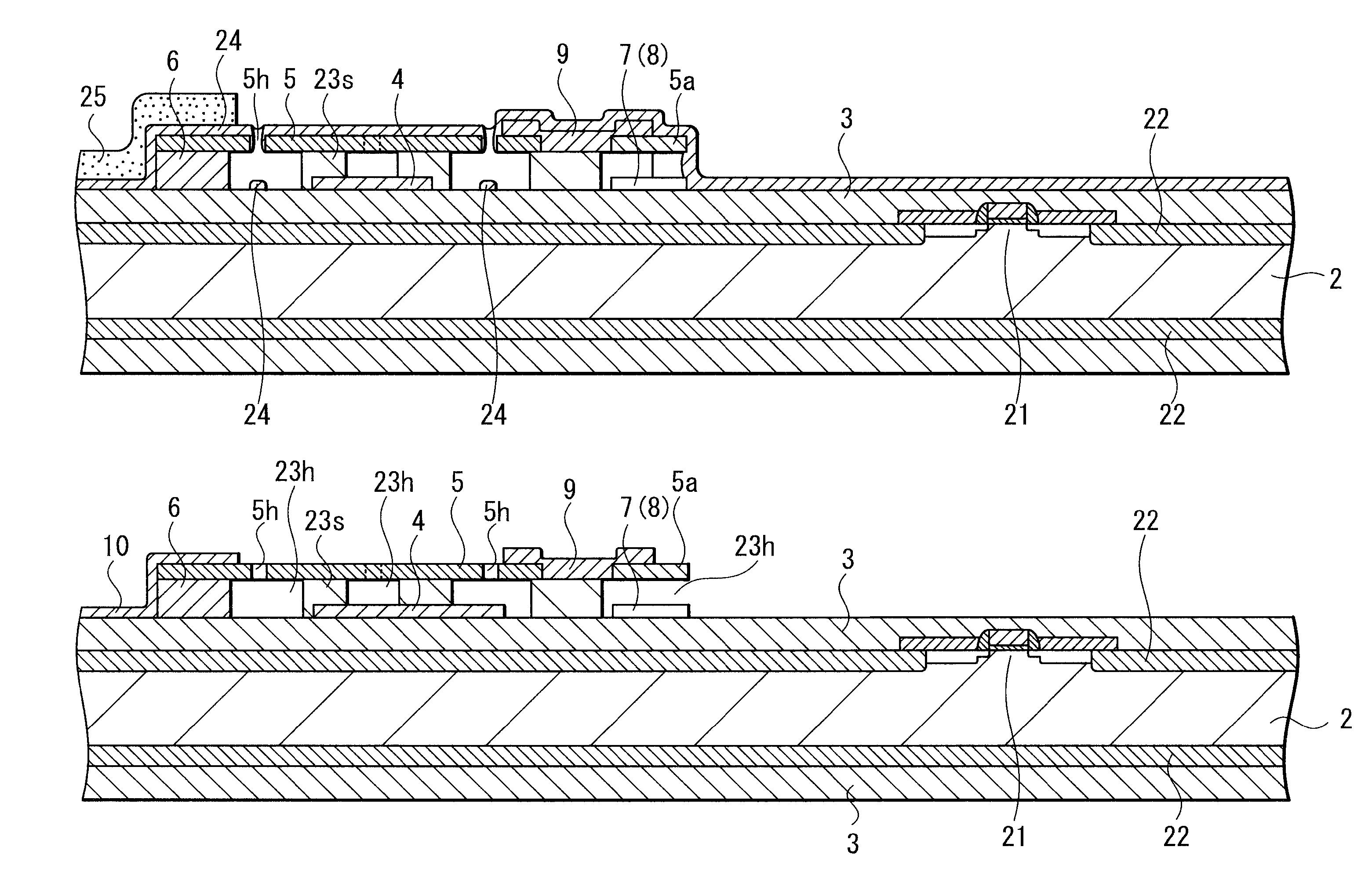

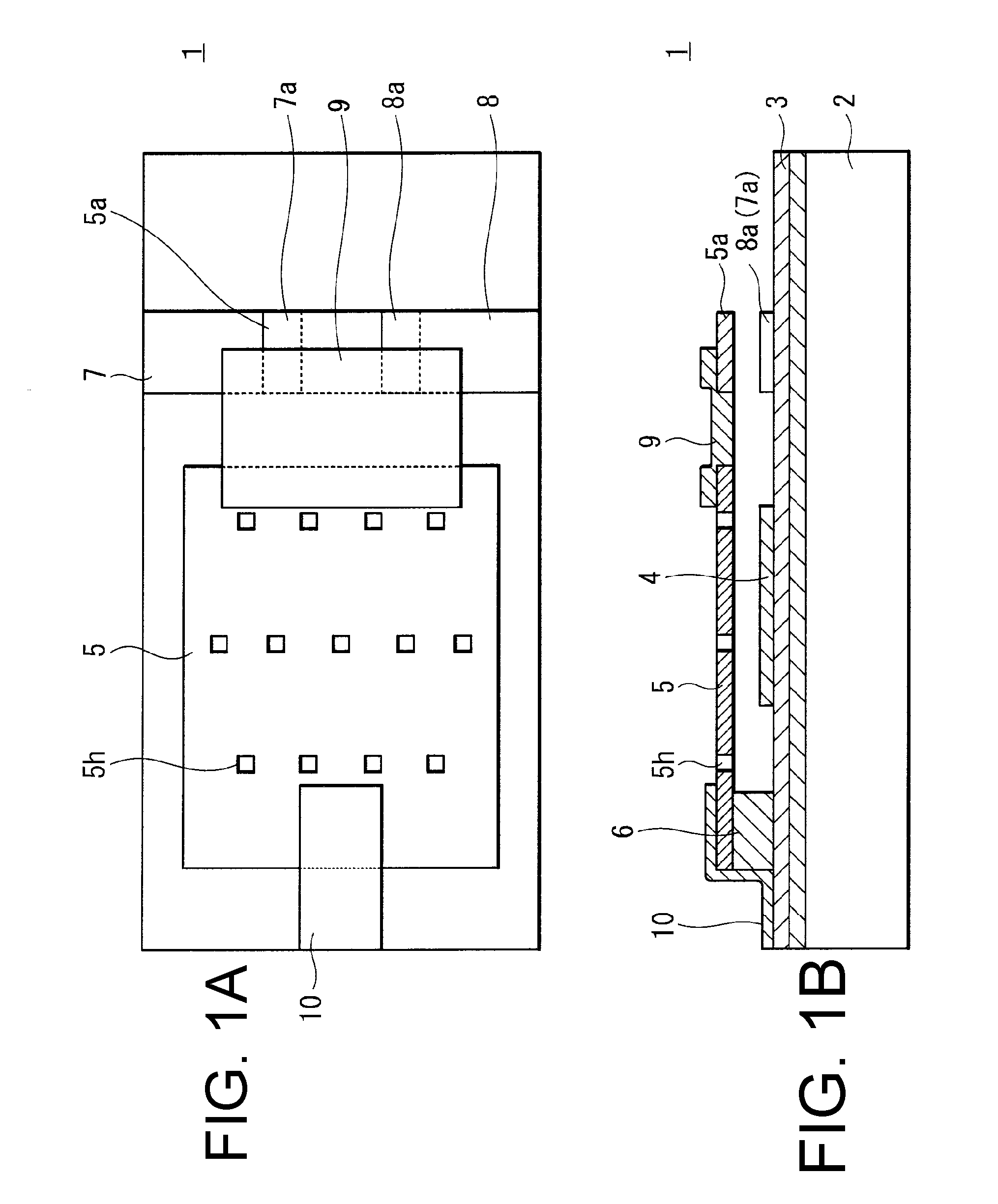

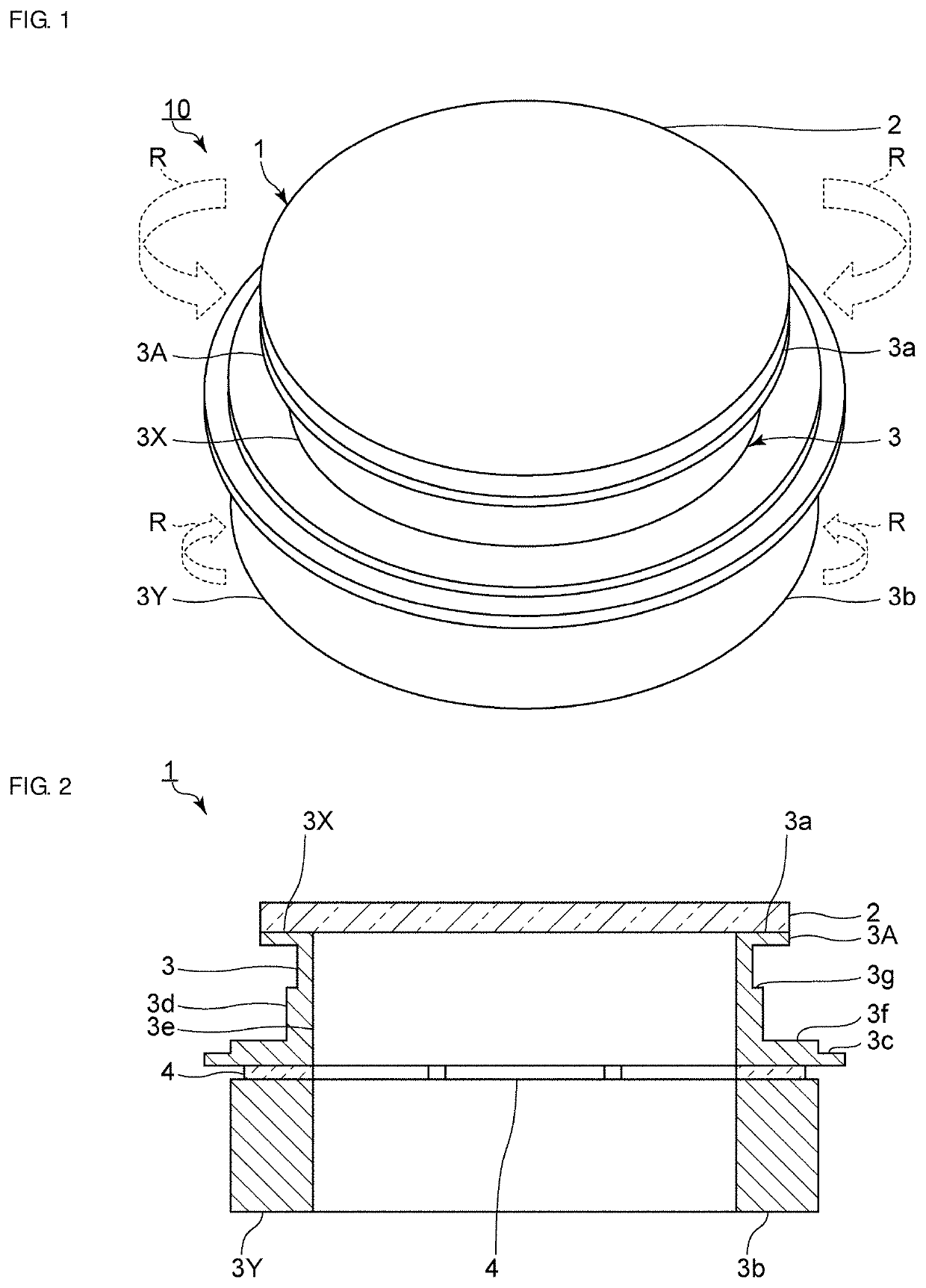

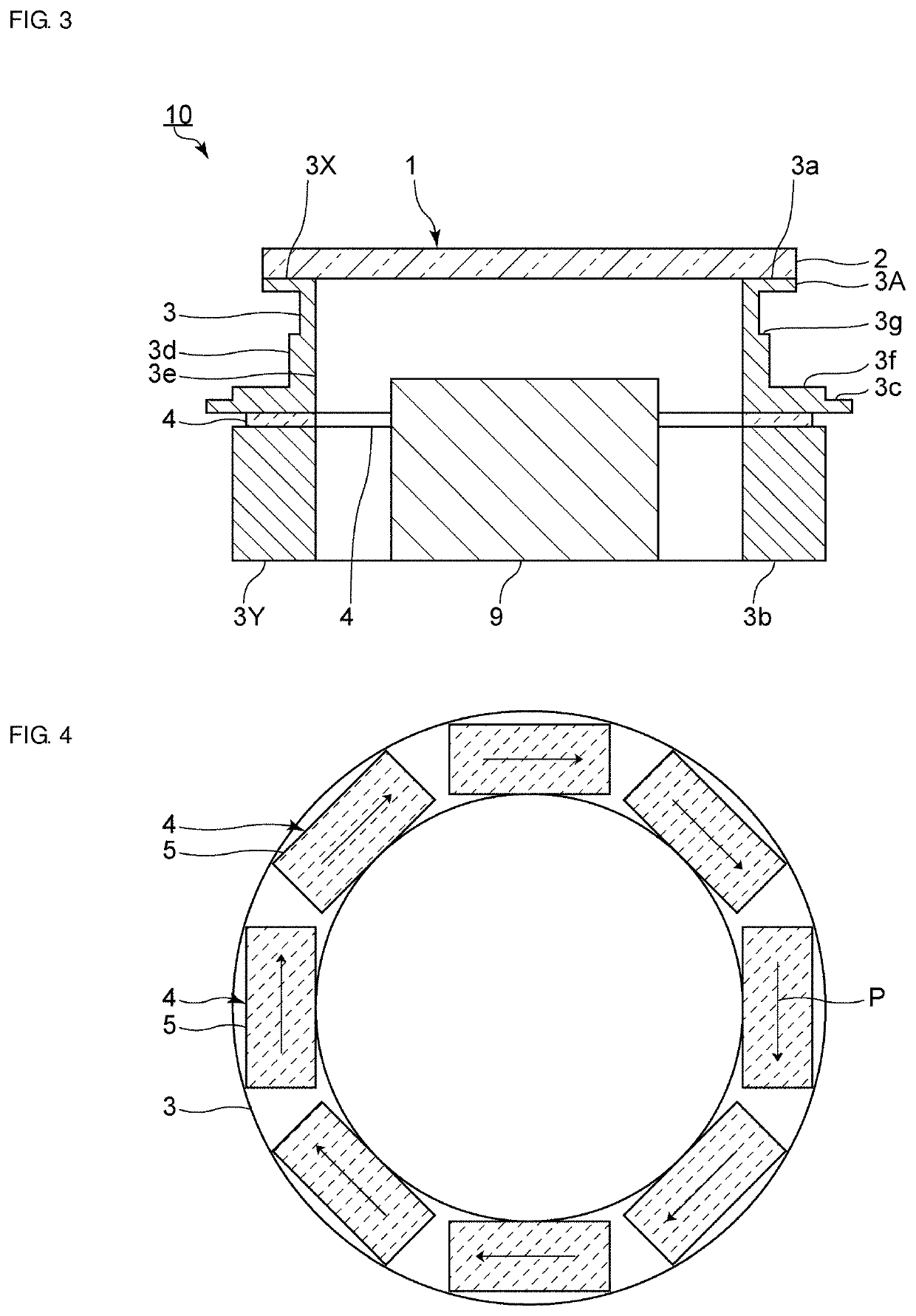

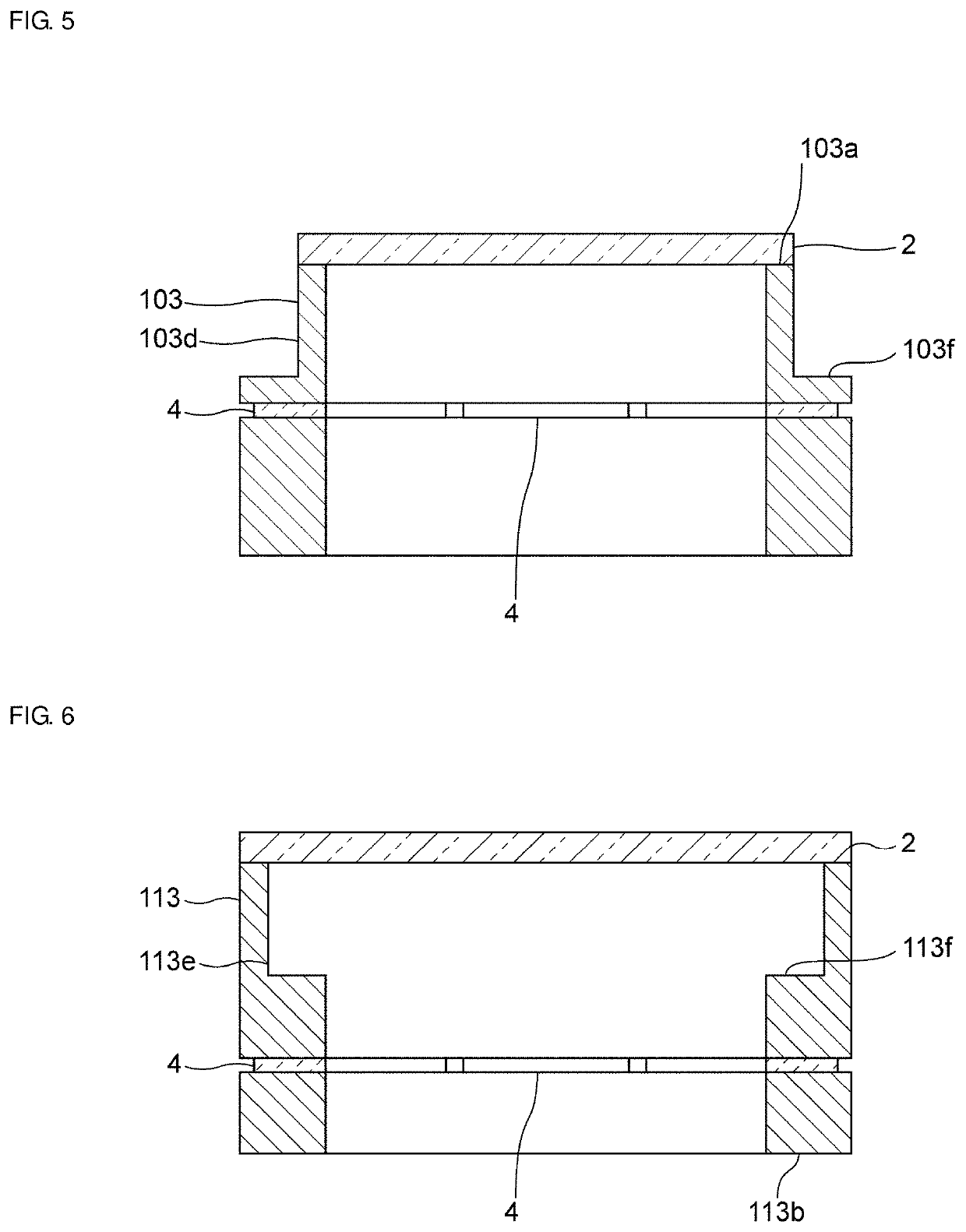

Electromechanical element, electric circuit device and production method of those

InactiveUS8142669B2Reliably removedReduce incidenceDecorative surface effectsSemiconductor/solid-state device manufacturingHollow formElectrical and Electronics engineering

Owner:SONY CORP

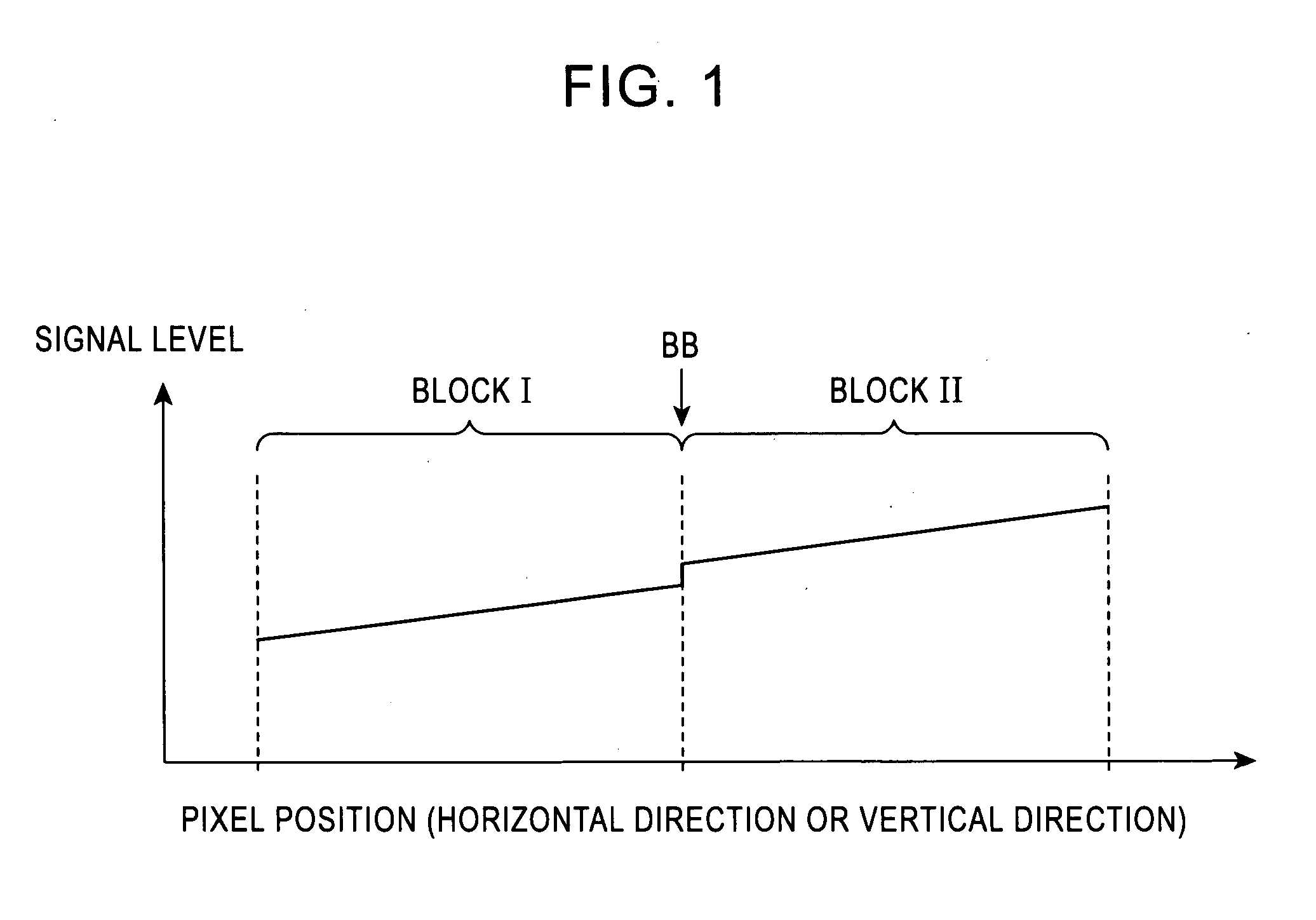

Block noise removal device

InactiveUS20080037893A1Reliable removalReduce image qualityCharacter and pattern recognitionDigital video signal modificationNoise removalAlgorithm

A block noise removal device calculates a block boundary correction value. This correction value indicates a correction amount for a pixel sample value immediately before a block boundary position and a correction amount for a pixel sample value immediately after the block boundary position for each block boundary position in a pixel sample value sequence. Each pixel sample value represents a level of each pixel in a video signal. The block noise removal device obtains the block boundary correction value based on at least two consecutive pixel sample values immediately before the block boundary position and at least two consecutive pixel sample values immediately after the block boundary position. The block noise removal device then generates a block noise correction signal representing a correction amount for the pixel sample values corresponding to respective pixels in the pixel block is generated by performing interpolation computations based on the block boundary correction value found for each two adjacent block boundary positions. The block noise removal device adds the block noise correction signal to the video signal to produce a noise-removed video signal from which block noise has been removed.

Owner:PIONEER CORP

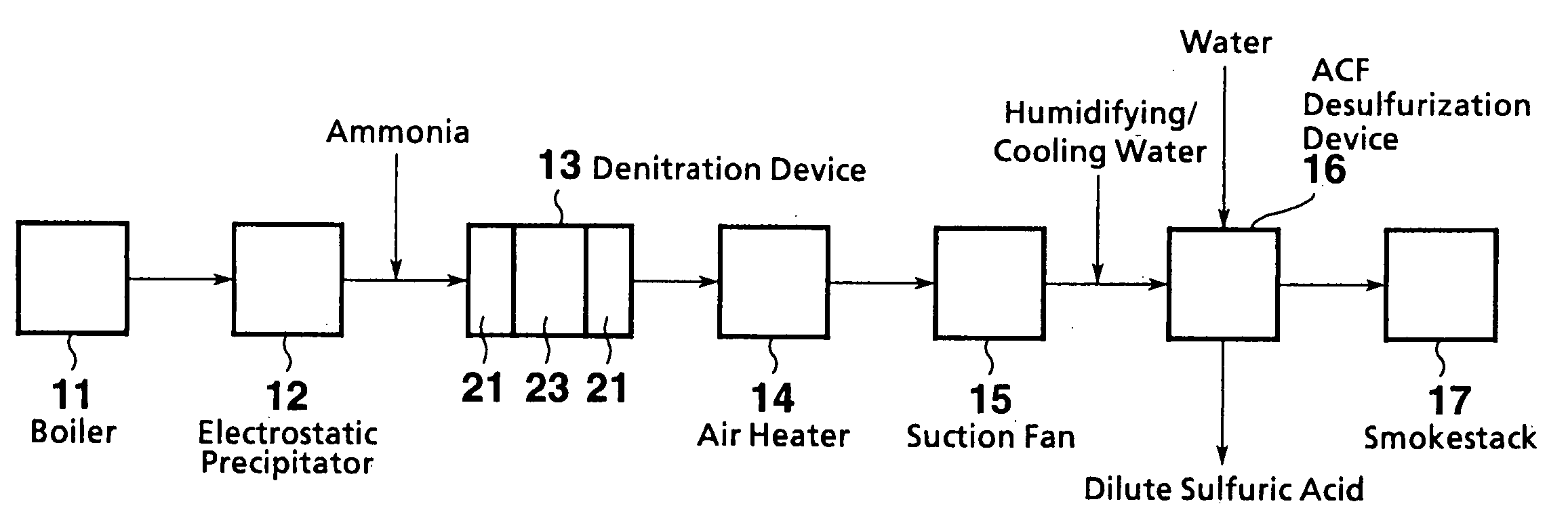

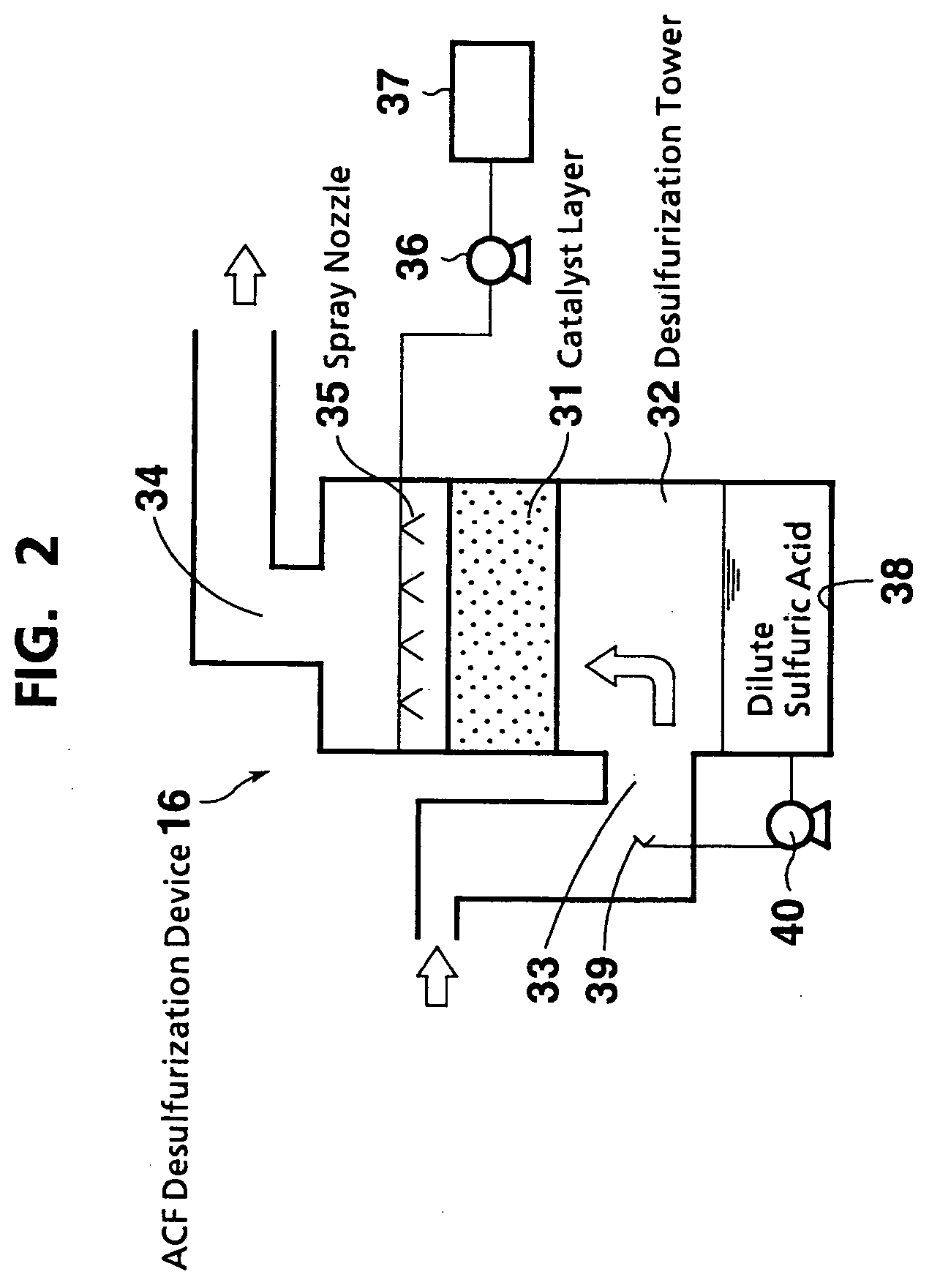

Exhaust gas treatment system

InactiveUS20050008546A1Low costSystem degradationCombination devicesExhaust apparatusEngineeringCost of treatment

In an exhaust gas treatment system, dust in a high temperature exhaust gas is caught by a high temperature dry electrostatic precipitator, a nitrogen oxide NO2 in the exhaust gas is removed by denitration means, then the exhaust gas is cooled by an air heater, and the exhaust gas is passed through an activated carbon fiber layer of activated carbon treatment means to remove sulfur oxides SO2 and SO3 contained in the exhaust gas. The exhaust gas treatment system reduces the costs of treatment and equipment, and downsizes the system.

