A method of manufacturing a monovalent ion selective cation exchange membrane

A cation-exchange membrane and ion-selective technology, applied in the direction of coating, etc., can solve the problems of difficulty in ensuring the consistency of the treatment effect, damage to the basement membrane structure, etc., and achieve the effects of long-lasting monovalent cation selection performance, improved production efficiency, and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

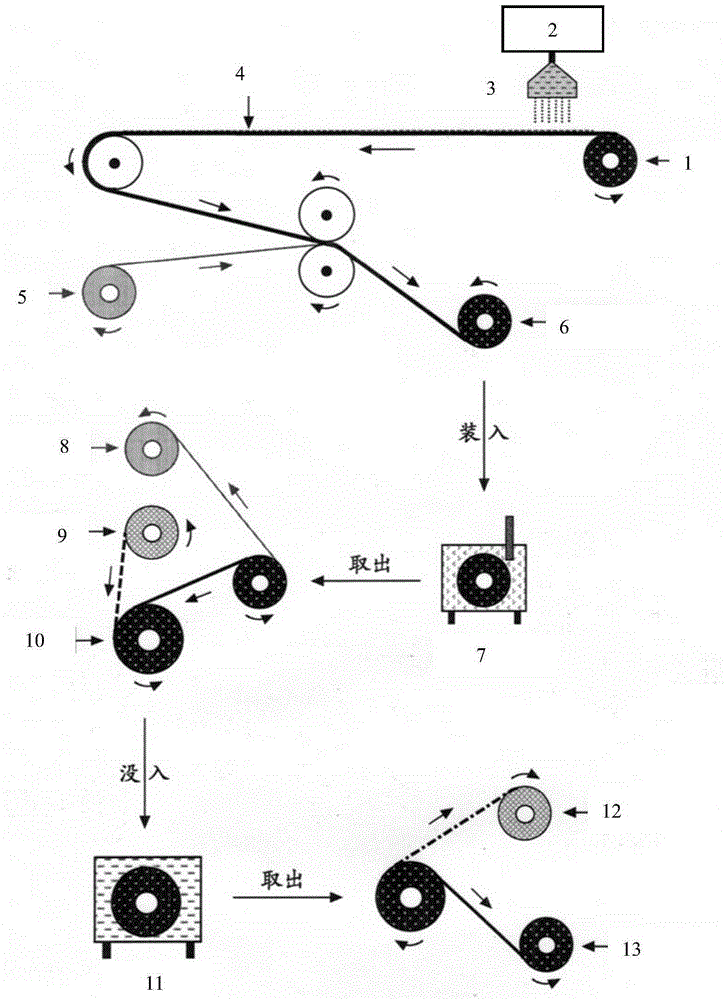

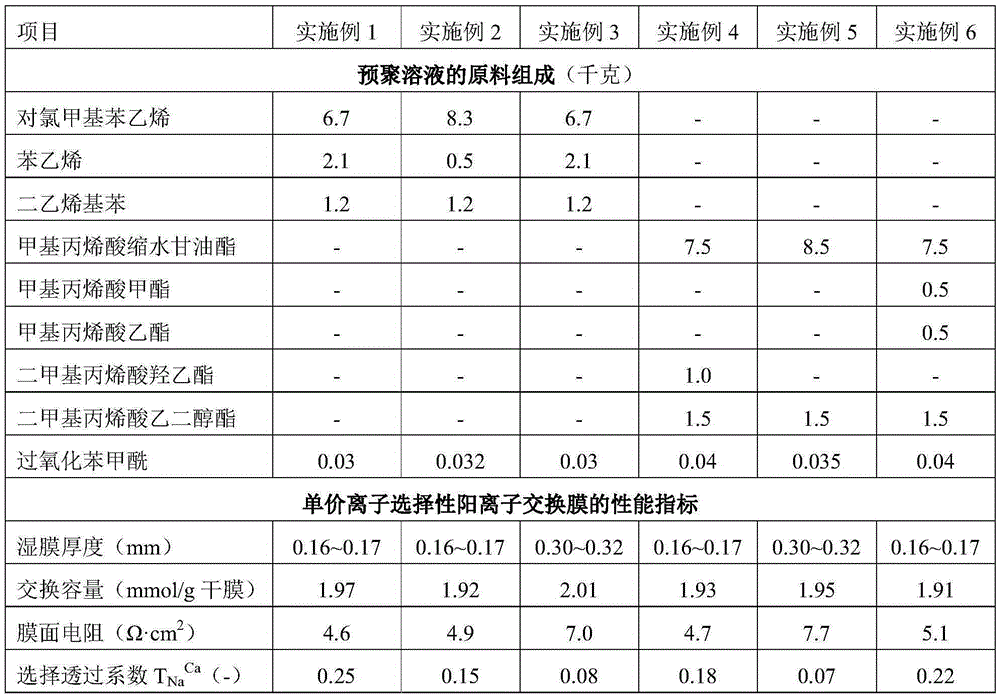

[0030] Step 1: a) First prepare the prepolymerization solution: in a 20-liter glass jacketed reactor, add 6.7 kilograms of p-chloromethylstyrene (the content is 91.3%, containing 6% of m-chloromethylstyrene, o-chlorine Methylstyrene 1.5%), 2.1 kilograms of styrene, 1.2 kilograms of divinylbenzene (the content is 80.2%), 30 grams of benzoyl peroxide, stirred at room temperature for 30 minutes; nitrogen gas was blown into, and the temperature was raised after 45 minutes to 50°C, pre-polymerized at a constant temperature for 220 minutes, and transferred to a spray container for later use; b) dry film rolls of LCM series cation exchange homogeneous membranes (provided by Liaoning Yichen Membrane Technology Co., Ltd., width 60.0 cm, thickness 0.15 mm, The length is 120 meters) according to the linear speed of 2.4 meters per minute, after passing through the working box with a constant temperature of 54-58 ℃; the spraying device is turned on, and the spraying speed is controlled at 3...

Embodiment 2

