Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

84results about How to "Guarantee stamping quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

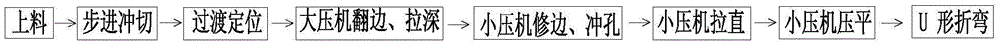

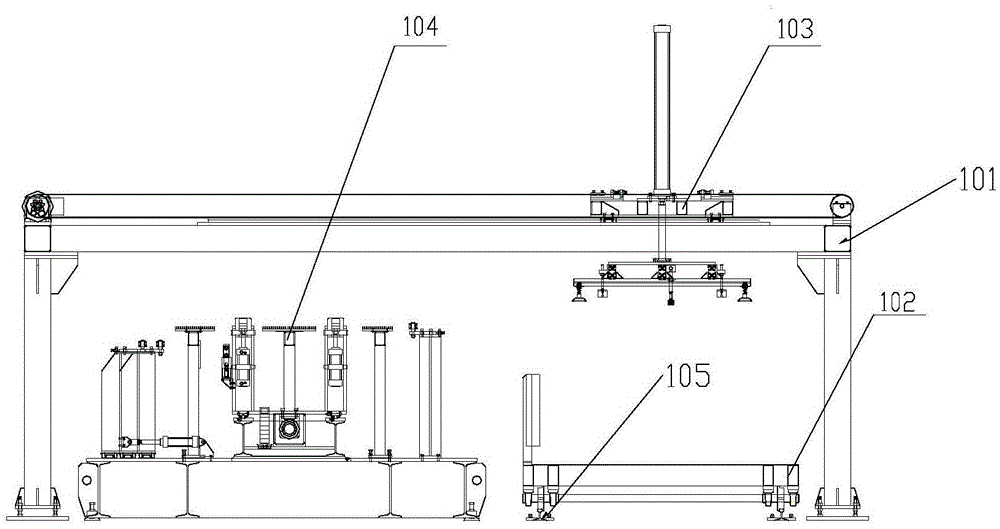

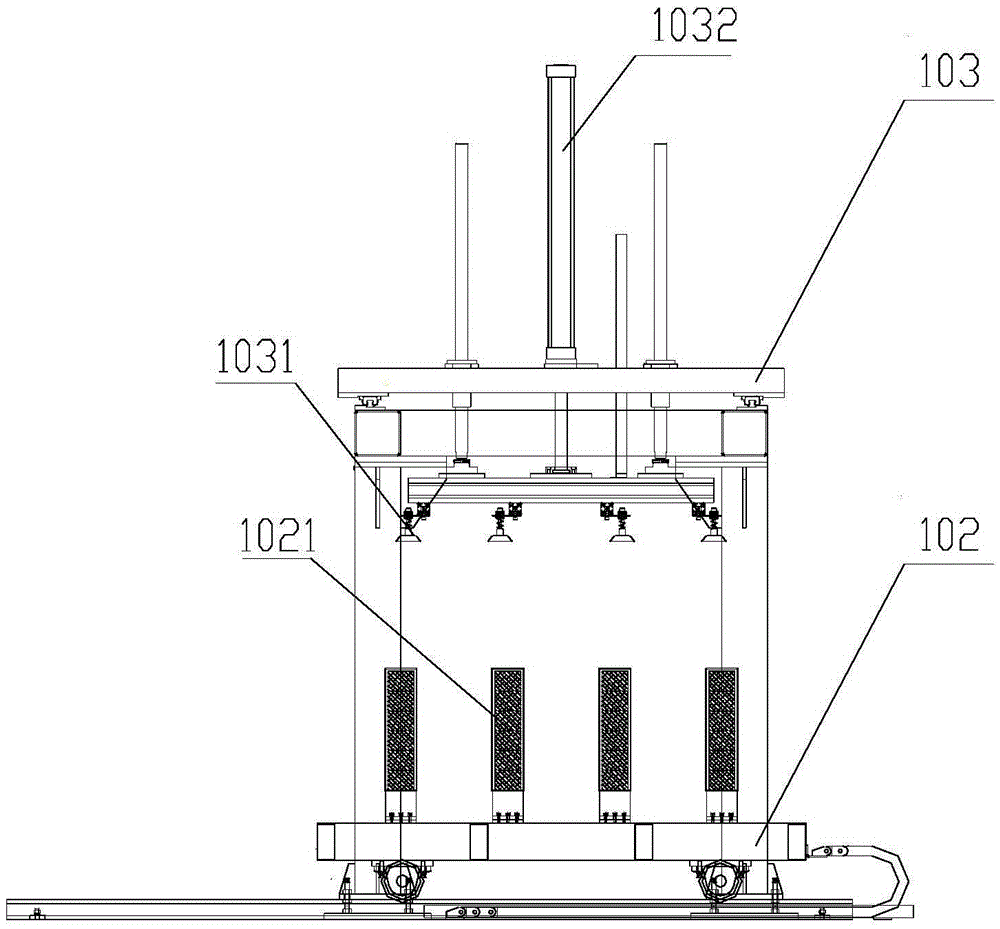

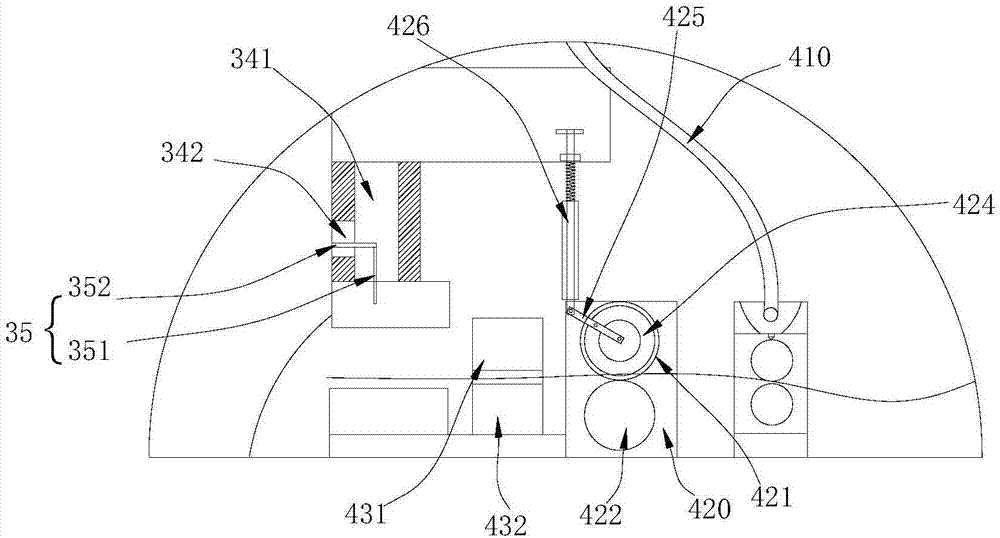

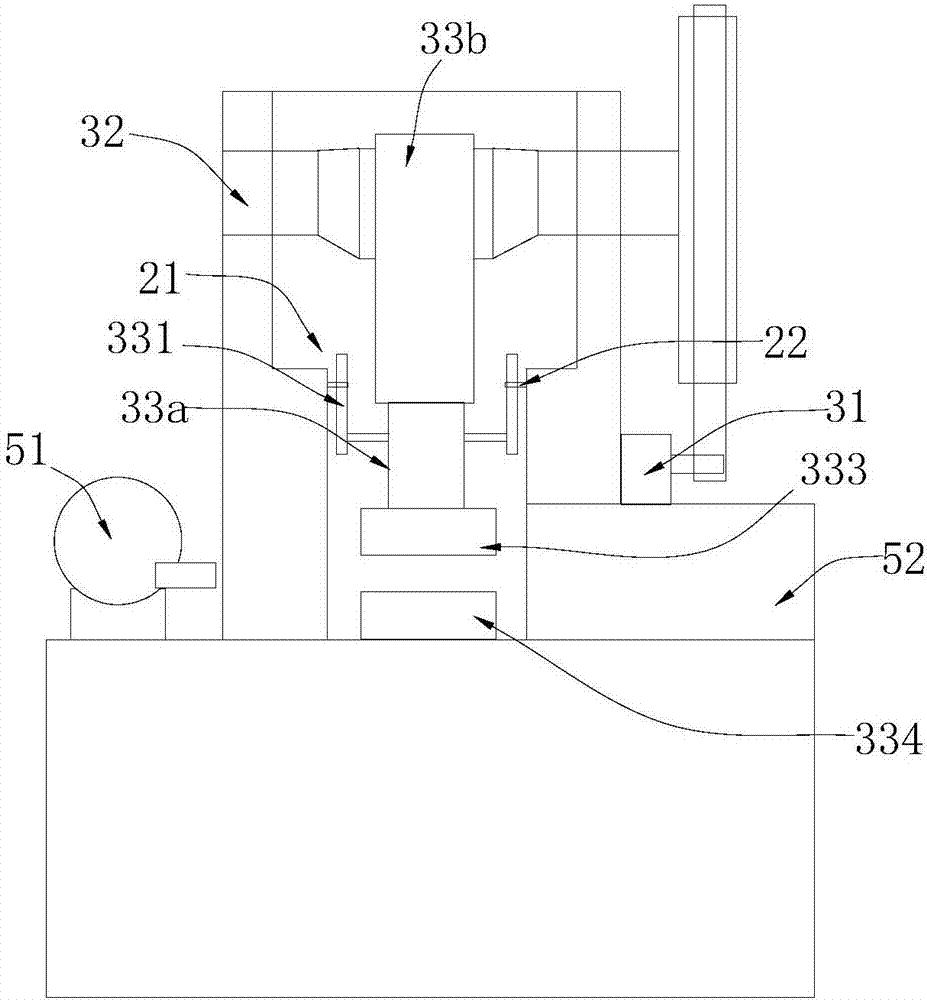

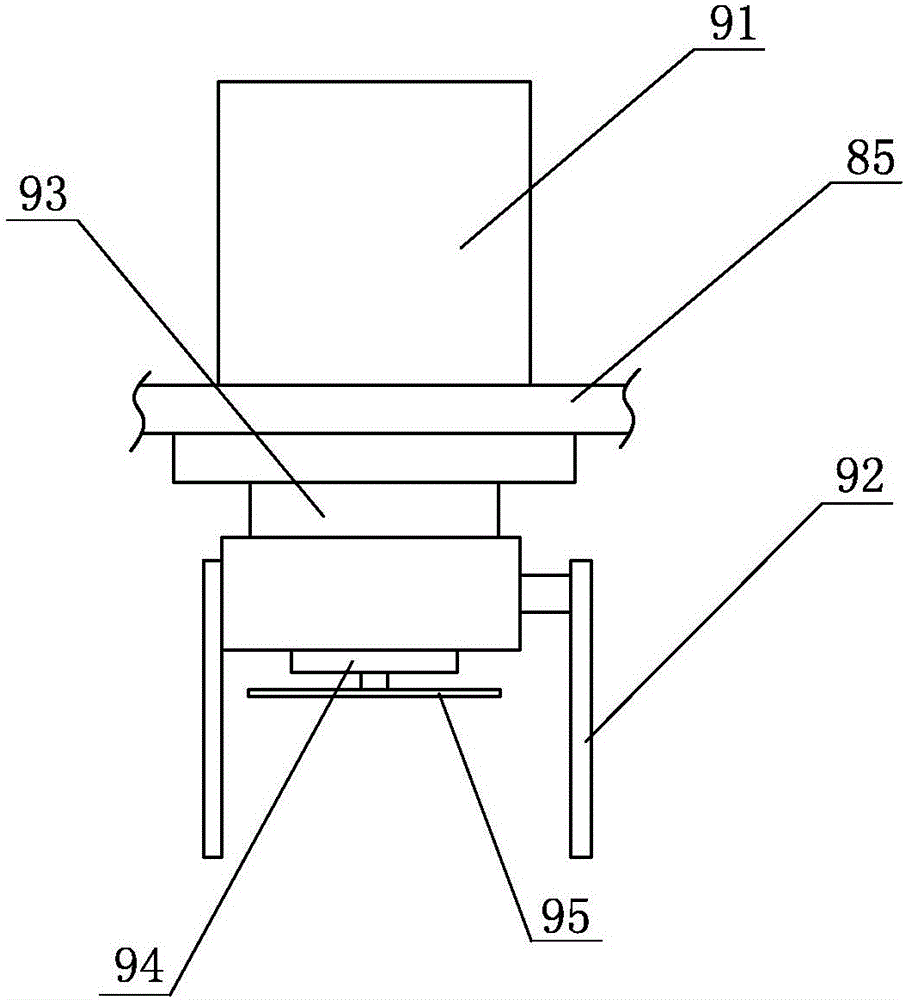

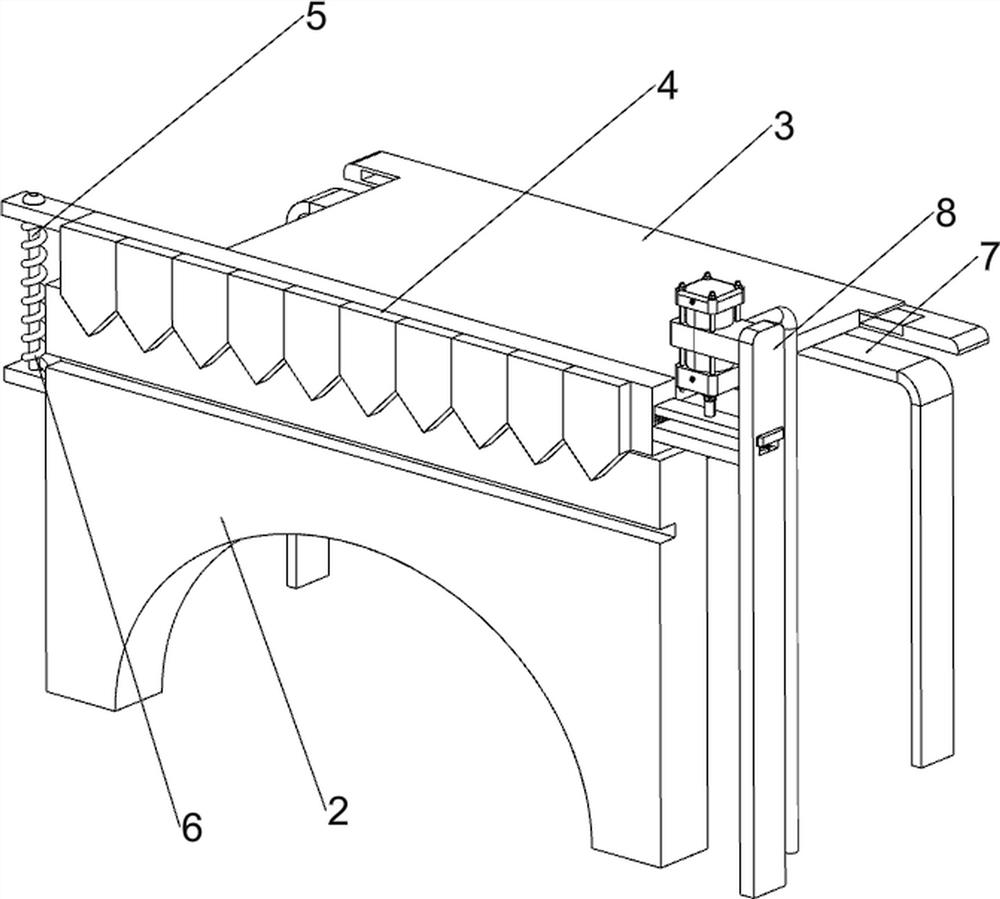

Production line of water fountain metal plate shells

ActiveCN105537391AGuaranteed arc transitionGuarantee stamping qualityMetal-working feeding devicesPositioning devicesElectrical controlFlanging

The invention discloses a production line of water fountain metal plate shells. By adopting combination of a feeding machine, a stepping cutting press, a flanging-drawing machine, a trimming and punching machine, a straightening machine, a flat pressing machine, a suction cup manipulator, a 180-degree turning machine and a U-shaped bending machine, through an electrical control system, actions of feeding, cutting, flanging-drawing, trimming and punching, straightening, flat pressing, turning and U-shaped bending of the water fountain metal plate shells are automatically completed, circular arc transiting and flanging forming of the water fountain metal plate shells are achieved, the product quality is guaranteed, and the production efficiency is improved.