Owner:MITSUBISHI HEAVY IND LTD

Cleaning device, fixing device, and image forming apparatus

InactiveUS20090003898A1Reliable removalExtend warm-up timeElectrographic process apparatusTarget surfaceMechanical engineering

Owner:RICOH KK

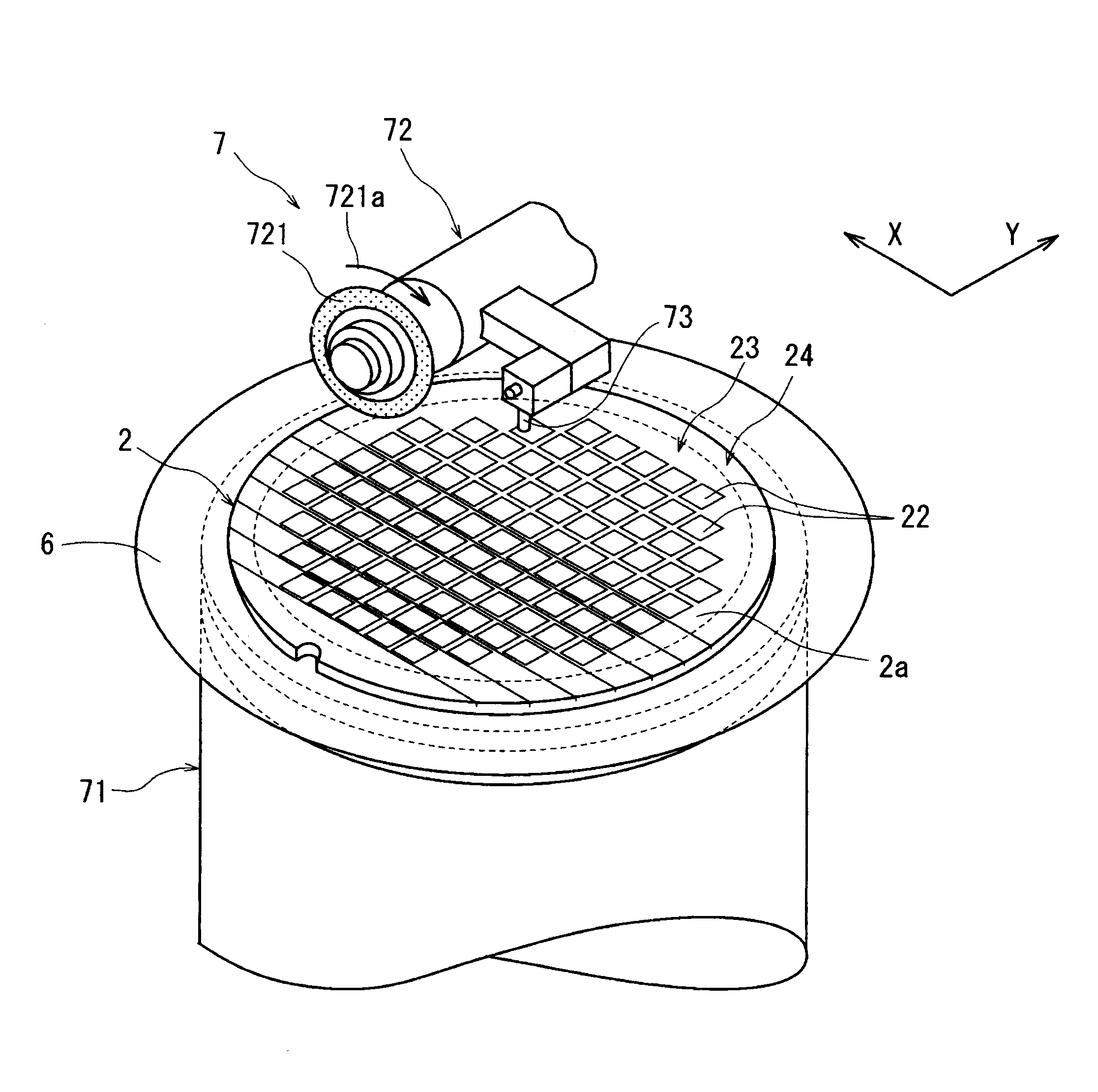

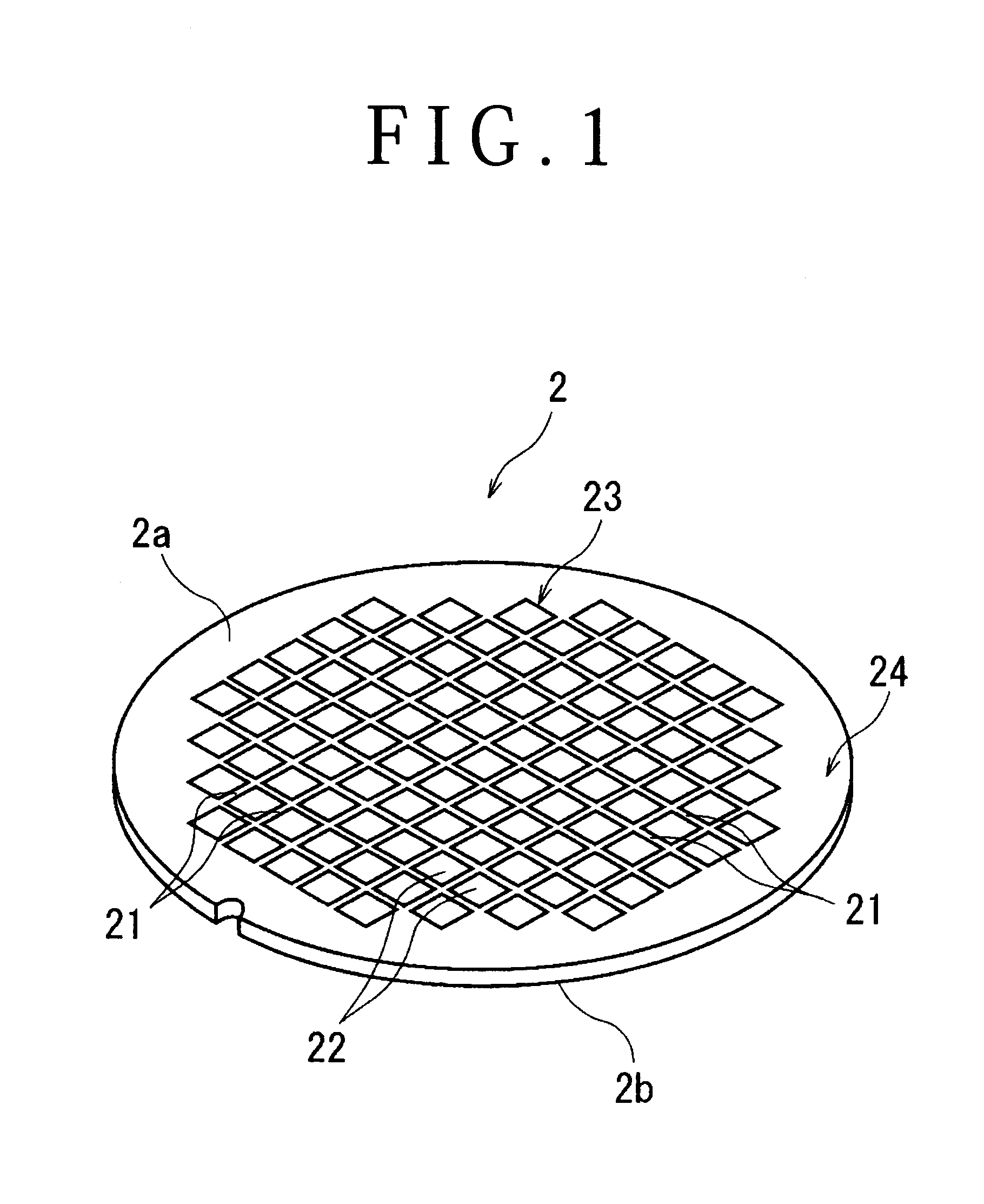

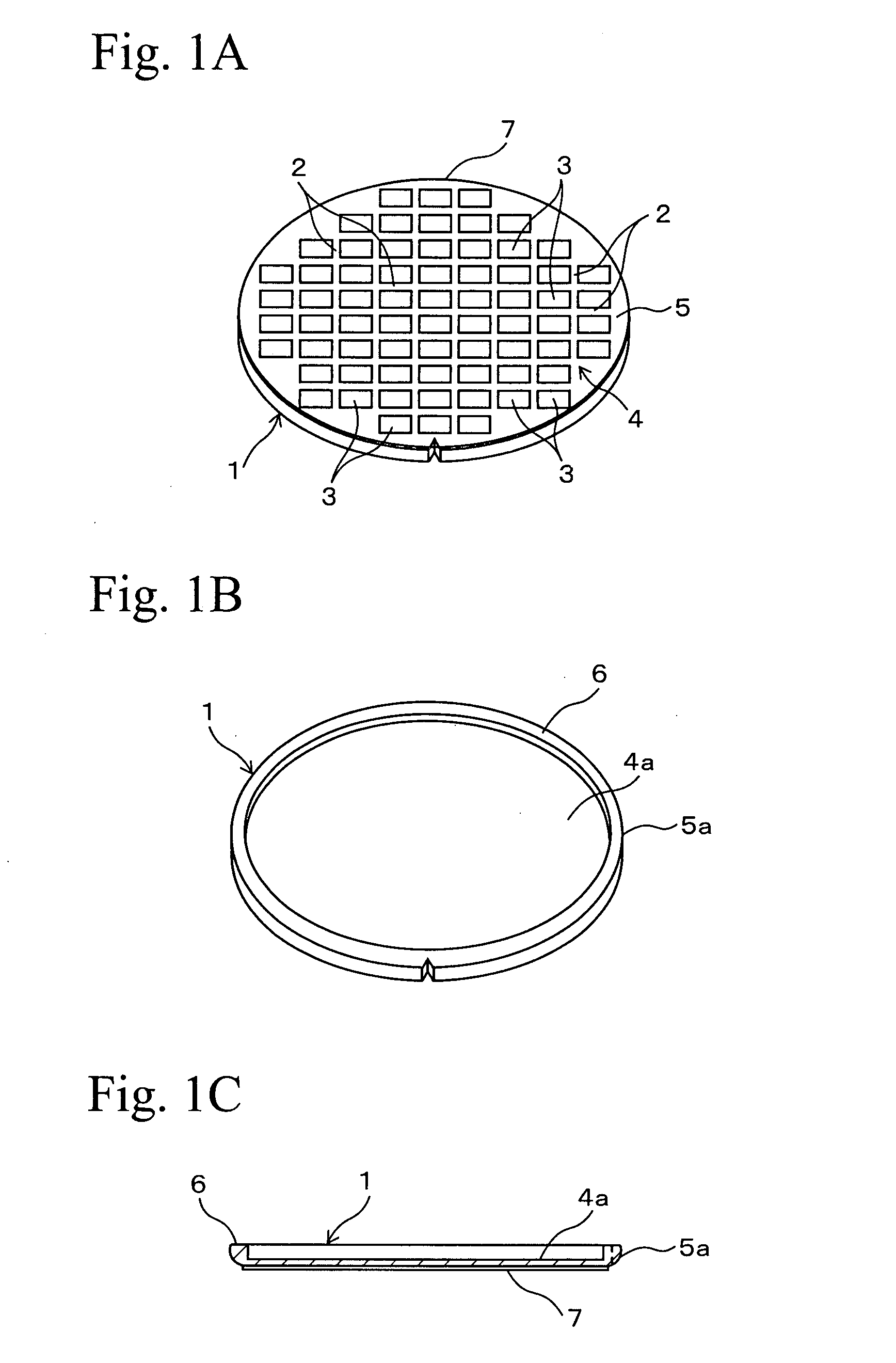

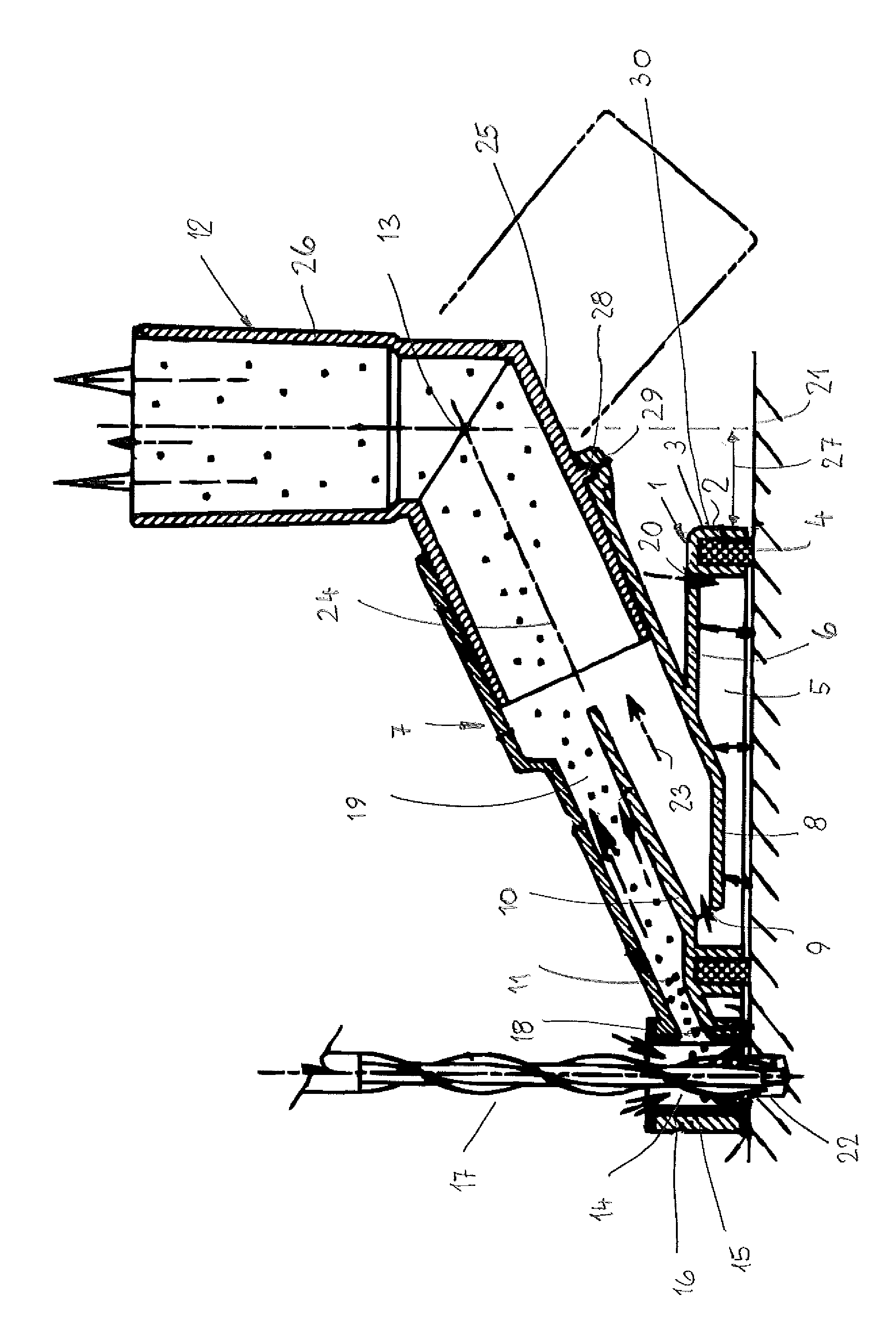

Wafer processing method

ActiveUS20100055877A1Reliable removalReliably removedSolid-state devicesSemiconductor/solid-state device manufacturingDicing tapeEngineering

Disclosed herein is a wafer processing method for dividing a wafer along a plurality of streets. The wafer processing method includes a back grinding step of grinding the back side of the wafer in an area corresponding to a device area to thereby reduce the thickness of the device area to a predetermined finished thickness and to simultaneously form an annular reinforcing portion on the back side of the wafer in an area corresponding to a peripheral marginal area, a wafer supporting step of attaching the back side of the wafer to a dicing tape, a kerf forming step of cutting the front side of the wafer along each street to thereby form a kerf having a depth corresponding to the thickness of the device area along each street, thereby dividing the device area into individual devices, and a peripheral marginal area removing step of peeling off the peripheral marginal area from the dicing tape.