[0035] The composition of the prepolymerization solution in step 1-a of Example 1 is changed to: 8.3 kilograms of p-chloromethylstyrene (purity consistent with Example 1), 0.5 kilogram of styrene, 1.2 kilograms of divinylbenzene (purity Consistent with embodiment 1), 32 grams of benzoyl peroxide. The rest of the materials used (including the base cationic membrane), the operation method, the implementation process and other manufacturing conditions are consistent with those described in Example 1, and the monovalent ion-selective cation exchange membrane is obtained.

[0036] Measured by the same method: the wet film thickness of the prepared monovalent ion-selective cation exchange membrane is 0.16 to 0.17 millimeters, the cation exchange capacity is 1.92 millimoles per gram of dry film, and the membrane surface resistance is 4.9 Ω cm 2 , select the transmission coefficient T Na Ca = 0.15.

Embodiment 3

[0038] Replace the dry film roll of the LCM series cation-exchange homogeneous membrane in step 1-b of Example 1 with the dry film roll of the HCM series cation-exchange homogeneous membrane (provided by Liaoning Yichen Membrane Technology Co., Ltd., width 60.0 cm , thickness 0.28 millimeters, length 150 meters), all the other materials used (comprising pre-polymerization solution), operating method, implementation process and other manufacturing conditions are all consistent with those described in Example 1, making the described monovalent ion-selective cation exchange membrane .

[0039]After inspection: a) The wet film thickness of the base cathodic membrane is 0.30-0.32 mm, the cation exchange capacity is 2.08 millimoles per gram of dry film, and the membrane surface resistance is 5.8Ω·cm 2 , select the transmission coefficient T Na Ca =1.4; b) measured by the same method: the wet film thickness of the prepared monovalent ion-selective cation exchange membrane is 0.30~0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com