Method for manufacturing organic electroluminescent display device

An electroluminescent display and manufacturing method technology, applied in the direction of electroluminescent light sources, electric light sources, lighting devices, etc., can solve the problem of low directivity of evaporation beams, reduction of evaporation beam density, and adverse effects on the characteristics of organic EL elements And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

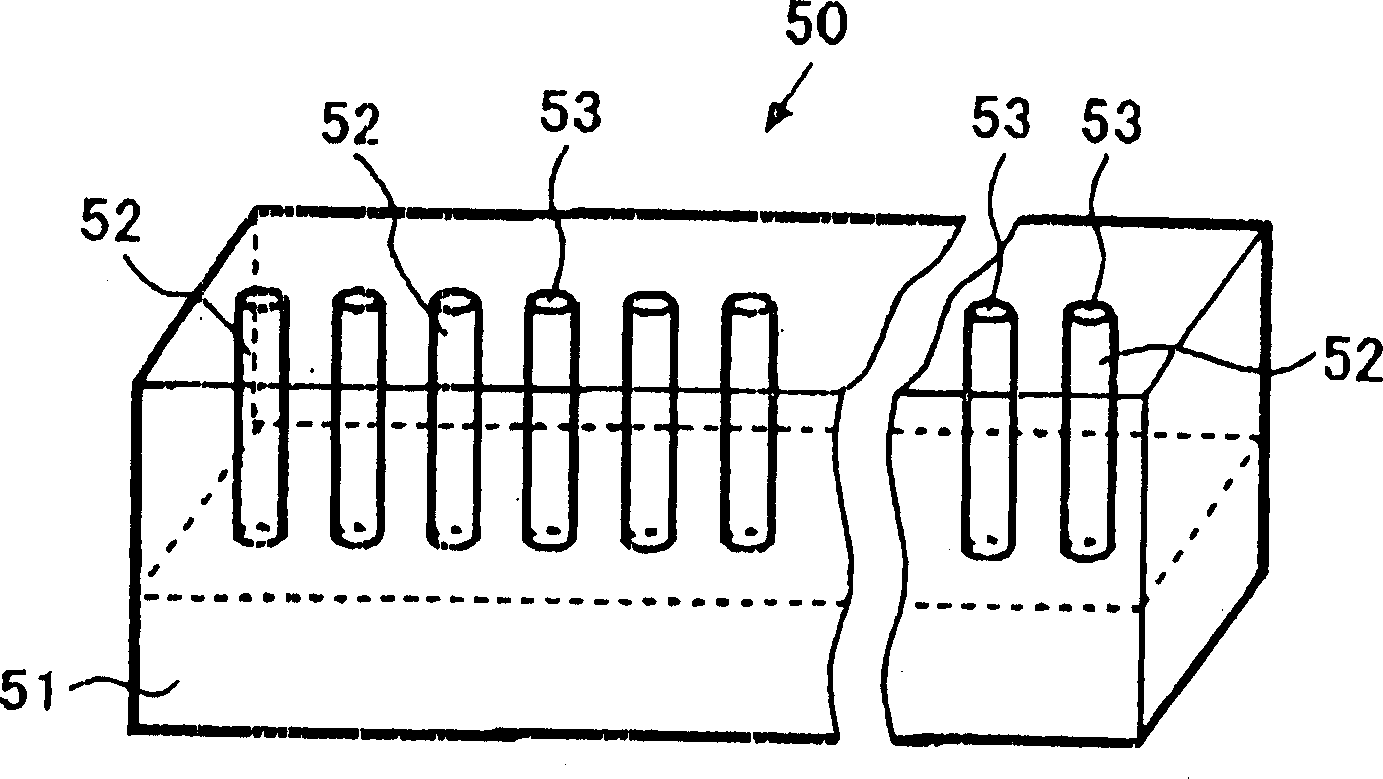

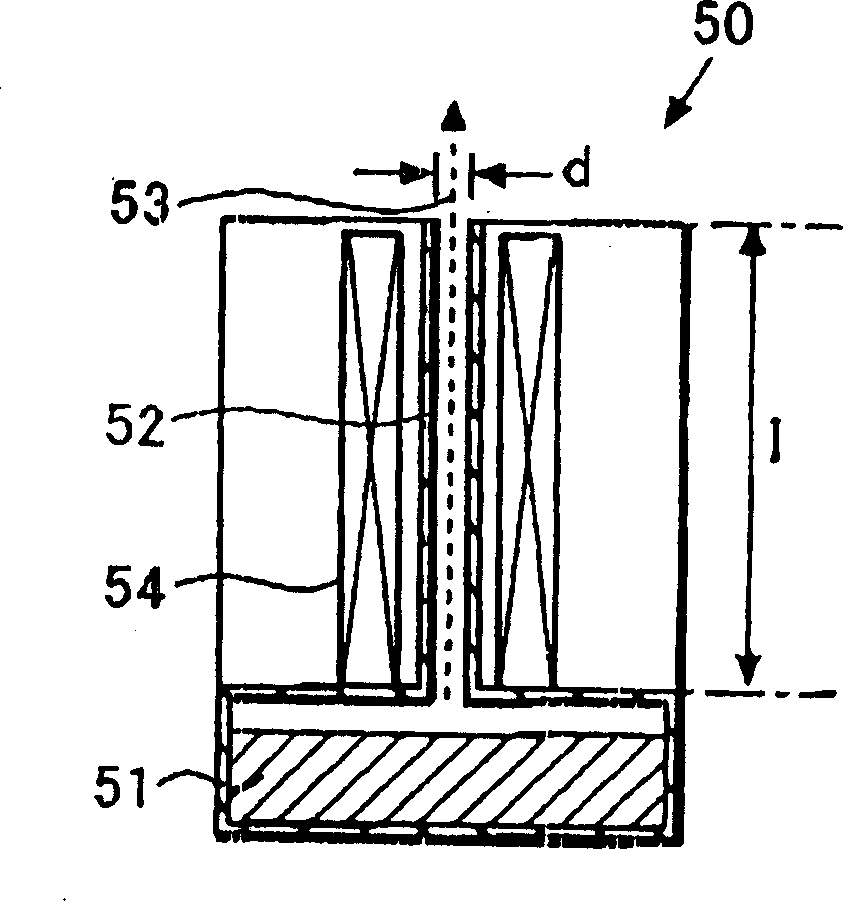

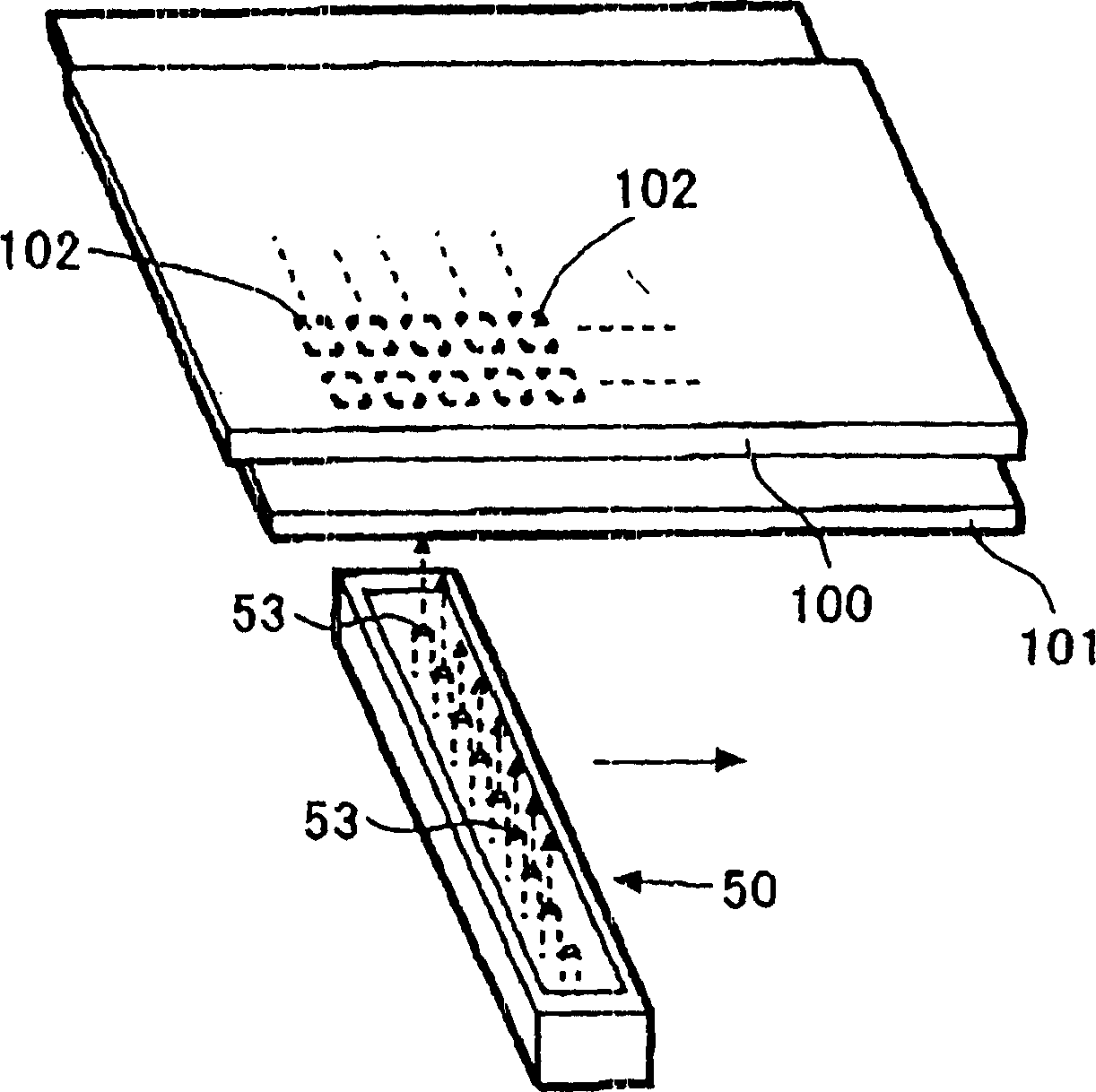

[0035] Hereinafter, the first embodiment of the present invention will be described in detail with reference to the accompanying drawings. figure 1 is a perspective view of the vapor deposition beam generating source 50, figure 2 for figure 1 sectional view, image 3 is a perspective view showing the vapor deposition process of the organic EL material, Figure 4 then image 3 sectional view.