Owner:DISCO CORP

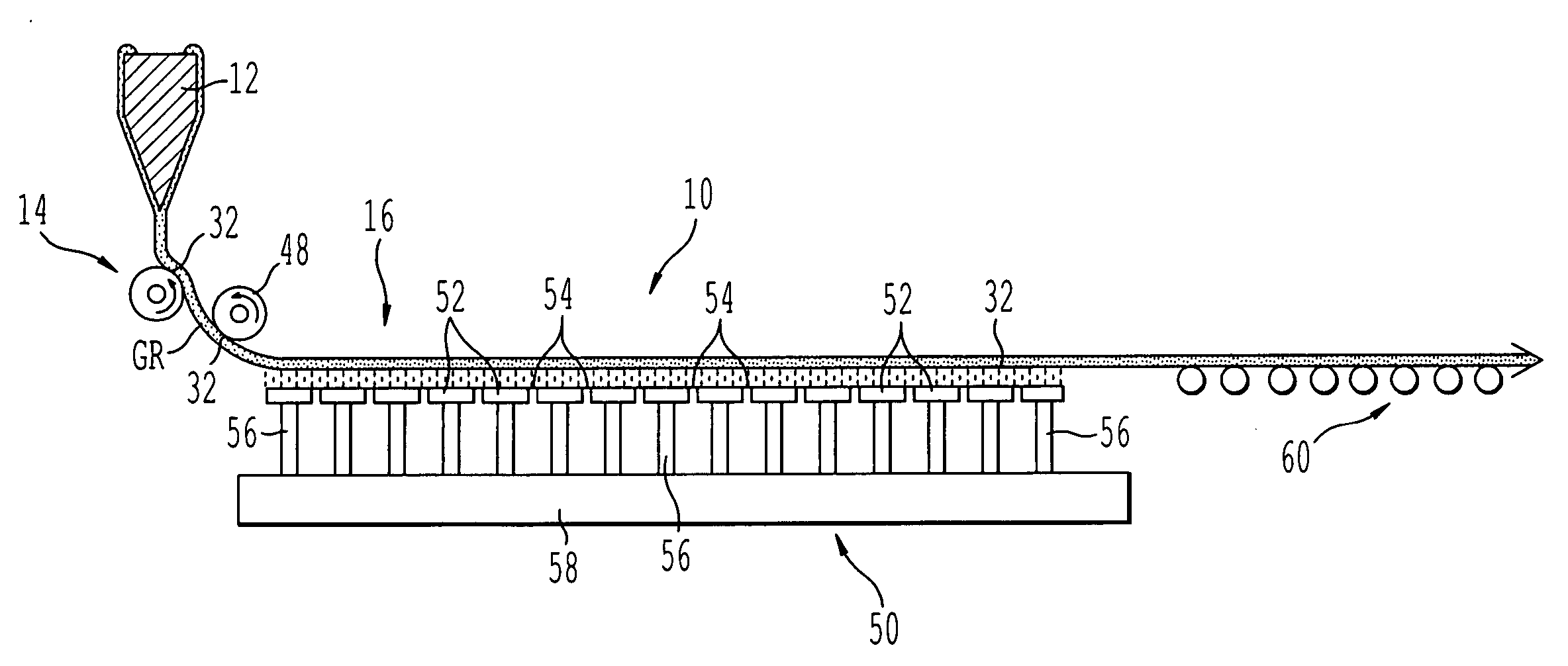

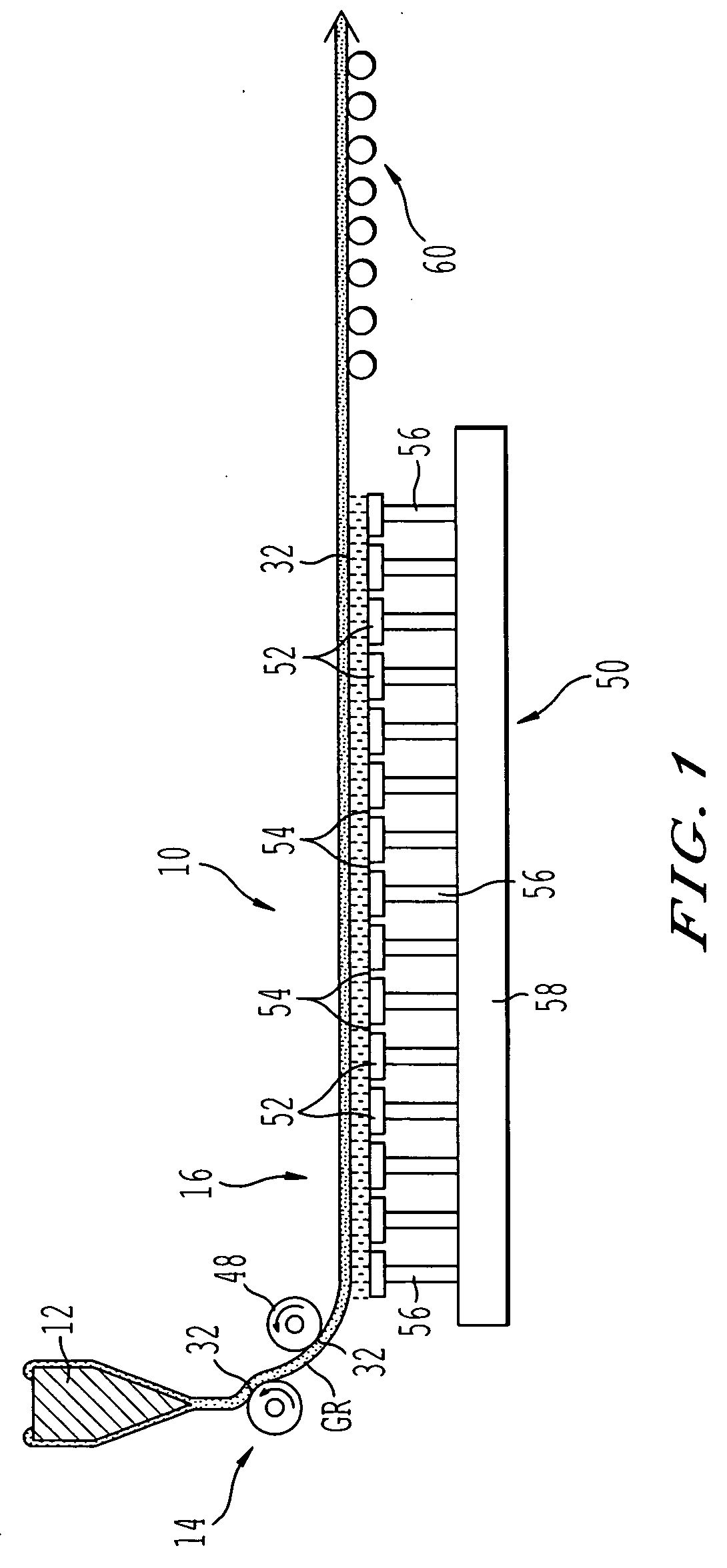

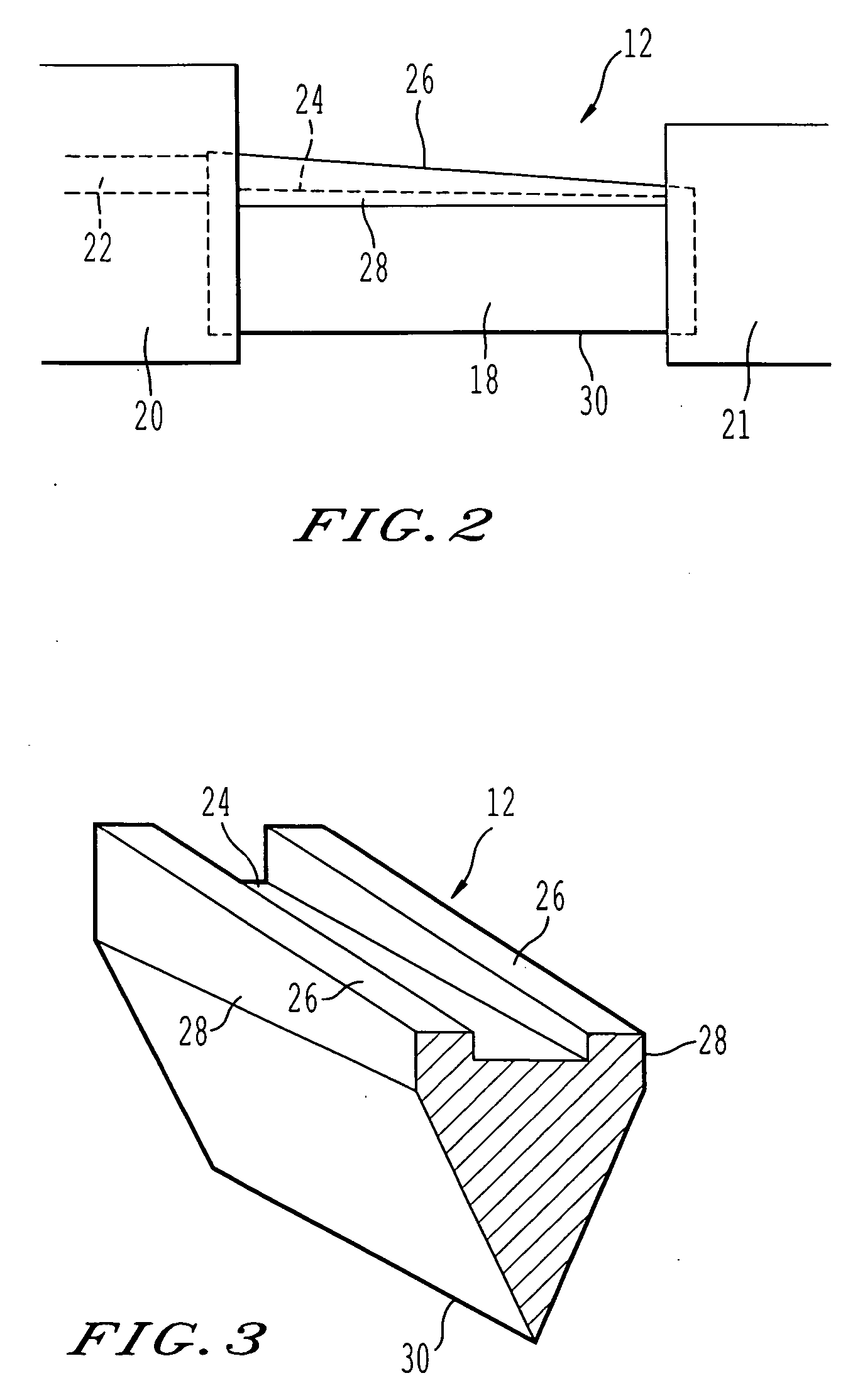

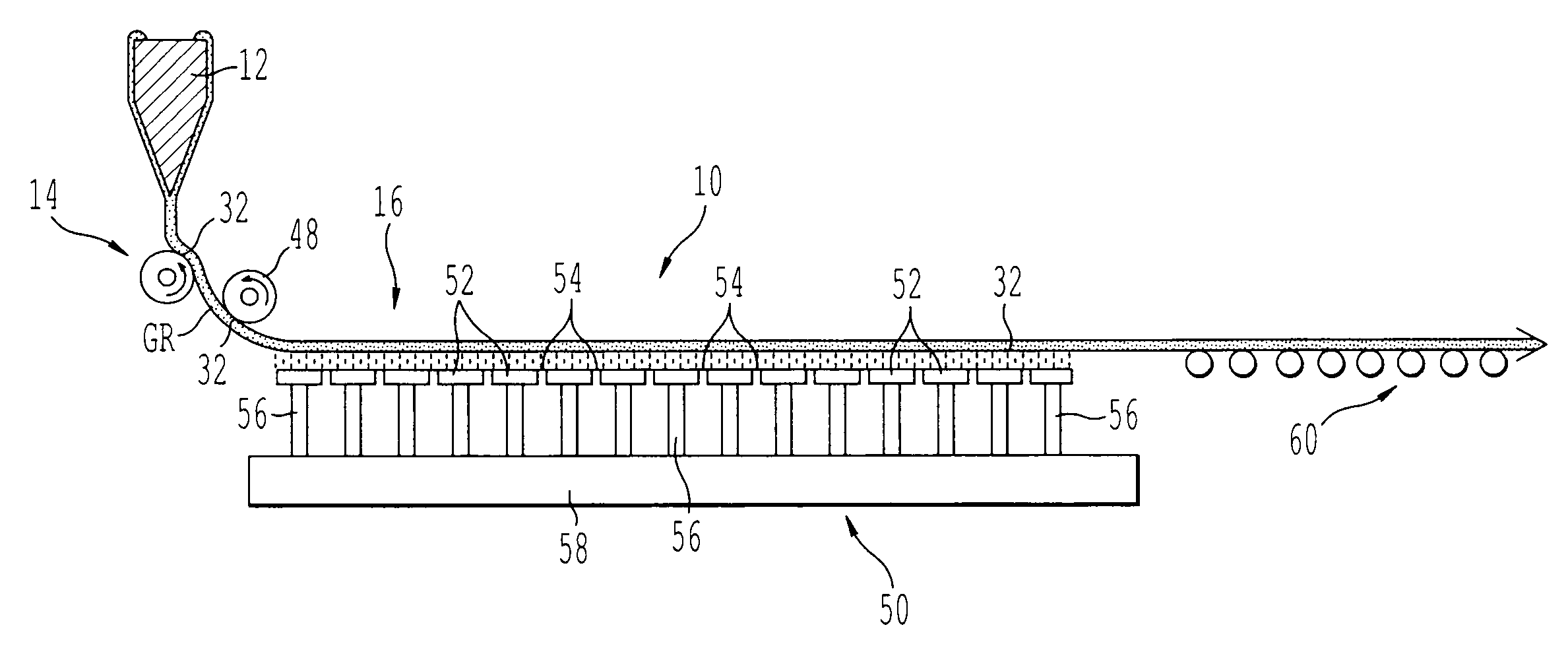

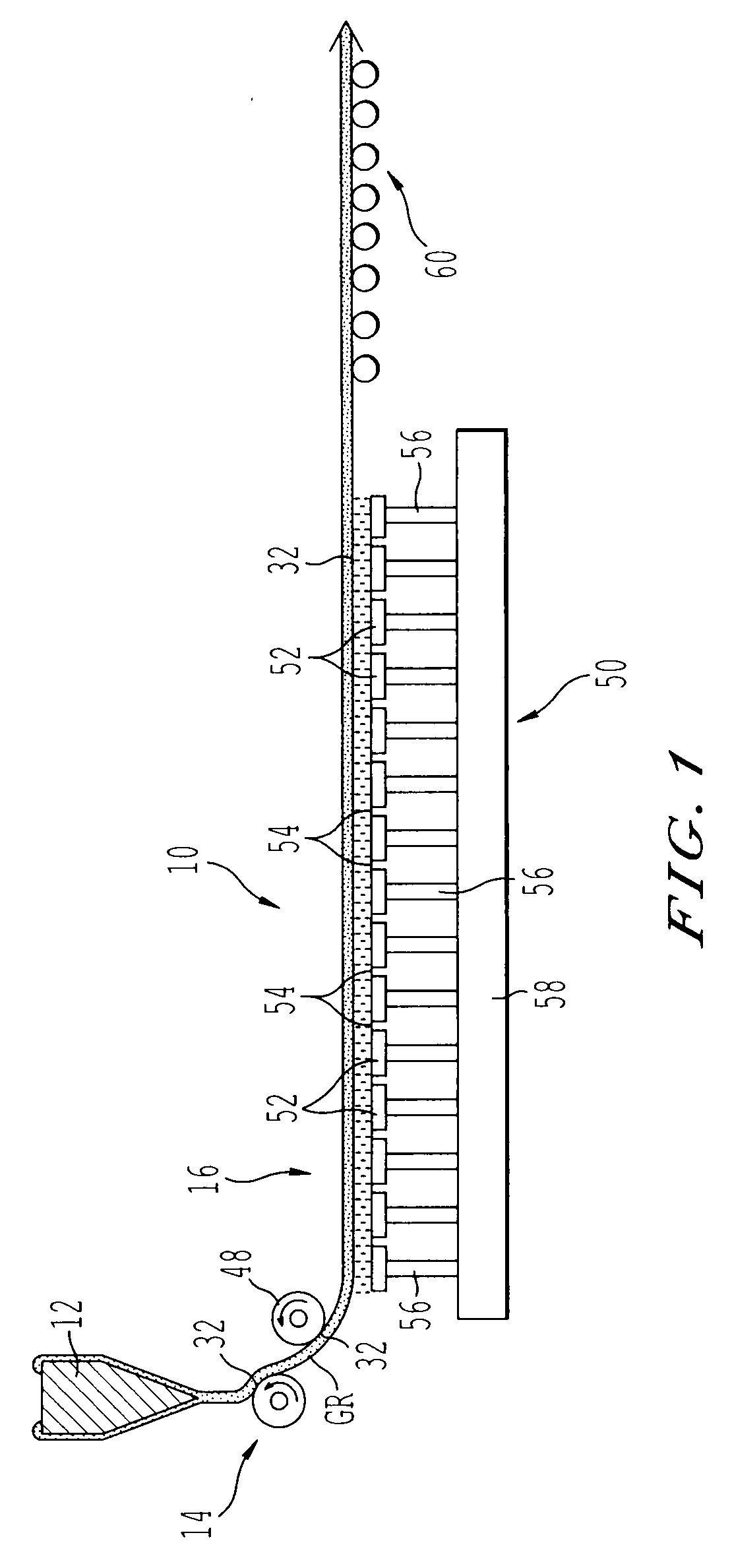

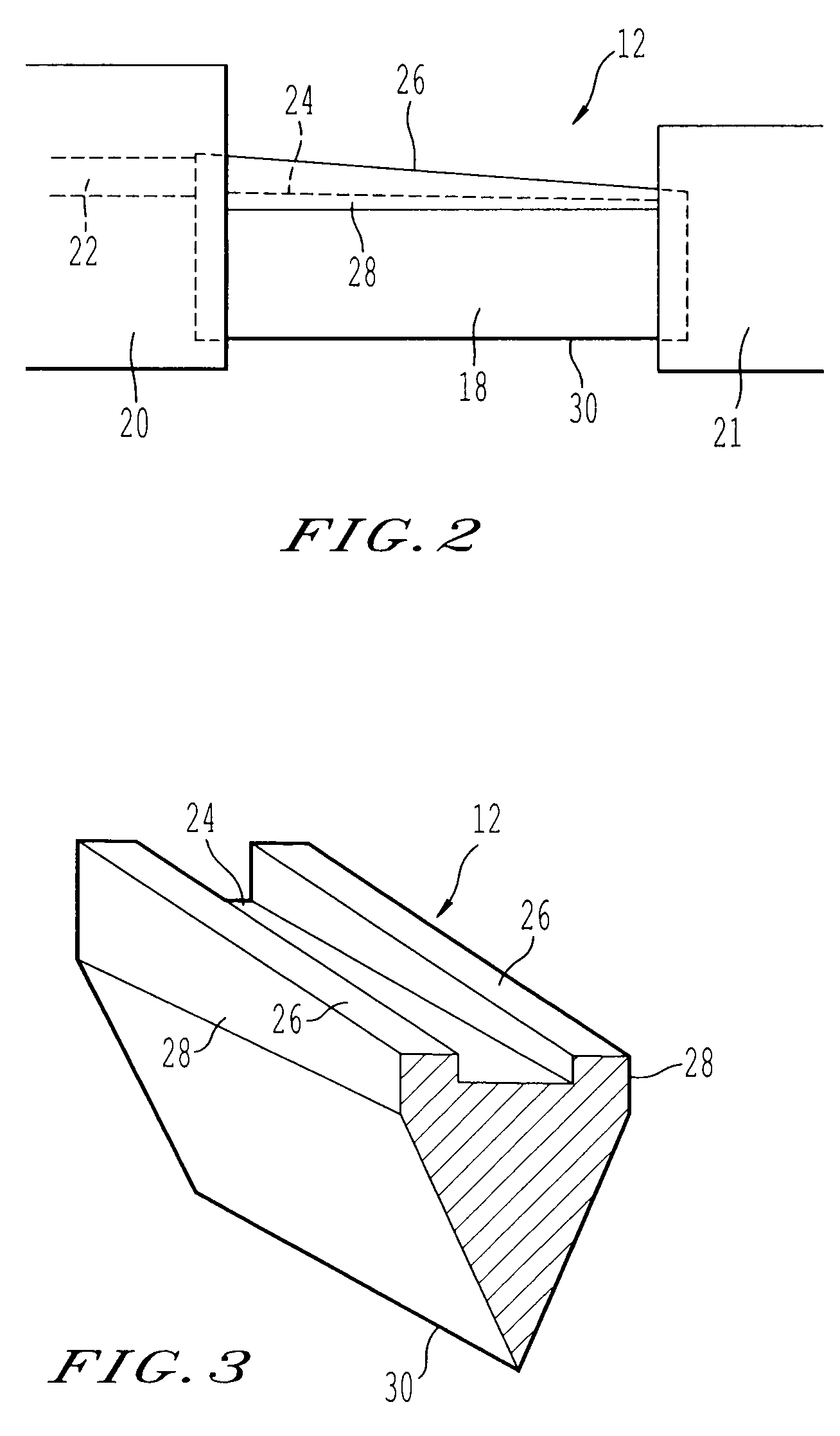

Apparatus for manufacturing sheet glass

InactiveUS20050178159A1Well formedHigh devitrificationGlass drawing apparatusGlass transportation apparatusFlat glassThin sheet

In an apparatus for manufacturing thin sheet glass, comprising a forming body 12 including a main body having a cross-sectional shape converging downwardly, the main body being configured to converging streams of molten glass into a single glass ribbon at a lower converged edge portion thereof, the streams of the molten glass flowing down along both surface of the main body; and edge members, the edge members being configured to restrict a width of the molten glass, wherein the glass ribbon formed by the forming body 12 is downwardly pulled to form thin sheet glass; the apparatus further includes a non-contact support member disposed in the vicinity of the lower converged edge portion of the main body, the non-contact support member being configured to form a thin gas layer on a supporting surface thereof, wherein the glass ribbon is supported over an entire width thereof in a non-contact way by the non-contact support member in a course wherein the glass ribbon is downwardly pulled.

Owner:ASAHI GLASS CO LTD

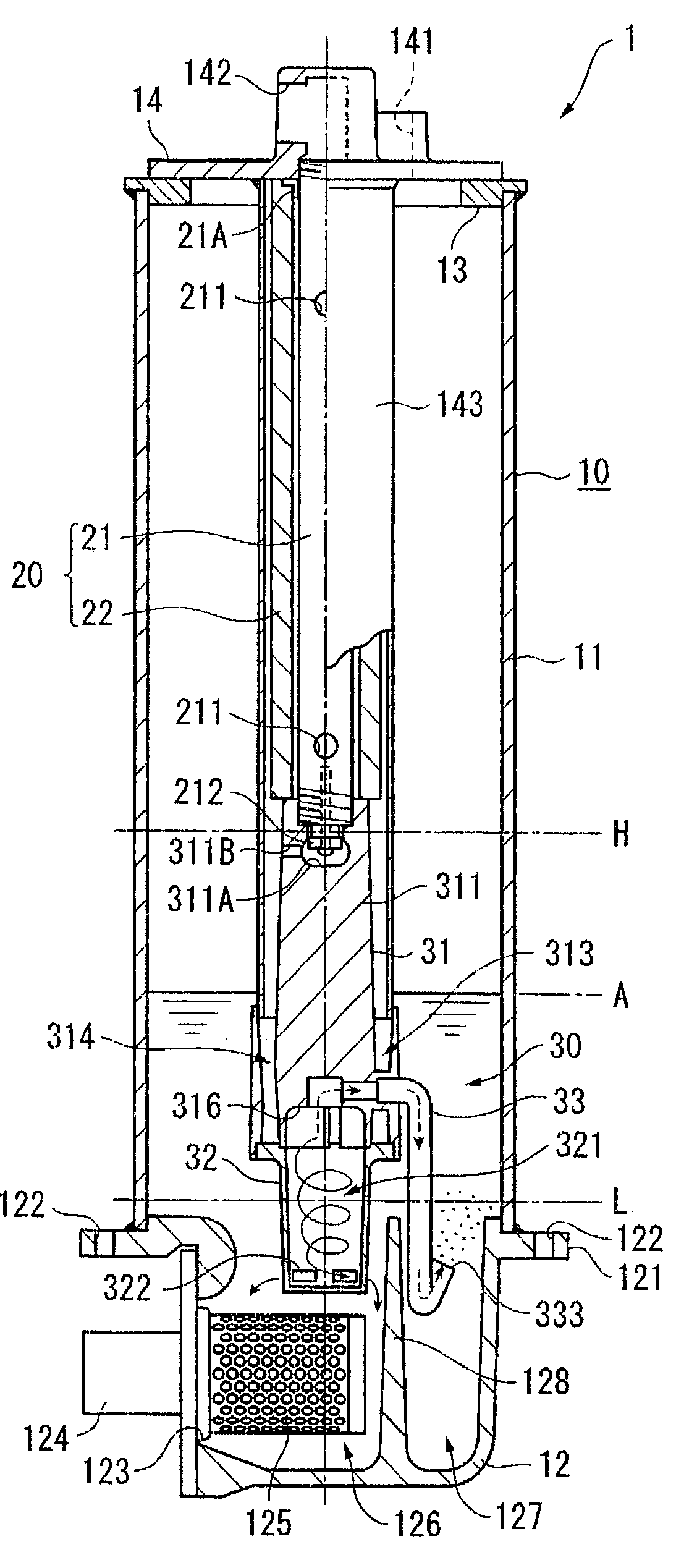

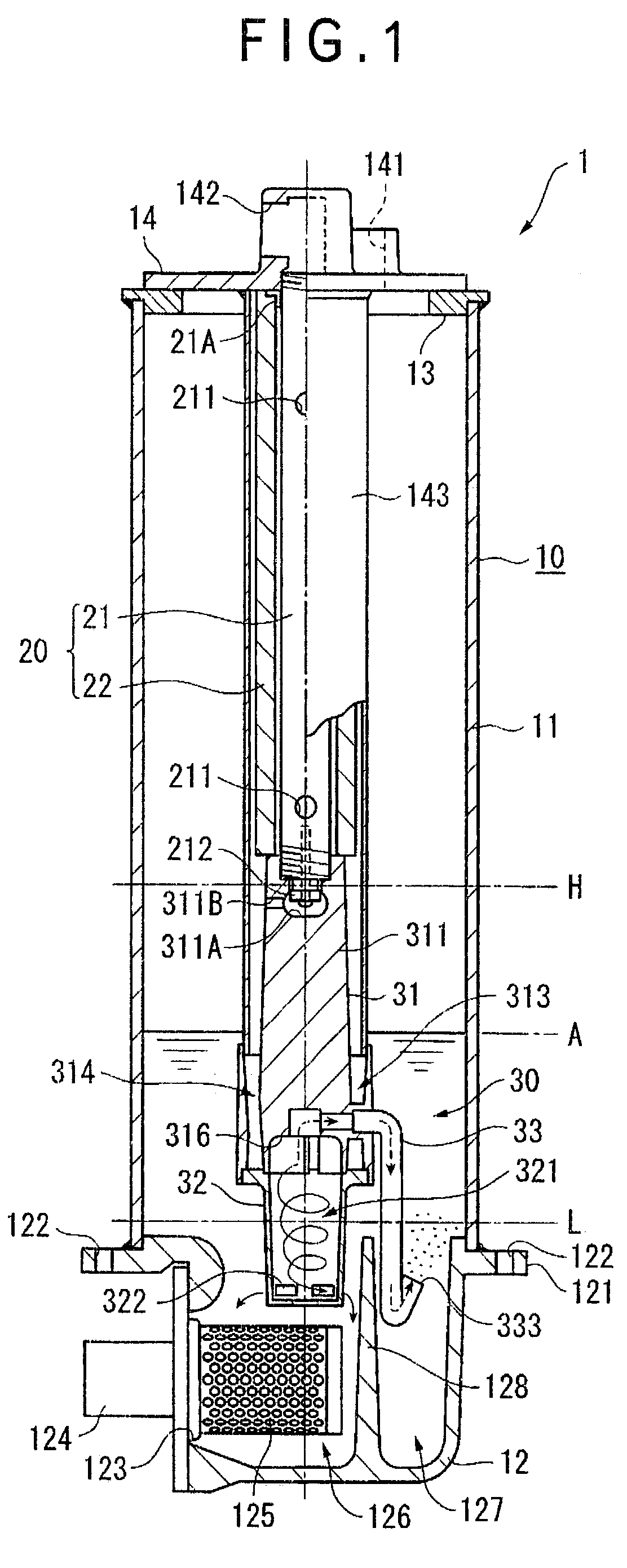

Fluid tank

InactiveUS7105044B2Effectively removes bubbleHigh strengthLiquid degasificationPump assembliesEngineeringAir bubble

A fluid tank fluid is provided which includes a bubble removing device provided therein to remove bubbles from the fluid. The bubble removing device includes a cyclone chamber for generating a swirling current in the fluid flowing therethrough to separate bubbles from the fluid. At least one outflow port is provided through which the fluid from which the bubbles have been separated flows from the cyclone chamber. And an exhaust port is provided through which the bubbles separated from the fluid are driven from the cyclone chamber.

Owner:KOMATSU LTD

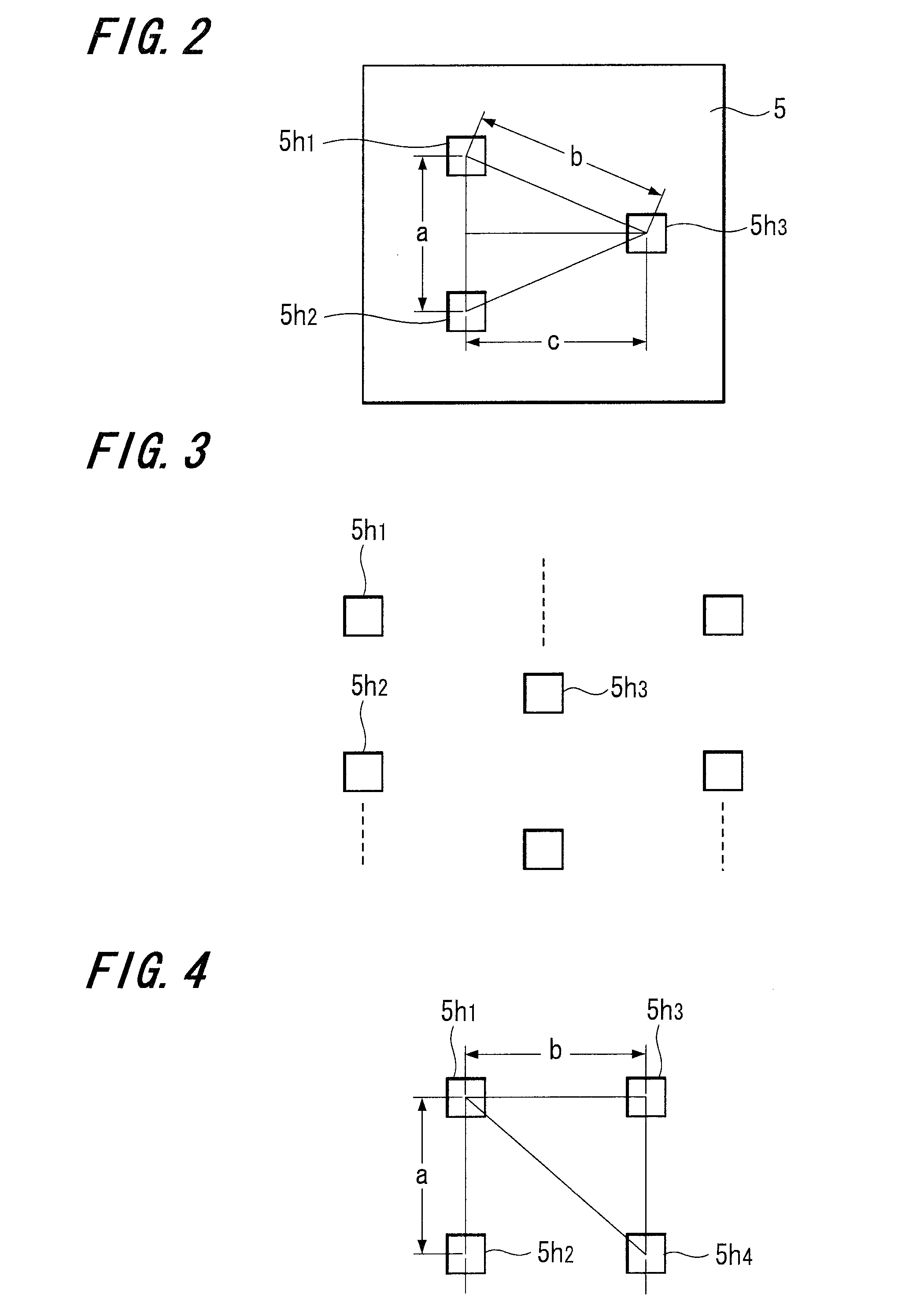

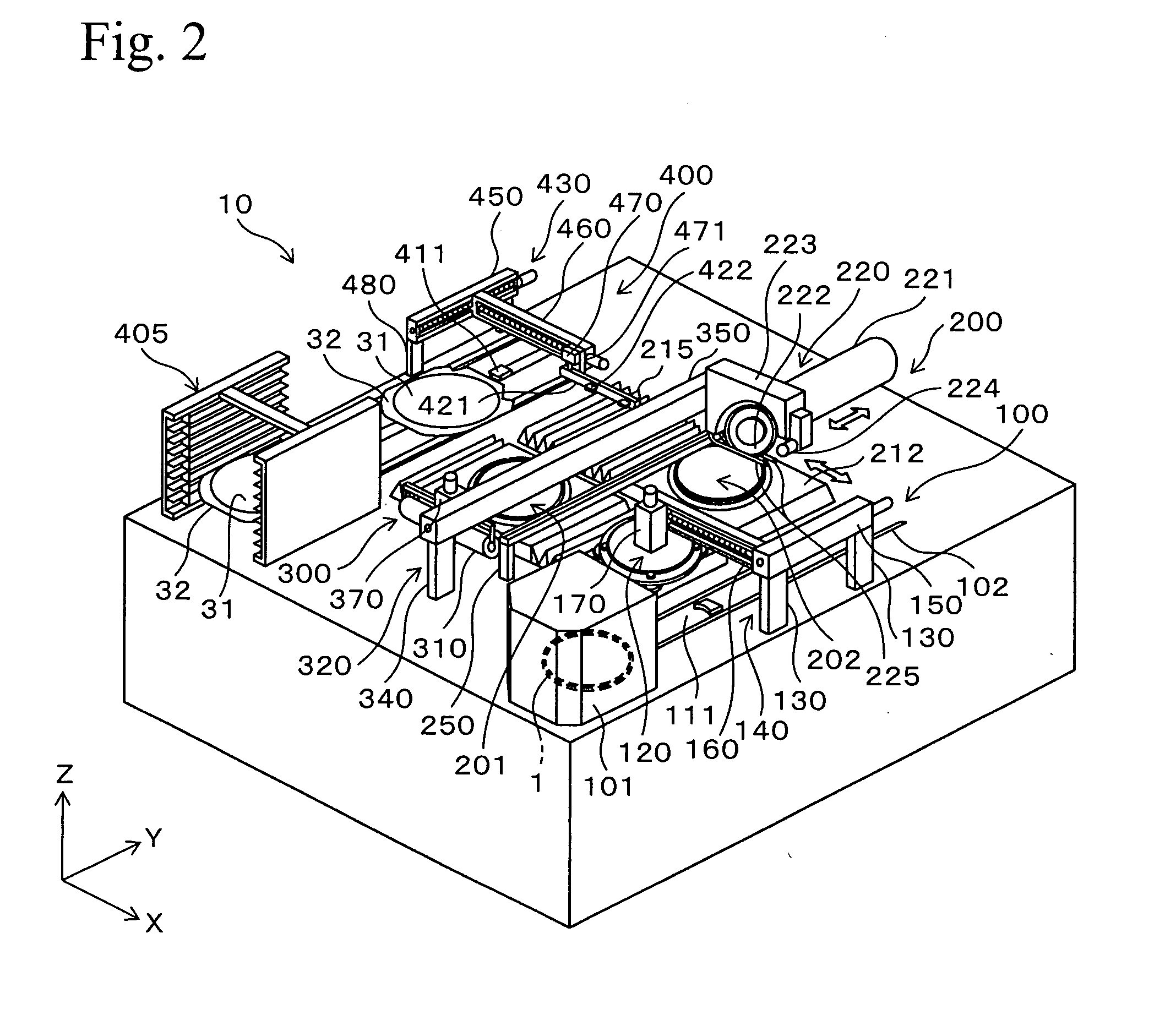

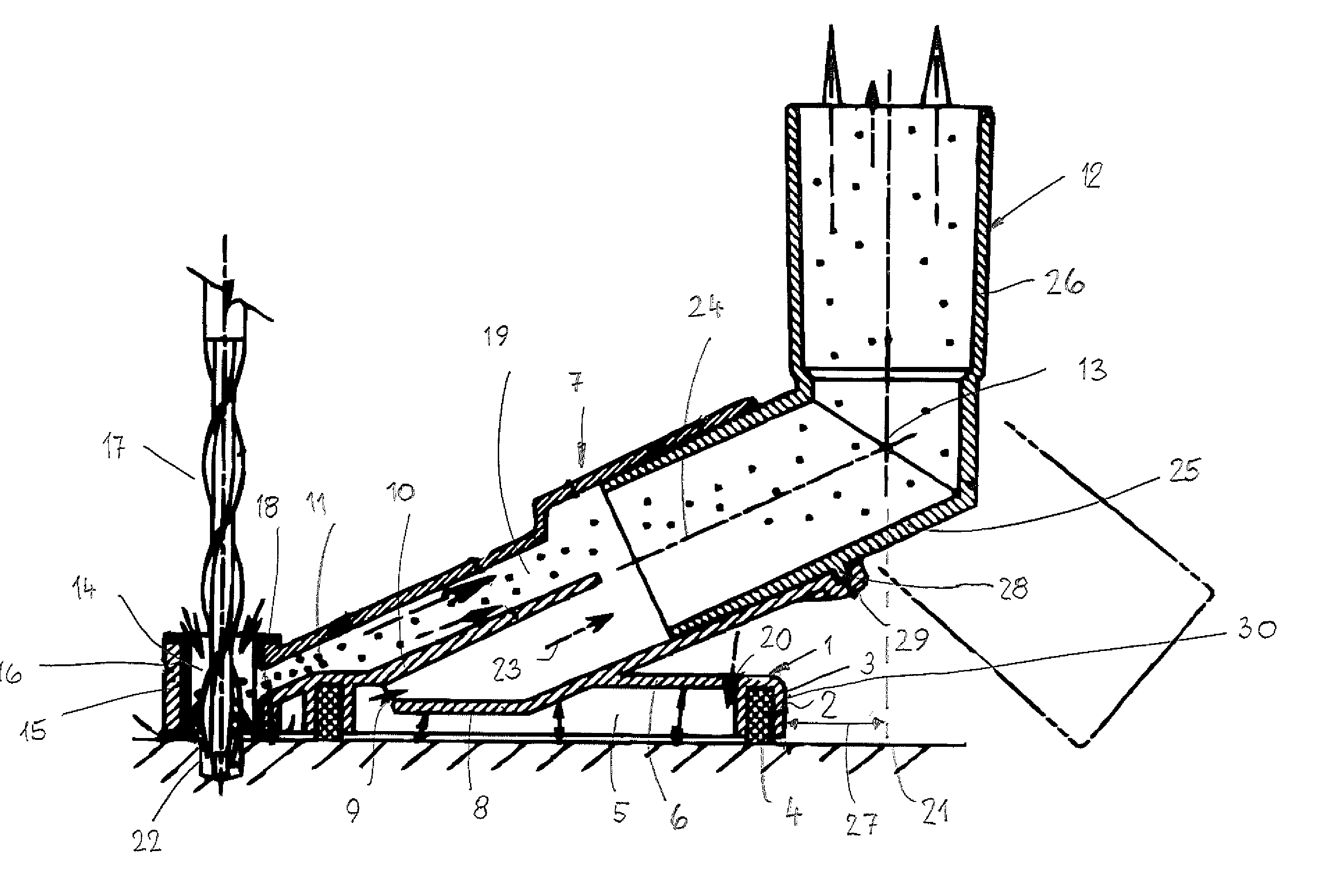

Processing method for wafer

ActiveUS20070231929A1Efficient removalIncreased durabilitySemiconductor/solid-state device manufacturingDevice formEngineering

A processing method for a wafer includes: preparing a wafer which has a device region having plural devices formed on a surface of the wafer; and a peripheral reinforcing portion which is integrally formed around the device region and has a projection projecting outwardly on a rear surface of the wafer. The processing method further includes: holding the wafer on a holding surface of a rotatable holding table such that the rear surface of the wafer is exposed and the surface of the wafer closely contacts the holding table. The processing method further includes: thinning the peripheral reinforcing portion by cutting and removing at least the projection of the peripheral reinforcing portion of the wafer by using a cutting tool having a rotational shaft parallel to the holding surface, while rotating the wafer by rotating the holding table after the holding of the wafer. The peripheral reinforcing portion is thinned so as to have a thickness equal to or thinner than that of the device region by the thinning.

