Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2812results about "Broadcast seeders" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

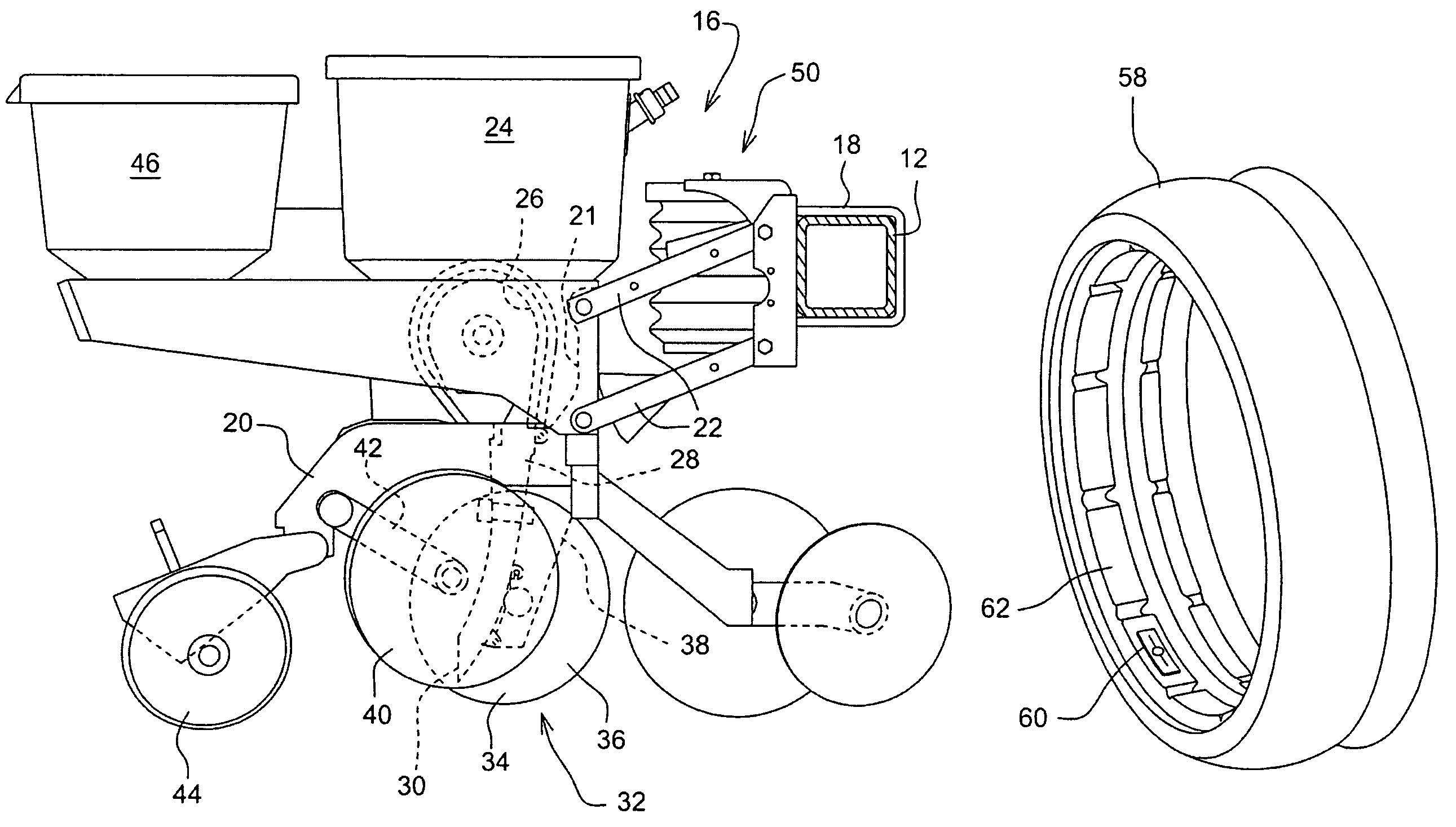

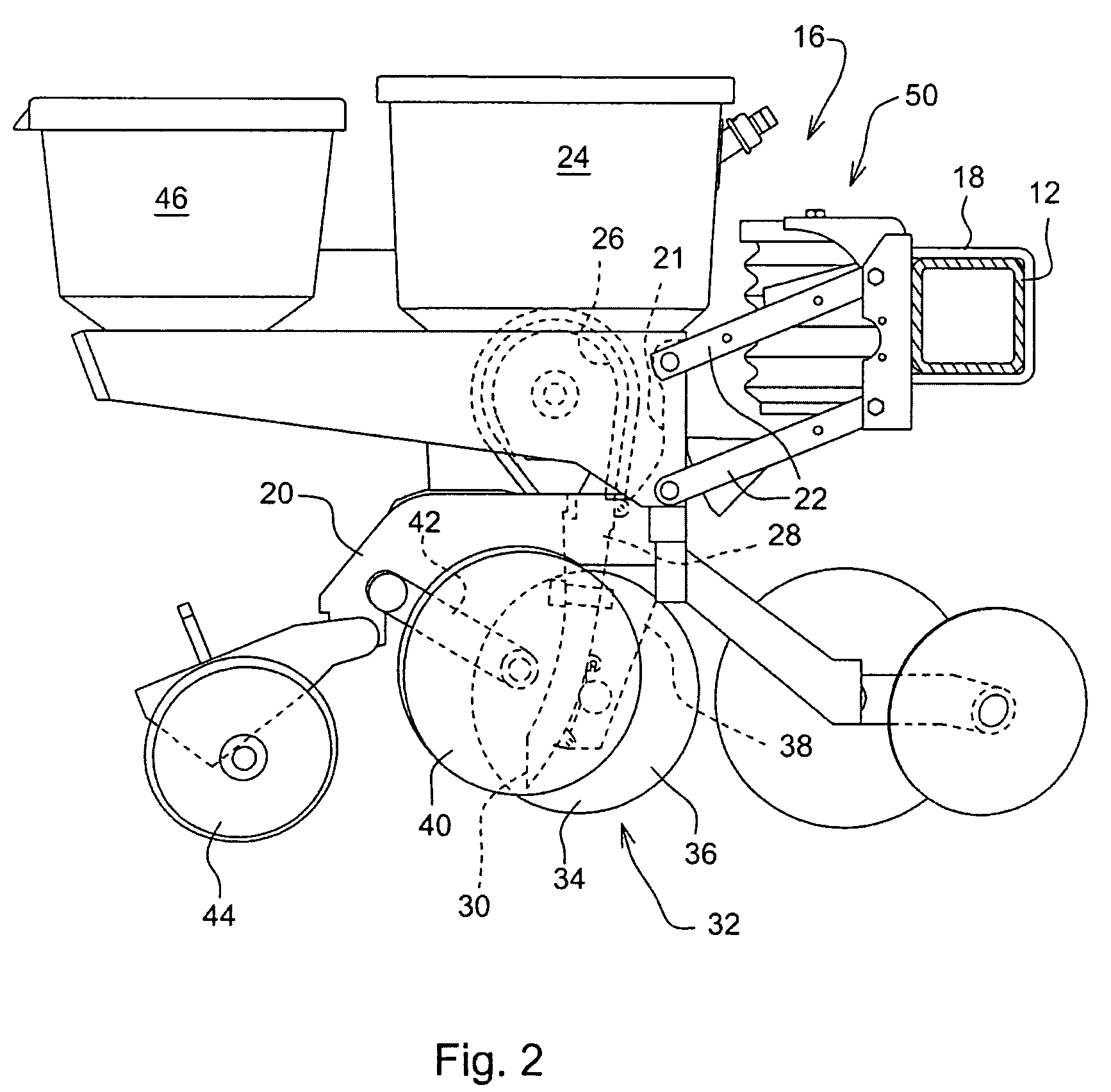

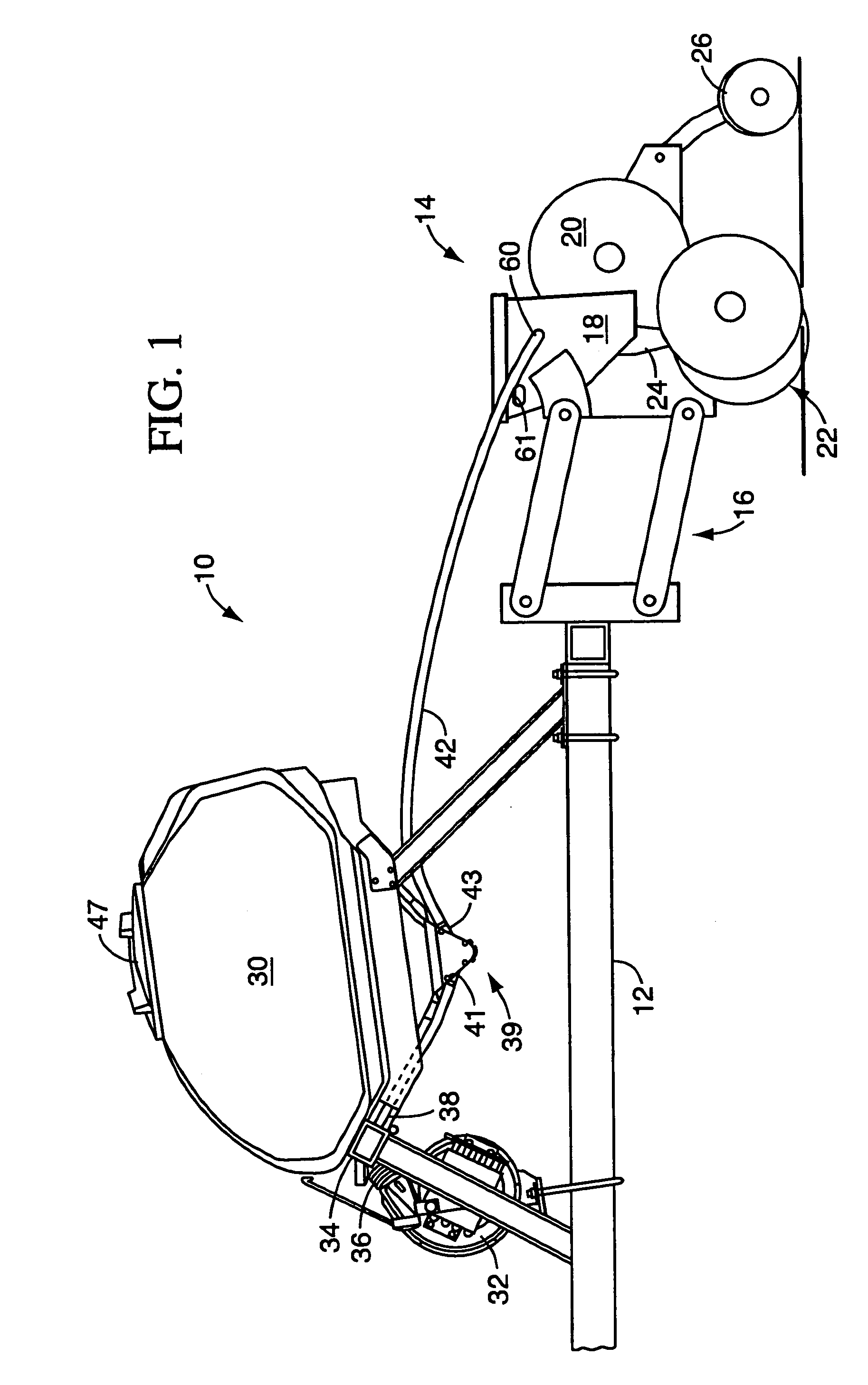

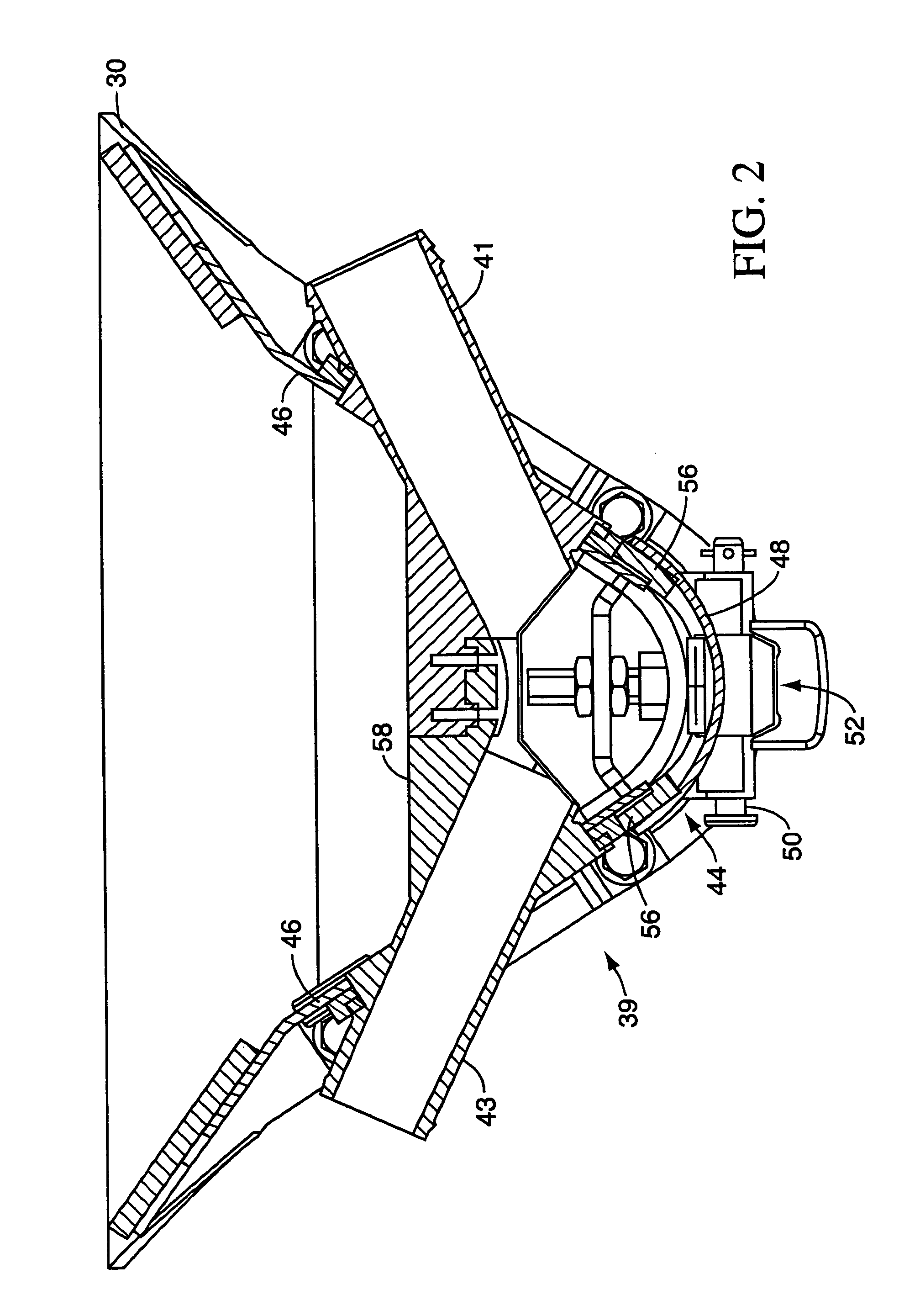

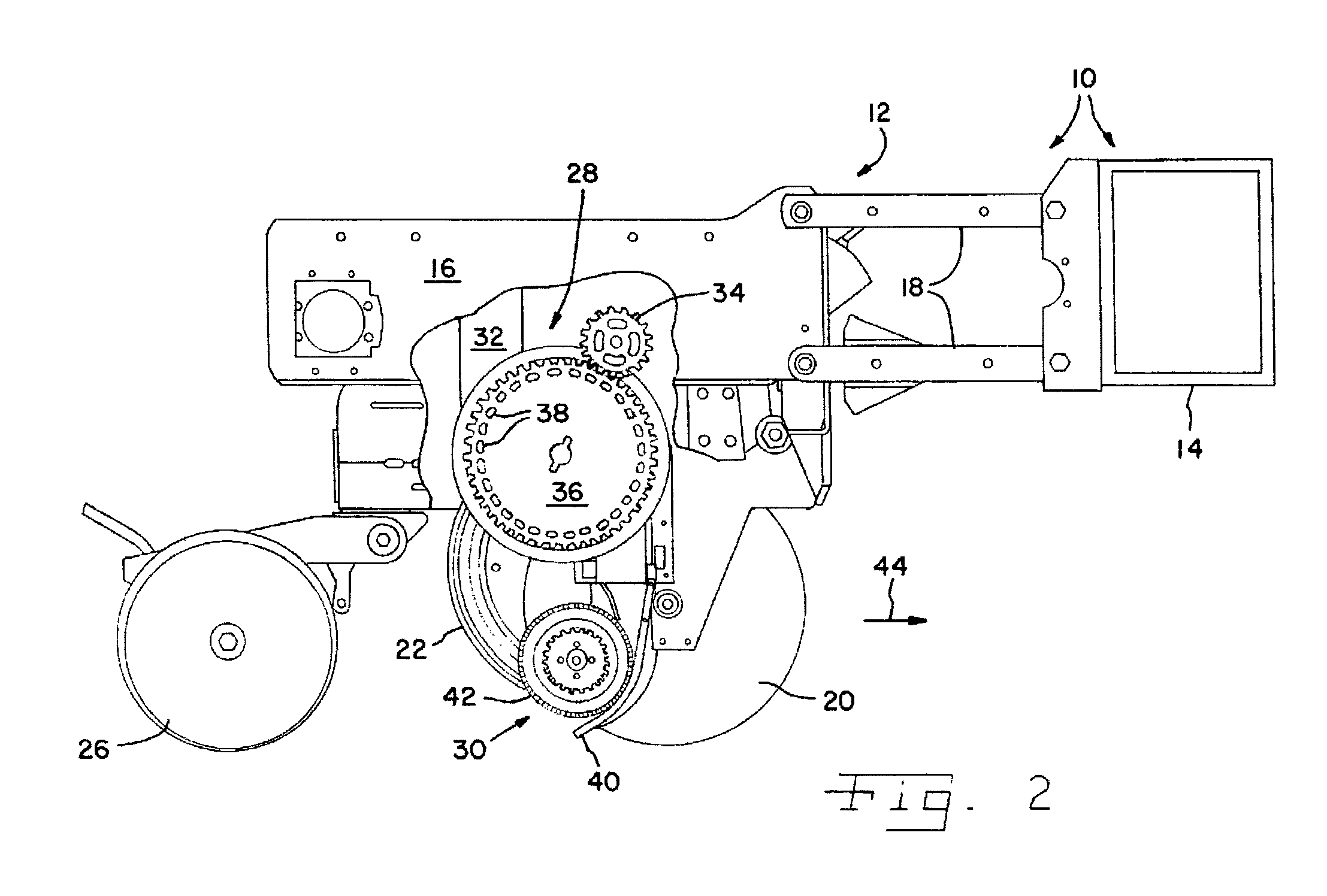

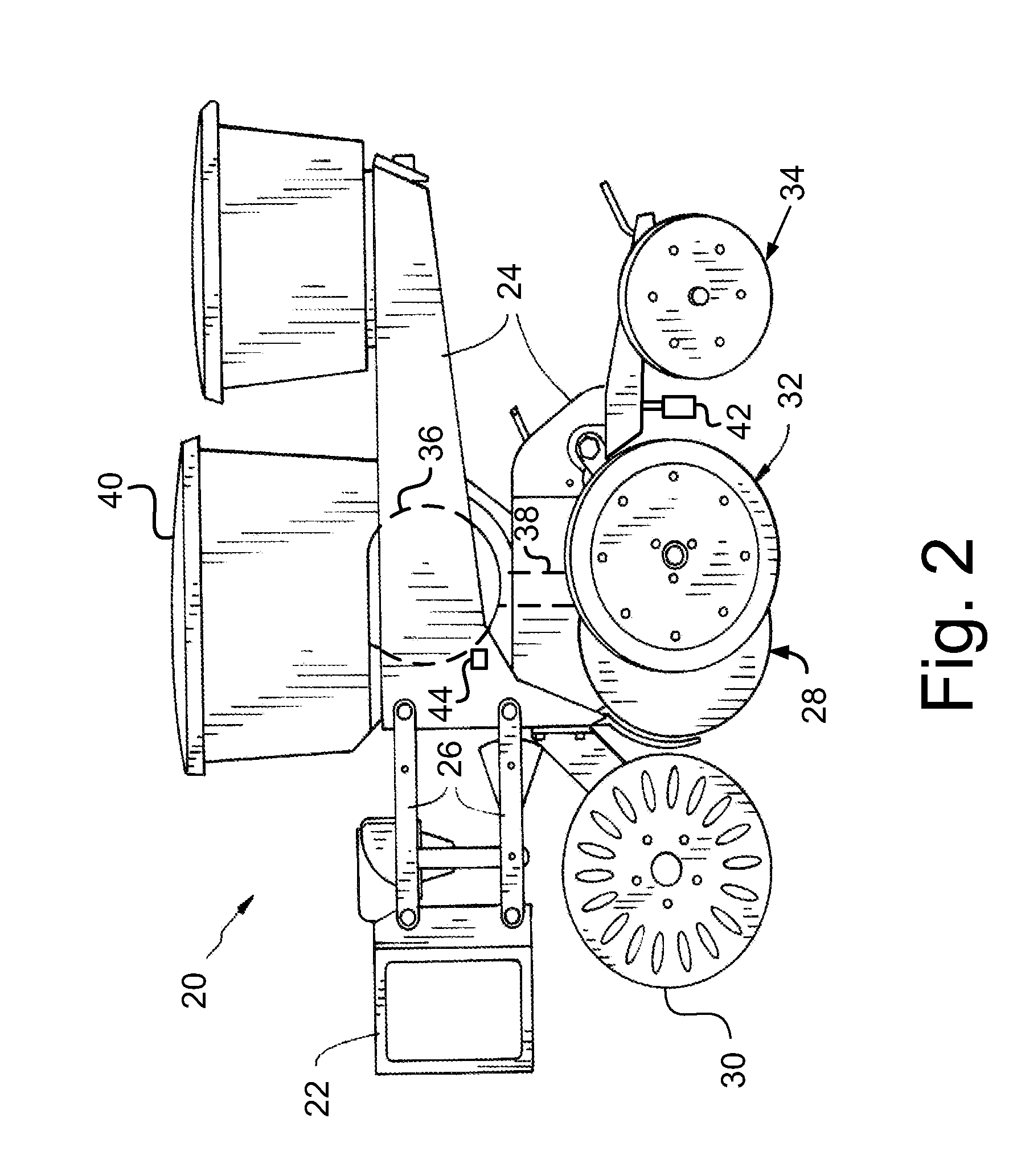

Pressure sensing system for a planter

A pressure sensing system for a seeding machine such as a planter to measure the down force on a planter row unit uses a wireless pressure sensor embedded in a load carrying wheel of the row unit. In a preferred embodiment, the pressure sensor is a passive piezoelectric pressure sensor that is a transmitter only, transmitting both pressure and RFID the information that identifies the particular sensor. Multiple sensors may be employed in each wheel and sensors may be employed in more than one wheel of the row unit, such as the gauge wheels on opposite sides of the trench opening disks. The sensors may be made of a PVDF, a known piezoelectric material. A wireless receiver is located on the planter frame or could be located elsewhere to receive the signals from the pressure sensor. A controller determines from the signal, any change in down force and commands the change to a down force generator on the row unit.

