Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

180results about How to "Improve stamping precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

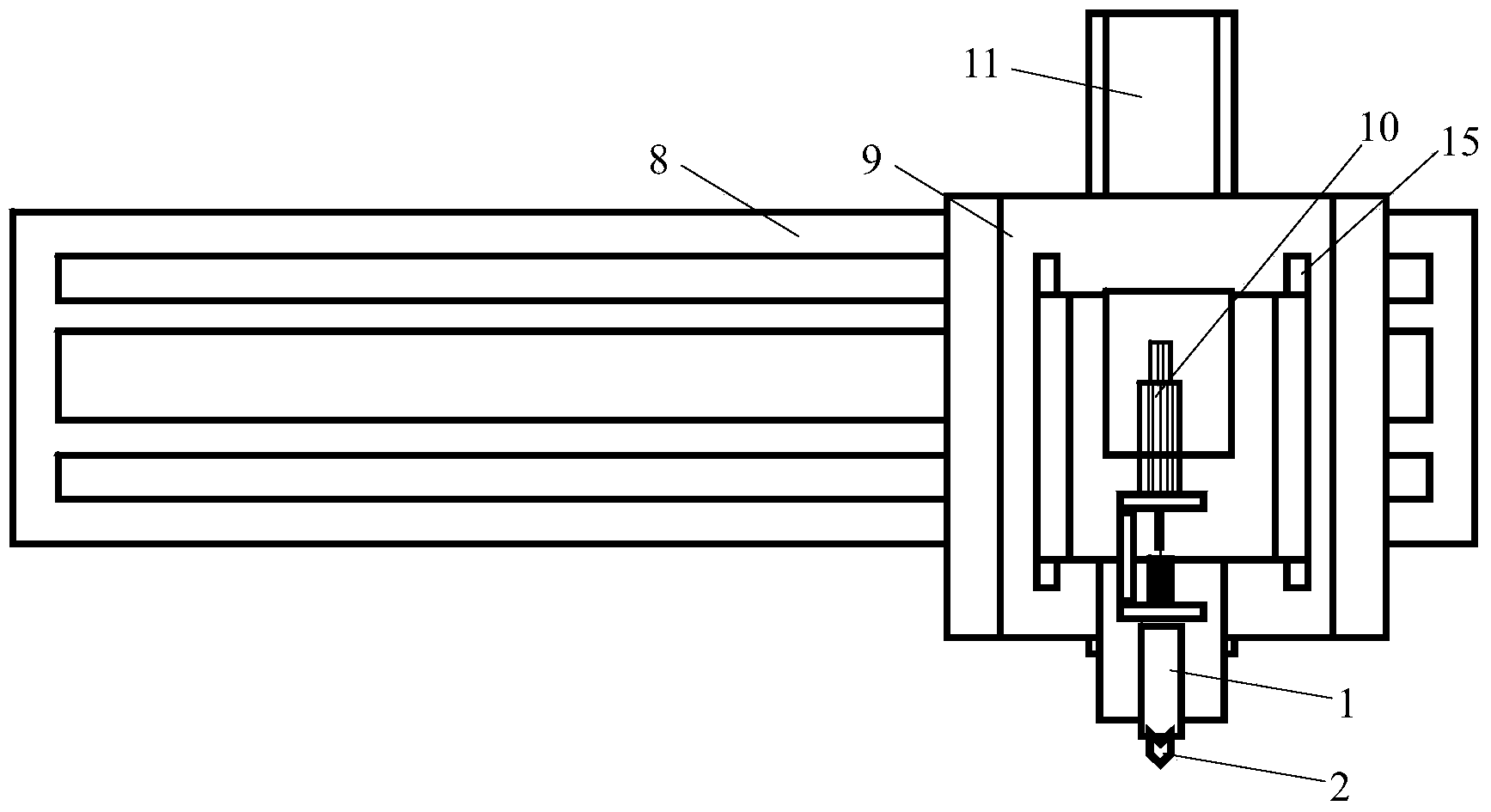

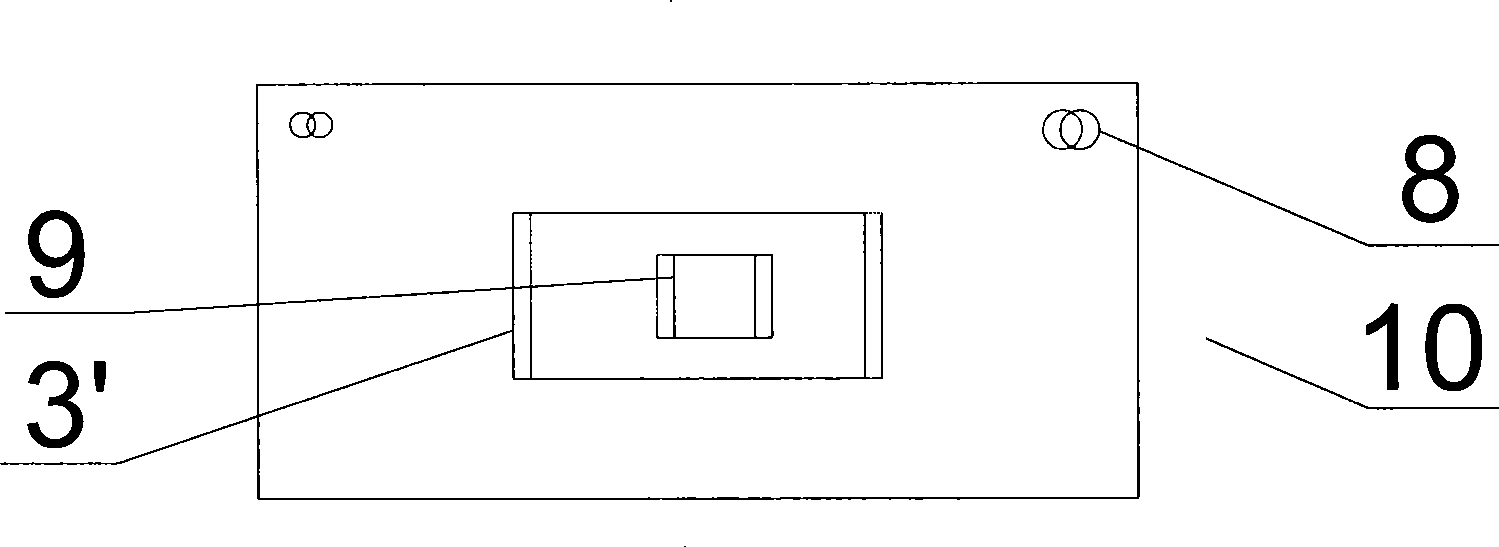

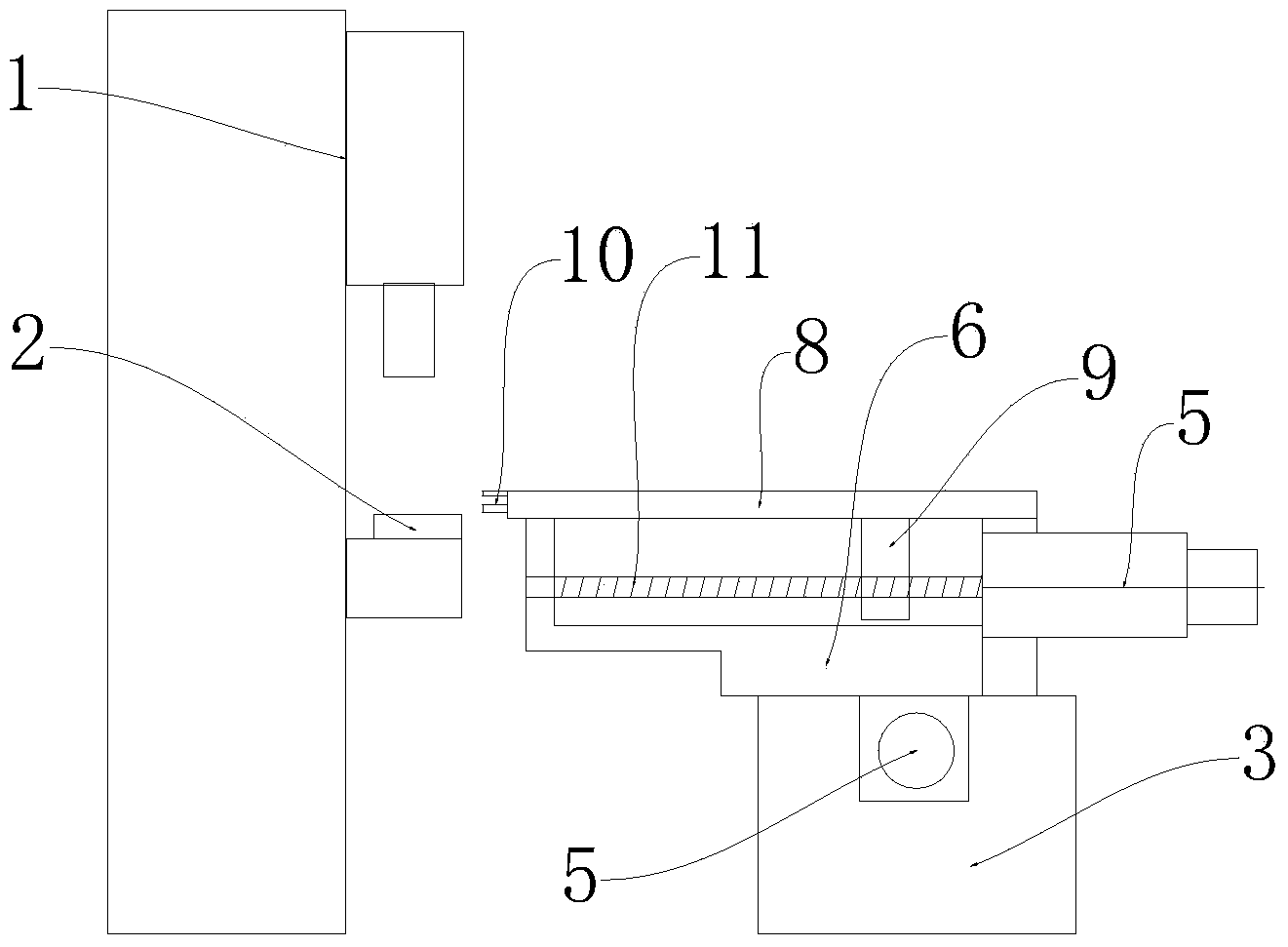

Net point punching device for die core

InactiveCN103878227APrecise Control of UniformitySmall toleranceMetal working apparatusPunchingMeasuring instrument

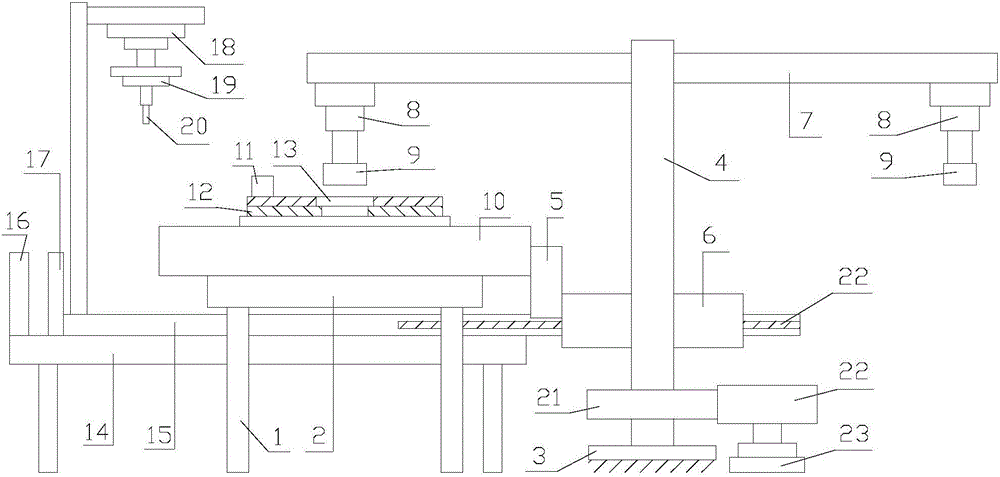

The invention relates to the technical field of displaying and discloses a net point punching device for a die core. The net point punching device comprises a punching mechanism, a laser distance measuring instrument, a displacement calculation controller and an upper computer. The punching mechanism and the laser distance measuring instrument are installed on an installation support, the installation base is installed on a first horizontal guide rail and can horizontally move along the first horizontal guide rail. A first driver is installed on the first horizontal guide rail and connected with the installation base through a first transmission mechanism. The displacement calculation controller is respectively and electrically connected with the laser distance measuring instrument and the upper computer. The upper computer is electrically connected with the punching mechanism and the first driver. The laser distance measuring instrument is adopted for accurately measuring the depth and bore diameter of net points, the flatness of the die core surface and the distance between the net points in real time. In the punching process, net point punching force and the moving position of the punching mechanism can be adjusted in real time, so that the bore diameter, the depth and evenness are accurately controlled, and then the depth and bore diameter tolerance of the net points is reduced.