Owner:DISCO CORP

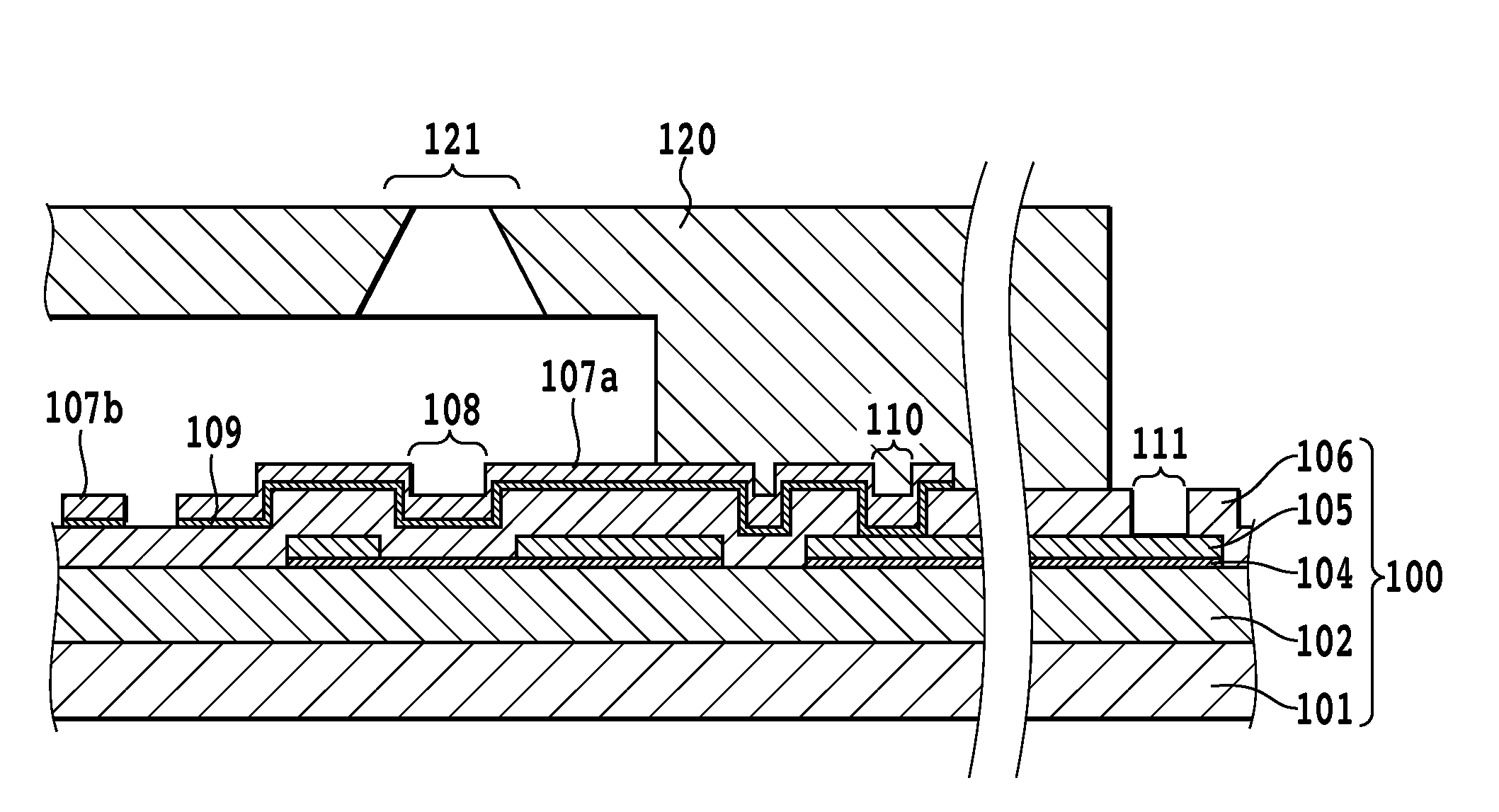

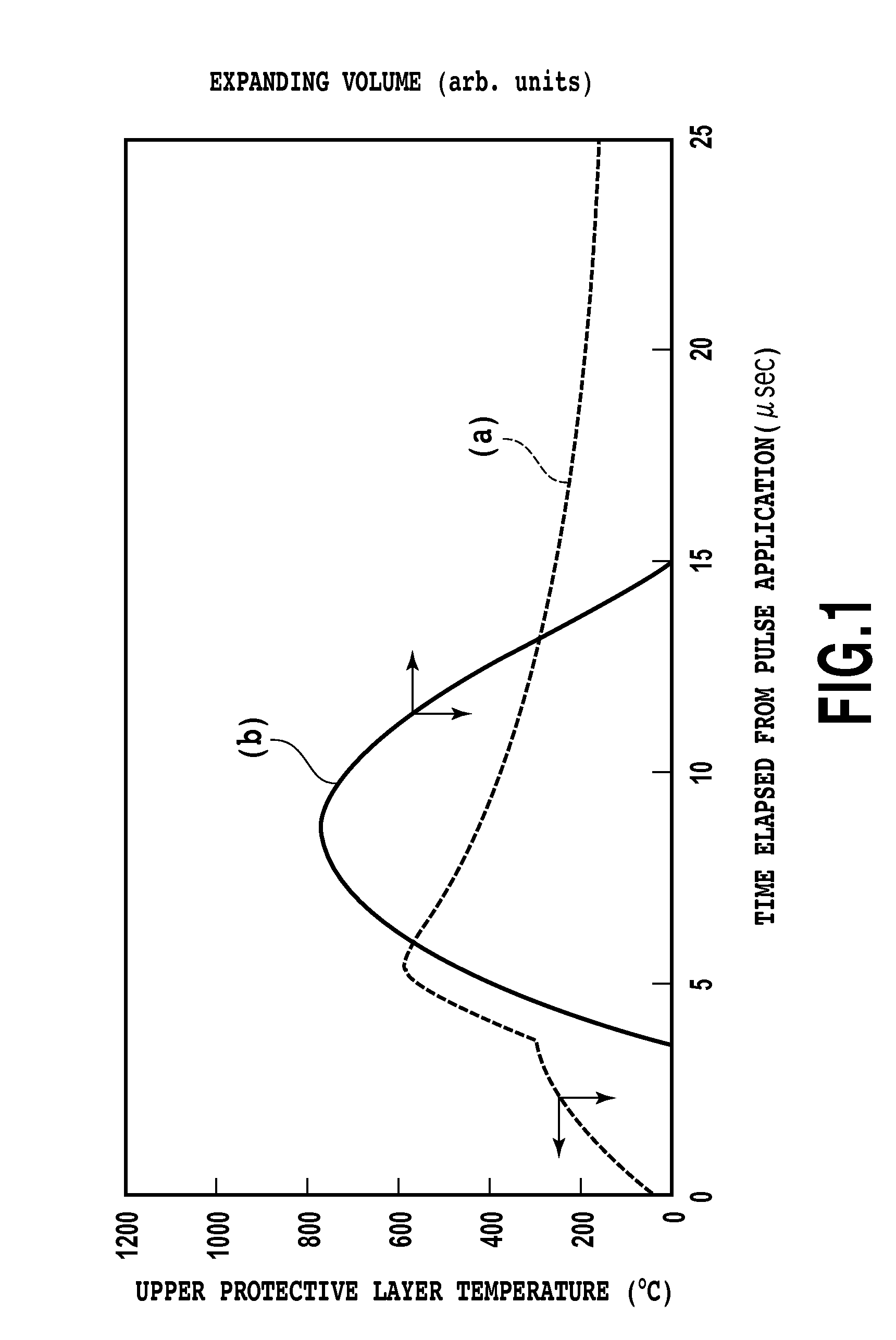

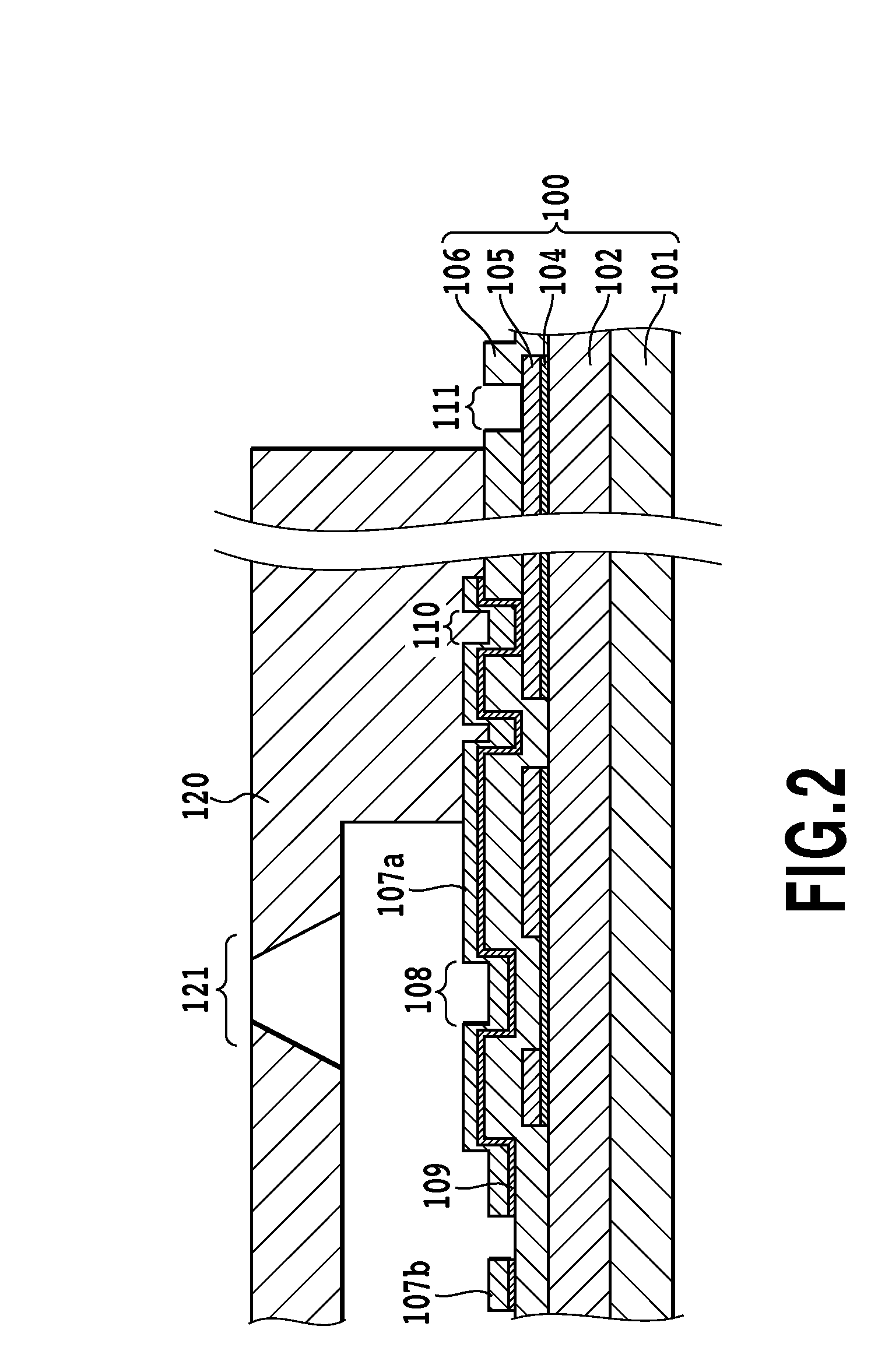

Liquid ejection head

On the liquid ejection head substrate, an upper protective layer, as well as coming into contact with the resin layer which configures a path forming member such as a ejection opening, comes into contact with ink in an heat generating portion inside the channel formed. The upper protective layer contains iridium and silicon. The upper protective layer is configured so that, at a surface in contact with the ink and resin layer, Ir100-xSix attains a 15 at. %≦X≦30 at. % silicon content rate, and that X more becomes zero as a position in the upper protective layer more approaches an adhesion layer. As a result, at the interface where the upper protective layer comes into contact with the path forming member, by the silicon attaining the heretofore described content rate, it is possible to improve the adhesion with the path forming member made of resin compared with a case of using iridium alone.

Owner:CANON KK

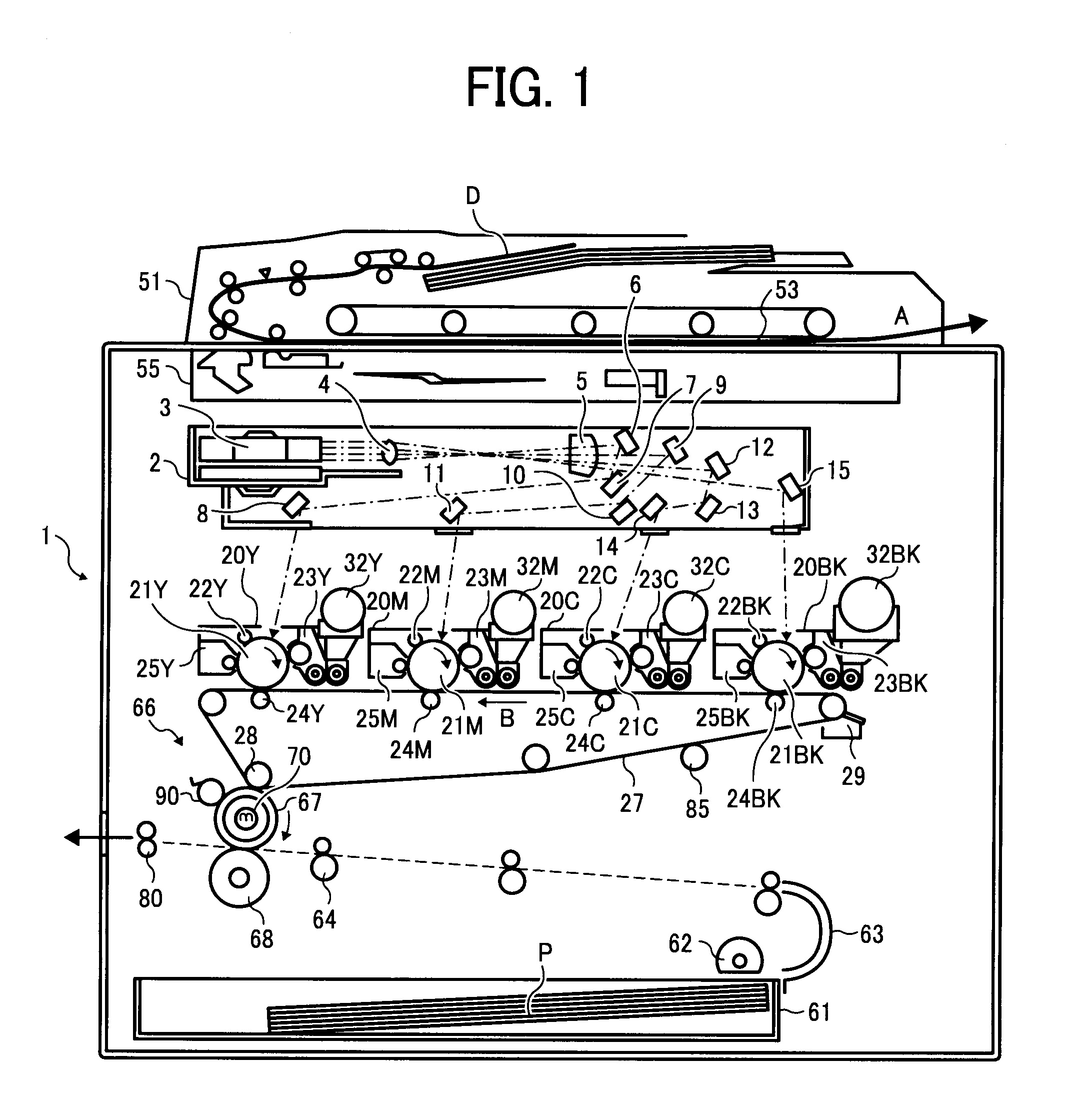

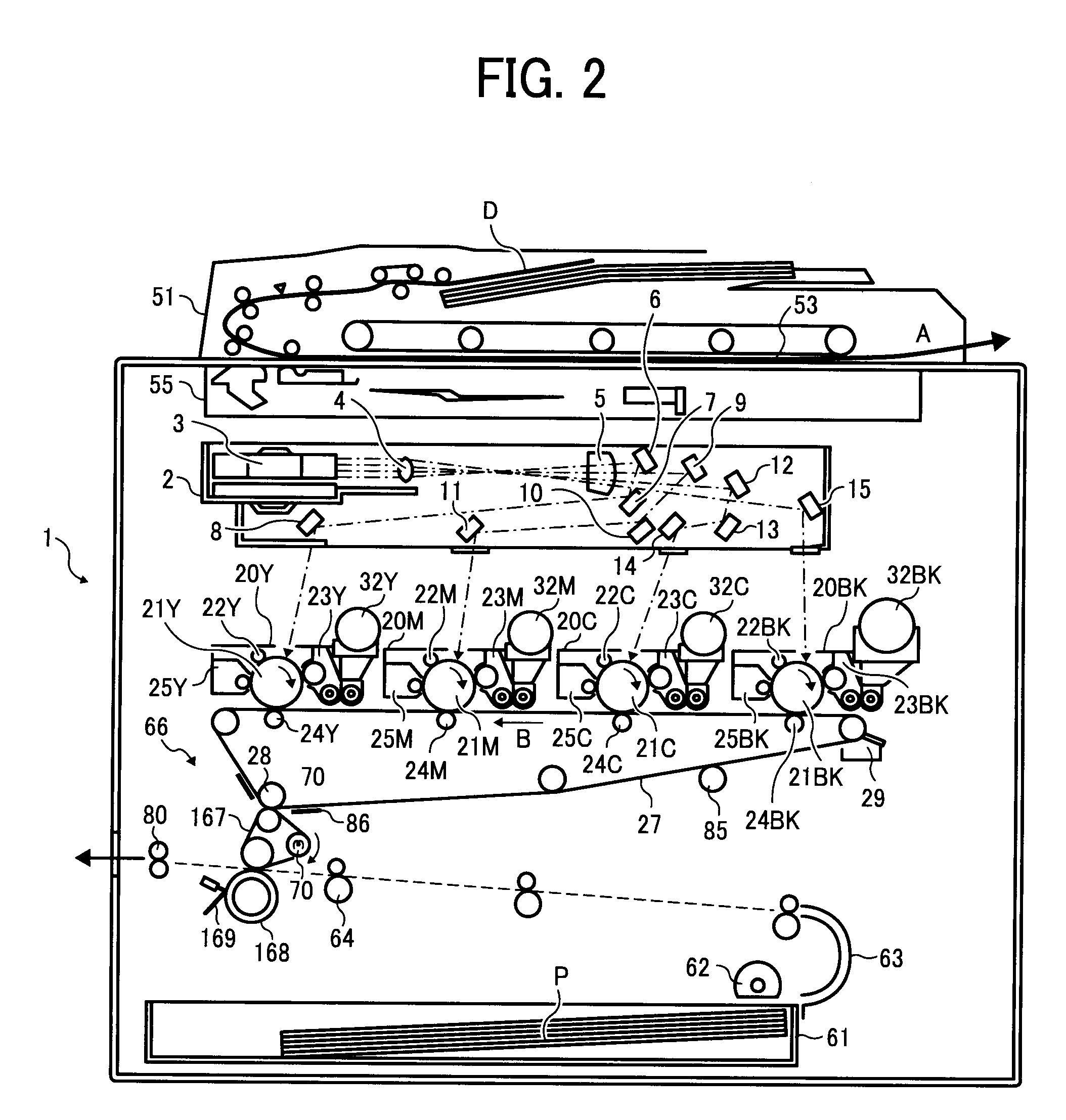

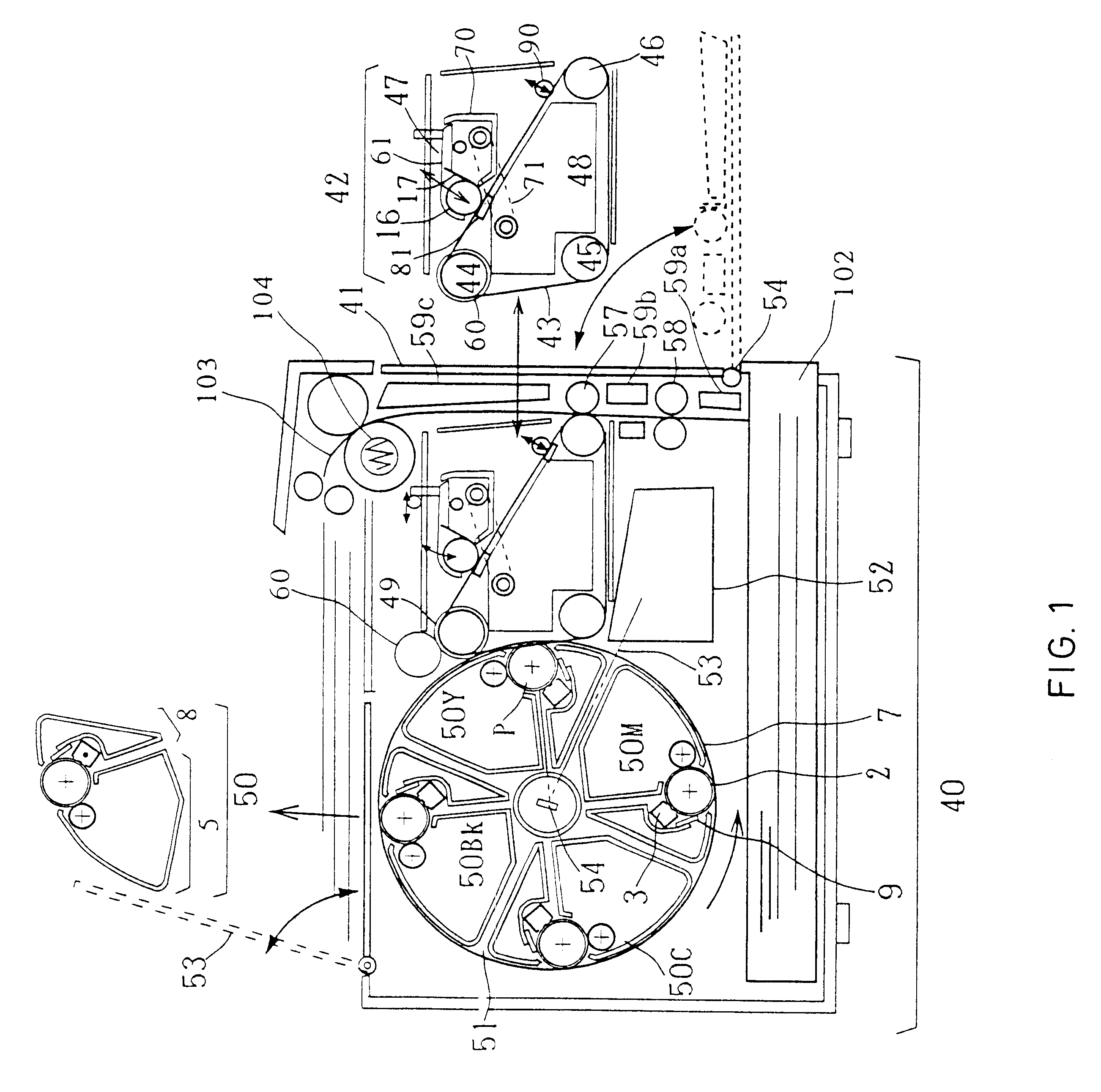

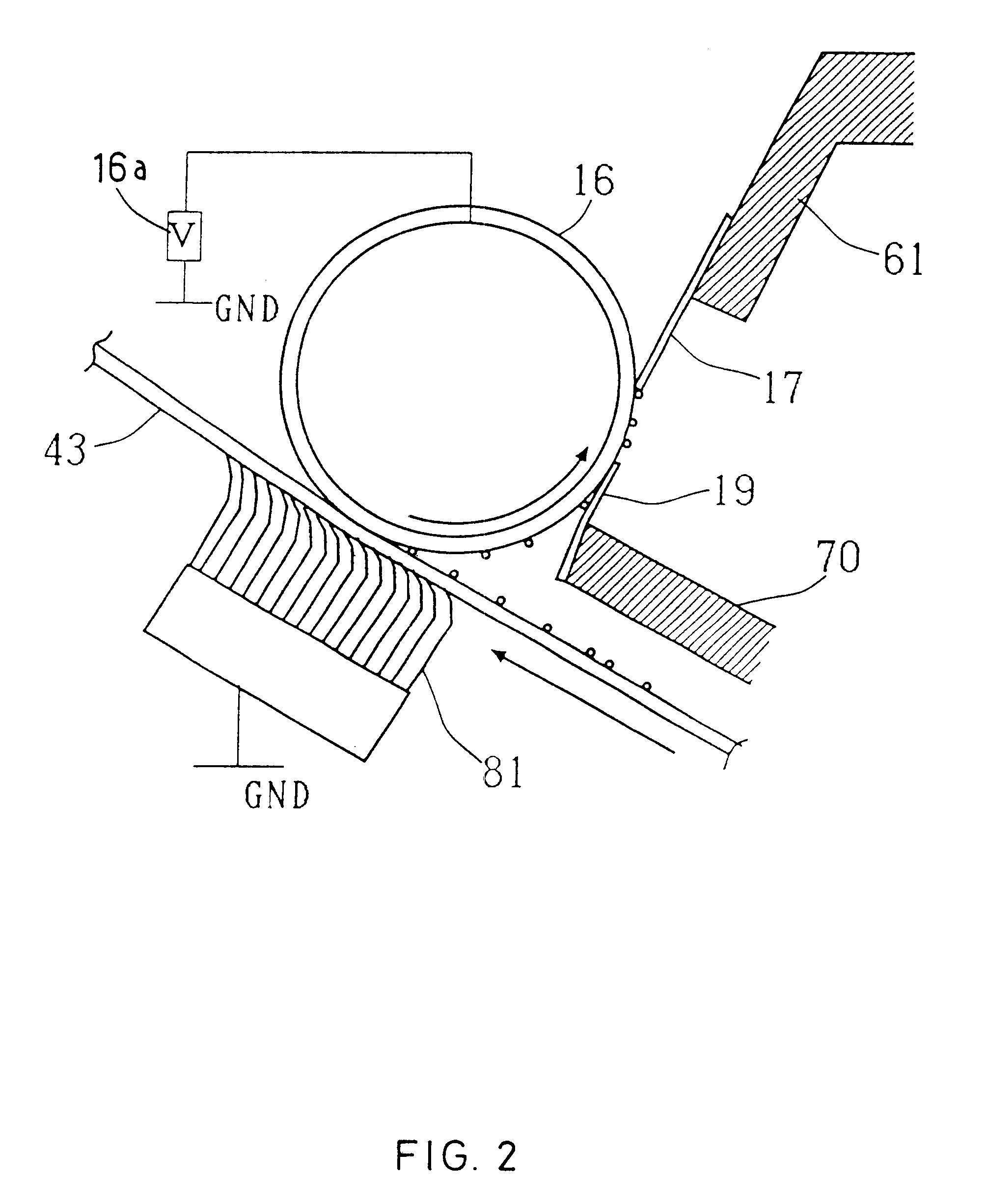

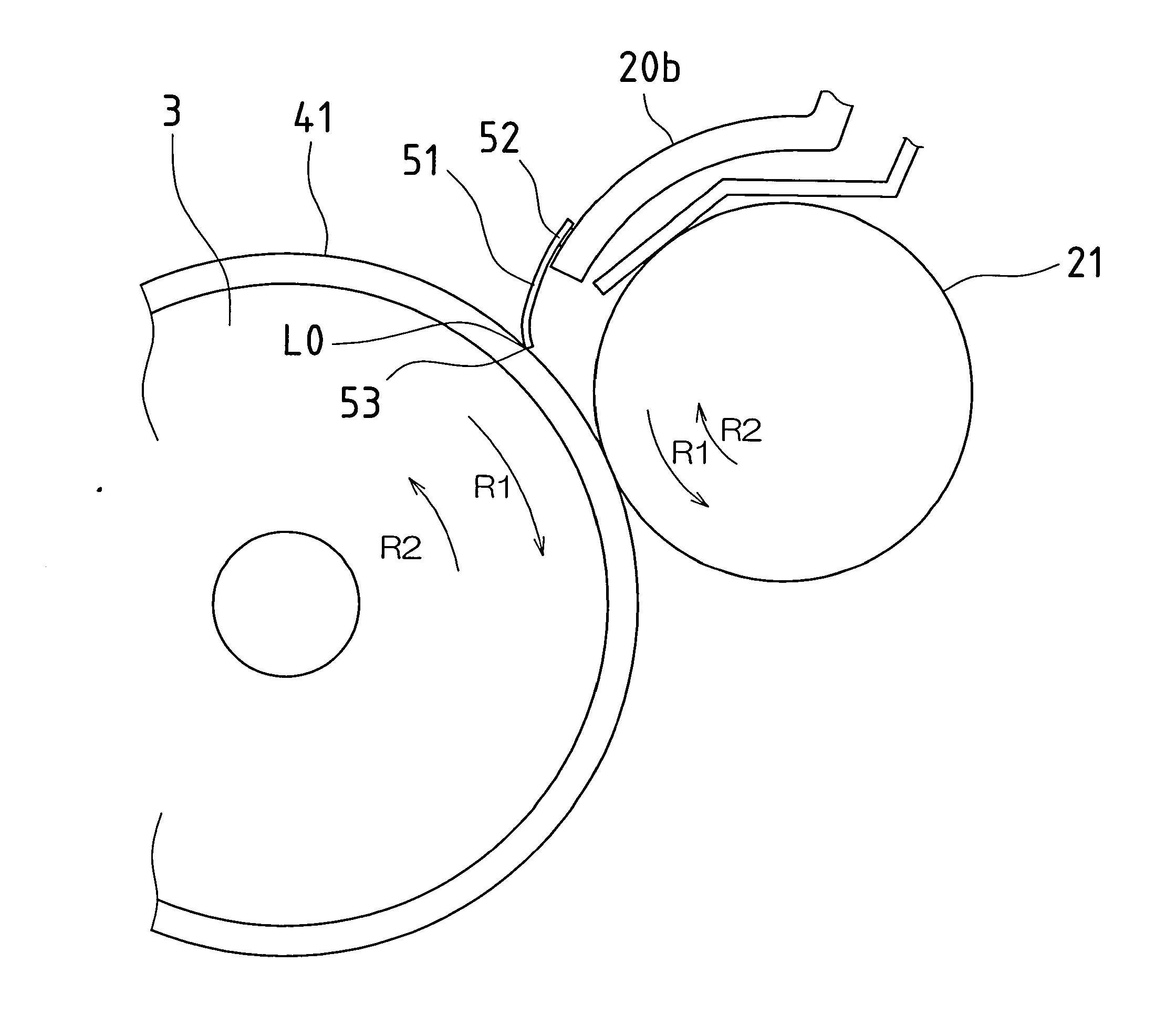

Image forming apparatus, transfer belt unit, cleaning device and cleaner unit used for image forming apparatus

InactiveUS6477344B1Reliable removalSimple configurationElectrographic process apparatusImage formationMechanical engineering

Owner:PANASONIC CORP

Image forming apparatus

InactiveUS20070110482A1Easy and reliable removalPrevent outflowElectrographic process apparatusImage formationEngineering