[0036]In the method of manufacturing an organic EL display device of the present invention, an insulating substrate 10 is prepared in advance, and an organic EL element driving TFT and an organic EL element 60 are sequentially formed on the insulating substrate 10, except for the formation of the organic EL element 60. Except for the steps, the steps are the same as those described above.

[0037] The hole transport layer 62 , the light emitting layer 63 , the electron transport layer 64 , and the cathode 65 constituting the organic EL element 60 are patterned by vapor deposition...

no. 2 Embodiment approach

[0049] Hereinafter, a second embodiment of the present invention will be described in detail with reference to the accompanying drawings. Image 6 A perspective view of the vapor deposition beam generation source 150 and the vapor deposition beam direction adjustment plate 70 provided so as to face the vapor deposition beam generation source 150, Figure 7 for Image 6 sectional view, Figure 8 is a perspective view showing the vapor deposition process of the organic EL material, Figure 9 then Figure 8 sectional view.

[0050] In the method for manufacturing an organic electroluminescence display device of the present invention, an insulating substrate 10 is prepared in advance, and an organic EL element driving TFT and an organic EL element 60 are sequentially formed on the insulating substrate 10, except for the organic EL element 60. Except for the forming process of , it is the same as the process described above.

[0051] The hole transport layer 62 , the light emi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com