Owner:BOE TECH GRP CO LTD +1

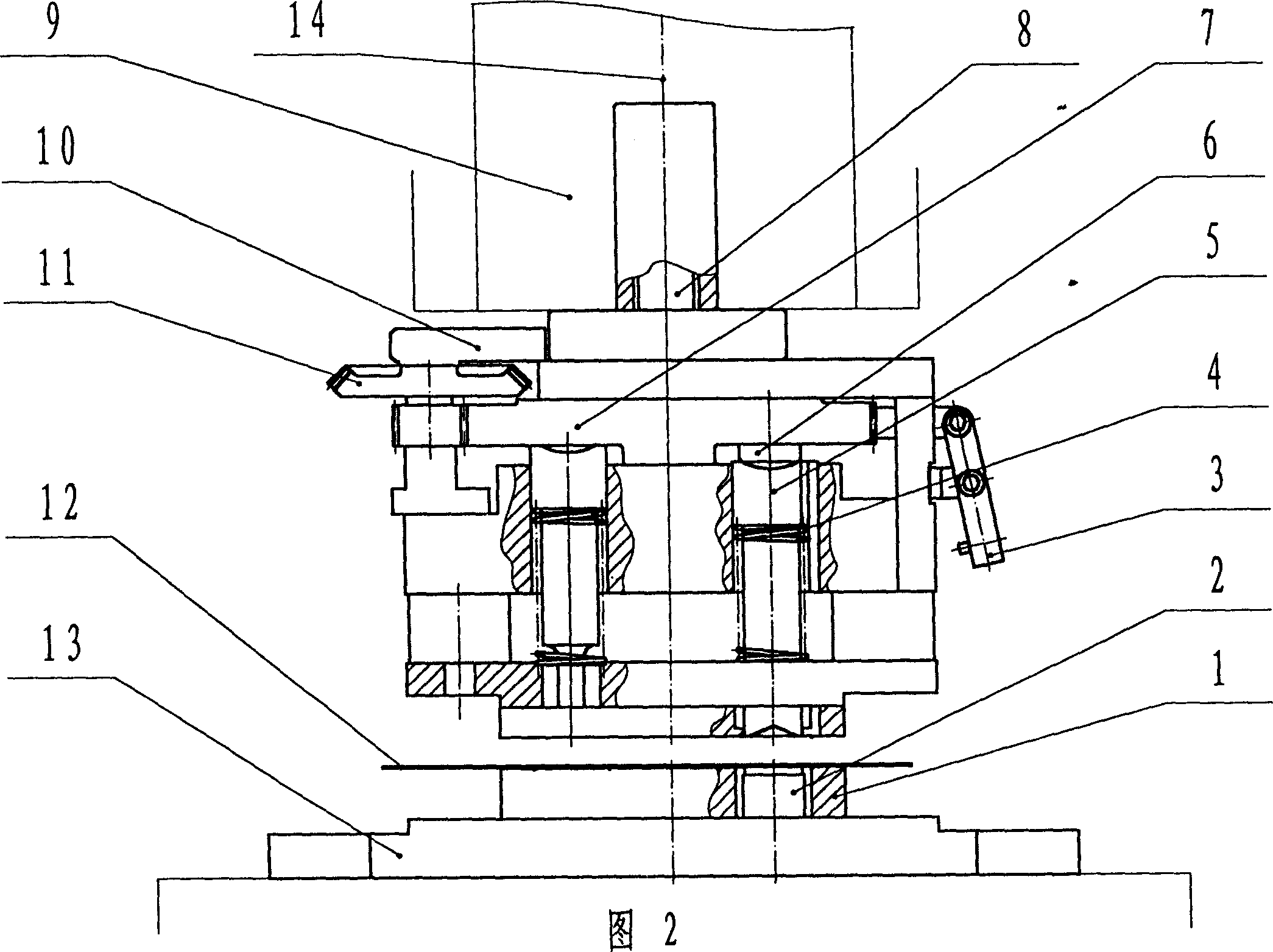

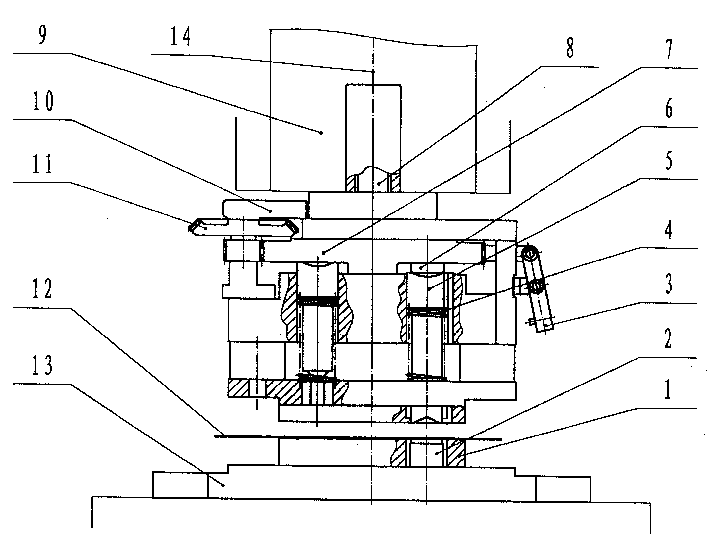

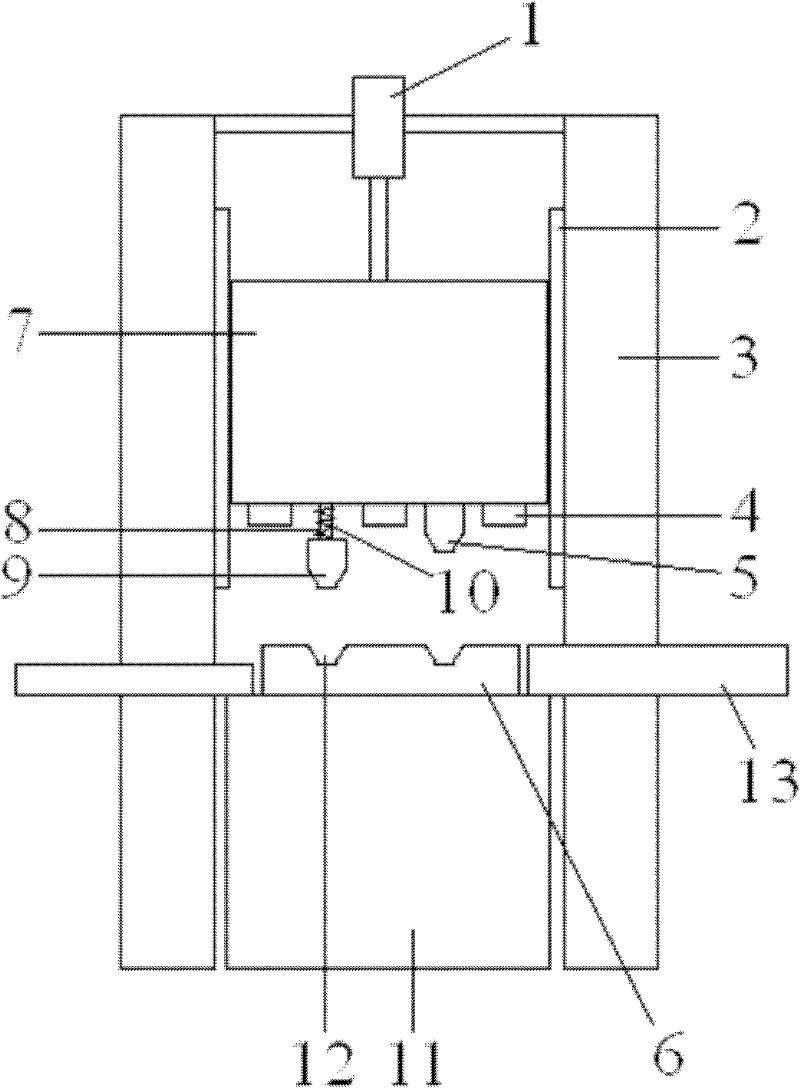

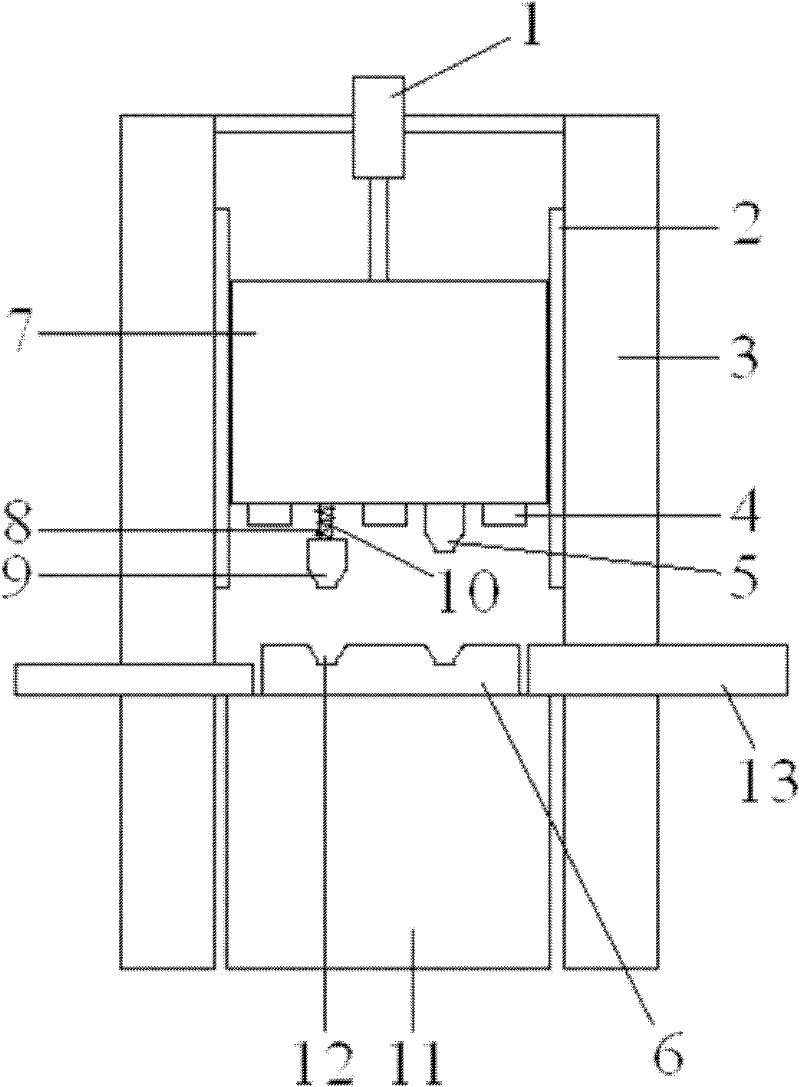

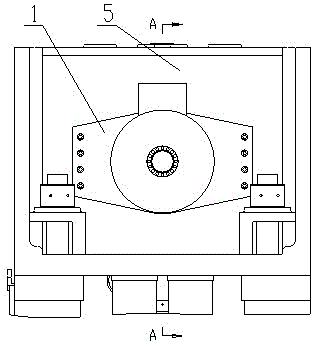

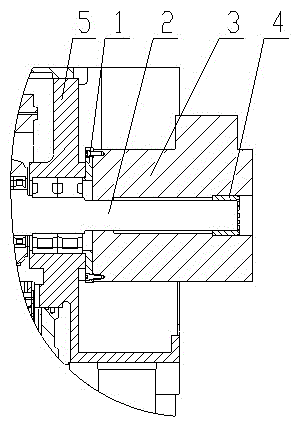

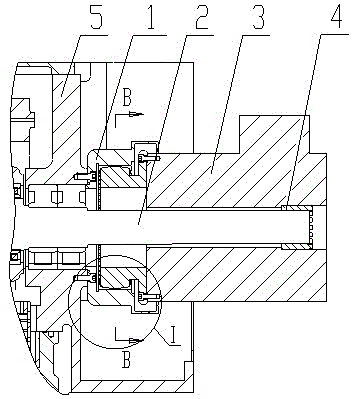

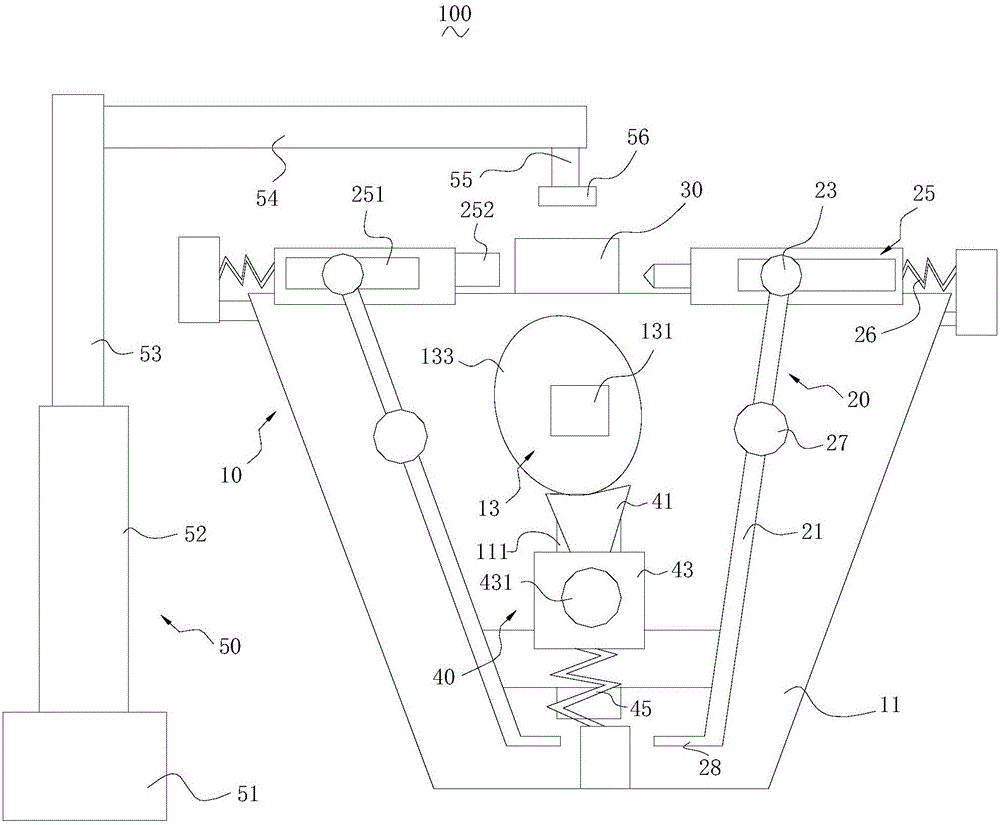

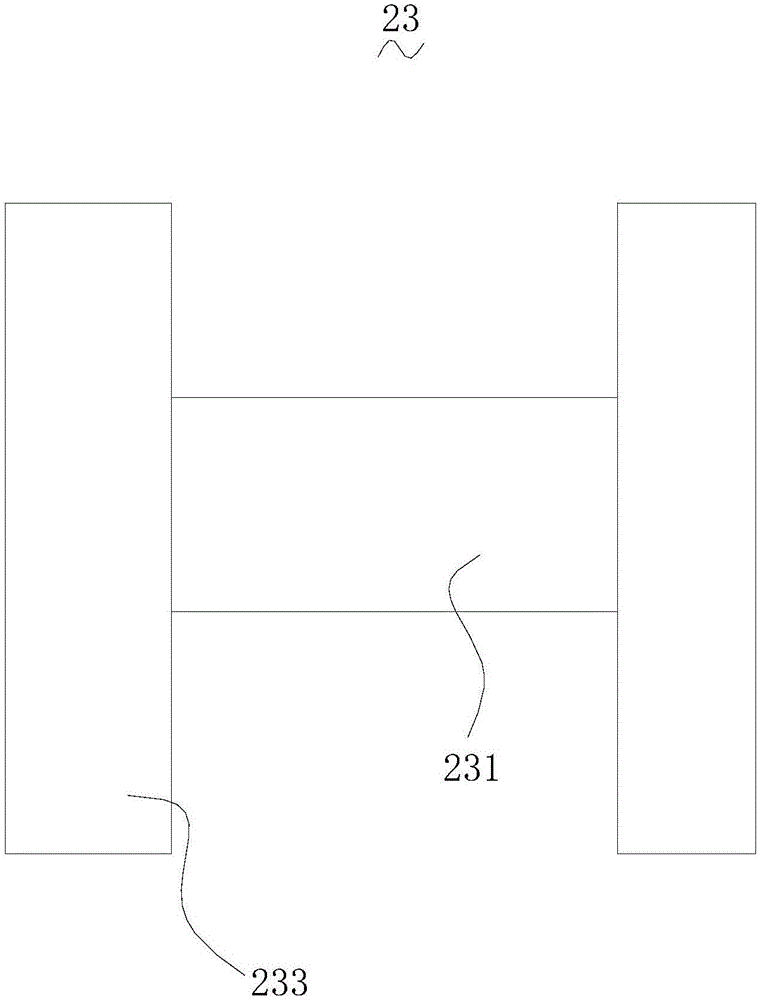

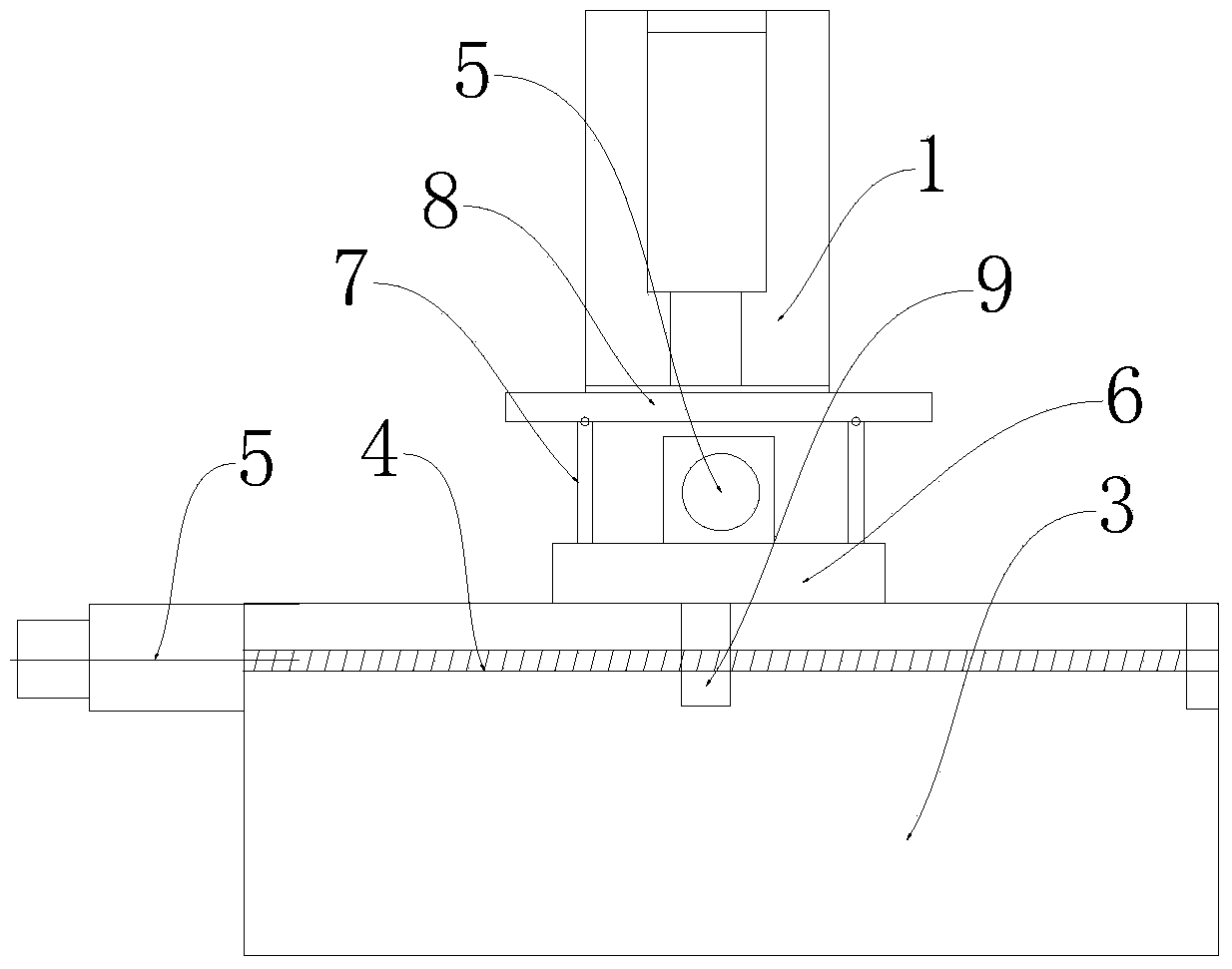

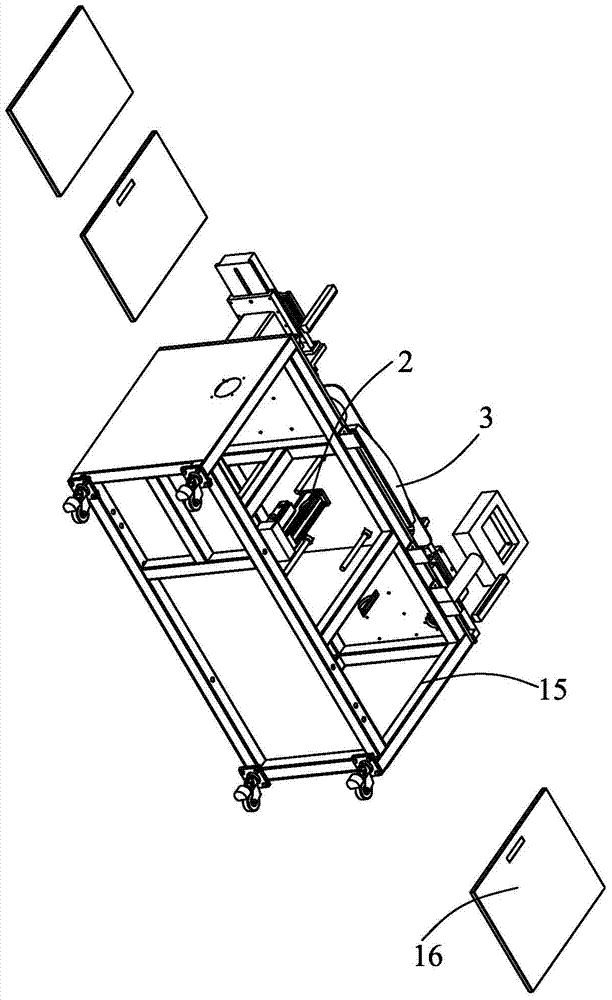

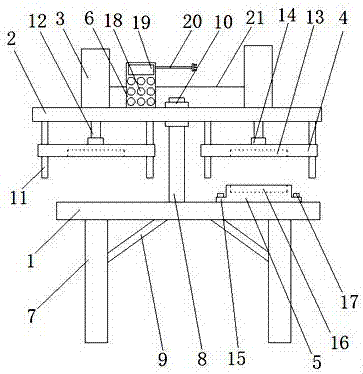

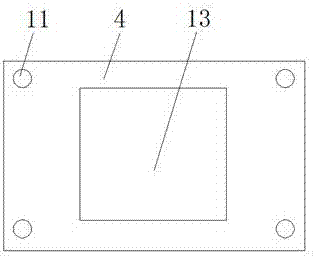

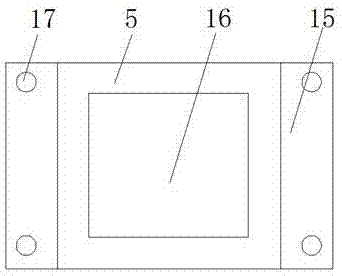

Die changing method and device for stamping processing multiple die of sheet material

The invention provides a mould changing method and device for multi-mould press working of a plate. The process is provided by arranging the up-down moulds mounted on the up-down mould frames on the circle with the press drive-hammer central line as axle, and by the selection of the mould changer and its cam rotated around the axle to the up-mould and transmission of the press force, completing mould-changing process for the plate in the same station. The device comprises an up-down mould, a rotary mould changer, and a cam, wherein the circular motion track corresponds to the arrangement position of the up-mould, the press force is transferred to the up-mould by the mould changer and the cam, and the up-mould and the down-mould are matched together. In the device, multiple corresponding press mould is fixed, which simplifies the structure and improves the working precision and stability.

