Manufacturing of high-transmittance flexible electrochromic film

An electrochromic and flexible electrical technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of low transparency, complex process, and limitations in large-area preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Lithium perchlorate of purchase, resin powder are placed in 100 ℃ of vacuum ovens and dried for 24 hours for subsequent use.

[0023] Electrolyte Solution Preparation 1

[0024] Weigh 1.54g of lithium perchlorate and place it in a beaker, then measure 10ml of polycarbonate and add it into the beaker, stir and dissolve at room temperature, and store it in a vacuum drying oven after the dissolution is complete.

[0025] Electrolyte Slurry Preparation 1

[0026] Weigh 5.50g of the dried PVB resin powder and place it in a 500ml beaker, then add 1.25g of the prepared electrolyte solution, stir well and then add 0.85g of triethylene glycol diisocaprylate, polydimethylsiloxane 0.25 g, 0.31 g of dibutylhydroxytoluene. After stirring evenly, add 40ml of dimethylformamide to dissolve, completely dissolve and store in an airtight seal.

[0027] Preparation of Flexible Electrochromic Films 1

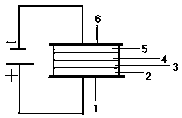

[0028] First, dry KPT-EL9 in a 120-degree oven for 15 minutes, and then vapor-deposit...

Embodiment 2

[0032] Electrolyte slurry preparation 2

[0033] Weigh 11.50g of the dried PVDF resin powder and place it in a 500ml beaker, then add 2.55g of the prepared electrolyte solution, stir well and then add 1.75g of diethylene glycol dibenzoate and 0.55g of polyoxypropylene glyceryl ether , 0.62 g of tert-butyl-p-hydroxyanisole. After stirring evenly, add 90ml of a mixed solvent of dimethylformamide and xylene with a volume ratio of 2:1, completely dissolve and store in an airtight seal.

[0034] Preparation of Flexible Electrochromic Films 2

[0035] First, dry KPT-EL9 in a 120-degree oven for 15 minutes, and then vapor-deposit KPT-EL5 on the surface of the transparent conductive film by magnetron sputtering process. The production line prepares a solid electrolyte membrane from the prepared electrolyte slurry, adjusts the thickness of the film to 0.05mm, and then laminates the flexible electrochromic layer conductive film, flexible solid electrolyte film and flexible transpare...

Embodiment 3

[0039] Electrolyte Slurry Preparation 3

[0040] Weigh 11.50g of the dried PDMS resin powder and place it in a 500ml beaker, then add 2.55g of the prepared electrolyte solution, stir well and then add 1.75g of triethylene glycol diisocaprylate, 0.55g of emulsified silicone oil, tert-butyl 0.62g of p-hydroxyanisole. After stirring evenly, add 90ml of acetone and toluene mixed solvent with a volume ratio of 3:5, completely dissolve and store in an airtight seal.

[0041] Fabrication of Flexible Electrochromic Films 3

[0042] First, dry KPT-EL9 in a 120-degree oven for 15 minutes, and then vapor-deposit KPT-EL5 on the surface of the transparent conductive film by magnetron sputtering process. The production line prepares a solid electrolyte membrane from the prepared electrolyte slurry, adjusts the film thickness to 0.1mm, and then laminates the flexible electrochromic layer conductive film, flexible solid electrolyte film and flexible transparent conductive film using a vac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com