Polishing apparatus and polishing method

A grinding device and grinding method technology, which is applied in the direction of grinding devices, grinding machine tools, electrical components, etc., can solve the problems of sensors changing, different, sensors not being able to correctly evaluate the film thickness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below, refer to Figure 1 to Figure 24 Embodiments of the present invention will be described in detail.

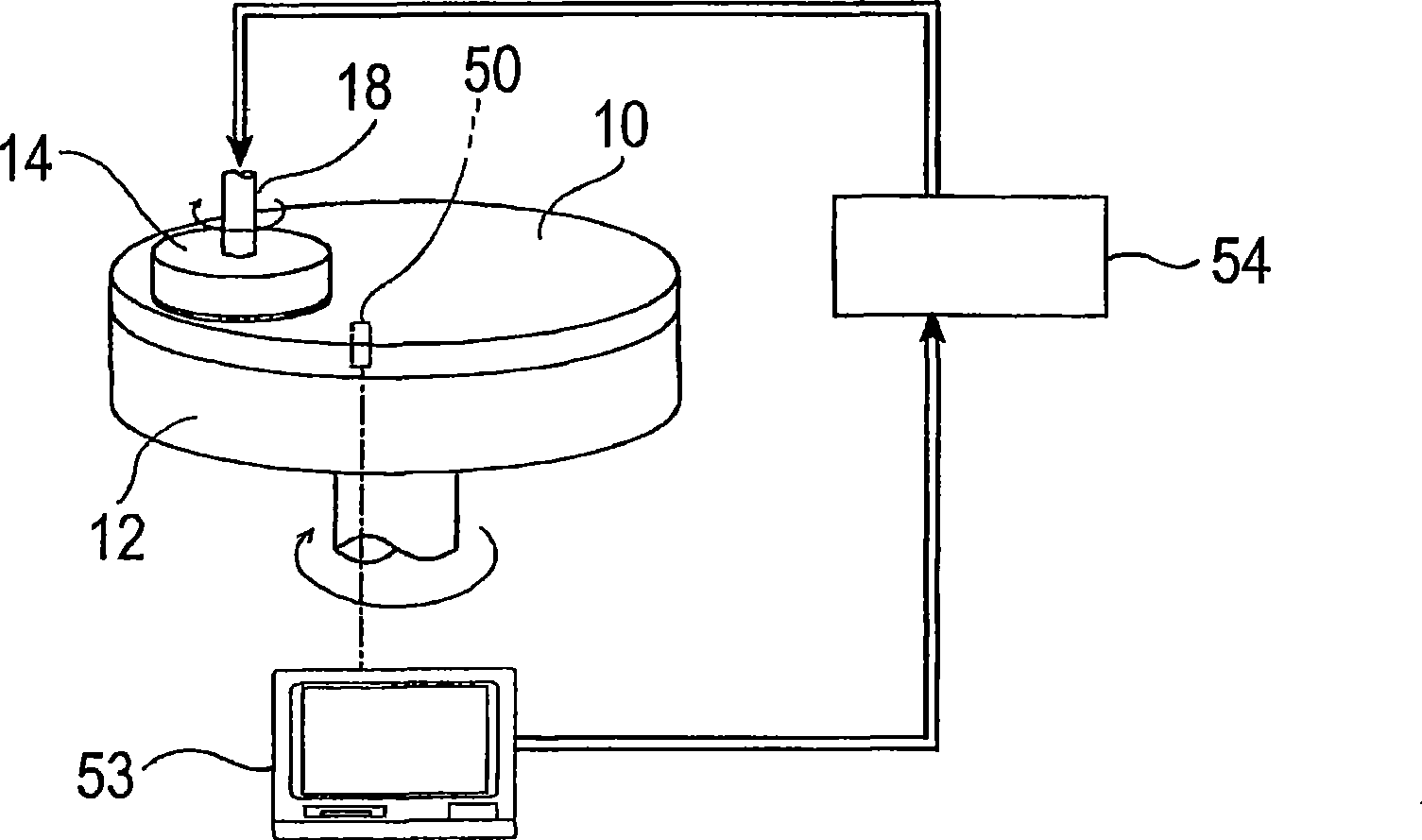

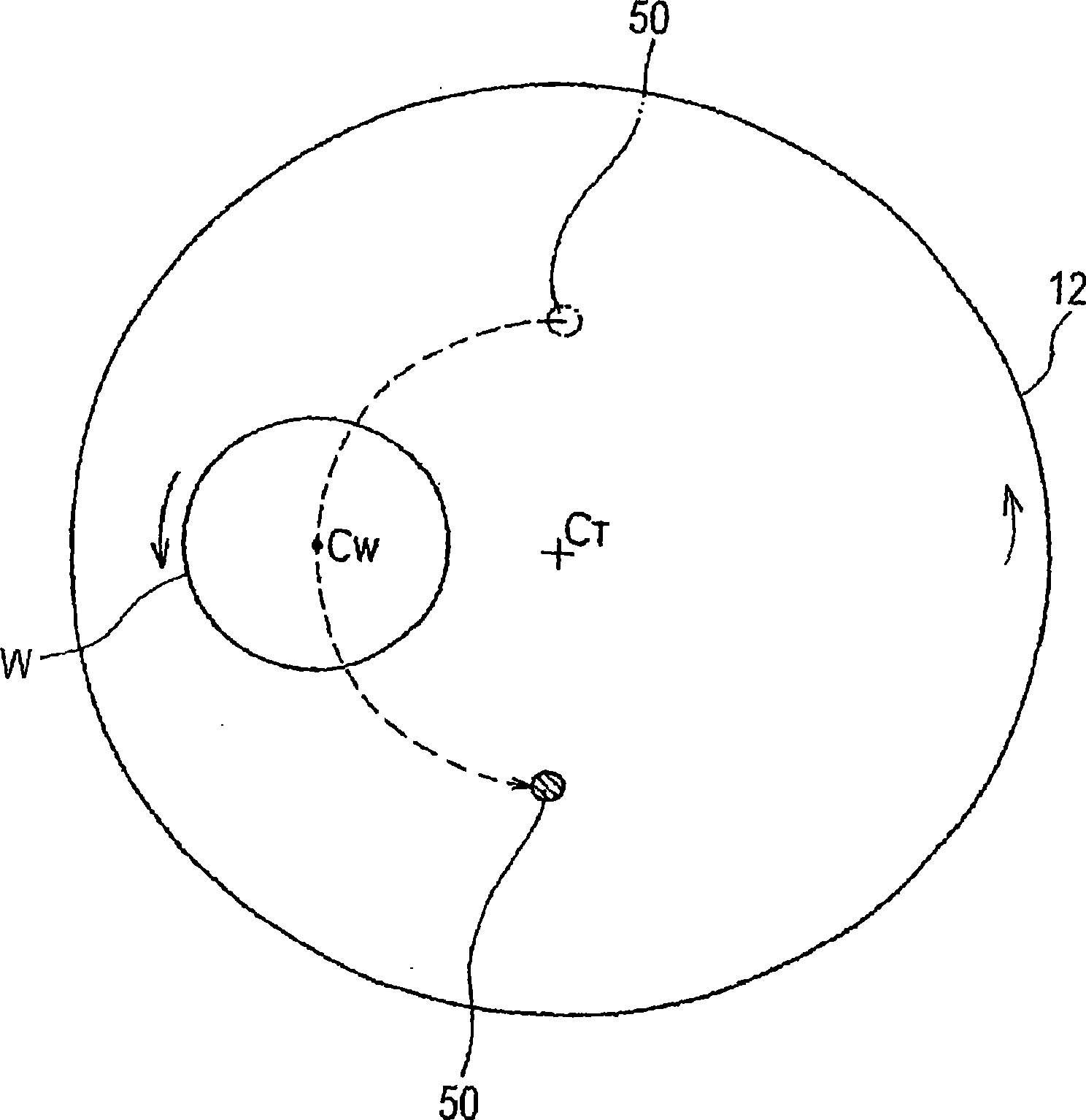

[0044] figure 1 It is a schematic diagram which shows the whole structure of the polishing apparatus concerning embodiment of this invention. like figure 1 As shown, the polishing apparatus includes: a polishing table 12 on which a polishing pad 10 is pasted; The upper surface of the polishing pad 10 constitutes a polishing surface that is in sliding contact with a wafer as an object to be polished.