Owner:武汉工研光学科学技术股份有限公司

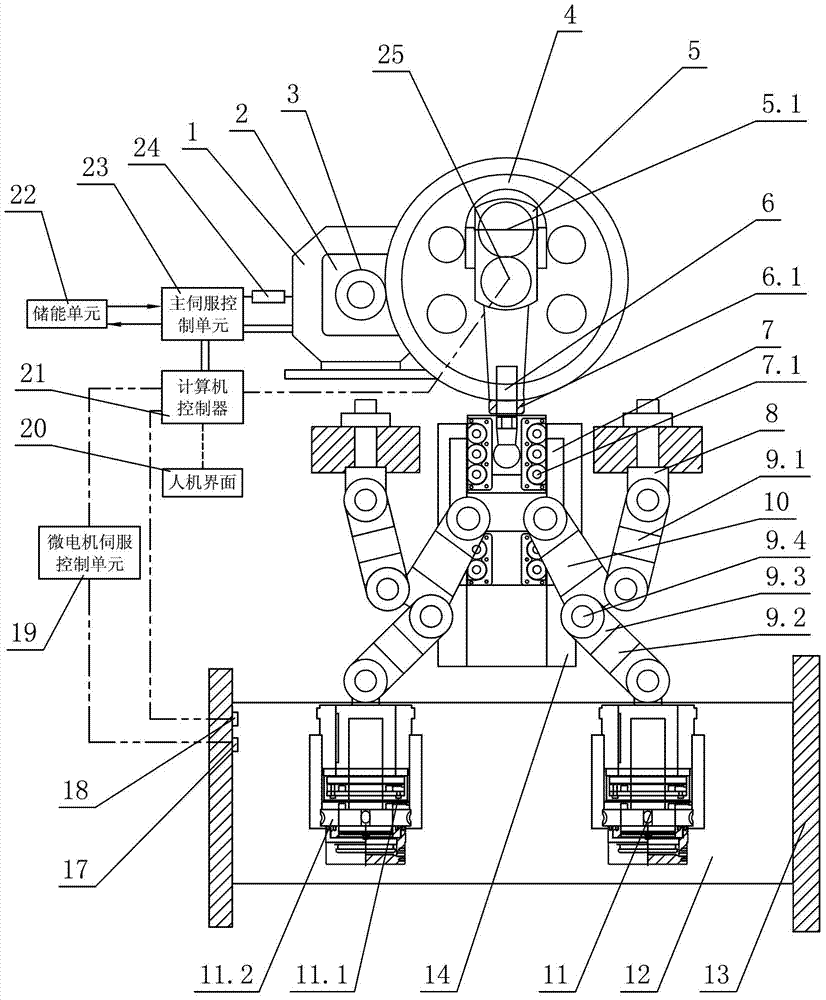

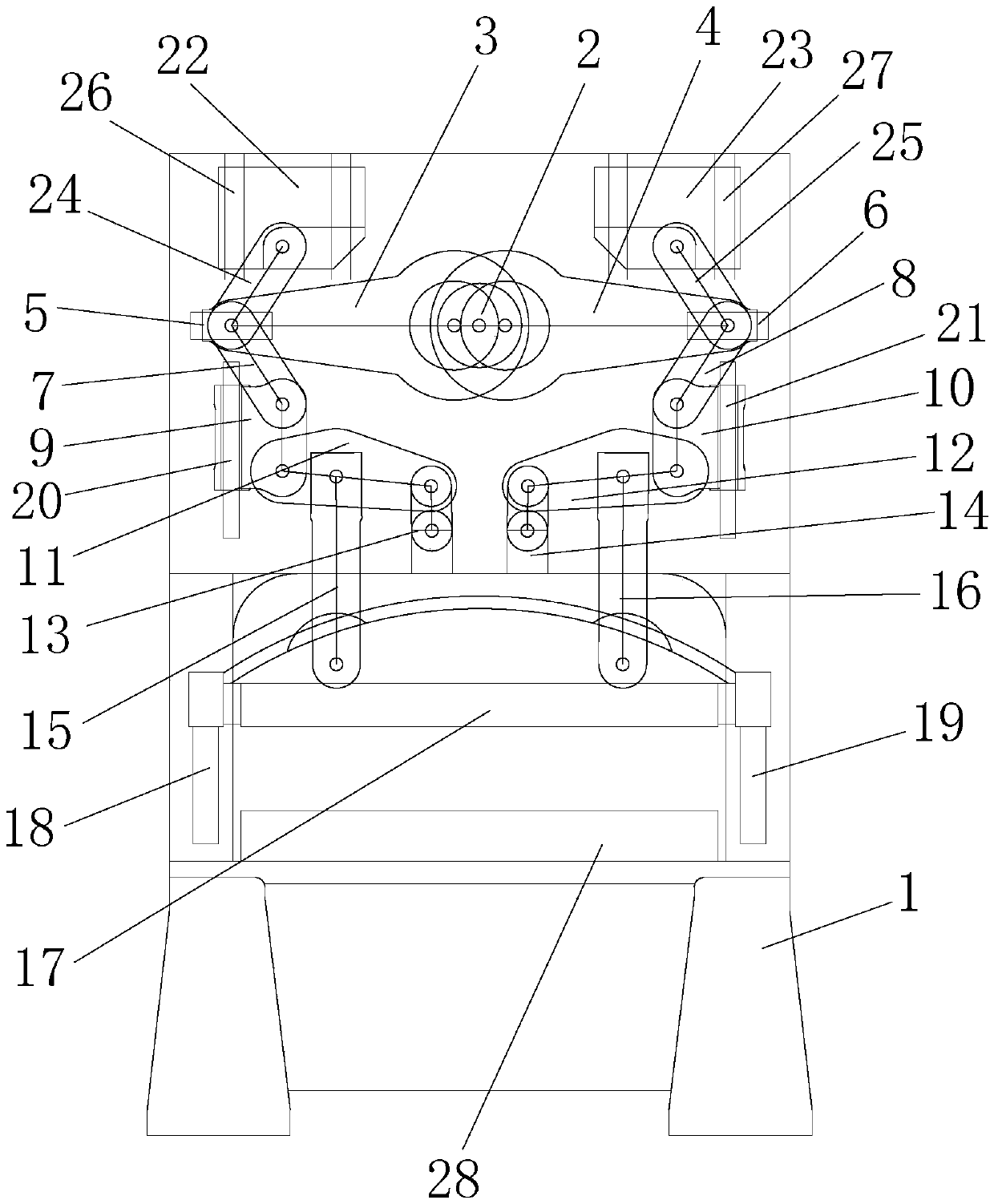

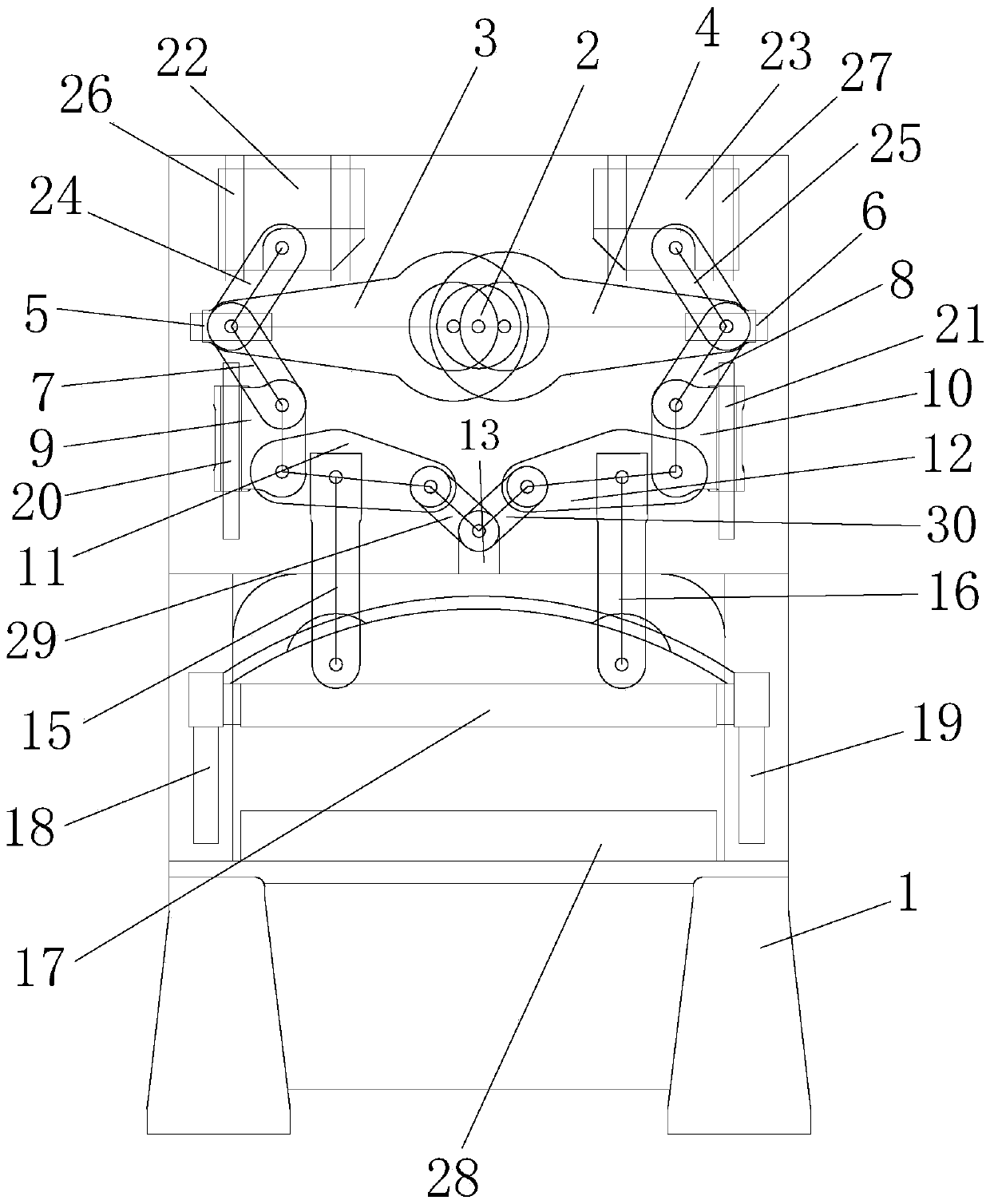

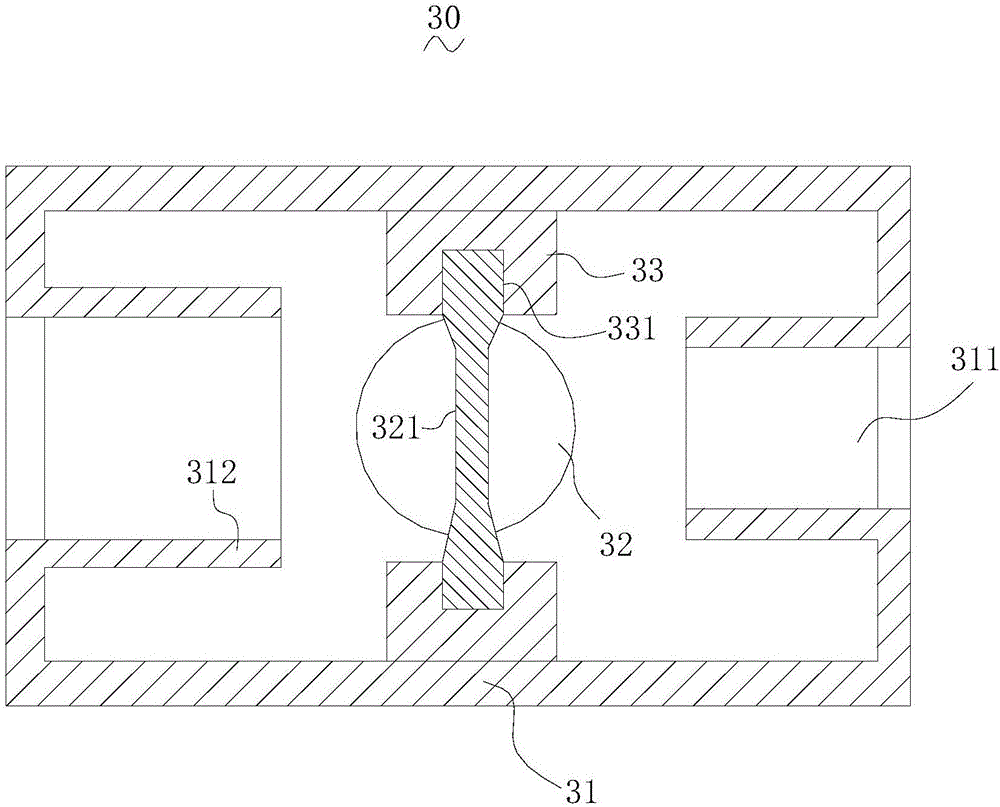

Multifunctional servo crank knuckle-lever press

A multifunctional servo crank knuckle-lever press comprises a servo motor, a crankshaft, a connecting rod, a ram, a sliding block body and a control system, wherein the servo motor is connected with the crankshaft through a speed-reducing mechanism in a driving mode, a crank of the crankshaft is connected with a rotary bearing at the upper end of the connecting rod, the lower end of the connecting rod is hinged to the center of the ram through a bulb screw rod, and the ram is hinged to a symmetrical knuckle lever structure. The symmetrical knuckle lever structure is composed of a triangular connecting rod, an upper knuckle lever and a lower knuckle lever, wherein three angle ends end of the triangular connecting rod are respectively provided with a pin hole, are large semicircular column bodies, and are hinged to semicircular square bearing bushes arranged on an upper knuckle lever and a lower knuckle lever through pin shafts, and the upper knuckle lever and the lower knuckle lever are hinged to an upper support of a machine body and a lower support of the sliding block body respectively. According to the multifunctional servo crank knuckle-lever press, the servo control system controls the servo motor to drive the sliding block to make vertical reciprocating motion operations, different punching curves are achieved through preset control programs according to different processes, and multifunctional punching operations such as blanking, silent punching, tensioning and fine press forming and stamping are carried out.

Owner:广东宏兴机械有限公司

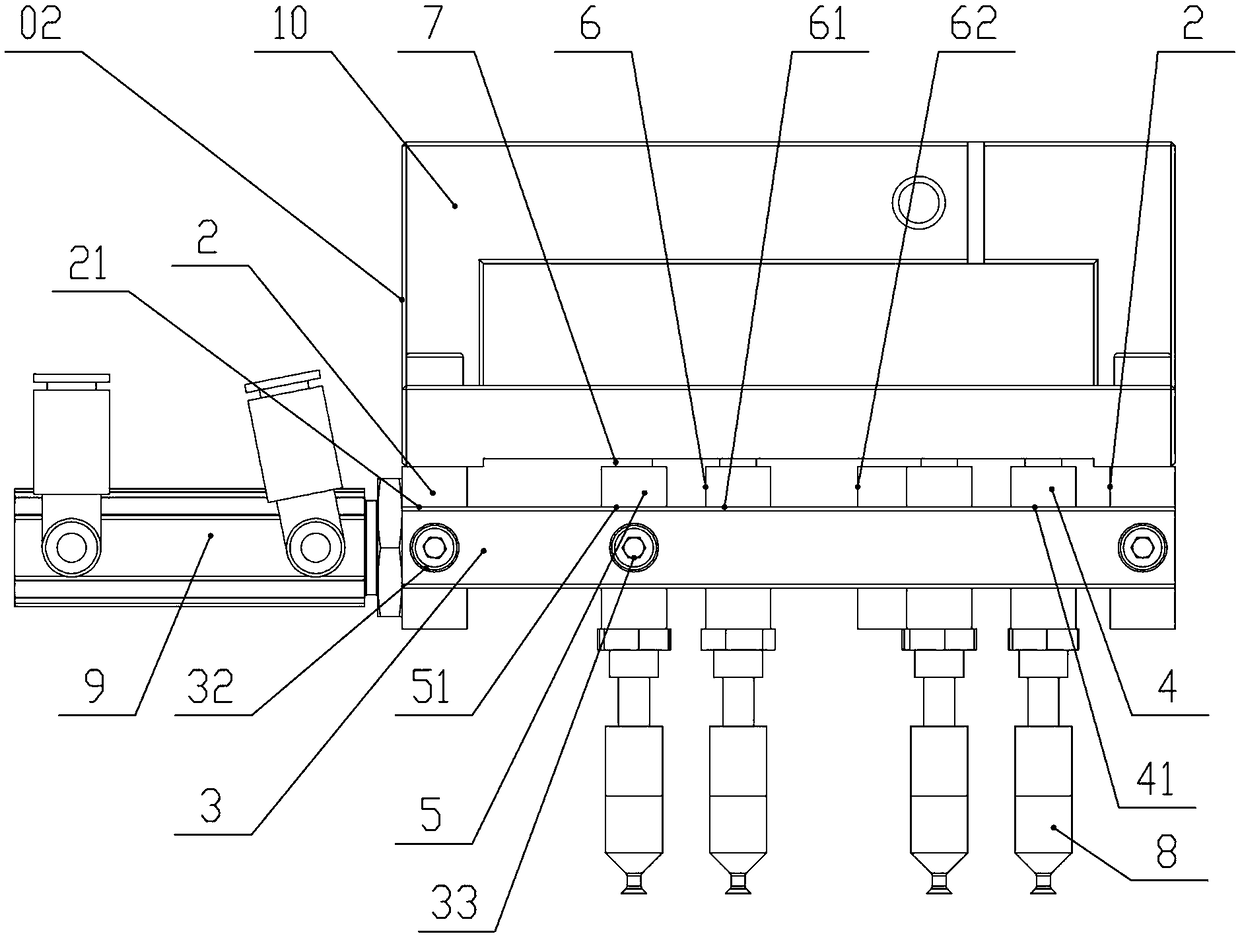

System for carrying out punching on parts

InactiveCN105855348AIncrease movement speedReduce movement speedShaping toolsStripping-off devicesPunchingEngineering

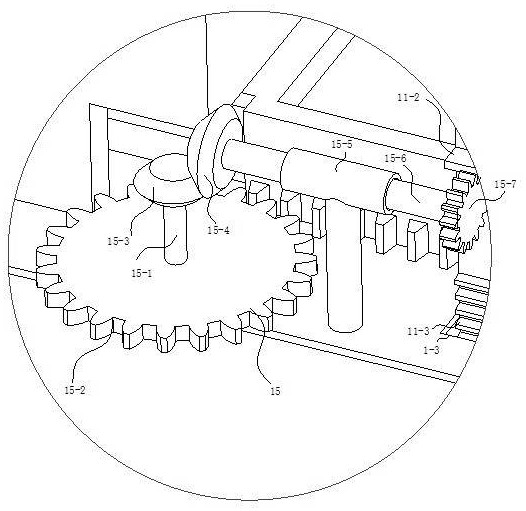

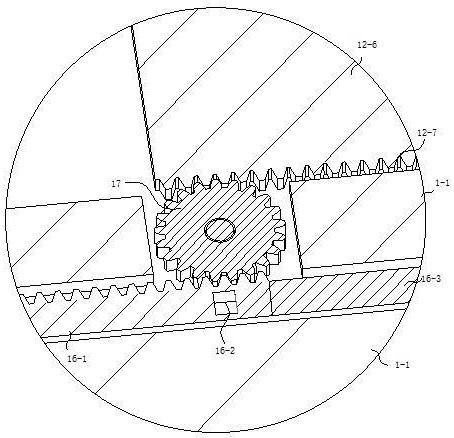

The invention discloses a system for stamping parts, including a bracket, a first moving plate, multiple molds, a mounting frame, a rotating shaft, two stamping parts, a driving mechanism, a thickness sensor, a first position sensor, The controller; guide rails are arranged on the bracket, and the guide rails are set along the horizontal direction; the first moving plate is movably installed on the guide rails, the first moving plate is set horizontally, and one side of the first moving plate is provided with the first wheel in continuous distribution Teeth; multiple molds are installed on the first moving plate at intervals along the length direction of the guide rail, and the distance between any two adjacent molds is equal; the mounting frame and the rotating shaft are all placed on the side of the first gear teeth away from the first moving plate On the side, the rotating shaft is rotatably installed on the mounting frame, the rotating shaft is arranged along the vertical direction, and a part of the circumferential surface of the rotating shaft is provided with second gear teeth matched with the first gear teeth. The invention has good processing effect and high processing precision.

Owner:WUHU HONGFEI MACHINERY CO LTD

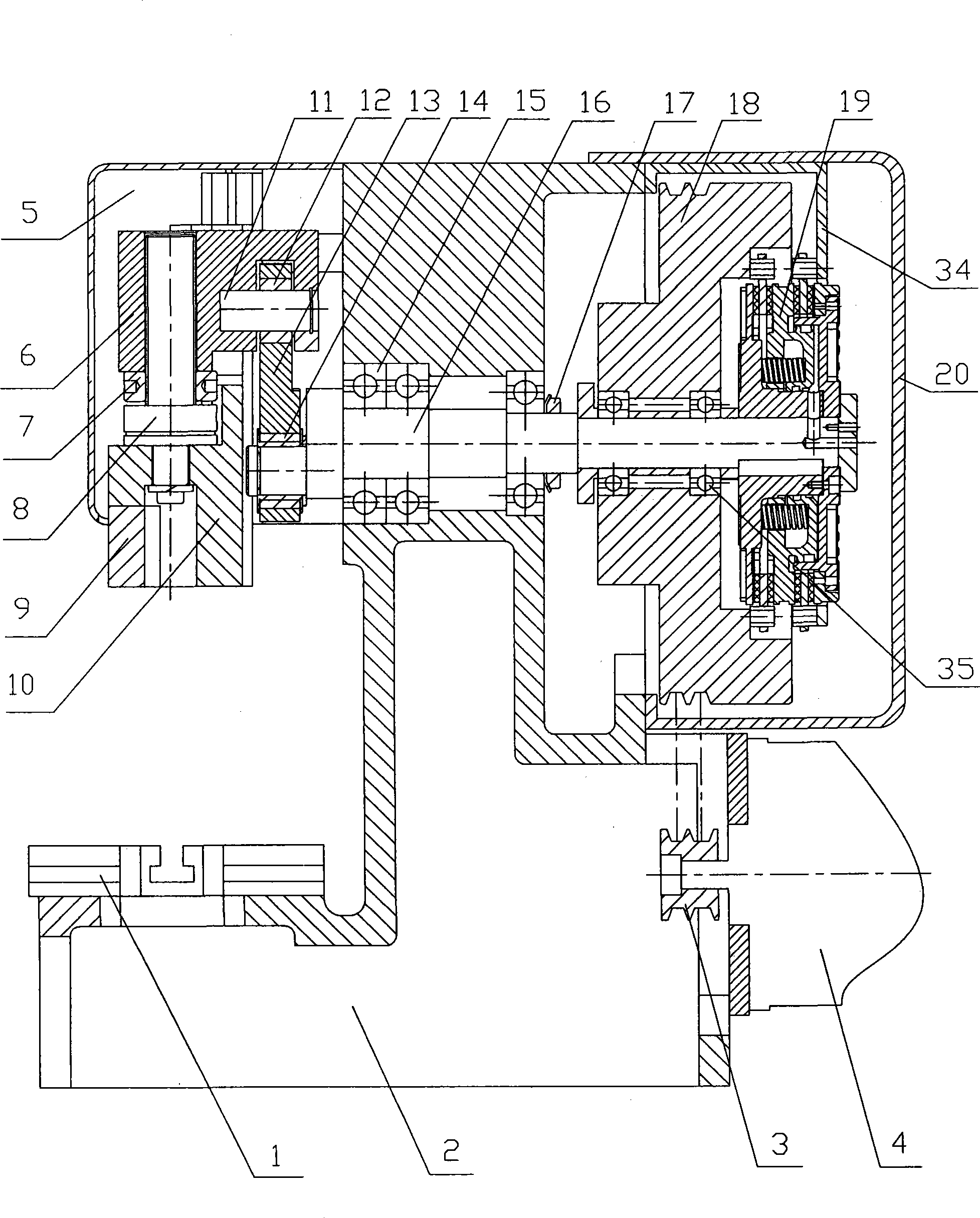

Desk type accurate punching machine

The invention provides a table type precise punching machine which comprises a working table, a table body and a motor, wherein, clutch brake components are formed by the matching of a brake clutch pressure plate with brake blocks and a piston which is arranged in a cylinder of a body and provided with a spring; the brake clutch pressure plate is fixed on a fly wheel and the table body; a crank shaft and the body which is connected on the crank shaft are provided with an air inlet and an air inlet hole which are connected with a gas source; a connecting rod slide block device is formed by the following steps: the upper end of the connecting rod with a joint bearing is connected with an adjustment slide block by a pin, the lower end of the connecting rod with the bearing is connected with the crank shaft, and the slide block and the adjustment slide block are connected into a whole by a saw tooth with a nut and a screw rod, and the slide block and a guide rail are matched. The clutch and the brake which are originally installed in a dispersion way are integrated to be centrally installed and are compact in structure, small in volume, good in braking performance and safe and flexible in use; the lubrication of each rotational position is ensured by a rolling bear, thus sufficiently reducing the resistance and improving the working efficiency; the connecting rod slide block device greatly reduces the volume of the whole machine and is easy to be processed and installed, thus improving the installation precision and causing a die to be simple and convenient in adjustment and operation.

Owner:宁波米斯克精密机械工程技术有限公司

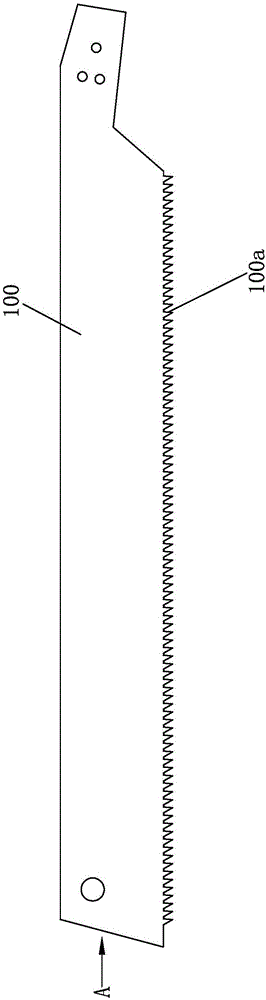

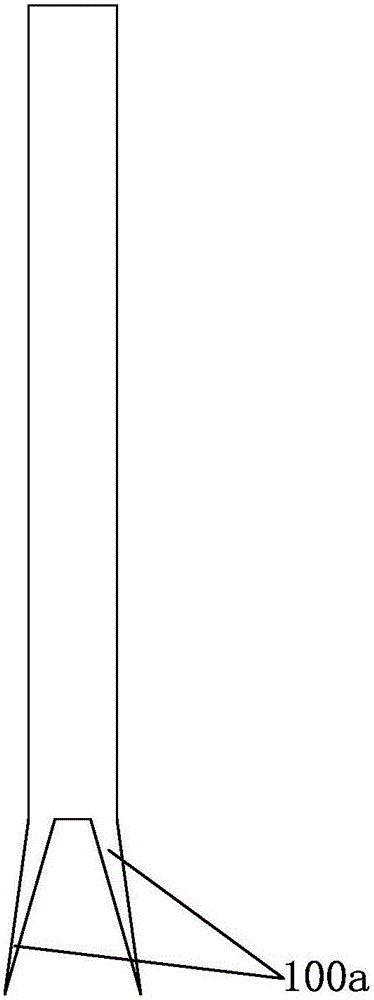

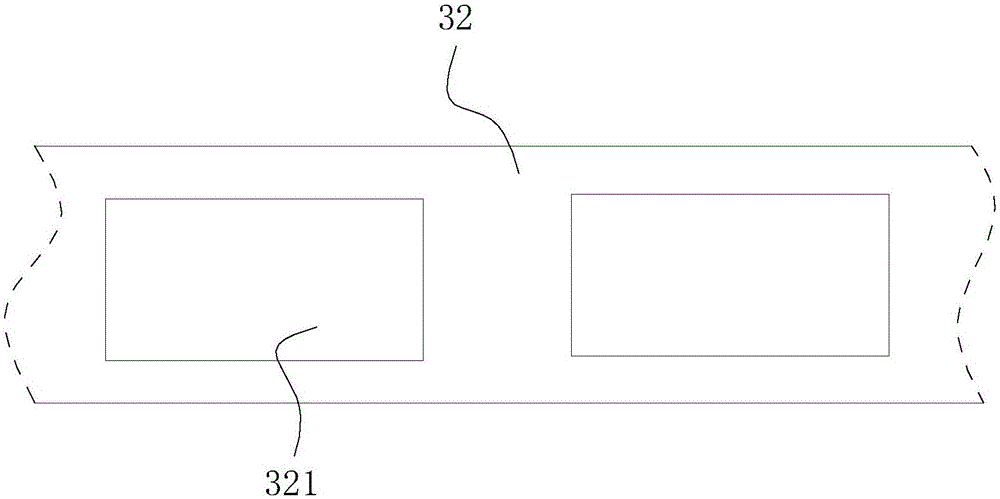

Handle saw web and sawtooth machining process

InactiveCN106180895AReduce workloadReduce wearMetal sawing tool makingGear grindingNumerical control

The invention discloses a sawtooth processing technology of a handle saw blade, which is characterized in that it comprises the following steps: step a: shaping the saw blade (100); step b: punching out a set of edges on the saw blade (100) The saw teeth (100a) arranged in the lengthwise direction of the saw blade; step c: use a CNC gear grinding machine to grind both sides of each saw tooth (100a) to form a cutting edge; step d: deburring and polishing. The upper and lower sides of (100) are deburred and polished; step e: divide the teeth, in this step, the second punch press is used to press the saw blade (100), so that all the saw teeth (100a) on a piece of saw blade (100) ) to complete the tooth division at one time. This process method effectively simplifies the process, greatly improves the processing efficiency and precision, effectively eliminates the cumulative error, and reliably reduces the processing cost. The waste produced after stamping can also generate a certain economic value, thus effectively overcoming the existing process method. disadvantages, has good practicality.

Owner:CHONGQING MINGYOU STEEL PROD MFG CO LTD

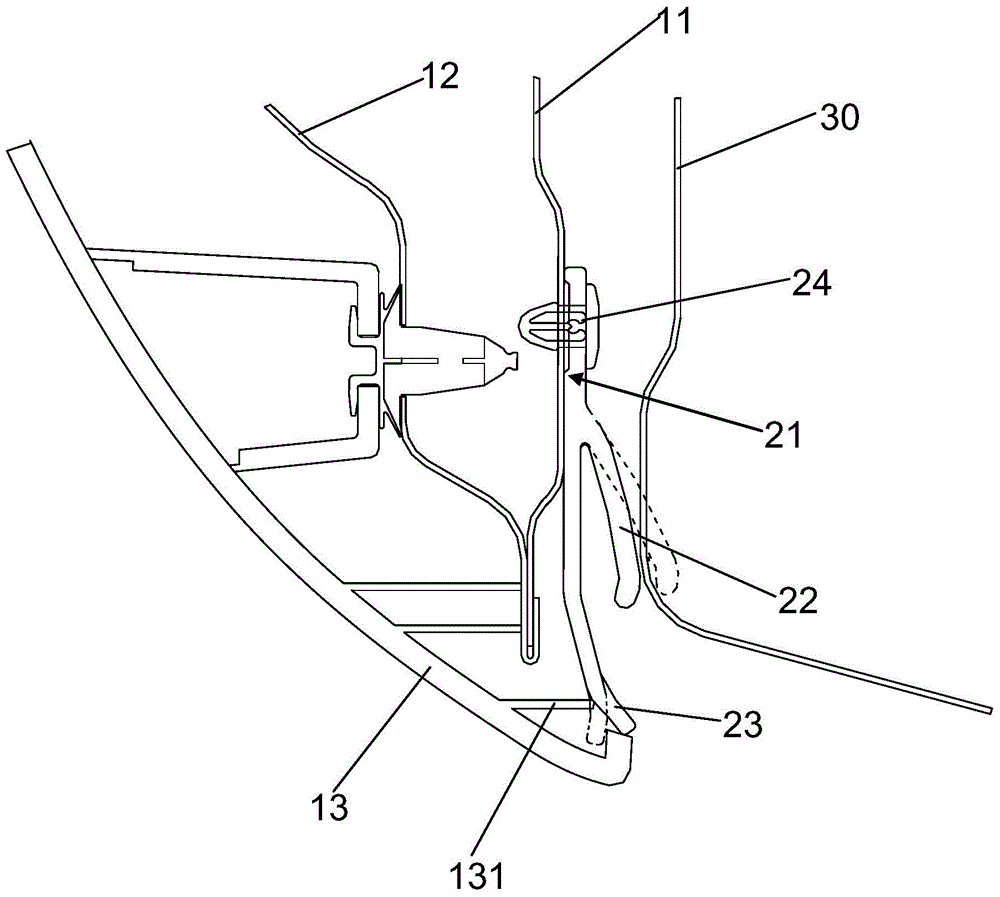

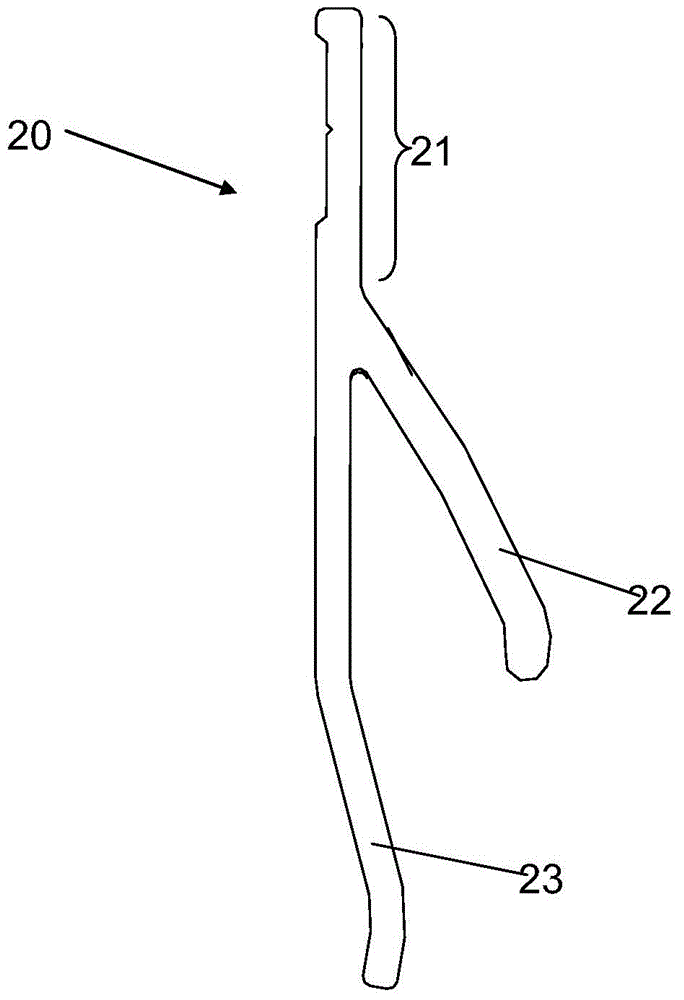

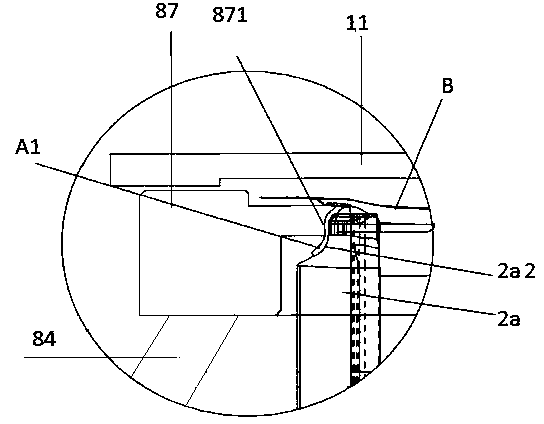

Lower sealing structure for door

ActiveCN104149585APrevent direct knockAvoid accumulationEngine sealsVehicle sealing arrangementsMechanical engineeringSilt