Owner:DEERE & CO

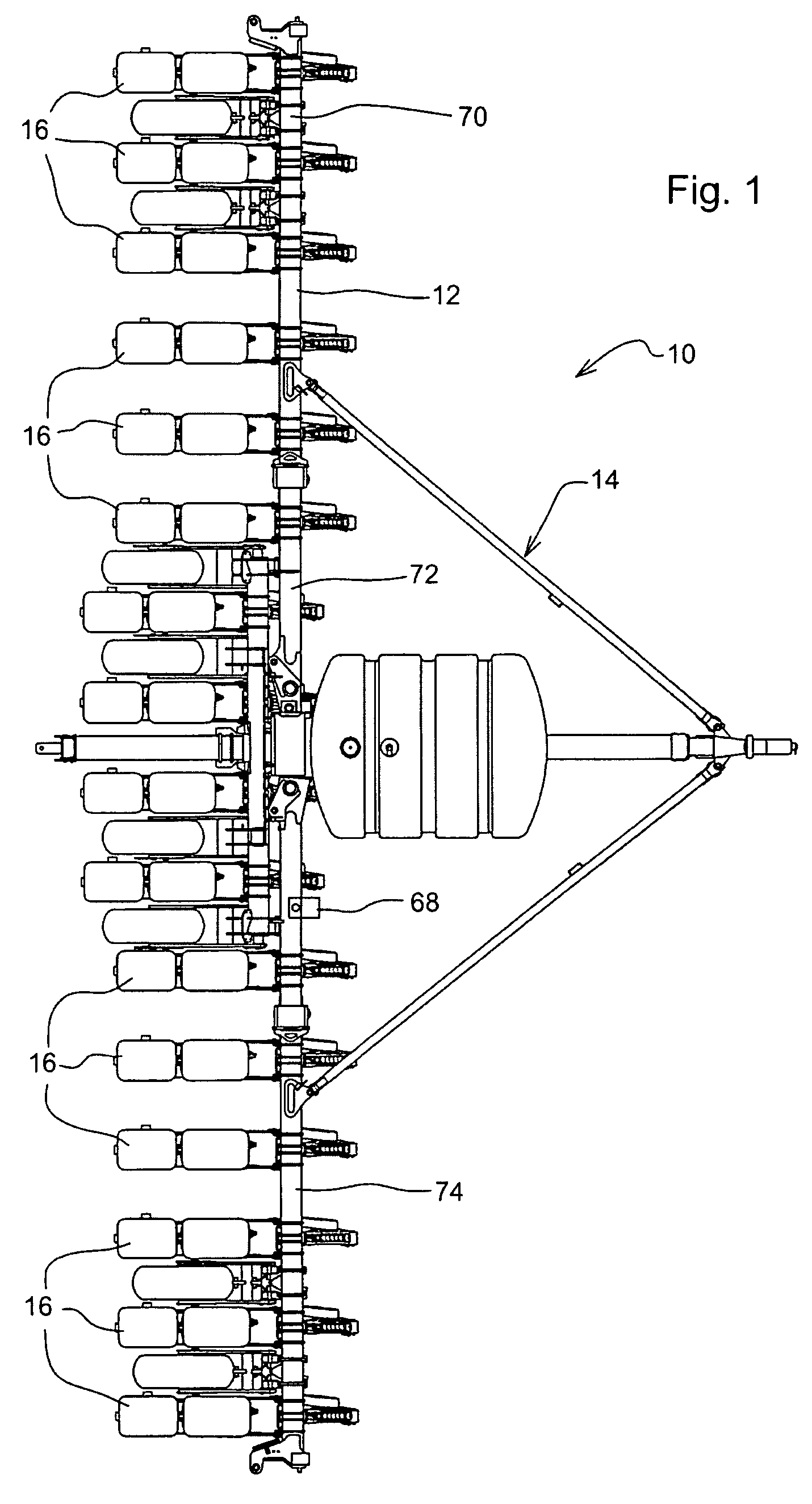

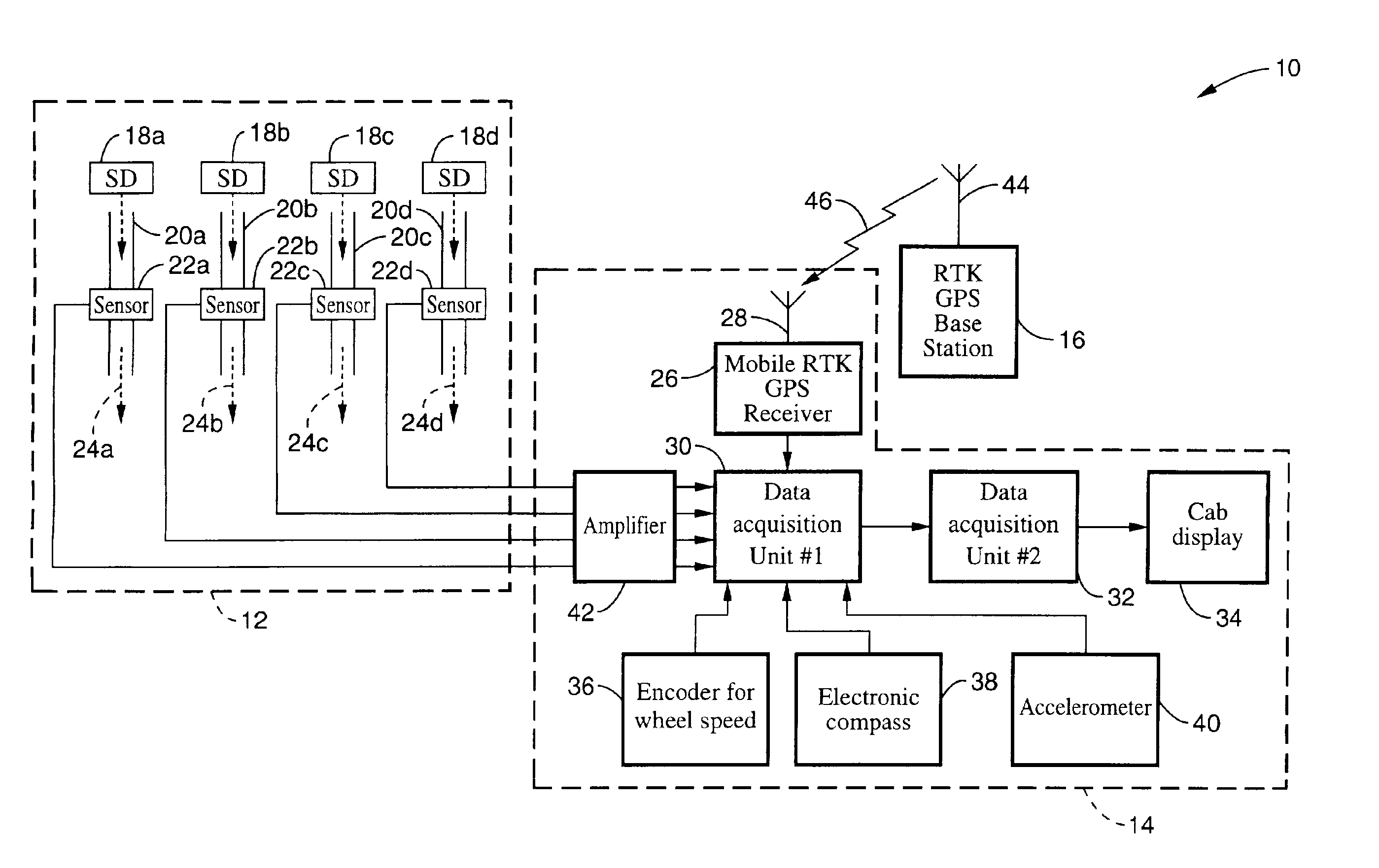

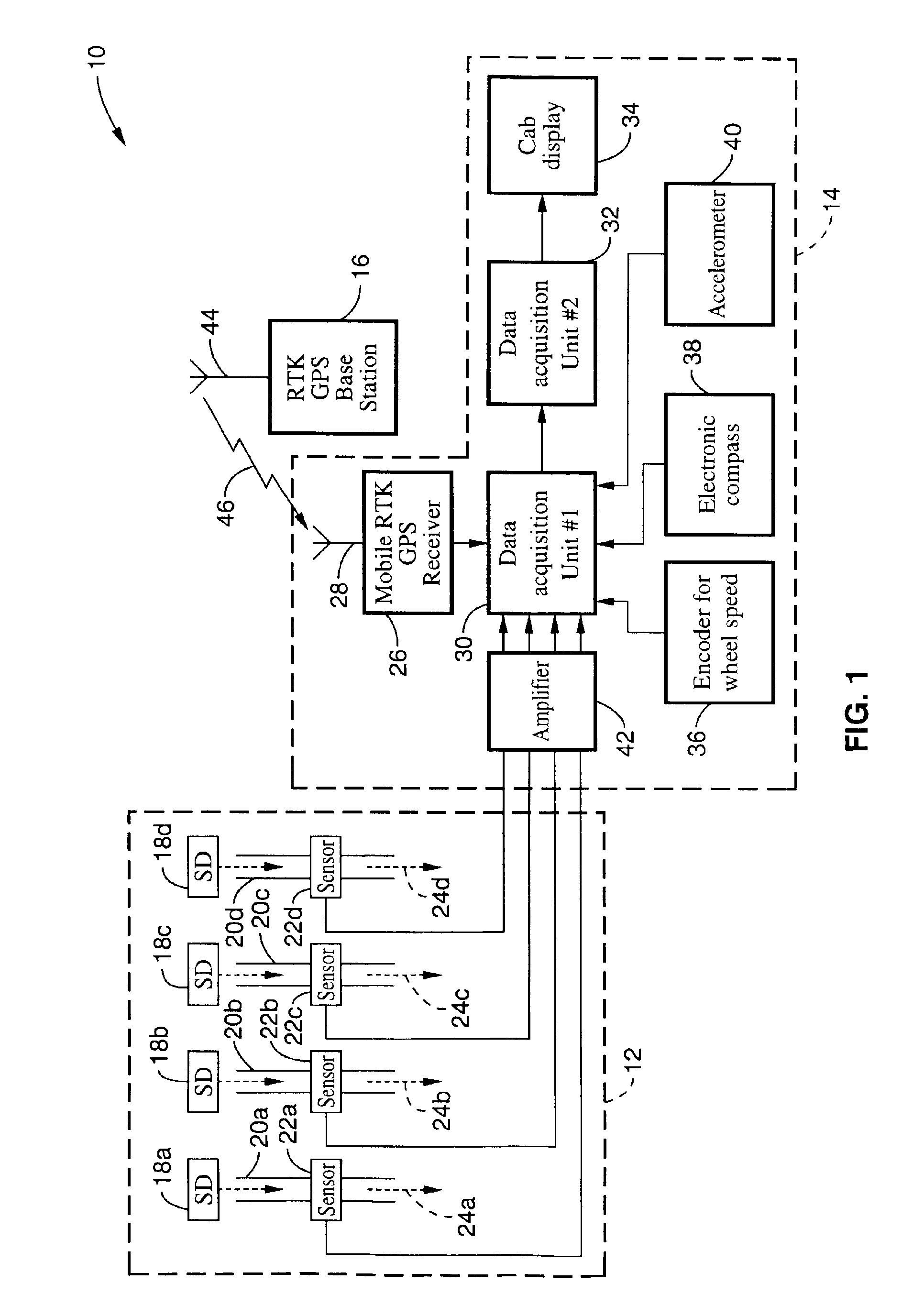

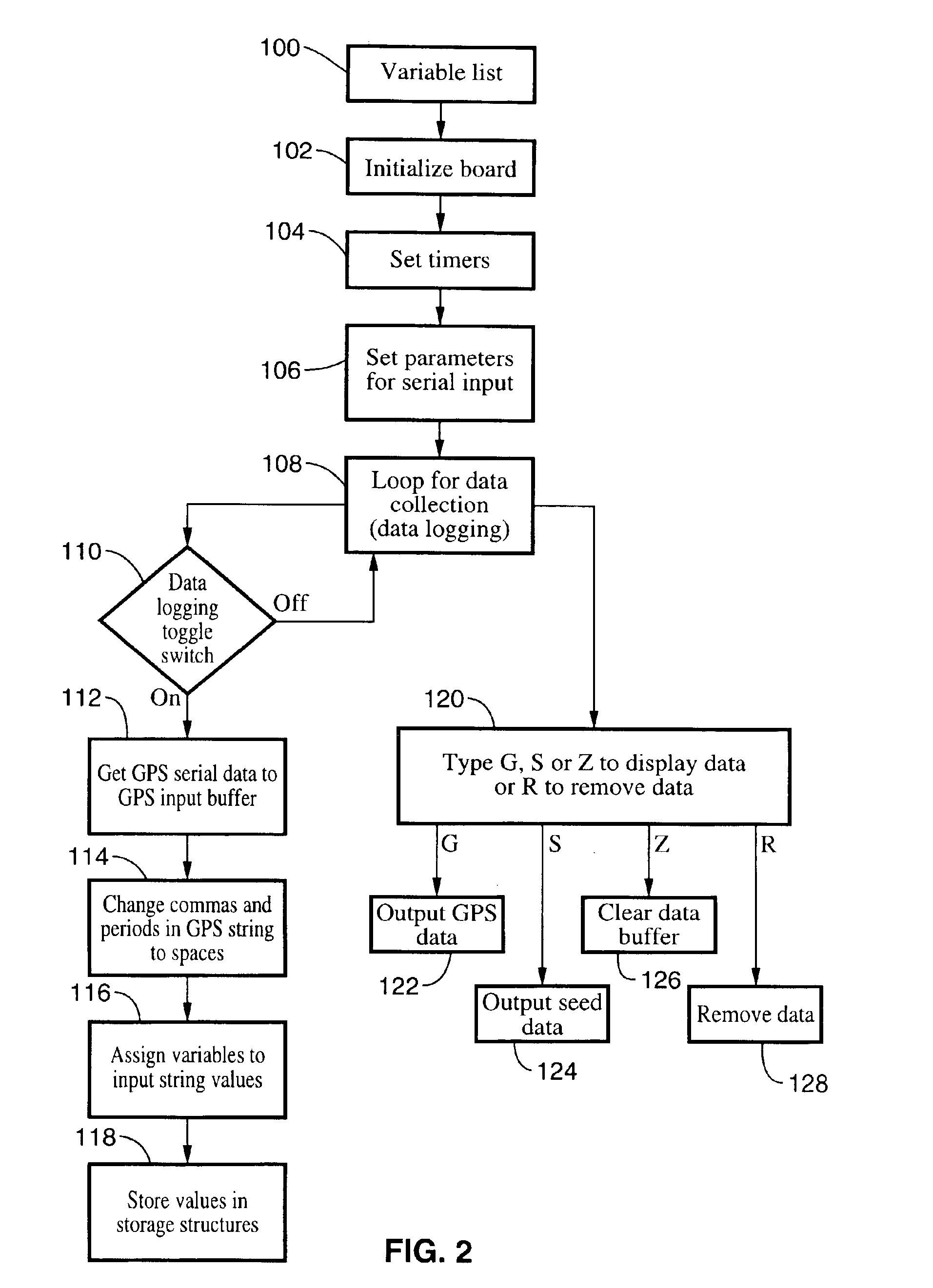

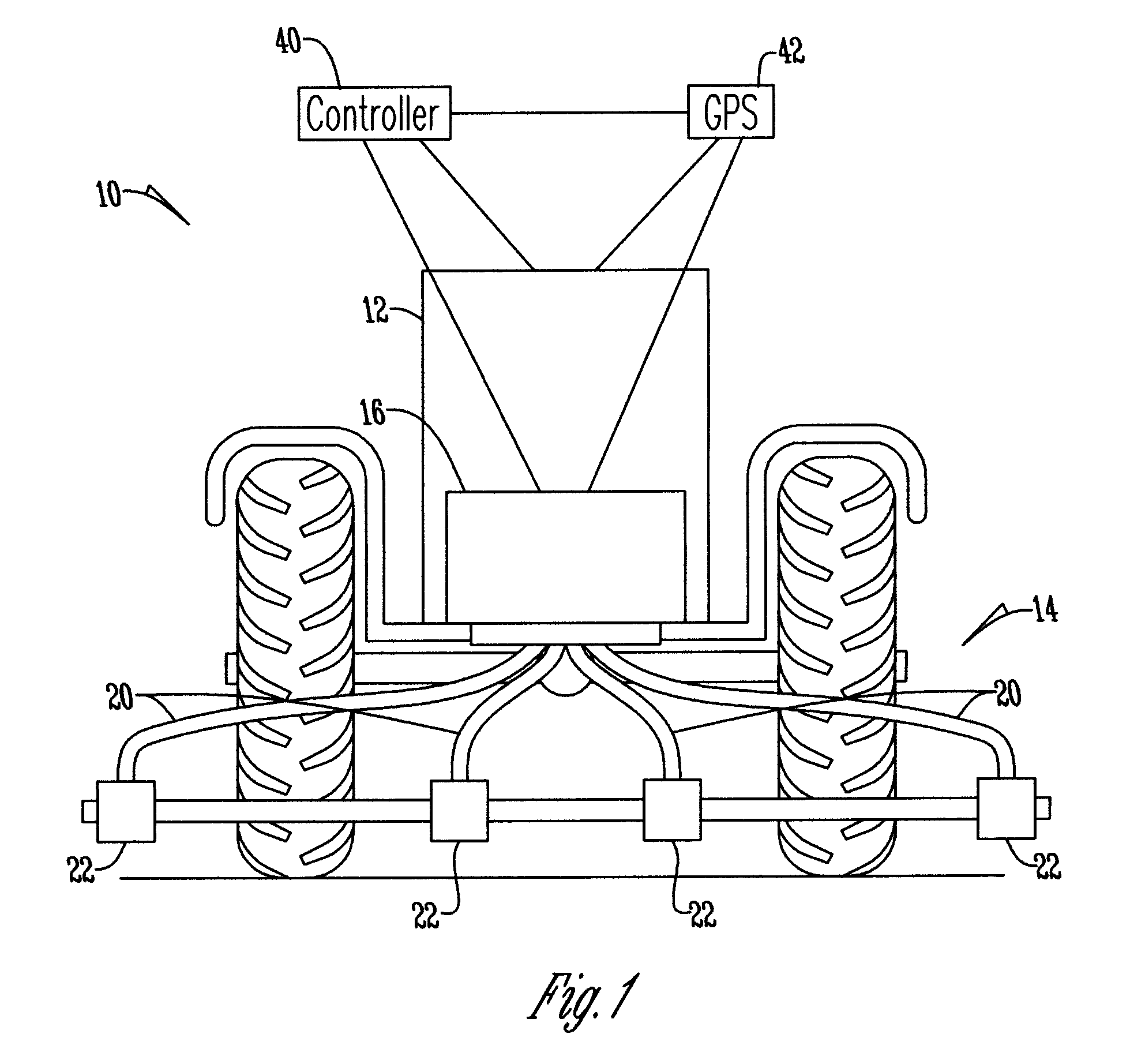

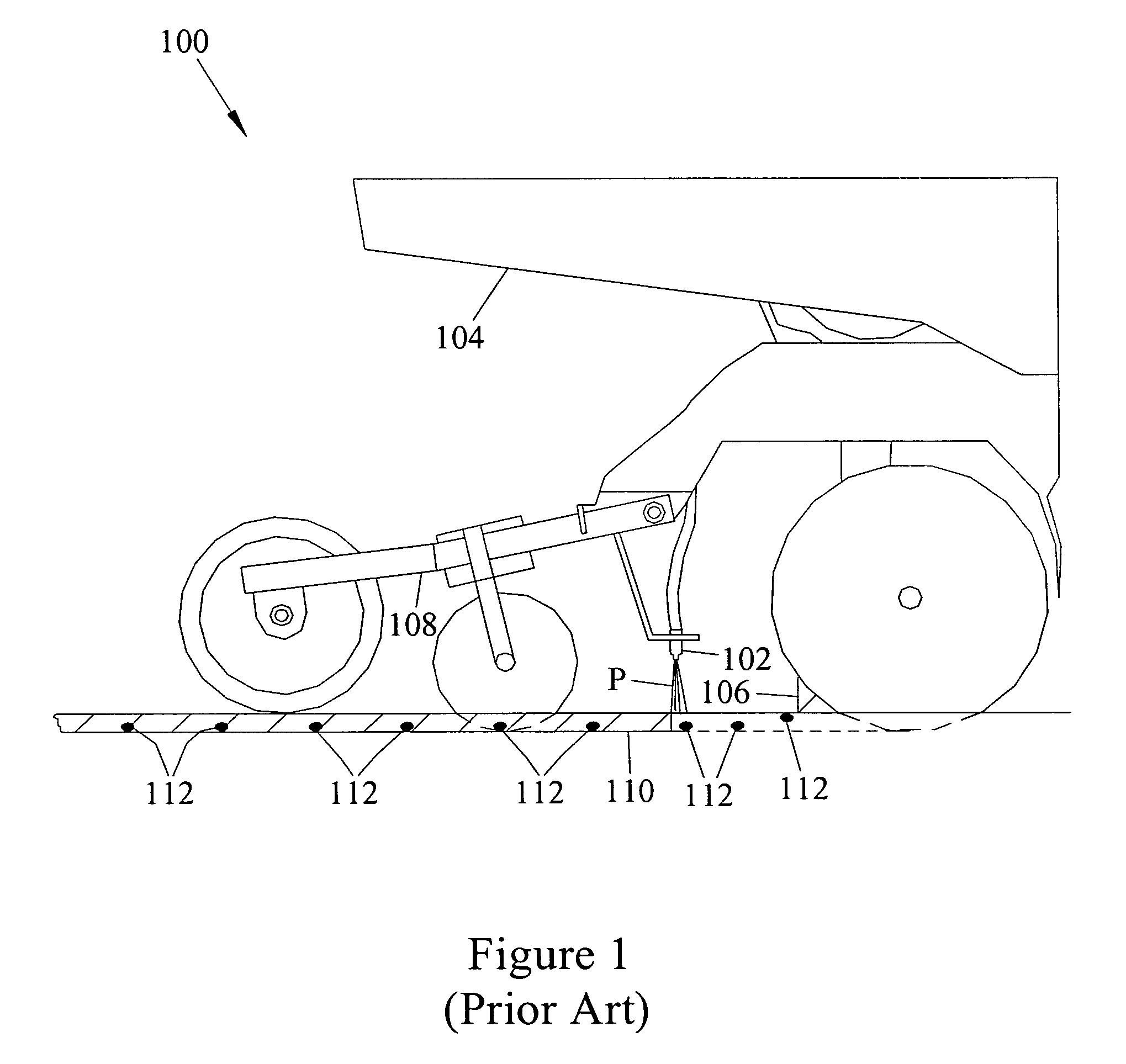

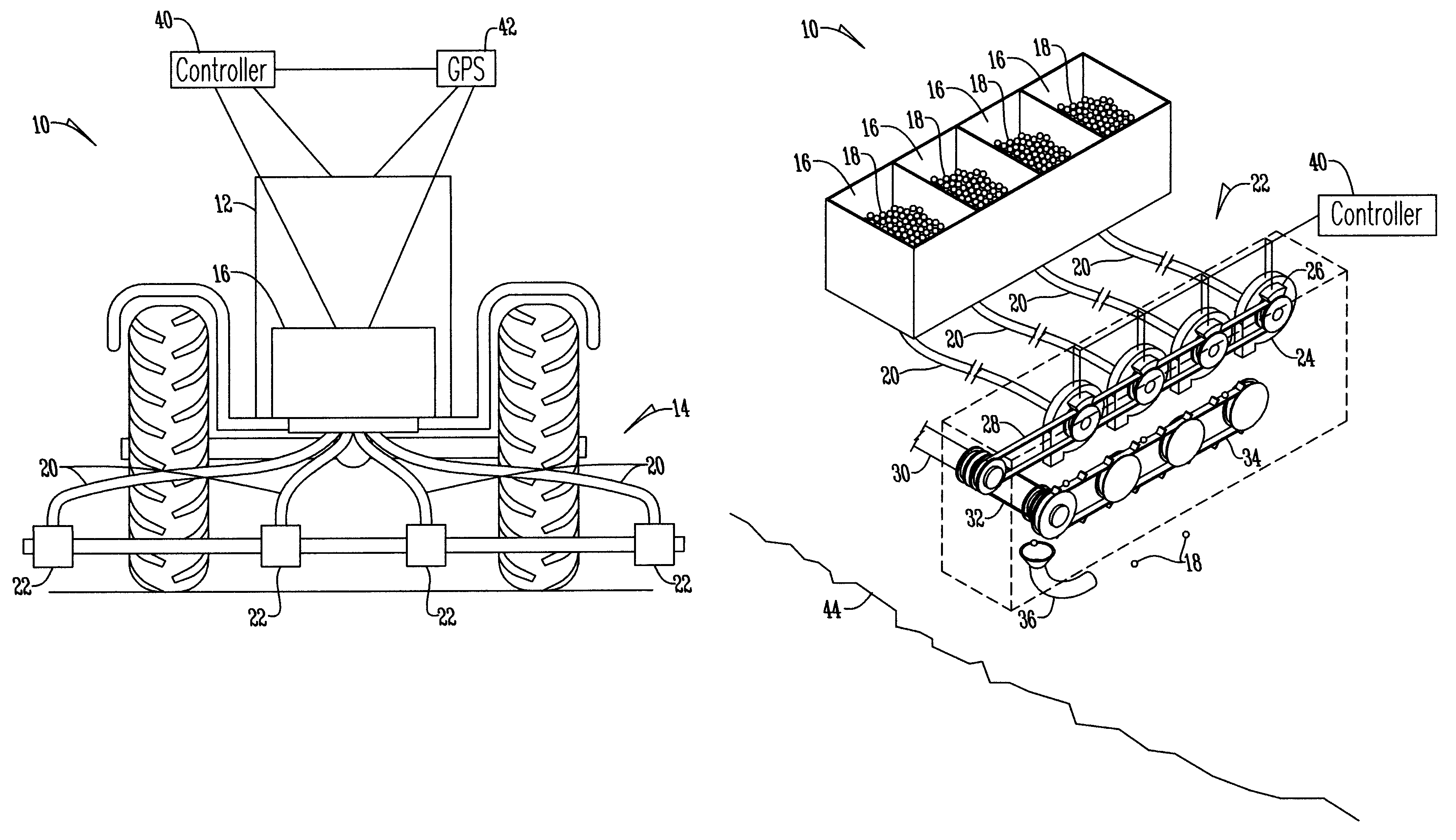

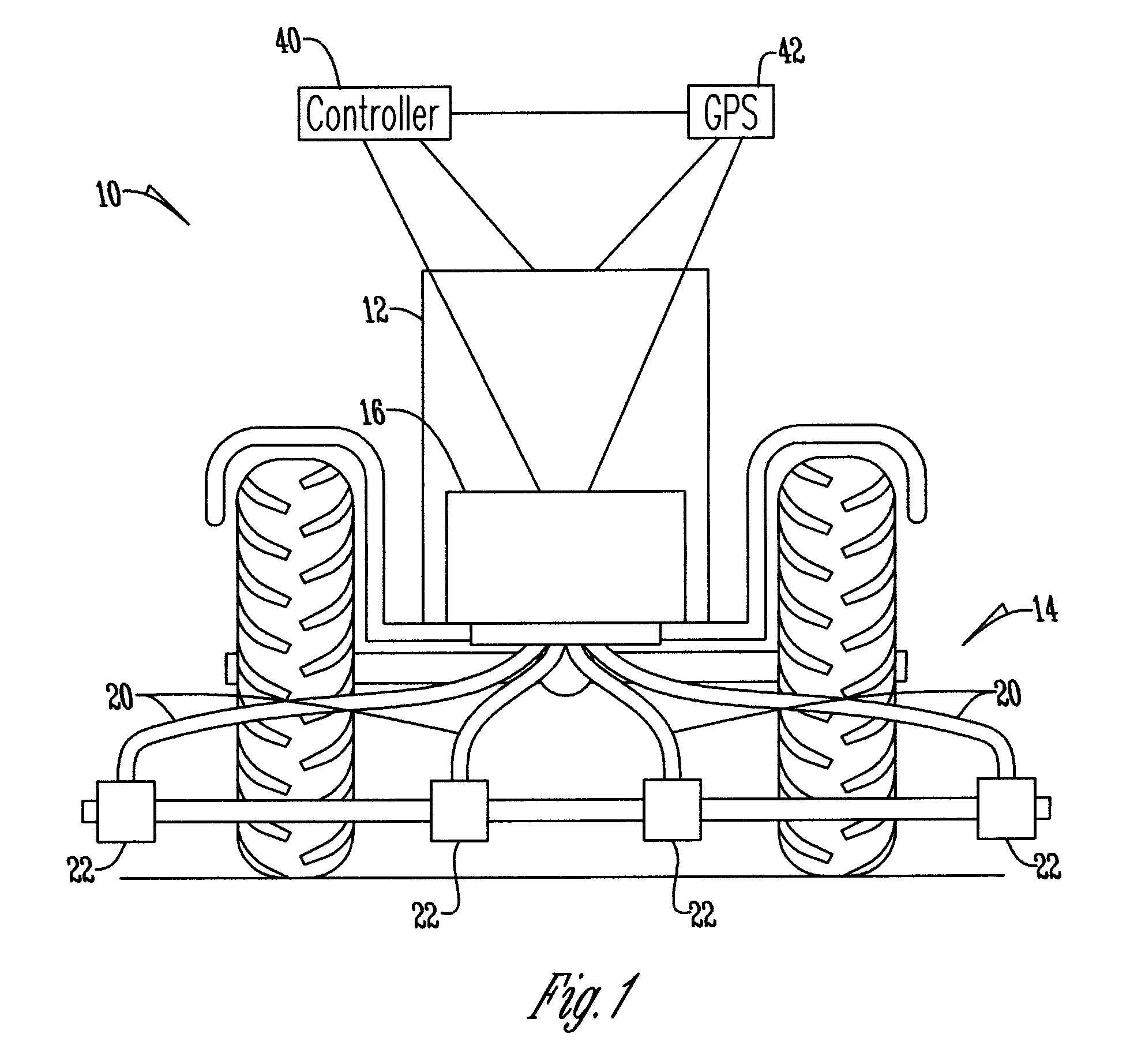

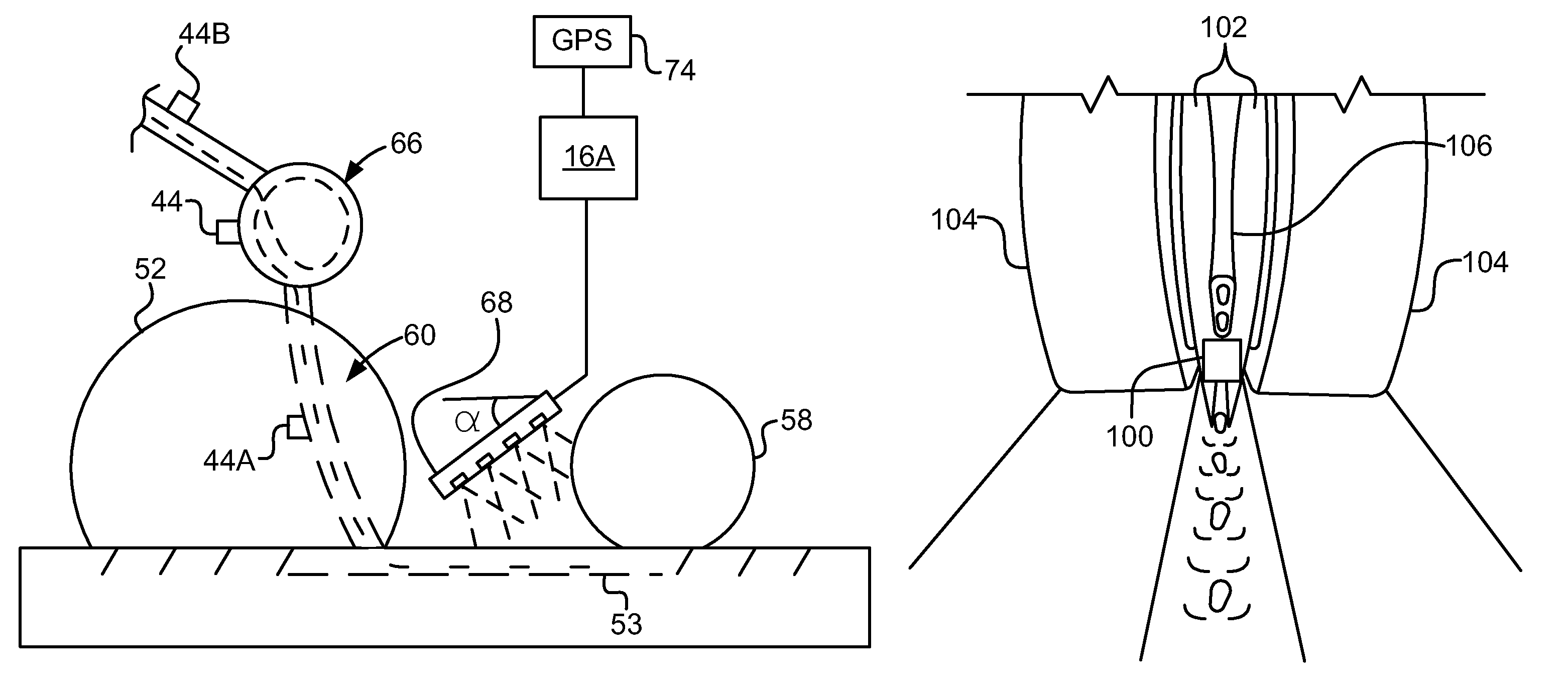

Method and apparatus for ultra precise GPS-based mapping of seeds or vegetation during planting

InactiveUS6941225B2Application can be controlledLow costMowersFertiliser distributersVegetationGps receiver

An ultra precise seed planter apparatus and method for generating a centimeter accuracy map of the location of seeds or vegetation as they are planted from an agricultural planting machine. The apparatus is fitted with a GPS receiver feeding a data logger, and optical sensors that are placed adjacent seed or vegetation dispenser. The data logger monitors GPS time and UTM coordinates, as well as the optical sensors. Ground speed and azimuth are also monitored. The seeds or vegetation are time-tagged as they are dispensed, and software is used to process the dispensing time and GPS location data and estimate the exact coordinates of each seed or plant and its distance from adjacent seeds or plants. As a result, a precise planting map is generated. The invention may also be used to determine the location to dispense seeds or vegetation, and activating the dispenser when that location is reached.

Owner:RGT UNIV OF CALIFORNIA

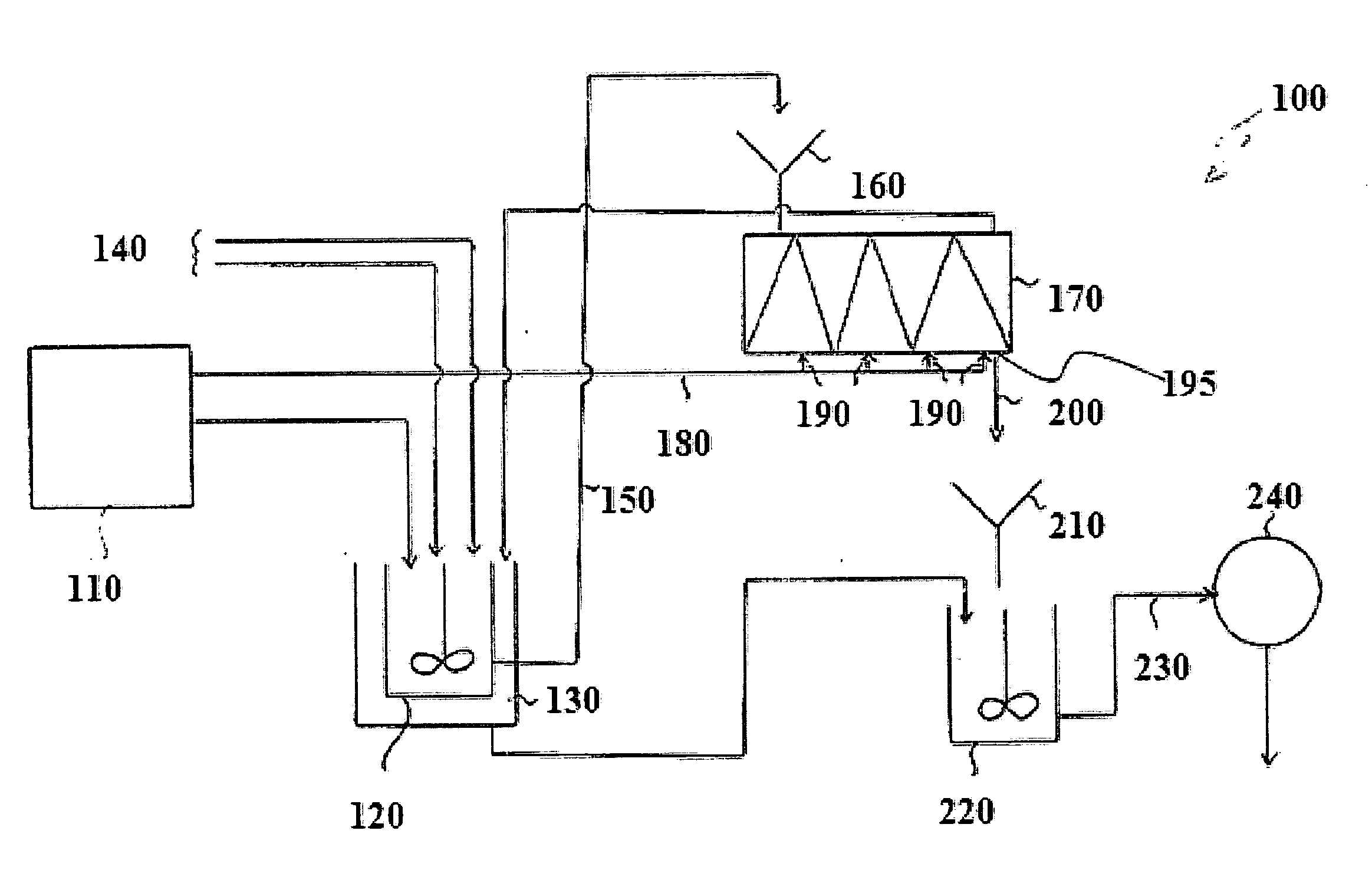

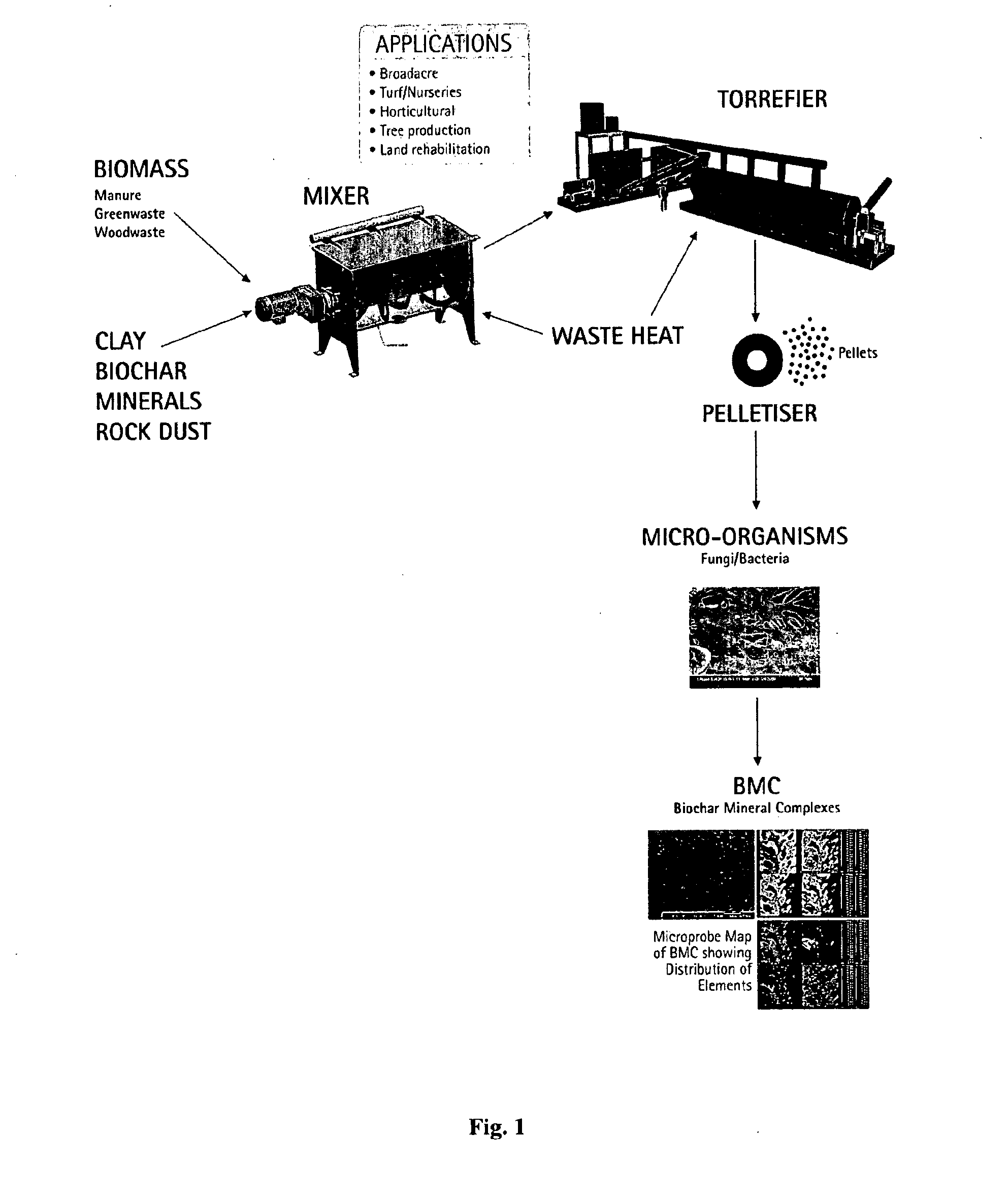

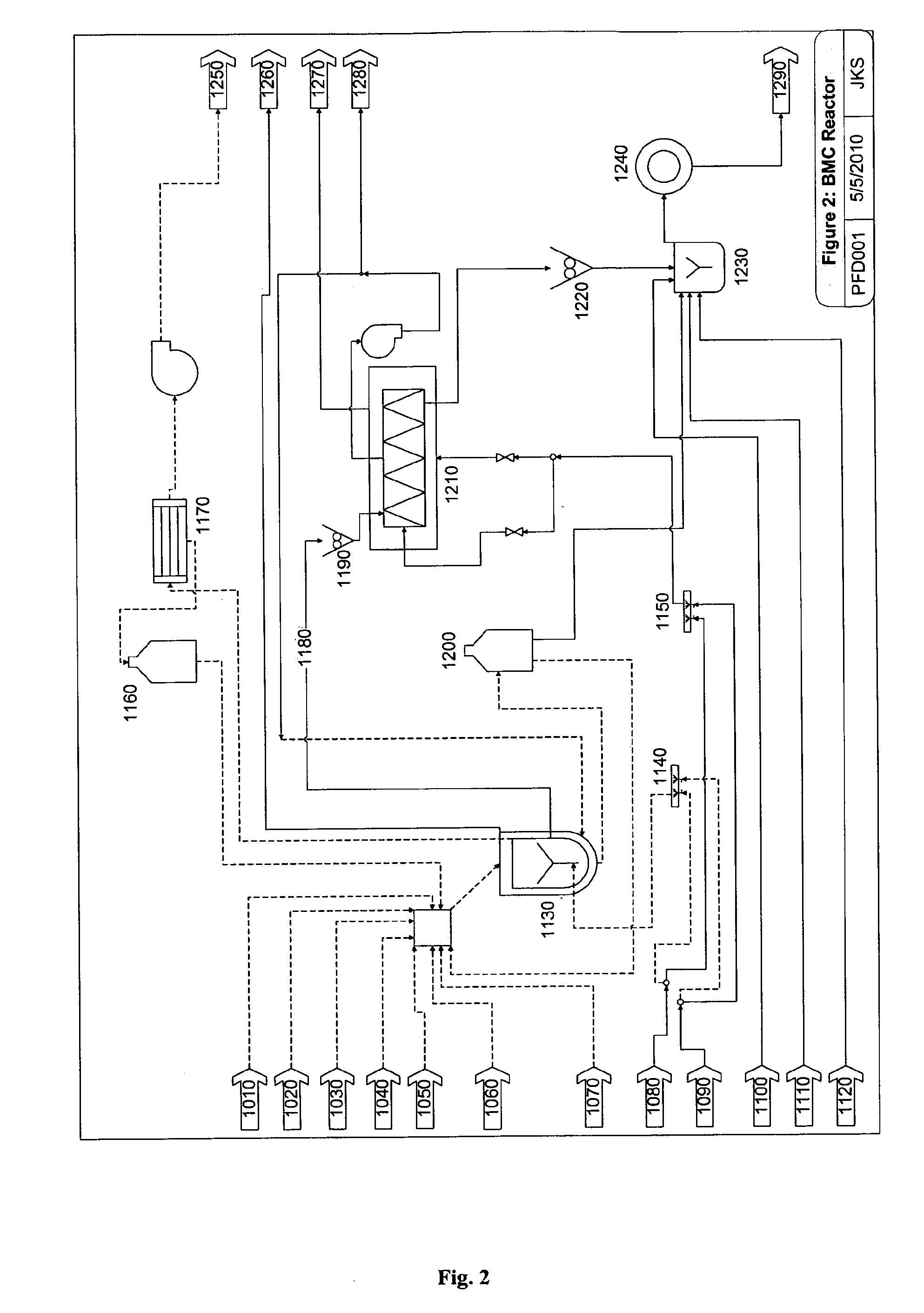

Biochar complex

InactiveUS20120125064A1Increase productionLow application rateDirect heating destructive distillationBiofuelsGrowth plantClay minerals

The invention relates to a biochar-containing composition comprising biochar having organic matter therein and / or thereon, clay associated, optionally intercalated, with the organic matter, a non-clay mineral and optionally also a plant growth promoter.

