Method for preparing white-light LED package device with high color rendering index

A technology of LED packaging and high CRI, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of low color rendering index, achieve low color rendering index, easy monitoring of process flow, and reduce blue light output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

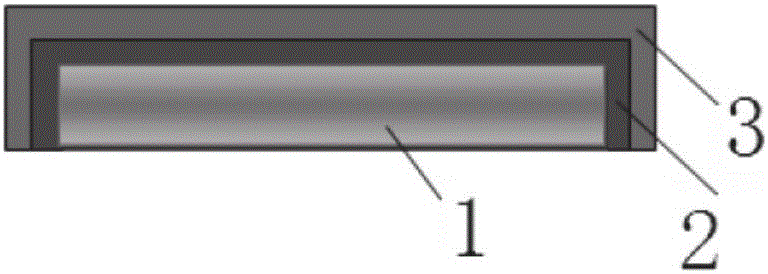

Image

Examples

Embodiment 1

[0034] A method for preparing a high CRI white LED packaging device, comprising the following steps:

[0035] Step 1, use the existing technology to carry out crystal bonding on the 5555 chip, mix the fluorescent powder, silica gel and thinner for R1 type nitride red LED according to the mass percentage ratio of 1:1:1, and use a planetary vacuum mixer to mix evenly, and prepare Fluorescent paste, use atomization spraying machine to spray, apply R1-type nitride red fluorescent paste to the upper surface of the chip substrate after crystal bonding, spray the first layer, and bake at 150°C for 10 minutes;

[0036] Step 2, then, on the basis of step 1, use the red rubber powder mixture that sprays the second layer and bakes at 150°C for 5 minutes; sprays the third layer and bakes at 150°C for 5 minutes; until it reaches the preset thickness index;

[0037] Step 3: Next, mix the silica gel, diluent and LY1 aluminate yellow-green LED fluorescent powder according to the mass percenta...

Embodiment 2

[0042] A method for preparing a high CRI white LED packaging device, comprising the following steps:

[0043] Step 1: Use the existing technology to carry out crystal bonding on the 5555 chip, and mix the silica gel, diluent and R4-type nitride LED phosphor powder with a planetary vacuum mixer according to the mass percentage ratio of 1.5:1:1 to prepare the fluorescent powder. Slurry, use atomization spraying machine to spray, apply R4 type nitride red fluorescent slurry to the upper surface of the chip substrate after crystal bonding, spray a layer, and bake at 150°C for 10 minutes;

[0044] Step 2: Next, mix the silica gel, diluent and LY1 aluminate yellow-green LED fluorescent powder according to the mass percentage ratio of 1:1:1, stir evenly with a planetary vacuum mixer, and use an atomizing sprayer, Apply the LY1-type aluminate yellow-green fluorescent slurry to the surface of the R4-type nitride red fluorescent adhesive layer after step 2 by using the atomization spray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com