The invention relates to the field of automobile parts, in particular to a lower sealing structure for a door. A sealing strip is installed on an automobile door inner plate and comprises a straight-wall-shaped base part, a first lip edge and a second lip edge, wherein the first lip edge and the second lip edge are fixed to the portion below the base part and extend in a suspended mode. The first lip edge corresponds to a lateral surrounding outer plate on a sill in position, when an automobile door is closed, the first lip edge is attached to the lateral surrounding outer plate, the second lip edge is attached to an automobile door decorative plate, the tail end of the lower portion of the automobile door decorative plate extends to the lower portion of the second lip edge, and the base part is provided with a through hole used for being connected with the automobile door inner plate. The lateral surrounding outer plate on the sill is shielded through the first lip edge, so that silt is prevented from directly knocking the lateral surrounding outer plate and prevented from being accumulated on the sill. Through the structure, an installation hole does not need to be formed in the lateral surrounding outer plate on the sill, so that rainwater or dust is effectively prevented from entering an automobile. The second lip edge is attached to the automobile door decorative plate so that the silt can be effectively prevented from being accumulated. When the door is opened, the sealing strip on the lower portion of the door is shielded through the automobile door decorative plate, so that attractiveness of the whole automobile is not affected.

Owner:CHERY AUTOMOBILE CO LTD

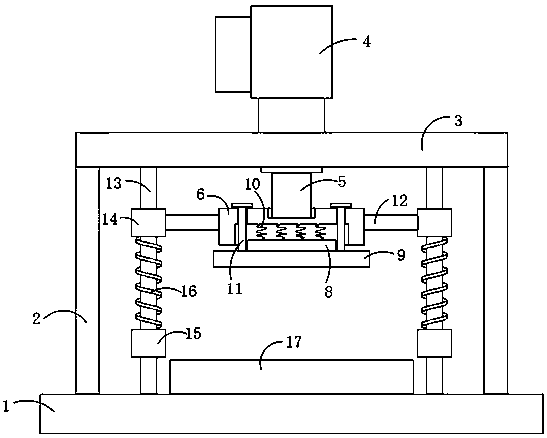

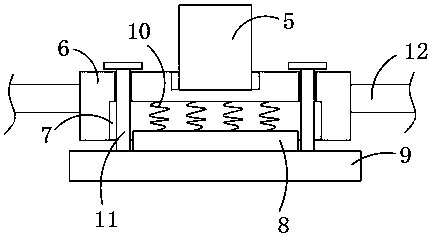

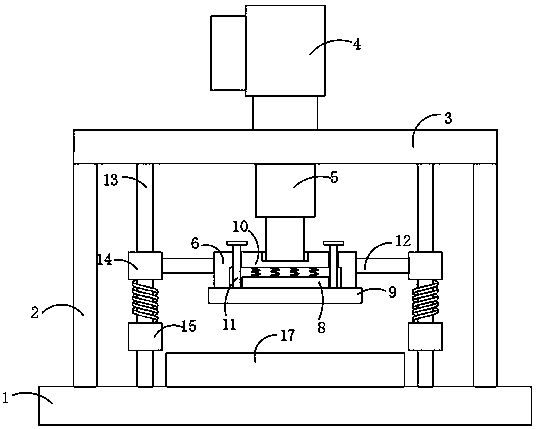

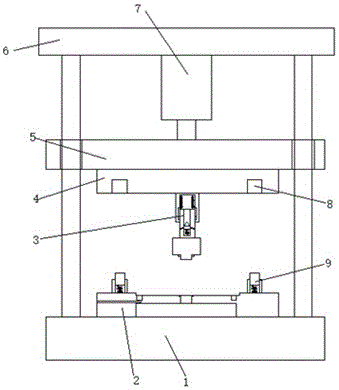

Press machine high in machining precision

InactiveCN109332495AHigh precisionImprove stamping precisionShaping toolsShaping safety devicesHydraulic cylinderPunching

The invention discloses a press machine high in machining precision. A base is included. The upper end of the base is fixedly connected with an upper cover plate through two supporting plates. A hydraulic cylinder is fixedly connected to the upper end of the upper cover plate. The two supporting plates are symmetrically arranged on the two sides of the lower end of the hydraulic cylinder. The telescopic end of the hydraulic cylinder penetrates through the upper cover plate and is fixedly connected with a punching head. The lower end of the punching head is fixedly connected with a punching buffering device. The two sides of the punching head are symmetrically provided with guiding columns corresponding to the punching buffering device in position. The upper ends and the lower ends of the two guiding columns are fixed to the opposite side walls of the upper cover plate and the base correspondingly. The press machine is compact in structure, the punching buffering device is arranged at the lower end of the punching head and matched with a damping mechanism, damping buffering and protection functions are achieved for to-be-punched accessories and other mechanical structures on the press machine in the punching process, and meanwhile the punching precision is improved under the guiding action of the guiding columns.