Owner:VENEARTH GRP

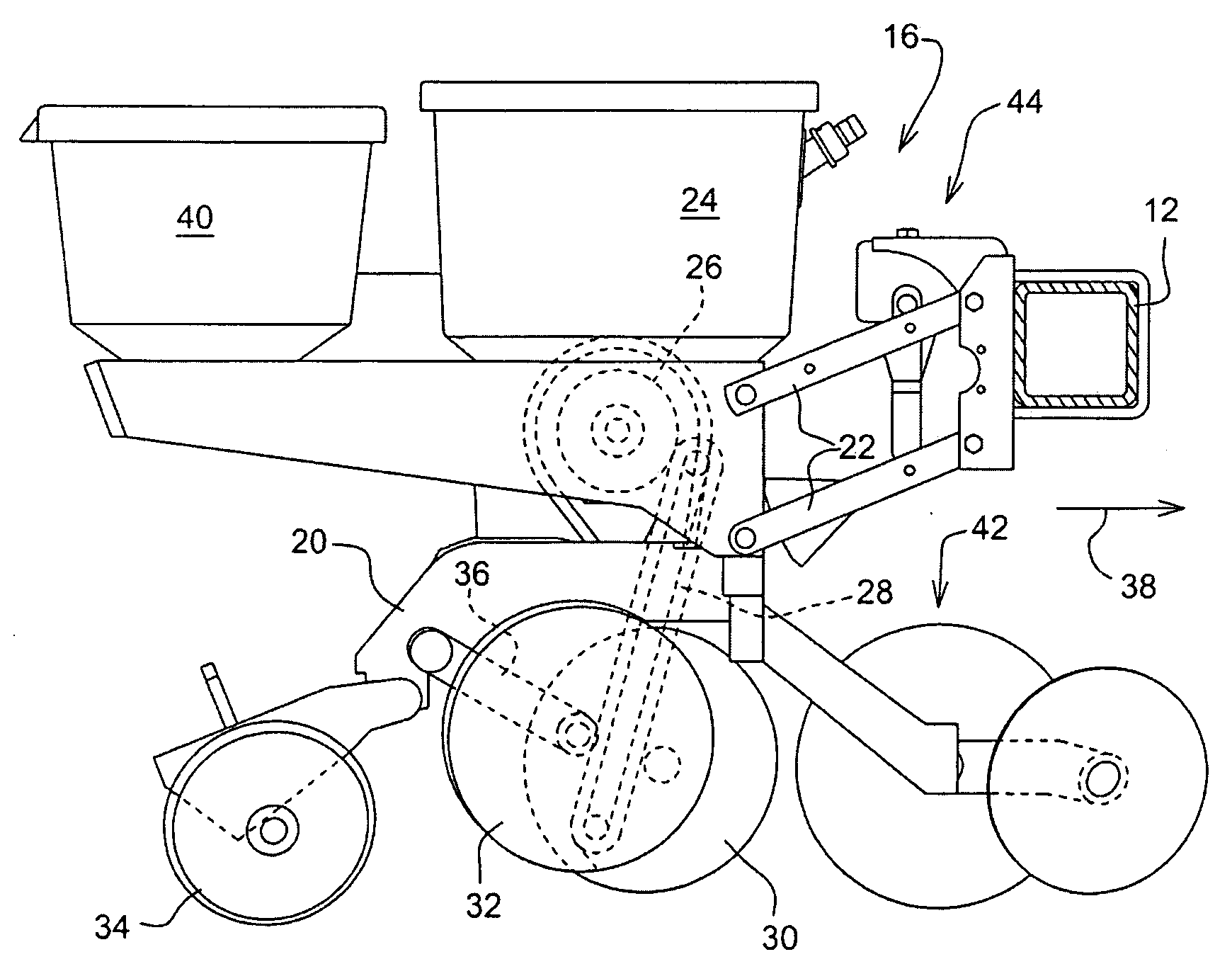

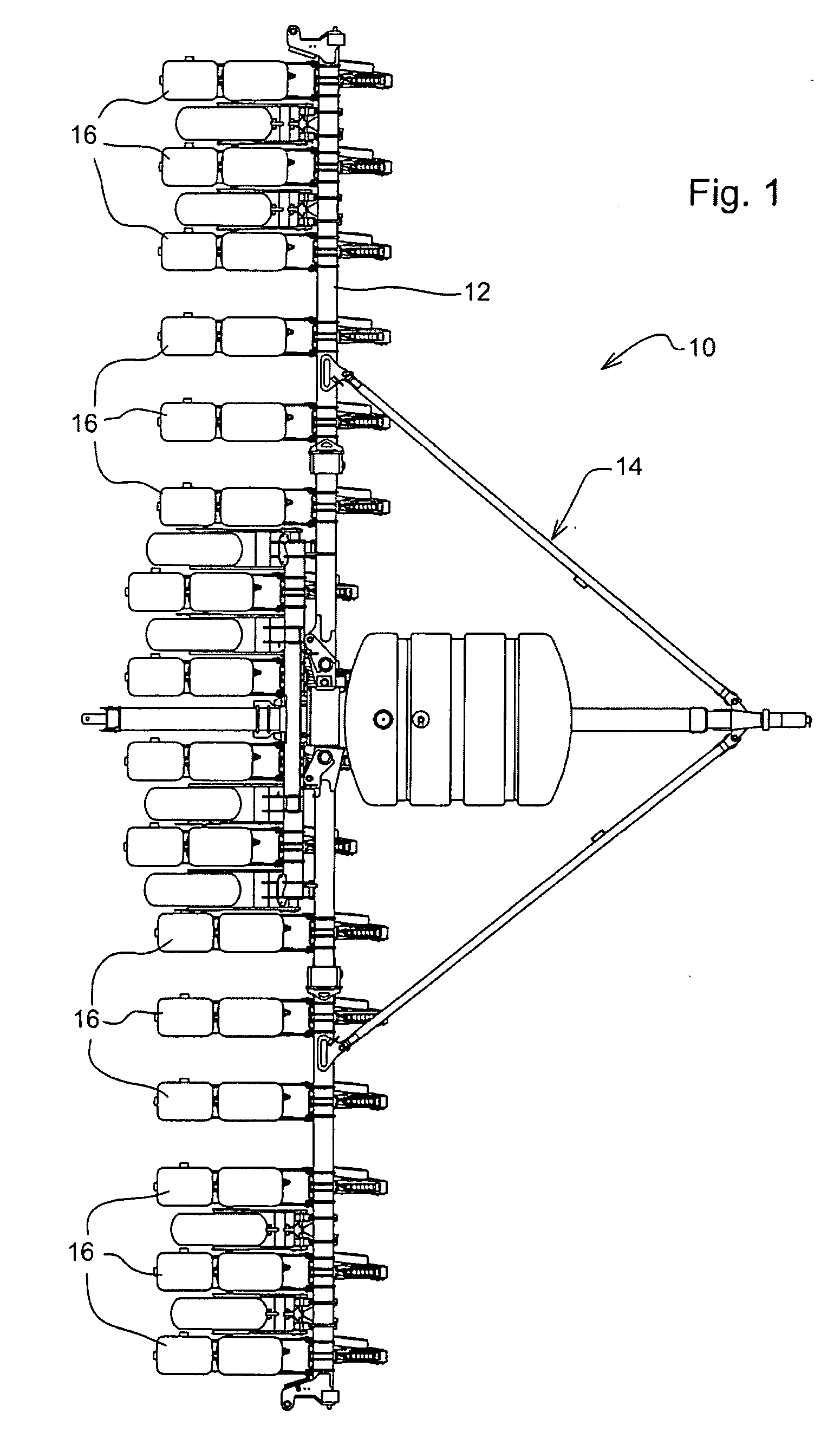

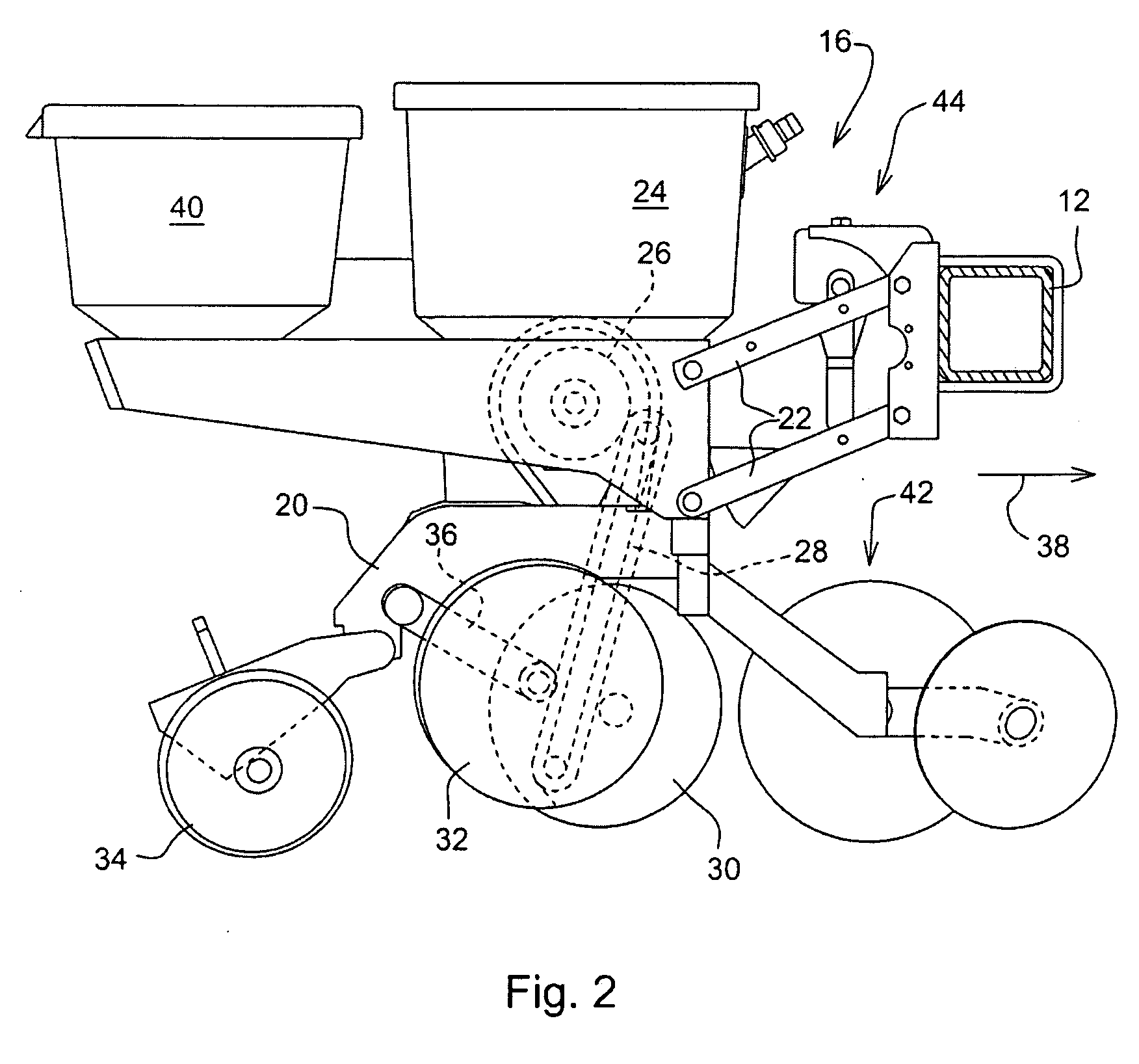

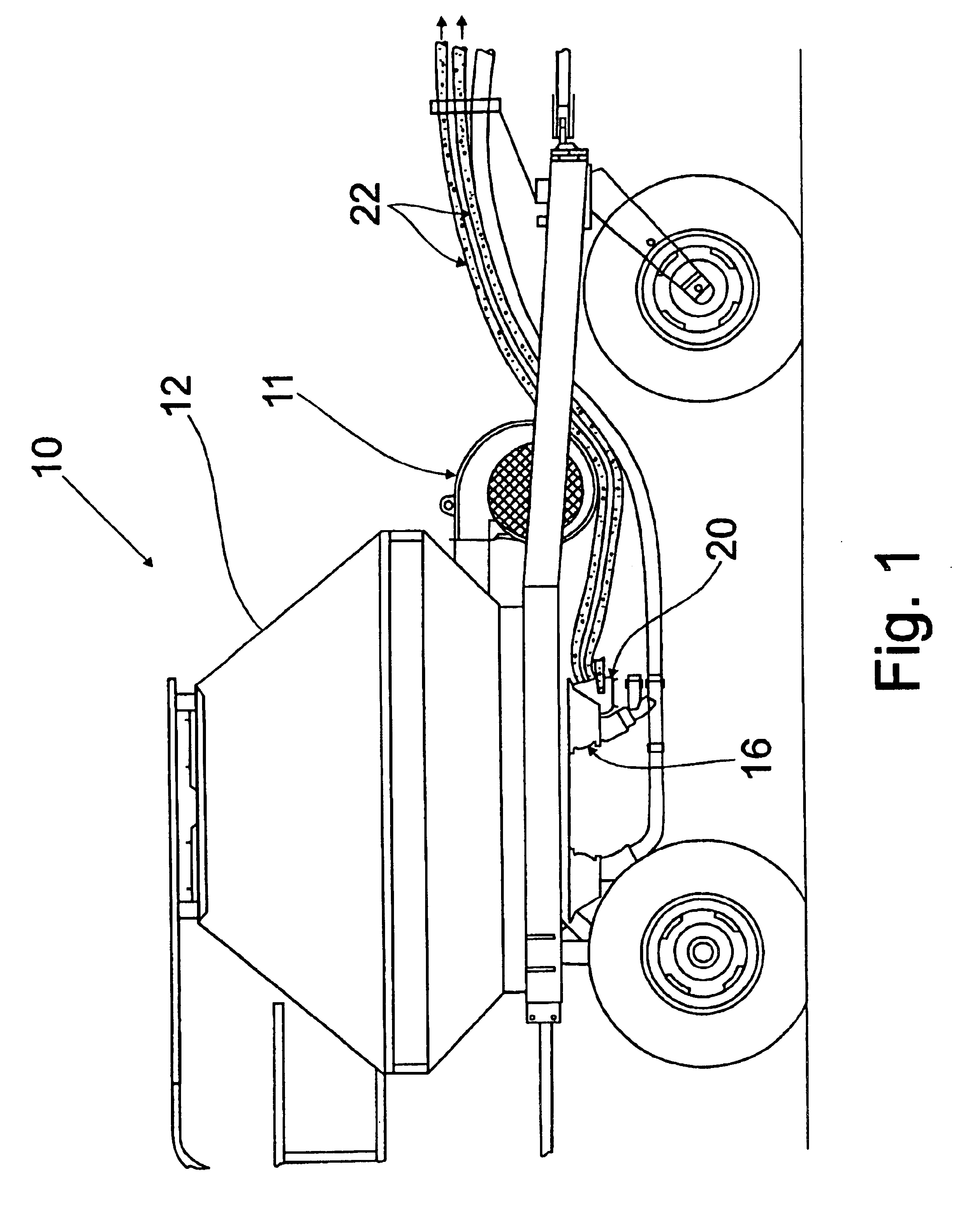

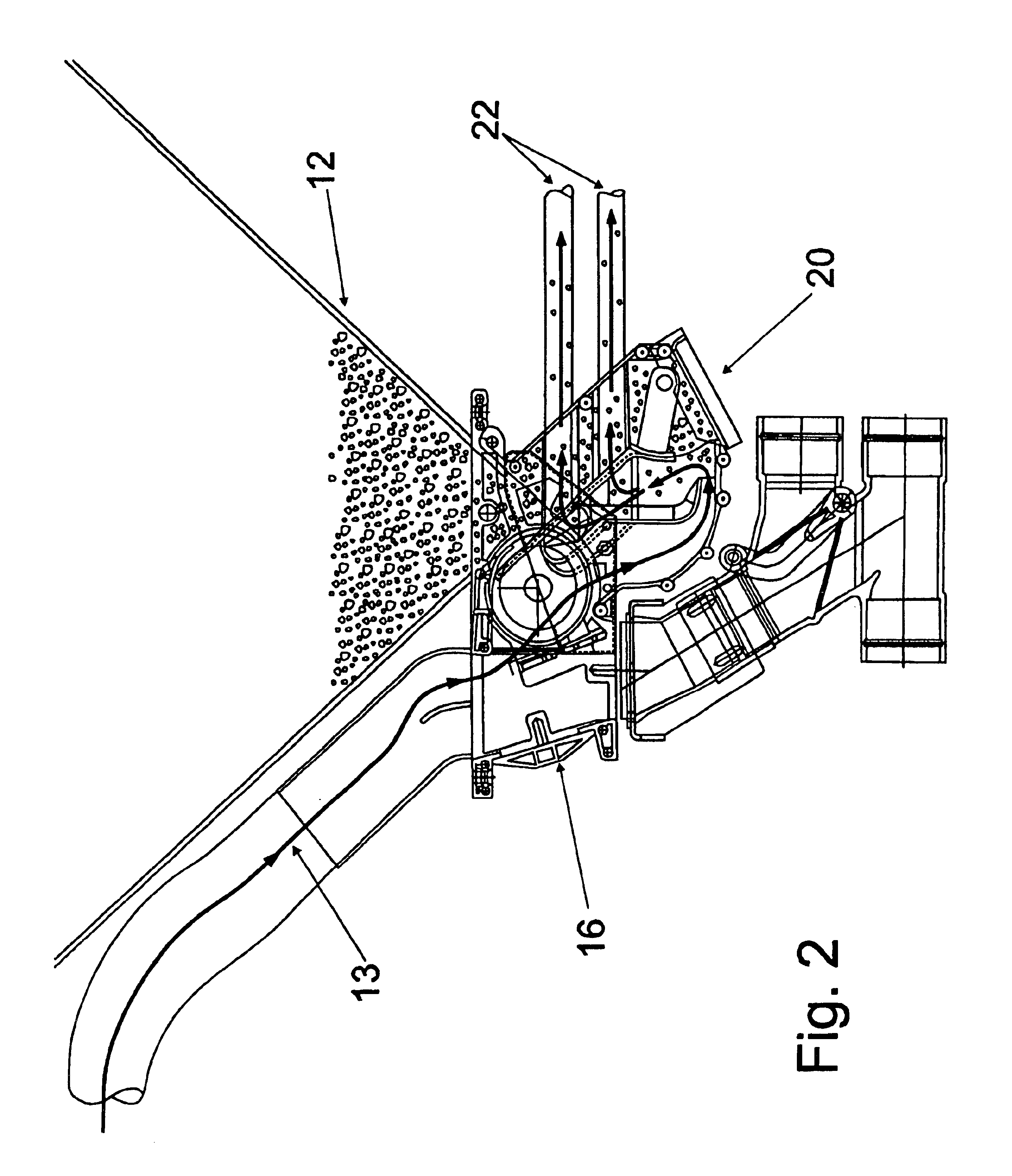

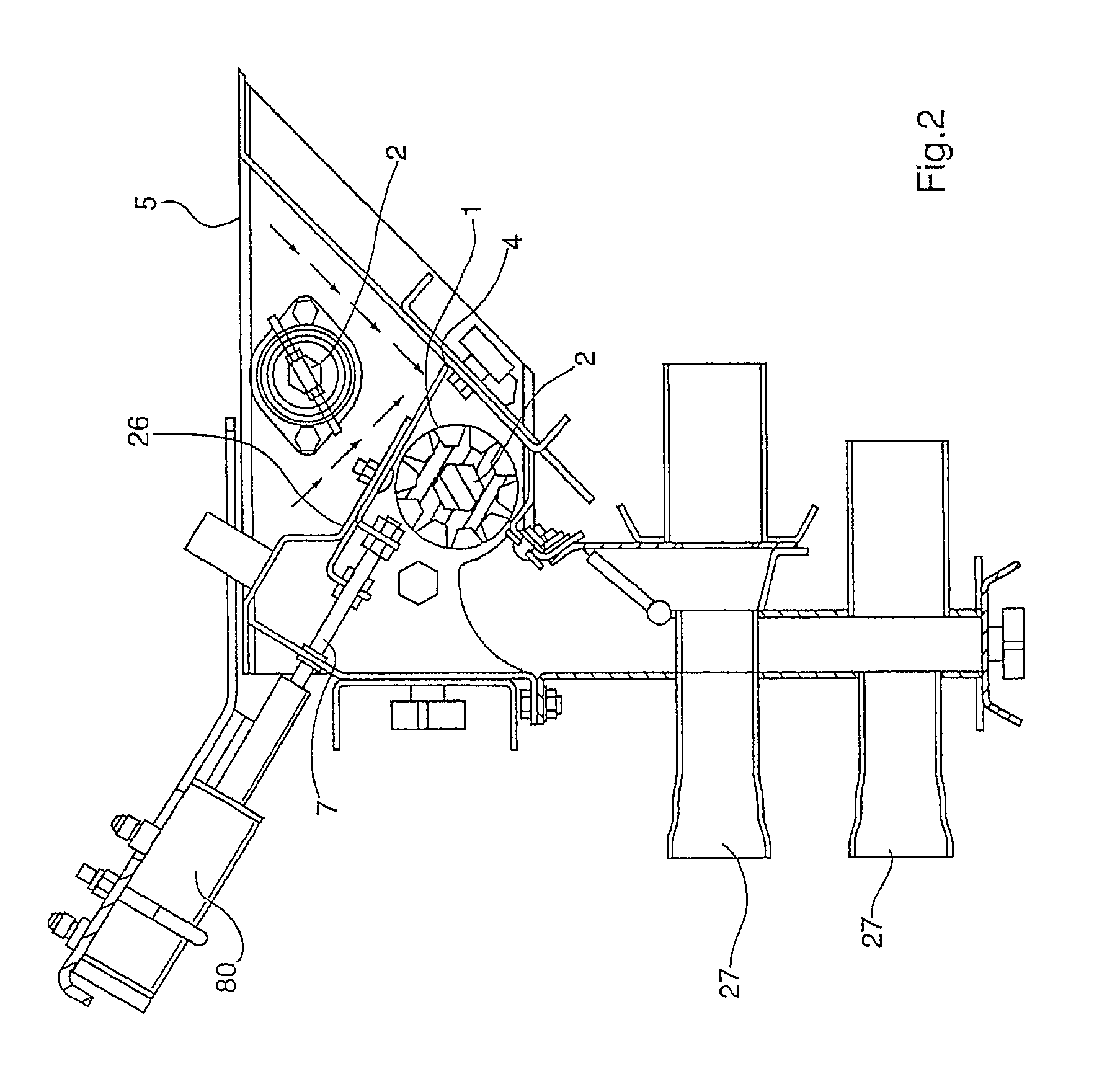

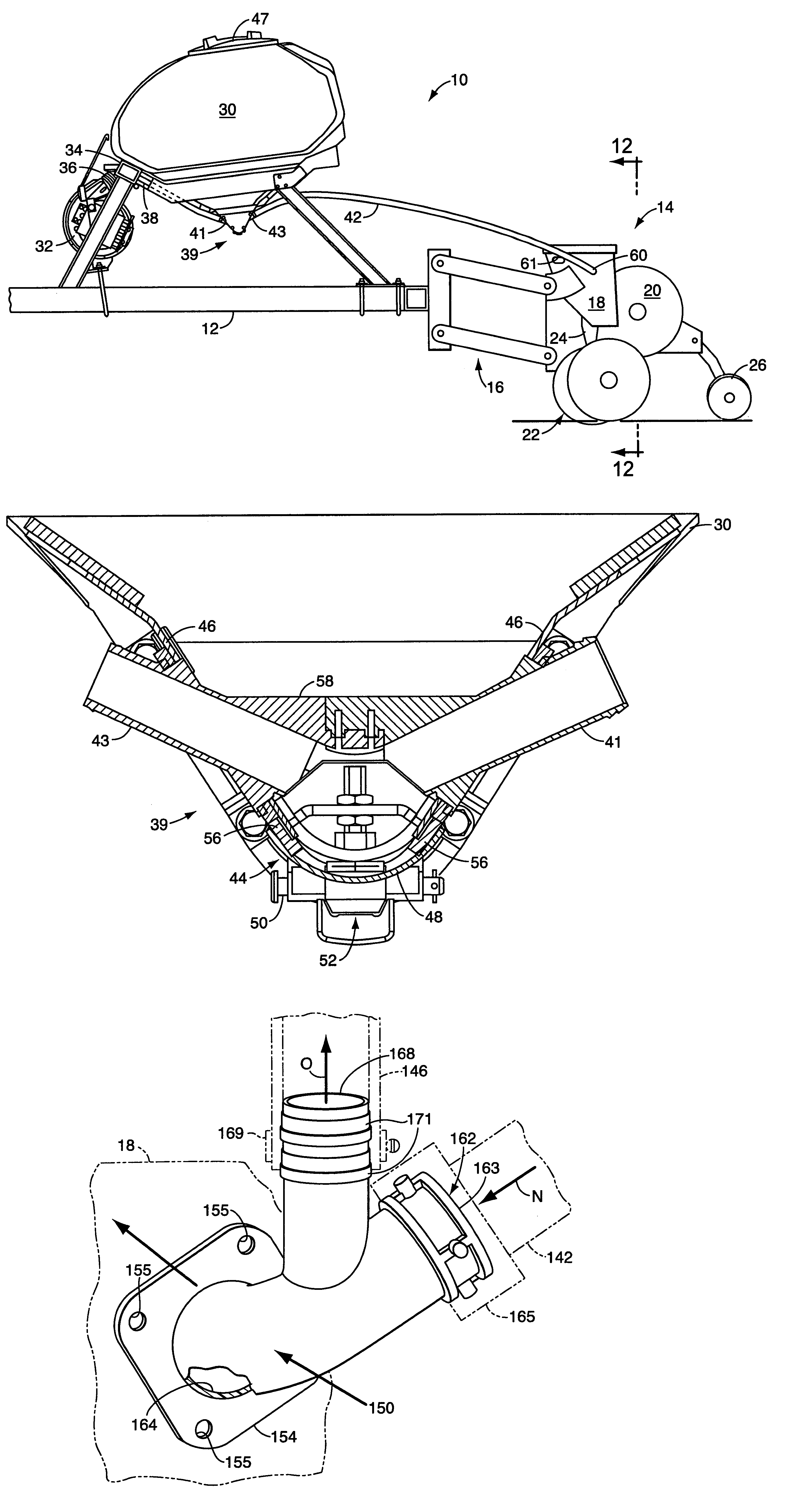

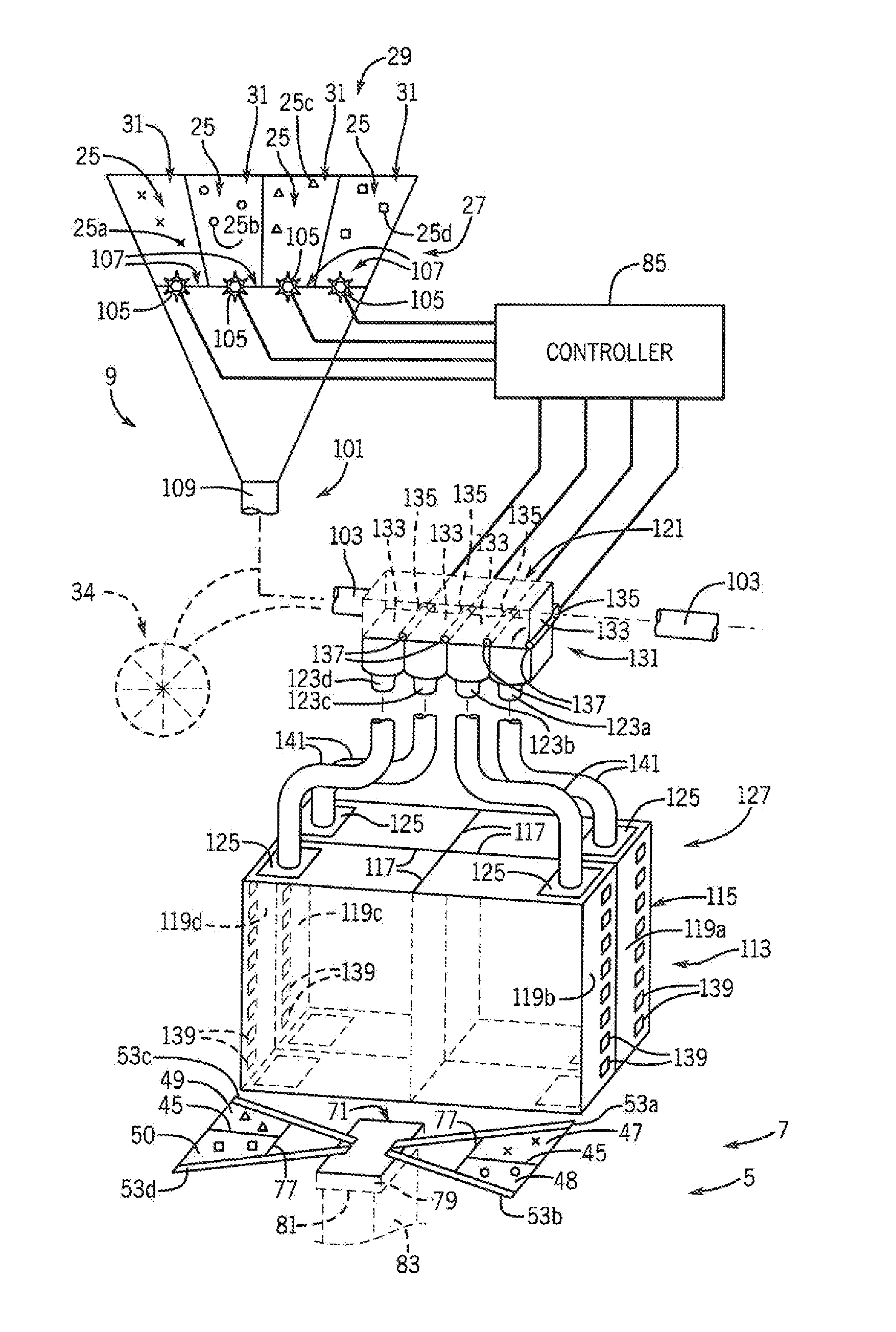

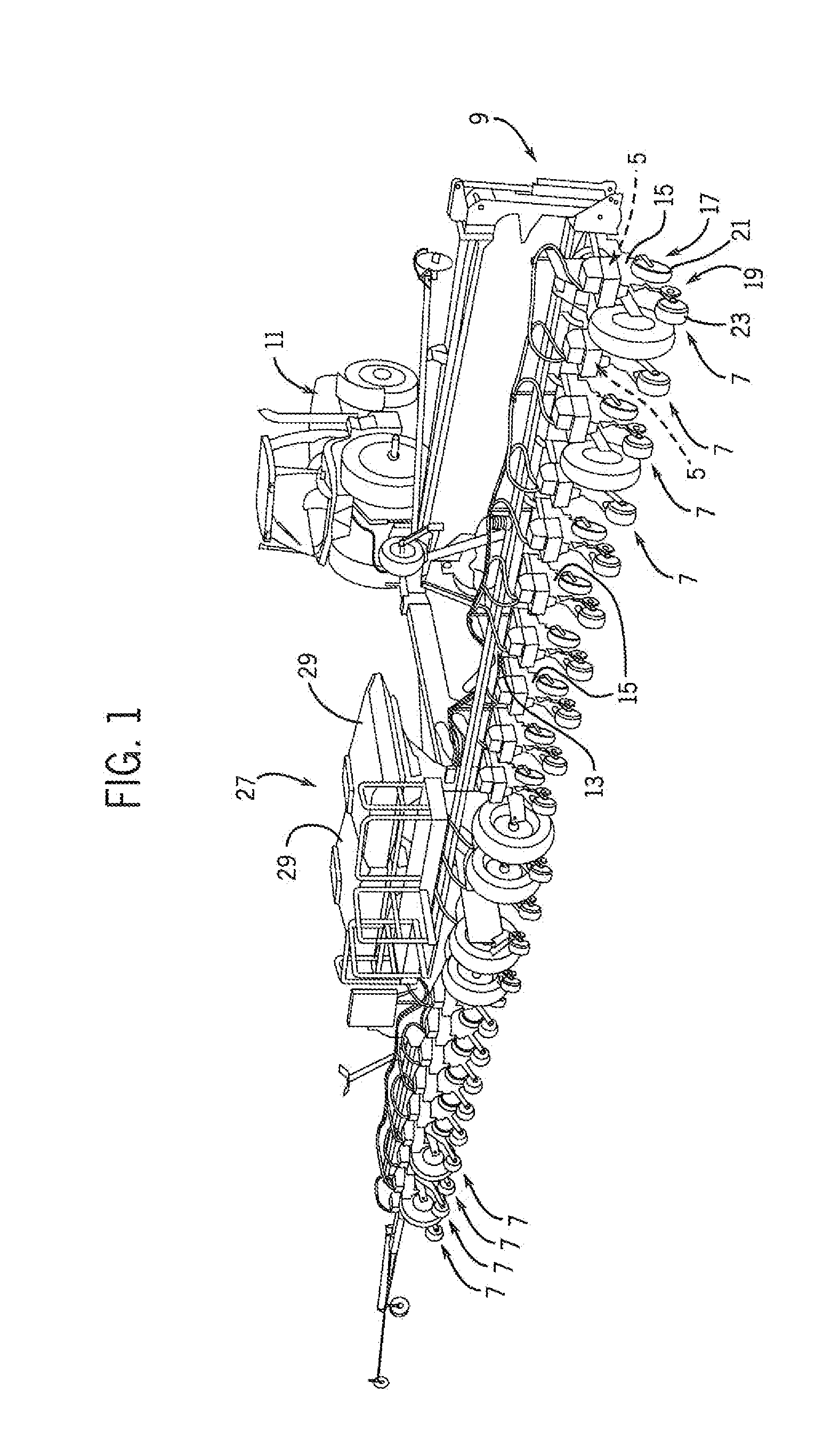

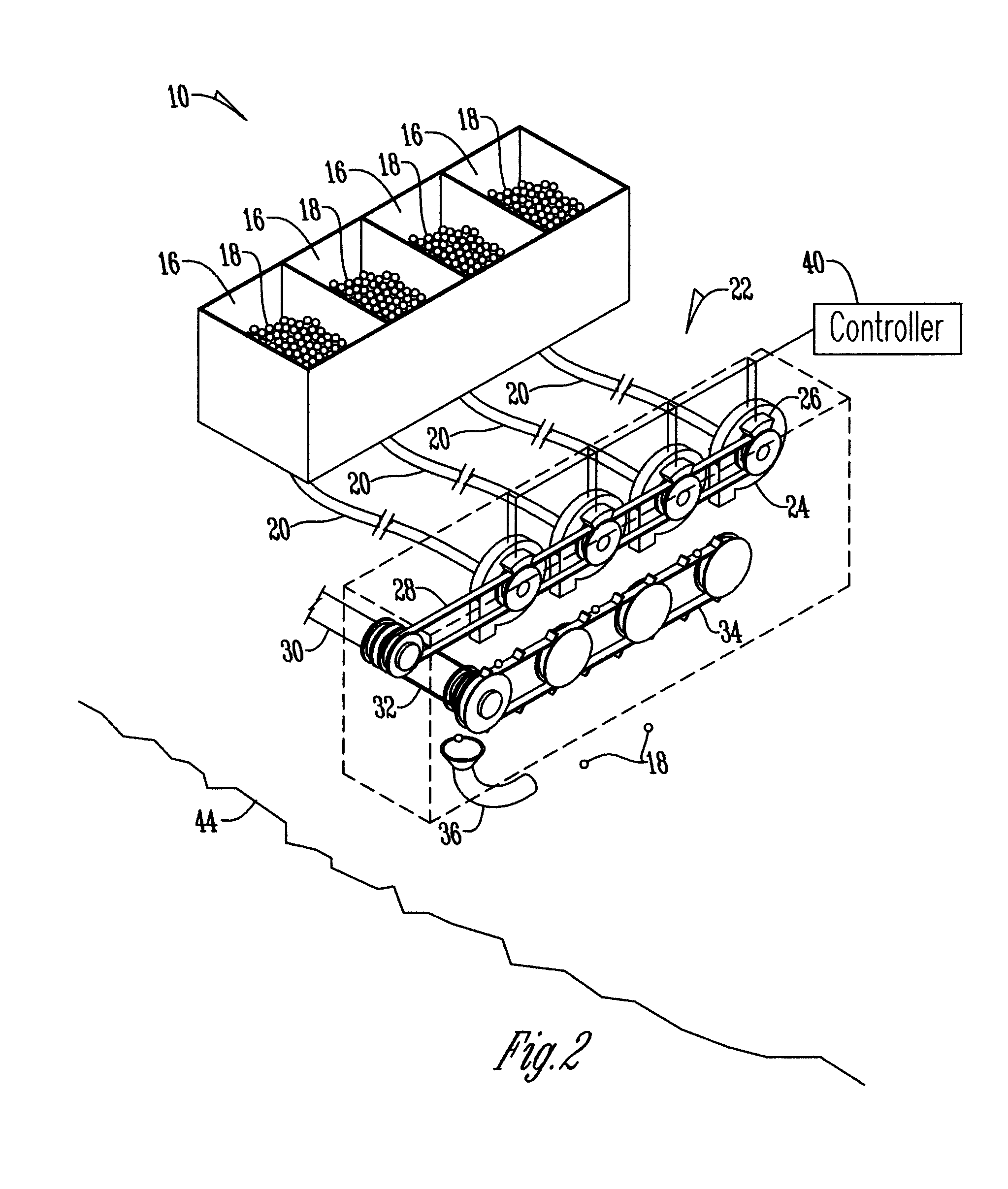

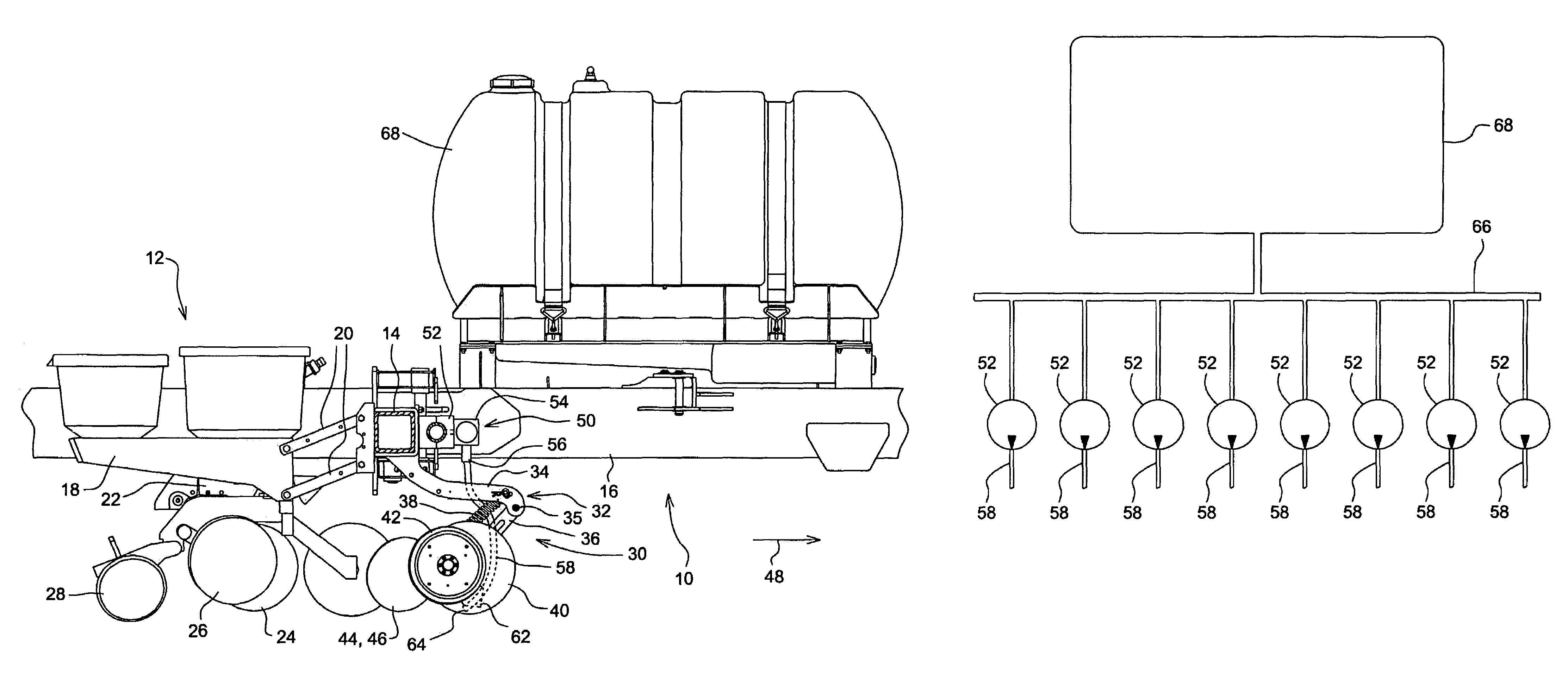

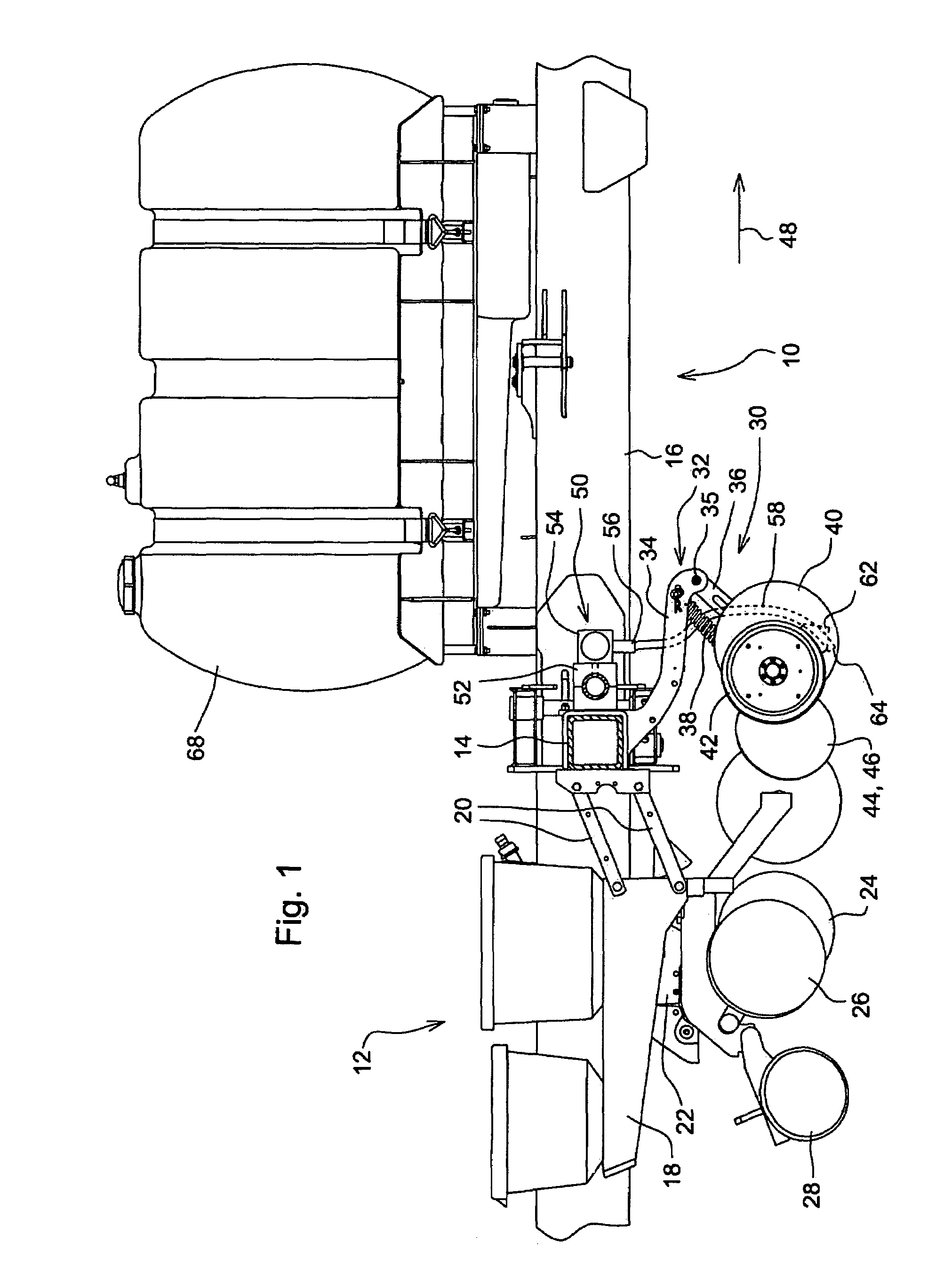

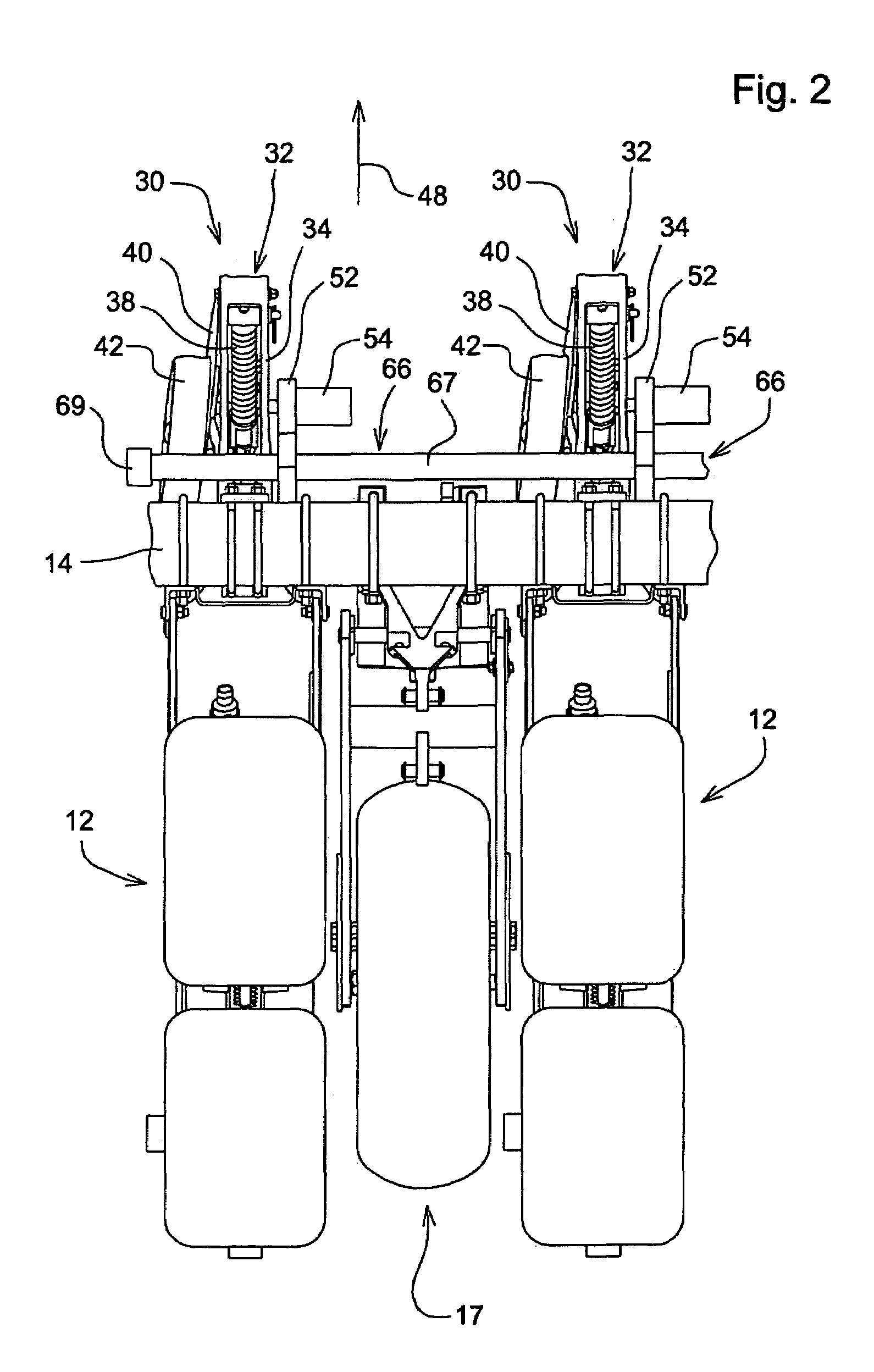

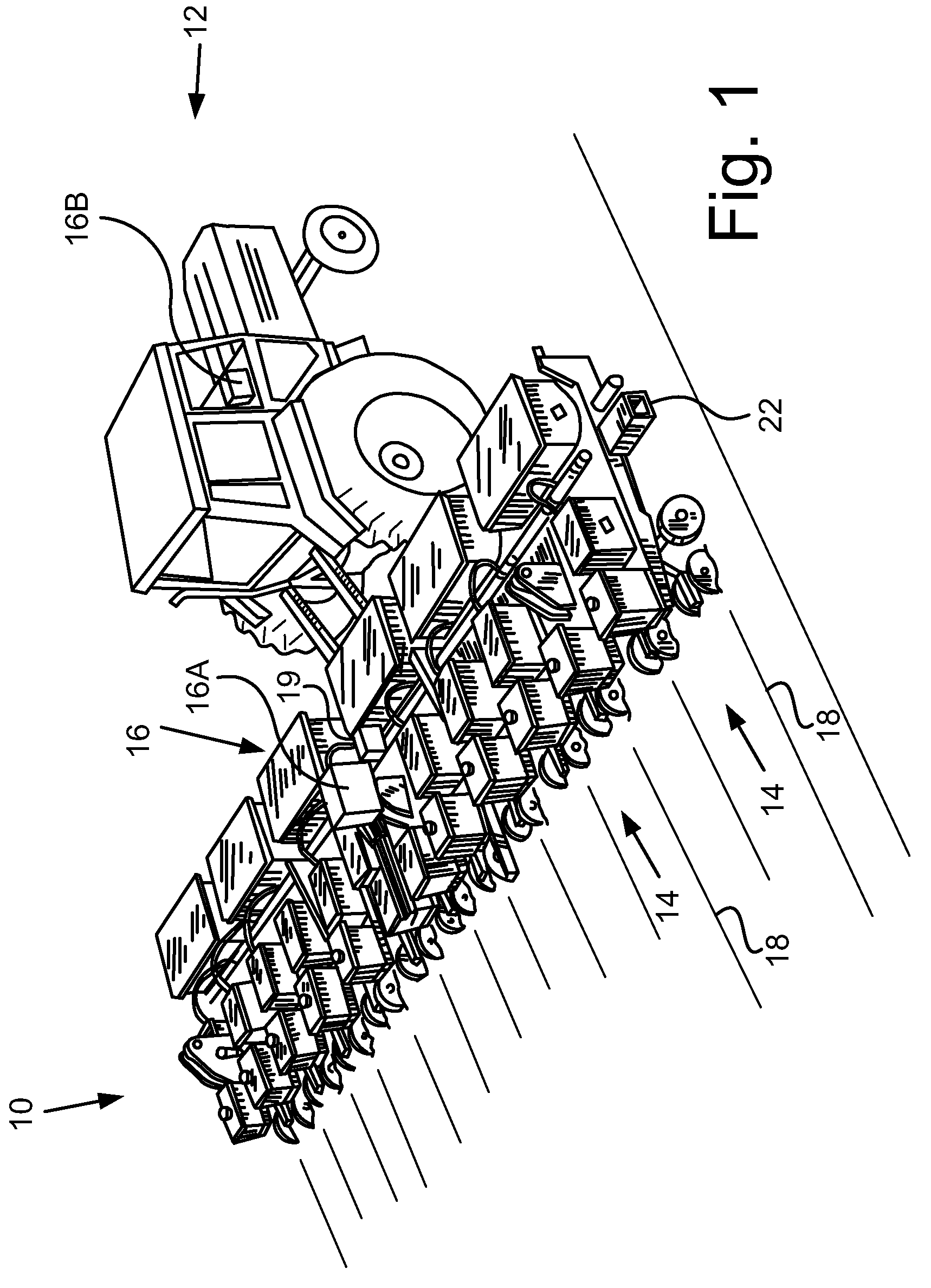

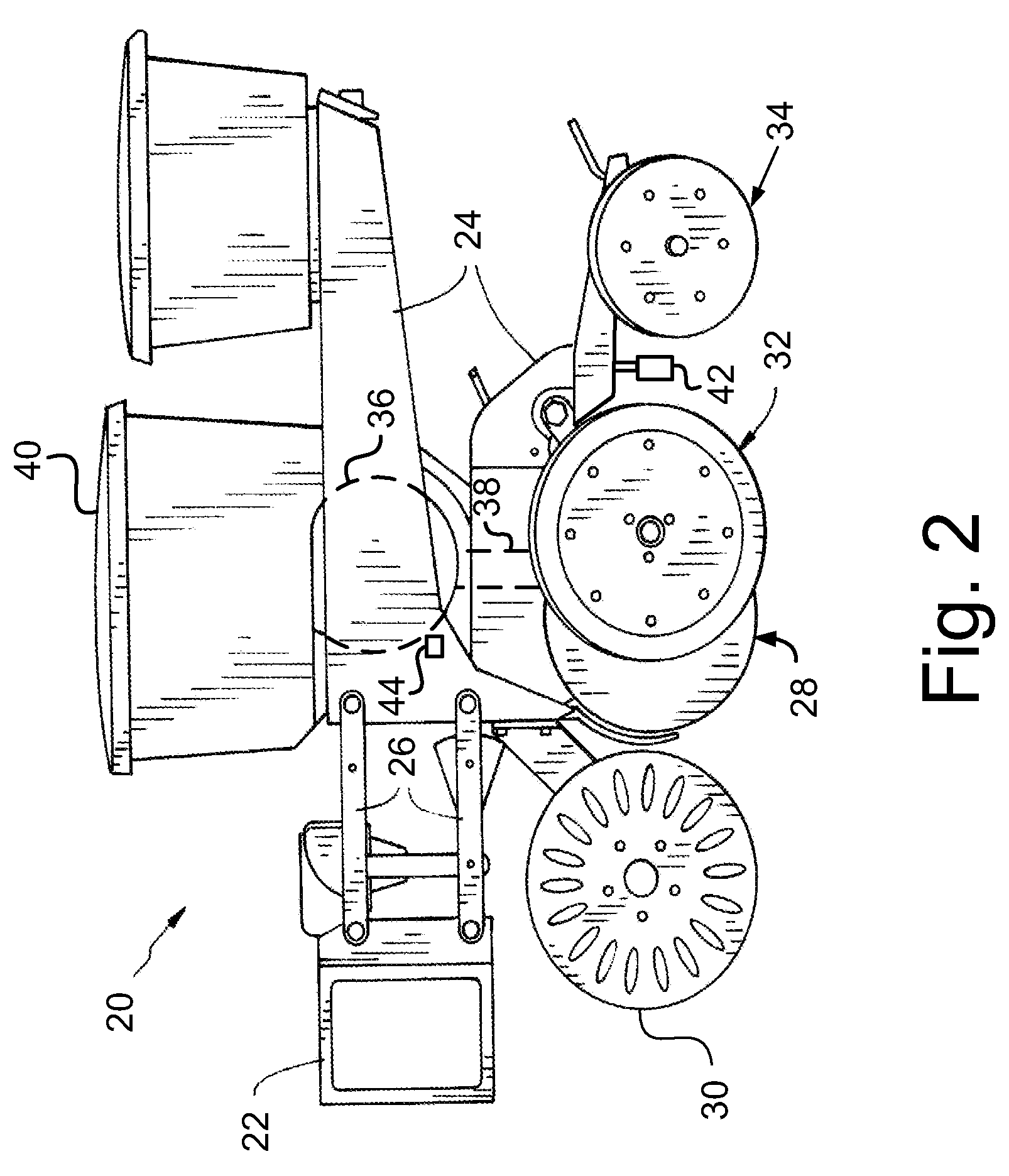

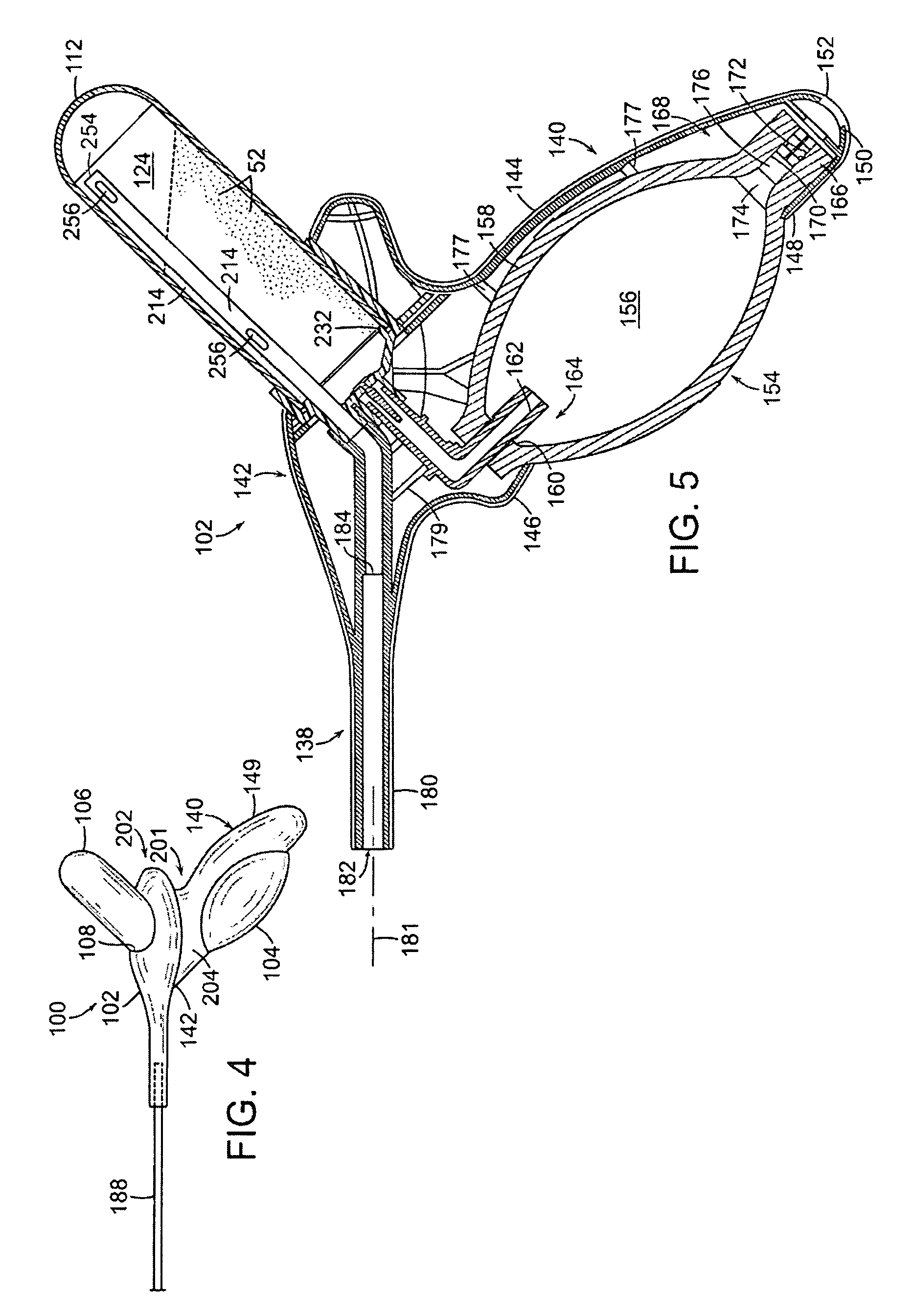

Seeding Machine With Seed Delivery System

ActiveUS20100192819A1Reduces seed spacing variabilityReduce scrollingFertiliser distributersCentrifugal wheel fertilisersEngineeringDelivery system

A seed delivery system for use in a seeding or planting machine that removes the seed from a seed meter by capturing the seed therefrom. The delivery system then moves the seed down to a lower discharge point and accelerates the seed horizontally rearward to a speed approximately equal to the forward travel speed of the seeding machine such that the seed, when discharged has a low or zero horizontal velocity relative to the ground. Rolling of the seed in the trench is thus reduced. Furthermore, as the seed only has a short drop from the outlet to the bottom of the seed trench, the seed has little vertical speed to induce bounce. The delivery system uses a brush belt to capture, move and accelerate the seed. By capturing the seed and moving it from the meter to the discharge, the seed is held in place relative to other seeds and the planter row unit. As a result, the seeds are isolated from row unit dynamics thereby maintaining seed spacing.

