PBT/PET alloy material and preparation method thereof

A technology of alloy material and PBT resin, which is applied in the field of PBT/PET alloy material and its preparation, to achieve the effect of improving coating ability, increasing interface strength and improving appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

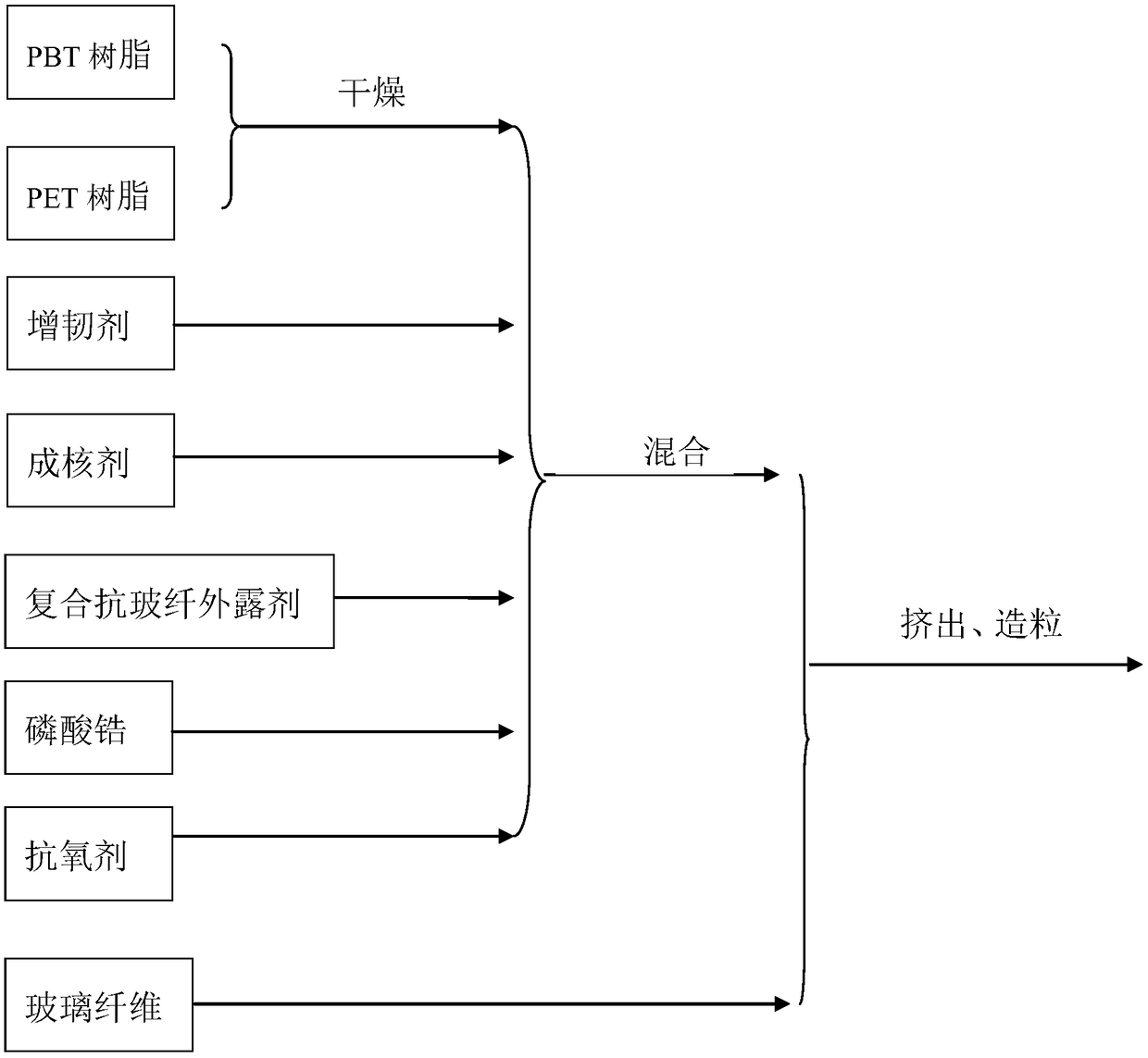

Method used

Image

Examples

Embodiment 1

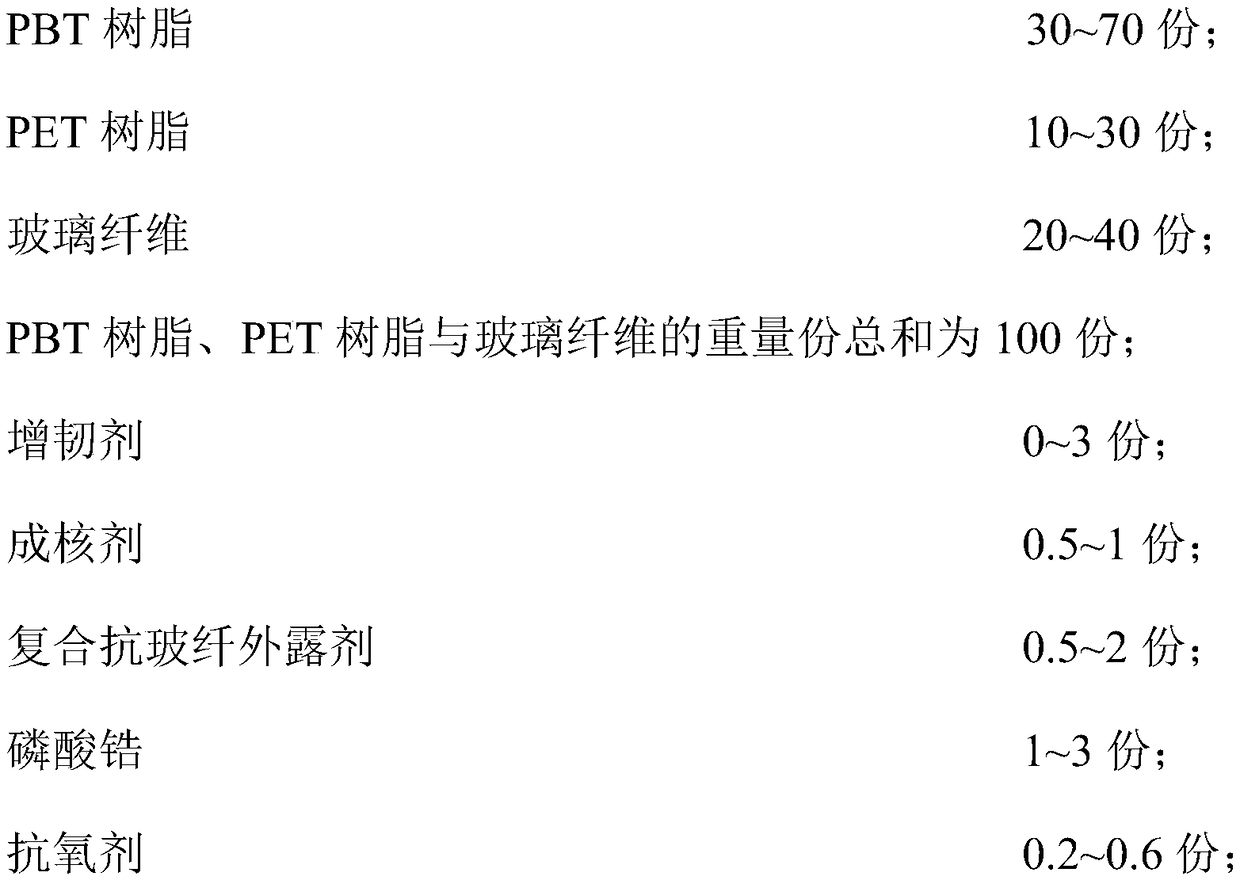

[0050] In this embodiment, a PBT / PET alloy material is prepared from the following raw materials by weight:

[0051]

[0052]

[0053] The composite anti-glass fiber exposing agent is made by mixing modified ethylene bis fatty acid amide, polydimethylsiloxane and polyethylene wax in a mass ratio of 2:2:1, and the added amount is 0.2 of modified ethylene bis fatty acid amide. Parts, 0.2 part of polydimethylsiloxane and 0.1 part of polyethylene wax.

[0054] The preparation method of the above-mentioned PBT / PET alloy material includes the following steps:

[0055] Step 1: Weigh the raw materials in each part by weight, and dry the weighed PBT resin and PET resin at a temperature of 120°C for 6 hours. After the drying is completed, cool to room temperature;

[0056] Step 2: Cool down to room temperature PBT resin, PET resin, toughening agent (ethylene-methyl acrylate-glycidyl methacrylate copolymer), nucleating agent (long-chain carboxylic acid sodium salt), composite anti-glass fiber P...

Embodiment 2

[0059] In this embodiment, a PBT / PET alloy material is prepared from the following raw materials by weight:

[0060]

[0061] The composite anti-glass fiber exposing agent is made by mixing modified ethylene bis fatty acid amide, polydimethylsiloxane and polyethylene wax in a mass ratio of 2:2:1, and the added amount is 0.2 of modified ethylene bis fatty acid amide. Parts, 0.2 part of polydimethylsiloxane and 0.1 part of polyethylene wax.

[0062] The preparation method of the above-mentioned PBT / PET alloy material includes the following steps:

[0063] Step 1: Weigh the raw materials in each part by weight, and dry the weighed PBT resin and PET resin at 120°C for 6 hours. After the drying is completed, cool to room temperature;

[0064] Step 2: Cool down to room temperature PBT resin, PET resin, toughening agent (ethylene-methyl acrylate-glycidyl methacrylate copolymer), nucleating agent (long-chain carboxylic acid sodium salt), composite anti-glass fiber Put the dew agent, zirconiu...