Owner:江苏纽克光谱科技有限公司

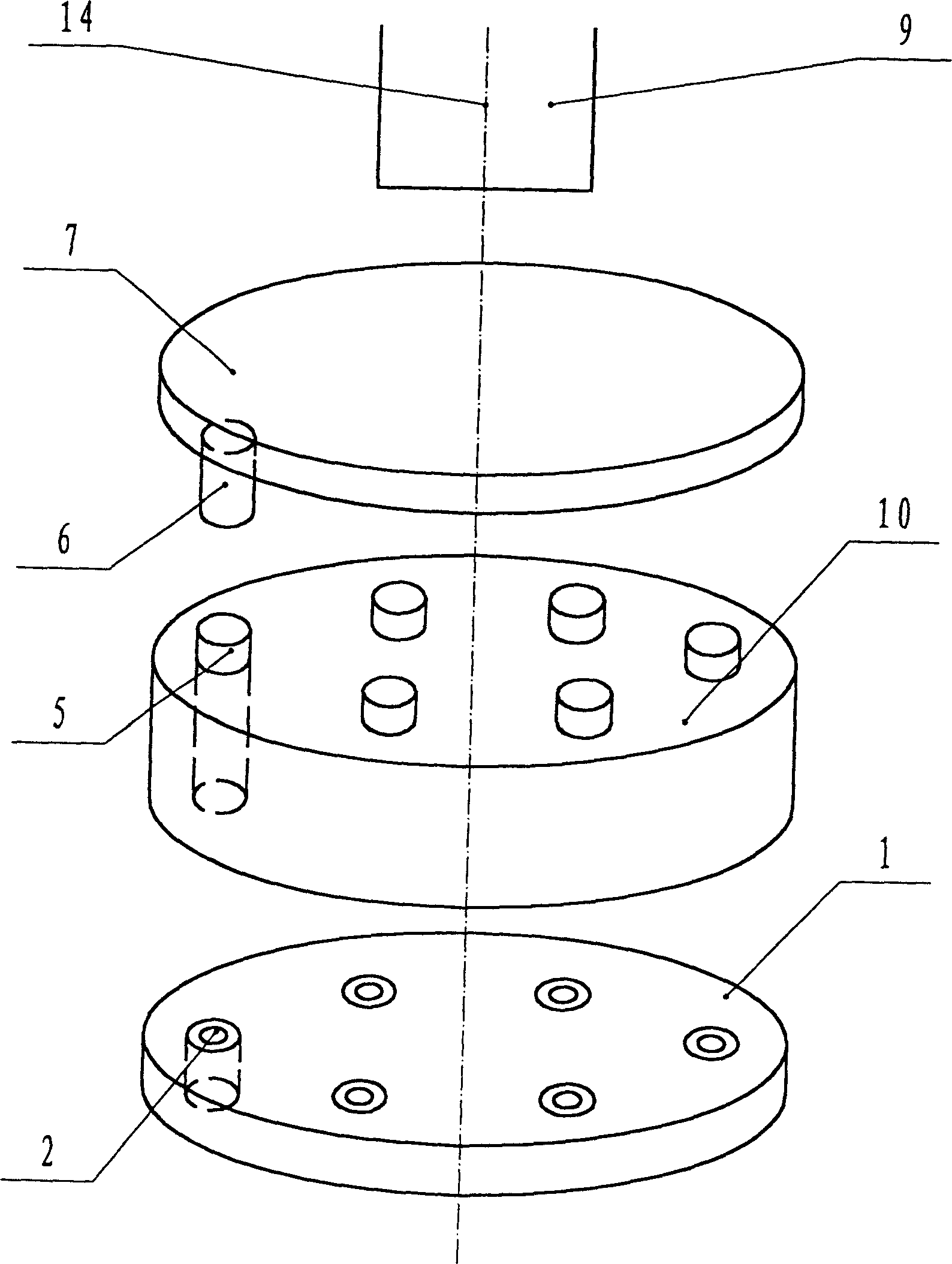

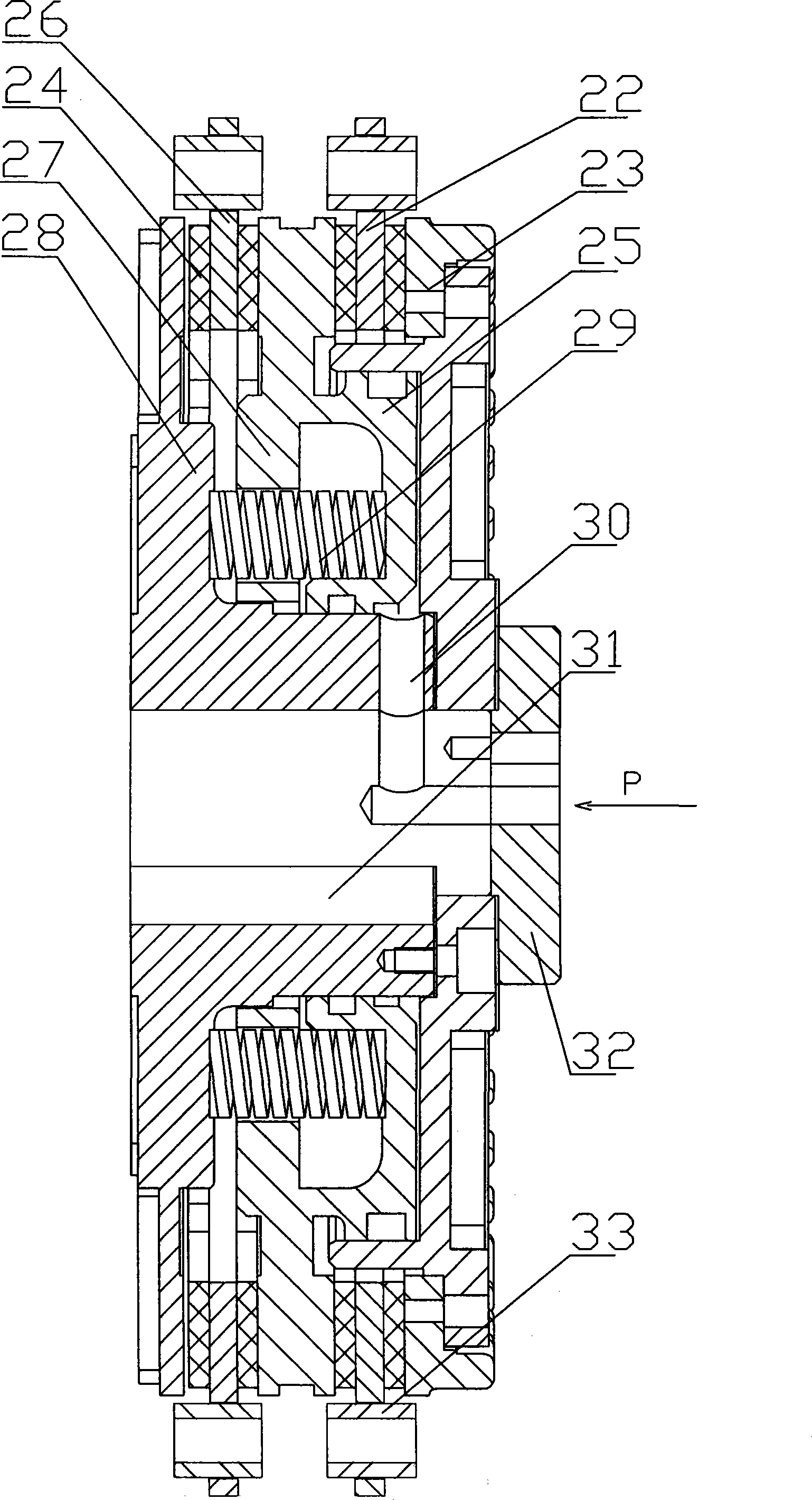

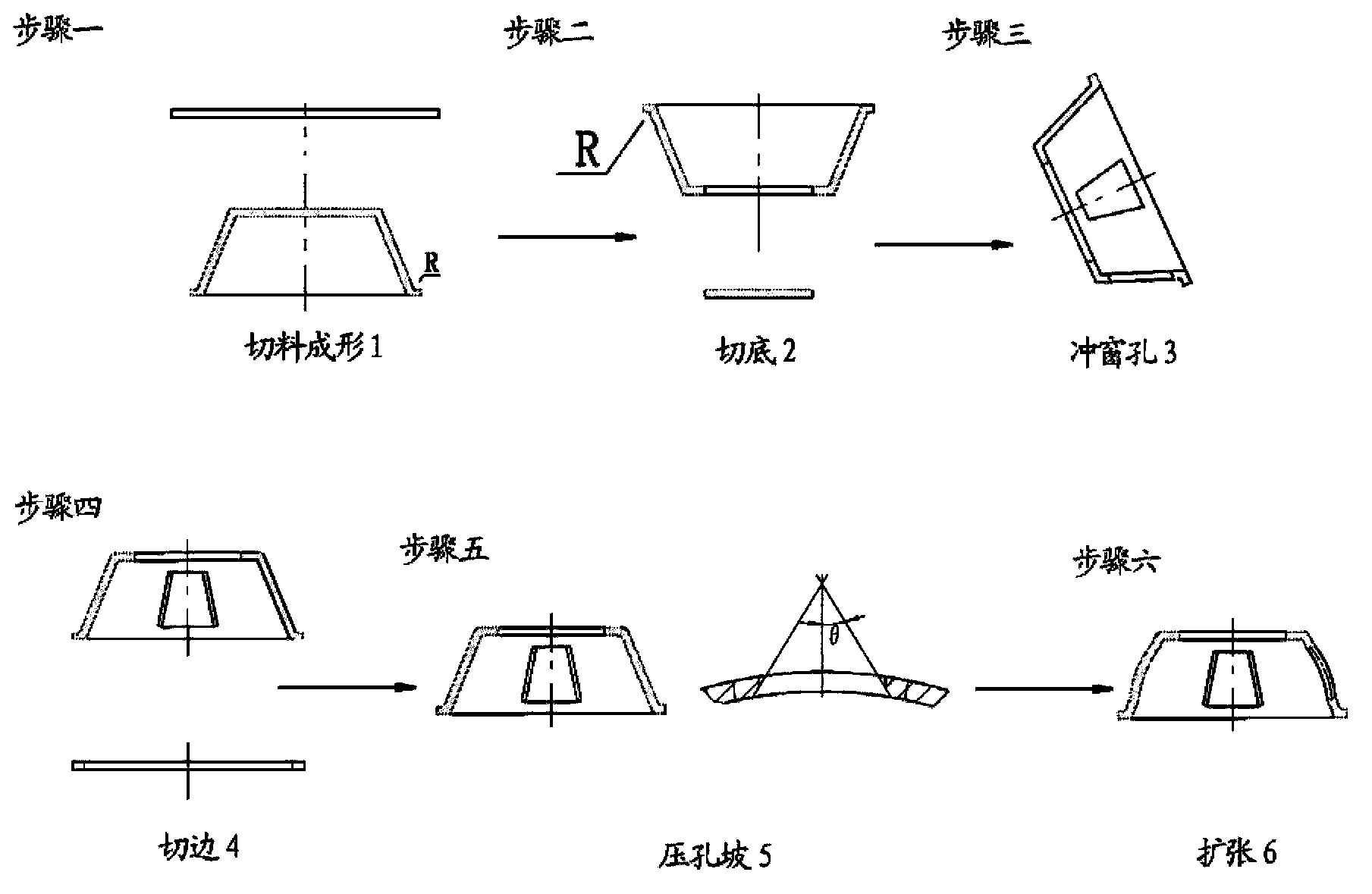

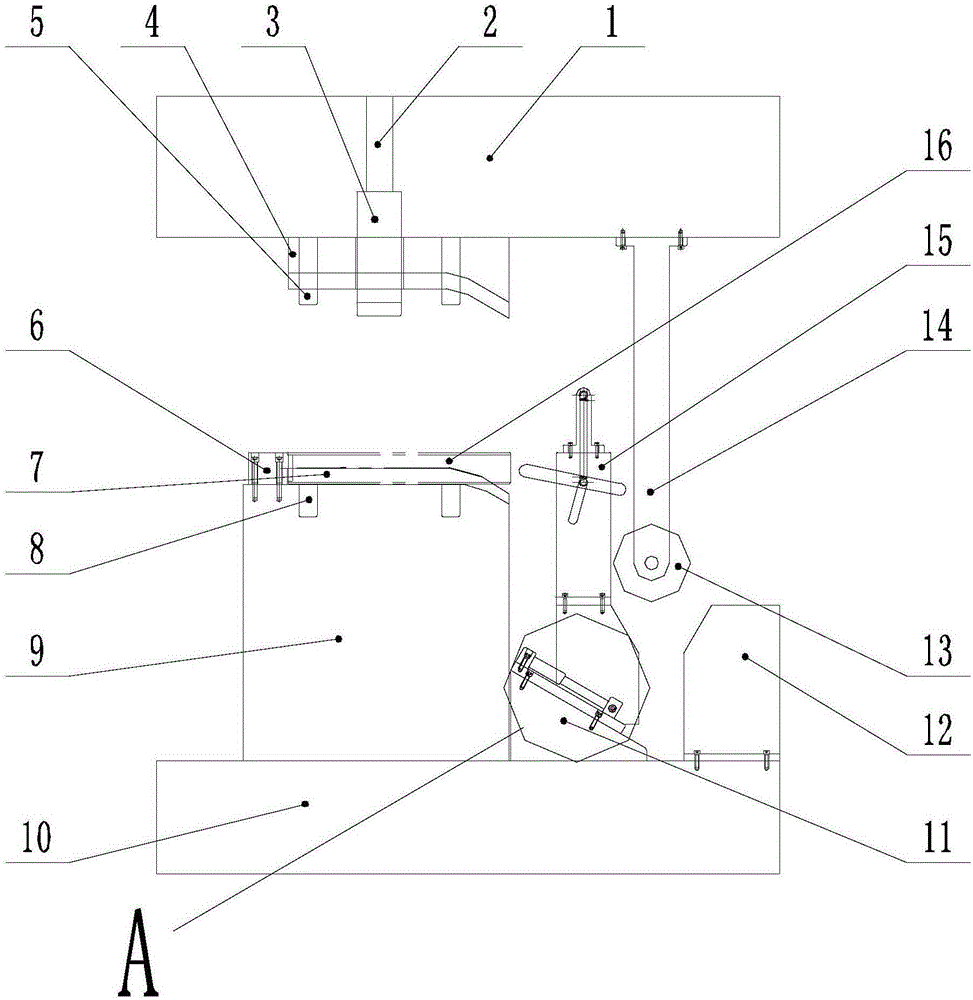

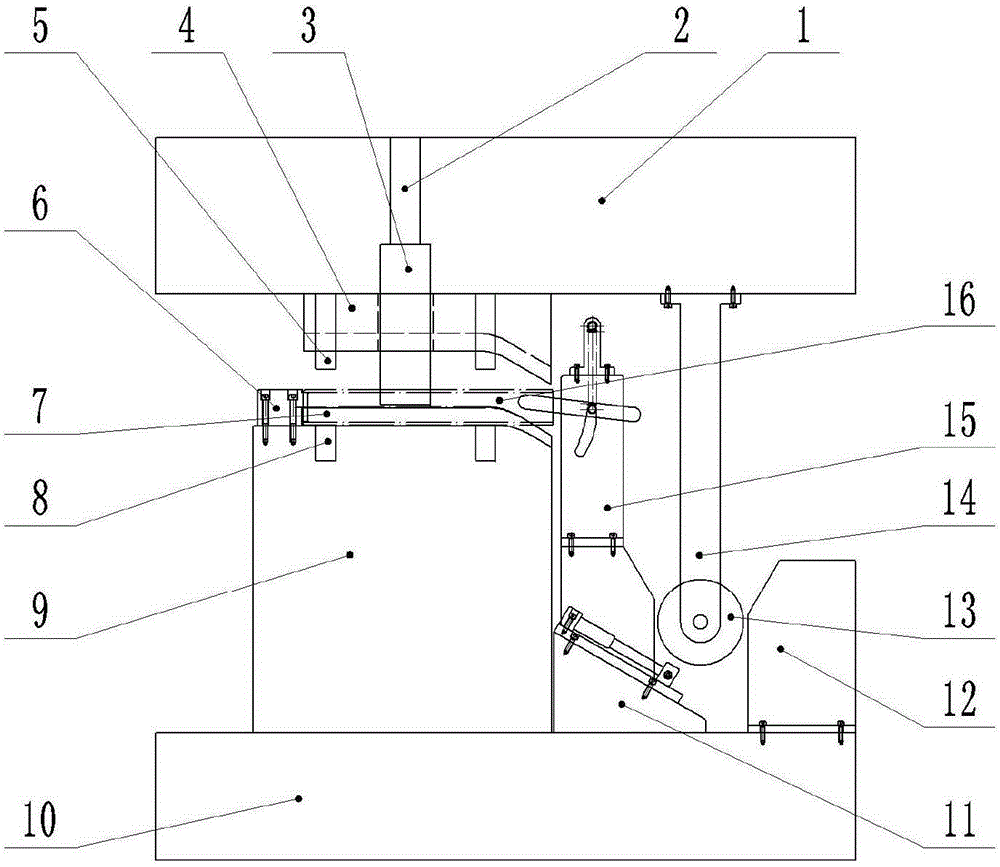

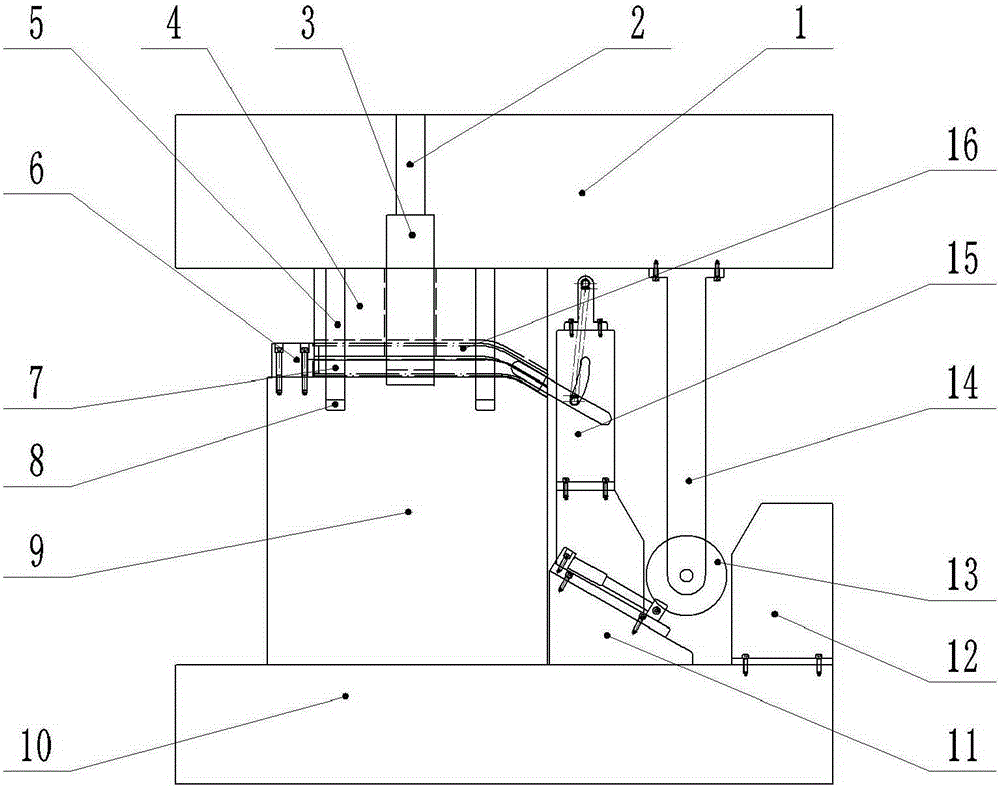

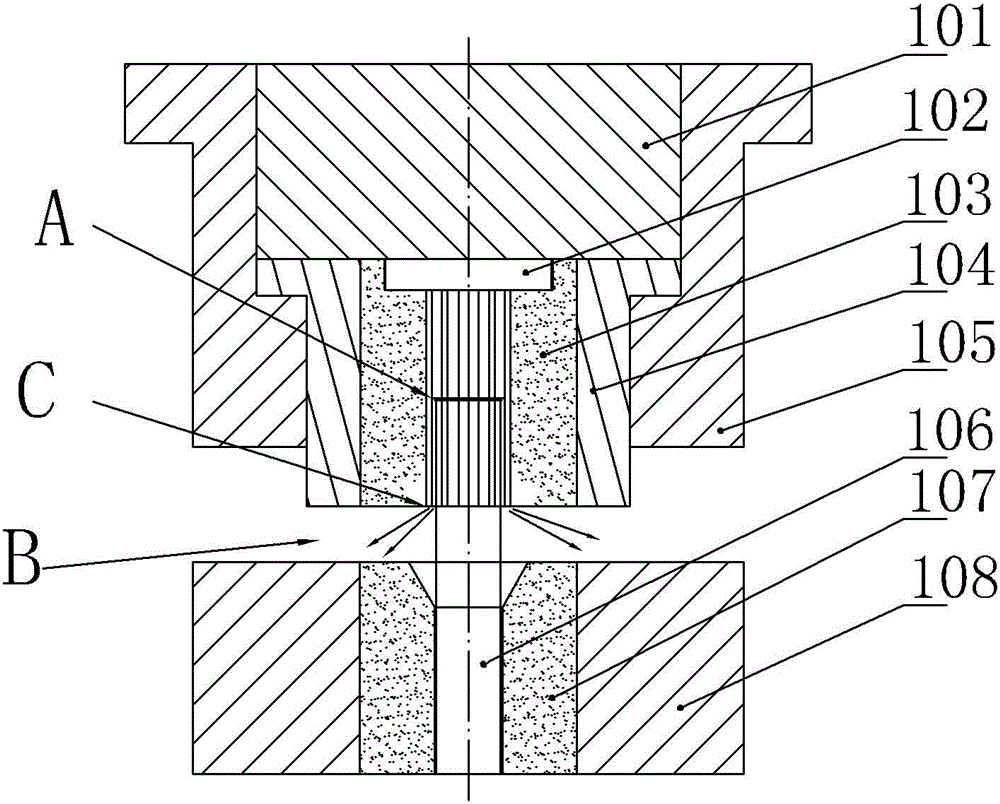

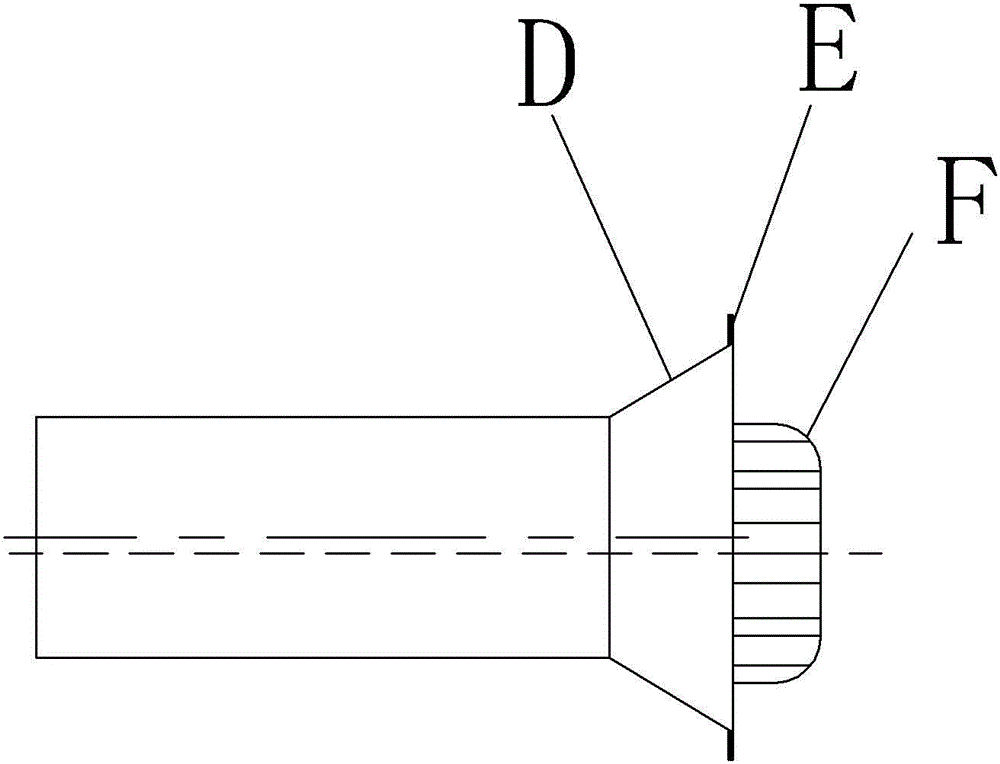

Whole-stamping retainer structure for tapered roller bearings

The invention relates to a whole-stamping retainer structure for tapered roller bearings, which comprises a retainer annular main body formed by a cellular beam and an inner hole, a flange, window holes, a bottom, and arc-shaped bumps; a plurality of window holes are uniformly distributed on the retainer annular main body in a circumferential direction; the annular flange is disposed at the large end and extends outwards in a direction of the central axis of the inner hole away from the retainer annular main body; the arc-shaped bumps are disposed respectively at two ends of each window hole in the axial direction of the retainer annular main body. A trimming die device of the whole-stamping retainer for tapered roller bearings comprises a retainer, a push rod, a discharging ring, a female die, a male die, a lower discharging plate, a spring, a positioning plate, and residual materials; the lower discharging plate is disposed at the outer side of the male die; the upper part of the male die is sleeved with the positioning plate and the retainer; the discharging ring is connected with the push rod, and the inner side of the female die is sleeved with the discharging ring; the purposes of the invention are to innovate the retainer structure, to reduce the plate thickness, and to realize the manufacturing of the retainer by a whole-stamping method.

Owner:LUOYANG YISONG PRECISION BEARING TECH DEV

Flat bending mold of round pipe

The invention relates to a flat bending mold of a round pipe. A sliding mechanism comprises a triangular frame, wherein a slide way is mounted on the inclined plane of the triangular frame through a bolt; a sliding seat is located in the slide way; a flat mechanism comprises a bracket; a spring frame is fixed at the upper part of the bracket through a bolt; a spring shaft is mounted at the high part of the spring frame; the upper ends of two springs are fixed at the two ends of the spring shaft respectively; and a flat template shaft is arranged at the lower ends of the two springs on one side of the bracket and is connected with the two ends of the flat template shaft. The flat mechanism is combined with the sliding mechanism so that flat bending of the round pipe is realized by one-step molding and a product is positioned in one step; the punching precision of the product is improved; and meanwhile, the production efficiency is improved. The resistance is reduced and the design is reasonable. By utilizing regular motion of the flat template shaft in a sliding groove, the front end of the flat template shaft is located in an inner cavity of the pipe and moves along the bending of the pipe, and the movement precision is improved; and meanwhile, the resetting is rapid and powerful, and the front end of a flat template can be conveniently released from the pipe.