Owner:DEERE & CO

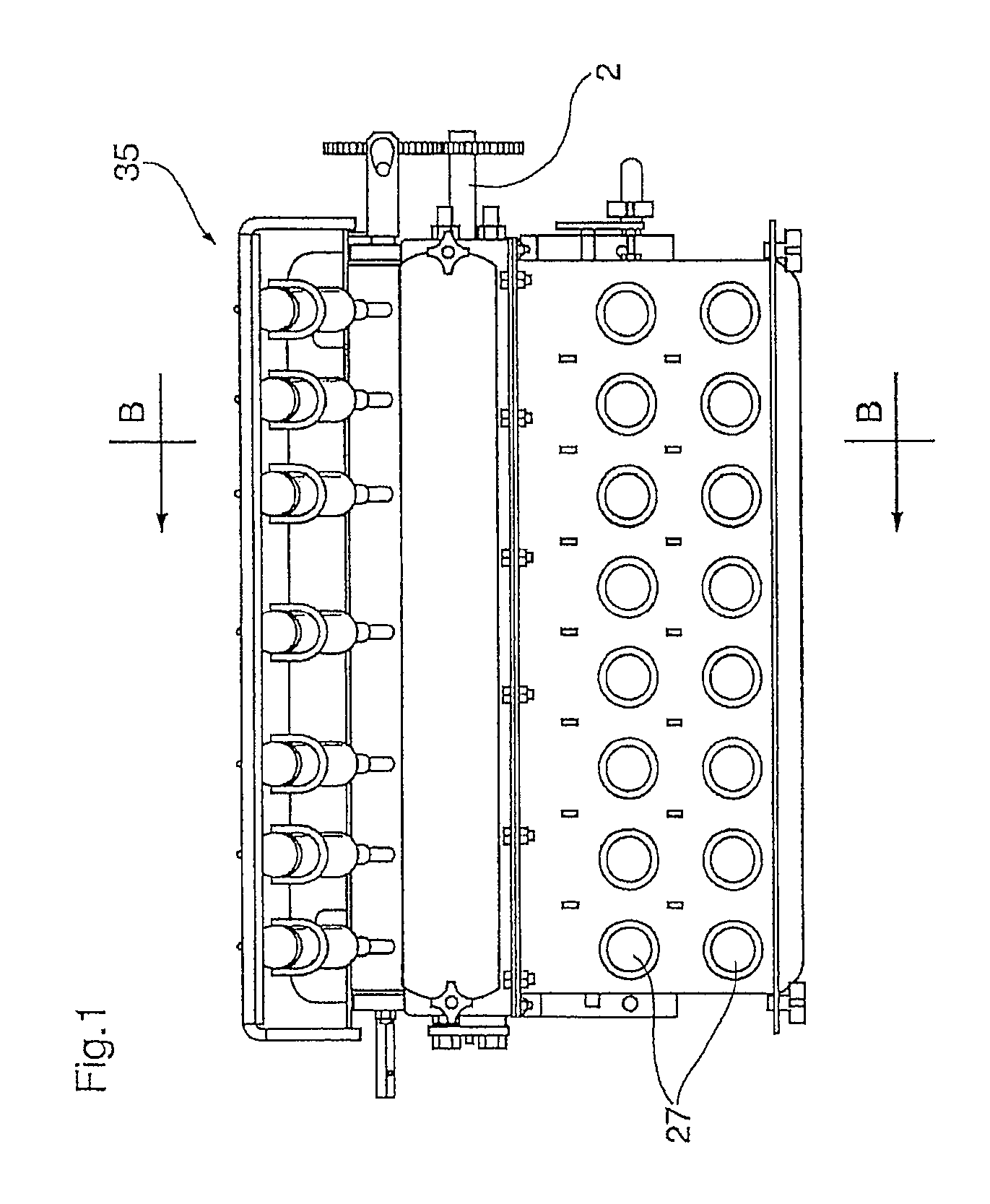

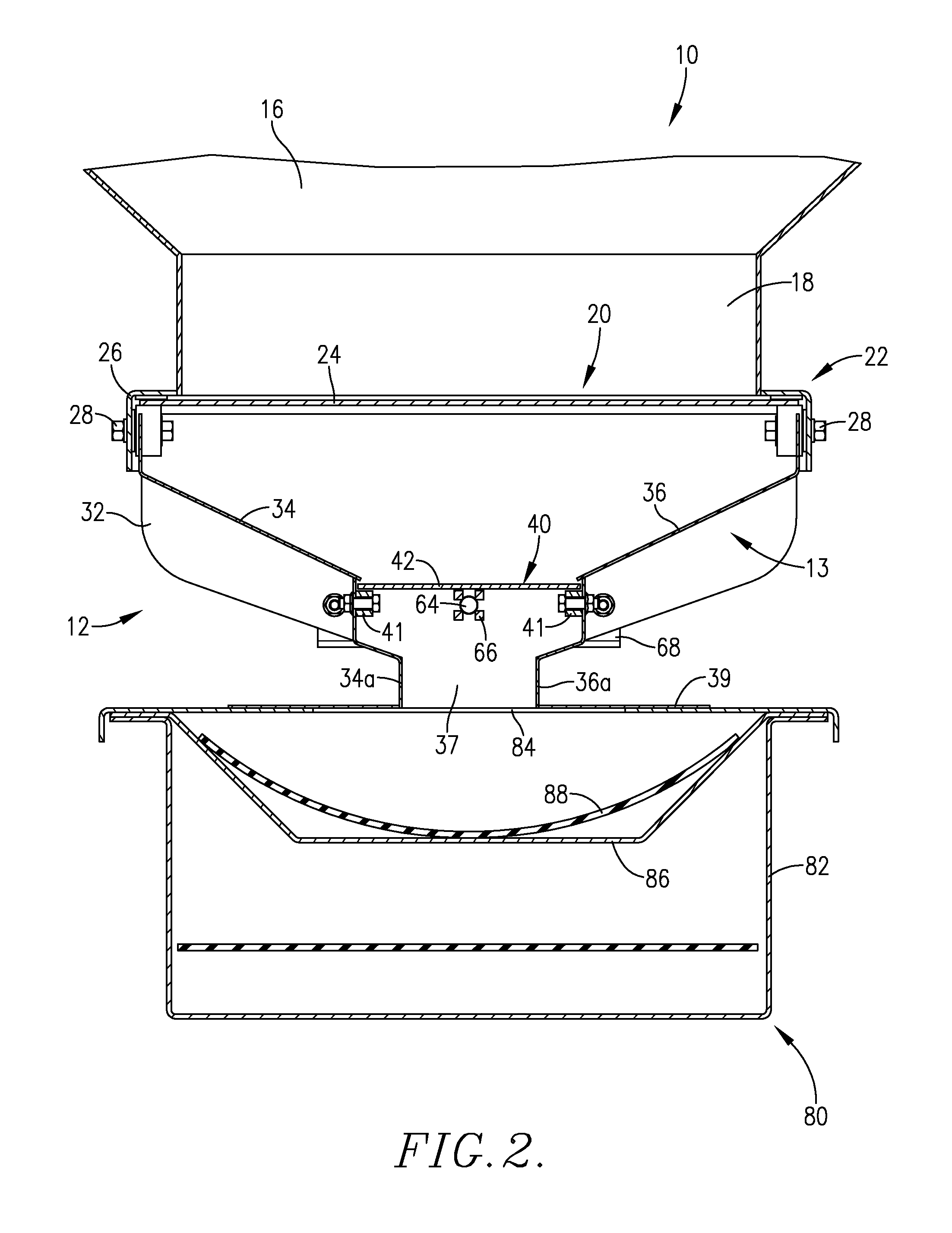

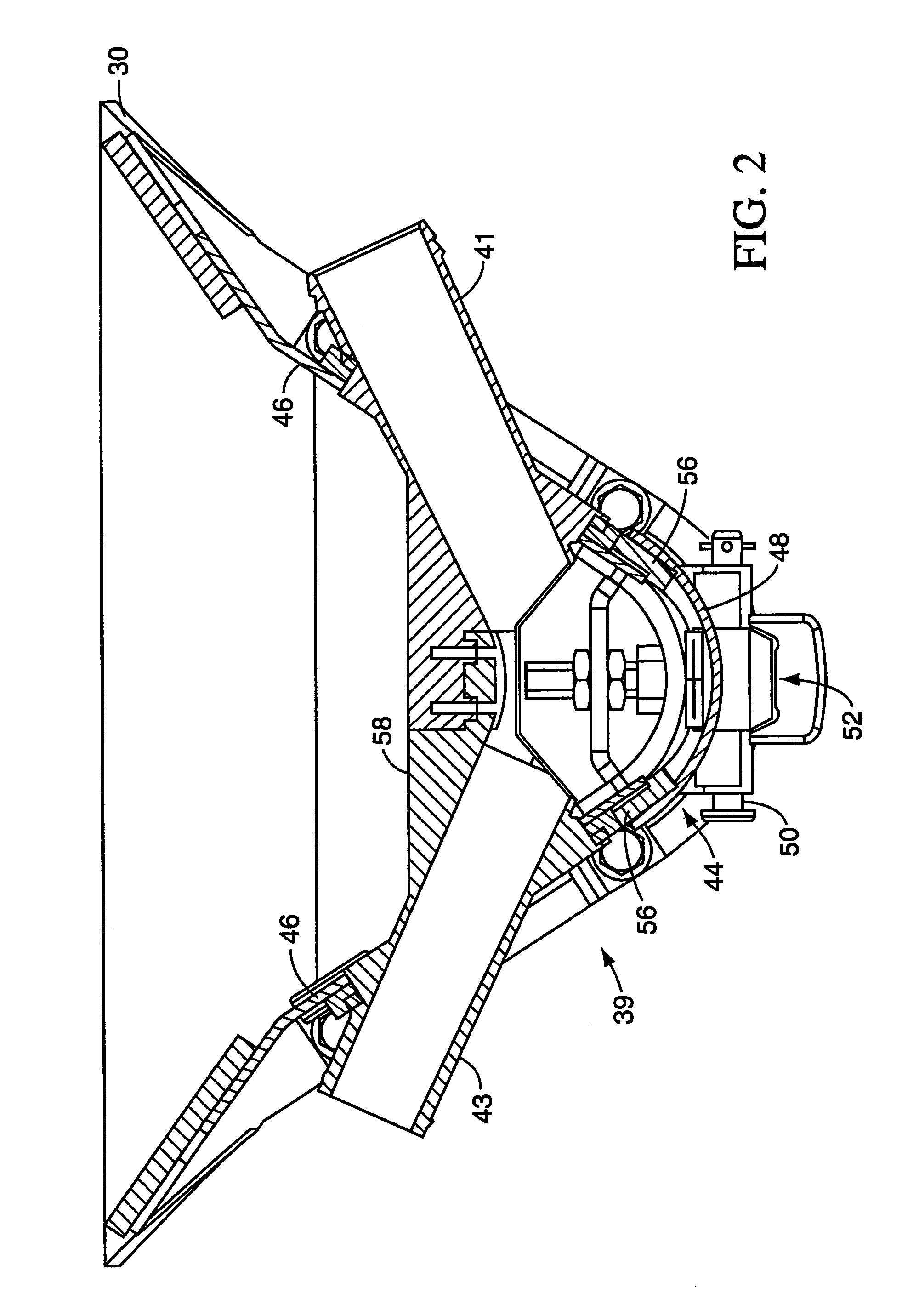

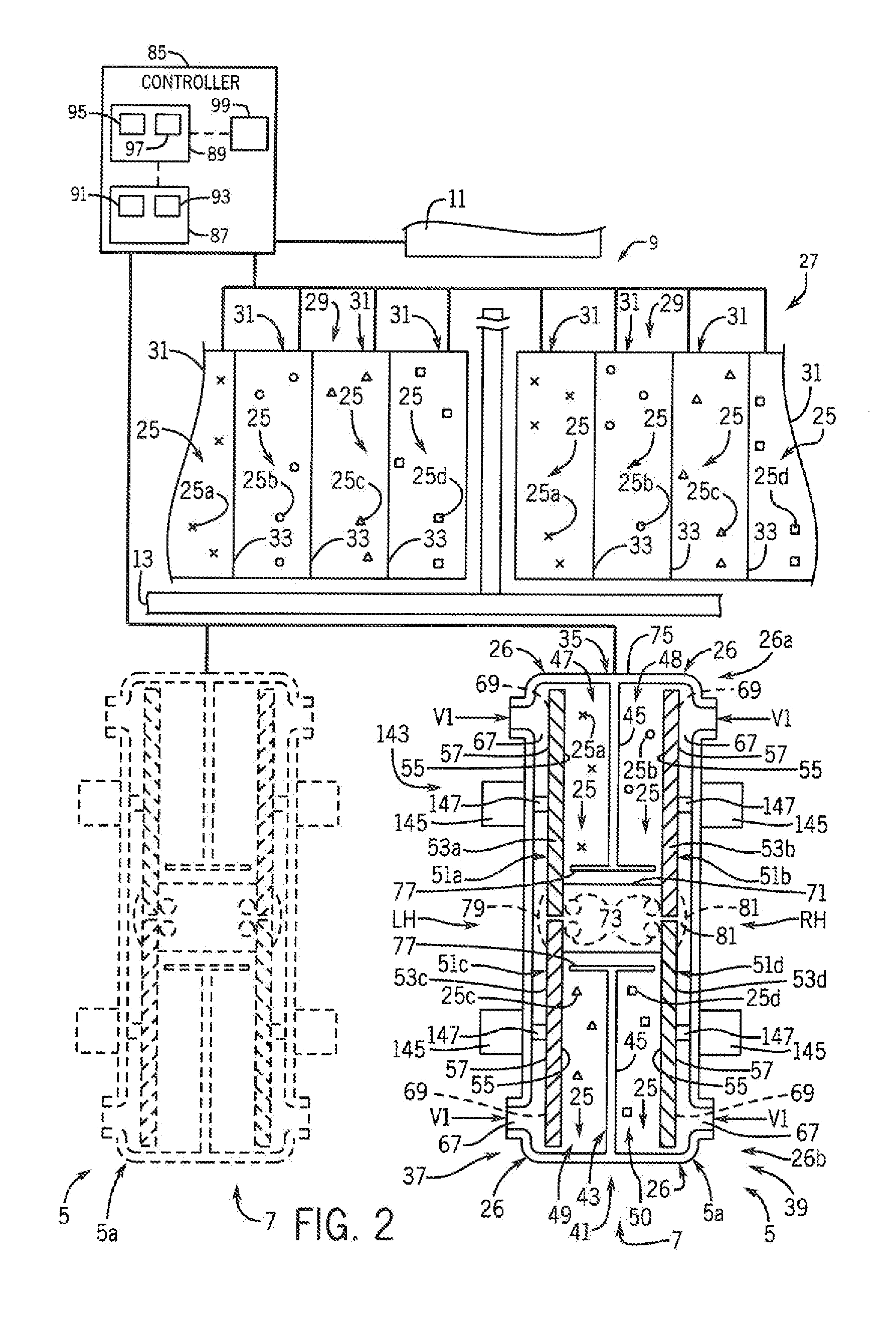

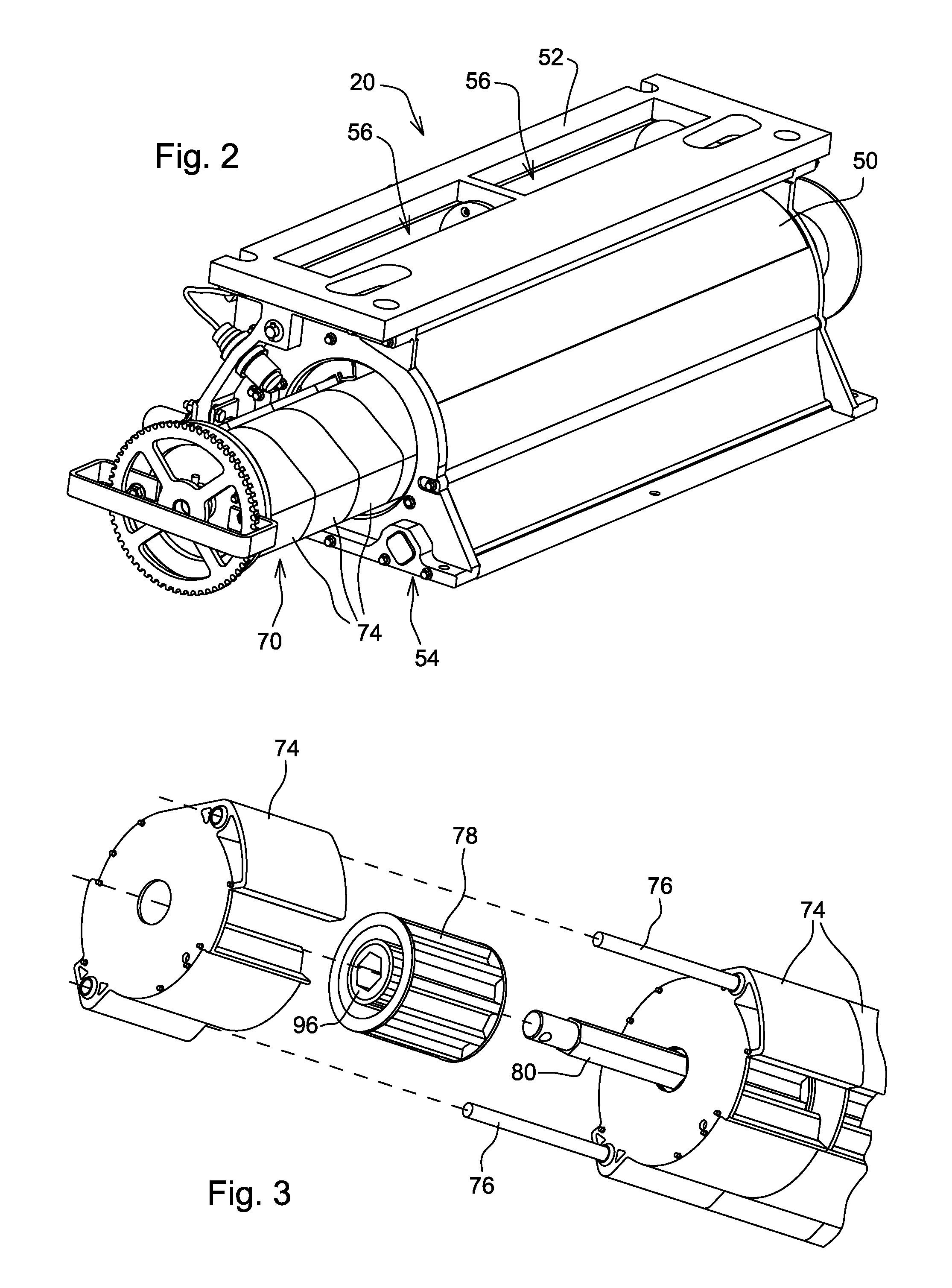

Differential Pressure Seed Meter With An Endless Belt Seed Transport Member

ActiveUS20100192818A1Great freedomFertiliser distributersPotato plantersSpatial OrientationsDifferential pressure

A seed meter is provided having an endless belt as a seed transport member together with a pressure differential to hold the seed onto the belt. The use of an endless belt as the seed transport member enables the spatial orientation of the seed transport member to vary from location to location along the path of the belt where different seed meter functions are performed. The belt allows greater freedom in determining the location of the seed pick-up region and the seed release or removal region beyond the constraints of a fixed diameter seed disk. The belt further allows for a narrow envelope seed meter which can cross-feed seed into a substantially vertically oriented delivery device.

Owner:DEERE & CO

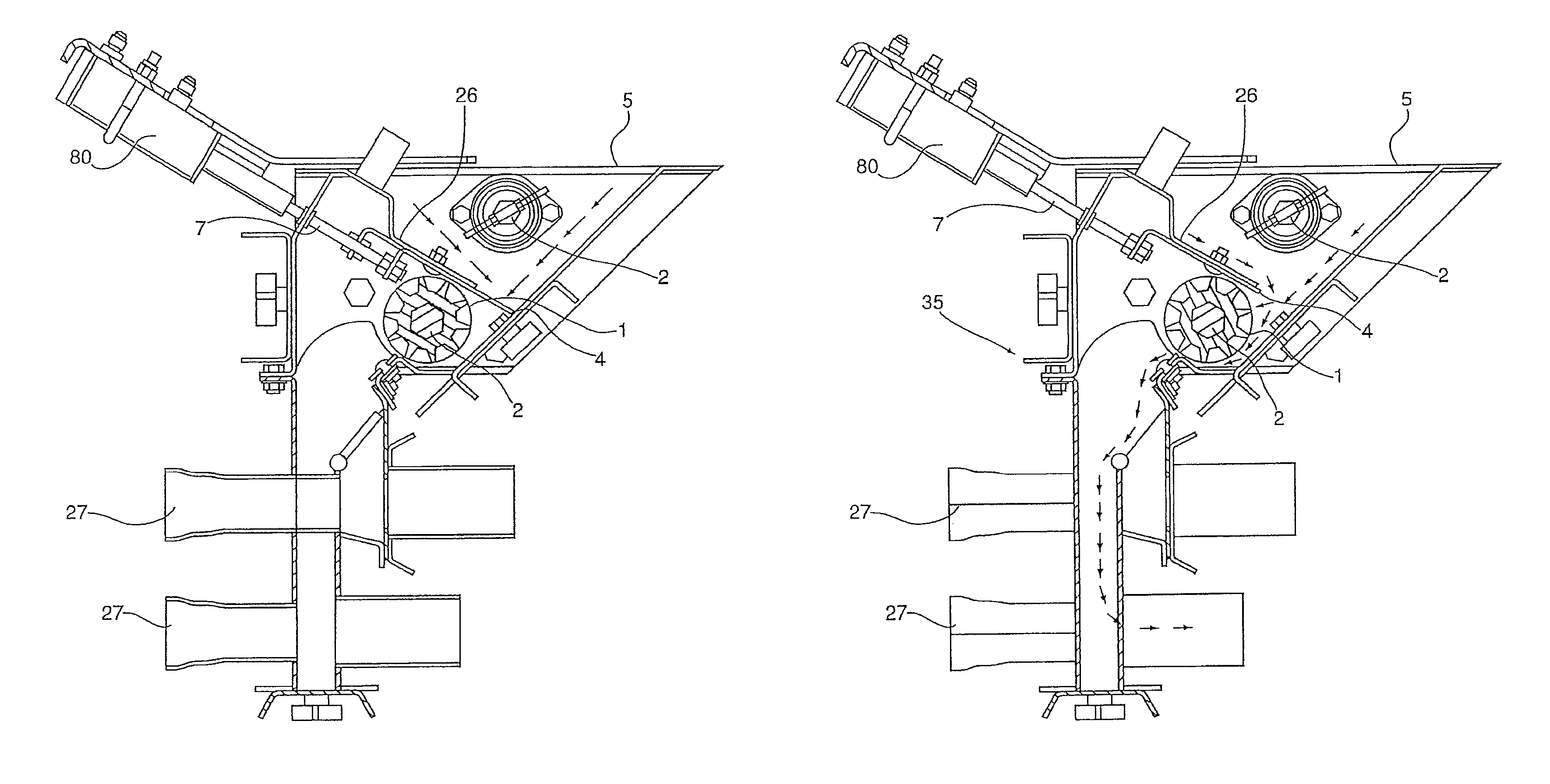

Dual capability nurse distribution system

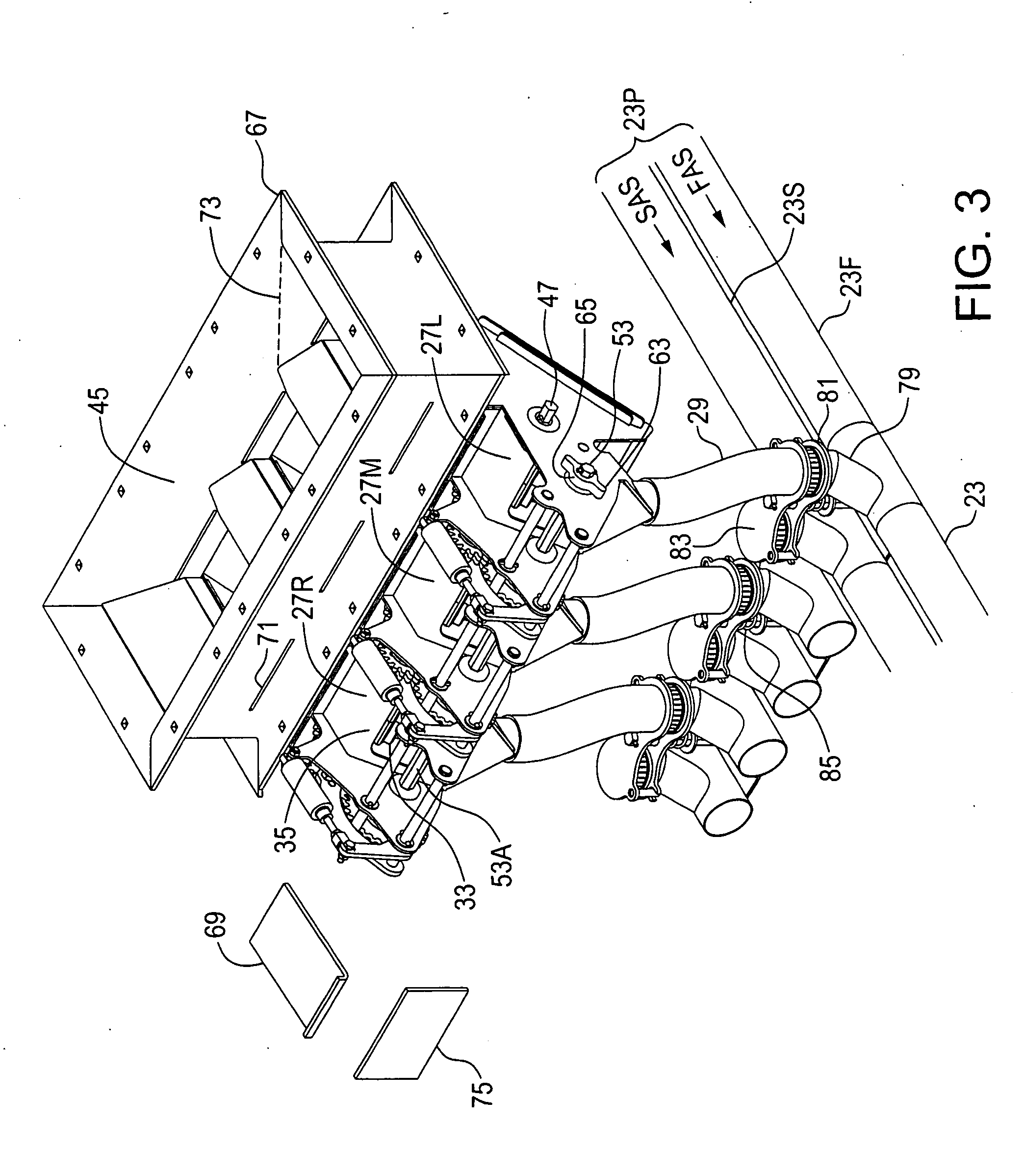

InactiveUS6845724B2Quick changeReliable constructionCoin-freed apparatus detailsFertilising methodsDistribution systemEngineering

A nurse distribution system provides dual capabilities for planting different seed varieties from a single planting mechanism. The air cart carries two tanks in which different seed varieties can be placed. The nurse mechanism selectively distributes seed from one tank to the on-row singulation meters, yet can switch to the seed in the second tank to correspond to different soil conditions encountered by the planting mechanism. The planting mechanism carries a first line from the first tank to the nurse receiver and a parallel second line from the second tank to the same nurse receiver. By keeping the nurse receiver as small as possible, thus having a small seed reservoir, the seed variety selection can be switched from one tank to the other in an effective manner.