Owner:ANHUI WEIJIA EQUIP & TECH

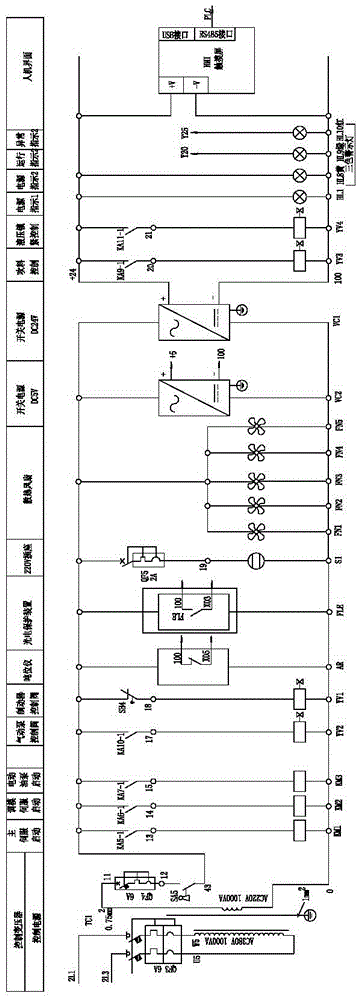

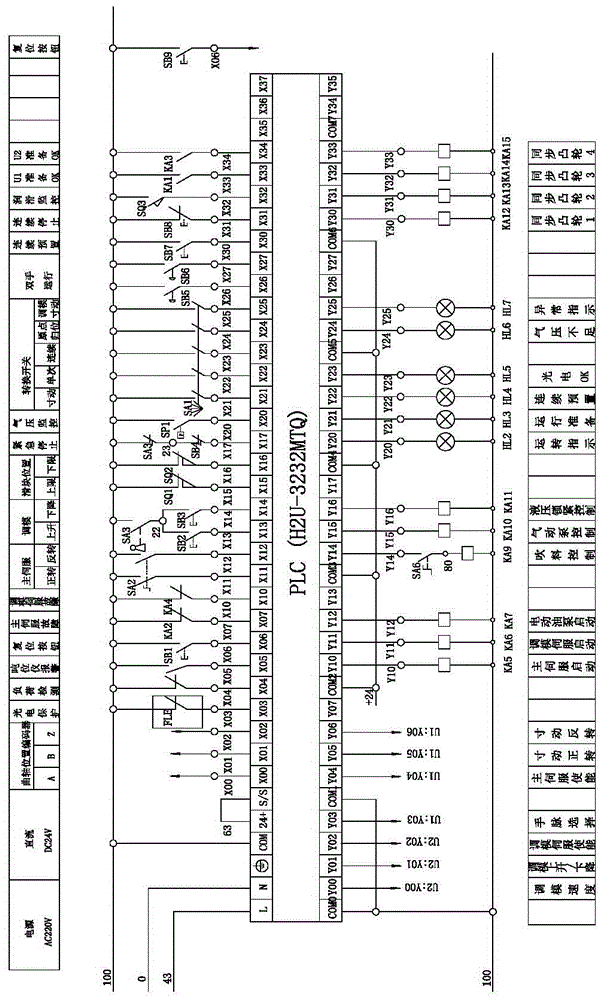

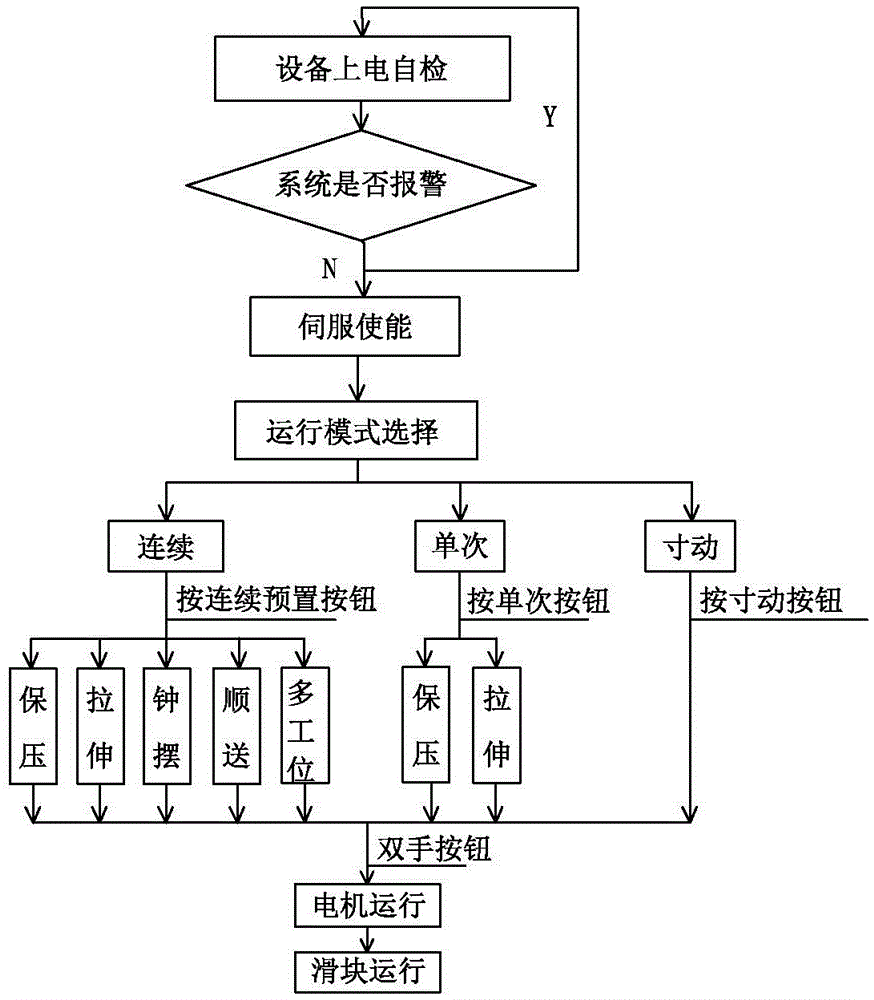

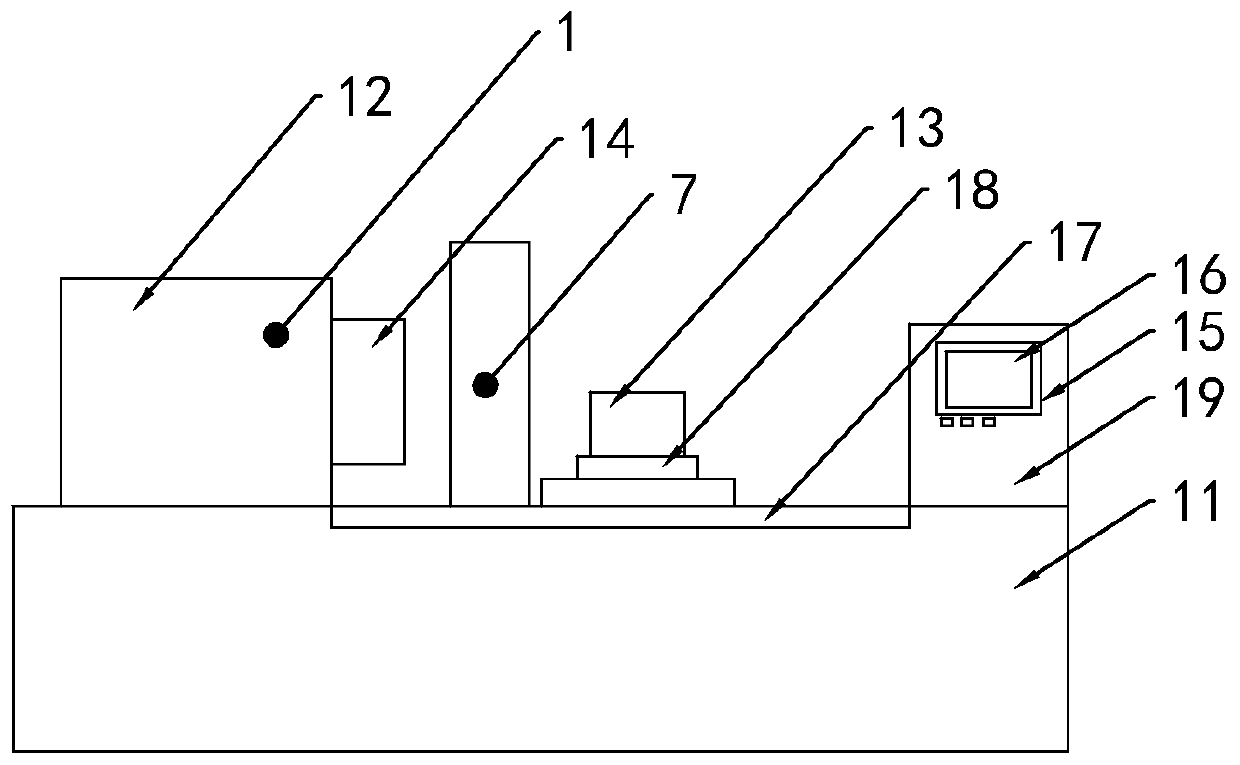

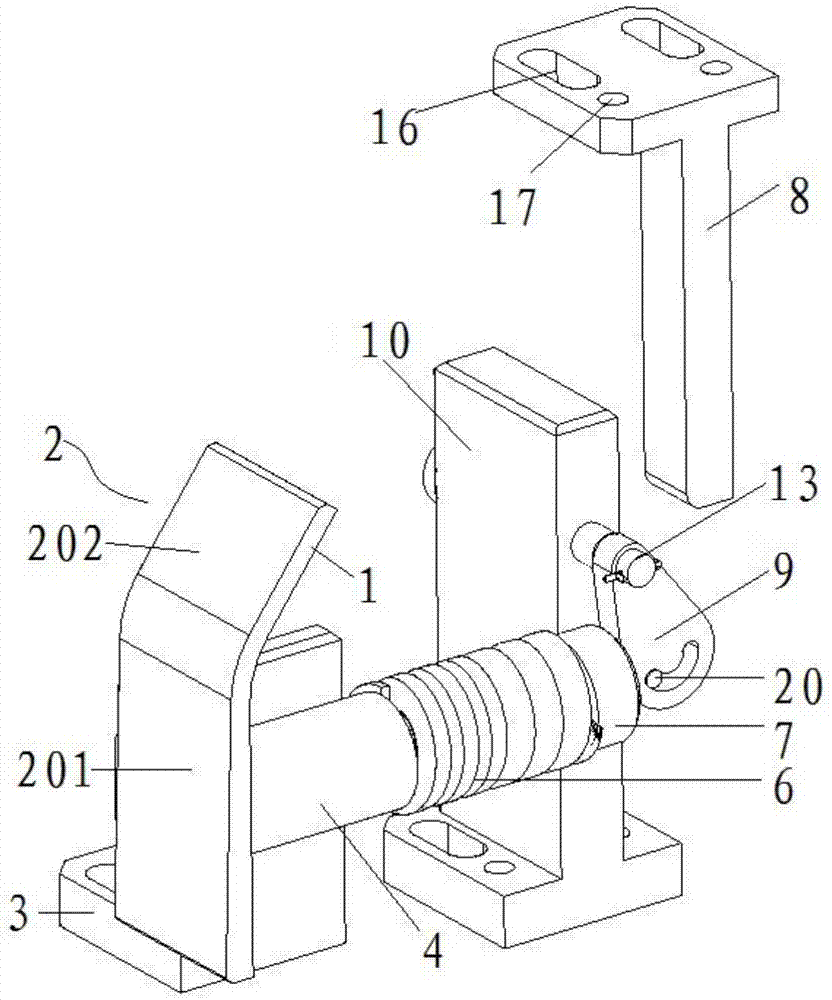

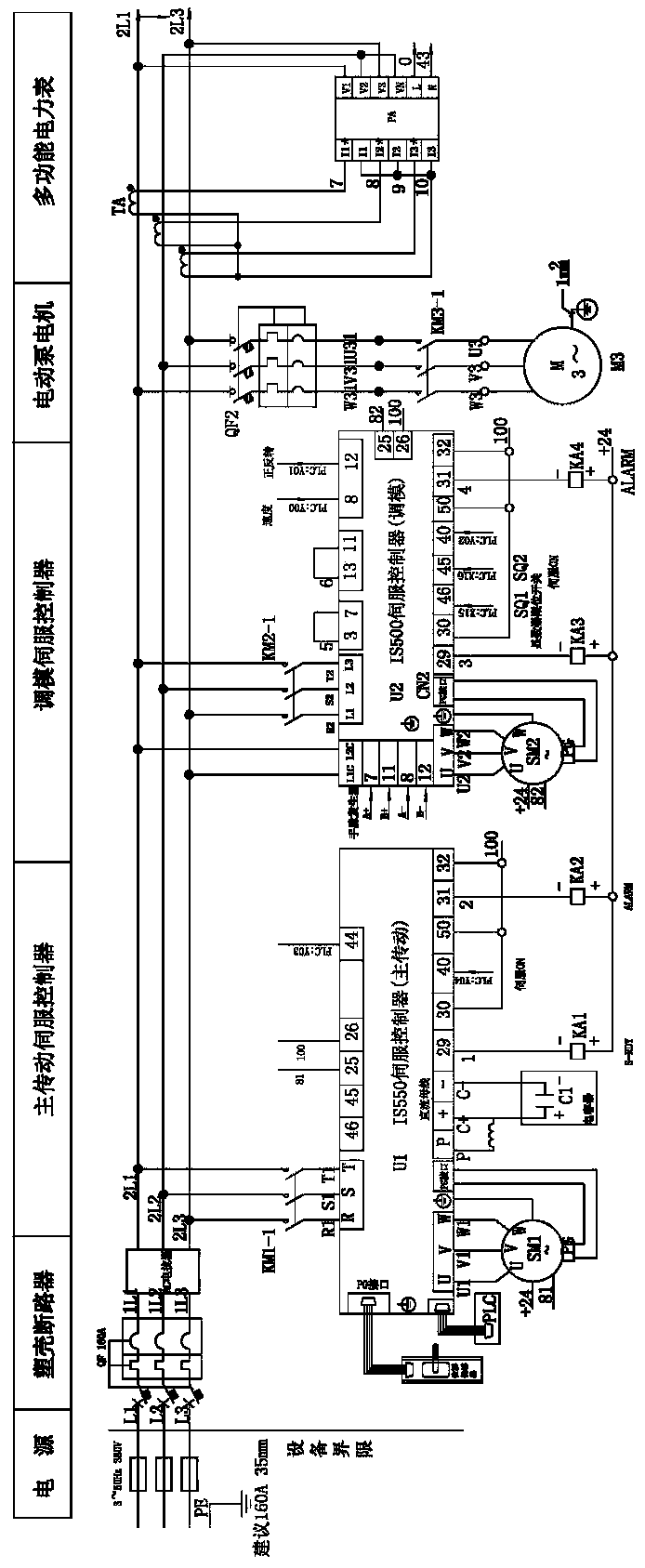