Owner:浙江炜驰汽车零部件股份有限公司

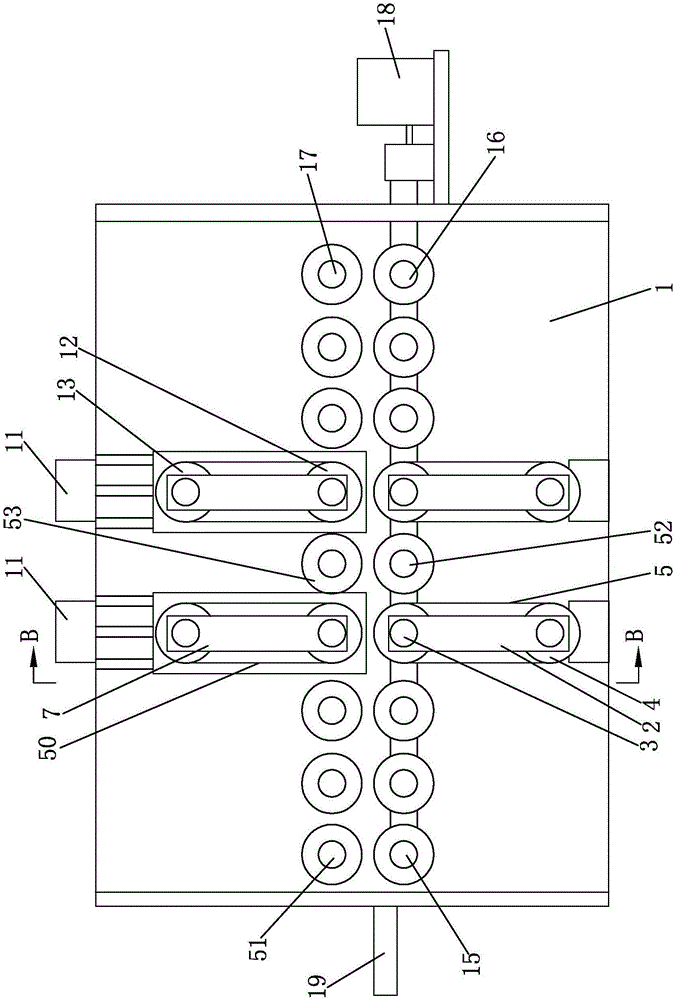

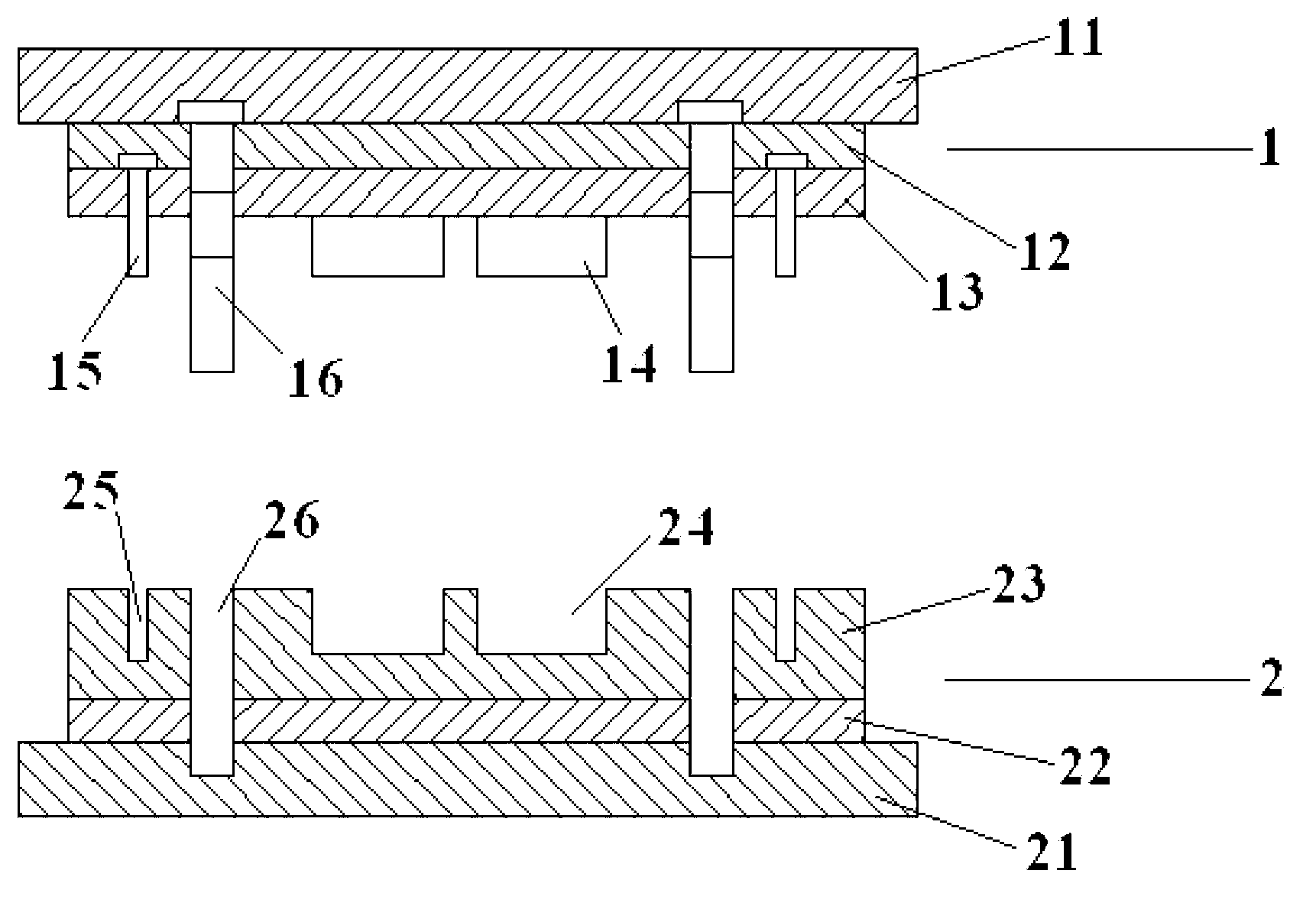

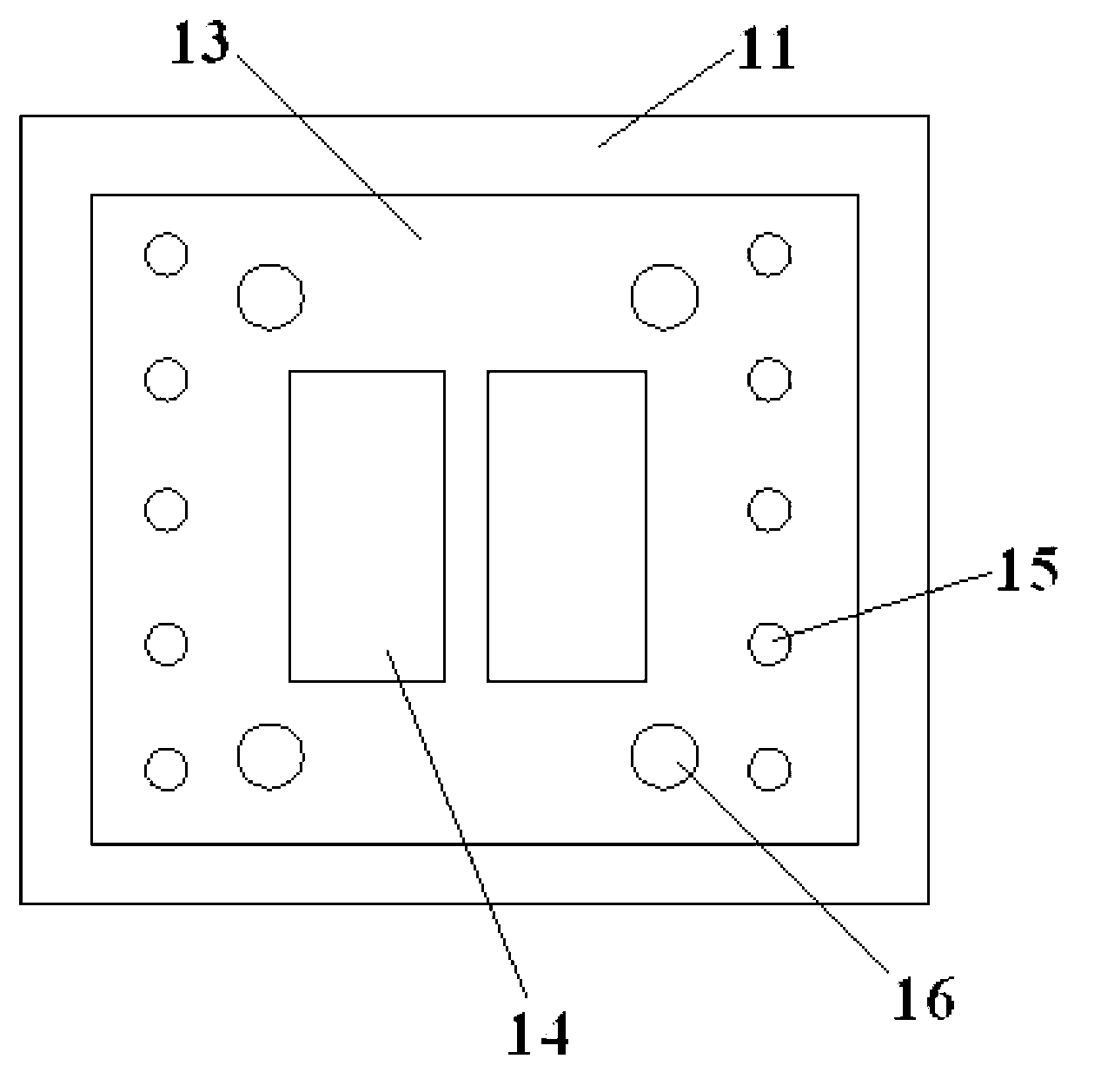

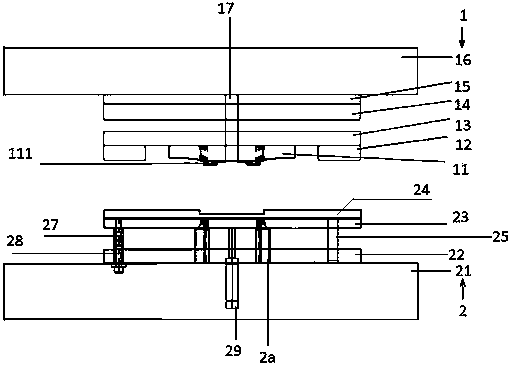

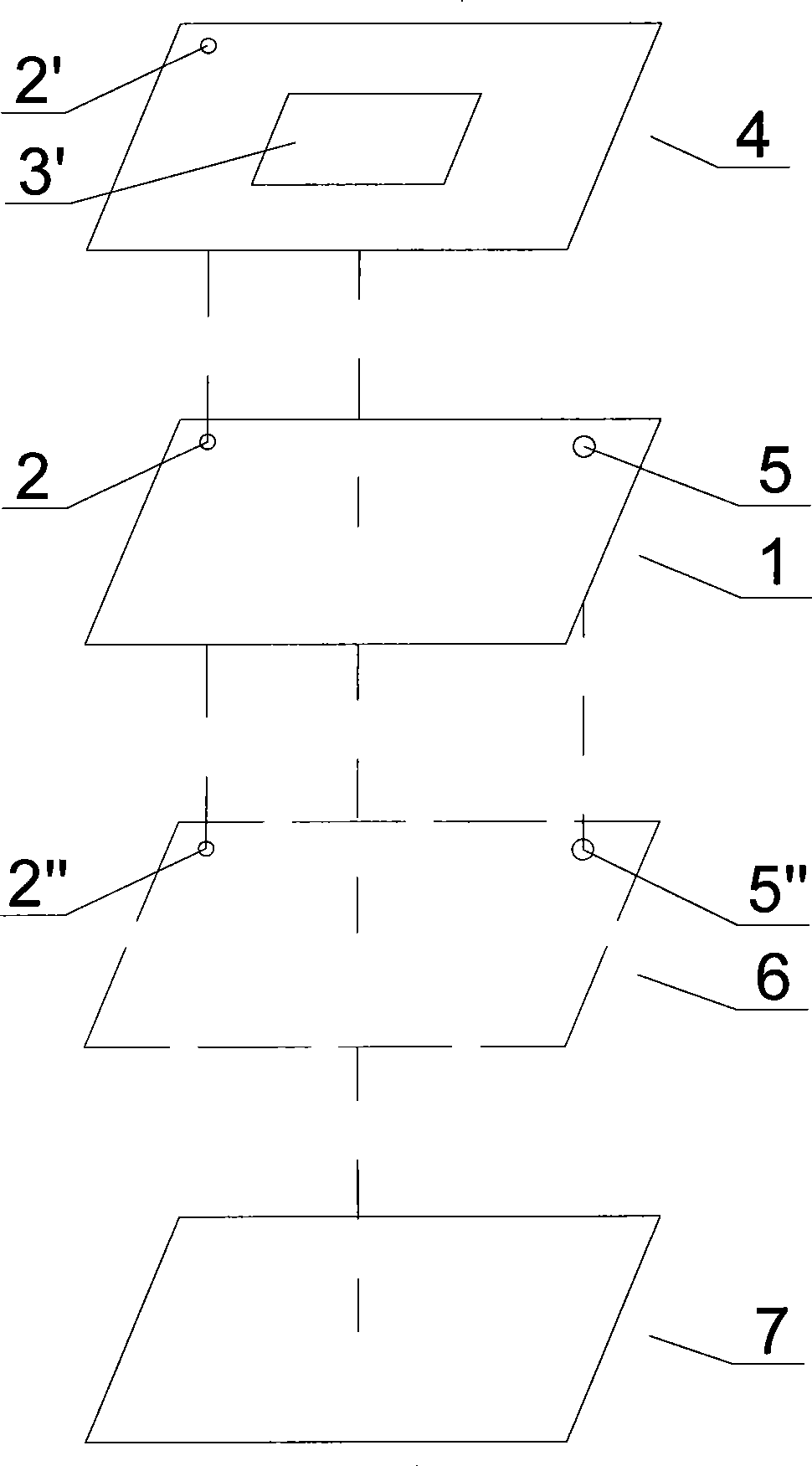

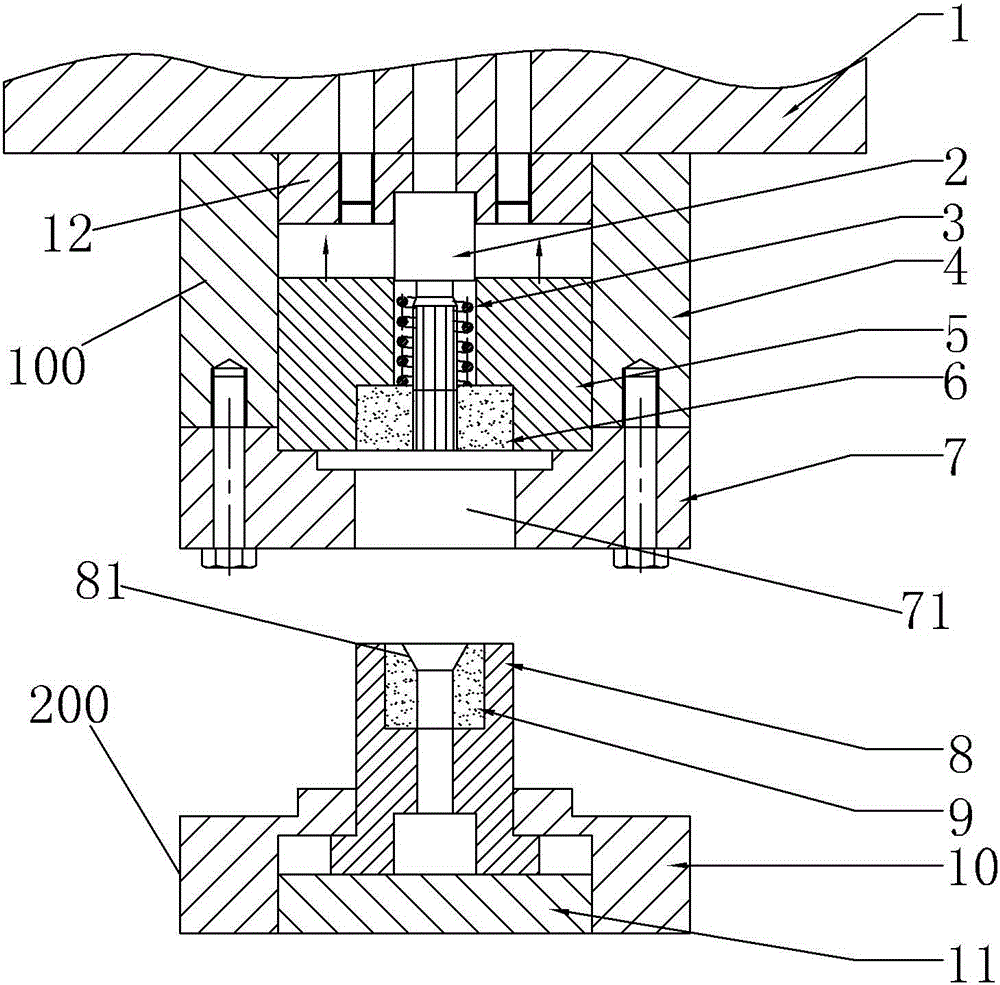

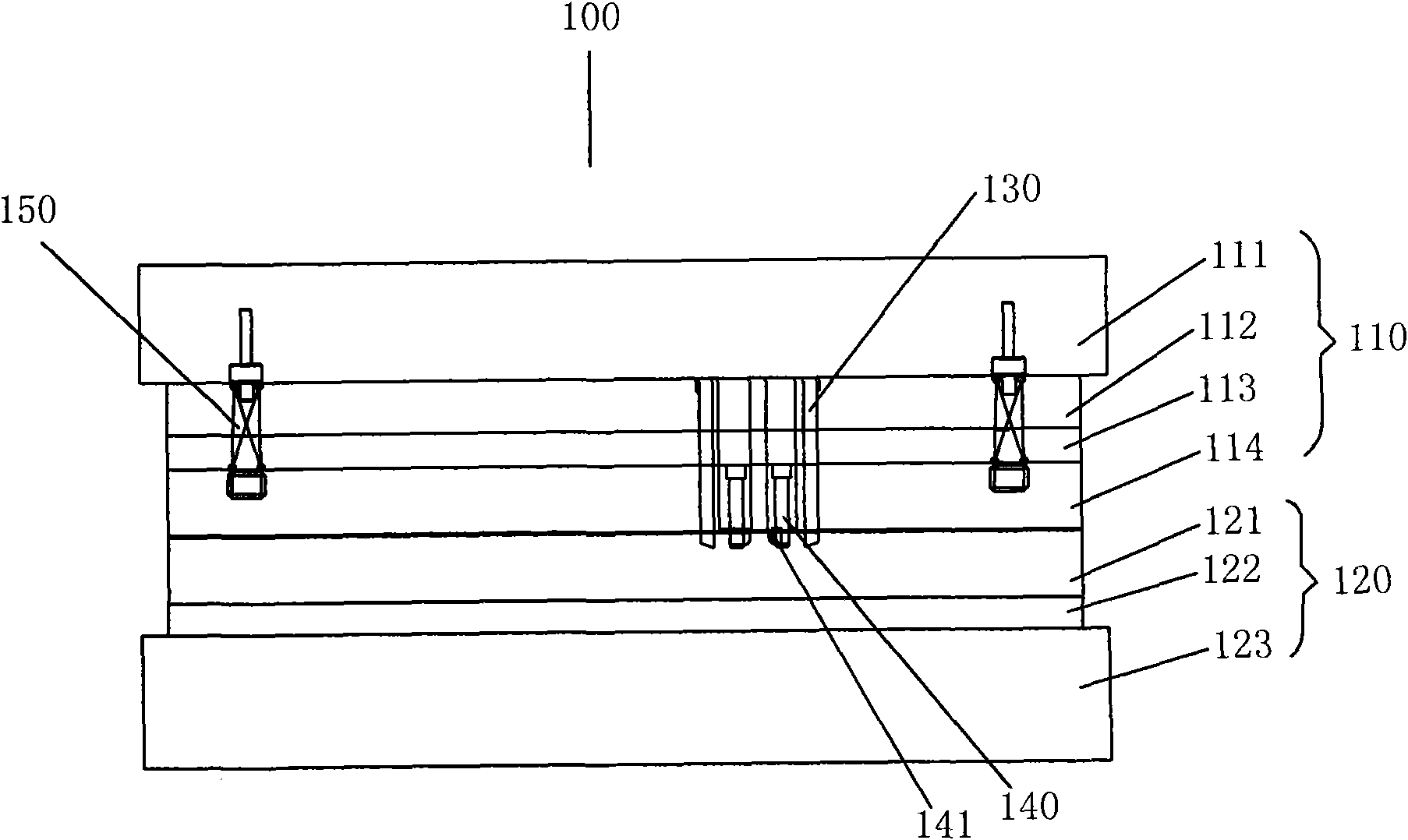

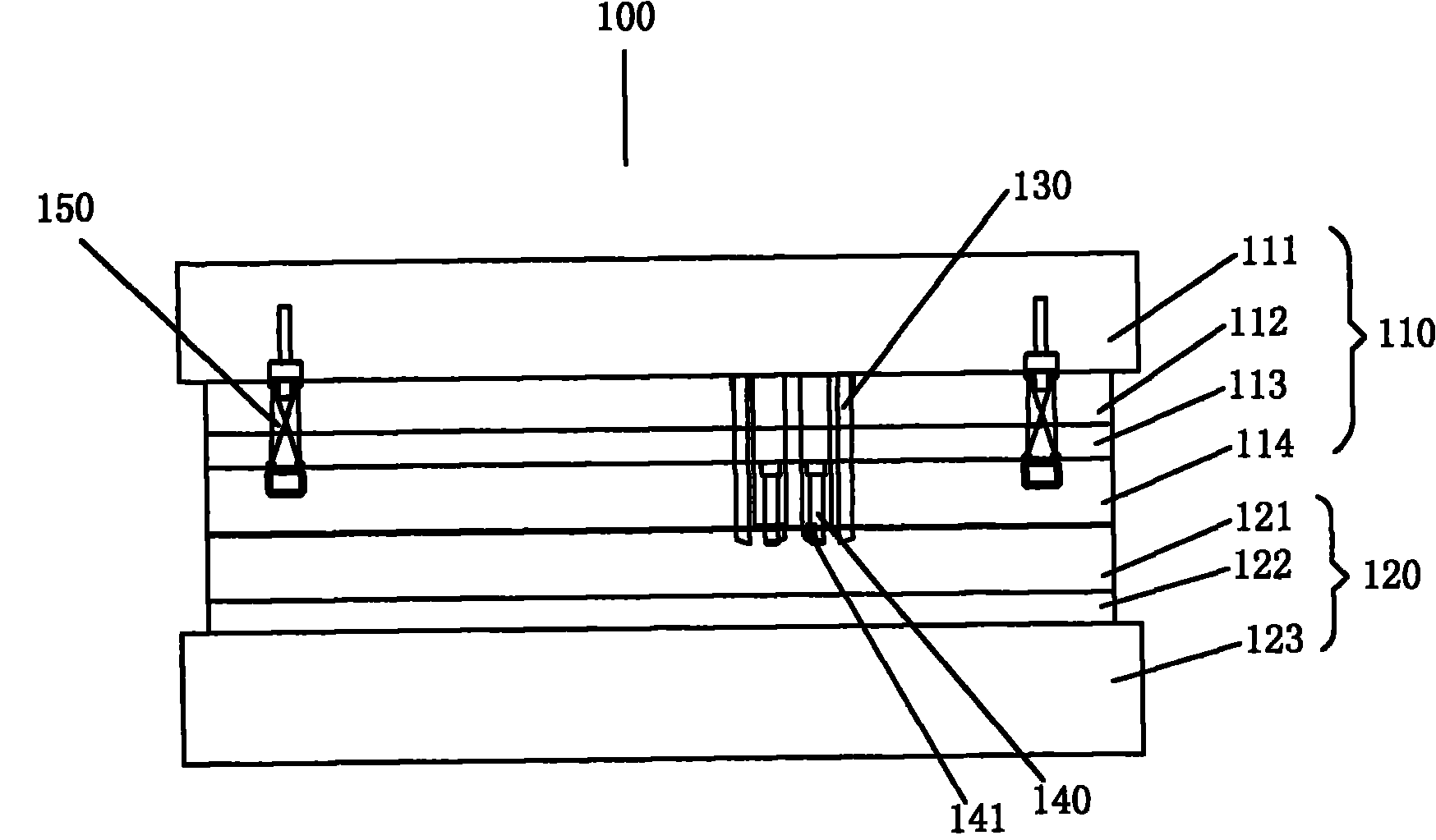

Continuous punching die for punch forming standard component

InactiveCN103071730ASimple production processRealize one-time stampingShaping toolsPunchingResource utilization

The invention provides a continuous punching die for a punch forming standard component. The continuous punching die for the punch forming standard component comprises a moving die and a fixed die, wherein the moving die comprises a moving template, an upper base plate and a fixed plate; the moving template, the upper base plate and the fixed plate are successively connected in sequence; the surface of the fixed plate is provided with a terrace die punch; the inside of the moving die is also provided with a positioning nail and a guide post; the guide post and the terrace die punch are both outwards extruded vertically; the fixed die comprises a fixed template, a lower base plate and a lower template, wherein the fixed template, the lower base plate and the lower template are successively connected in sequence; the surface of the lower template is correspondingly provided with a forming die; the inside of the lower template is also correspondingly provided with a positioning hole and a guide sleeve; the guide sleeve passes through the lower base plate to extend into the fixed template; and the moving die and the fixed die are oppositely installed. According to the die, a plurality of single-working-procedure dies are integrated into one composite die which supports multiple punching working procedures by a simpler structure, one-time punch forming of a standard component product is realized, the production technology is simplified, the manufacture speed is quickened, the product processing precision is improved, and the rejection rate is lowered, so that the enterprise production cost can be lowered, and the production efficiency and the resource use ratio are improved.

Owner:HWA 1 PRECISION MACHINERY KUNSHAN

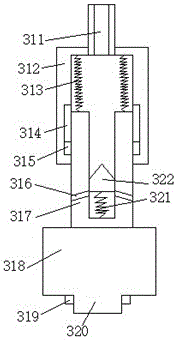

Stamping die control method

ActiveCN104289578AGuarantee stamping qualityPlay the role of automatic safe unloadingShaping toolsMetal-working feeding devicesEngineering

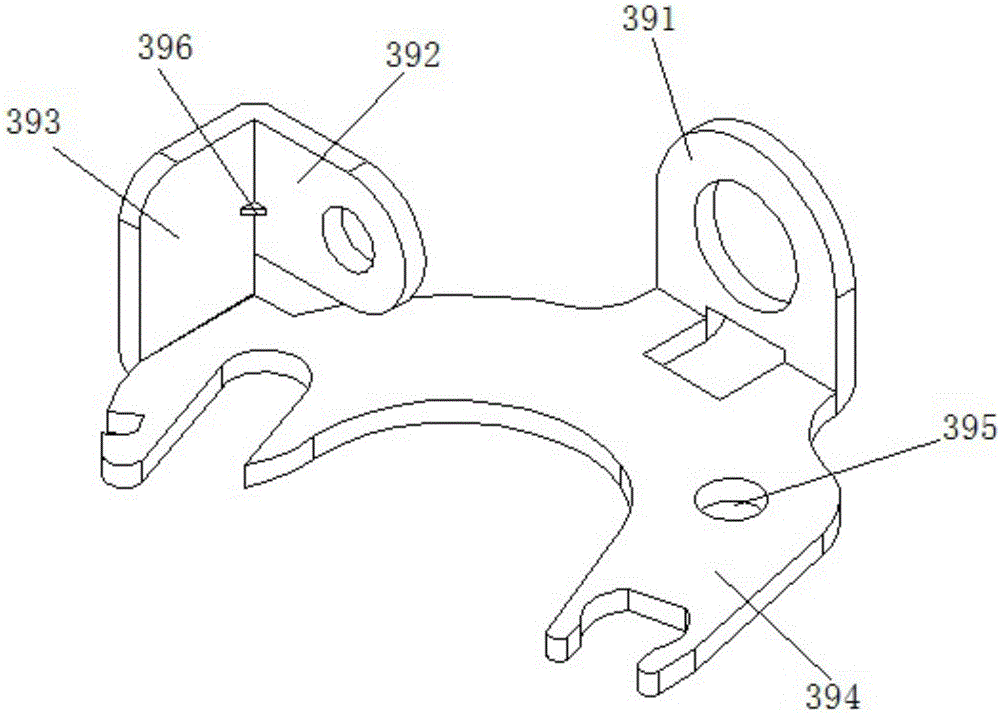

The invention relates to a stamping die control method. The lower end of a locating rod (39) is sleeved with a compression spring (391), the upper end of the compression spring (391) is connected with a T-shaped supporting plate (392), a through hole is formed in the vertical portion of the T-shaped supporting plate (392), the locating rod (39) penetrates through the through hole, and the horizontal portion of the T-shaped supporting plate (392) is used for supporting a stamping part; columnar storing grooves (394) are formed in the upper end of the locating rod (39) in the axial direction, the upper ends or the lower ends of the storing grooves (394) are connected with connecting shafts (395), the two ends of each connecting shaft (395) are fixed on the walls of the storing grooves (394), elastic stop rods (393) are connected with the connecting shafts (395) and are rotatable, and the included angle between each elastic stop rod (393) and the locating rod (39) changes within 0-90 degrees. A stamping part pressing and limiting mechanism has a discharging function, arrangement space in a die is saved, and stamping efficiency is improved.

Owner:东莞市盈德精密五金有限公司

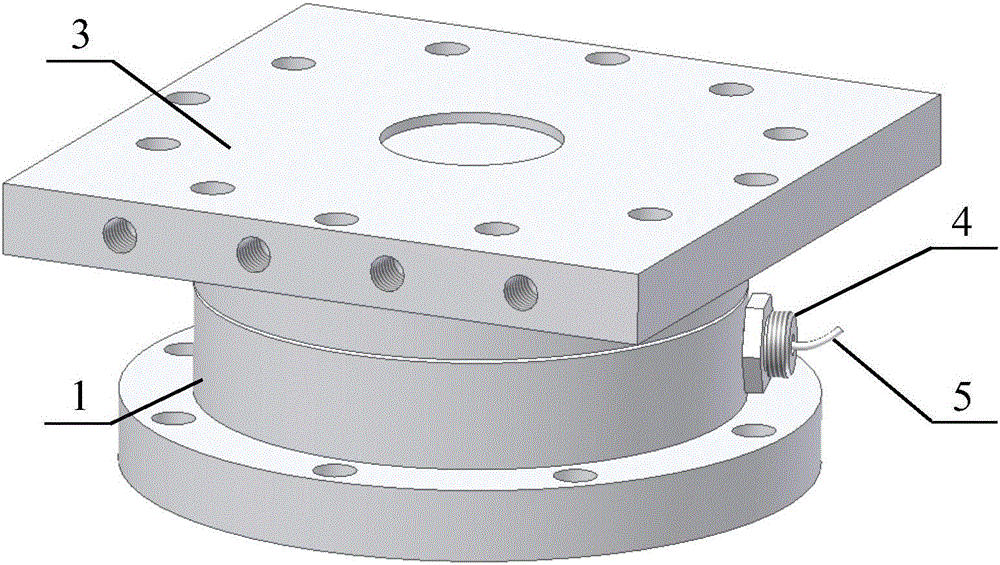

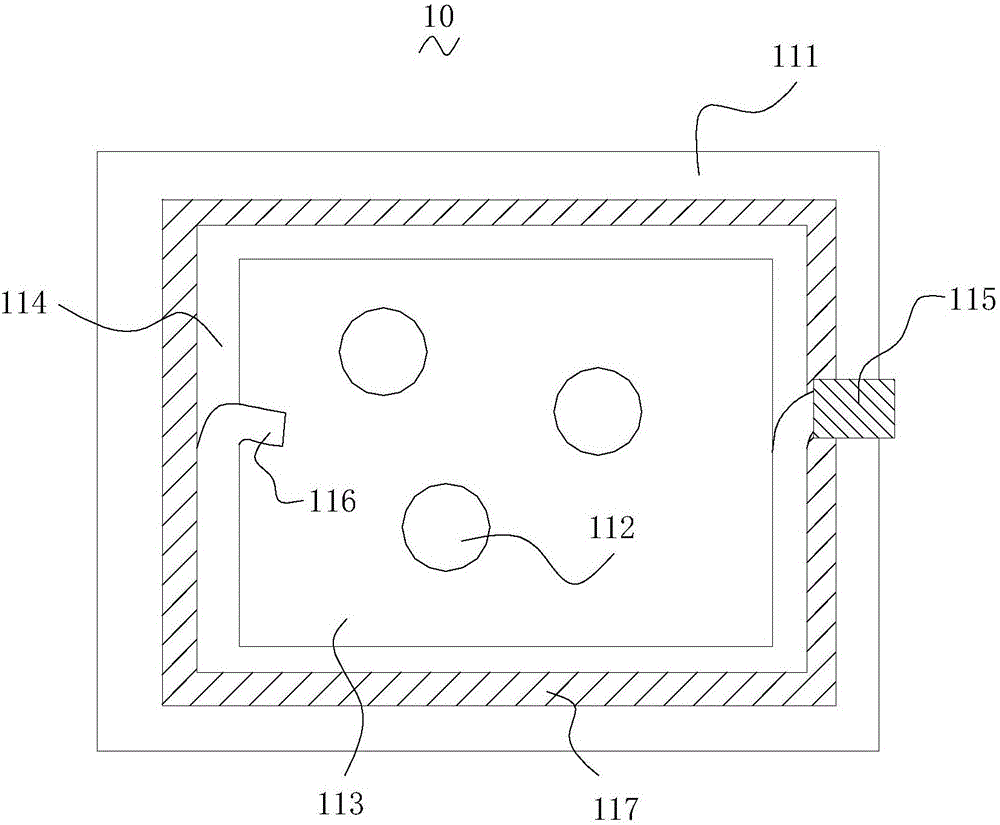

Sheet metal hot stamping force measurement device

ActiveCN106568544AAvoid destructionEnables direct measurementApparatus for force/torque/work measurementHot stampingMeasurement device

A sheet metal hot stamping force measurement device of the present invention belongs to the sensing, measurement and control technology field, in particular relates to a stamping force test technology during a sheet metal hot stamping processing process. The force measurement device is composed of a pedestal, an upper cover, four piezoelectric quartz sensors, a lead wire output interface, a lead wire, a sealing ring, a pre-tightening bolt and a protection pad. The four piezoelectric quartz sensors are distributed inside the force measurement device evenly, and the sensitivity of the force measurement device is improved by a method of combining a plurality of sensors. An integrated load sharing ring structure is arranged in the center of the pedestal, so that the force measurement device is compact in structure and large in rigidity, the situation that the sensors are damaged by the overlarge stamping forces, can be avoided, and the measuring range of the force measurement device is expanded. The upper cover is equipped with a cooling hole, so that the situation that the high temperature is transmitted to the sensors and a press, can be avoided, the service life of the force measurement device and the stamping precision of the sheet material are improved. The force measurement device has the excellent characteristics of being high in rigidity and sensitivity and being high temperature resistant, and can be installed between a hot stamping press sliding block and an upper die directly, thereby measuring the stamping force directly.

