Method for recovering byproduct silicon tetrachloride produced in process of producing polycrystalline silicon

A silicon tetrachloride and polysilicon technology, applied in the directions of halogenated silicon compounds, halogenated silanes, energy input, etc., can solve the problems of the quality of trichlorosilane, high safety requirements, equipment wear, etc., and achieve easy industrialized continuous production. , The effect of production safety is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Absorption and analysis of silicon tetrachloride by 1-butyl-3-methylimidazolium tetrafluoroborate ionic liquid:

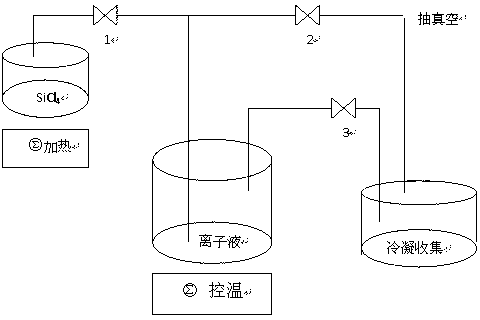

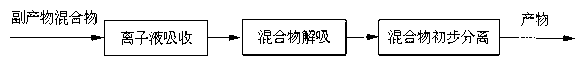

[0045] The simple diagram of the experimental device for the absorption and analysis of silicon tetrachloride by ionic liquid image 3 Shown: SHAPE \* MERGEFORMAT

[0046] Firstly, the system is evacuated to remove moisture as much as possible. Thereafter, the silicon tetrachloride waste liquid from which moisture has been removed is heated into a gas, which is passed into a container containing 100 g of ionic liquid for absorption. The absorption temperature is 20 ° C. After the absorption is saturated, the The ionic liquid was weighed to be 244g, and its absorption capacity was calculated to be 144g. Heat the weighed ionic liquid to 120 o C analysis, the gas passes through the cold trap device (-20 o C) Recycling, weighing the silicon tetrachloride obtained, and analyzing SiCl 4 140 g, the recovery rate was 97.2%.

Embodiment 2

[0048] Absorption and analysis of silicon tetrachloride by 1-butyl-3-methylimidazolium hexafluorophosphate ionic liquid:

[0049] First, vacuumize the system to remove moisture as much as possible. After that, heat the silicon tetrachloride waste liquid that has been removed into gas, and put it into a container with 100 g of ionic liquid for adsorption. The absorption temperature is 20 ° C. After the absorption is saturated, The ionic liquid was weighed to be 289g, and its absorption capacity was calculated to be 189g. Heat the weighed ionic liquid to 120 o C analysis, the gas passes through the cold well device (-20 o C) Recycling, weighing the silicon tetrachloride obtained, and analyzing SiCl 4 185 g, the recovery rate was 97.9%.

Embodiment 3

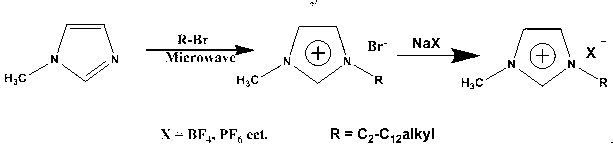

[0051] 1-methyl-3-alkylimidazolium hexafluorophosphate and 1-methyl-3-alkylimidazolium tetrafluoroborate ionic liquid, wherein the alkyl groups are respectively C 2 -C 12 , the prepared ionic liquids all have a good recovery effect on silicon tetrachloride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com