Embodiment 3

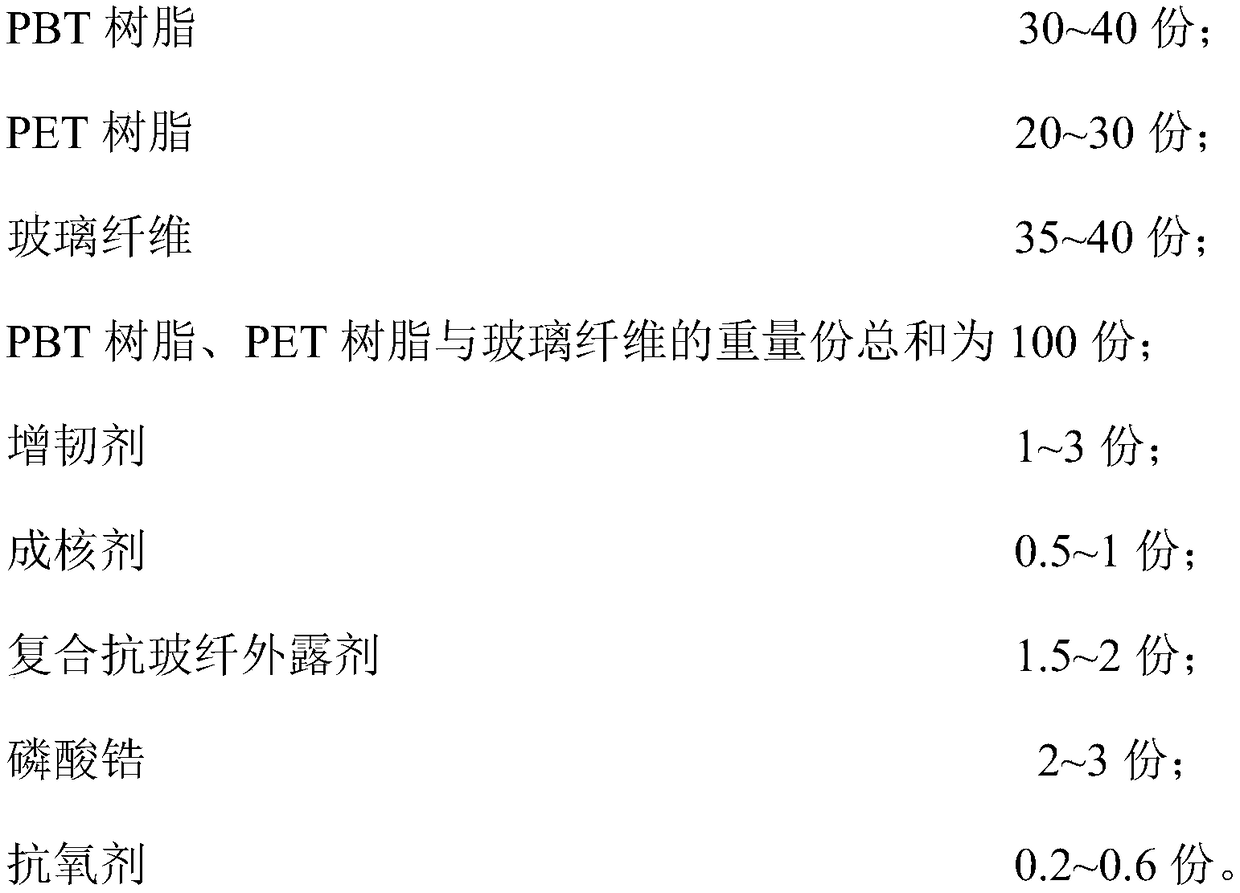

[0067] In this embodiment, a PBT / PET alloy material is prepared from the following raw materials by weight:

[0068]

[0069] The composite anti-glass fiber exposing agent is made by mixing modified ethylene bis fatty acid amide, polydimethylsiloxane and polyethylene wax in a mass ratio of 2:2:1. The addition amount is 0.2 of modified ethylene bis fatty acid amide. Parts, 0.2 part of polydimethylsiloxane and 0.1 part of polyethylene wax.

[0070] The preparation method of the above-mentioned PBT / PET alloy material includes the following steps:

[0071] Step 1: Weigh the raw materials in each part by weight, and dry the weighed PBT resin and PET resin at 140°C for 4 hours. After the drying is completed, cool to room temperature;

[0072] Step 2: Cool down to room temperature PBT resin, PET resin, toughening agent (ethylene-methyl acrylate-glycidyl methacrylate copolymer), nucleating agent (long-chain carboxylic acid sodium salt), composite anti-glass fiber Put the dew agent, zirconium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com