Owner:YANTAI VOCATIONAL COLLEGE

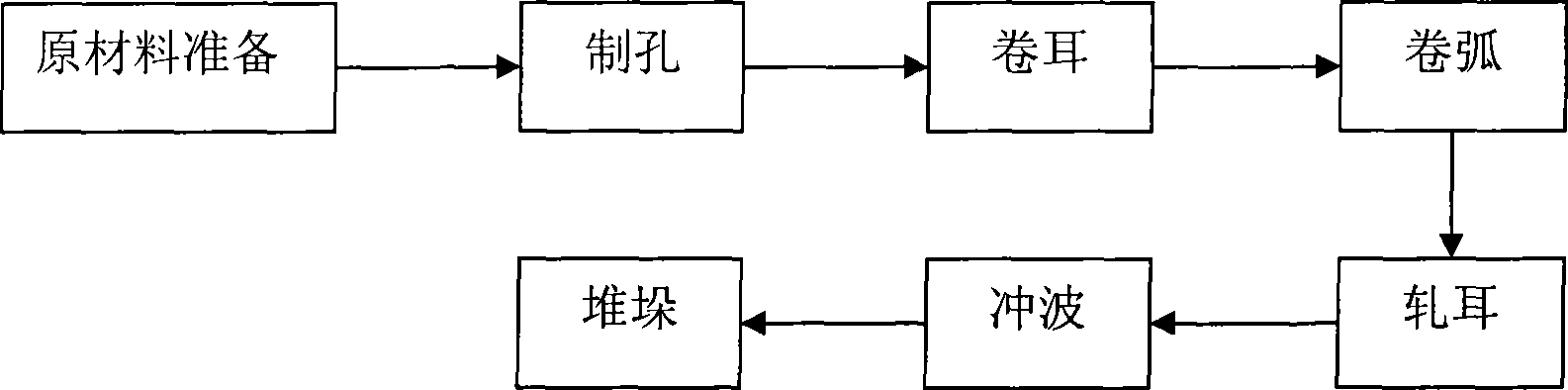

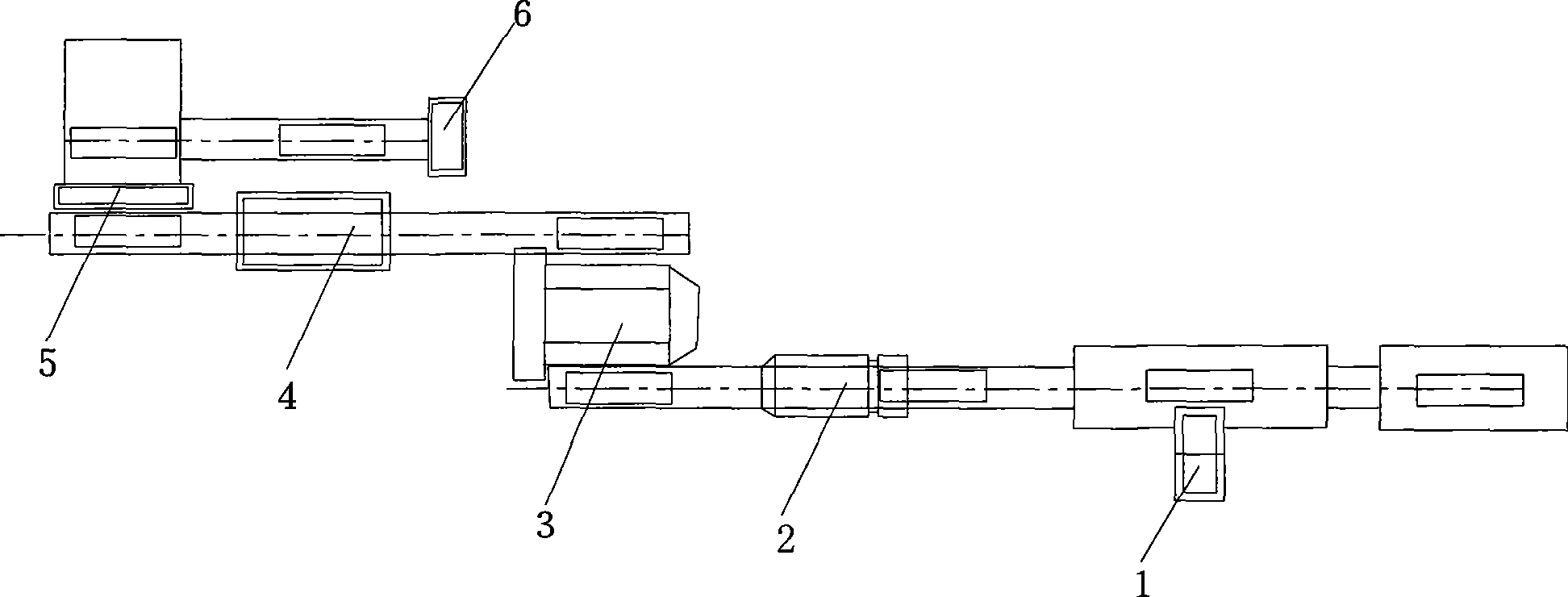

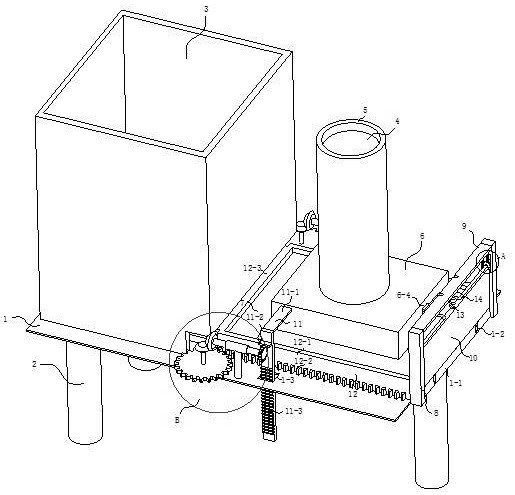

Three-dimensional corrugated steel production technique and special device thereof

The present invention provides a process for producing three-dimensional wave steel plates and special equipment thereof. The producing flow of the process comprises: preparing raw materials, machining holes, reeling lugs, reeling arcs, rolling lugs, punching waves and stacking. The special equipment of the process is formed by sequentially connecting a punching press, a beading machine, a plate reeling machine, a lug rolling press, an overturning mechanism and a wave punching press through a producing and conveying chain, wherein a wave punching protecting mechanism is arranged on the wave punching press. The process adopts PLC programmable control technology on a production line, so as to improve the punching efficiency and precision of holes and waves on the three-dimensional wave steel plates. The visualized screen operation of the process realizes the integrated control of a system; at the same time, through establishing a fault mode, every node in the process of production is monitored, so that the reliability and the intellectualization level of the whole system are improved. At the time of improving production efficiency and finished product quality, manual operation procedures are reduced and labor strength is reduced.

Owner:GUANGZHOU MILITARY AREA AIR FORCE ENG CONSTR BUREAU PLA

Corrugated plate punching device

The invention discloses a corrugated plate punching device, which comprises a bracket. Two parallel vertical guide rails are arranged on the bracket. A sliding block is installed on the bracket in a sliding matched manner. A cylinder is installed on the bracket above the two parallel vertical guide rails. The front end of the piston rod of the cylinder is fixedly connected with the end of the sliding block. An opening is arranged at the bottom of the sliding block. A guide rod is installed in the opening in a sliding matched manner. A left punching block is fixedly welded at the bottom of the guide rod. A spring is sleeved on the guide rod. A right punching block is fixedly installed at the bottom of the sliding block at the right side of the left punching block. Pressure blocks are respectively arranged between the left punching block and the right punching block and outside the left punching block and the right punching block. A lower forming mould is just below the left punching block and the right punching block. The device disclosed by the invention is simple in structure; the device can be used for well locating after completing a previous punching stroke and before carrying out a subsequent punching stroke; the punching precision of corrugated plates is increased; simultaneously, the working efficiency is also increased; the defective percentage is reduced; and the device has good practical value.

Owner:MINGGUANG JIAYI ELECTRIC CONTROL TECH

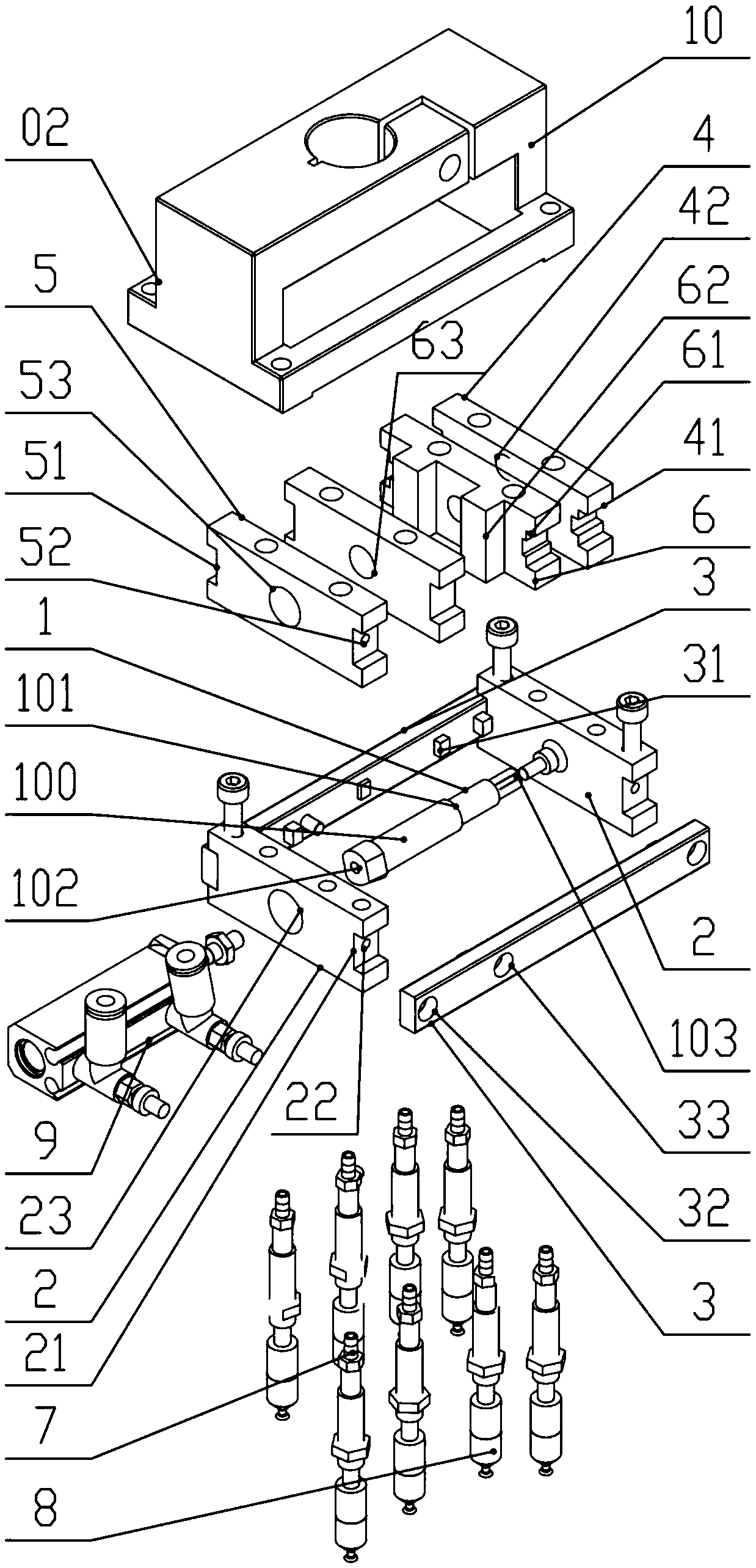

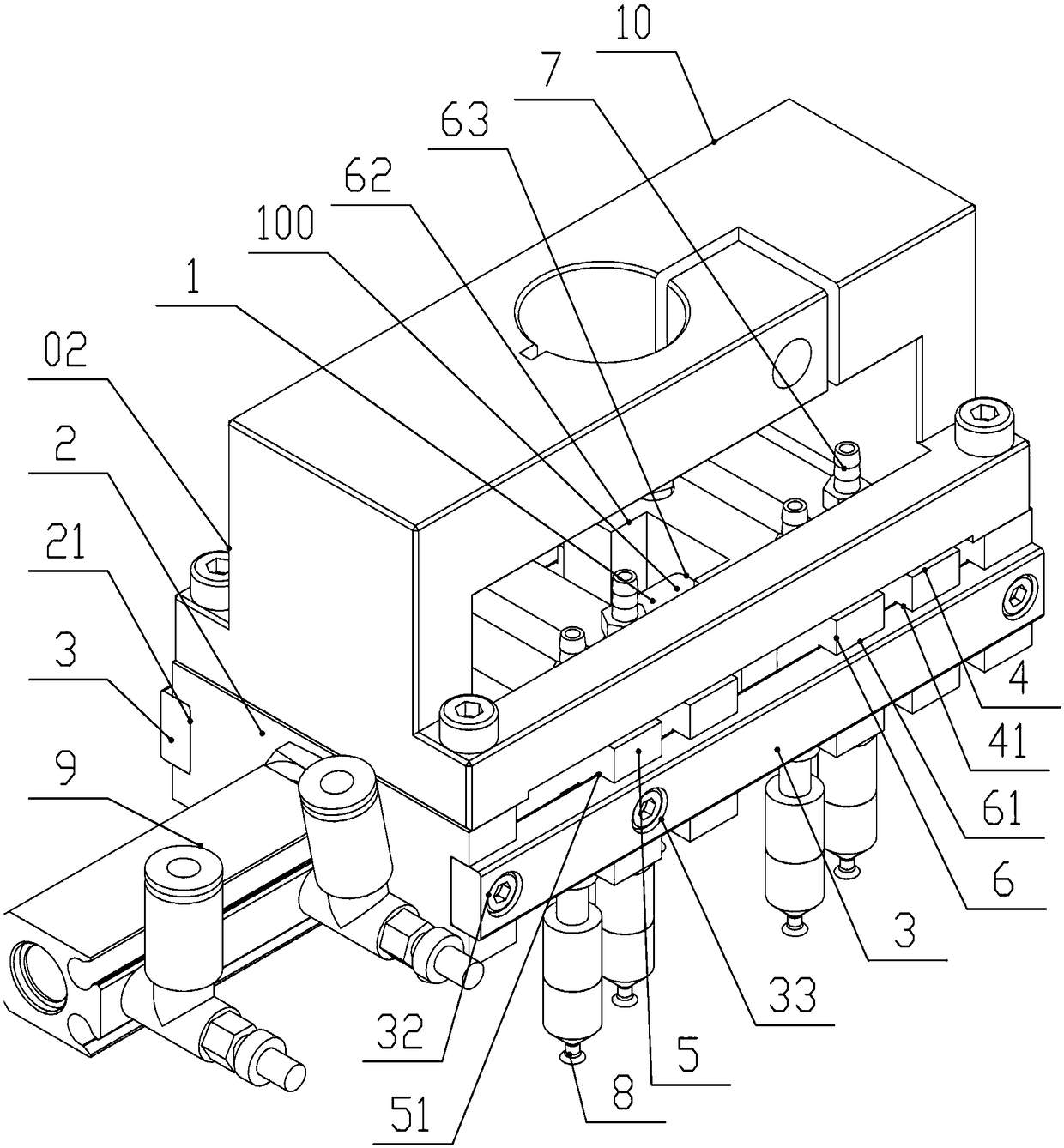

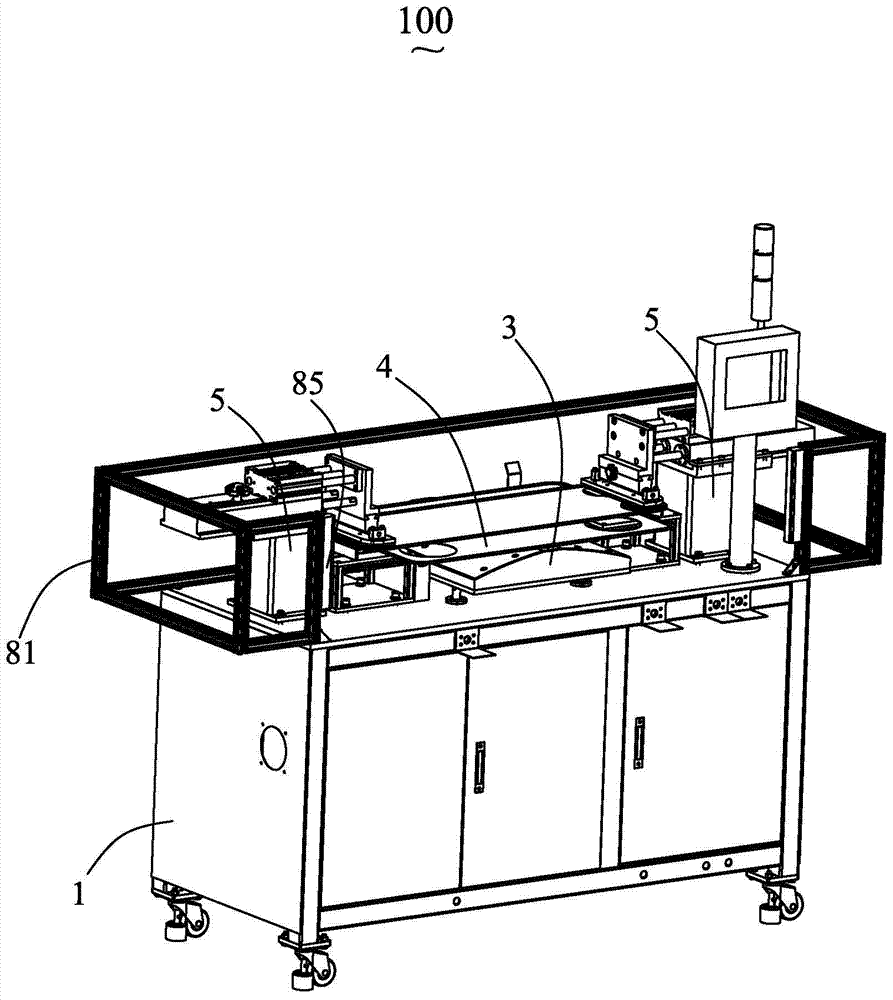

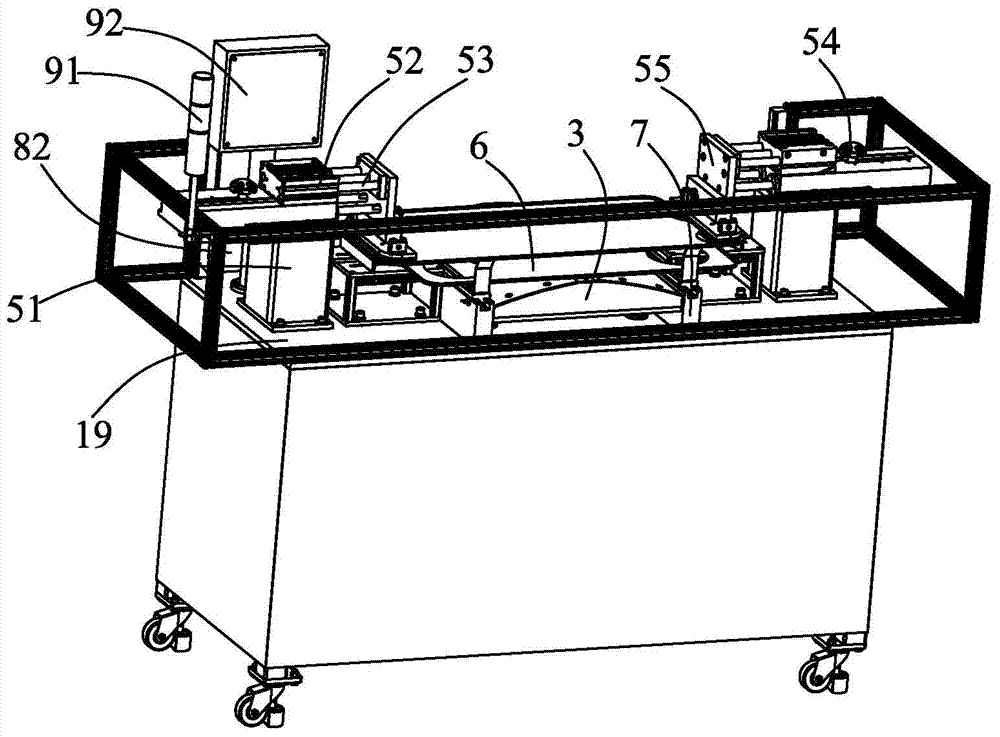

Novel suction head variable in spacing and packaging machine using same

The invention discloses a novel suction head variable in spacing and a packaging machine using the same. The suction head variable in spacing comprises a push rod, a front sliding block is fixed to the front end of the push rod, the rear end of the push rod is sleeved with a rear sliding block, each shaft segment is sleeved with a middle sliding block, the two ends of two wall plates are vertically connected into a rectangular frame through guide rails respectively, the rear sliding block is fixed to the rear ends of the inner side faces of the two guide rails, and the front sliding block andthe middle sliding blocks are slidingly connected to the guide rails; two spring retractable and fast-changing type vacuum suckers are fixed to the front sliding block and the lower end of each middlesliding block separately, the lower end of each air pipe connector is communicated with a vacuum sucker, multiple protrusive limiting blocks are arranged on the inner sides of the guide rails, and aretractable end of a clamping air cylinder penetrates through the wall plate on the rear side to be connected to the rear end of the push rod. The suction head has the advantages that the spacing canbe changed for transferring products, the production efficiency is high, the precision of placing the products is high, and the maintenance utilization rate is decreased.

Owner:SUZHOU LINGYU ELECTRONICS TECH CO LTD

Method for manufacturing hollowed-out board

ActiveCN101453832AImprove stamping precisionAvoid bad rushingPrinted circuit manufactureCopper foilEngineering

The present invention discloses a method for manufacturing a hollow board, which comprises the following steps: pressing a first covering film formed with a punching opening and a punching positioning hole on the first surface of a copper foil; then after a second surface of the copper foil is subjected to line molding, pressing a second covering film on the second surface of the copper foil so as to obtain a circuit board; subsequently, perforating in alignment with the punching positioning hole on the first covering film so as to form a punching positioning through hole on the circuit board; and then punching the circuit board taking the punching positioning through hole as a reference so as to punch out a hollow pattern within the area of the punching opening. The method for manufacturing the hollow board has the advantages that the distance between the punching opening and the punching positioning through hole is kept unchanged, so the distance between the punching opening and the hollow pattern is ensured to be unchanged, the punching precision is improved, and the phenomenon of poor deflective punching is avoided effectively.

Owner:靖江市城中村投资建设有限公司

Servo motor connecting mode

InactiveCN102975387AImprove reliability and stamping accuracyExtended service lifePress ramCrankshaftControl theory

The invention discloses a servo motor connecting mode, which belongs to the technical field of a large-scale closed type pressing machine and adopts a crankshaft, a hollow shaft servo motor, an expansion connecting sleeve and an upper transverse beam, wherein the hollow shaft servo motor is directly and fixedly connected with the crankshaft through the expansion connecting sleeve, an inner tooth sleeve seat and an outer tooth motor seat are also adopted, the outer tooth motor seat is in inner engagement connection with the inner tooth sleeve seat, and the inner tooth sleeve seat is fixedly arranged on the upper transverse beam. The hollow shaft servo motor can realize the position limitation in the circumferential direction, so the torque is provided for the crankshaft, in addition, the outer tooth top of the outer tooth motor seat is made into an ellipsoid surface, in addition, inner and outer teeth have the proper top gap and the side gap, the axial and radial displacement and the angular displacement of the outer tooth motor seat can be allowed, the servo motor and the outer tooth motor seat of the servo motor realize the flexible connection with the inner tooth sleeve seat, and the micro torsion bending deformation of the crankshaft can be automatically adapted at any time in the punching process, so the reliability and the punching precision of the servo motor are improved, the service life of the servo motor is prolonged, and the production cost is reduced.

Owner:JIANGSU XUZHOU METALFORMING MACHINE GROUP

Novel punching machine

The invention relates to a novel punching machine. The novel punching machine comprises a rack, a driving device, a crank shaft, a first crank shaft connection rod, a second crank shaft connection rod, a first horizontal guide block, a second horizontal guide block, a first adapter coupling connection rod, a second adapter coupling connection rod, a first vertical guide connection rod, a second vertical guide connection rod, a first lever, a second lever, a first mold adjusting connection plate, a second mold adjusting connection plate, a first slide block connection rod, a second slide block connection rod, a slide block and a worktable, wherein the driving device is in driving connection with the crank shaft; the crank shaft is in drive connection with the first crank shaft connection rod, and the second crank shaft connection rod respectively; and the slide block is located above the worktable. The novel punching machine provided by the invention has the advantages of simple structure, small inertia and high precision; the staying time of a bottom dead center is long, a punching surface of a punched workpiece is smooth and the quality of the punched workpiece is improved; and a stressed reversed impact force is small, abrasion to equipment is small and the service life of the equipment is prolonged.