Owner:CNH IND CANADA

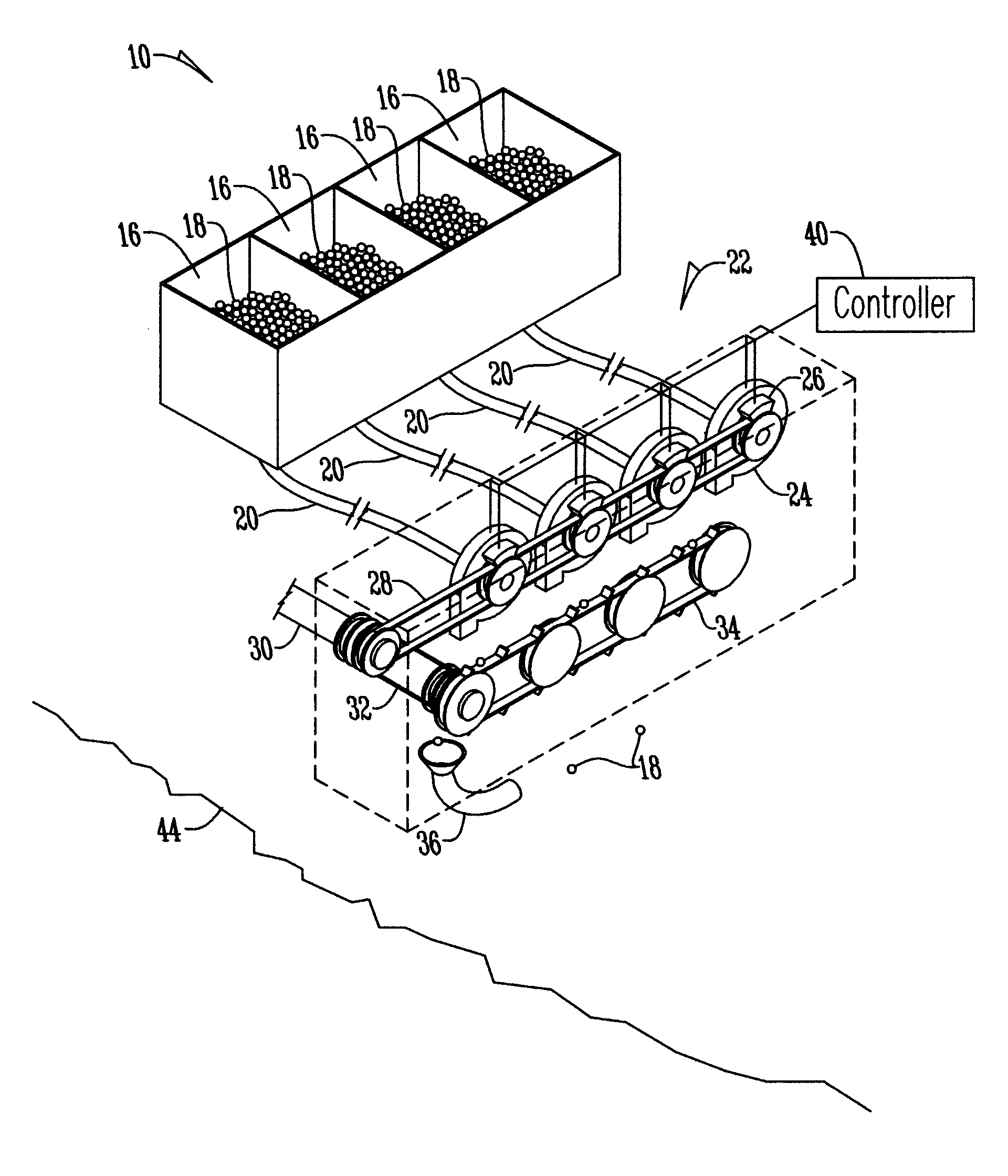

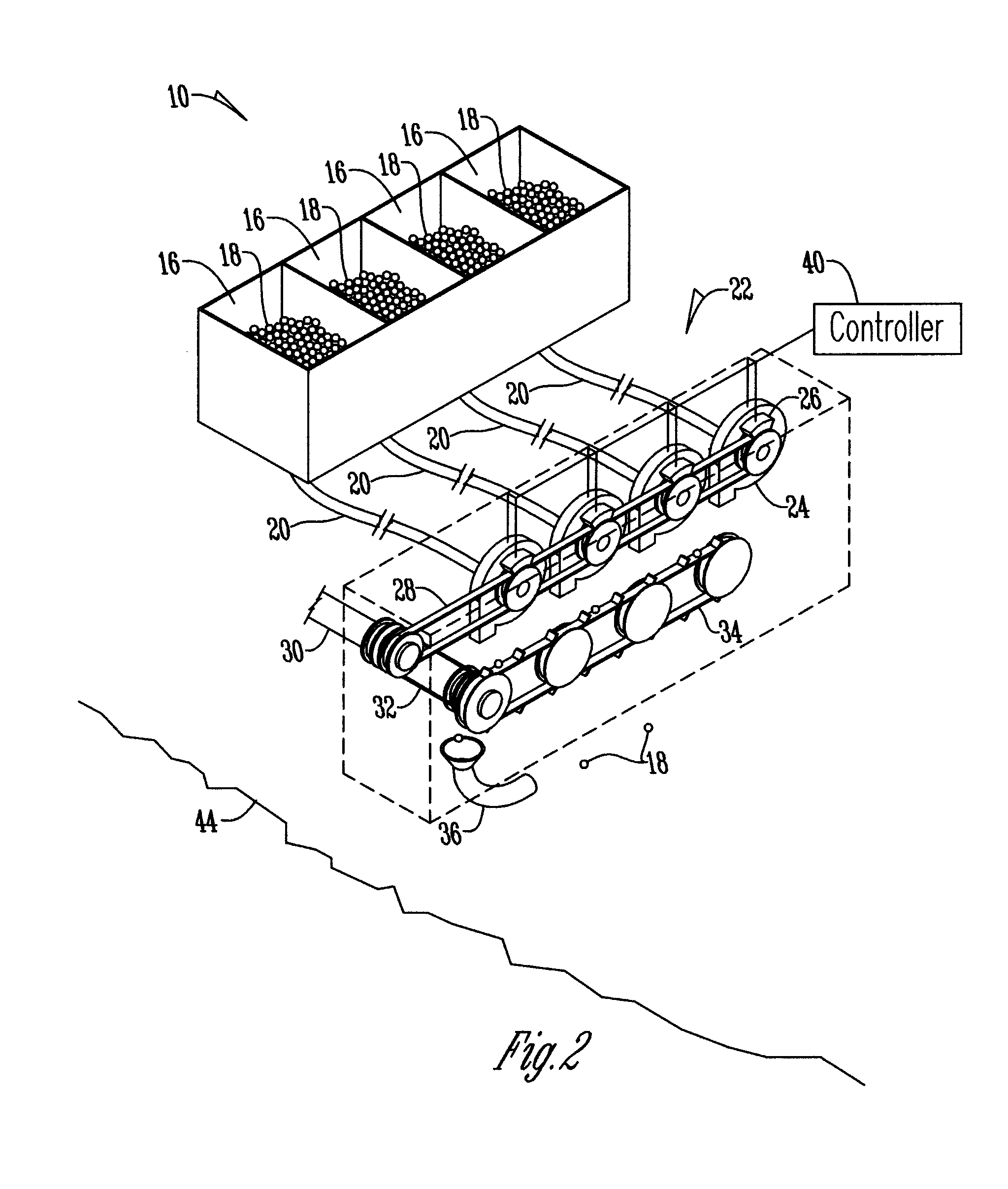

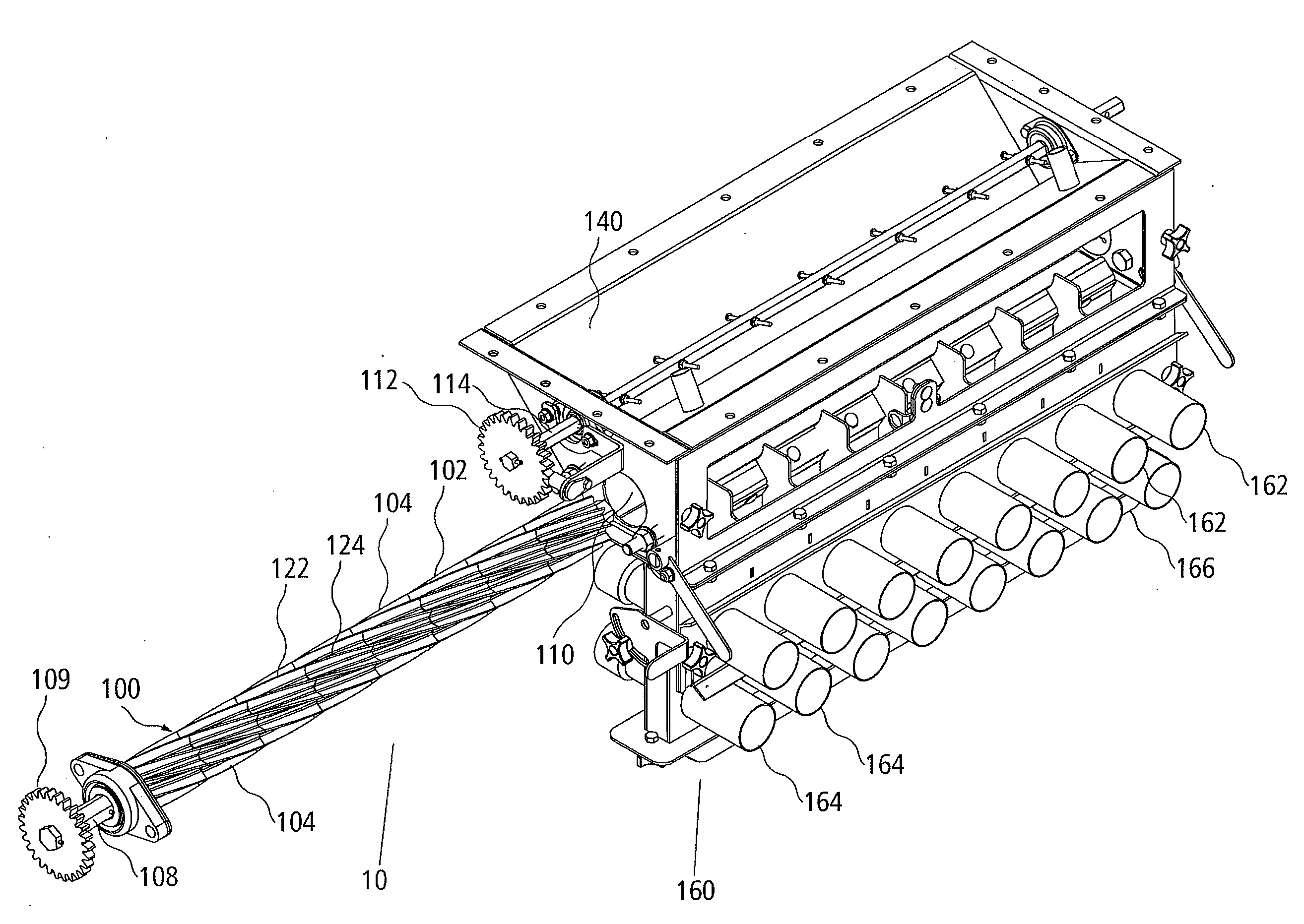

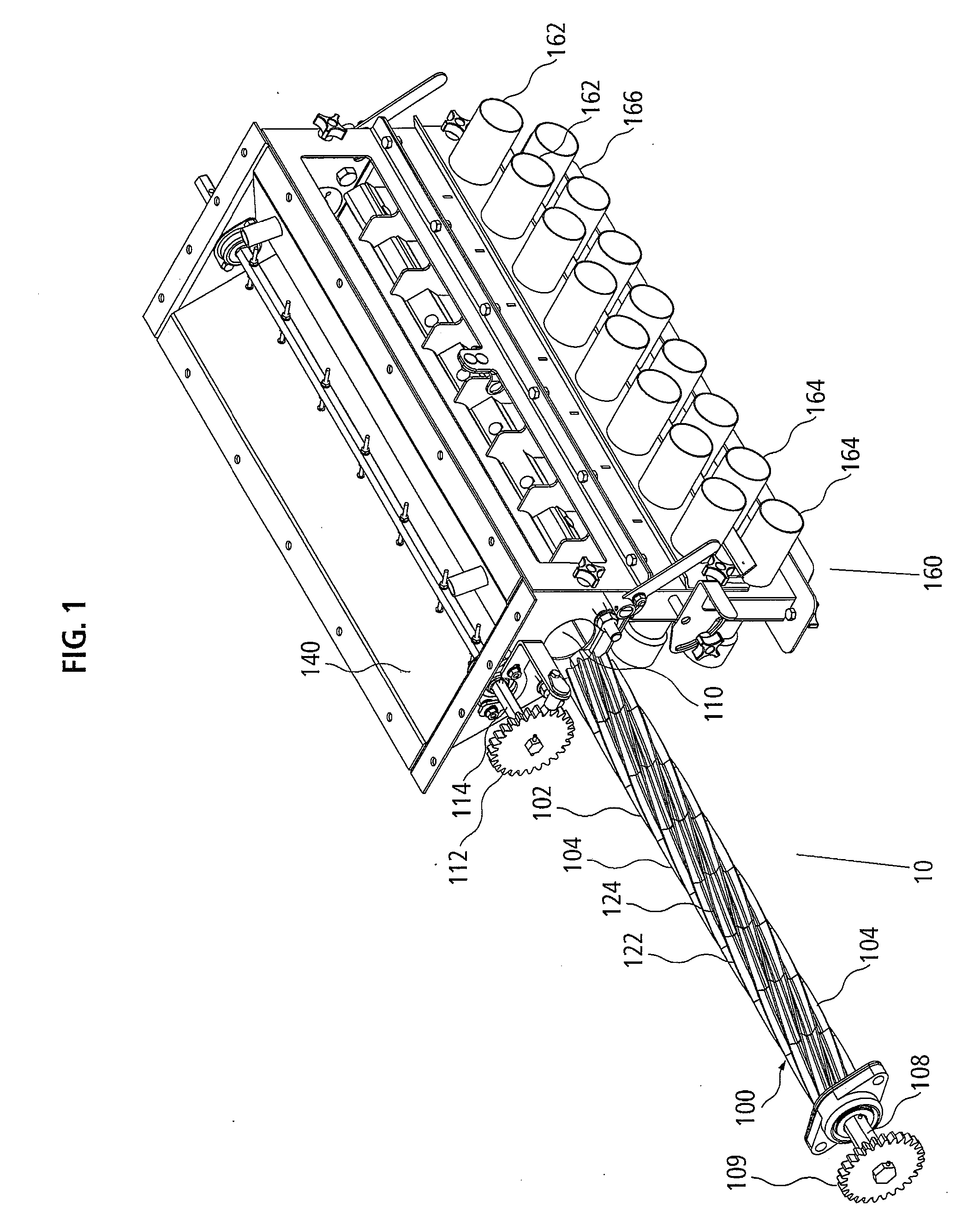

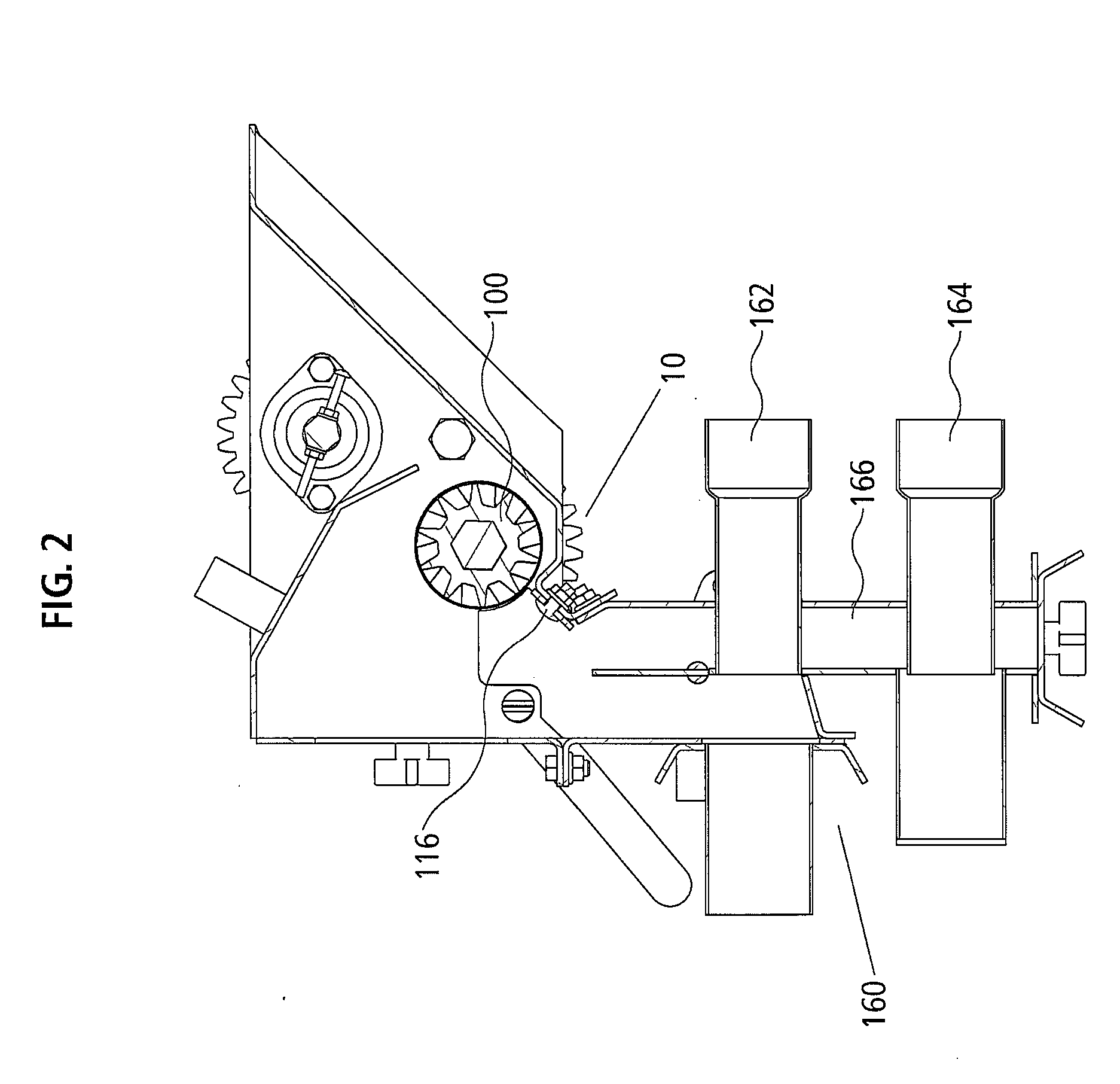

Method and apparatus for changing seed varieties at the row unit of a planter

A planting system for planting multiple seed varieties. The planting system includes a planter having a plurality of tanks and a plurality of row units. A plurality of seed meters are included in of the plurality of the row units. A seed transport belt is disposed below the plurality of seed meters to transport seed from each of the plurality of seed meters into a seed tube. Each of the plurality of seed meters is engaged and disengaged by a clutch, and the seed transport belt is disposed below the plurality of seed meters in an angled orientation.

Owner:KINZE MFG INC

Seed metering gate assembly

Owner:RENOVATORS LLC

Seed Metering Assembly For Farm Implement And Having Quick-Change Capability And Sectional Control

ActiveUS20120174844A1Improve efficiencyReduce flowFertilising methodsPotato plantersEngineeringMechanical engineering

A seed metering assembly for a farm implement has a meter roller that can be accessed and removed in a relatively quick manner. The seed metering assembly includes a fluted meter roller that is segmented into a number of discrete fluted sections. Each fluted section has an associated flow control member that is selectively operable to impede the flow of granular material from a seed hopper to its corresponding section of the fluted meter roller.

Owner:CNH IND CANADA

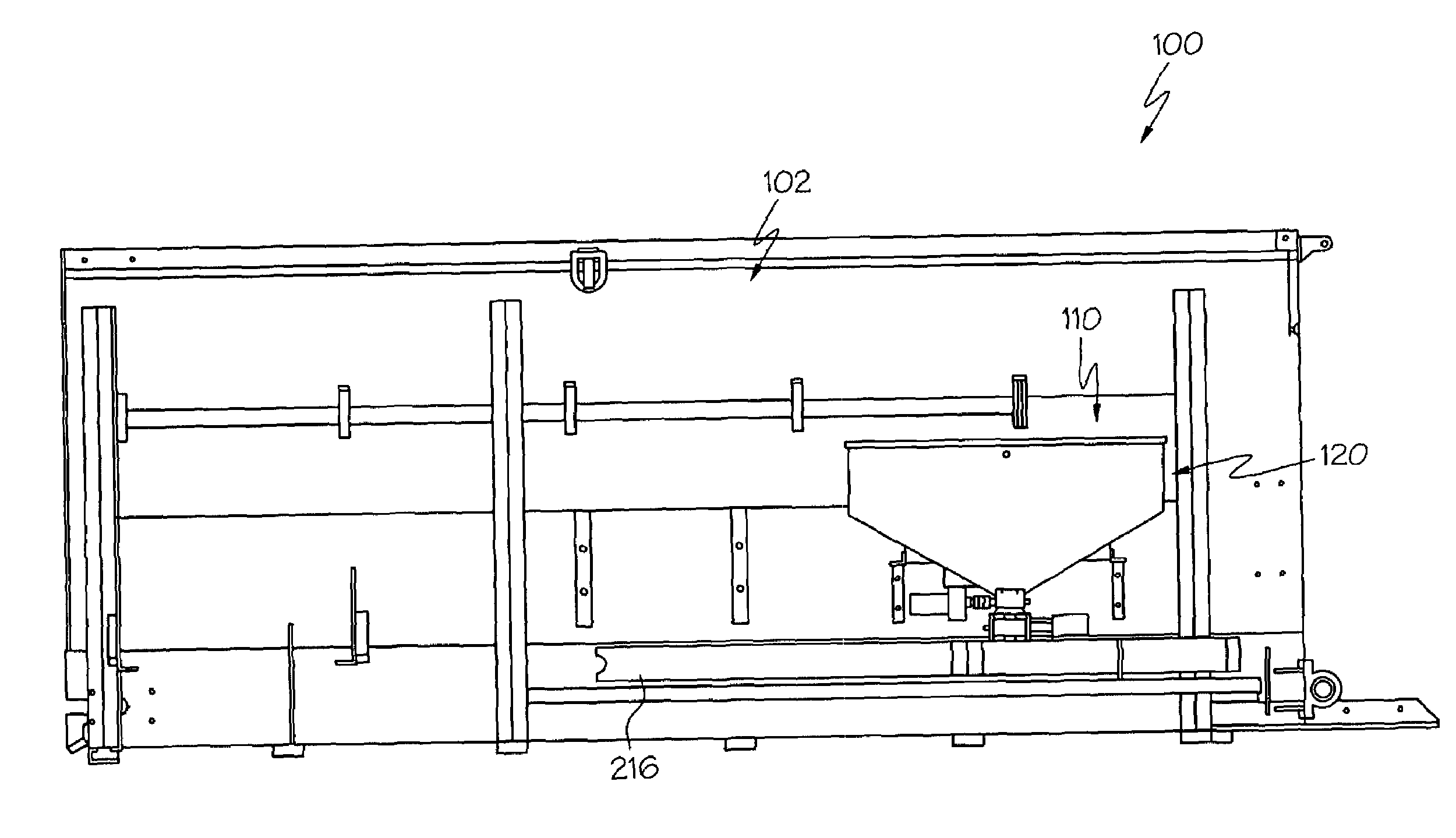

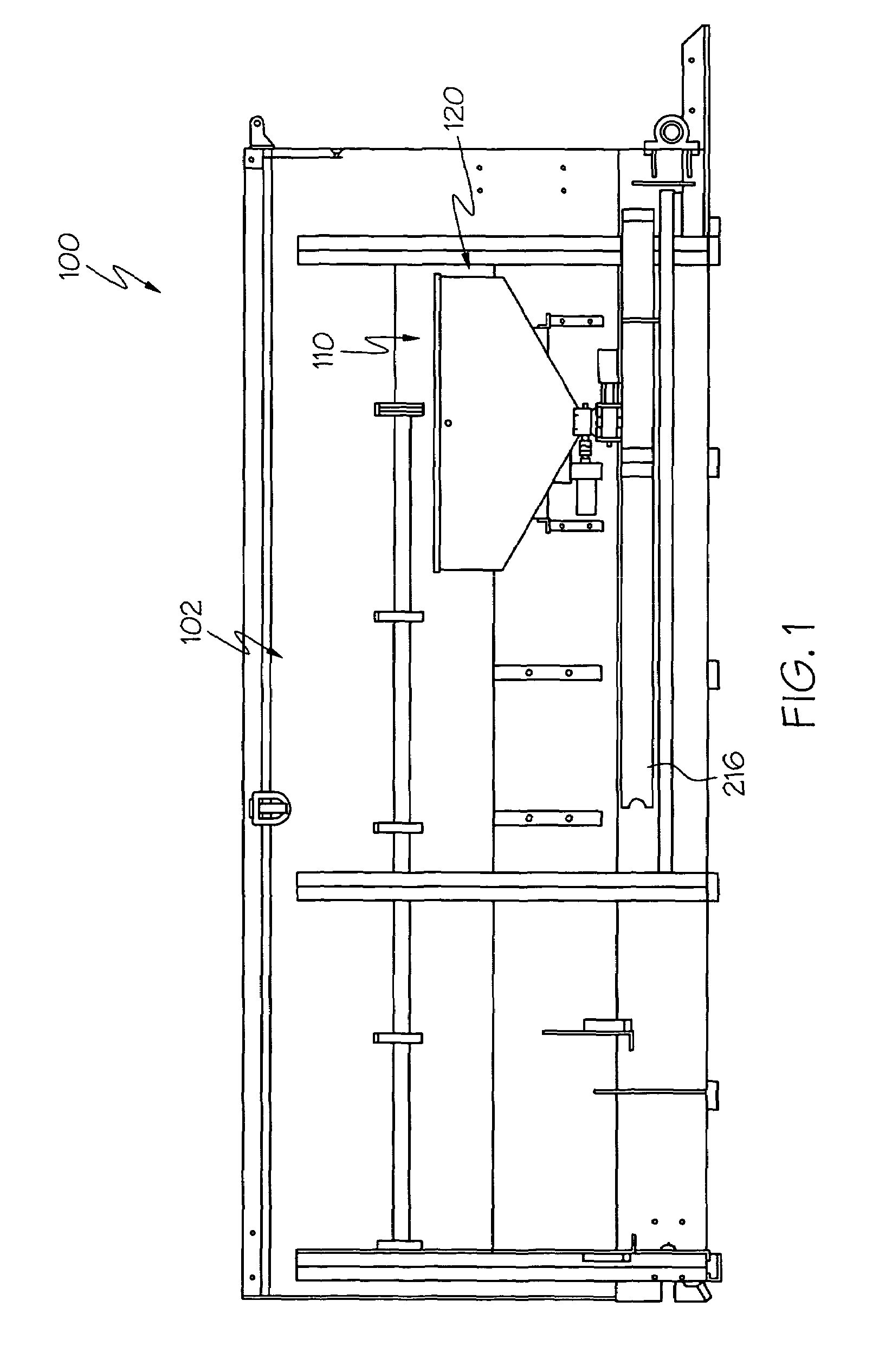

Sectional meter shut-off and agricultural implement having sectional meter shut-off

ActiveUS8141504B2Fertiliser distributersAgriculture and animal husbandary industrySeederMaterial supply

An assembly for selectively supplying particulate material to an air seeder, an agricultural implement able to selectively supply and dispense particulate material into the ground and a method of selectively dispensing particulate material into the ground are provided. The assembly has at least one supply receptacle for receiving particulate material from a source and a metering roller for supplying the material to an air seeder. The assembly is operative to selectively supply the material to the air seeder and prevent the material from being supplied to the air seeder. The implement can use the assembly to selectively supply particulate material to ground engaging openers where the particulate material will be dispensed into the ground. Particulate material can be selectively supplied to the implement when it is desired to have the particulate material dispensed into the ground and then prevented from being supplied to the implement when it is not desirable.

Owner:ONE PASS IMPLEMENTS

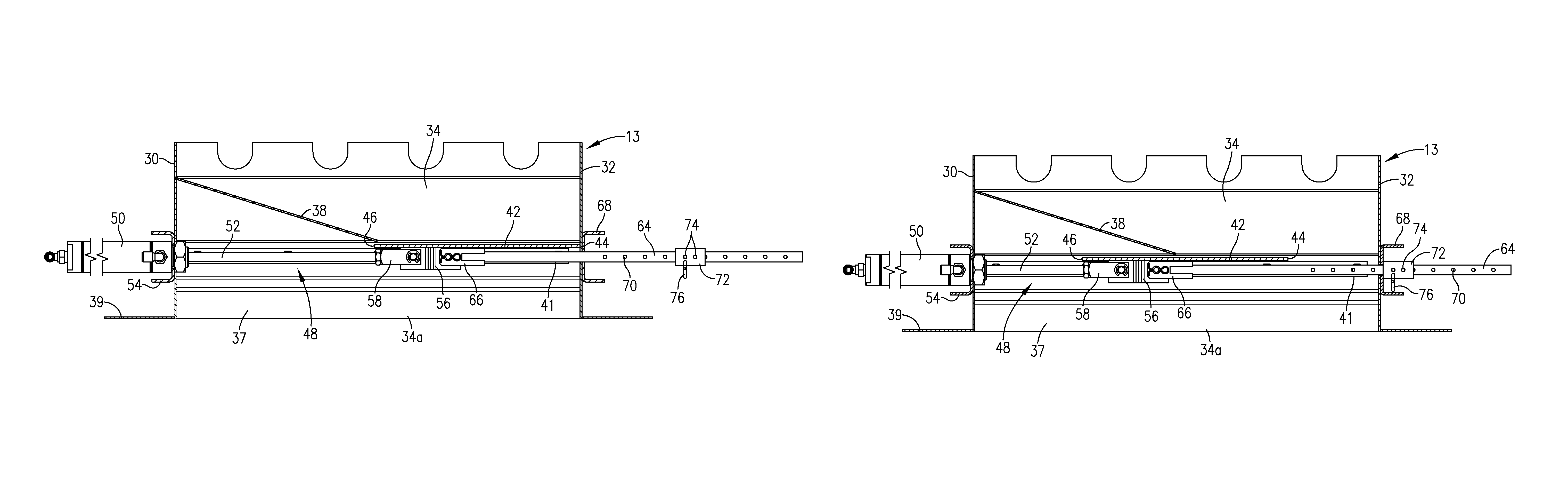

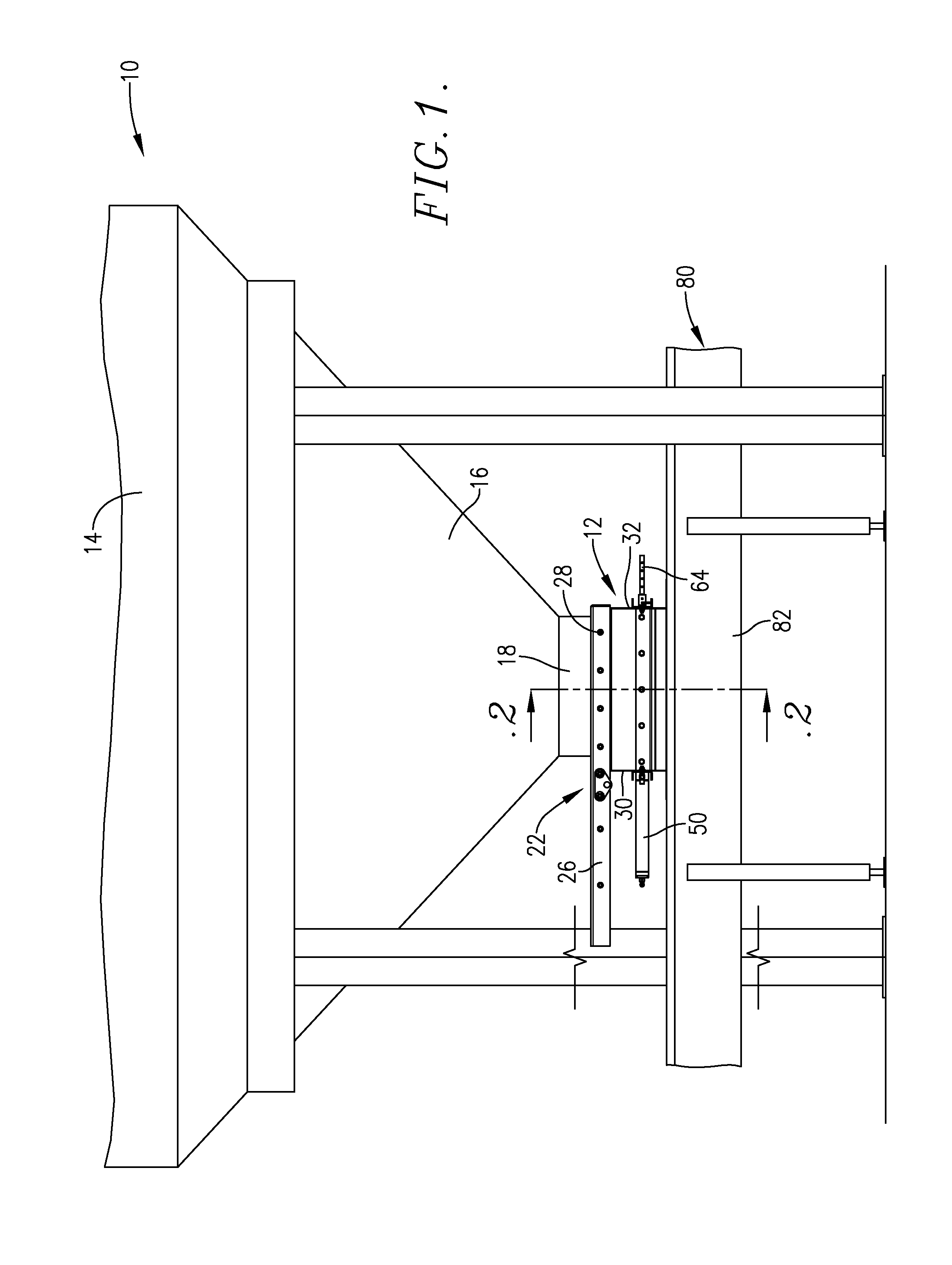

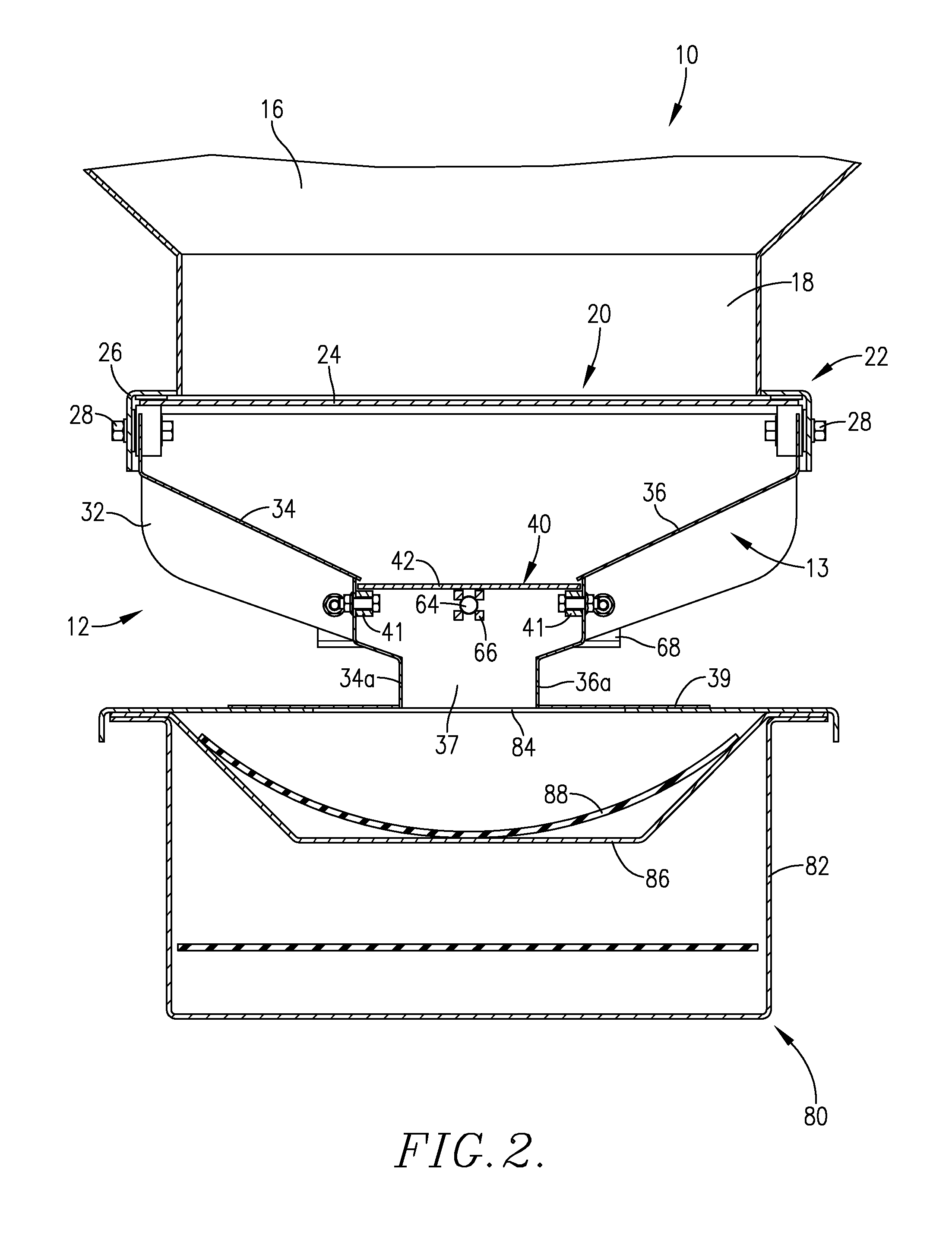

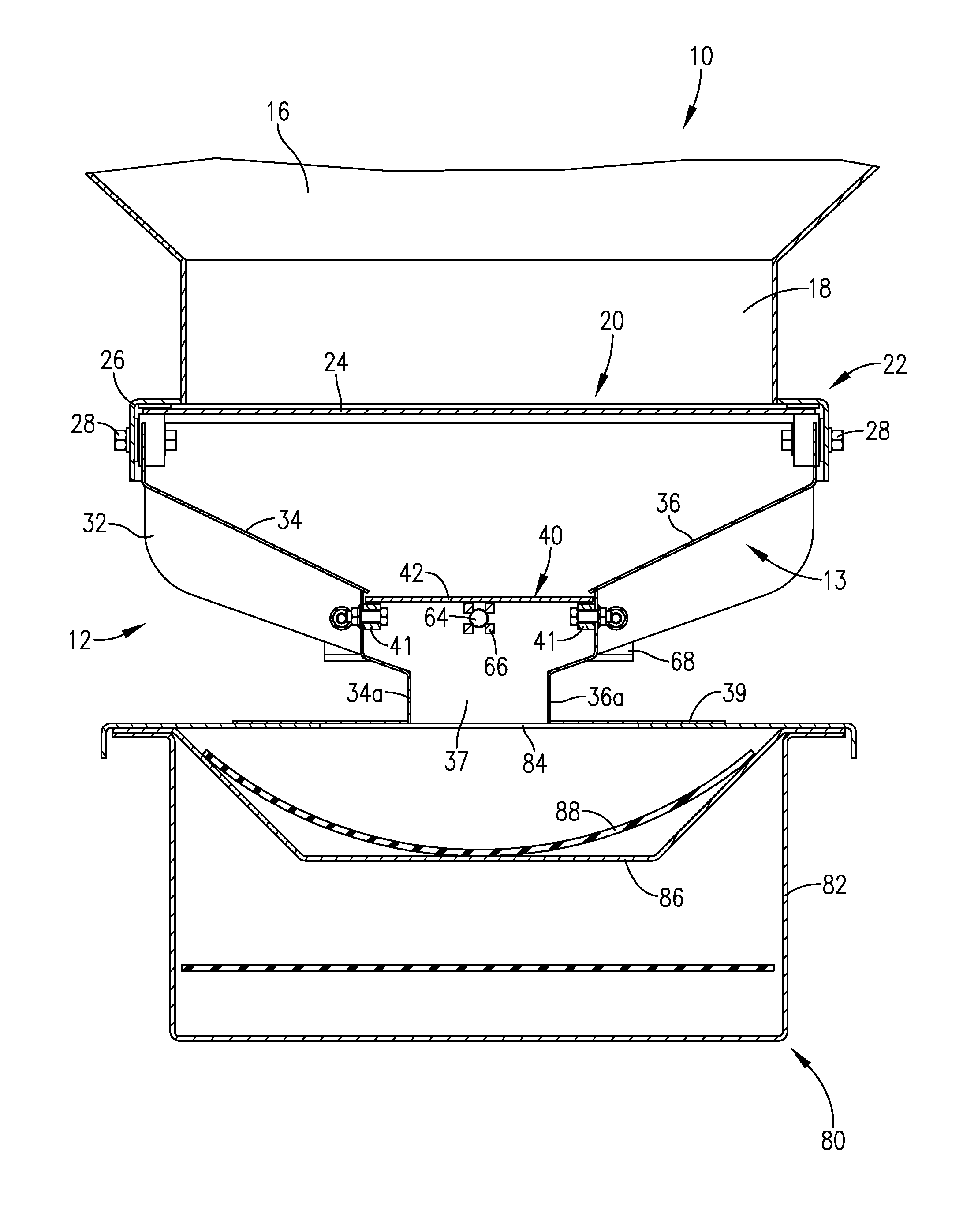

Seed metering gate assembly

A seed metering gate assembly (12) is provided for use with an upright seed bin (10) having a shiftable primary gate (24), wherein the gate assembly (12) provides an additional seed flow control function allowing more accurate dispensing of seed from the bin (10). The gate assembly (12) includes a seed hopper (13) equipped with a fore and aft-shiftable metering gate (42) movable between a closed position and an open position presenting a seed output passageway (40). Apparatus (62) is operably coupled with the gate member (42) in order to determine the travel of metering gate member between the fully closed position and a plurality of open positions presenting respective, differently sized passageways (40). The apparatus (62) preferably includes a rod (64) having a series of through openings (70) and coupled with the gate member (42), with a shiftable, motion-limiting collar (72) mounted on the rod (64) and securable at any of the openings (70) by means of clip (76). The opening movement of the rod (64) is limited by engagement between the collar (72) and a bracket (68) affixed to hopper (13).

Owner:USC

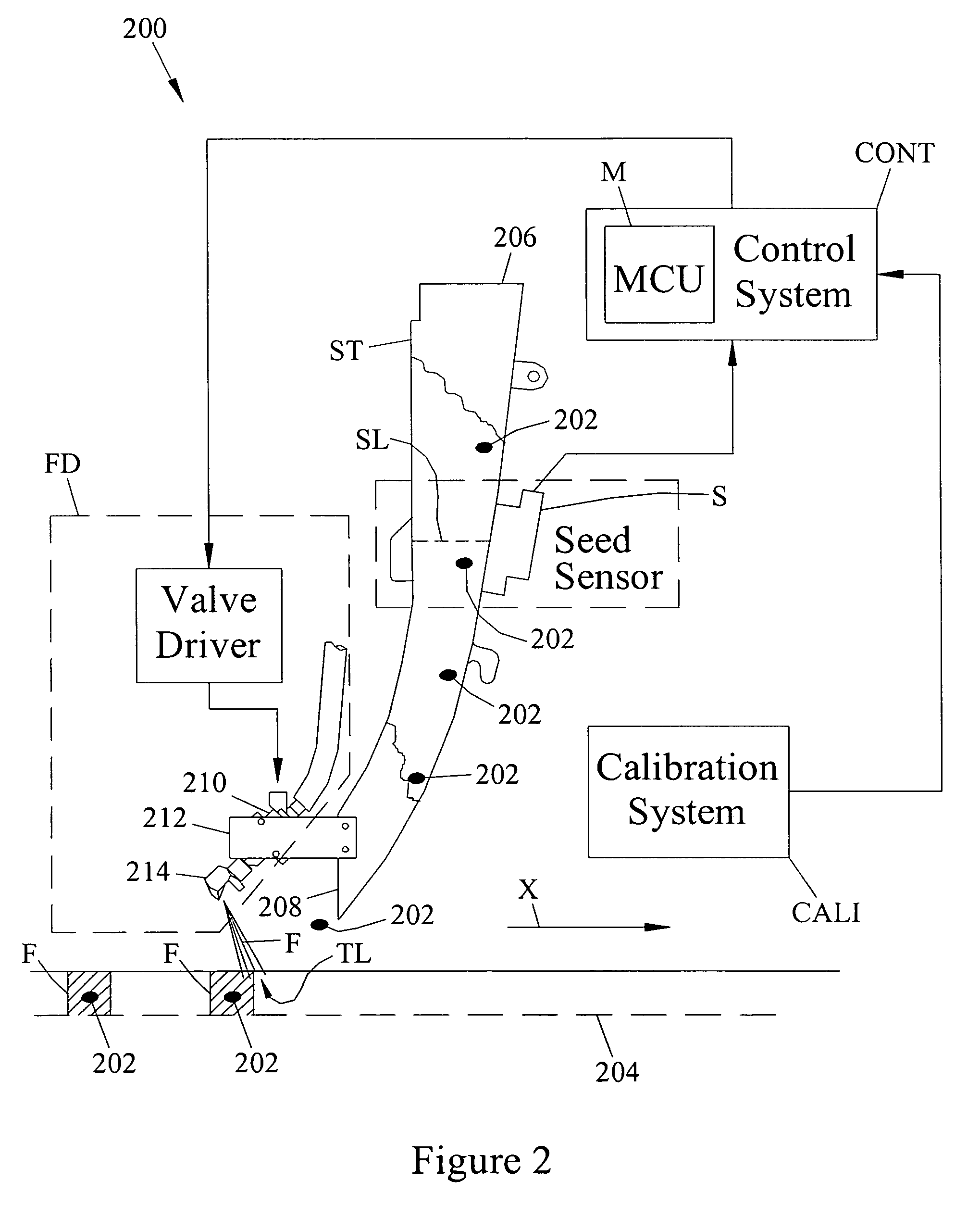

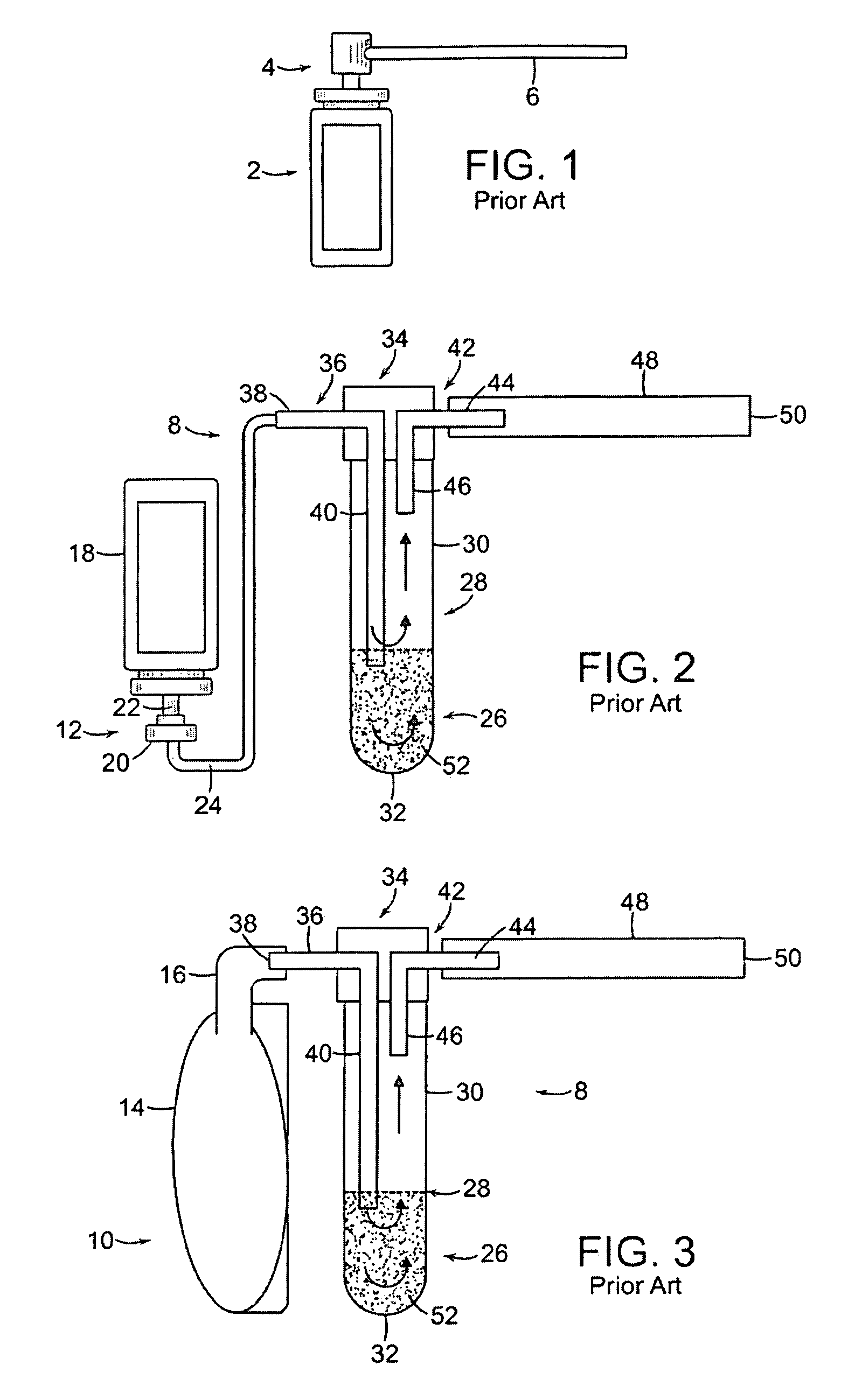

Systems and methods for fluid dispensing

Systems and methods are disclosed for dispensing fluids. The systems can include a sensor operable to detect when an object passes a first location as the object moves to a second location. The systems can also include a fluid dispenser operable to dispense fluid at the second location. In addition, the systems can include a control unit in communication with the sensor and the fluid dispenser. The control unit can receive information from the sensor that the object has passed the first location and to control the fluid dispenser to dispense fluid at the second location at a predetermined time after the object passes the first location.

