White light LED and light converting luminophore

A technology of light-emitting diodes and phosphors, which is applied in the direction of light-emitting materials, semiconductor devices, and gas discharge lamps, and can solve problems such as not being applied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

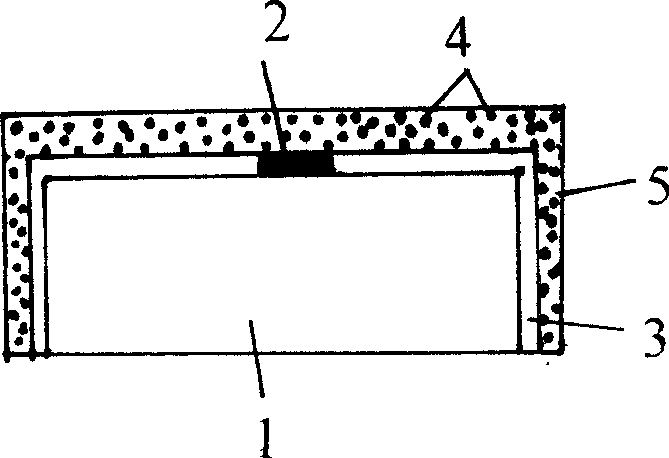

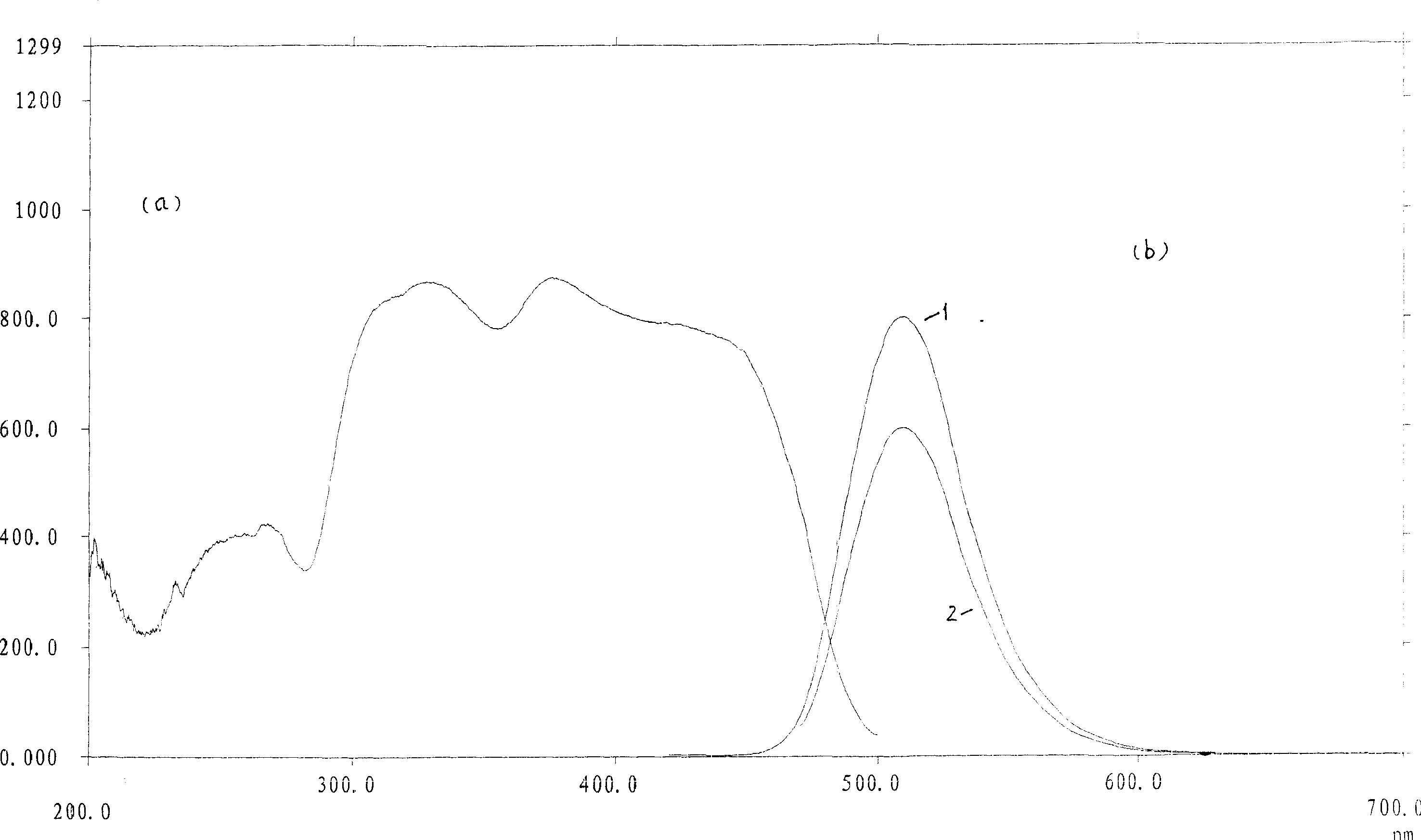

[0040] Example 1: Weigh CaCO 3 10.50g, ZnO 1.2g, SiO 2 3.61g, CaCl 2 5.00g was ground and mixed uniformly, put into a corundum crucible, and after being kept at 1150°C for 3 hours, it was taken out and cooled to jade room temperature to obtain a white matrix material. Then weigh Eu 2 O 3 0.079g, Li 2 CO 3 0.52g and the above-mentioned matrix material were mixed and ground, then put into a crucible, and burned in a weak reducing atmosphere generated by the combustion of carbon particles at 1000°C for 3 hours. Take it out, wash with deionized water, sieving, and drying to obtain Ca with green body color 8 Zn(SiO 4 ) 4 Ce: 0.1Eu phosphor (CZSC: Eu). By the CZSC: Eu green phosphor, the second type (Y, Gd) 3 Al 5 O 12 : Ce yellow phosphor, use InGaN with emission wavelength of 455nm as LED chip, press figure 2 The light-emitting unit is made by the process shown. After the semiconductor light-emitting chip 1 is solidified, a thin transparent resin protective layer 3 is carefully coate...

Embodiment 2

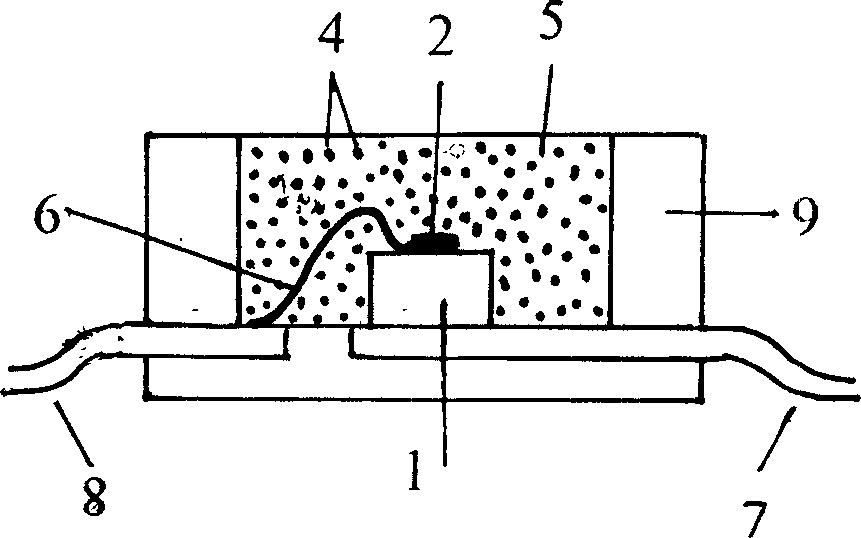