Owner:SHARP KK

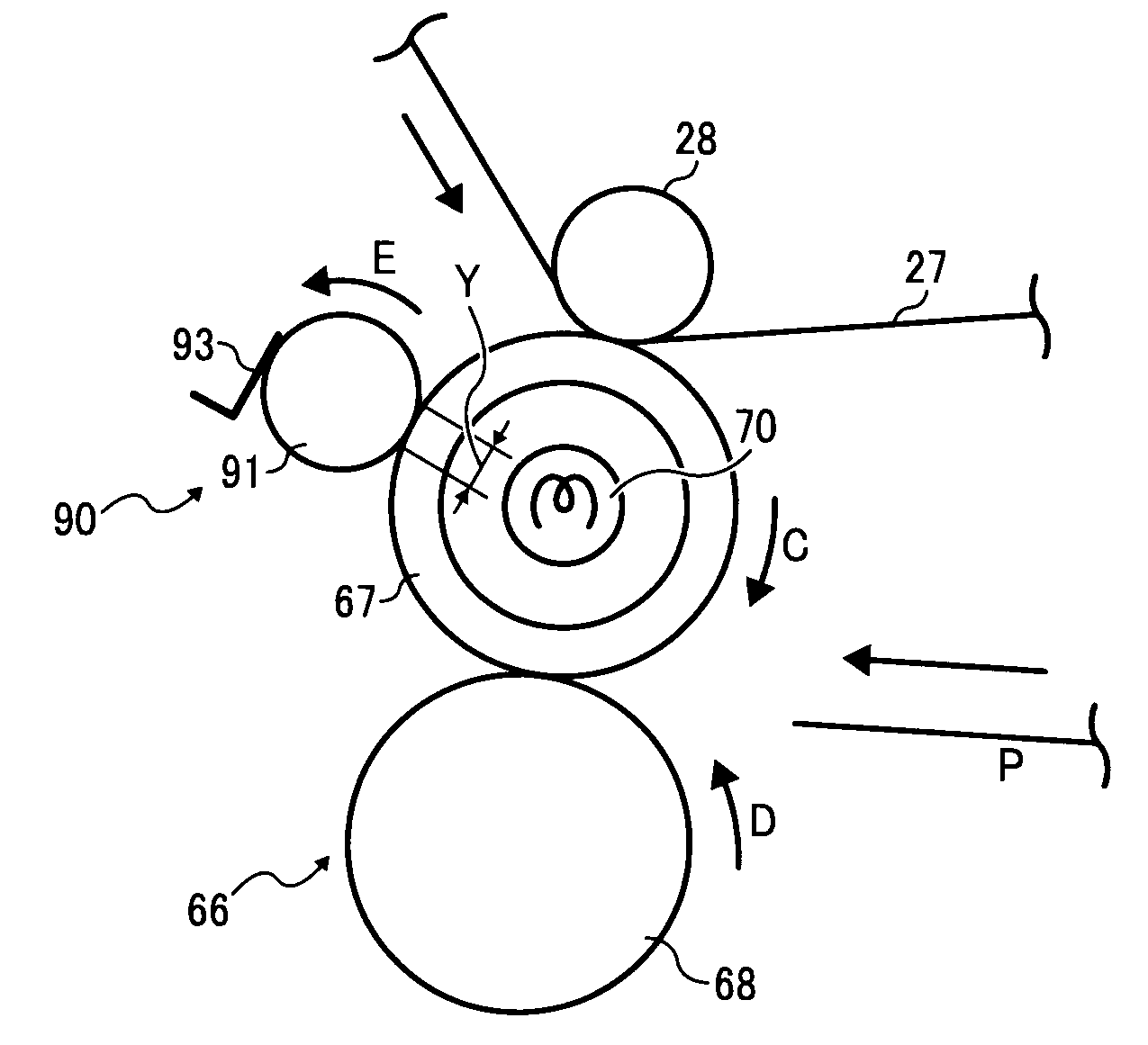

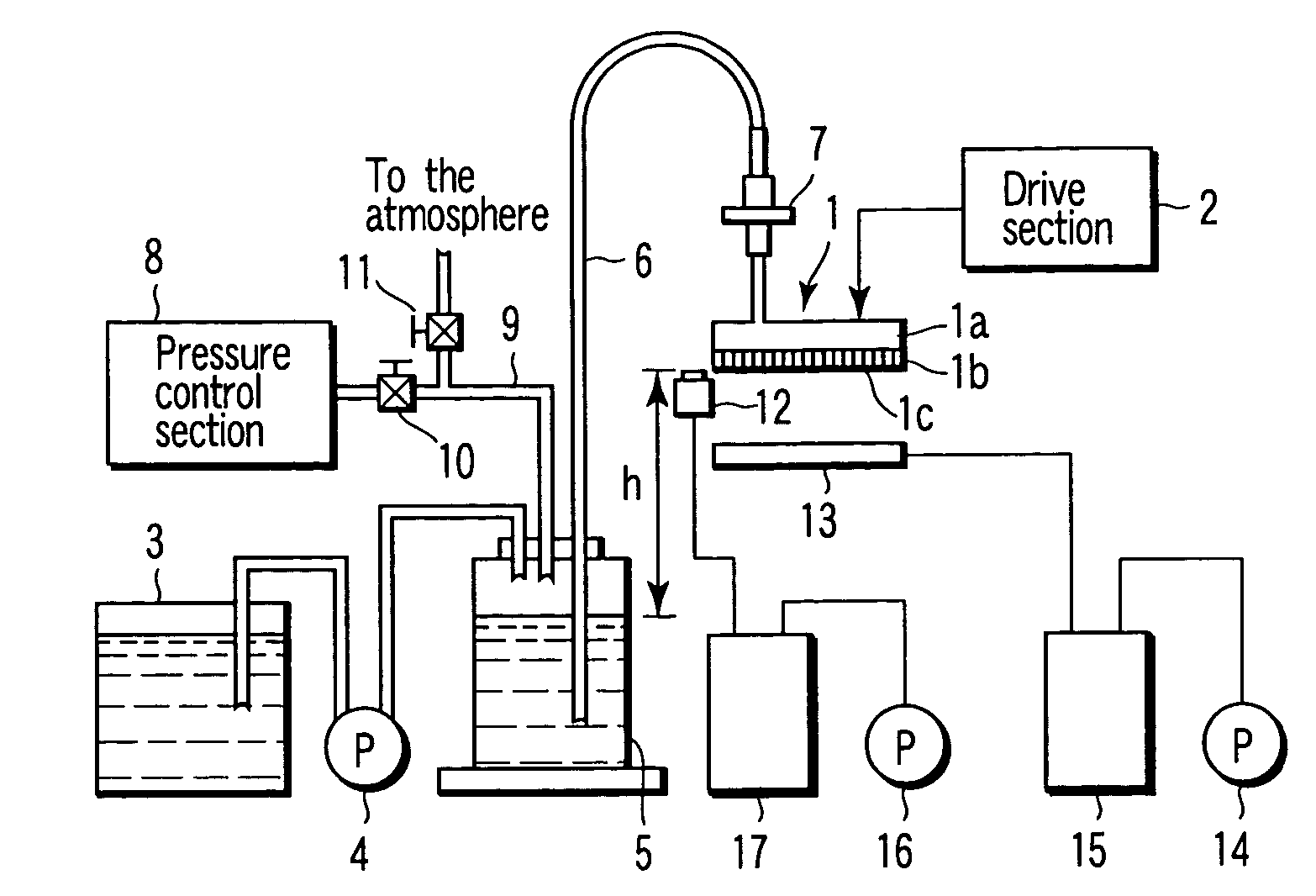

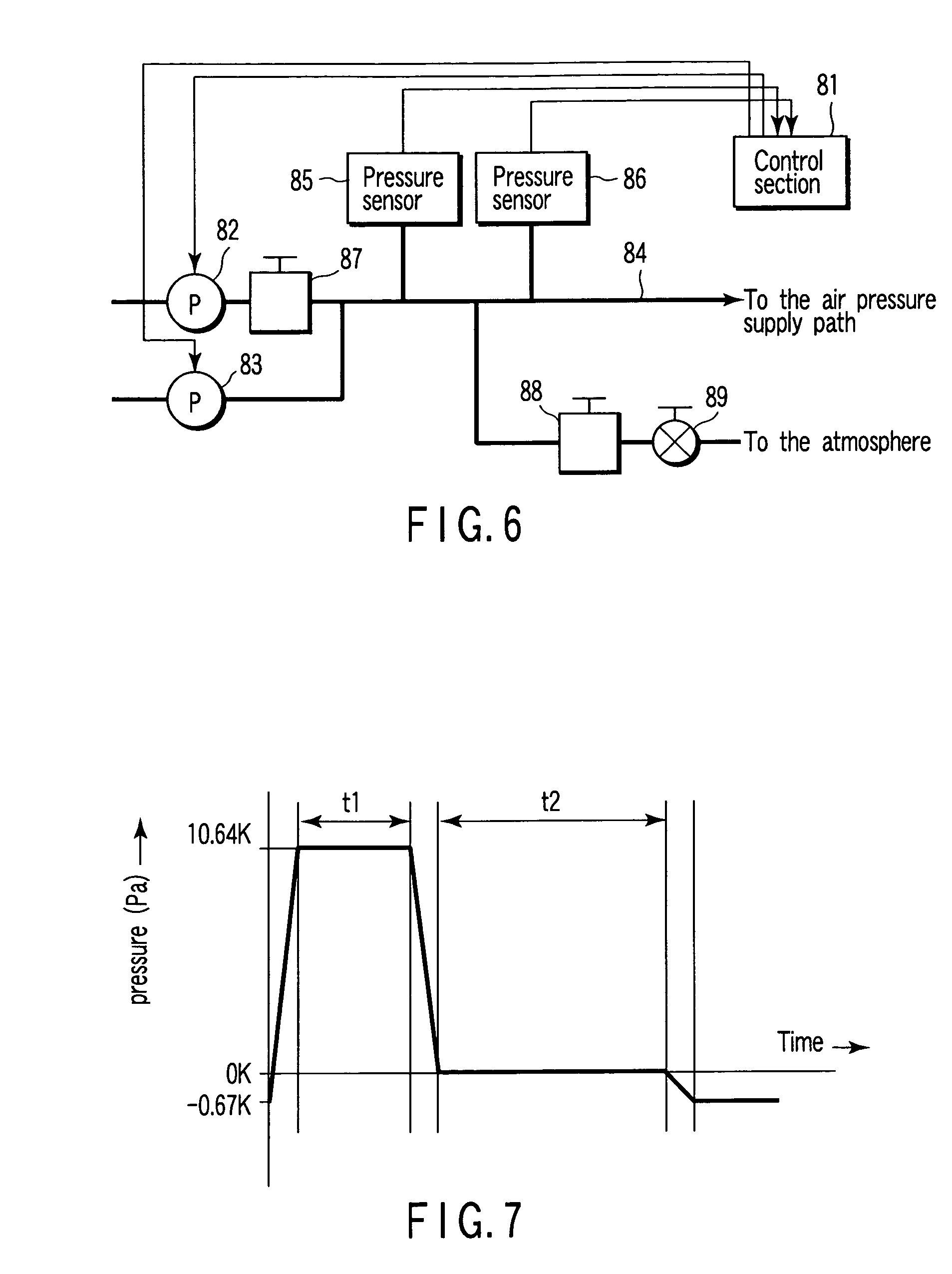

Maintenance method and maintenance apparatus for ink jet head

InactiveUS7044579B2Reliable removalReliably removedPrintingVena contracta diameterAtmospheric pressure

A maintenance apparatus is used for maintaining an ink jet head which ejects ink supplied via an ink supply path, as ink droplets from a plurality of orifices arranged in an orifice plate. The apparatus comprises a pressure control section which controls the pressure in the ink supply path against the atmospheric pressure applied to a surface of the ink to push ink out of each orifice and then align the surface of the ink to a surface of the orifice plate, and an ink suction section which sucks ink near each orifice in a state where the ink surface is approximately aligned to the surface of the orifice plate by the pressure control section.

Owner:TOSHIBA TEC KK

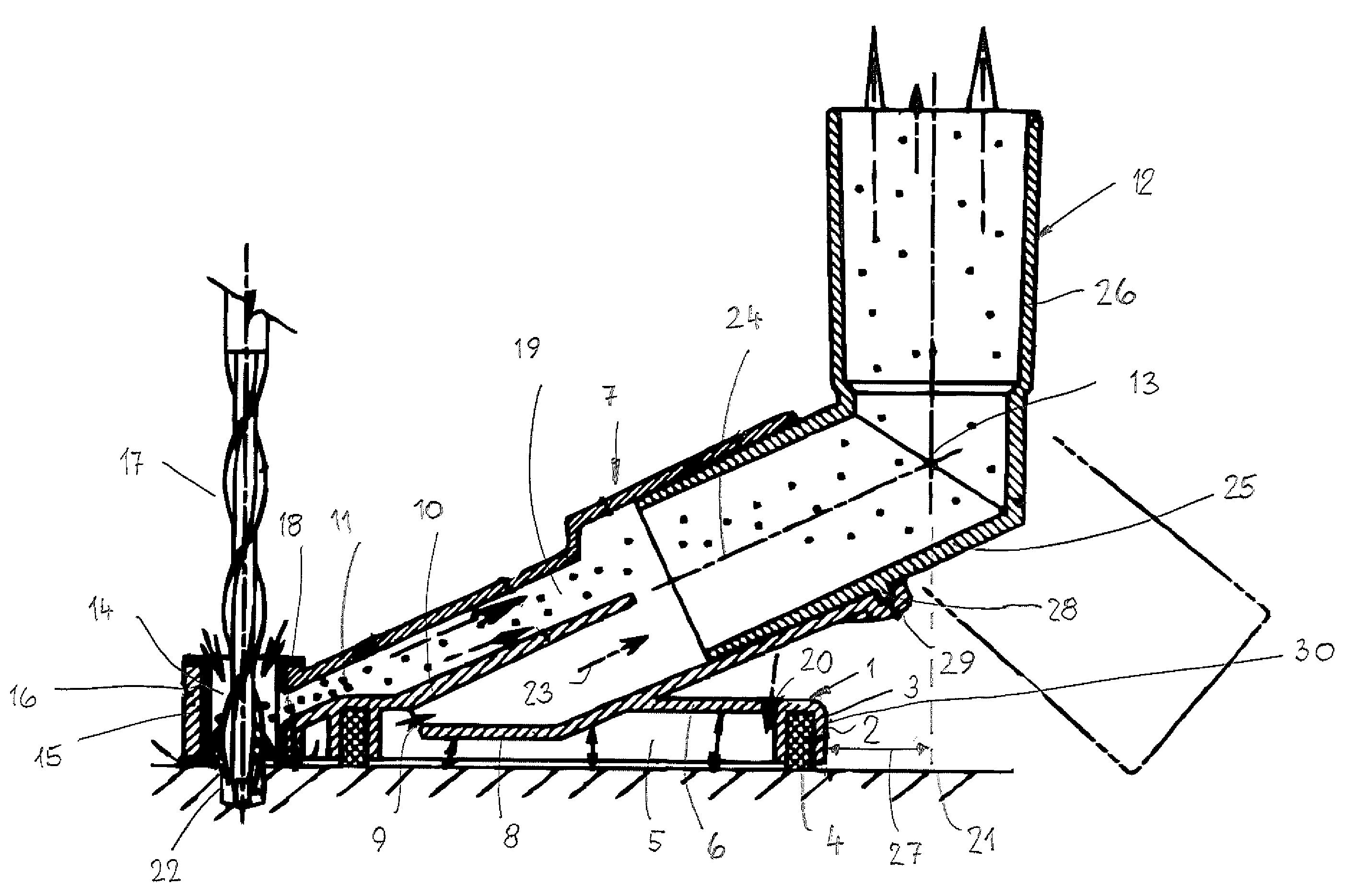

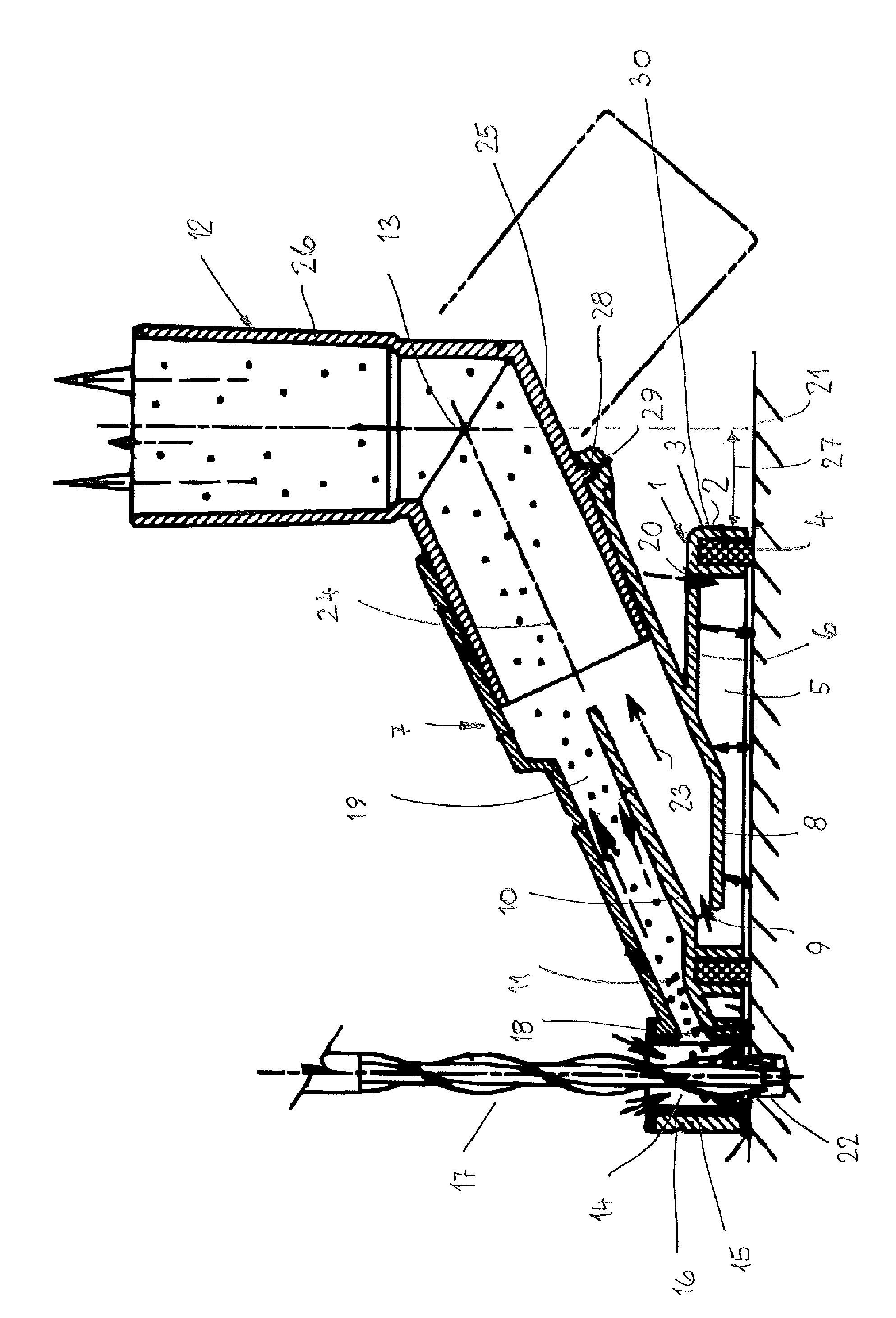

Device for Removing by Suction Drill Dust when Drilling Holes into Walls

InactiveUS20090317200A1Convenience to workMinimal spaceDrilling/boring measurement devicesThread cutting feeding devicesEngineeringVacuum chamber

A device for removing drill dust when drilling a hole into a wall has a base member and at least one vacuum chamber provided in the base member. At least one suction site is provided. A connector is connected to the base member and adapted to connect a vacuum unit that removes by suction at the suction site the drill dust produced by drilling. The at least one suction site and the at least one vacuum chamber are spatially separated from one another.

Owner:ELECTROSTAR SCHOETTLE

Intermediate transfer device and image forming device

InactiveUS7190919B2Reliably removedReduce mechanical stressElectrographic process apparatusEngineeringVoltage

An intermediate transfer device has: an intermediate transfer belt supported by a plurality of belt supporting mechanisms so as to be able to circulate, and having elasticity at least in a direction of circulating; a first bias applying mechanism applying a first bias voltage to toner on a toner carrier surface of the intermediate transfer belt; a layer thinning mechanism contacting the toner carrier surface and electrostatically attracting the toner which is on the toner carrier surface so as to thin a layer of the toner; a second bias applying mechanism applying a second bias voltage to the toner whose layer has been thinned; an image carrier carrying a visible image to be transferred onto the toner carrier surface, the toner on the toner carrier surface, to which the second bias voltage has been applied, being transferred onto the image carrier; and a toner removing mechanism removing the toner on the image carrier.

Owner:FUJIFILM BUSINESS INNOVATION CORP

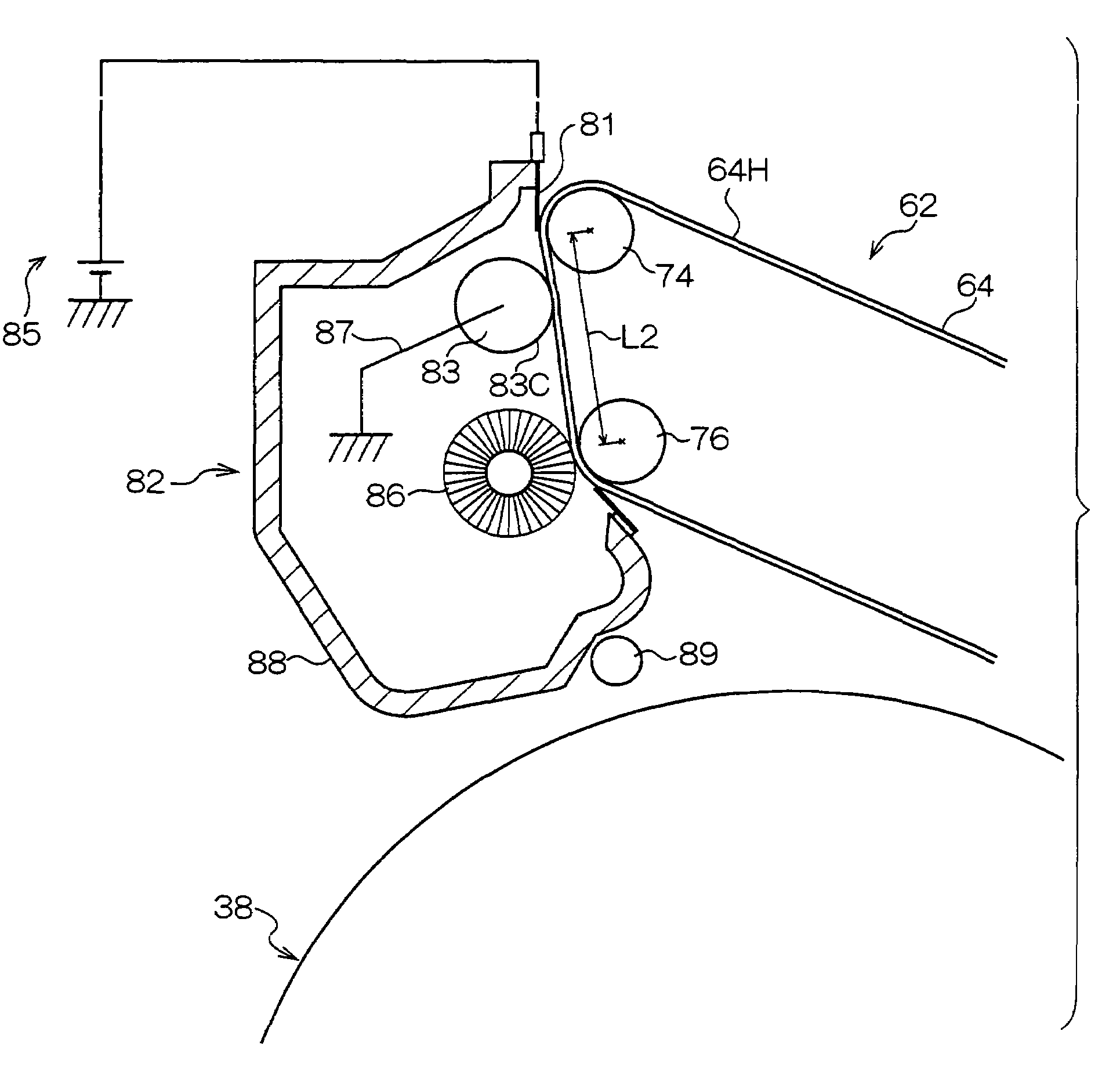

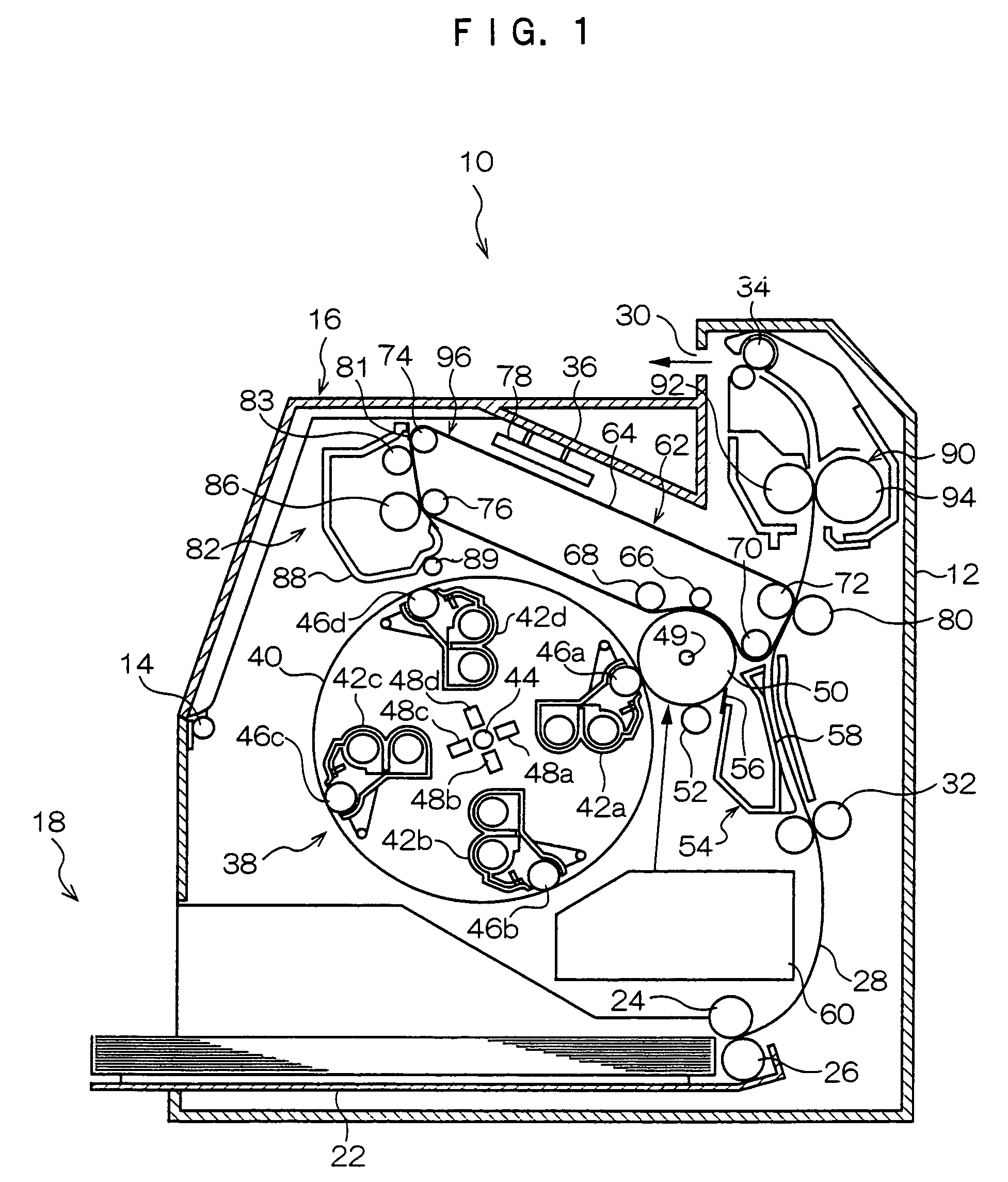

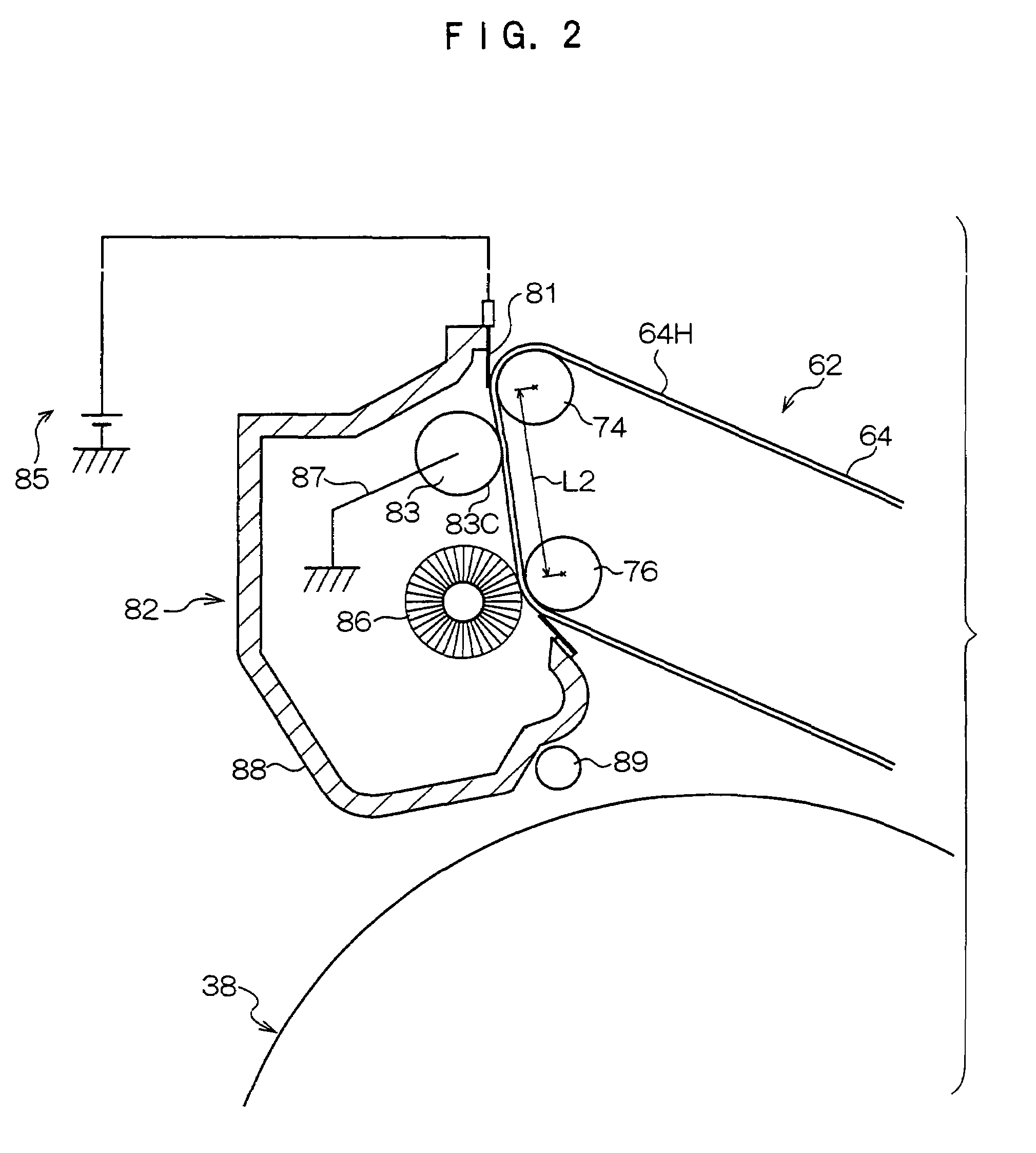

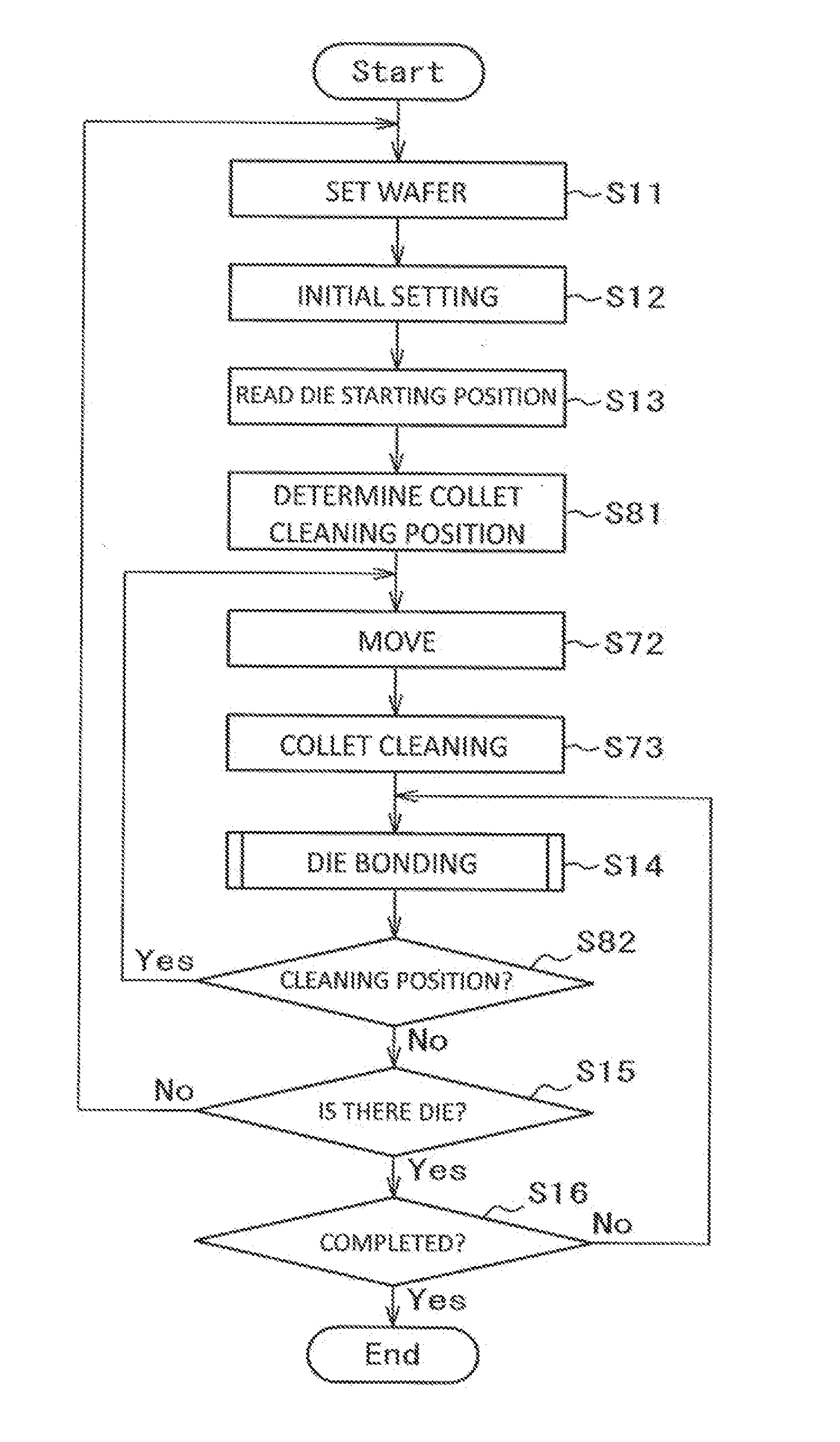

Collet Cleaning Method and Die Bonder Using the Same

ActiveUS20140251535A1Reliable removalImprove adhesionLamination ancillary operationsSynthetic resin layered productsForeign matterDicing tape

An object of the present invention is to provide a collet cleaning method and a die bonder using the same in which a collet can be cleaned without adding a new unit, and foreign substances with high adhesive power can be reliably removed without scattering the foreign substances.A die bonder includes a pickup device, a bonding head unit having a collet that absorbs dies from a wafer at the timing of lifting of the pickup device, and a control unit that controls the pickup device and the bonding head unit. The collet is moved to a position of a dicing tape at which no dies of the wafer held by a wafer ring exist to be brought into contact with the adhesive surface of the dicing tape, so that foreign substances attached to the tip end of the collet are removed.