Owner:UNIV OF TENNESSEE RES FOUND

Nozzle assembly for product-on-demand delivery system

Owner:DEERE & CO

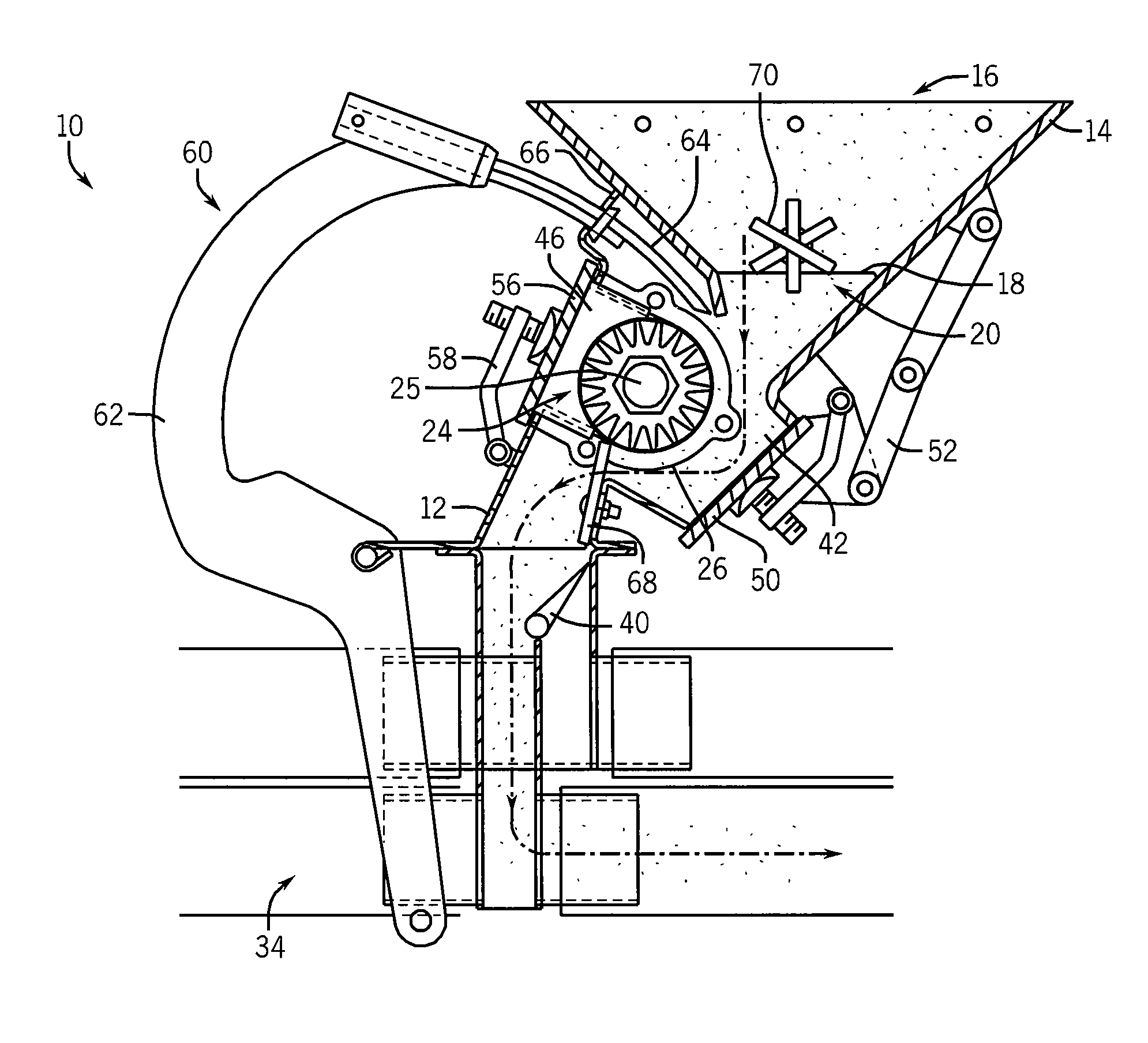

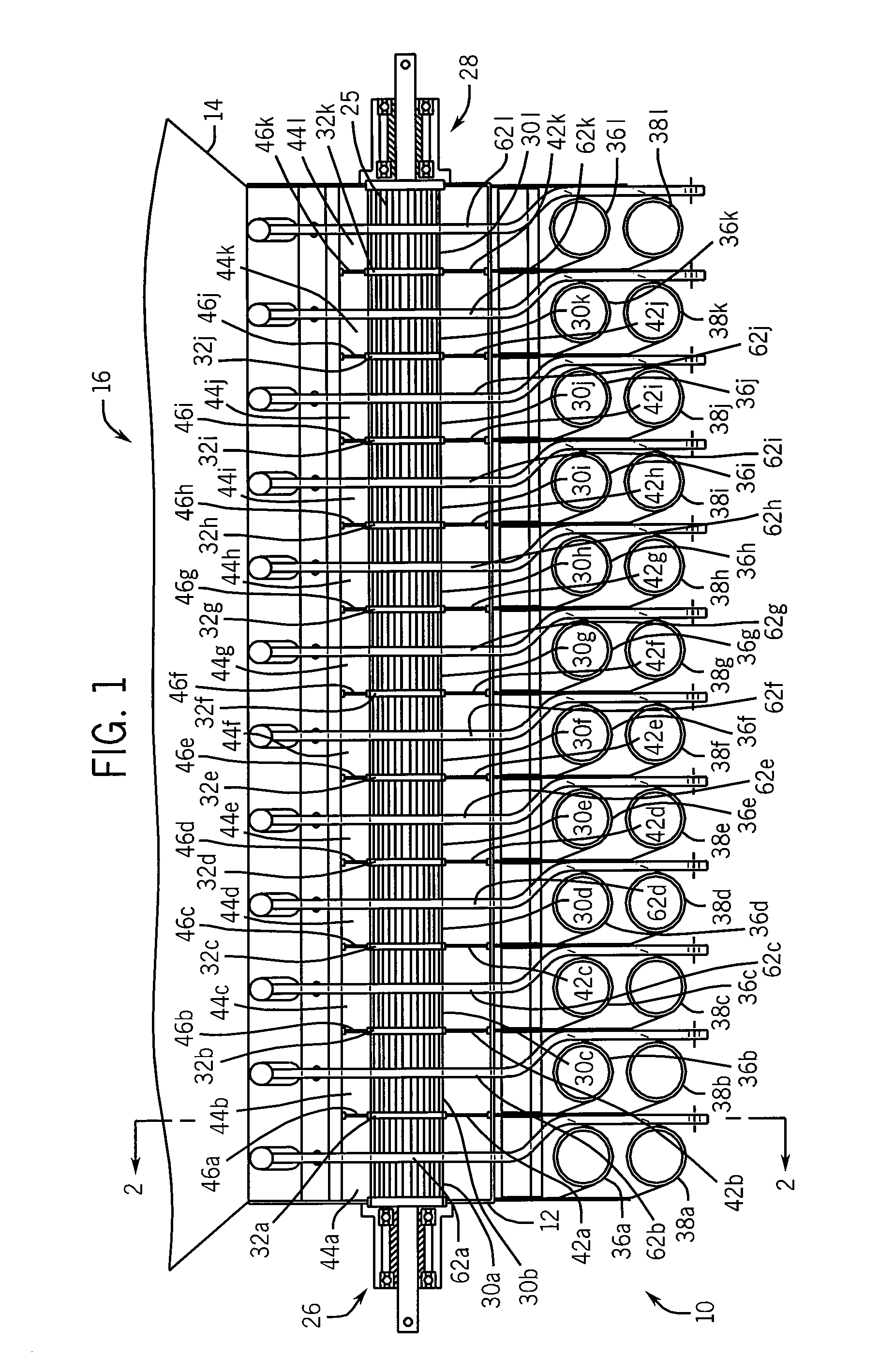

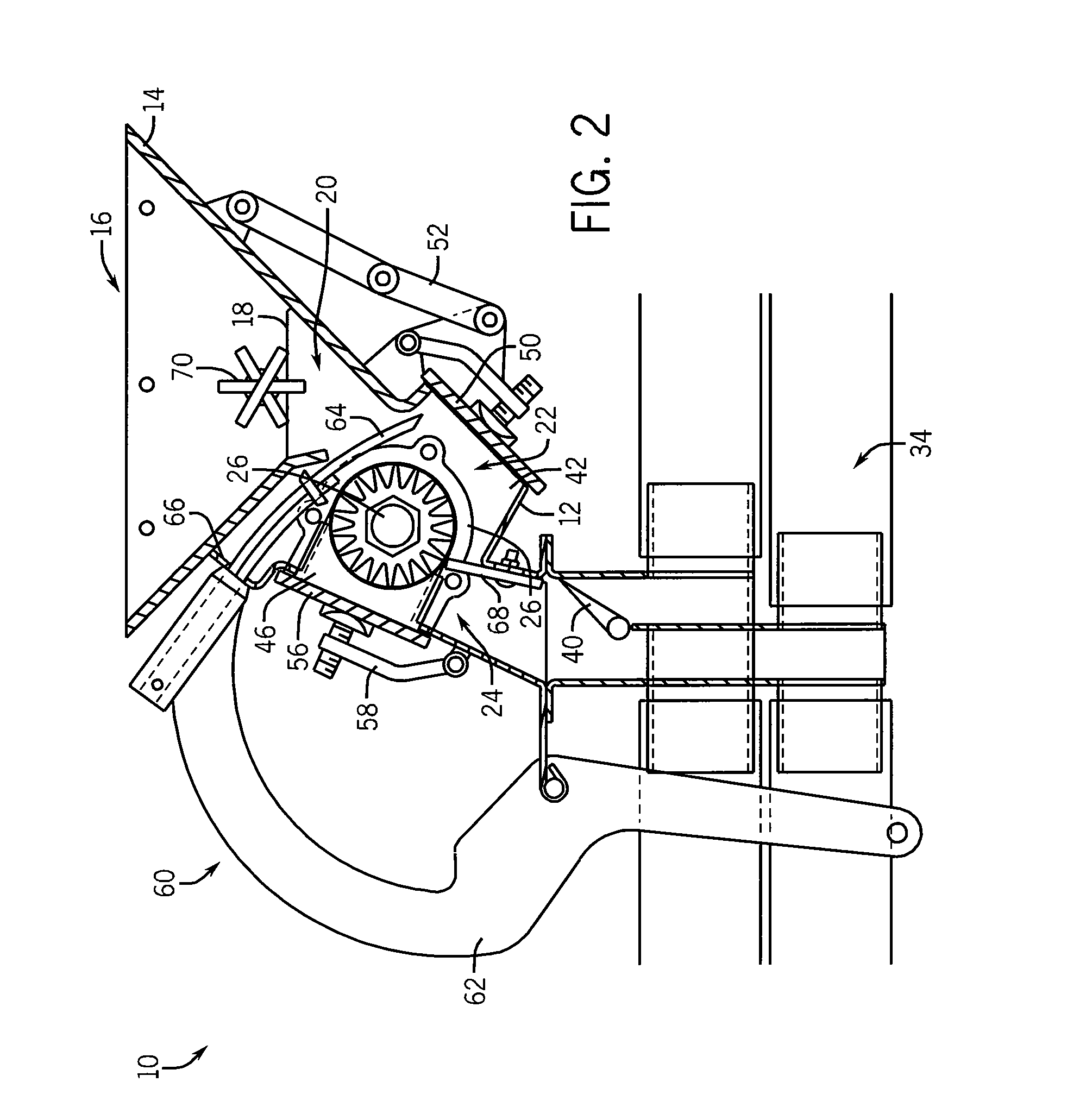

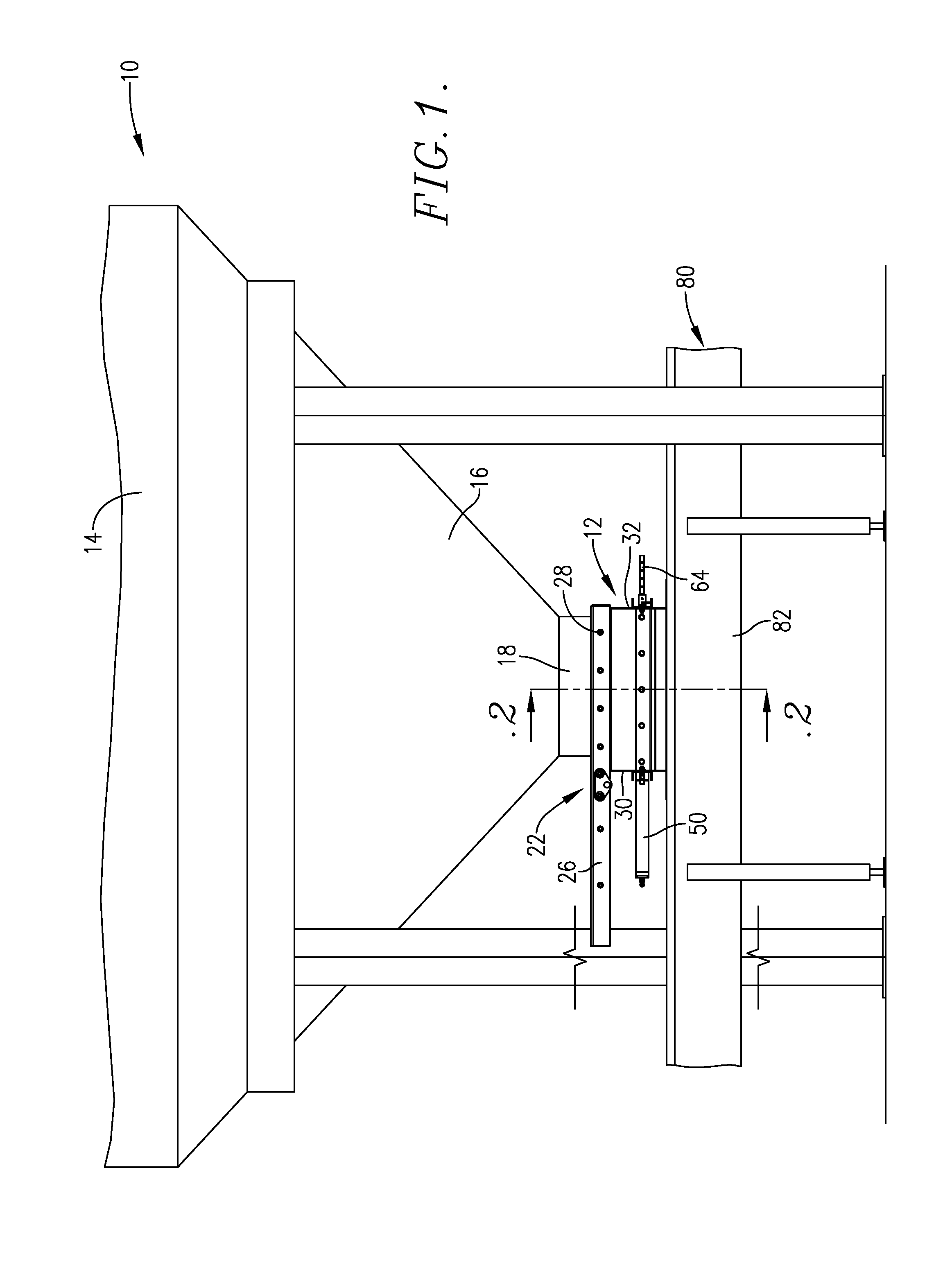

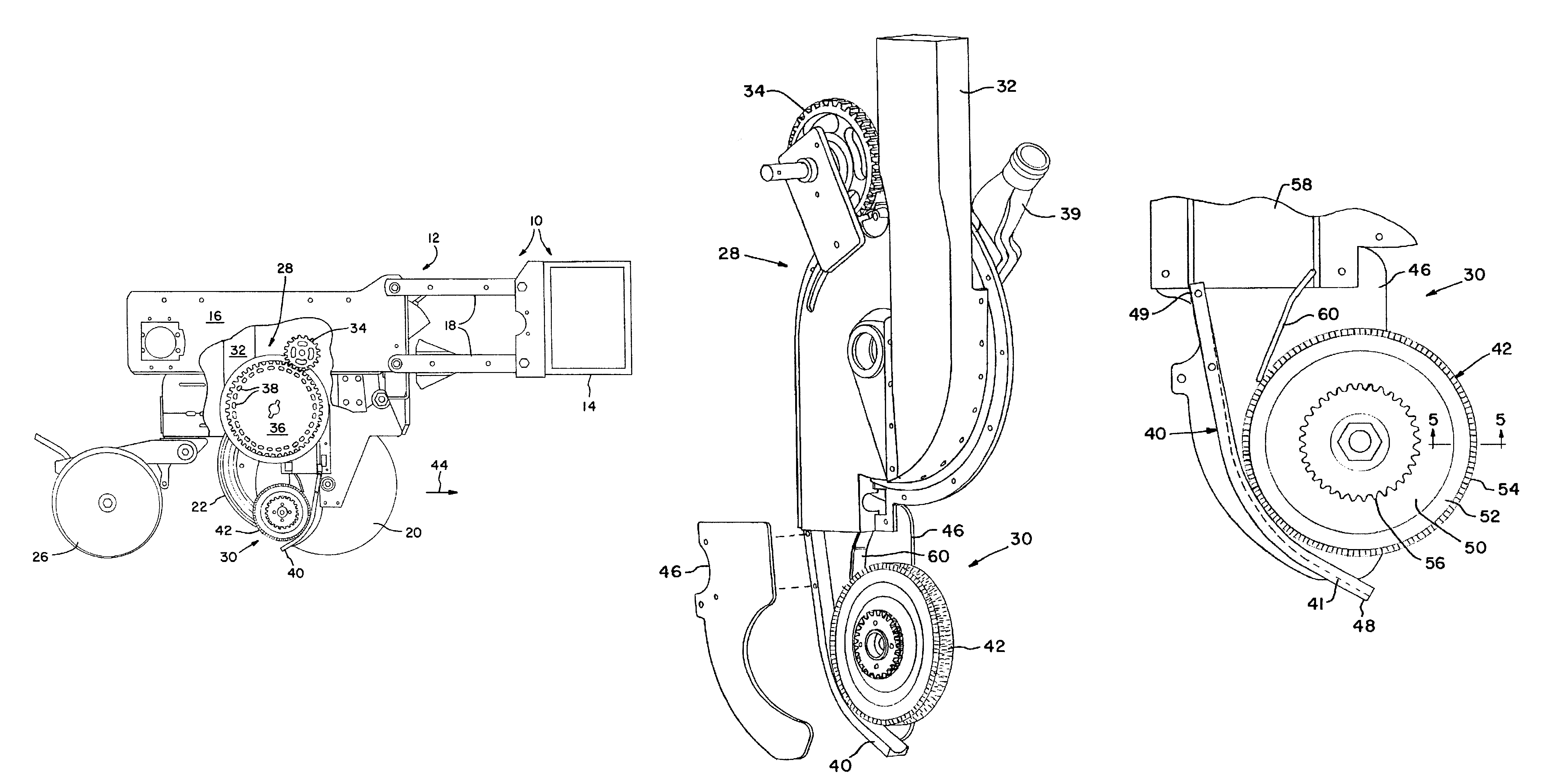

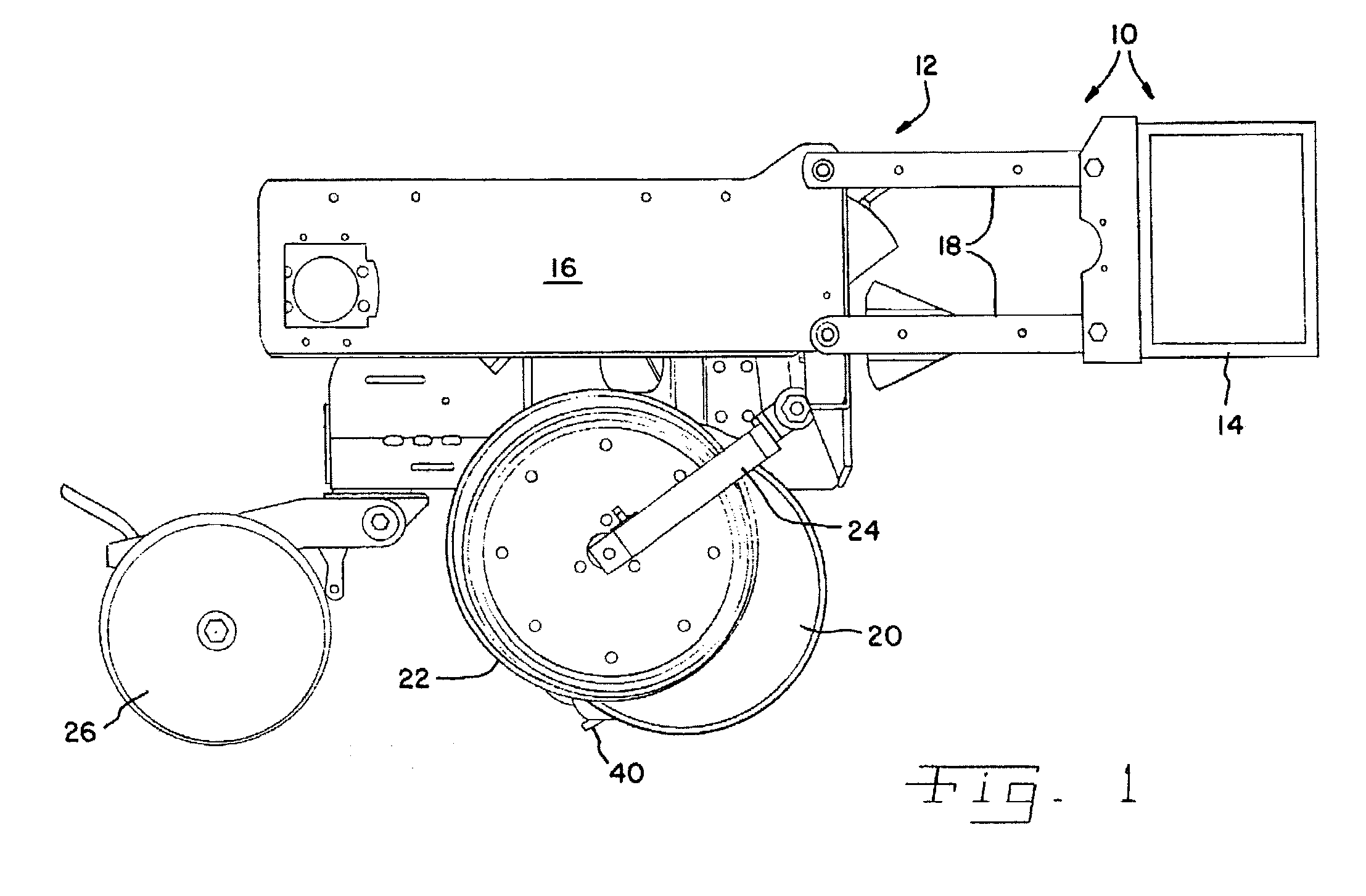

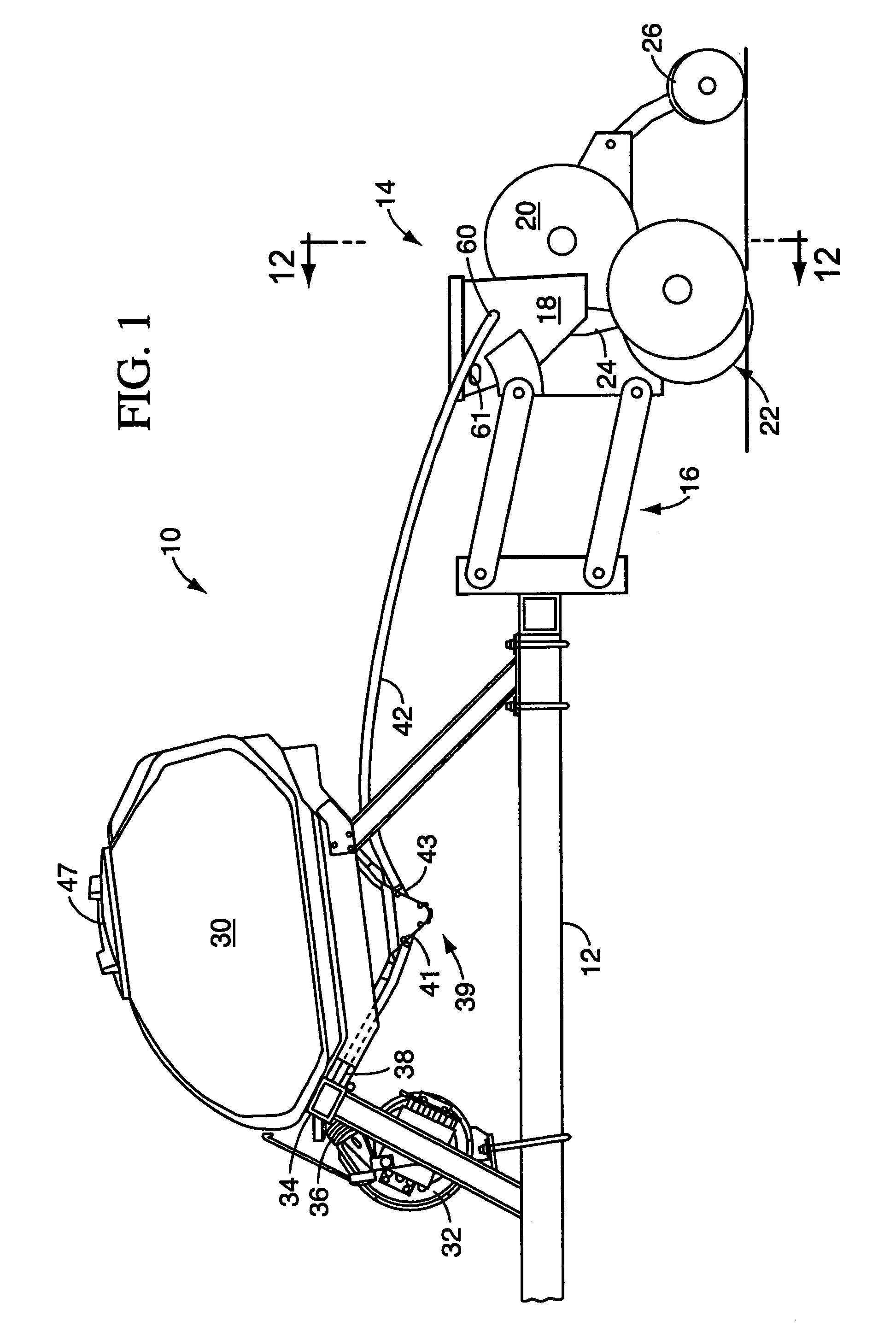

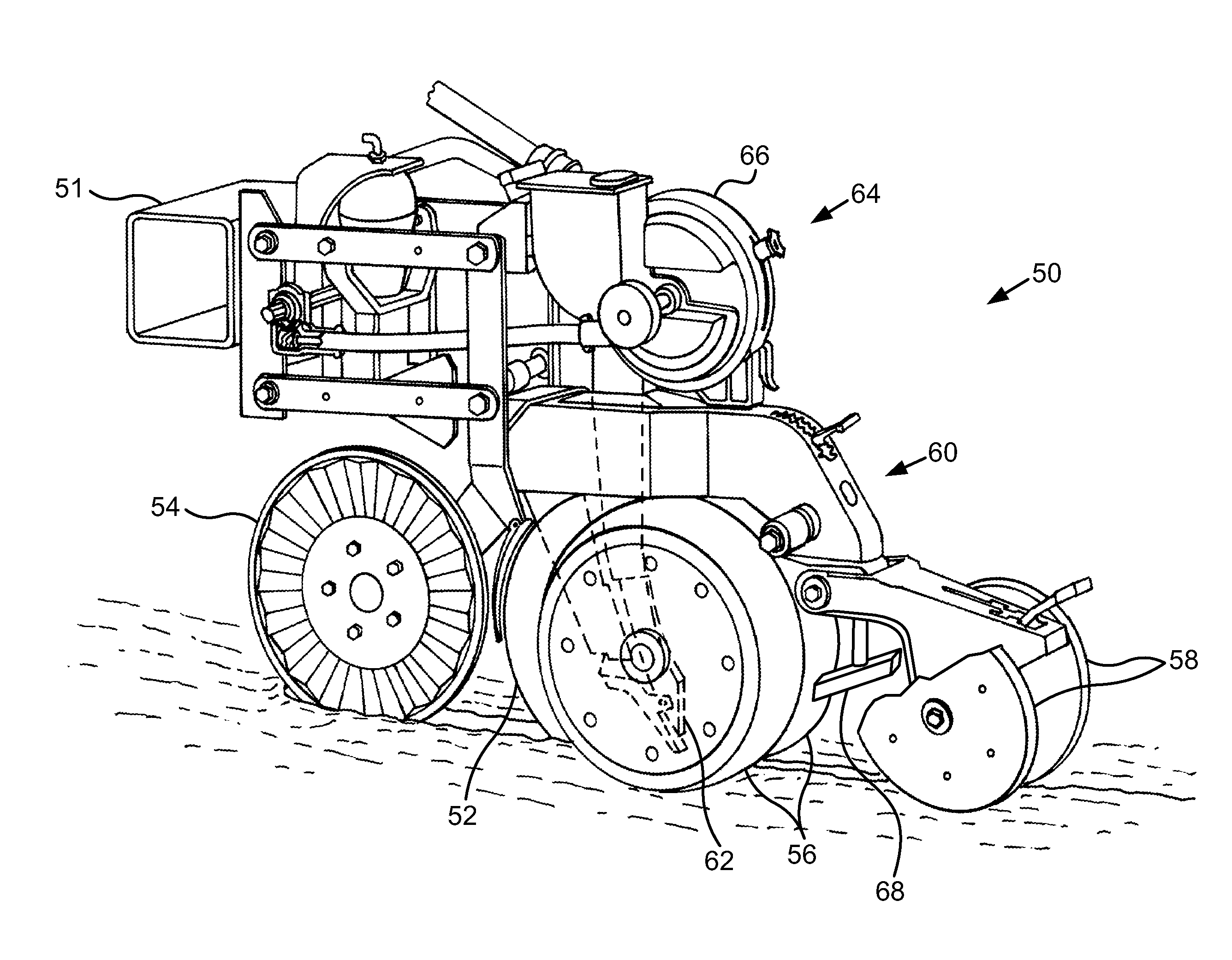

Seed placement system for use in a seeding machine

ActiveUS7343868B2Easy sowingSimply and effectively definedSpadesCoin-freed apparatus detailsCircular discSeeder

A seeding machine includes at least one seed metering system and at least one seed placement system. Each seed placement system is in communication with a corresponding seed metering system. Each seed placement system includes a housing having a seed slide, and a wheel at least partly disposed within the housing. The wheel has a circumferential periphery with a plurality of contiguous disc joint surfaces. The periphery is positioned adjacent to at least part of the seed slide. The invention comprises, in another form thereof, a method of placing seeds with a seeding machine in a trench formed in soil. Seeds are received at a predetermined rate at a seed placement system. The seed placement system includes a seed slide, and a wheel having a conferential periphery position closely adjacent to at least part of the seed slide. The seeds are engaged at the predetermined rate against the wheel periphery. The seeds are carried past a closely adjacent area of the seed slide using the wheel periphery. The seeds are released from the wheel periphery.

Owner:DEERE & CO

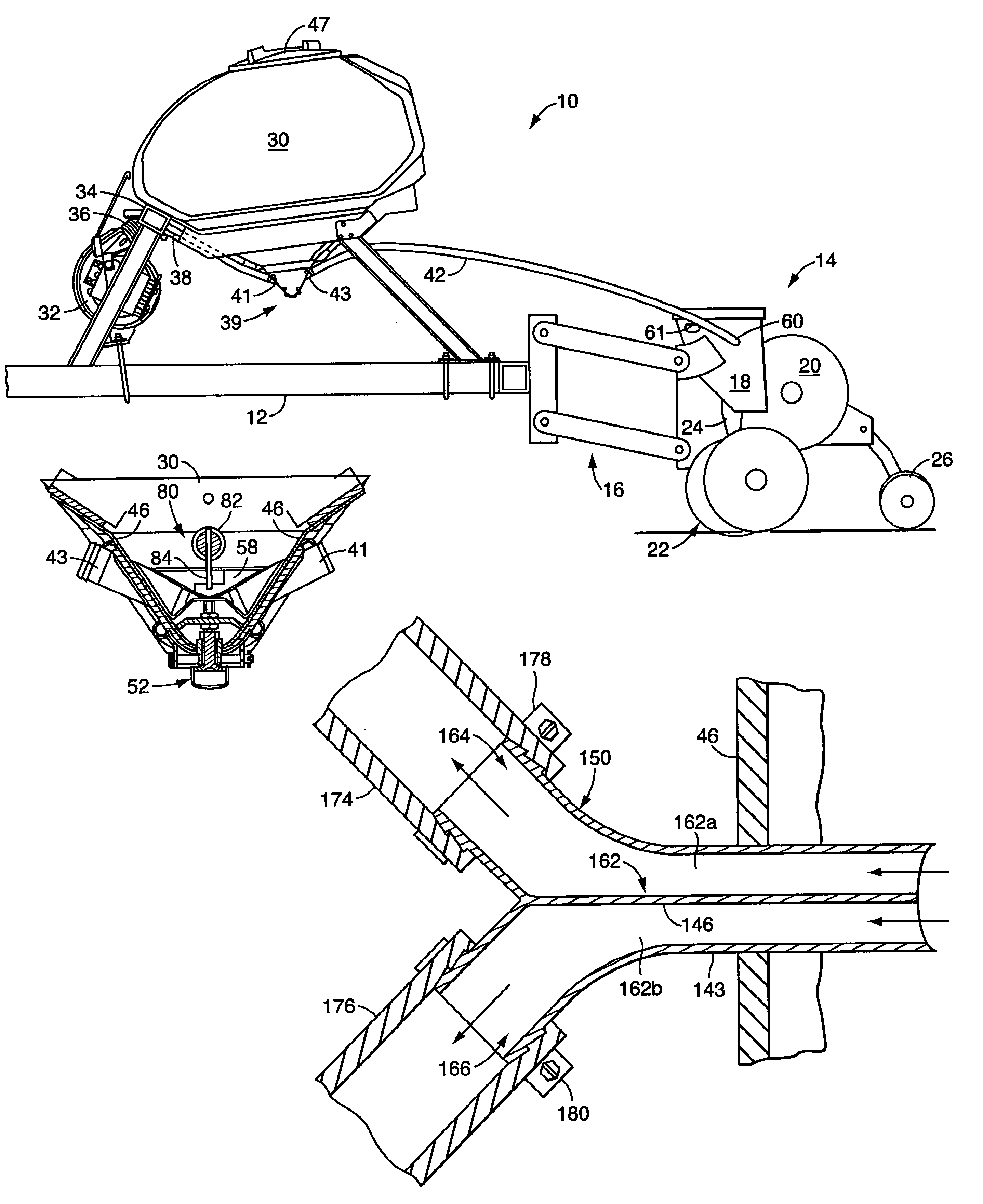

Flow splitter arrangement for series fed product application units

ActiveUS7025010B2Avoid cloggingReduce in quantityPotato plantersFurrow making/coveringVelocity vectorInlet flow

A product-on-demand delivery system applies an agricultural product, such as seed, to a field. The system includes a frame that mounts a main hopper, a splitter fitting, a primary product hose, a secondary product hose, a primary application unit and a secondary application unit. The main hopper has an air nozzle wherein an air stream through the air nozzle entrains product within the air stream and delivers the air / product to the primary outlet hose. The splitter fitting has a splitter inlet flow-connected to the primary product hose and two splitter outlets flow-connected to the application units. The secondary application unit is coupled to the primary product supply hose by the secondary product hose connected at an outlet branch. The outlet branch is connected at an angle such that a product flow velocity vector in the primary product supply hose at the outlet branch is at an obtuse angle to a flow velocity vector of product flowing through the outlet branch. The outlet branch is oriented for a vertical upward flow of air and product.

Owner:DEERE & CO

Multiple Seed-Type Seed Meter

ActiveUS20160037713A1Highly controllable mannerCompact configurationFertilising methodsPotato plantersBiological activationAgronomy

A seed meter is provided for planting multiple types of seed and rapidly switching between the types being planted in a single planting pass of a planting session of row-crop planting. The seed meter has a segmented seed meter reservoir with multiple seed meter chambers arranged between two pairs of seed disks that may be better parallel to each other or angled with respect to each other to define an X-shaped arrangement of the seed disks in the seed meter. Activation and deactivation of the seed disks within the seed meter are synchronized to selectively deliver a single one of the multiple types of seed from the respective seed meter chamber for delivery out of a single seed tube of the seed meter, which may provide absolute and instantaneous on-the-go seed switching within a single row from each seed meter.

Owner:BLUE LEAF I P INC

Method and apparatus for changing seed varieties at the row unit of a planter

A planting system for planting multiple seed varieties. The planting system includes a planter having a plurality of tanks and a plurality of row units. A plurality of seed meters are included in of the plurality of the row units. A seed transport belt is disposed below the plurality of seed meters to transport seed from each of the plurality of seed meters into a seed tube. Each of the plurality of seed meters is engaged and disengaged by a clutch, and the seed transport belt is disposed below the plurality of seed meters in an angled orientation.

Owner:KINZE MFG INC

Volumetric metering system with clutch based sectional shut-off

A volumetric meter for seed or fertilizer having a plurality of roller segments driven by a common drive shaft is provided with clutch mechanisms radially between each roller segment and the drive shaft to enable the roller segments to be individually shut-off to provide section or swath control to the machine.