[0041] Example 2: According to the semiconductor blue light chip and phosphor selected in Example 1, press figure 1 The packaging process shown produces a flat white LED. The chip 1 is solid-bonded on the lower negative plate 7, and the positive electrode 2 and the electrode 8 on the top of the chip are ultrasonically welded by the lead 6. The component is fixed by the opaque bracket 9, and then the groove is filled with phosphor 4 and resin glue 5. Make a flat white LED.

Embodiment 3

[0042] Example 3: Weigh BaCO 3 15.00g, Eu 2 O 3 0.557g, Mg(OH) 2 , 4MgCO 3 , 5H 2 O 13.90g, MnO 2 1.376g, SiO 2 9.60g, NH 4 Cl 1.00g is ground and mixed uniformly, put into a corundum crucible, burned for 3 hours in a weak reducing atmosphere produced by the combustion of carbon particles at 1200℃, and the product is washed, sieved and dried to obtain (Ba0.96Eu 0.04 )(Mg 1.8 Mn 0.2 )Si 2 O 7 Red phosphor, and the bivalent europium and bivalent manganese co-activated chlorosilicate magnesium zinc calcium CMZSC: Eu, Mn green phosphor and BaMgAl prepared by the method in Example 1 10 O 17 :Eu blue phosphor is mixed at a relative weight ratio of 0.40:0.55:0.05. Then it is mixed with UV-resistant silicone glue to form a powder glue, and carefully coated on the InGaN blue-violet chip with an emission wavelength of 395nm. After the powder glue is cured, it is finally encapsulated with a UV-resistant transparent epoxy resin into a common 5White LED.

PUM

| Property | Measurement | Unit |

|---|---|---|

| color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com