Owner:FASFORD TECH

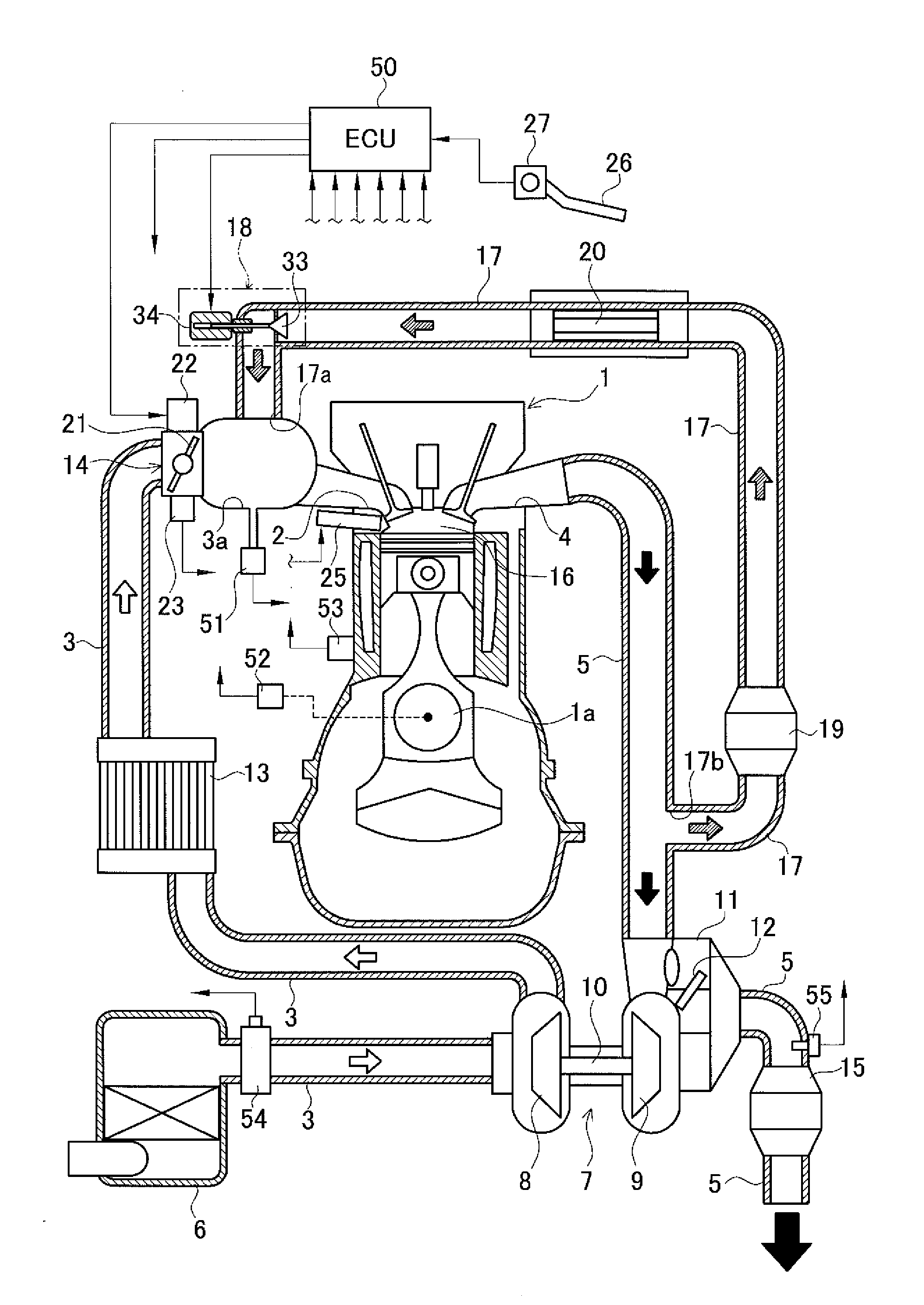

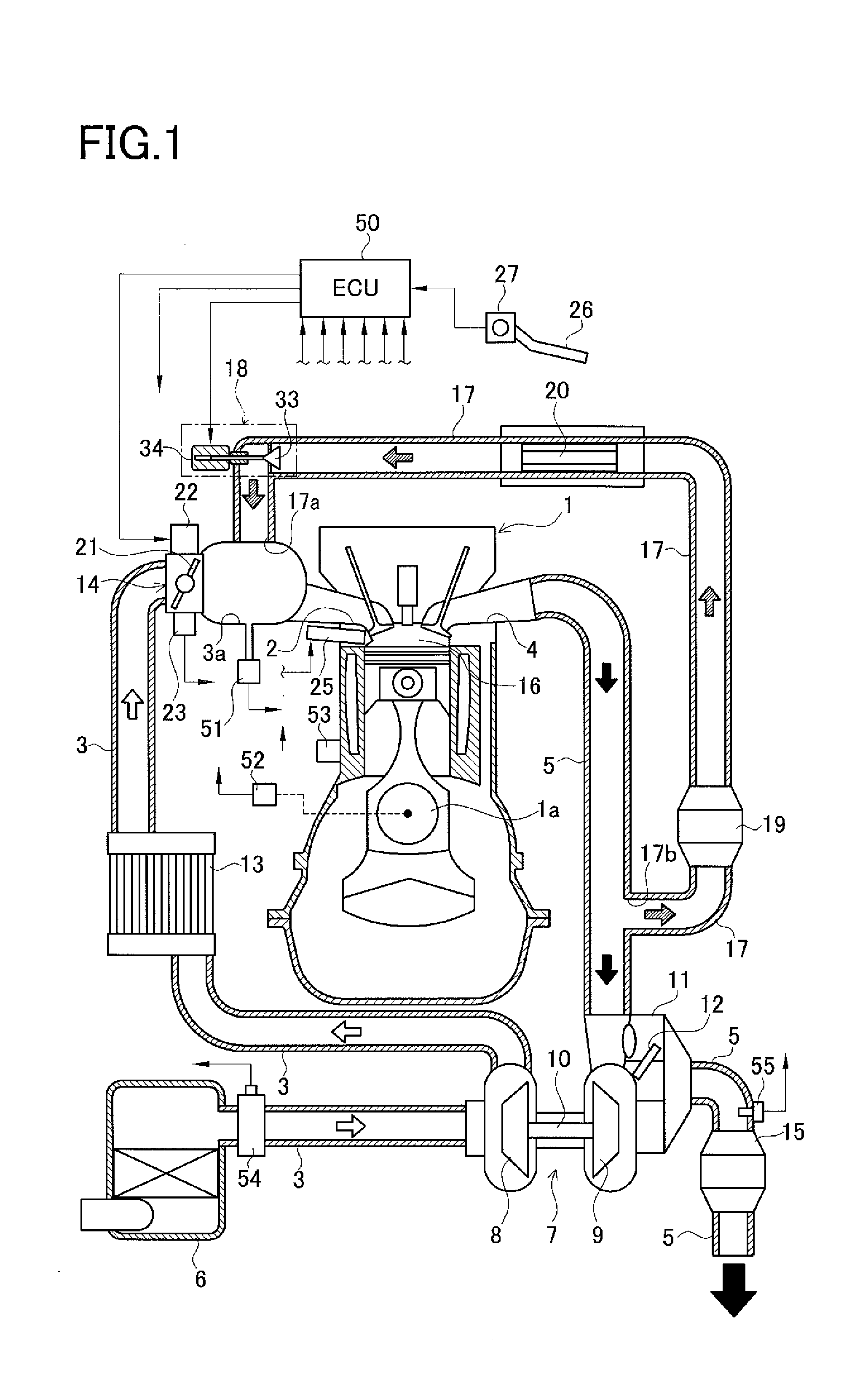

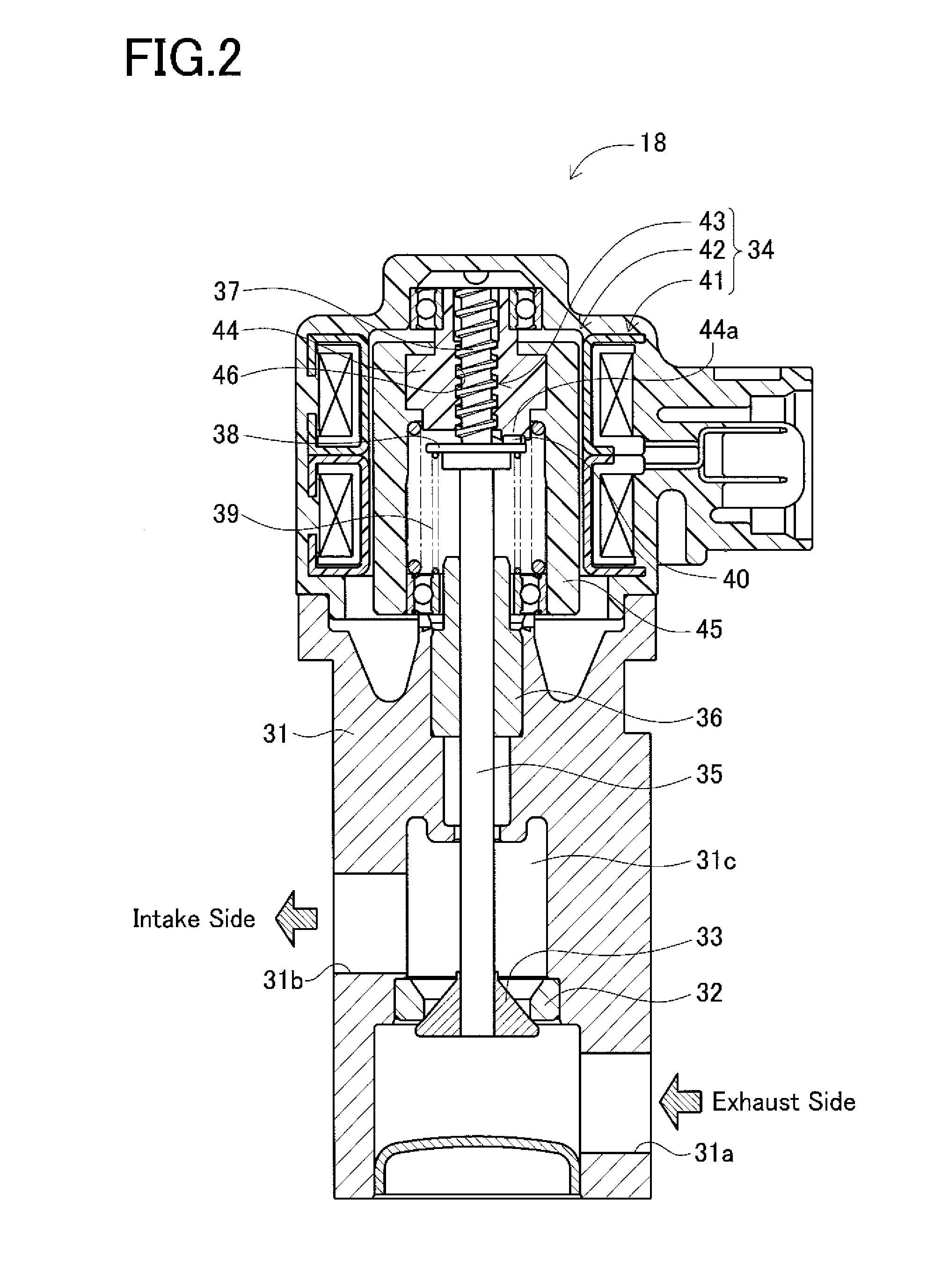

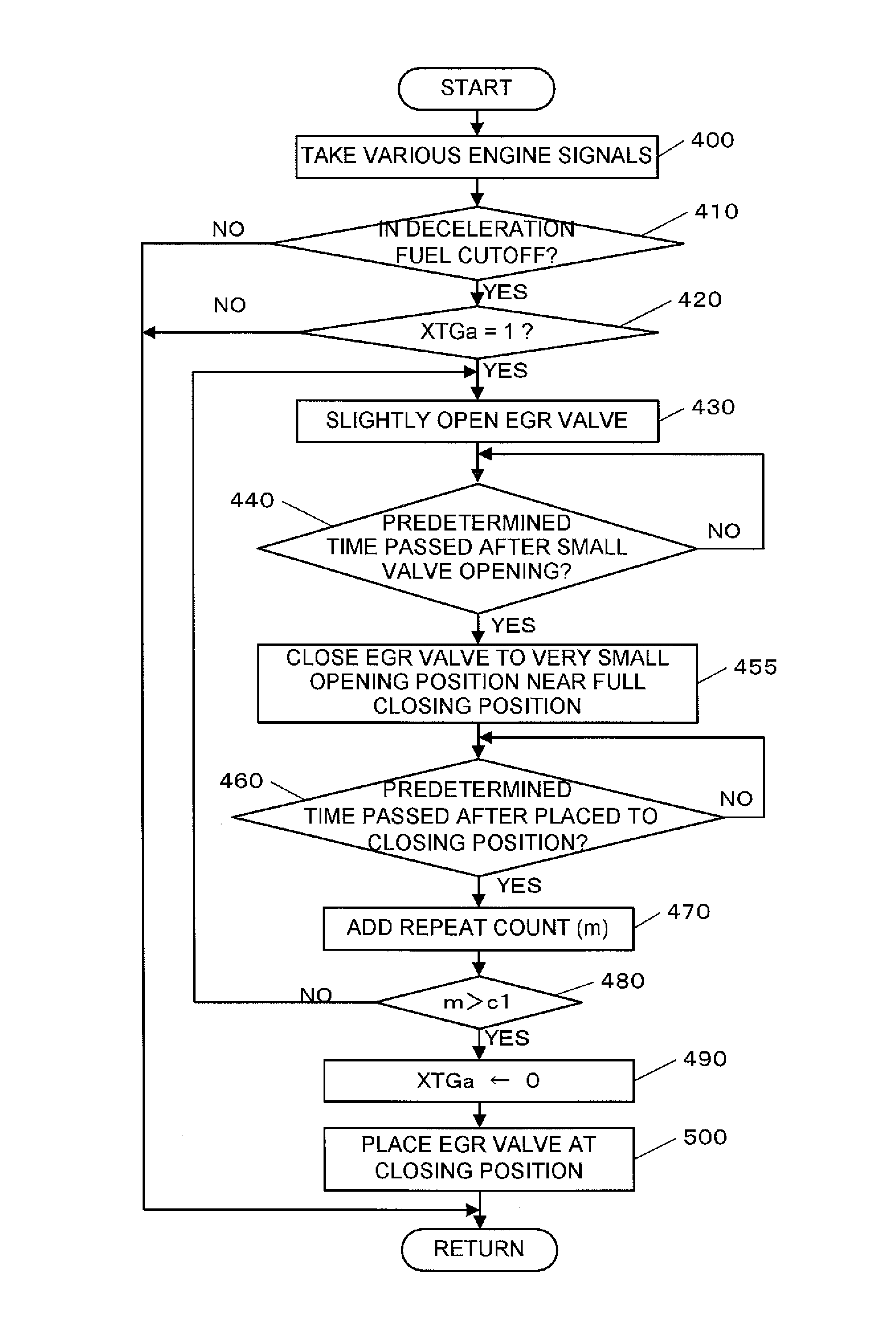

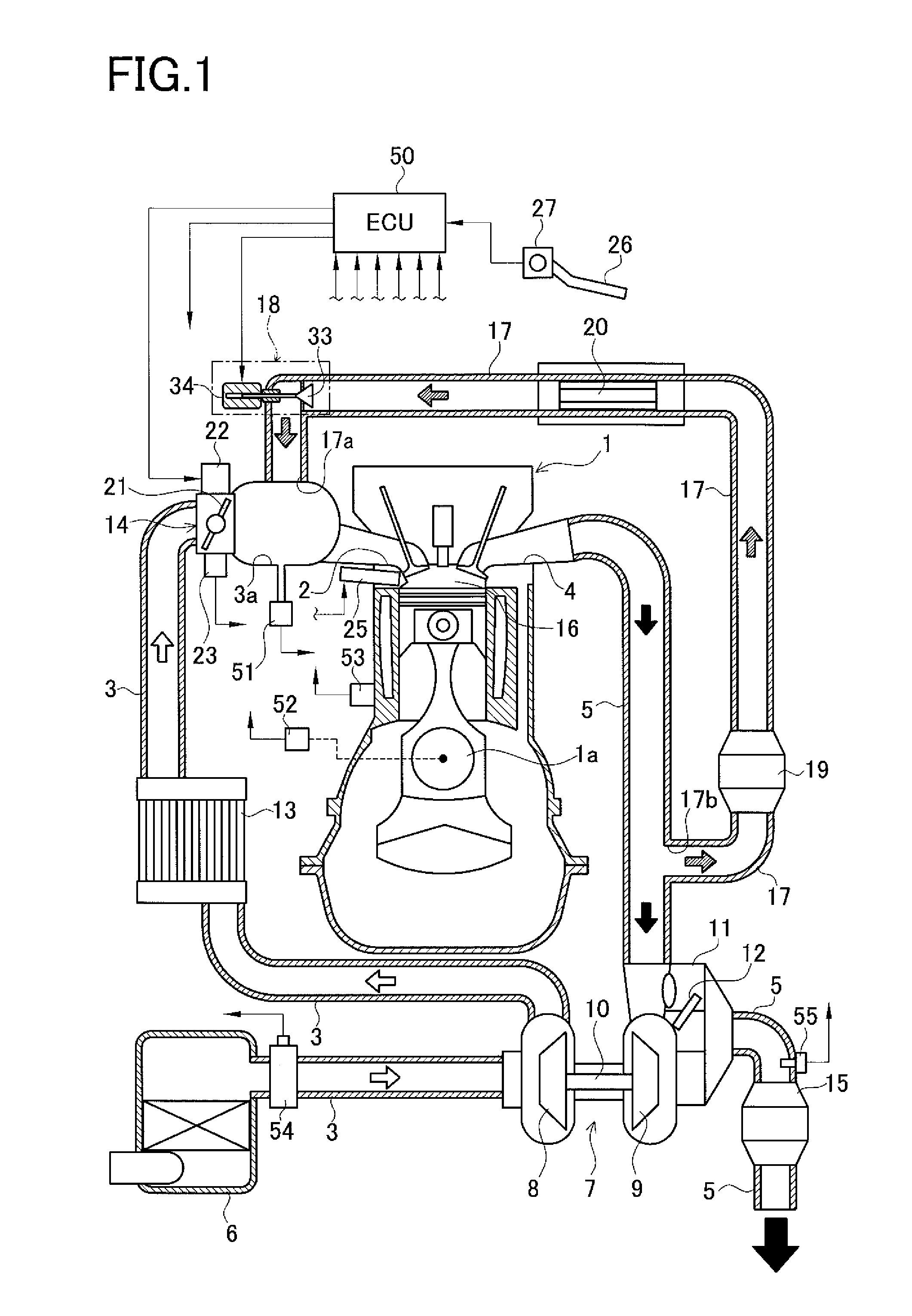

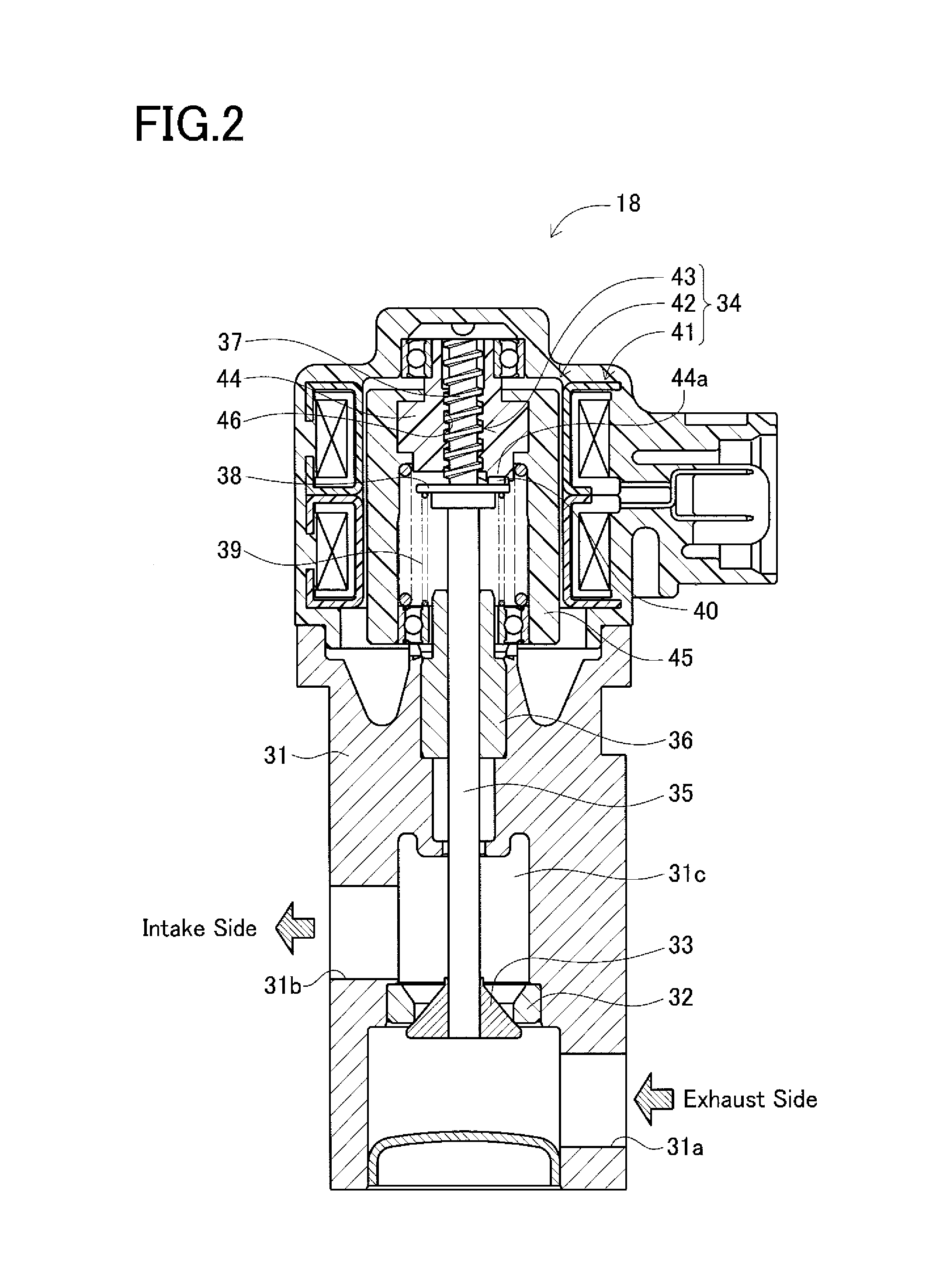

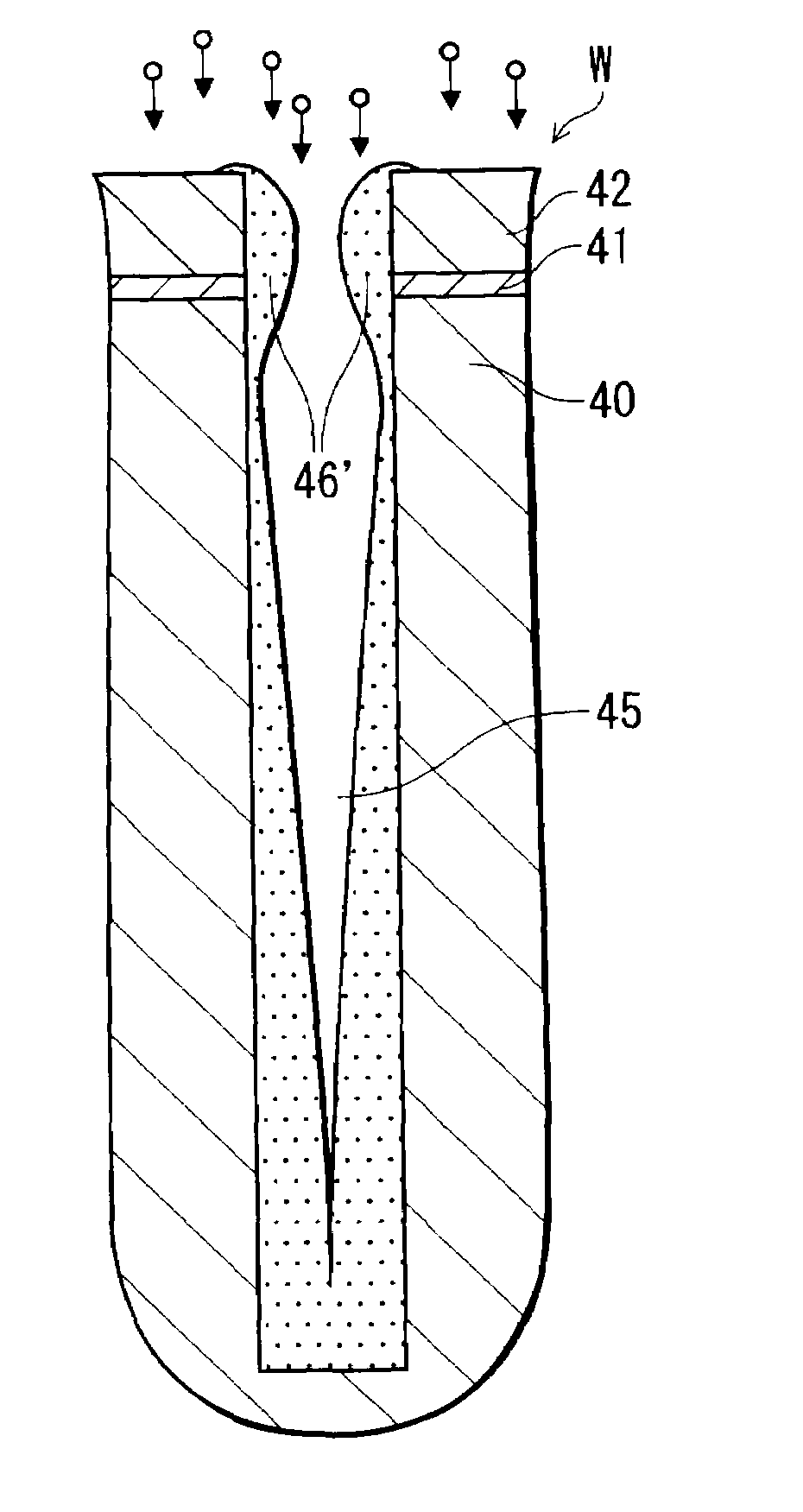

Exhaust gas recirculation apparatus for engine

ActiveUS20130319383A1Reliable removalReliably removedElectrical controlInternal combustion piston enginesForeign matterCombustion chamber

An EGR apparatus includes a EGR passage for allowing part of exhaust gas discharged from a combustion chamber of an engine to an exhaust passage to flow in an intake passage and recirculate back to the combustion chamber, and an EGR valve provided in the EGR passage to regulate an EGR passage in this passage. The EGR valve includes a valve seat, a valve element to be seatable on the valve seat, and a step motor for driving the valve element to open and close. An electronic control device controls the EGR valve to repeat opening and closing of the valve element between a closing position and a small opening position in order to remove foreign matters adhered to the valve seat or valve element during deceleration fuel cutoff of the engine.