Owner:DEERE & CO

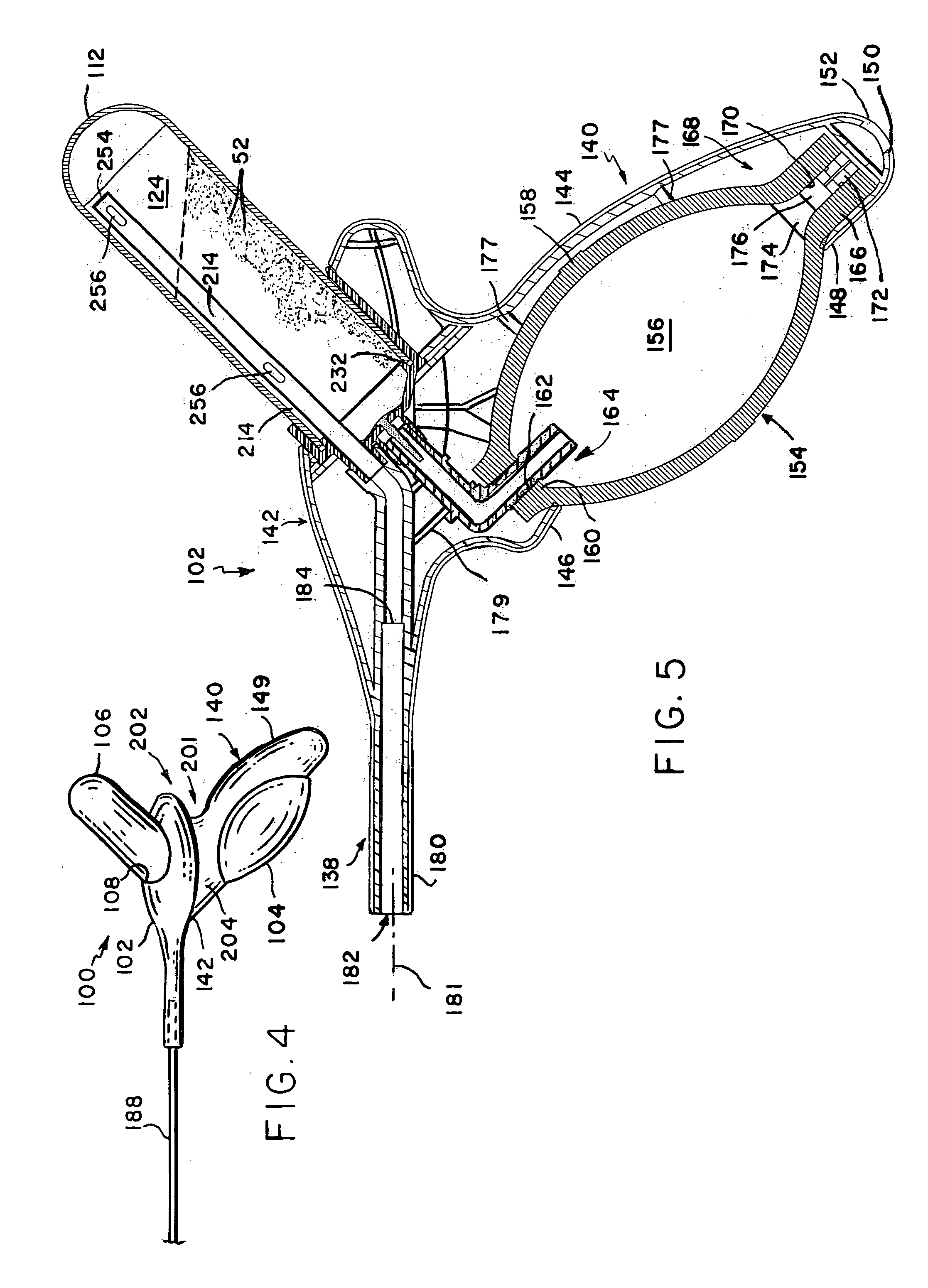

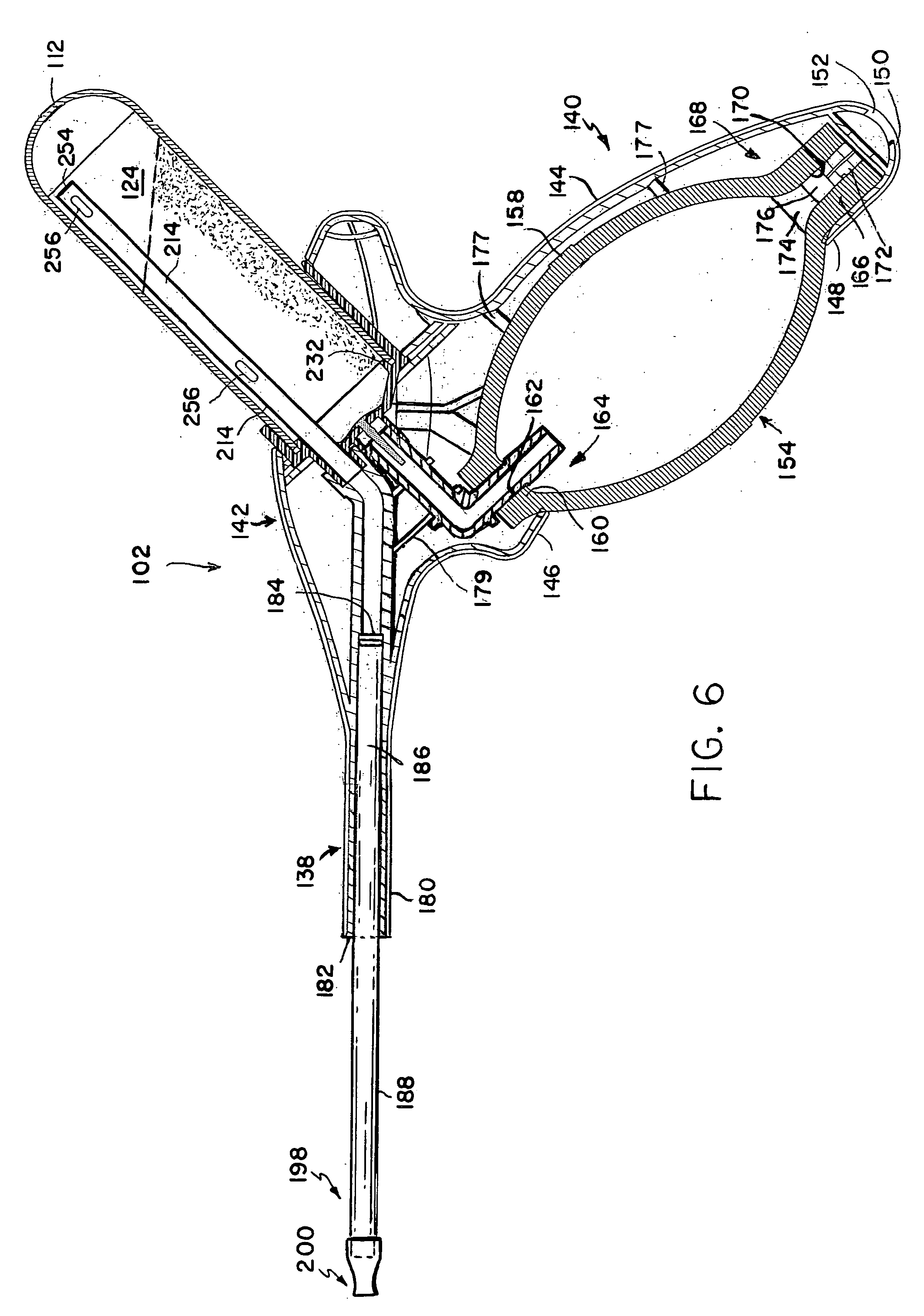

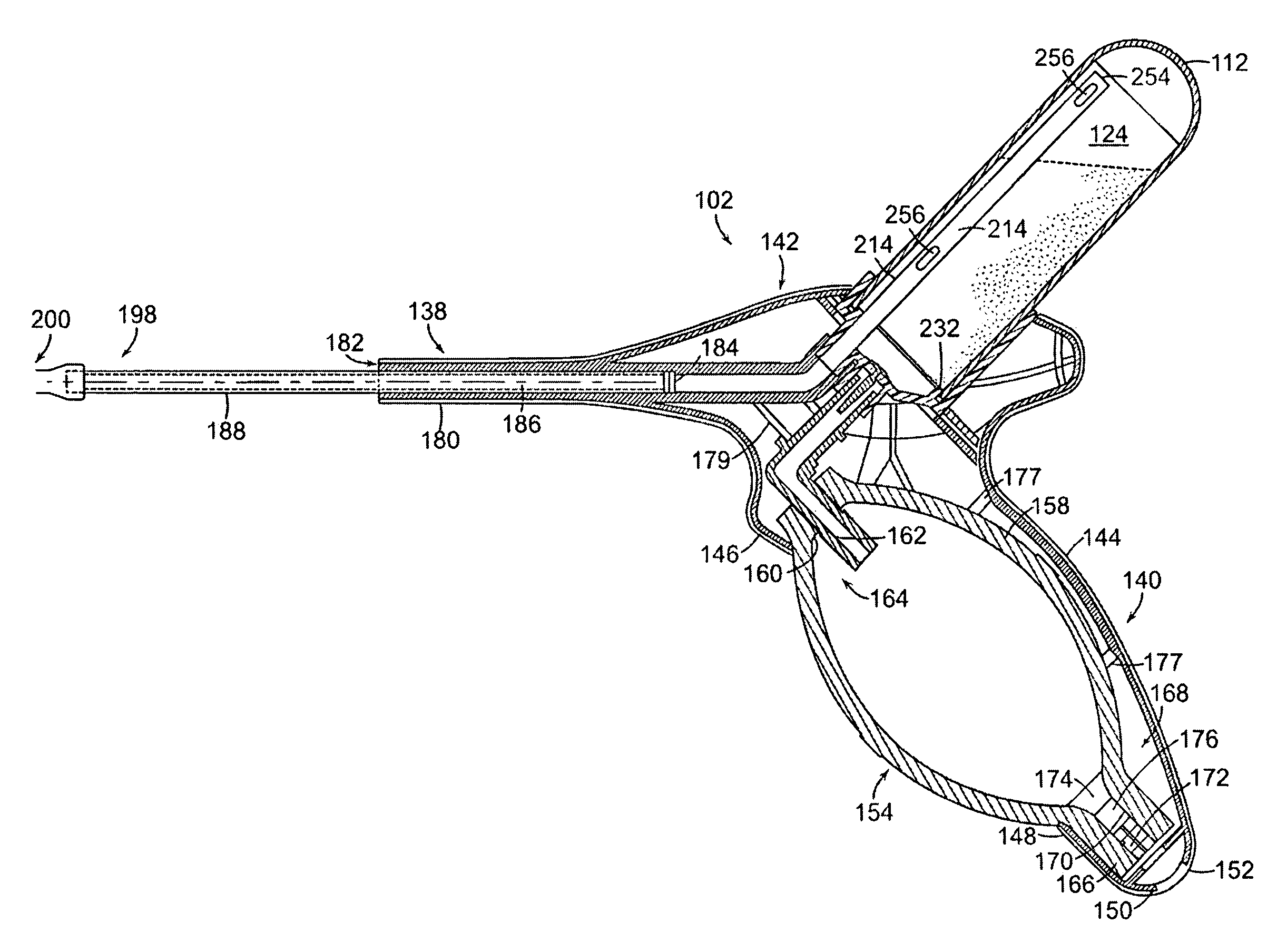

Powder delivery device

ActiveUS20050205087A1Easily and advantageously manufacturedEasily and advantageously and distributedPowder deliverySurgeryHand heldEngineering

A pistol-shaped powder delivery device consolidates propellant pulse creation, powder storage, powder aerosolization and aerolsolized powdered delivery in a single device while providing dose, pattern and coverage control of the output spray. The single-hand-held, single-hand-operated device includes a housing having a handle portion that is selectively collapsed to generate a propellant pulse that is conveyed into and through powder stored in a reservoir mounted at an upward angle to the horizontal in a receptacle provided in the housing. Powder in the reservoir is caused to be aerosolized by the propellant pulse whereupon aerosolized powder exits the reservoir through an open end of, and elongate slots provided in the sidewall of, an elongate hollow member extending from an outlet in the receptacle through the stored powdered material into a head space in the reservoir. The outlet is connected a barrel portion for output of the aerosolized powder spray.

Owner:GENZYME CORP

Modular liquid metering system for an agricultural implement

ActiveUS7694638B1Precise applicationOvercome difficultiesPlantingWatering devicesElectricityEngineering

A liquid metering system for an agricultural implement is modular, having individual metering pumps for each crop row. The pumps are individually controlled for precise application of the liquid input and are preferable electrically driven. A common pump is used, making the system modular in that varying sizes of implements can be produced by varying the number of pumps. A common supply line is used to supply a liquid input from a reservoir to the pumps. Each pump is connected to the common supply line. By connecting each pump to the common supply line, the difficulty of routing individual hoses from a central pump to each row unit are overcome.

Owner:DEERE & CO

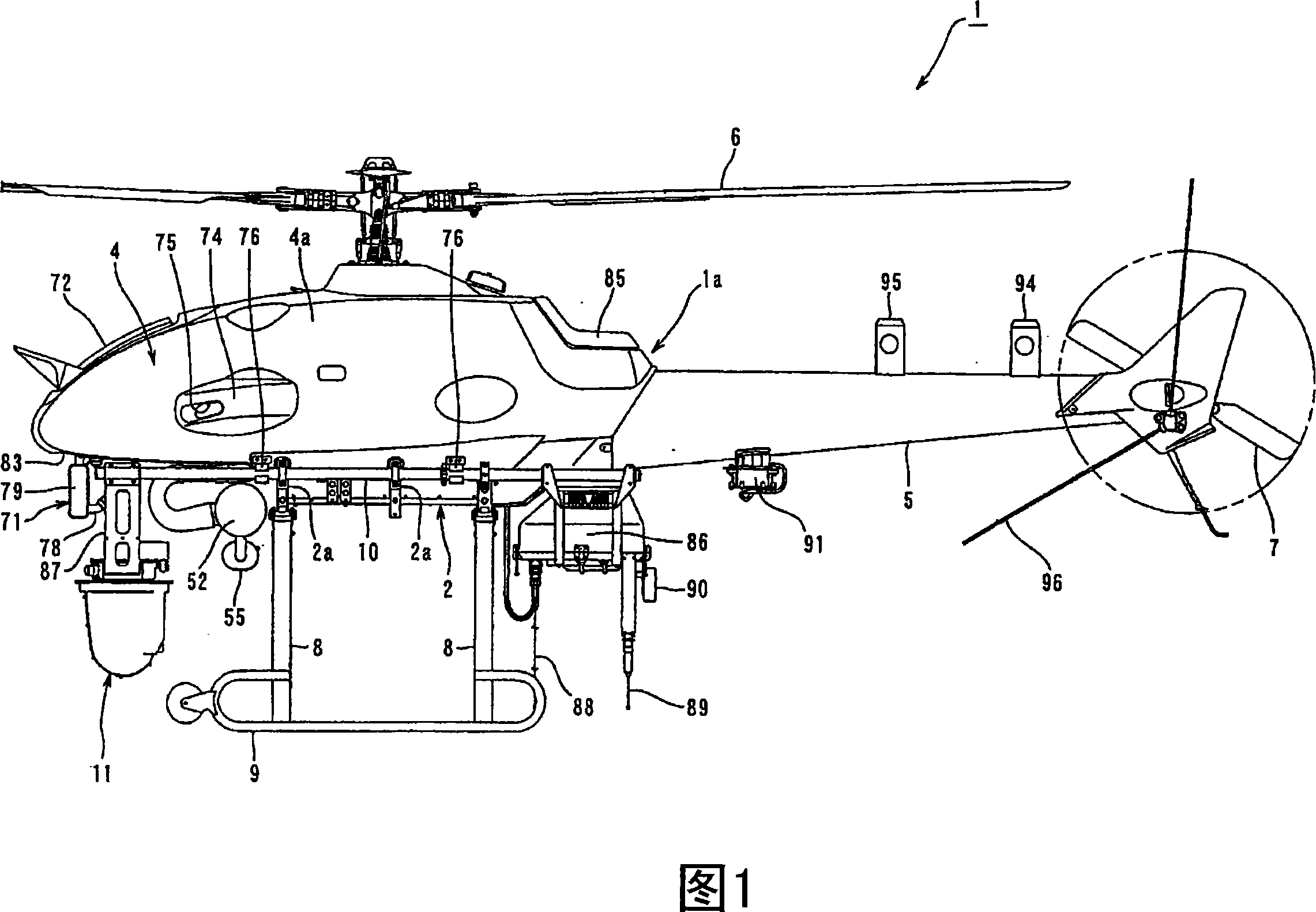

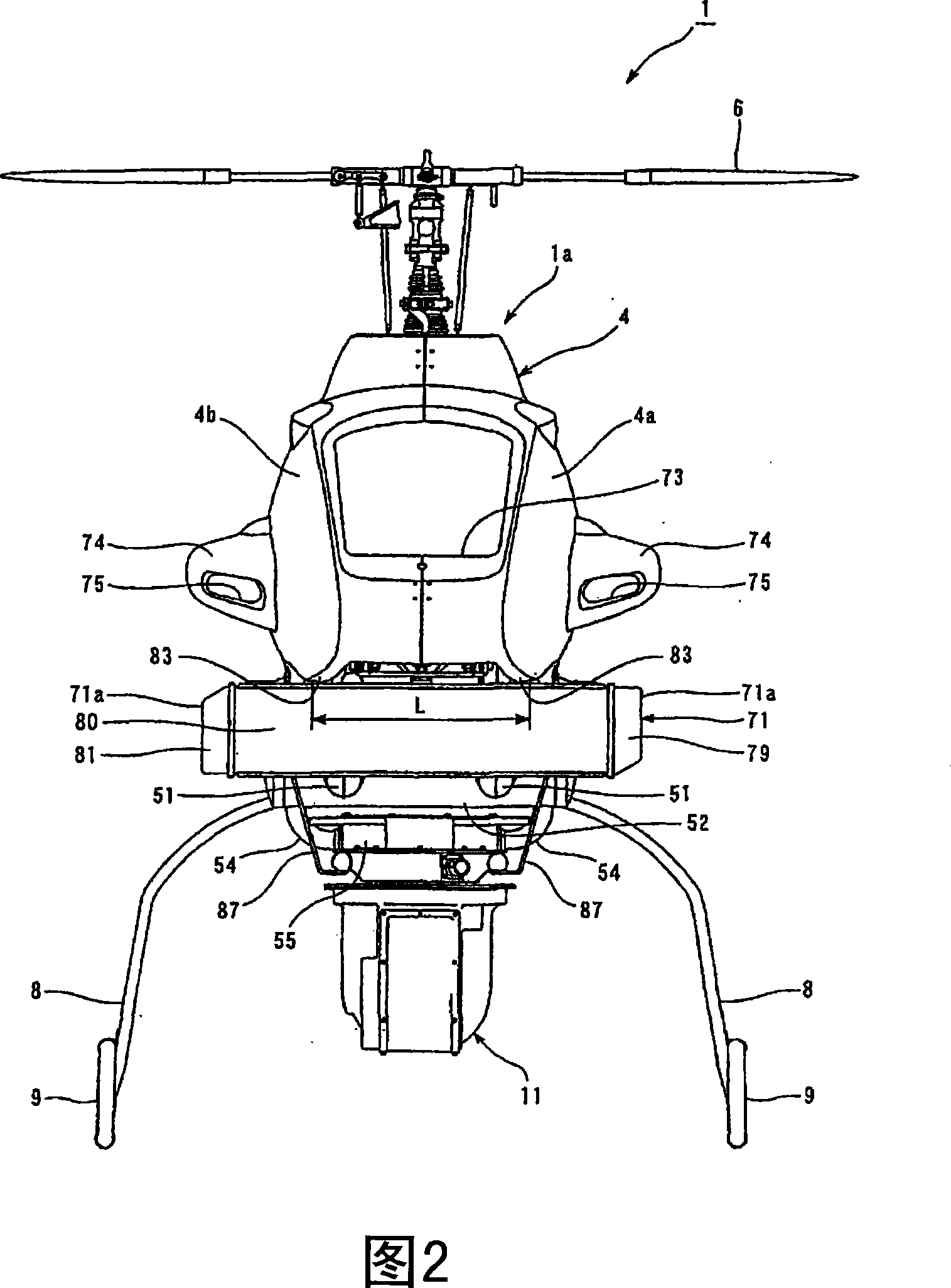

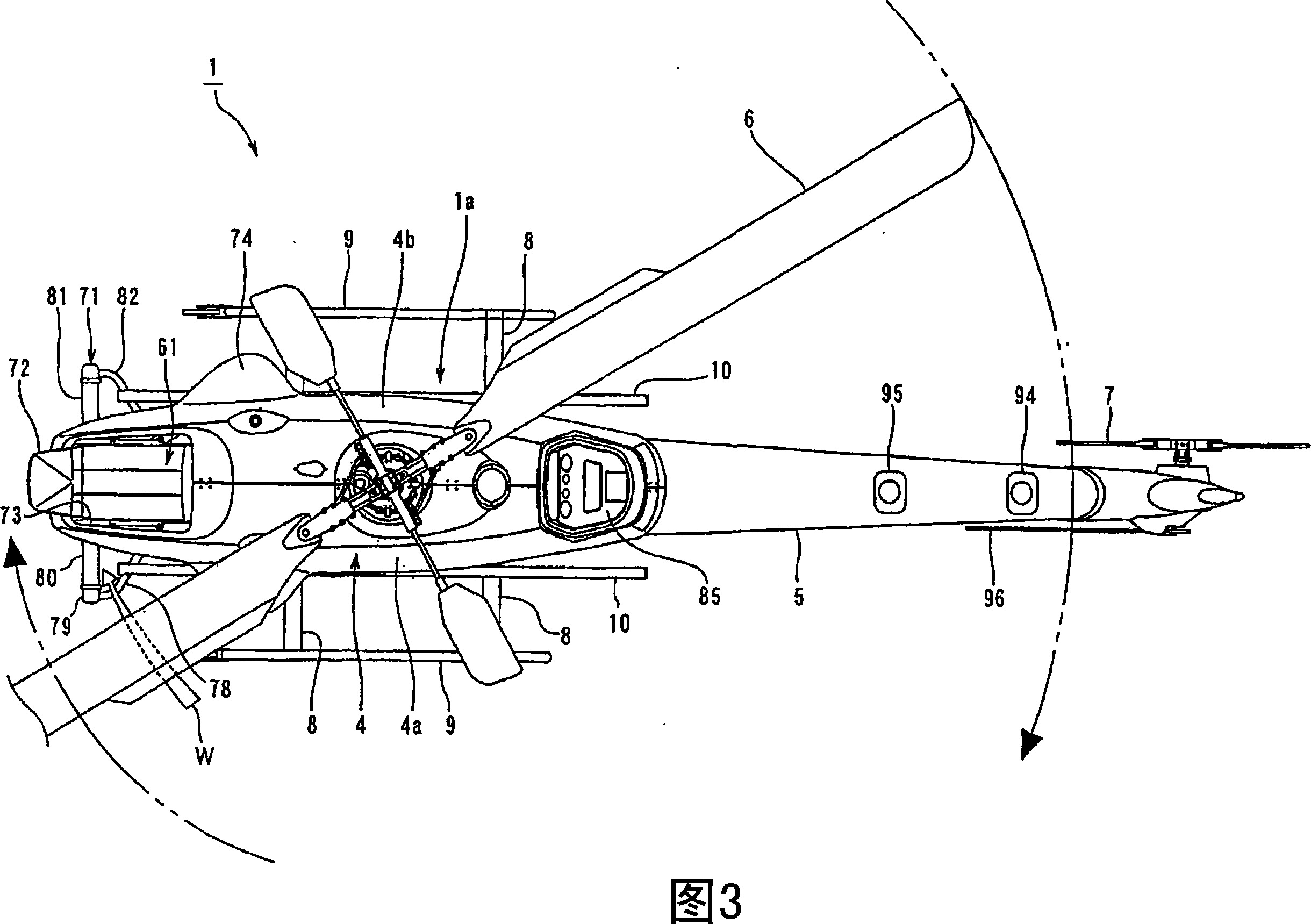

Unmanned helicopter

InactiveCN101238033AImprove cooling effectUnoccupied space expandsPower plant cooling arrangmentsUnmanned aerial vehiclesEngineeringFront edge

Owner:YAMAHA MOTOR CO LTD

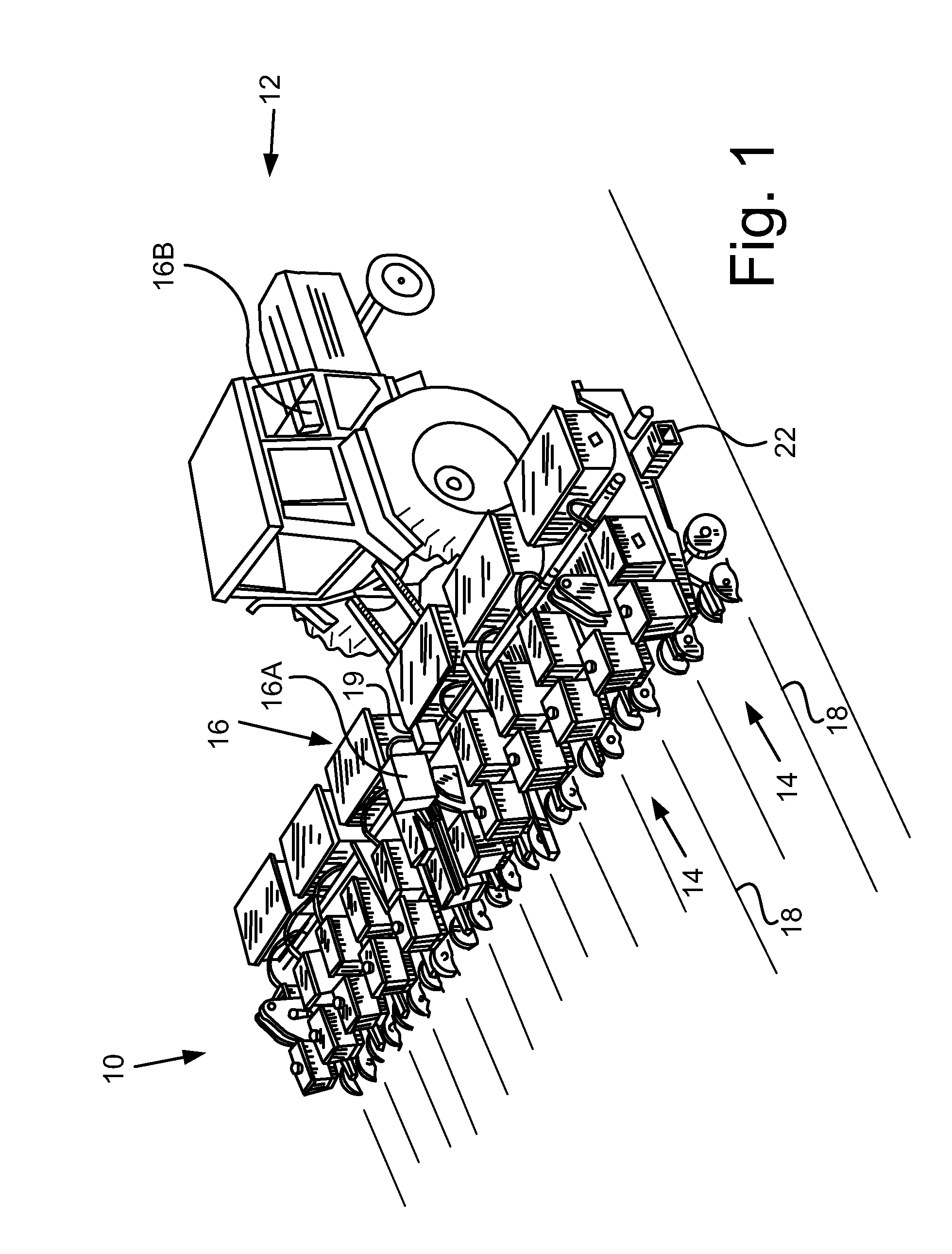

In-ground seed spacing monitoring system for use in an agricultural seeder

ActiveUS20120042813A1Reduce viewing angleHigh sensitivityRadiation pyrometryPlantingSensor arrayPositive pressure

A row crop unit for use in an agricultural seeder includes a furrow opener for opening a furrow in the soil, a seed metering system for metering seed to be placed in the furrow, and a seed placement system for placing seeds in the furrow. The seed placement system and the seed metering system are in communication with each other and at least in part define a seed travel path associated with the furrow. A furrow closer covers the seed in the furrow with soil. A seed temperature conditioner is associated with the seed travel path for varying a temperature of seed traveling through the seed travel path. A temperature sensitive sensor is positioned to sense seed which has been deposited in the furrow between the furrow opener and the furrow closer. An optional packaging tube holds a temperature sensor or sensor array. A lens is mounted with the same tube. A larger diameter tube may be positioned around the sensor packaging tube. A positive air pressure / air flow may be introduced between the two tubes. This positive air-flow forms a positive pressure and / or air flow barrier to push dust away from the sensor lens or sensor surface.

Owner:DEERE & CO

Variable displacement meter roller

ActiveUS20080163807A1Reduced and increased volumeFertiliser distributersPotato plantersSpecific volumeEngineering

Owner:ONE PASS IMPLEMENTS

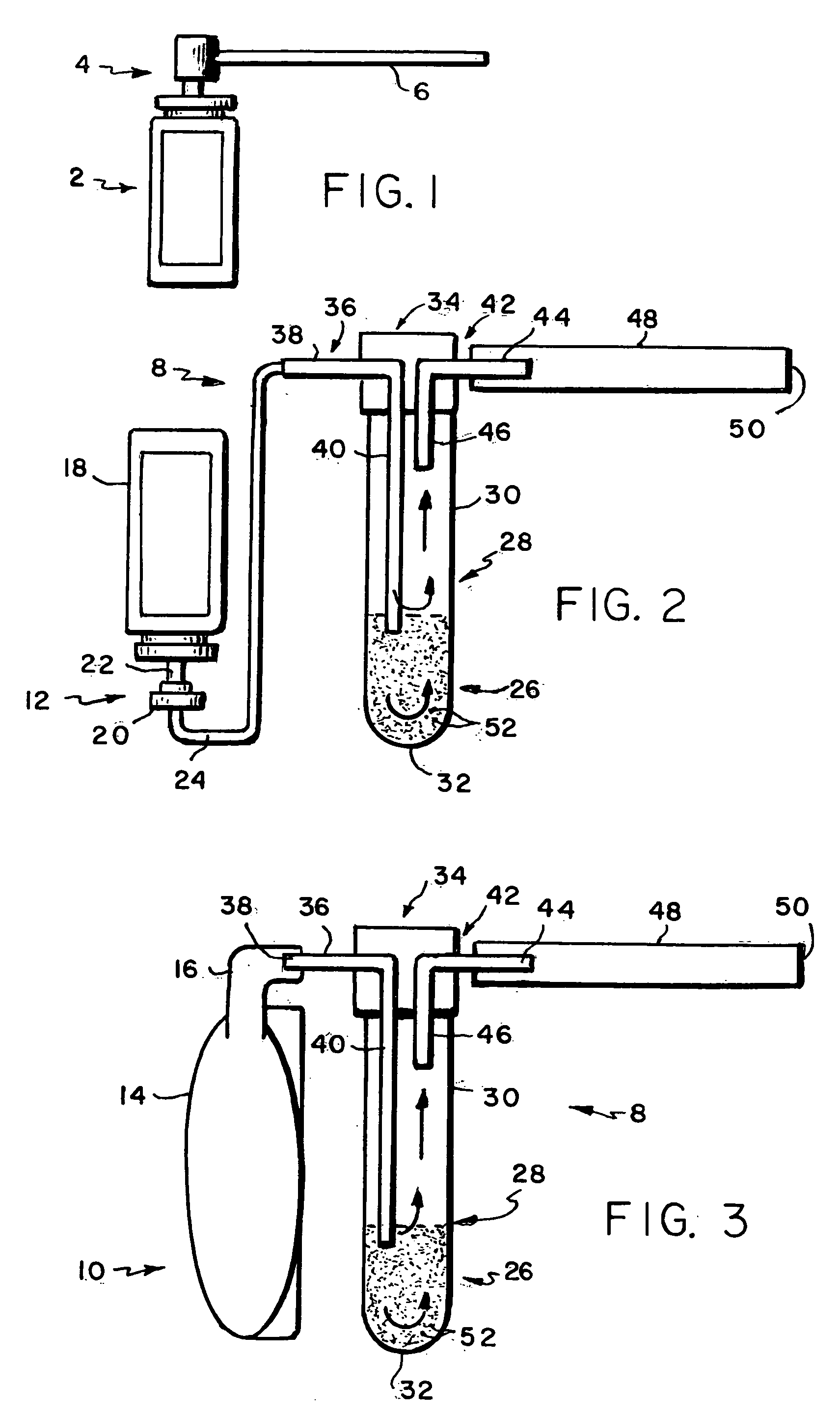

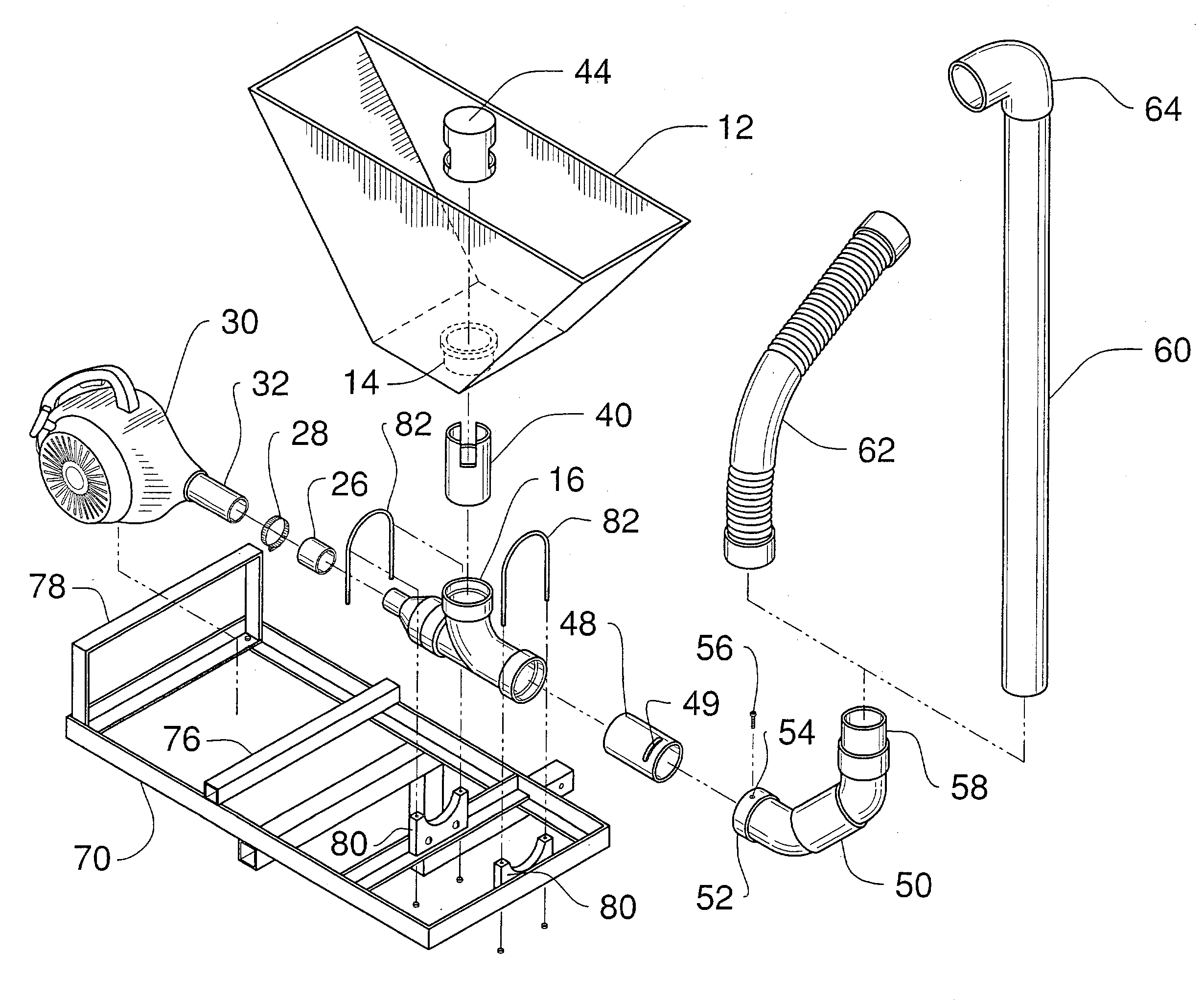

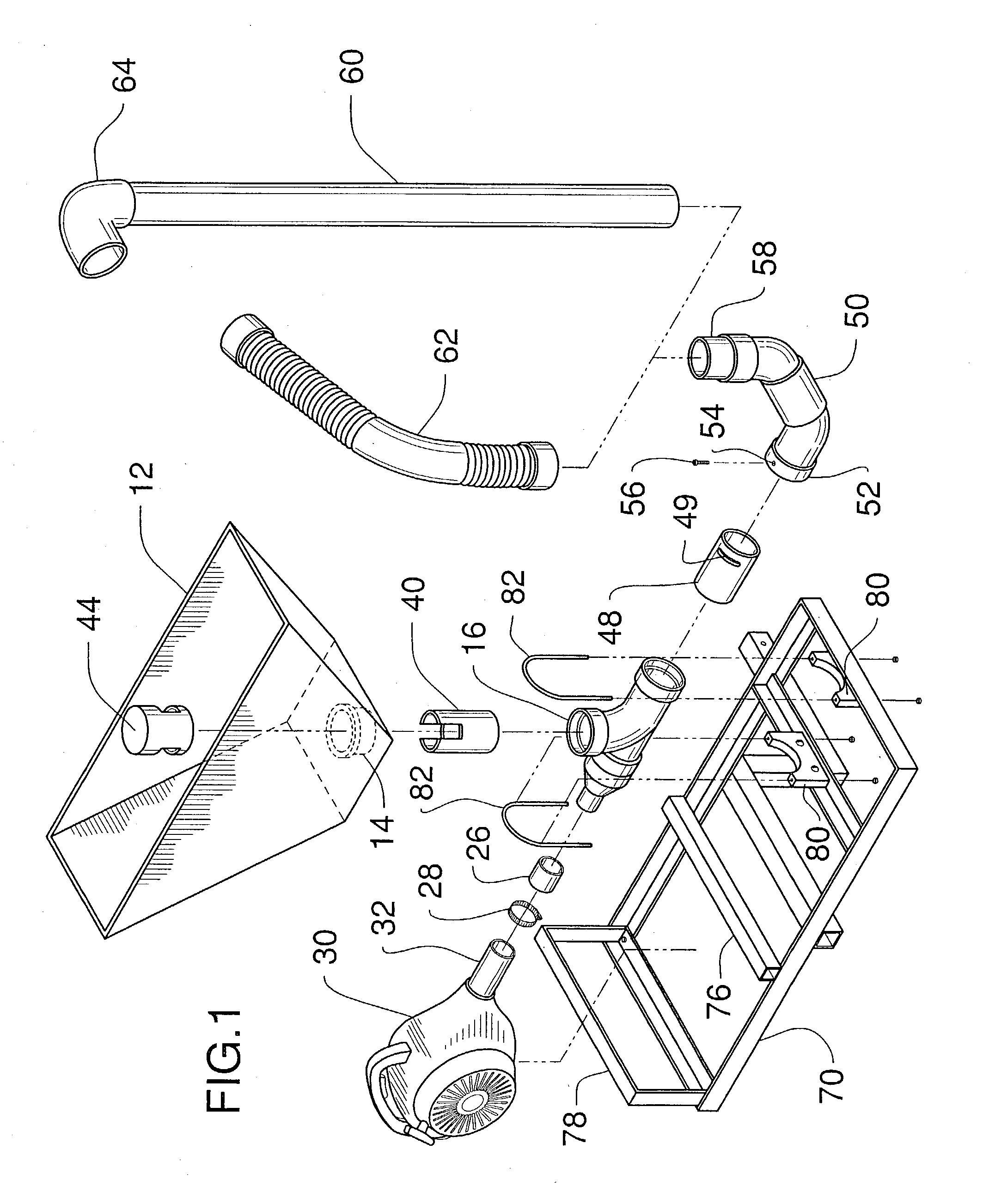

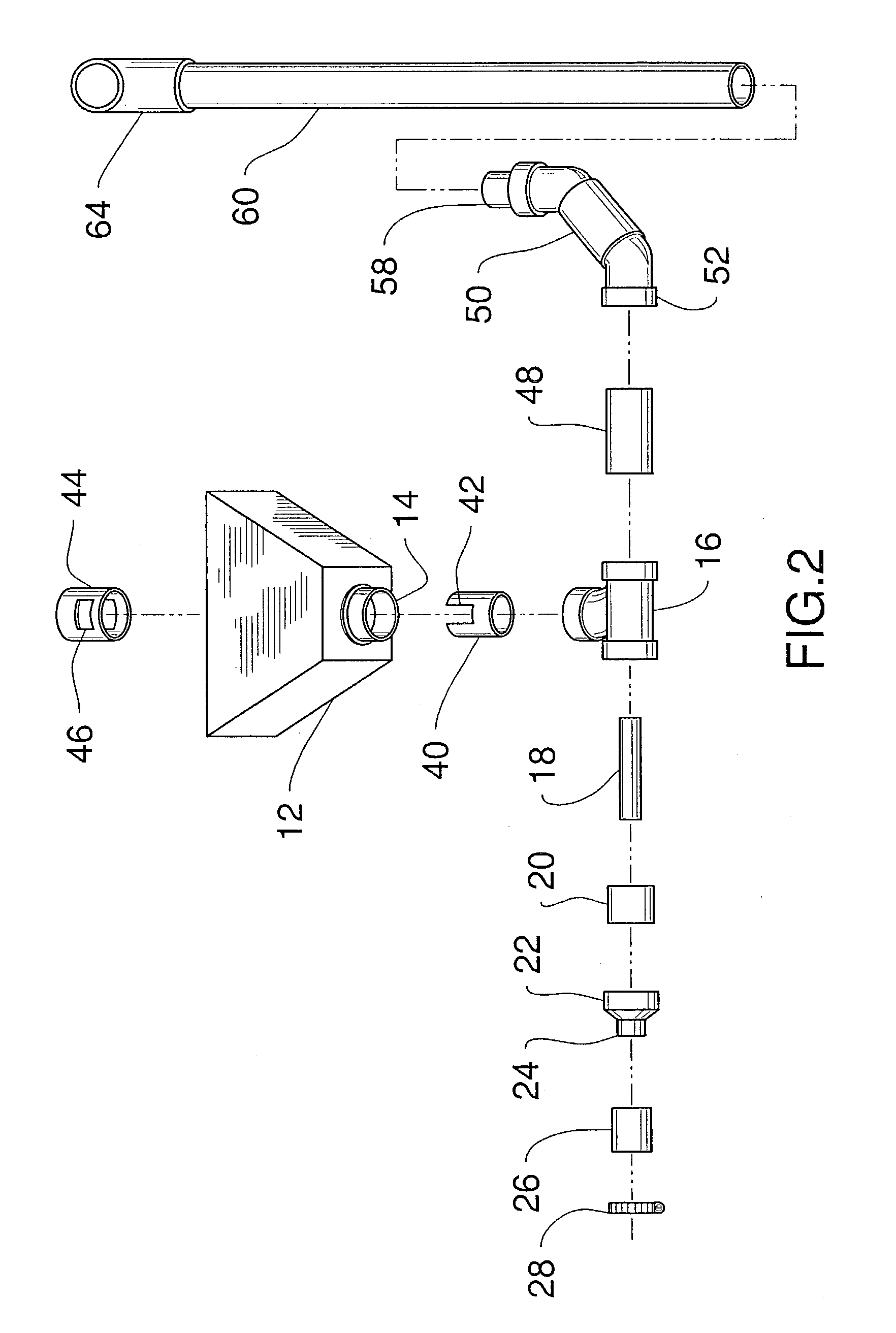

Pneumatic particulate dispensing system

InactiveUS6892909B1Easy and efficient to manufactureReduce manufacturing costLiquid fillingFertiliser distributersRotary valveEngineering

A pneumatic particulate dispensing system having a hopper for storing particulate material, such as animal feed, fertilizers, pesticides and the like. The hopper is connected to a T-fitting which encloses a velocity tube. An air blowing unit is connected to the T-fitting and the velocity tube through an interchangeable adaptor allowing for a variety of air blowing units to be installed. An adjustable rotary valve extends into the interior of the hopper from the T-fitting allowing for a user to adjust the amount of particulate material to be dispensed adjacent the velocity tube. A discharge tube is connected to the T-fitting downstream of the velocity tube, wherein the discharge tube has a rotating elbow for allowing the user to adjust the dispensing direction. A variety of nozzles can be attached to the end of the discharge tube. A support frame having a hitch insert and cradles is used to support and transport the particulate dispensing system to remote locations.