[0045]The grinding table 12 is connected to a motor (not shown) disposed below it, and can rotate around its axis as indicated by an arrow. In addition, a polishing liquid supply nozzle (not shown) is provided above the polishing table 12 , and the polishing liquid is supplied onto the polishing pad 10 from the polishing liquid supply nozzle.

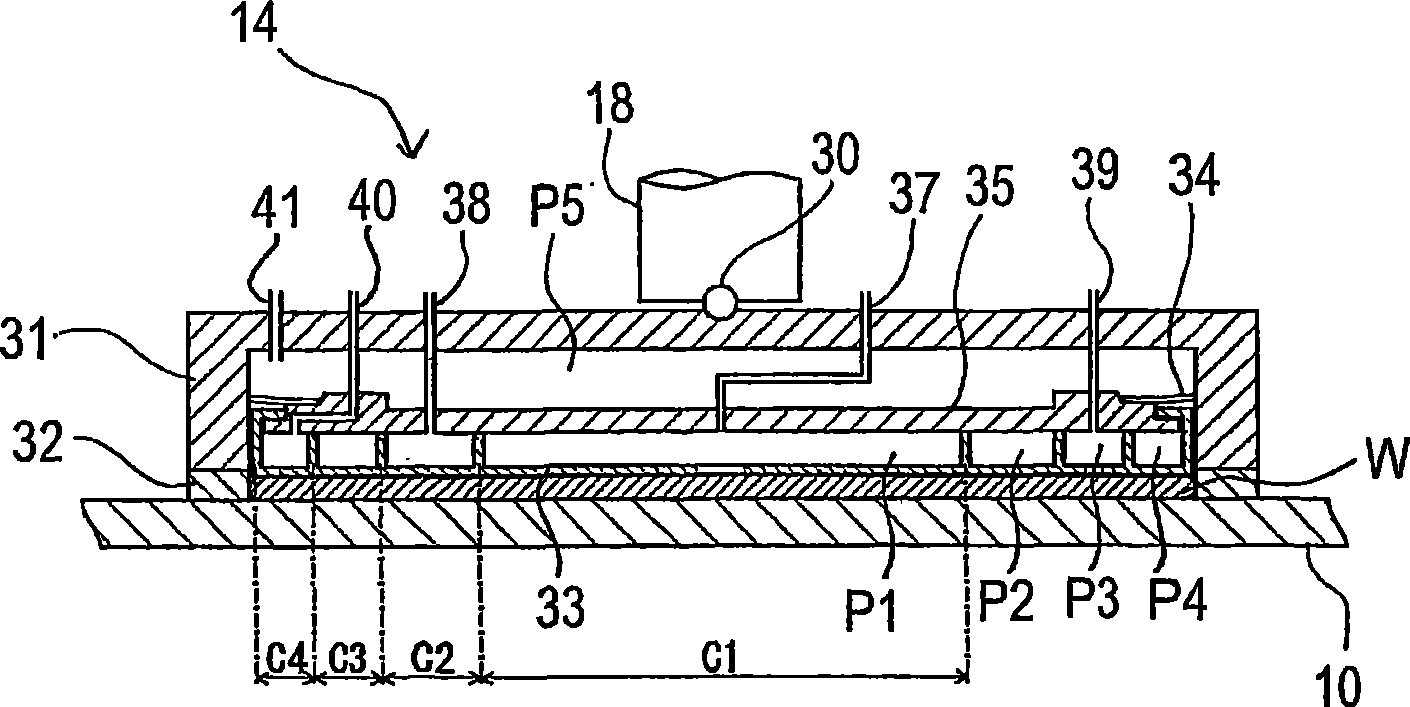

[0046] The top ring 14 is connected to a top ring shaft 18 via which it is connected to an electric motor and a lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com