Owner:AISAN IND CO LTD

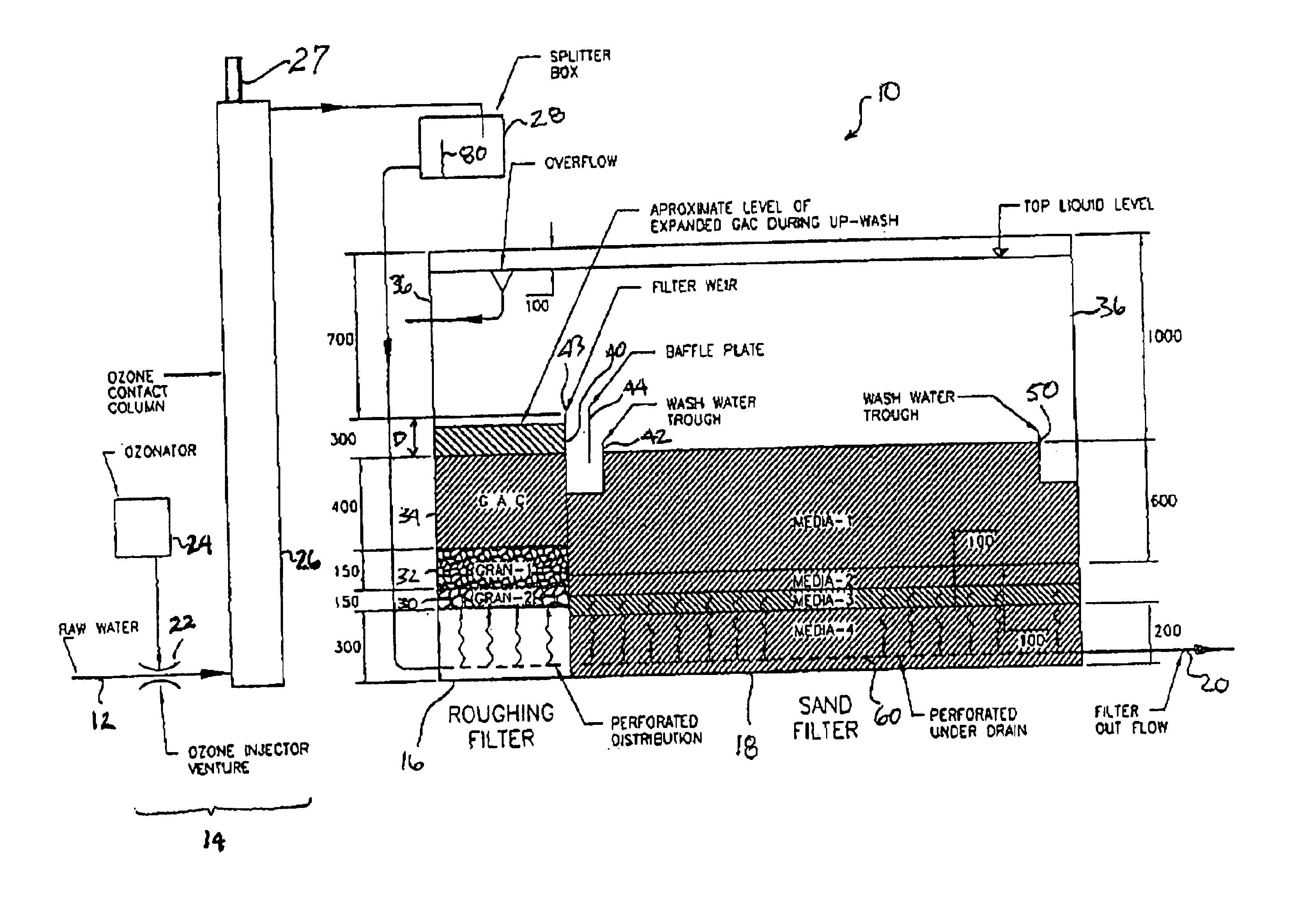

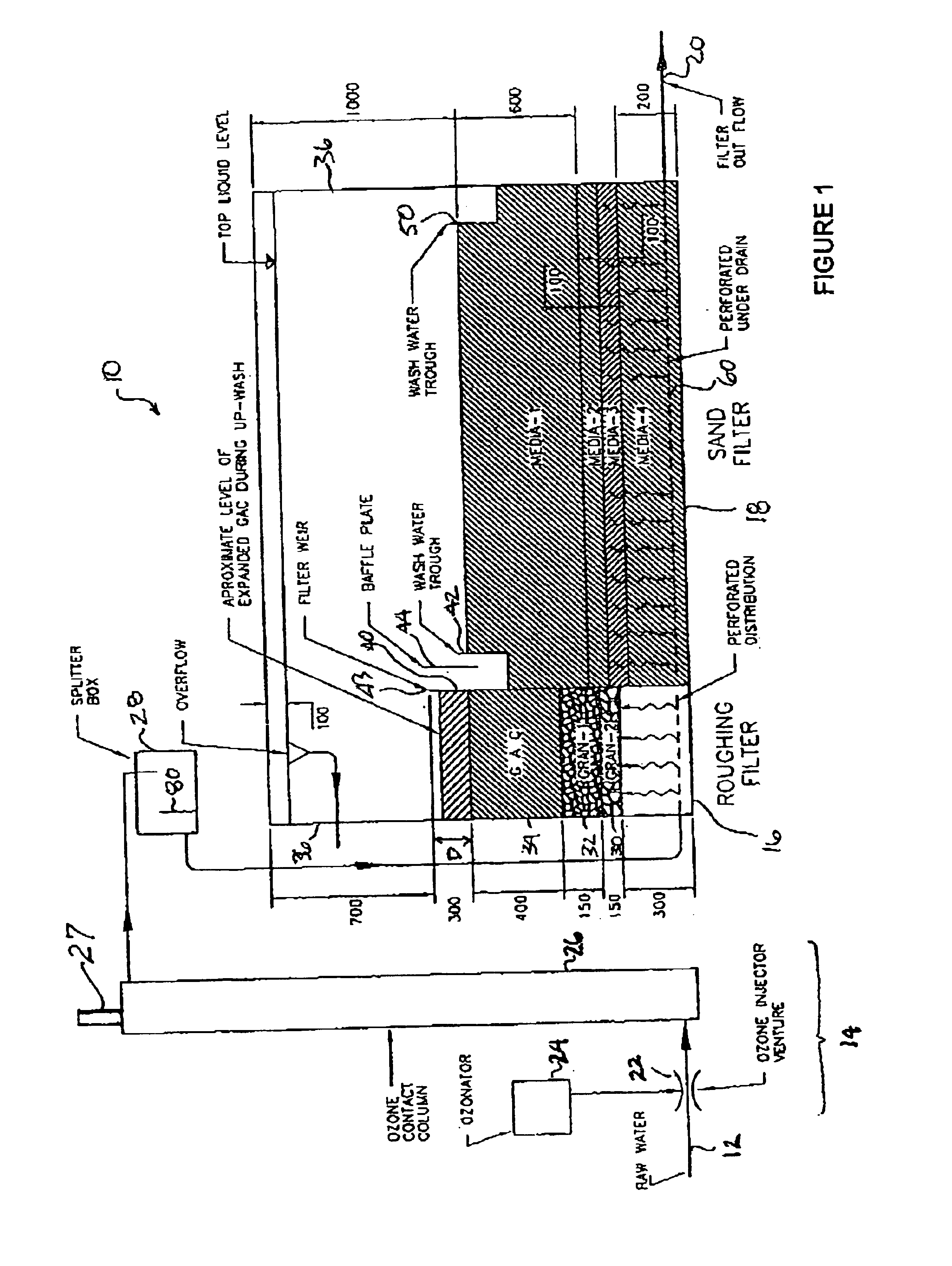

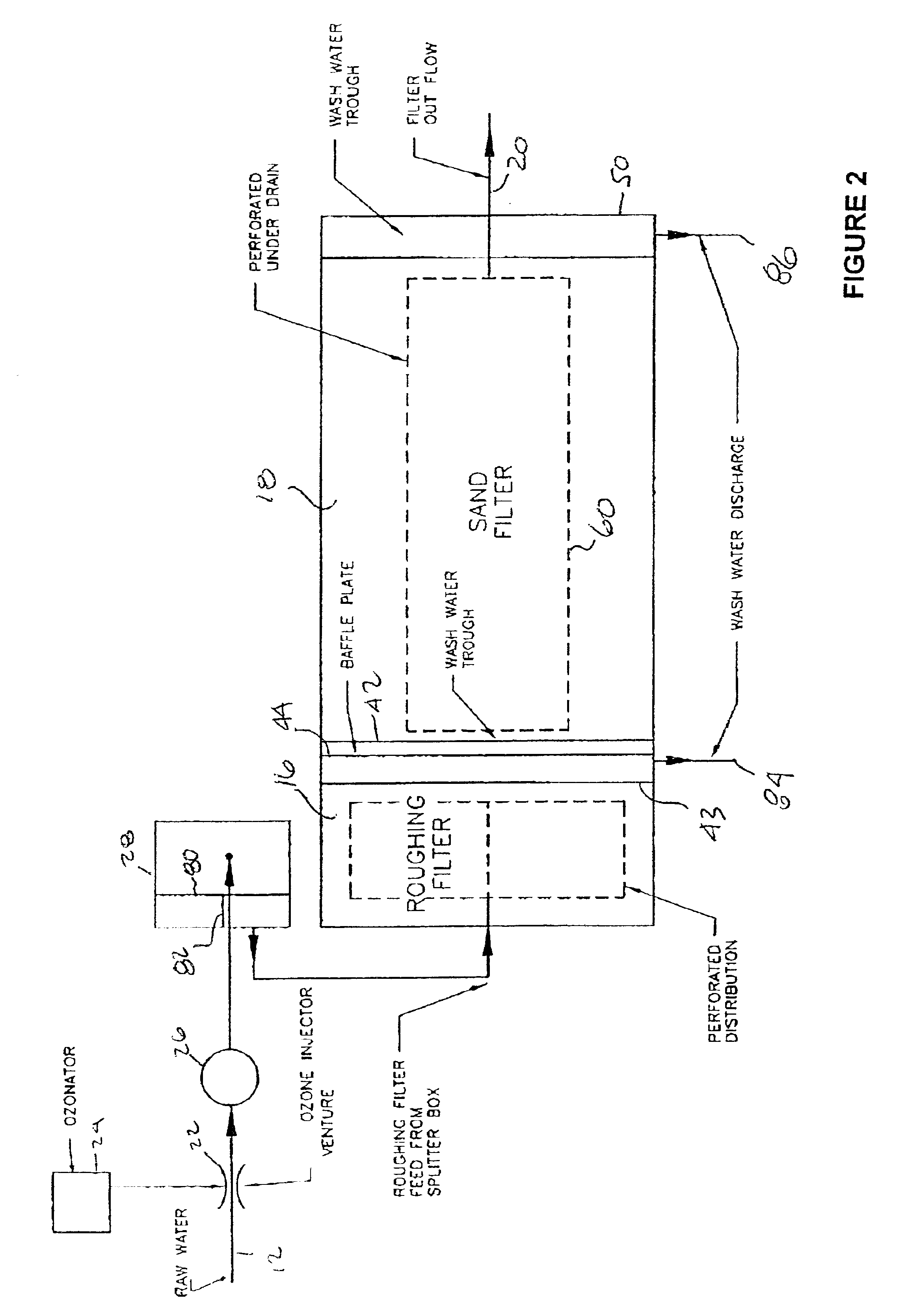

Potable water treatment plant and method of maintaining same

InactiveUS6953525B2Easy to useEasy maintenanceTreatment involving filtrationSolid sorbent liquid separationParticulatesPotable water

A package plant for treating raw water to yield potable water. The package plant includes an inlet for raw water, followed by an ozonator for disinfecting the water. Next is provided an up flow roughing filter including a chemically active layer, on top. A slow sand filter follows, which is sized and shaped to promote growth of a biomass for water purification. The up flow roughing filter removes particulates, contributes to the removal of dissolved organics, and protects the slow sand biomass by removing disinfection residuals. In another aspect a method of maintaining the plant is provided, including washing the up flow roughing filter by draining water down through it, providing a vigorous up flow to agitate the top layer, and then washing the slow sand filter.

Owner:MS FILTER SYST

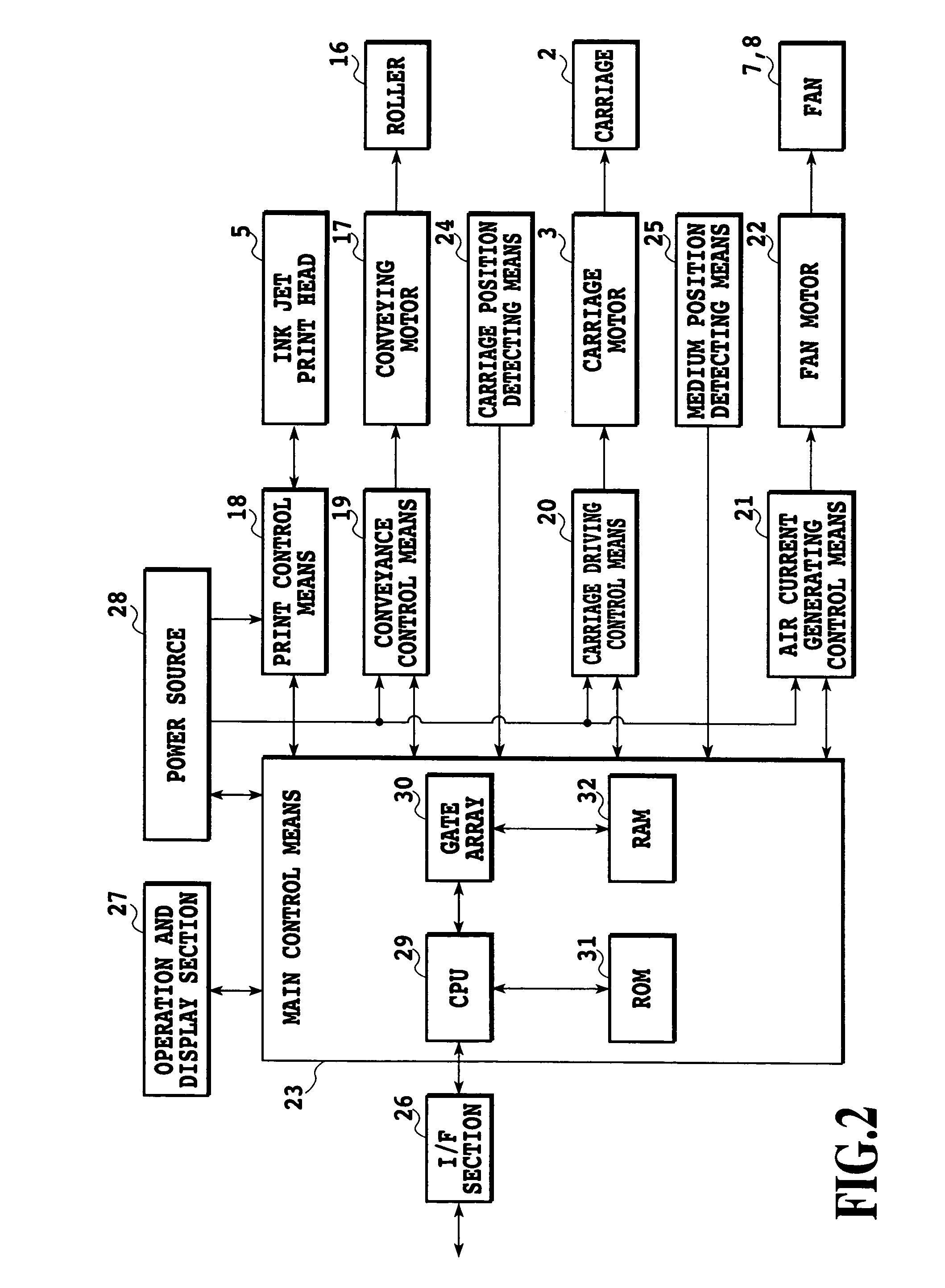

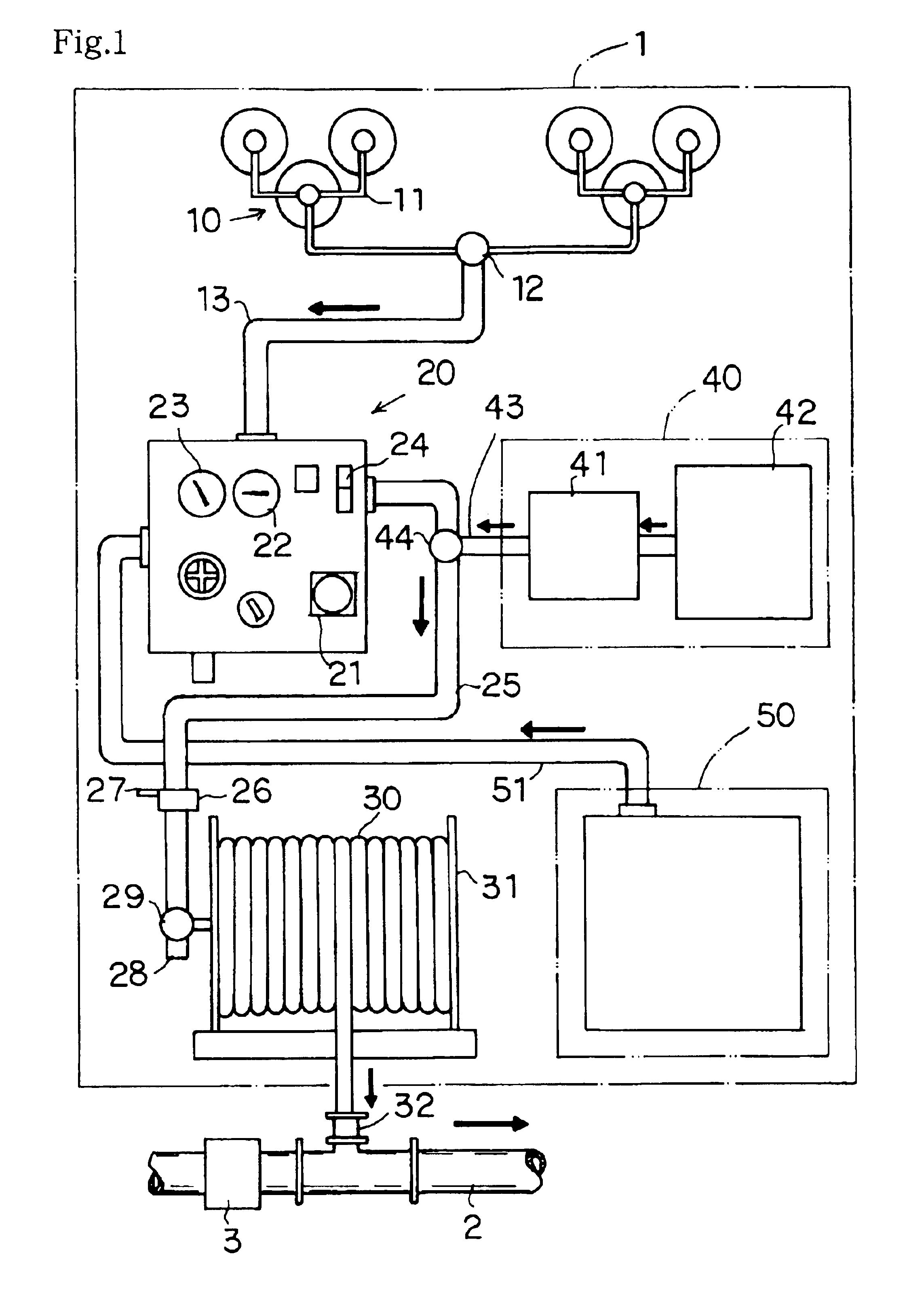

Ink jet printing apparatus and ink jet printing method with an air current generating means to remove ink mists generated in the apparatus

InactiveUS7044581B2Reliable removalEfficient driveOther printing apparatusEngineeringEnergy consumption

It is an object of the present invention to provide an ink jet printing apparatus which can appropriately remove ink mists generated in the apparatus and which can avoid wasteful energy consumption. Thus, the present invention provides an ink jet printing apparatus that carries out printing on a print medium using ink, the apparatus including an air current generating portion that generates air currents inside the printing apparatus, a determining section that determines driving conditions for the air current generating portion on the basis of information on the amount of ink to be provided per unit area of a print medium, and a control section that controls the air current generating portion in accordance with the driving conditions determined by the determining section.

Owner:CANON KK

Resist stripping composition and method of producing semiconductor device using the same

InactiveUS7087563B2Reduce widthRise of line resistance is suppressedSemiconductor/solid-state device manufacturingElectrostatic cleaningChemical treatmentResist

A resist stripping composition capable of reliably stripping off resist residue or polymer residue and keeping damage to the interconnects to a minimum and a method of producing a semiconductor device using the same, where the resist stripping composition comprises a salt of hydrofluoric acid and a base not including a metal, an organic solvent, a sugar alcohol such as xylitol, and water and has a hydrogen ion concentration of at least 8. The method of production of a semiconductor device comprises dry etching a metal layer or a semiconductor layer on a semiconductor substrate to form an interconnect layer having a predetermined pattern or forming an insulation layer on a semiconductor substrate formed with an interconnect layer and dry etching this to a predetermined pattern, then performing chemical treatment using a resist stripping composition comprising a salt of hydrofluoric acid and a base not including a metal, an organic solvent, a sugar alcohol such as xylitol, and water and having a hydrogen ion concentration of at least 8.

Owner:SONY CORP

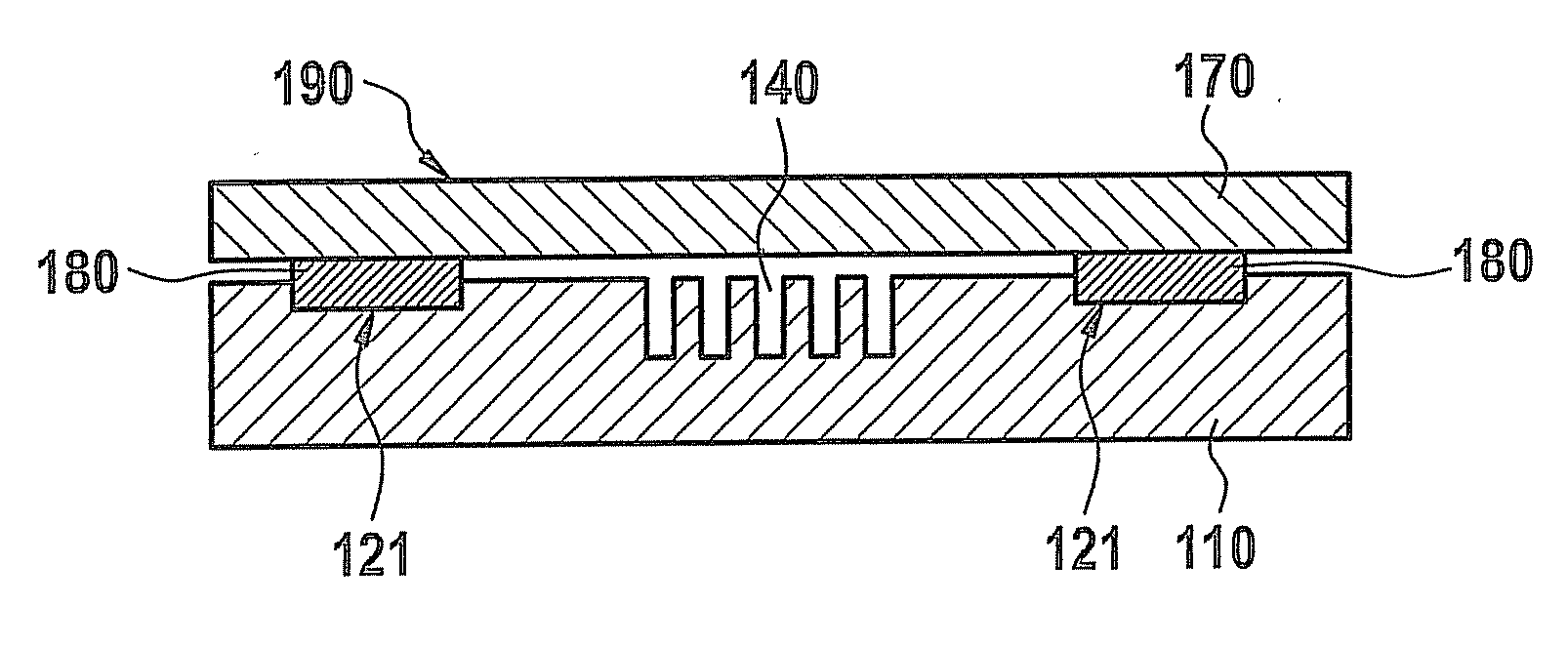

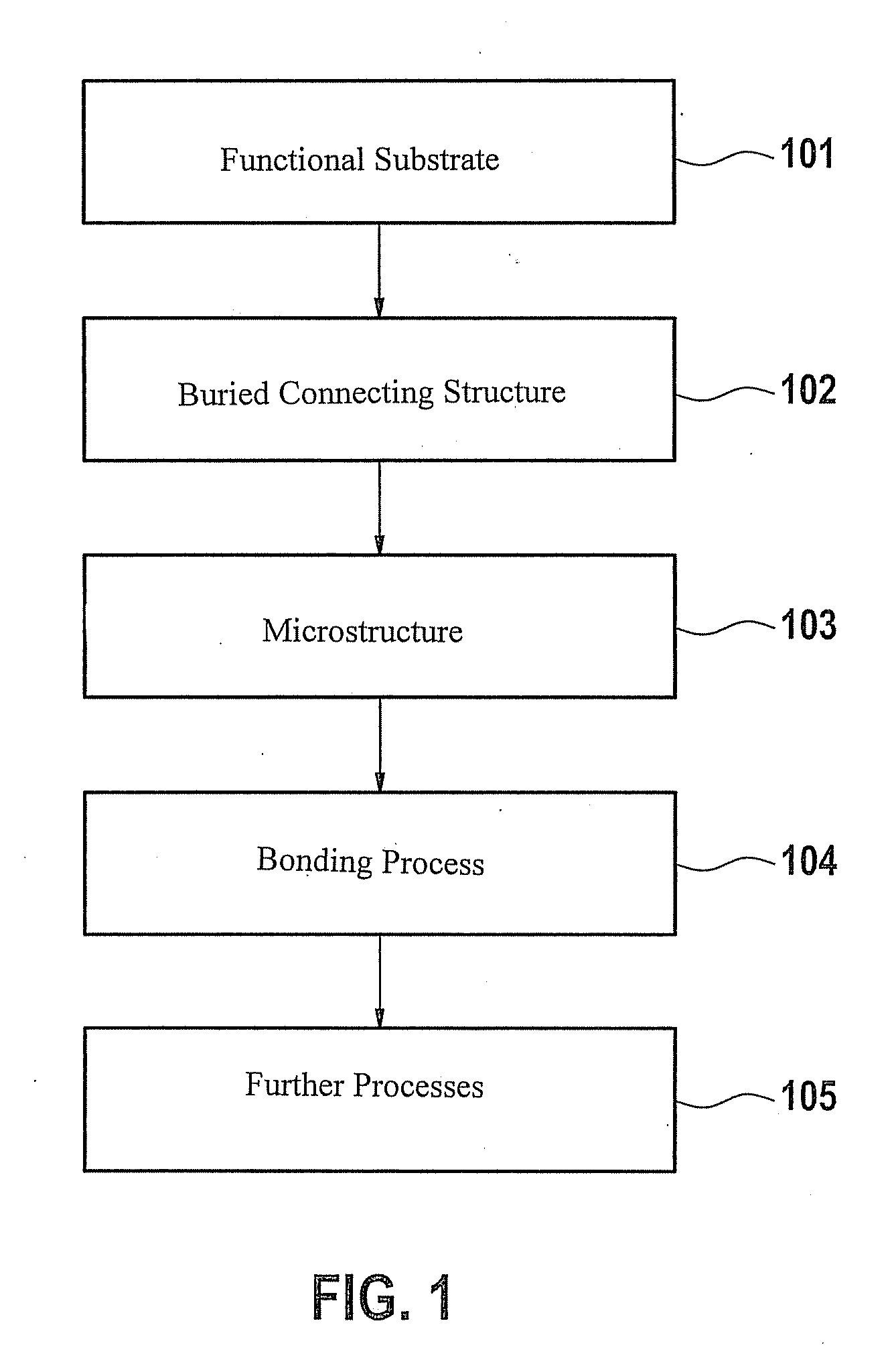

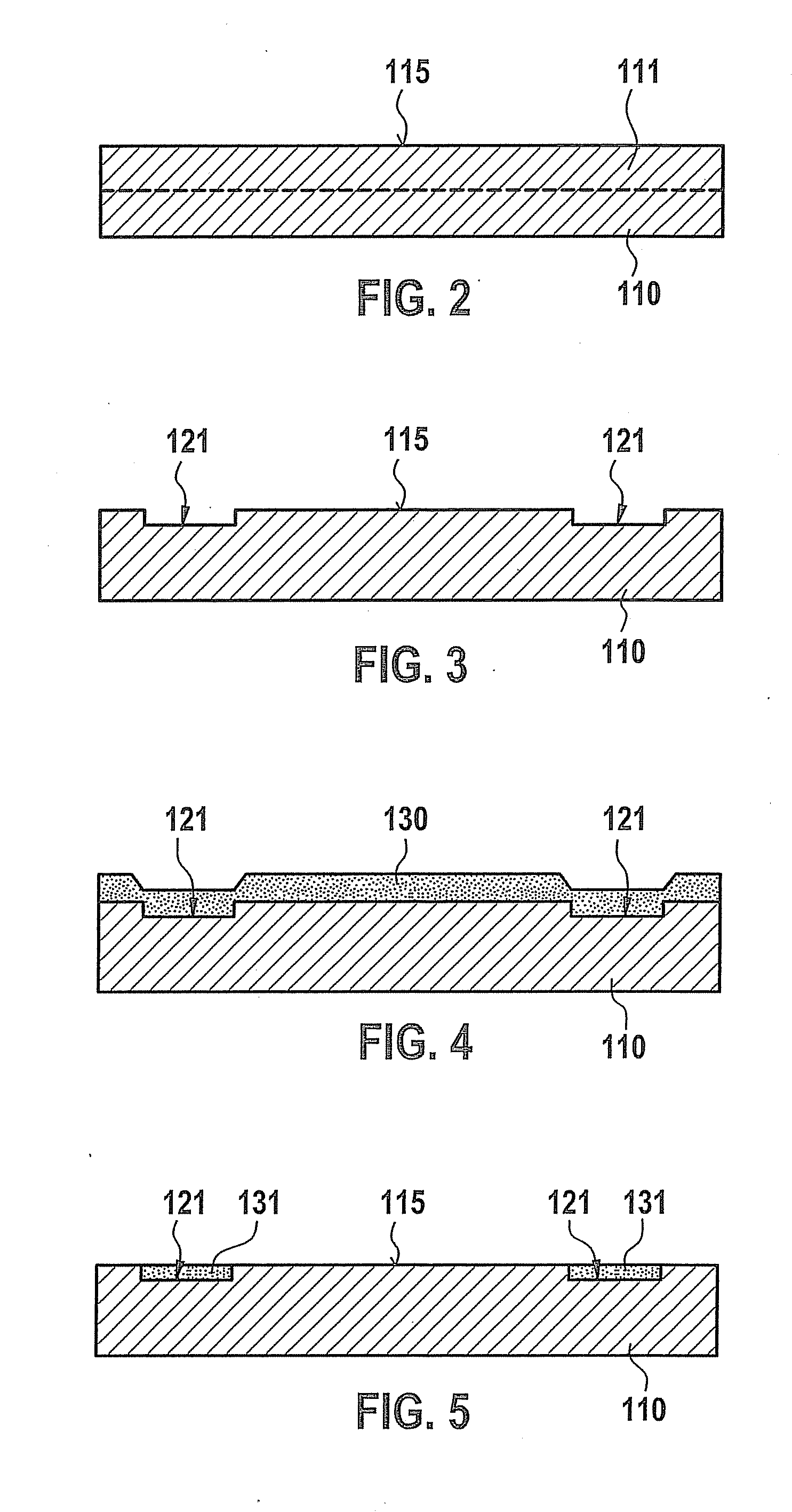

Micromechanical Component

ActiveUS20110298063A1Reliable removalLow costFixed microstructural devicesSemiconductor/solid-state device detailsBonding processEngineering

A method is described for manufacturing a micromechanical component. The method includes providing a first substrate, forming a first connecting structure on the first substrate, and forming a microstructure on the first substrate after forming the first connecting structure. The microstructure has at least one movable functional element. The method further includes providing a second substrate having a second connecting structure, and joining the first and second substrates by carrying out a bonding process, the first and second connecting structures being joined to form a common connecting structure, and a sealed cavity being formed in the region of the microstructure. The method provides that the first connecting structure takes the form of a buried connecting structure extending up to an upper surface of the first substrate. Also described is a related micromechanical component.