Owner:HEBERT SHELTON L +1

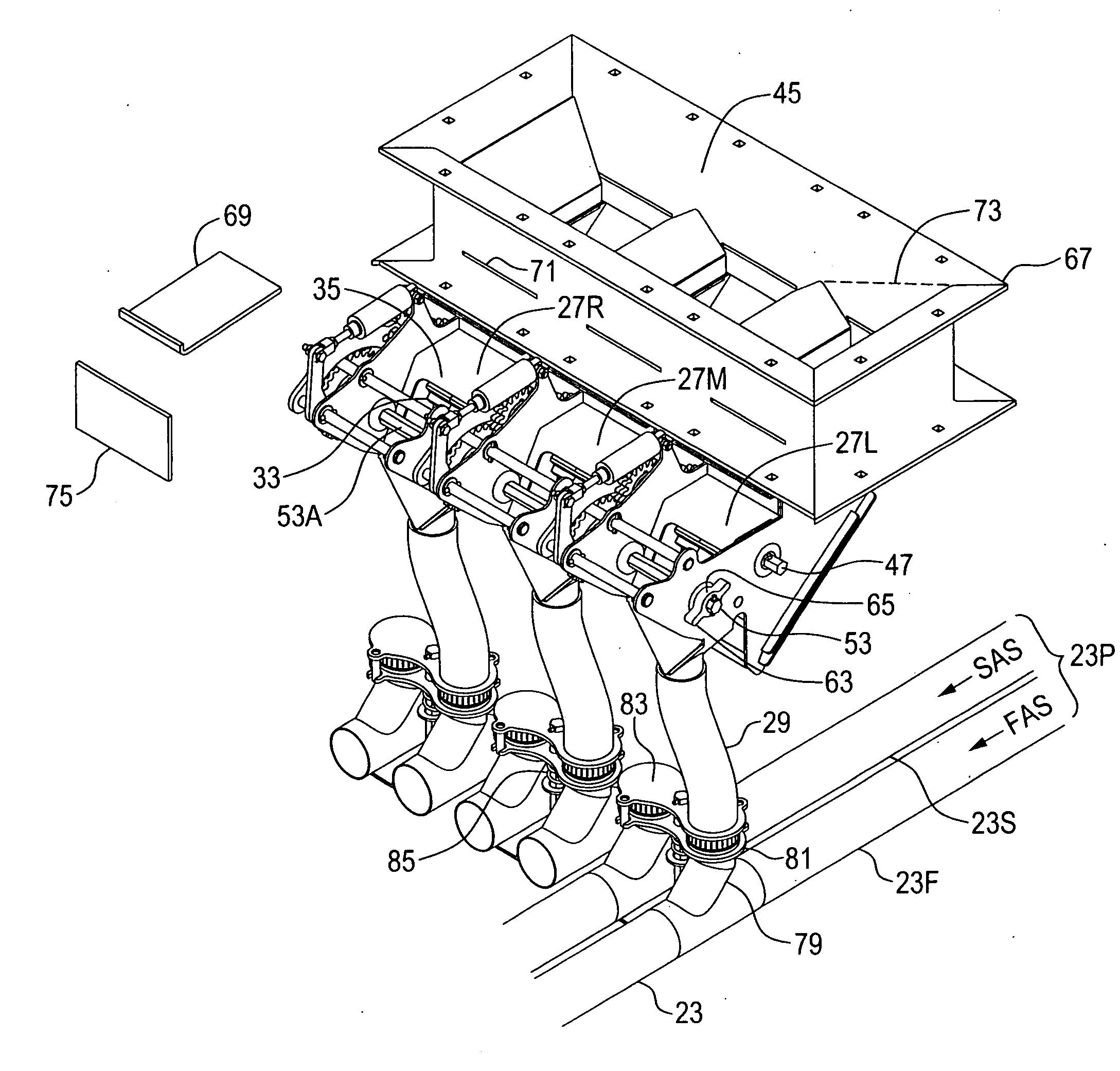

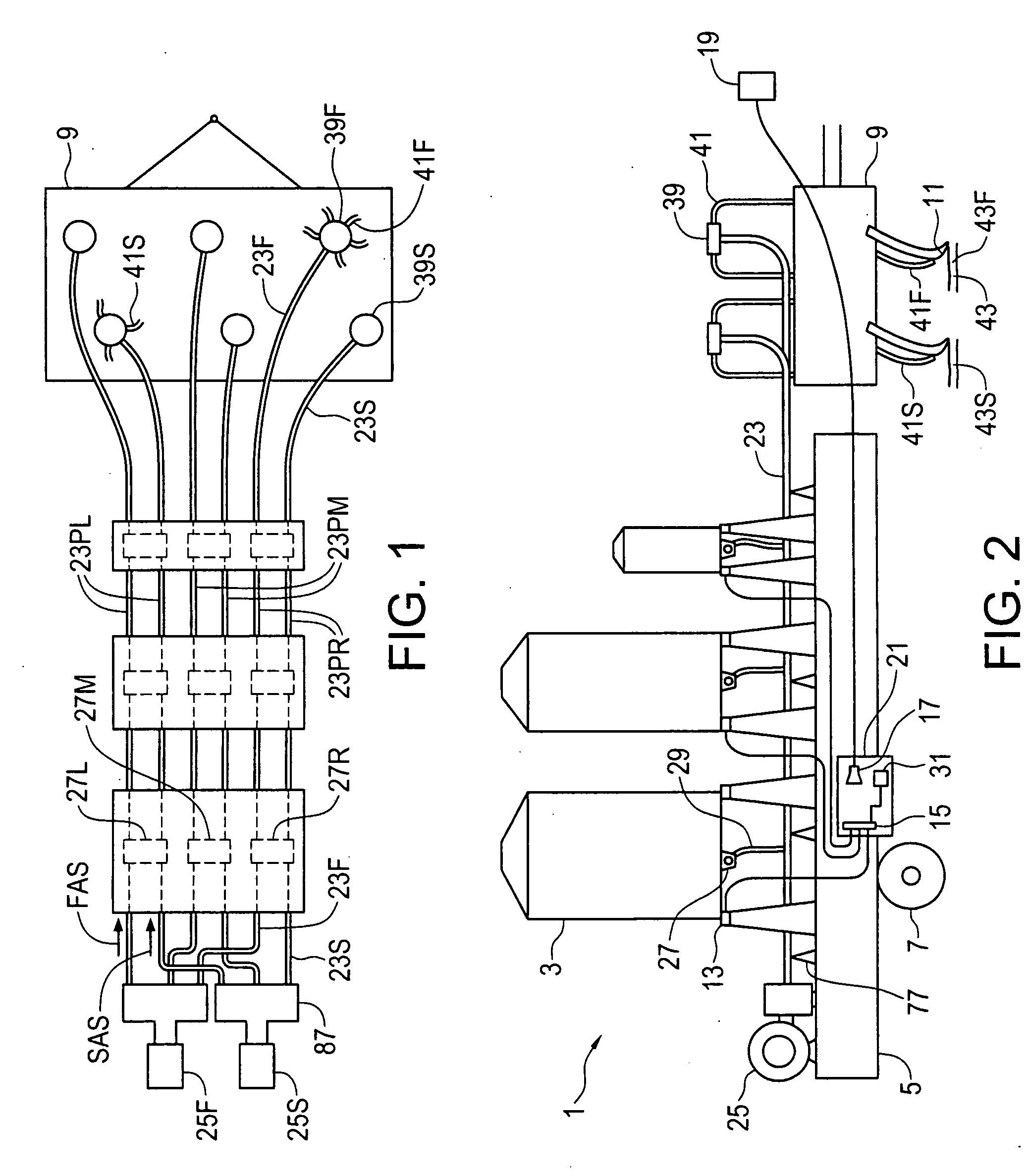

Air seeder tank and distribution apparatus

ActiveUS20120103238A1Different air speedDifferent pressureFertiliser distributersAgriculture and animal husbandary industryInternal pressureMechanical engineering

An air seeder distribution apparatus has seed and fertilizer tanks, and a like plurality of metering devices mounted on each product tank. A manifold set comprises a like plurality of product manifolds and each manifold is separately fed from one metering device on each of the seed and fertilizer tanks. A control selectively starts and stops rotation of the feed roller of each metering device to feed product from either tank, or both tanks to the connected manifold. The weight of each tank can be displayed on a weight indicator. Balancing of the pressure in each supply conduit can be provided. A remote opener exerts downward force on the tank lid to maintain interior pressure.

Owner:SEEDMASTER MFG

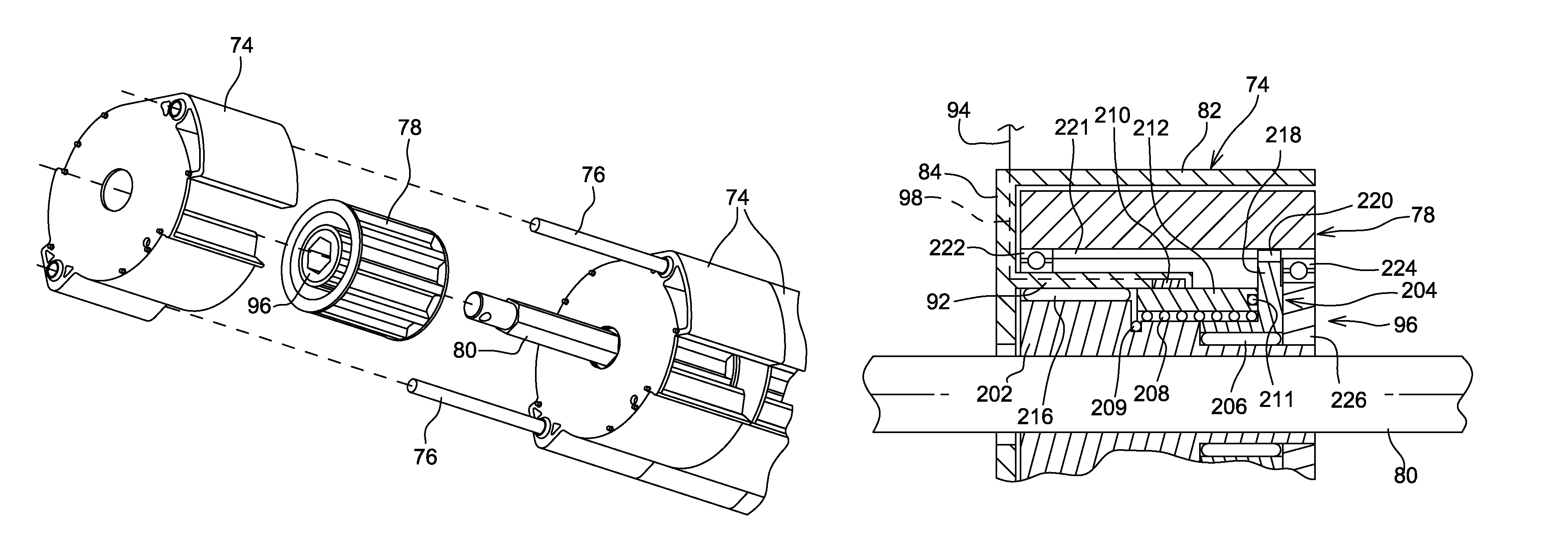

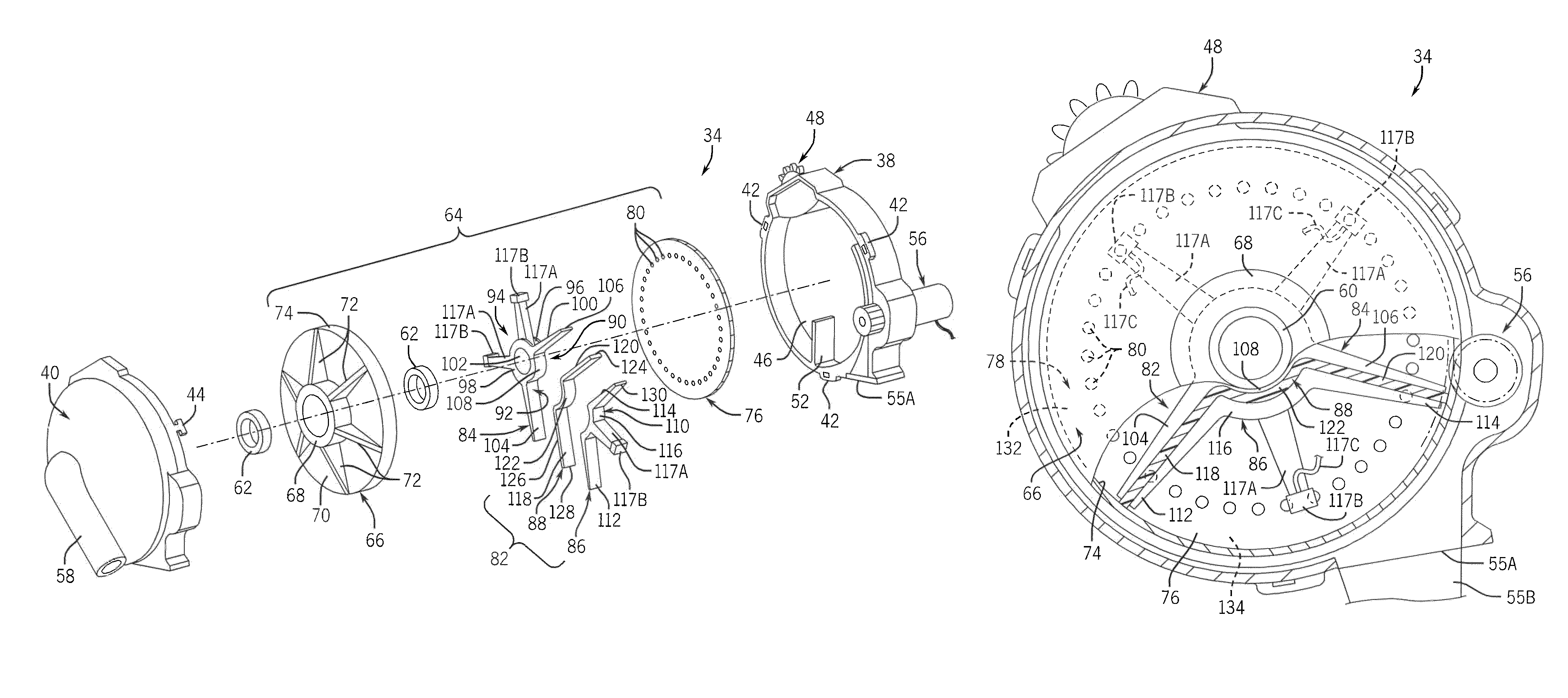

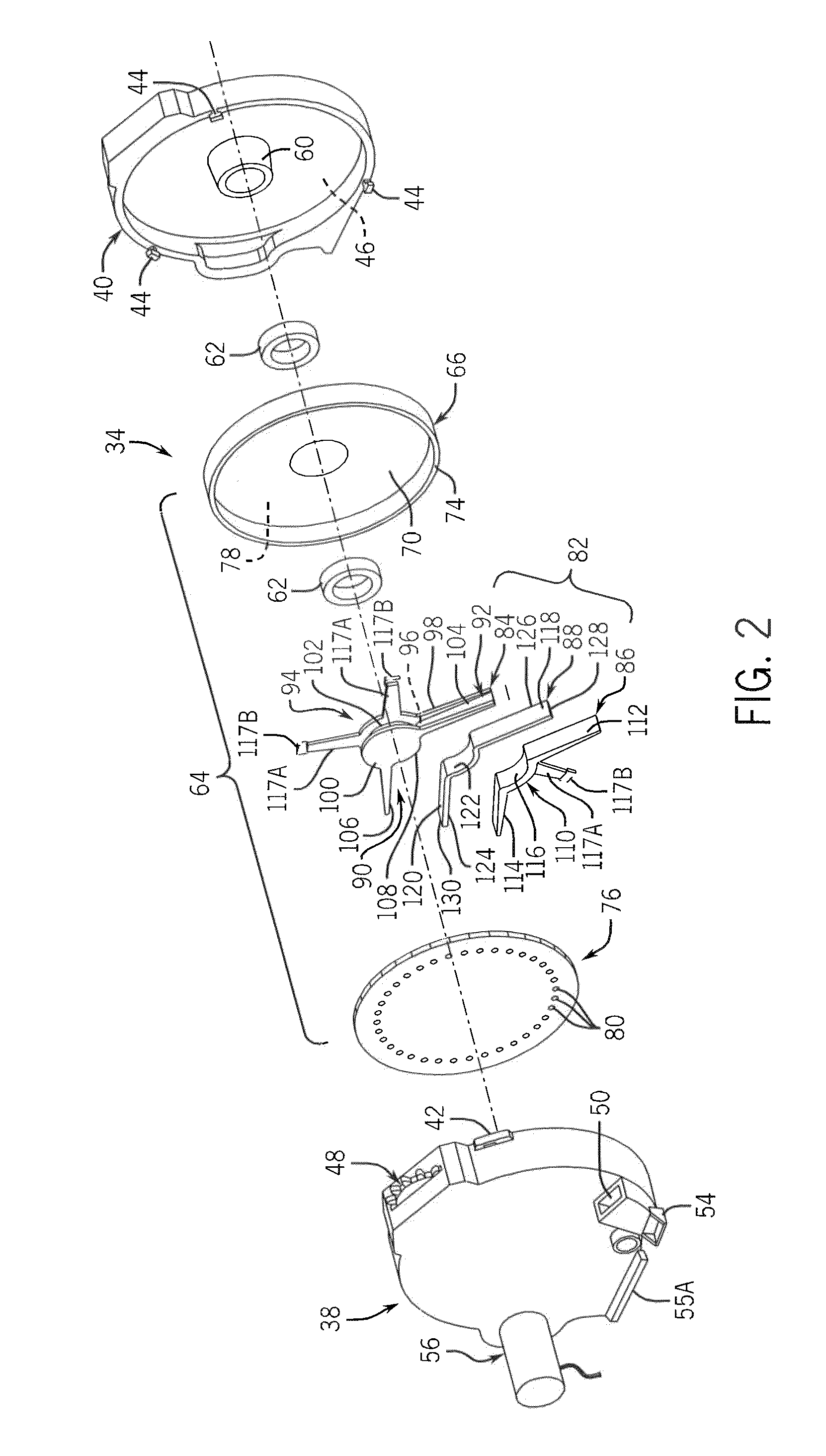

Low torque and vacuum seed meter

ActiveUS8925471B2Improve uniformityLess input vacuum pressurePotato plantersFurrow making/coveringVacuum pressureEngineering

A seed meter is provided for use with a row crop planter or seed planter that includes a seed disk assembly that rotates within a meter housing cavity and that has a seed disk assembly cavity in which a vacuum pressure is applied for pulling seeds into seed pockets of a seed disk of the seed disc assembly. The vacuum pressure is applied to the seed disk assembly by pulling a vacuum airflow through a spindle that supports the seed disk assembly. A wiper seal is arranged in a fixed position within the seed disk assembly cavity and seals against the seed disk assembly as a support plate and seed disk of the seed disk assembly rotate over the wiper seal, so that the wiper seal creates a boundary between a vacuum zone and a non-vacuum zone inside of the seed disc assembly cavity.

Owner:BLUE LEAF I P INC

Powder delivery device

ActiveUS7455248B2Efficiently and satisfactorily operablePowder deliverySurgeryHand heldCoverage control

A pistol-shaped powder delivery device consolidates propellant pulse creation, powder storage, powder aerosolization and aerolsolized powdered delivery in a single device while providing dose, pattern and coverage control of the output spray. The single-hand-held, single-hand-operated device includes a housing having a handle portion that is selectively collapsed to generate a propellant pulse that is conveyed into and through powder stored in a reservoir mounted at an upward angle to the horizontal in a receptacle provided in the housing. Powder in the reservoir is caused to be aerosolized by the propellant pulse whereupon aerosolized powder exits the reservoir through an open end of, and elongate slots provided in the sidewall of, an elongate hollow member extending from an outlet in the receptacle through the stored powdered material into a head space in the reservoir. The outlet is connected a barrel portion for output of the aerosolized powder spray.

Owner:GENZYME CORP

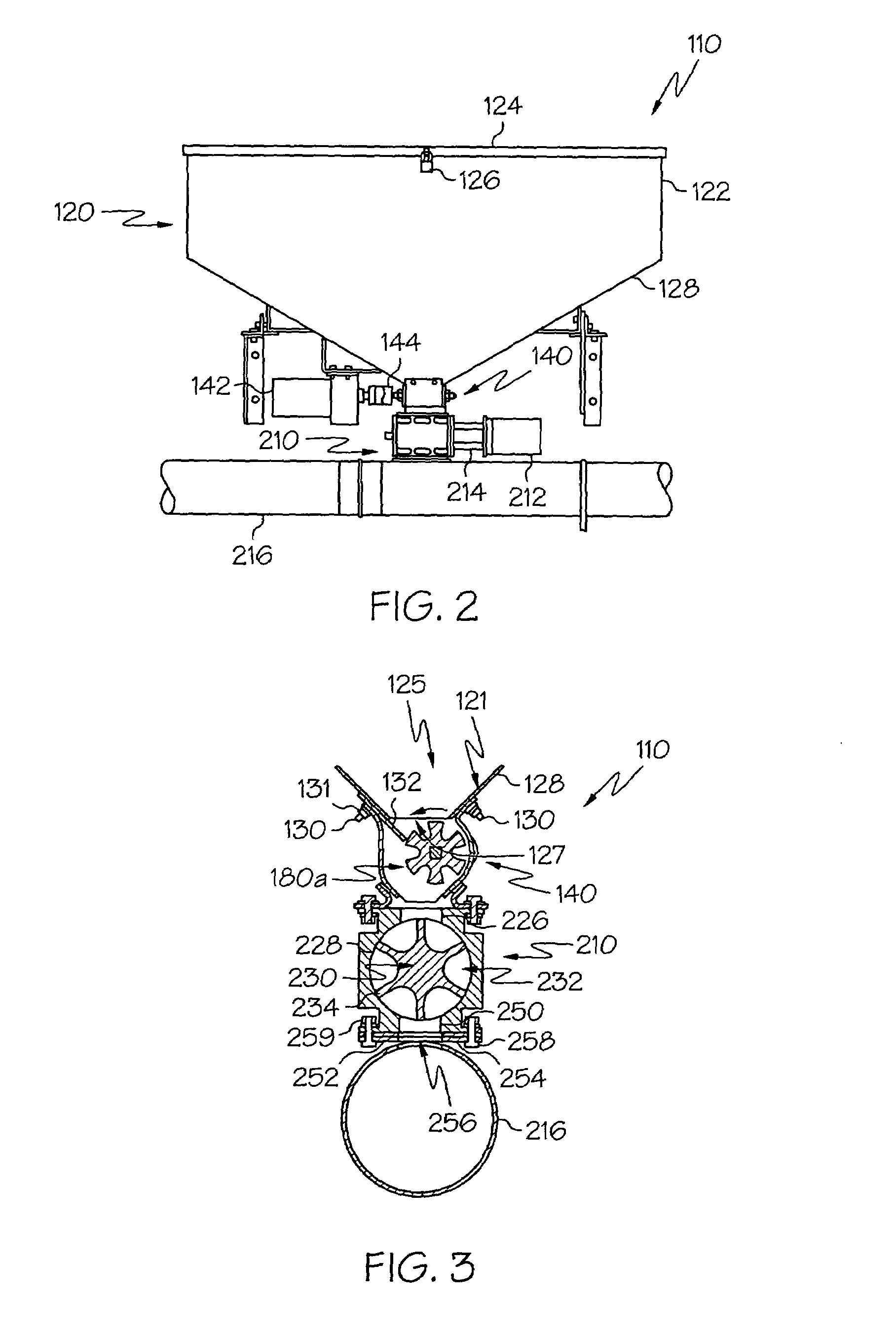

Bulk material discharge assembly with feeding apparatus

Bulk material discharge assemblies comprise a bulk material hopper, a conduit for delivering an air stream to entrain with bulk material from the bulk material hopper, and a feeding apparatus for introducing additive to the conduit. The feeding apparatus comprises an additive hopper and an airlock positioned adjacent the conduit. In addition, metering apparatus are provided that comprise an axle and first and second metering wheels. A noncircular perimeter of the axle and the shape of each hub opening of each of the metering wheels cooperate to nonrotatably mount each metering wheel to the axle. The first and second metering wheel are adapted to be selectively mounted in at least one of a first relative position and a second relative position. Still further, apparatus for dispensing additive are provided that comprise an additive hopper including at least one partition for dividing the additive hopper into at least two containment areas that are substantially isolated from one another and a metering device mounted to the additive hopper.

Owner:FINN CORP

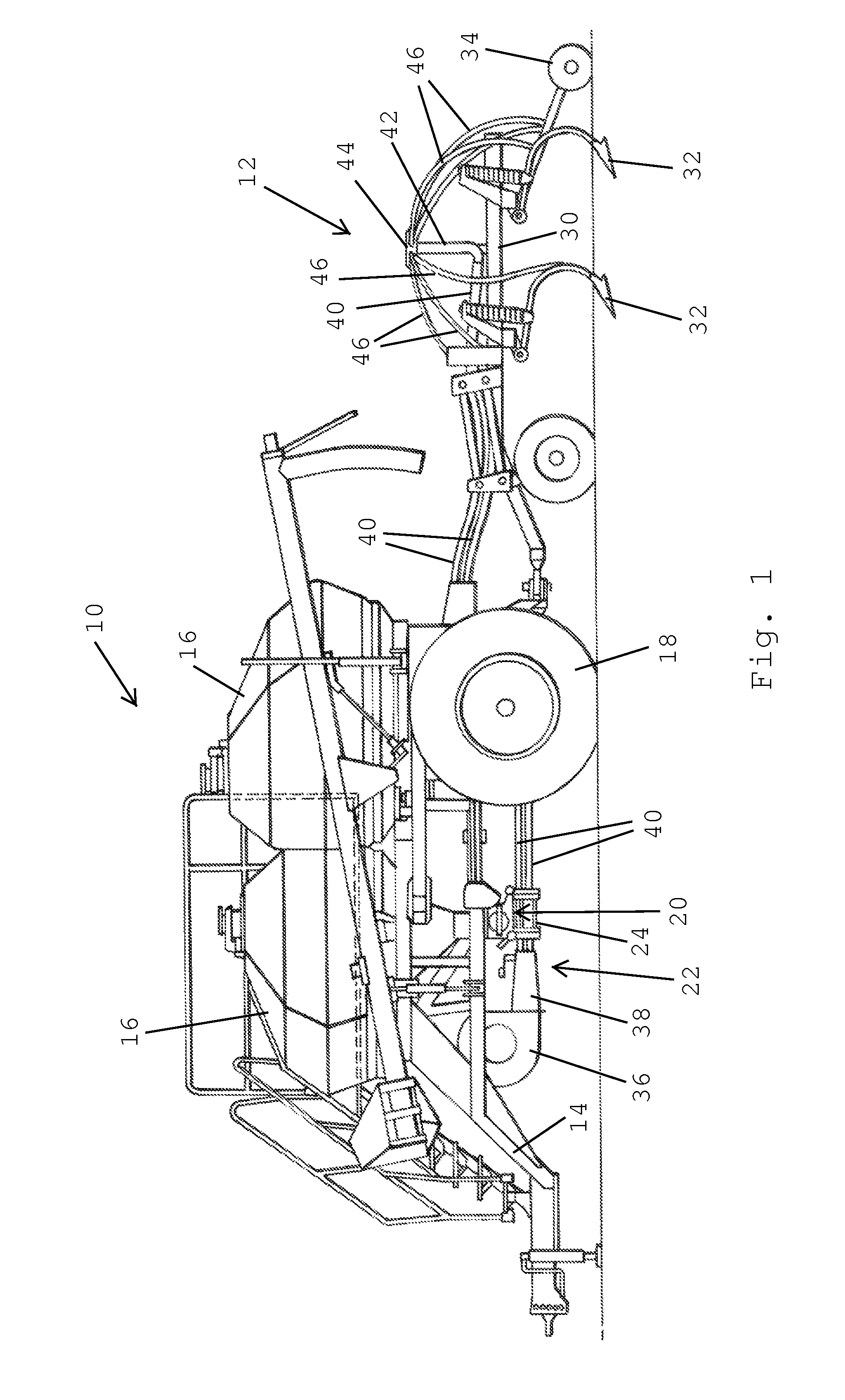

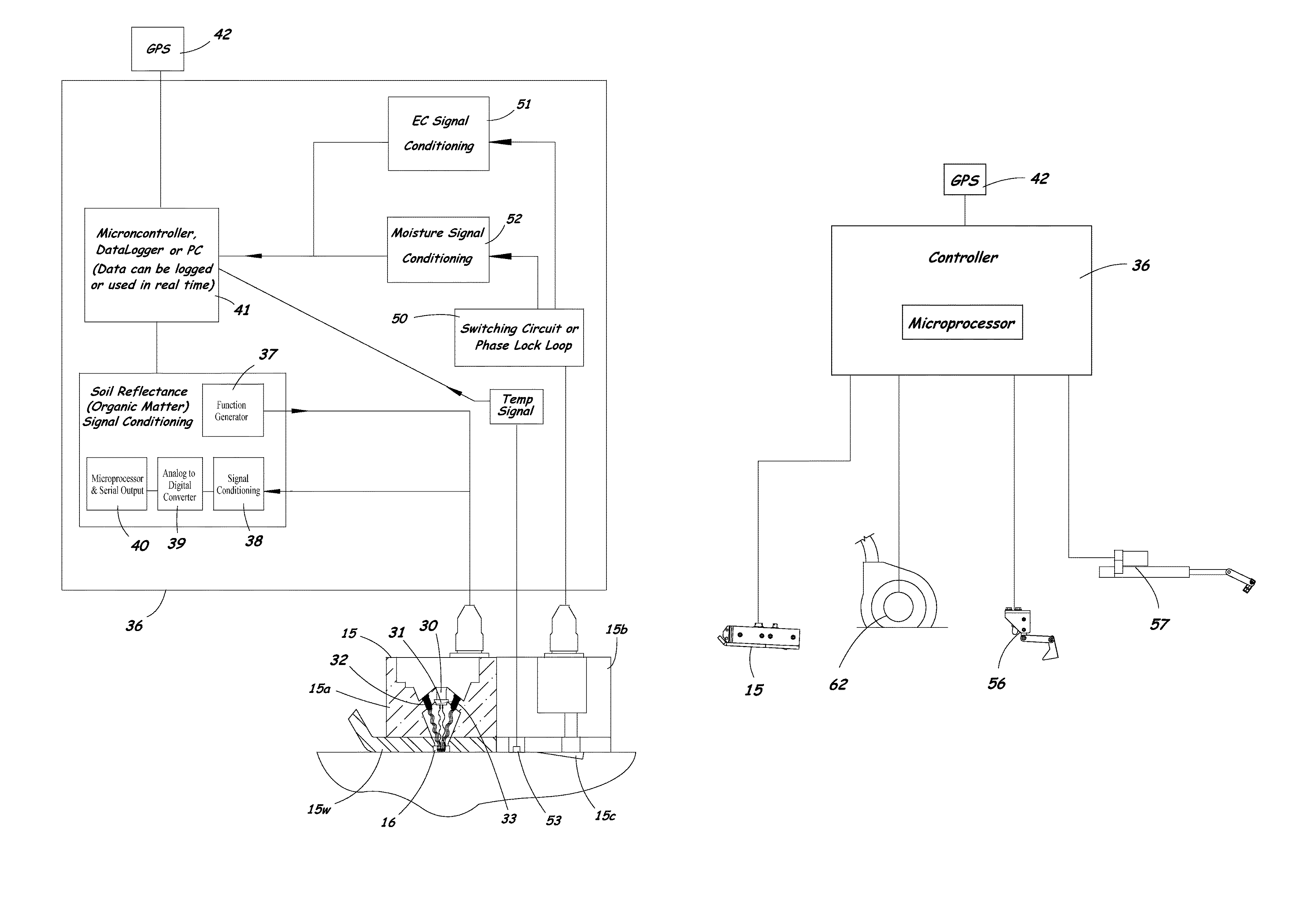

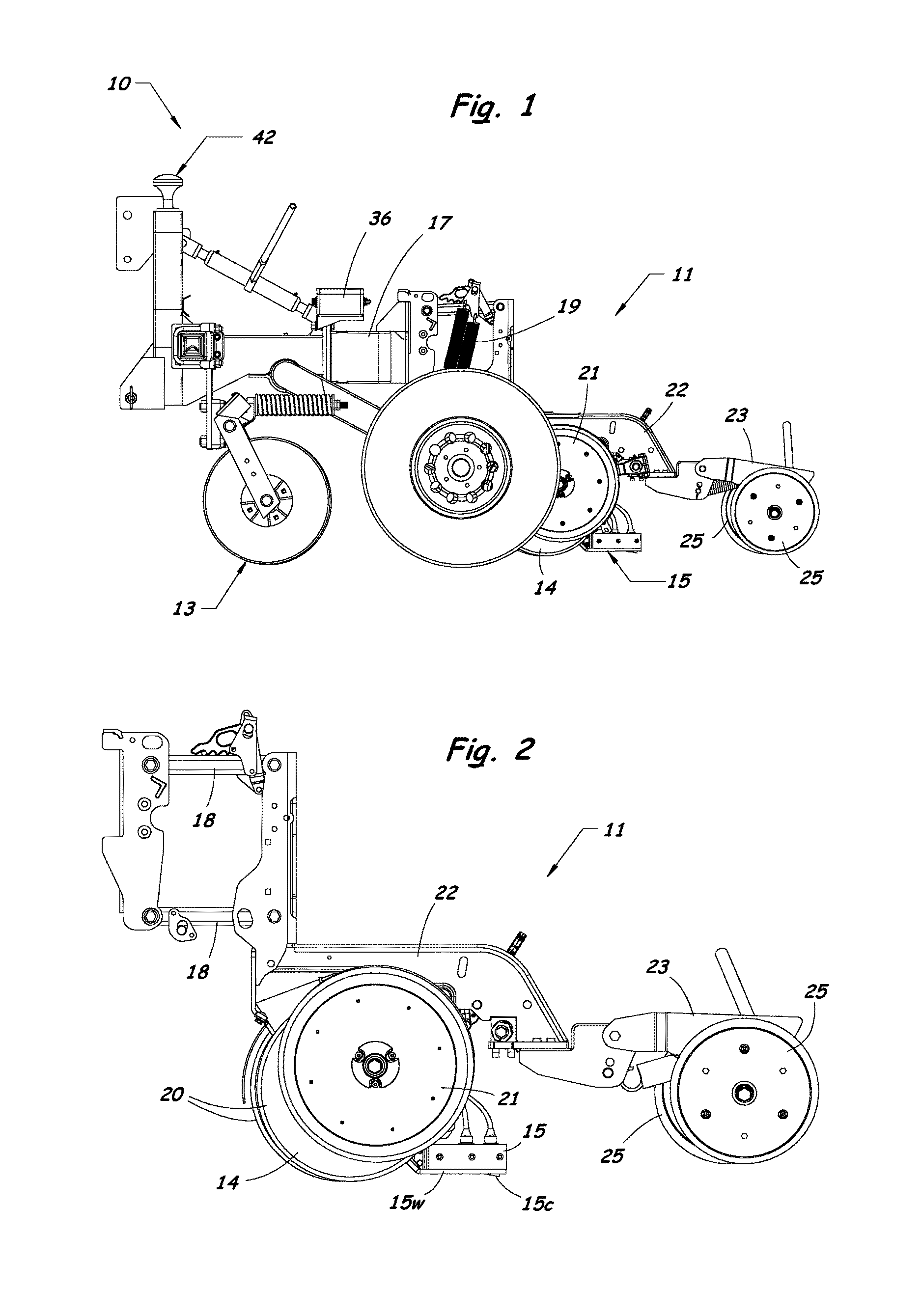

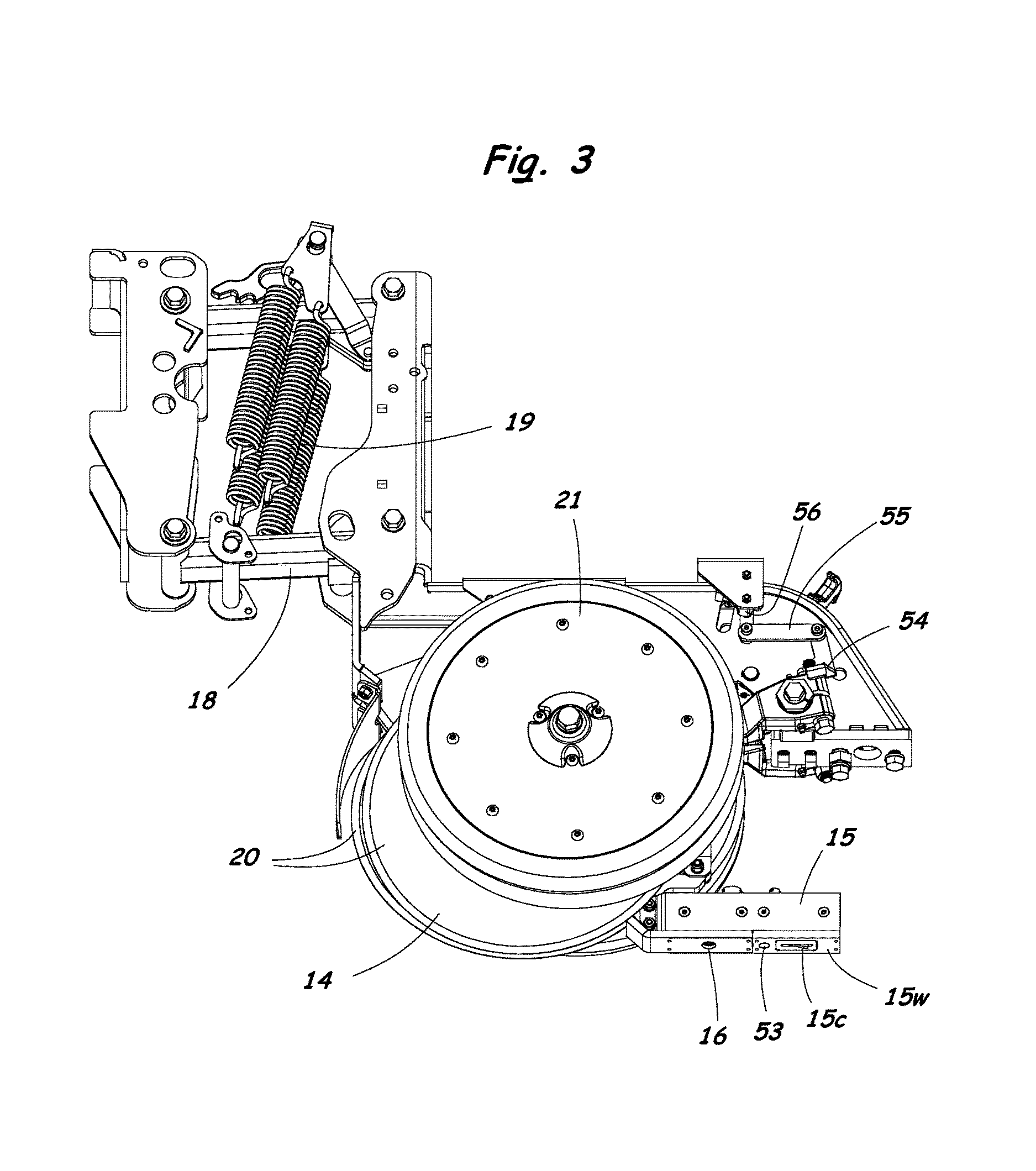

Agricultural planter with automatic depth and seeding rate control

An agricultural planter having sensors for measuring multiple soil properties adjusts planting depth and seeding rate in real time based on the measured soil properties. An optical module is carried by the planter for collecting soil reflectance data. A pair of soil contact blades protrude from or are embedded in the optical module for collecting soil EC data and soil moisture data. A switching circuit or phase lock loop allows the same soil contact blades to feed signals to both a soil EC signal conditioning circuit and a soil moisture signal conditioning circuit. The soil moisture data can be used to calibrate the soil EC data and the soil reflectance data to compensate for effects of changing soil moisture conditions across a field. The sensor module can be positioned behind a seed tube and used as a seed firmer, or incorporated into a seed tube guard.

Owner:VERIS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com