Owner:MINGXUDONGGUAN PRECISION MACHINARY CO LTD

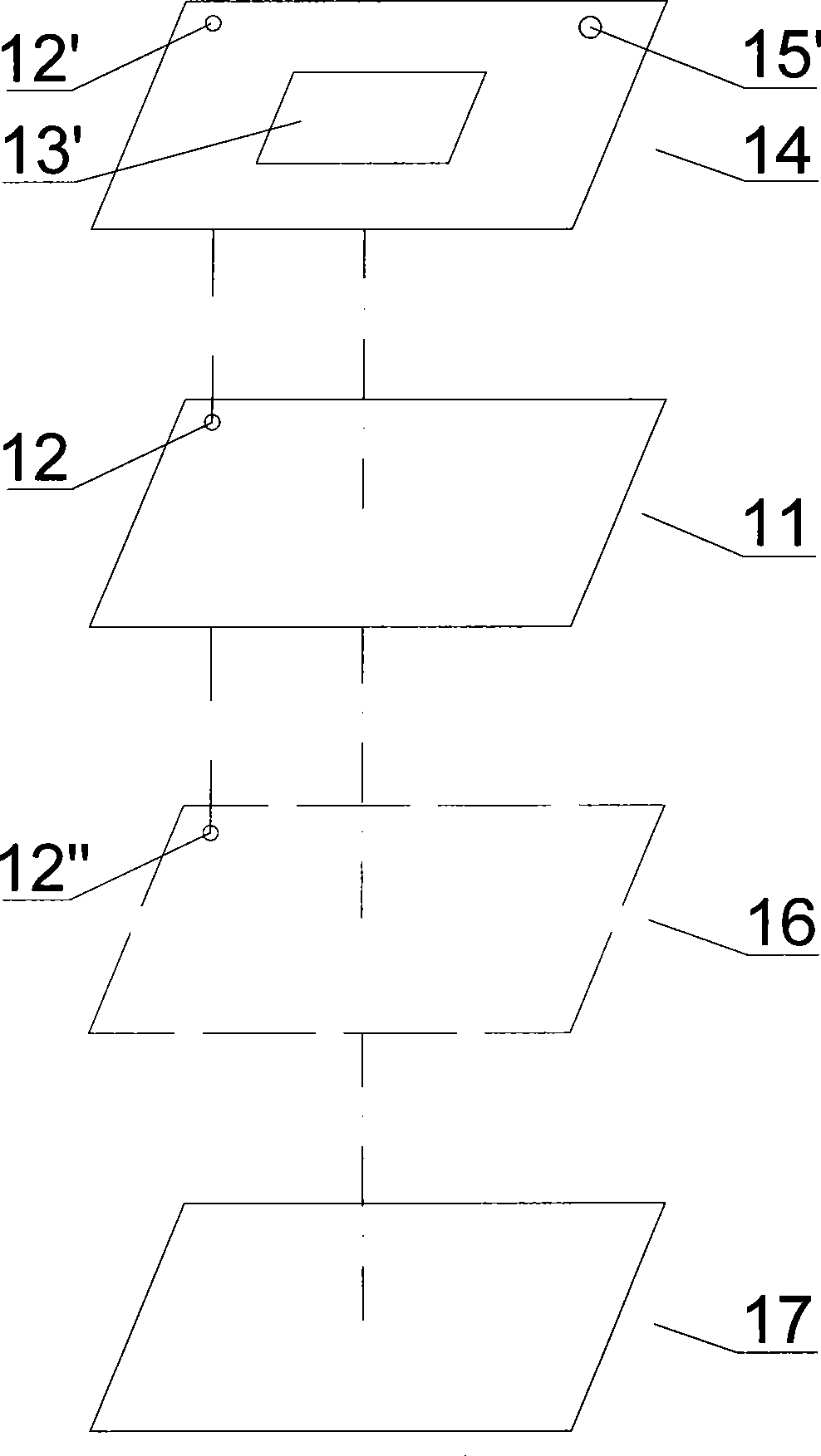

Shape-keeping fine stamping die for stamped part of refrigerator

ActiveCN106623636AReduce frictionReduce wasteShaping toolsPulp and paper industryRefrigerated temperature

The invention discloses a shape-keeping fine stamping die for a stamped part of a refrigerator. The shape-keeping fine stamping die for the stamped part of the refrigerator comprises an upper die plate and a lower die plate, wherein the upper die plate is positioned above the lower die plate; the bottom end of the upper die plate is connected with a stamping device; the stamping device comprises a first connecting column; a first groove is formed in the bottom end of the first connecting column; a second connecting column and a first spring are arranged in the first groove; the top end of the first spring is fixed at the top end of the first groove; and the bottom end of the first spring is connected with the second connecting column. The shape-keeping fine stamping die for the stamped part of the refrigerator comprises the stamping device; the stamping device is connected with an oil inlet tube; by matching effects of the first connecting column, the first spring, a third groove, limiting blocks, first through holes, the second connecting column, a second spring and a moving block, hydraulic oil in the first groove can be sprayed out during stamping every time, and lubricates the stamped part to make a preparation for next stamping, friction between contact surfaces is reduced, adhesion between metals is avoided, abrasion is reduced, and waste of the lubricating oil is also reduced.

Owner:滁州美业科技股份有限公司

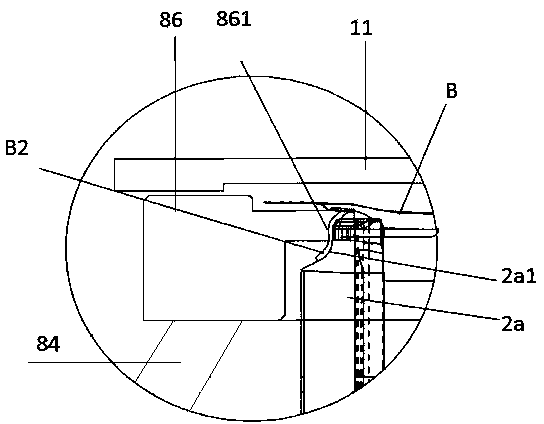

Hot upsetting die and upper die thereof

ActiveCN105195658AAvoid shakingAvoid misalignmentForging/hammering/pressing machinesCore componentEngineering

The invention provides a hot upsetting die and an upper die thereof. The hot upsetting die comprises the upper die and a lower die, wherein the lower die comprises a lower die core component; the upper die comprises an upper die sleeve; an upper die core component is assembled in the upper die sleeve along the up-down direction in a guide moving way; an ejector pin is arranged in the upper die sleeve; a spring which applies an acting force for forcing the upper die core component to downwards move, so that the upper die core component is butted with the lower die core component to form a closed formed cavity before the ejector pin stamps a workpiece, is arranged in the upper die sleeve; the ejector pin and the upper die core component are assembled along the up-down direction in a guide moving way; the upper end of the spring presses against the ejector; the lower end of the spring presses against the upper die core component; the ejector presses against and is assembled on a die cushion which is fixedly arranged on an upper die holder under the action of the spring; during die stripping, the ejector pin moves upwards along with the upper die holder, and the upper die core component moves downwards under the action of the spring, so that the ejector pin can be quickly separated from the stamped workpiece, and the die stripping is favorably realized.

Owner:河南航天精工制造有限公司

Automated punching equipment

The invention relates to automated punching equipment. The automated punching equipment comprises a punching device and a manipulator, wherein the punching device comprises a machine table, a driving assembly, two oppositely-arranged punching assemblies and a locating frame. A connecting assembly is arranged between the two punching assemblies and comprises an abutting member, a sliding member and a compression spring, the two ends of the sliding member are separately connected with the abutting member and the compression spring, the driving assembly is abutted against the abutting member, and the two sides of the sliding member are separately abutted against the two punching assemblies. According to the automated punching equipment, the accuracy of punching is relatively high, and the driving efficiency of the driving assembly is relatively high.

Owner:珠海市金质精密科技有限公司

Fast stamping die with bending stamping head

InactiveCN101850385AReduce manufacturing costTo achieve the purpose of one-time moldingShaping toolsStampingEngineering

The invention discloses a fast stamping die with a bending stamping head, which comprises an upper die and a lower die, wherein a space used for molding products is reserved between the upper die and the lower die, the upper die mainly consists of an upper die base, an upper splint, an upper backing plate and an upper template which are overlapped sequentially, the lower die consists of a lower template, a lower subplate and a lower die base which are overlapped sequentially, a half-cutting stamping head is vertically fixed on the upper splint, and a bending stamping head used for bending the products is vertically fixed on the upper splint. With the fast stamping die with bending stamping, when the upper die moves downwards, the bending stamping head and the half-cutting stamping head move downwards following the upper die, the product is cut by the half-cutting stamping head firstly, and then the cut product is bent by the bending stamping head so as to achieve the purpose of one-step molding and increase the work efficiency; and in addition, a spring is added between the upper die base and the template so as to obviously increase the stamping precision and reduce the production cost for enterprises.

Owner:JIANGSU RONGTENG PRECISION COMPONENTS

Automatic punching device

ActiveCN106734530AImprove processing efficiencyIncrease the feeding speedShaping toolsMetal-working feeding devicesEngineeringPunching

The invention relates to an automatic punching device. The automatic punching device comprises a base, a punching assembly and a feeding assembly; a punching platform is arranged on the base; a supporting part is arranged on the base in a protruding mode; a feeding channel is arranged in the punching platform; a plurality of punching holes are formed in the surface of the punching platform; the punching assembly comprises a driving part and a punch; the feeding assembly comprises a pulling piece and a feeding belt; a plurality of containing cavities are formed in the feeding belt; a guide rod is further arranged on the base in a protruding mode, and the guide rod and the supporting part are arranged at intervals; a guide sliding groove is arranged on the guide rod in a concave mode; a plurality of punching ends are arranged on the punch; and a guide bar is further arranged on the side wall of the punch in a protruding mode and is arranged in the guide sliding groove in a sliding mode. The automatic punching device is high in machining efficiency.

Owner:江苏环海机械科技有限公司

Stamping oil composition

ActiveCN106701274APrevent spoilageImprove extreme pressure performanceLubricant compositionChemical compositionAntioxidant

The invention provides a stamping oil composition. The stamping oil composition is prepared from, by weight, 1-5 parts of macromolecular polymerization ester, 1-3 parts of dialkyl pentasulfide, 2-8 parts of vulcanized cottonseed oil, 0.5-2.2 parts of oleic acid, 0.2-1 part of di-n-butyl phosphite, 0.03-0.05 part of antioxidant, 1-2 parts of petroleum sulfonate, 0.01-0.4 part of anti-rust agent and 78-95 parts of mineral base oil. The prepared stamping oil composition has very good extreme pressure, lubricity, anti-rust property and oxidation resistance, stamping oil acts on a stamping device and can prolong the service life of the device, and the stamping precision of the device can be improved.

Owner:ZHEJIANG OCEAN UNIV

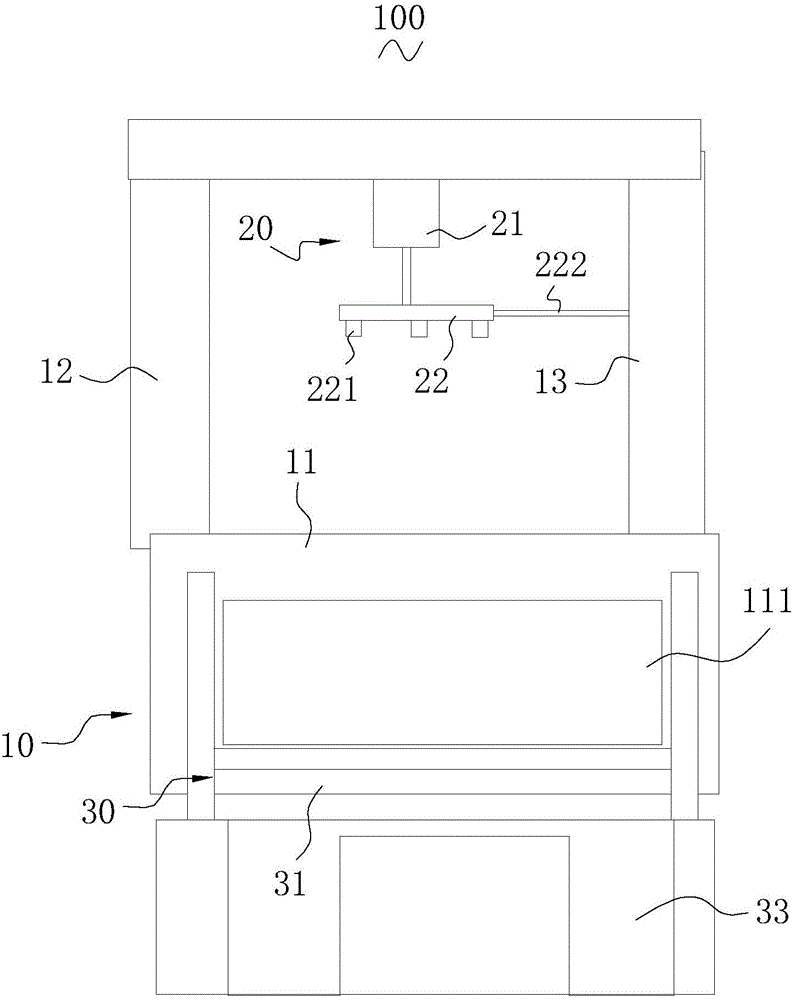

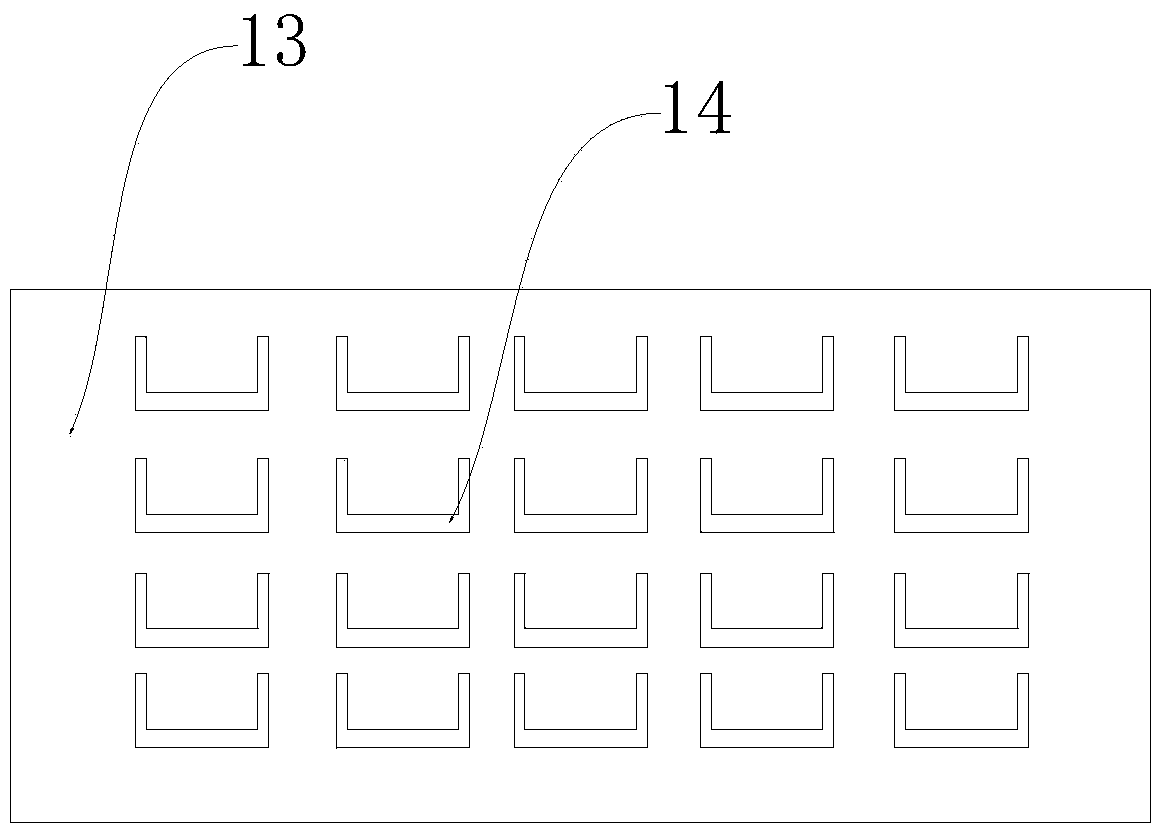

Stamping device of ventilation plate

InactiveCN103658299AImprove stamping precisionReduce volumeMetal-working feeding devicesPositioning devicesPunch pressMechanical equipment

The invention relates to the field of mechanical equipment and particularly discloses a stamping device of a ventilation plate, wherein the stamping device of the ventilation plate is low in production cost and little in energy consumption. The stamping device of the ventilation plate comprises a punch press and a moving clamp, the moving clamp is arranged on the face right opposite to the punch press, the moving clamp structurally comprises a base, a pedestal is arranged on the base, a longitudinal slide rail is arranged on the pedestal, a connecting arm is arranged on the longitudinal slide rail, a nut is arranged at the bottom of the connecting arm, and the nut is arranged on a longitudinal screw rod in a sleeved mode. A pneumatic gripper is arranged on the portion, close to one end of the punch press, of the connecting arm. According to the stamping device of the ventilation plate, a row of concave dies are arranged on a stamping die, the ventilation plate is stamped many times, and thus the size of the die can be effectively reduced, the stamping pressure and energy consumption can be reduced. Through transverse motion of the pedestal and longitudinal motion of the connecting arm, the pneumatic gripper can move in the horizontal plane so that the ventilation plate can be moved and positioned. Moreover, motion of the pneumatic gripper is achieved through the screw rod and the nut, so that the pneumatic gripper performs positioning more accurately, and thus the stamping accuracy of the ventilation plate is improved.

Owner:JIAXING YONGFA ELECTRONICS

Flattener

A flattener comprises a cabinet, a supporting platform, a servo electric cylinder and a punching head, wherein the supporting platform is mounted above the cabinet, and the punching head is positioned above the servo electric cylinder. The cabinet is provided with a containing cavity positioned below the supporting platform, at least part of the servo electric cylinder is placed in the containing cavity, and the servo electric cylinder drives the punching head to move upwards and is used for flattening a workpiece positioned above the punching head. By the aid of the servo electric cylinder with high control accuracy, punching accuracy of the flattener is improved.

Owner:SUZHOU TONG JIN AUTOMATION EQUIP

Adjustable press

The invention provides an adjustable press, which includes an operation table, an adjustment plate, a cylinder, an upper pressing block, a lower cushion block and a controller, and is characterized in that: the operation table is arranged on a support, and the adjustment The plate is set on the column through the connecting ring, the cylinder is set on the adjustment plate, the upper pressing block is set on the limit rod, and the lower cushion block is set with a mounting block and a bearing groove. The present invention is provided with a plurality of air cylinders on the adjustment plate, and an upper pressure block is arranged on the piston rod of the cylinder, and the adjustment plate is set as a structure that can rotate on the column, and the position of the adjustment plate on the column can be adjusted by rotating the position of the adjustment plate. Different upper pressing blocks stamp the workpiece on the lower block, which improves the scope of application of the press and reduces the cost of manufacturing multiple presses. Setting the upper pressing block on the limit rod not only improves the With the stability in the process of rising or falling of the piston rod, the stamping accuracy of the upper pressing block on the workpiece can also be enhanced.

Owner:ANHUI HAITUO ZHIYONG INTELLIGENT EQUIP CO LTD

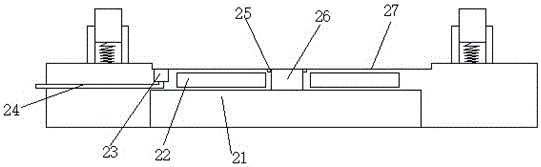

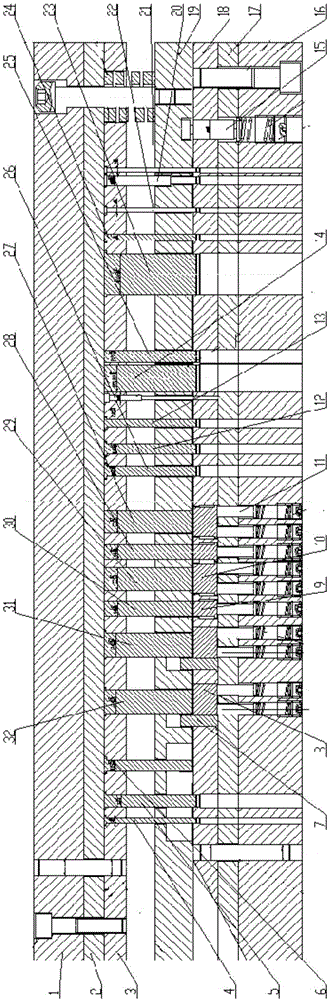

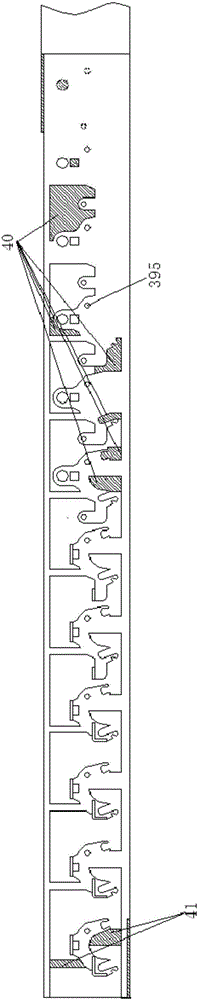

Multi-station progressive die for punching of electric appliance contact support and blanking process

ActiveCN106734600AIncrease productivityShorten the production cycleShaping toolsPerforating toolsPunchingElectrical equipment

The invention relates to a multi-station progressive die for punching of an electric appliance contact support and a blanking process of the multi-station progressive die. The progressive die comprises an upper die, a lower die, a work assembly and a fixed-distance positioning assembly. The work assembly comprises a punching male die, a bending shaping male die, a ribbing wedge, a cutting male die and a female die plate, wherein the punching male die, the bending shaping male die, the ribbing wedge and the cutting male die are sequentially arranged on the upper die, and the female die plate is arranged on the lower die. The female die plate is sequentially provided with a punching female die, a bending and shaping female die, a ribbing sliding block and a cutting female die, all of which are matched with corresponding work assemblies on the upper die. The fixed-distance positioning assembly is composed of a double-side-edge mechanism and a guide pin mechanism. The blanking process includes punching, bending shaping and ribbing which are sequentially conducted. Compared with the prior art, the multi-station progressive die for punching of the electric appliance contact support is wide in application range, high in production efficiency, high in manufacturing precision and convenient to maintain.

Owner:SHANGHAI UNIV OF ENG SCI

Steel plate straightening and stamping integrated equipment for rolled steel

InactiveCN111790809AEasy to unloadPrecise positioningMetal-working feeding devicesPositioning devicesSteel platesStamping

The invention discloses steel plate straightening and stamping integrated equipment for rolled steel, and relates to the field of rolled steel stamping. The equipment comprises a lower die plate, supporting columns, a stamping die column, a straightening pressing plate and a connecting sleeve; the lower die plate is fixedly connected with the ground through the supporting columns, the straightening pressing plate is connected with the stamping die column through the connecting sleeve, and the stamping die column and the straightening pressing plate are externally connected with a driving piece; and a feeding device, a material returning device, a reversing structure and a sealing plate are fixedly arranged on the lower die plate, the reversing structure is connected with a straightening pressing plate through a transmission plate, a lifting structure is arranged on the sealing plate, and a telescopic traction structure is arranged on the straightening pressing plate. The steel plate straightening and stamping integrated equipment for the rolled steel solves the technical problems that a traditional device is discontinuous in stamping and low in precision.

Owner:北京康乾白祥商贸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com