Owner:ROBERT BOSCH GMBH

Exhaust gas recirculation apparatus for engine

ActiveUS9222441B2Reliably removedElectrical controlInternal combustion piston enginesForeign matterCombustion chamber

An EGR apparatus includes a EGR passage for allowing part of exhaust gas discharged from a combustion chamber of an engine to an exhaust passage to flow in an intake passage and recirculate back to the combustion chamber, and an EGR valve provided in the EGR passage to regulate an EGR passage in this passage. The EGR valve includes a valve seat, a valve element to be seatable on the valve seat, and a step motor for driving the valve element to open and close. An electronic control device controls the EGR valve to repeat opening and closing of the valve element between a closing position and a small opening position in order to remove foreign matters adhered to the valve seat or valve element during deceleration fuel cutoff of the engine.

Owner:AISAN IND CO LTD

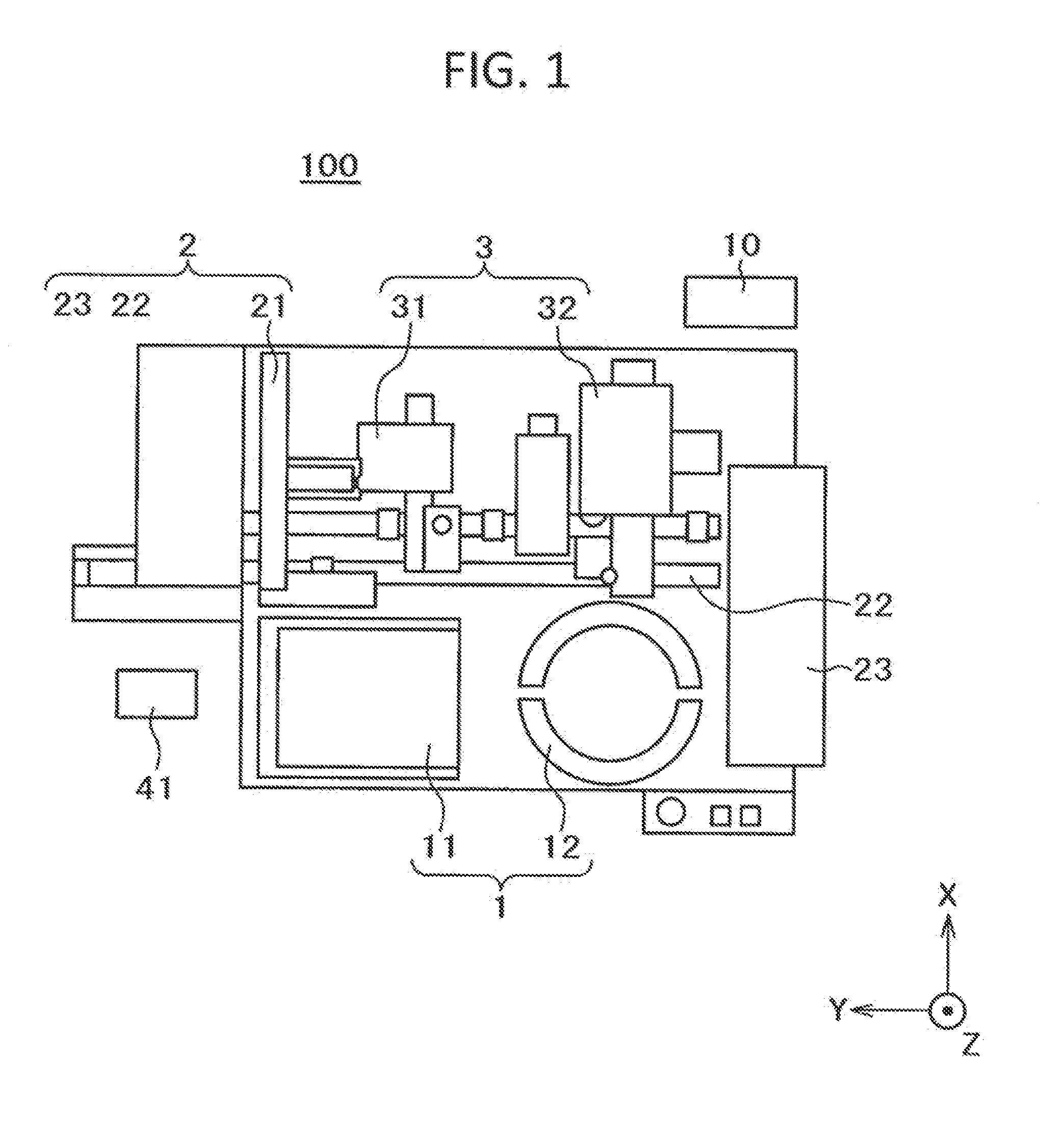

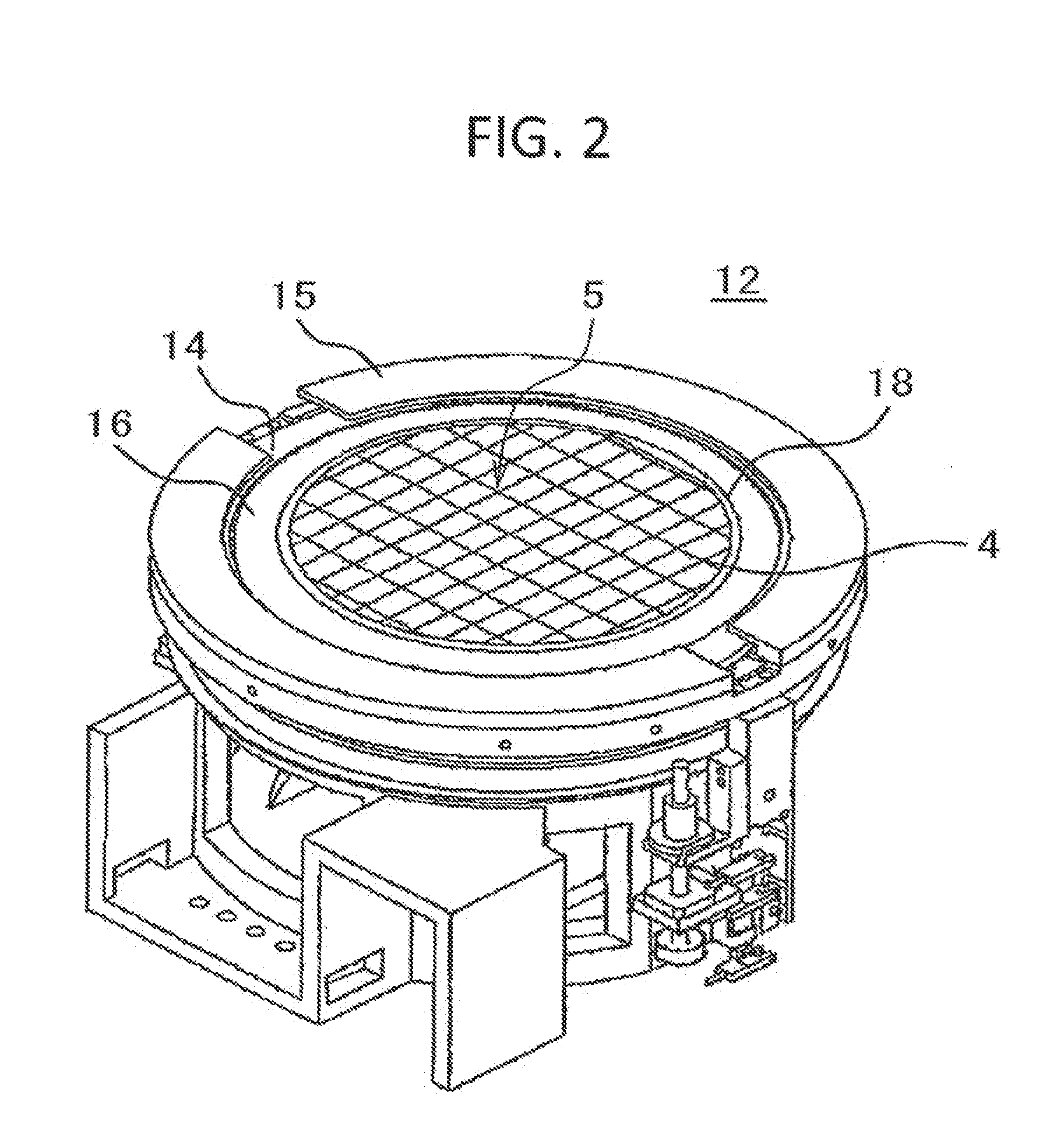

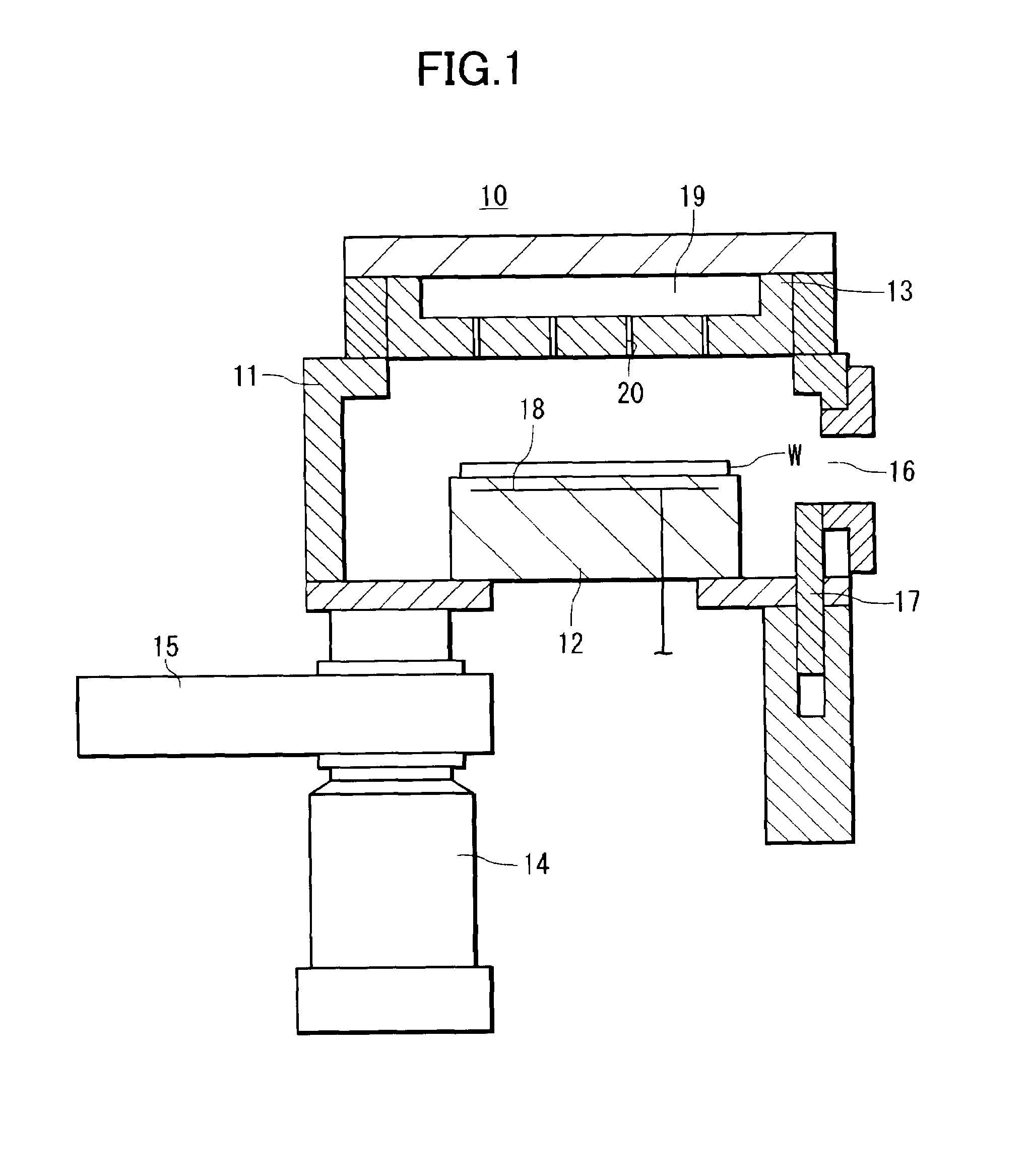

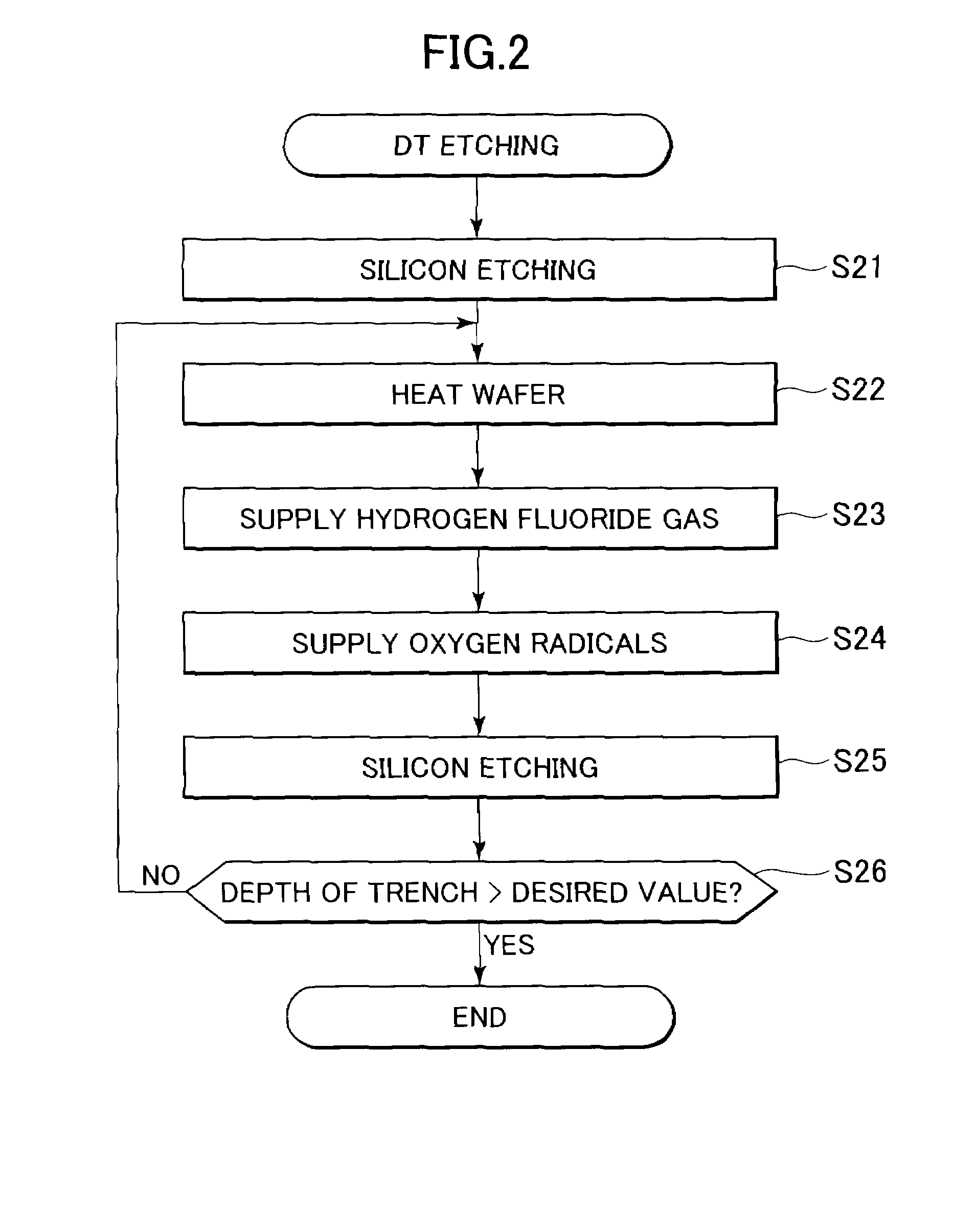

Substrate processing method and substrate processing apparatus

ActiveUS20080182421A1Reliable formingTrench can be prevented from becoming deformedSemiconductor/solid-state device manufacturingHydrogen fluorideSilicon oxide

A substrate processing method that can selectively remove deposit produced through dry etching of silicon. A substrate has a silicon base material and a hard mask that is made of a silicon nitride film and / or a silicon oxide film and formed on the silicon base material, the hard mask having an opening to which at least part of the silicon base material is exposed. A trench corresponding to the opening is formed in the silicon base material through dry etching using plasma produced from halogenated gas. After the dry etching, the substrate is heated to a temperature of not less than 200° C., and then hydrogen fluoride gas and helium gas are supplied toward the substrate.

Owner:TOKYO ELECTRON LTD

Apparatus for manufacturing sheet glass

InactiveUS20090217704A1Well formedHigh devitrificationGlass drawing apparatusGlass transportation apparatusFlat glassThin sheet

In an apparatus for manufacturing thin sheet glass, comprising a forming body 12 including a main body having a cross-sectional shape converging downwardly, the main body being configured to converging streams of molten glass into a single glass ribbon at a lower converged edge portion thereof, the streams of the molten glass flowing down along both surface of the main body; and edge members, the edge members being configured to restrict a width of the molten glass, wherein the glass ribbon formed by the forming body 12 is downwardly pulled to form thin sheet glass; the apparatus further includes a non-contact support member disposed in the vicinity of the lower converged edge portion of the main body, the non-contact support member being configured to form a thin gas layer on a supporting surface thereof, wherein the glass ribbon is supported over an entire width thereof in a non-contact way by the non-contact support member in a course wherein the glass ribbon is downwardly pulled.

Owner:ASAHI GLASS CO LTD

Vibration device

ActiveUS20200038914A1Reliable removalReliably removedMechanical vibrations separationMountingsAcoustics

Owner:MURATA MFG CO LTD

Device for removing by suction drill dust when drilling holes into walls

InactiveUS8052357B2Reliably removedLow production costDrilling/boring measurement devicesThread cutting feeding devicesEngineeringVacuum chamber

A device for removing drill dust when drilling a hole into a wall has a base member and at least one vacuum chamber provided in the base member. At least one suction site is provided. A connector is connected to the base member and adapted to connect a vacuum unit that removes by suction at the suction site the drill dust produced by drilling. The at least one suction site and the at least one vacuum chamber are spatially separated from one another.

Owner:ELECTROSTAR SCHOETTLE

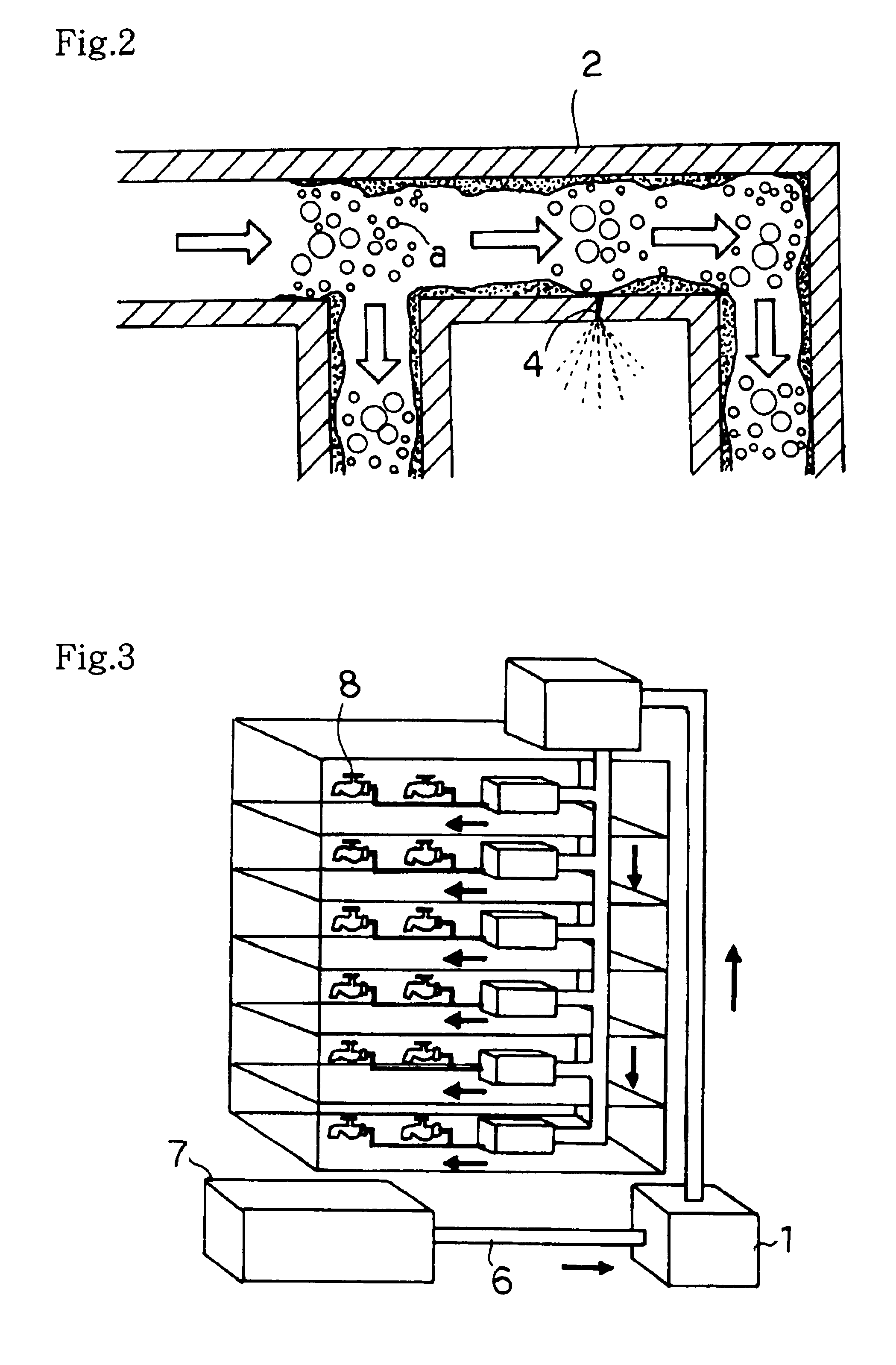

Pipe washing method and pipe washing apparatus

InactiveUS7017593B2Easy to evaporateReliably removedDecorative surface effectsHollow article cleaningCantileverMechanical engineering

A micro device in which a functional element can be moved between an operating position and a waiting position by the displacement of support means coupled to a substrate. The micro device has a cantilever structure in which one end of support means is made a fixed one fixed to the substrate and the other end to which an active element is provided is made a free end. A spring portion is provided to at least part of the support means, and thus the active element can be greatly displaced by a small stress.

Owner:HONDA TOSHIMI

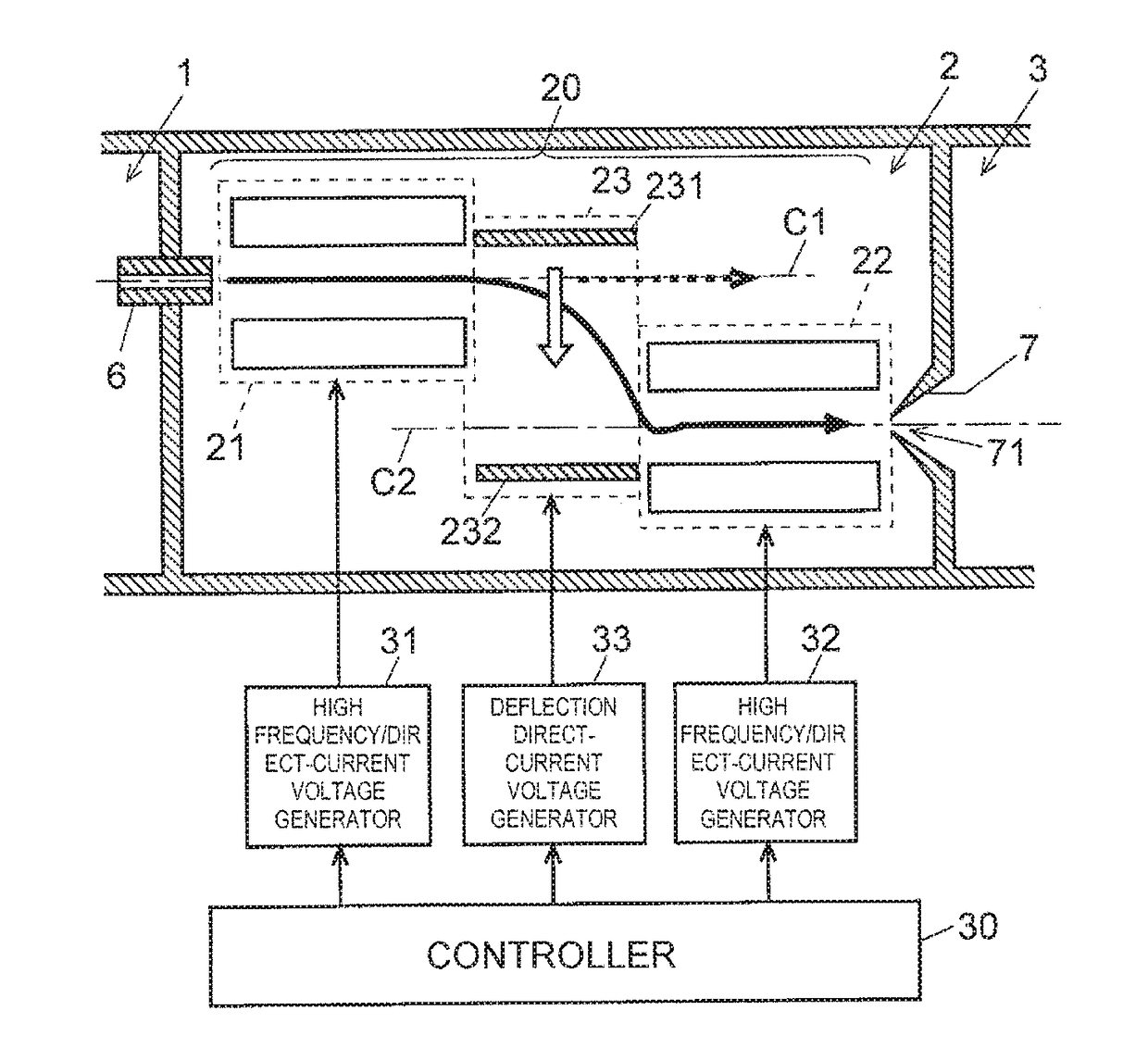

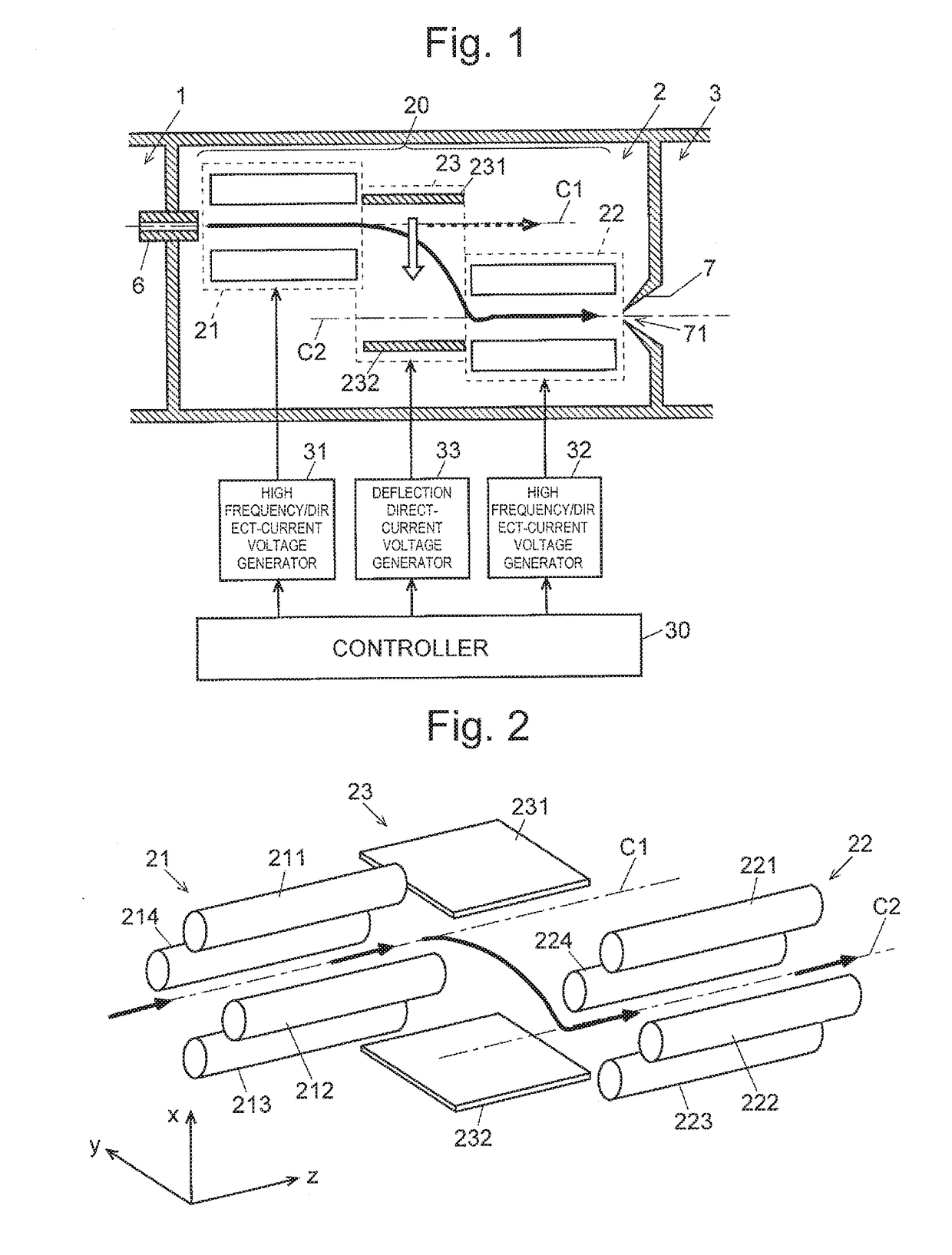

Ion transport apparatus and mass spectrometer using the same

InactiveUS20170148620A1Improve ion transmission efficiencySimple structureStability-of-path spectrometersElectron/ion optical arrangementsIonization chamberMass analyzer

An off-axis ion transport optical system (20) including a front-stage quadrupole ion guide (21), a rear-stage quadrupole ion guide (22), and an ion deflector (23) is disposed inside an intermediate vacuum chamber (2) in a stage next to an ionization chamber (1) maintained at an atmospheric pressure. Both of the quadrupole ion guides (21 and 22) have the same configuration as that of a conventional ion guide that transports ions while trapping the ions using a radio-frequency electric field. The ion deflector (23) includes a pair of parallel flat electrodes (231 and 232) and deflects ions using a direct-current electric field. By causing the deflected ions to reach the ion receiving range of the rear-stage quadrupole ion guide (22), it is possible to efficiency introduce ions while deflecting the ions. Meanwhile, the ions and neutral particles are separated from each other in the ion deflector (23). This provides an off-axis structure ion transport optical system that achieves a high ion transmission efficiency with a simple structure.

Owner:SHIMADZU CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com