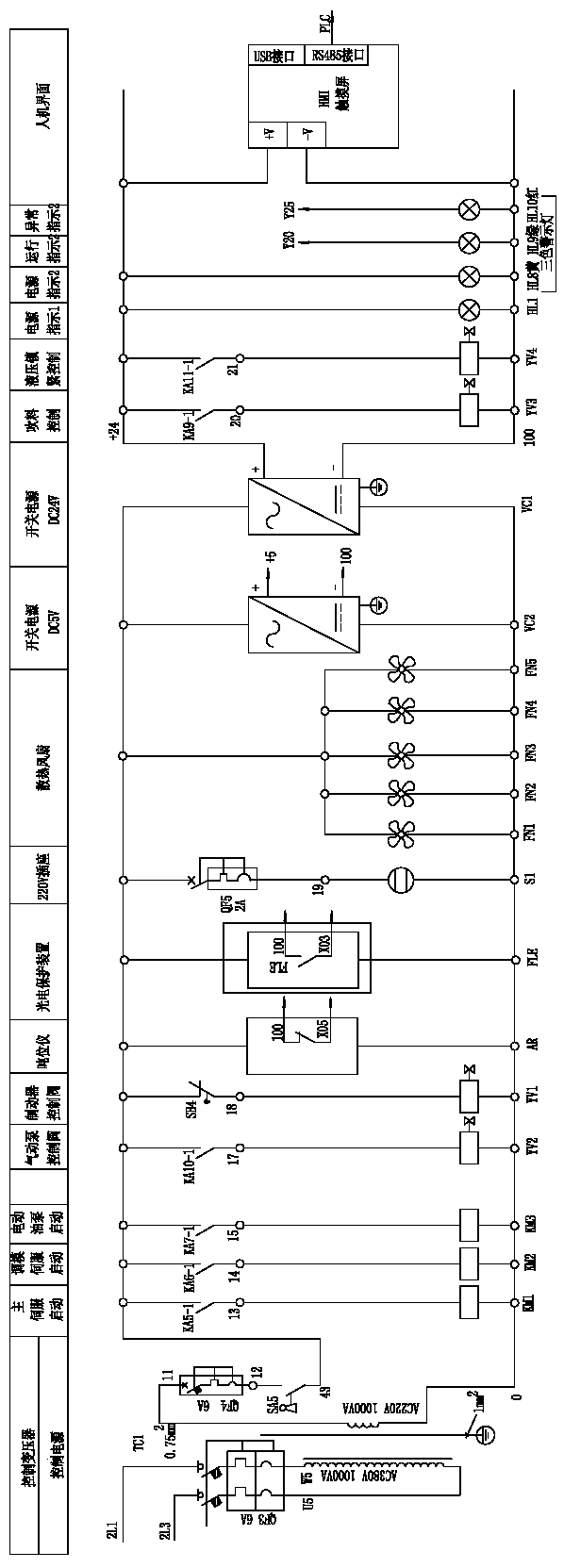

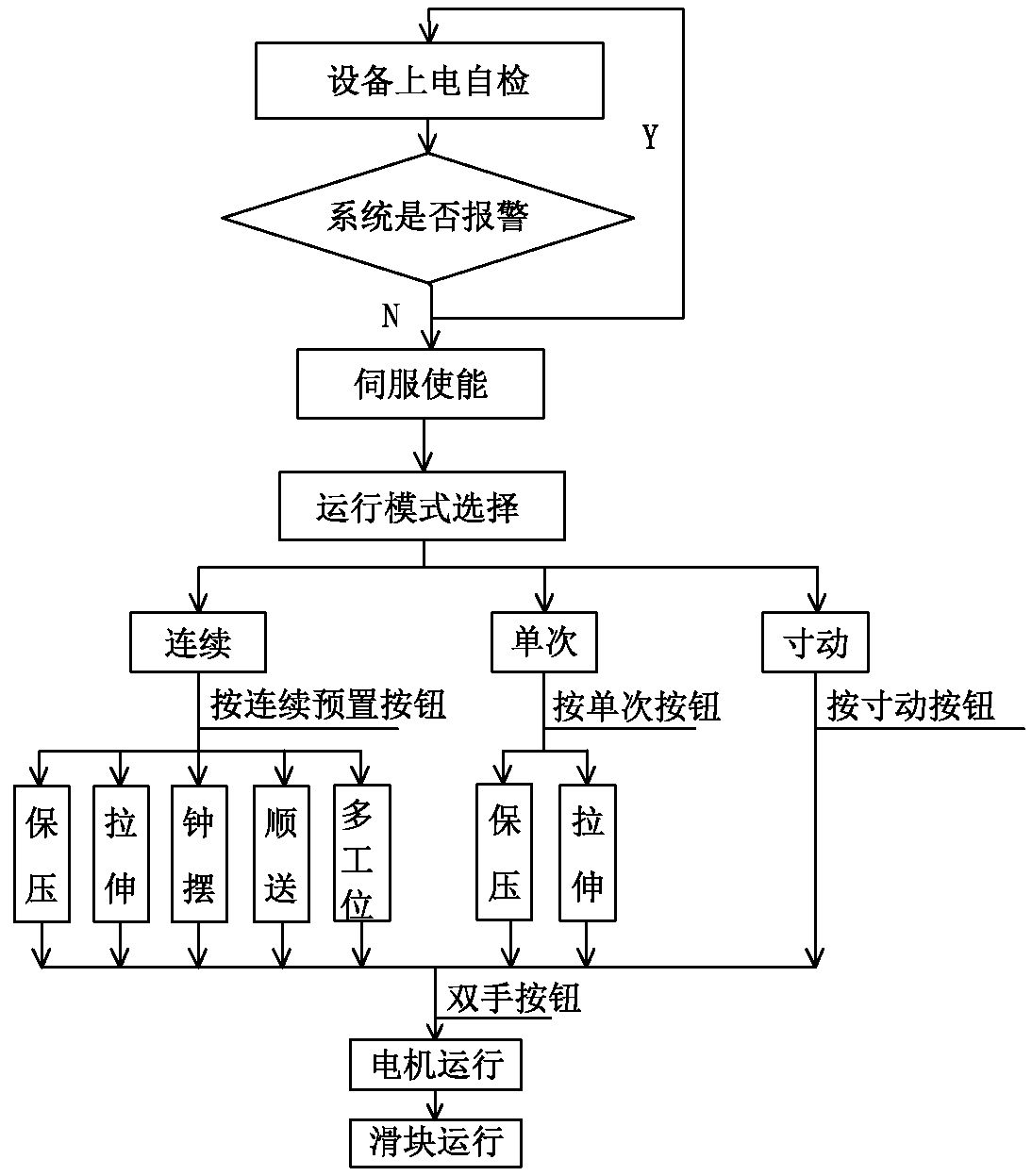

Control system and method for intelligent-type servo press

ActiveCN105700453AGuaranteed stamping accuracyGuarantee stamping qualityProgramme control in sequence/logic controllersPunchingControl power

The invention discloses a control system for an intelligent-type servo press, and the system comprises a servo drive unit, a PLC control unit, and a control power unit. The servo drive unit comprises a main drive servo controller, a mold adjustment servo controller, an electric pump motor, and a multifunction power meter, wherein the main drive servo controller, the mold adjustment servo controller, the electric pump motor and the multifunction power meter are connected to a three-phase power supply. The PLC control unit comprises a PLC, and a drive power end of the PLC is connected with an AC 220V power supply. A control power end of the PLC is connected with a DC 24V power supply, and the PLC collects the operation signals of all corresponding devices, and transmits the control signals for controlling the corresponding devices. The control power unit comprises a control transformer, wherein the front end of the control transformer is connected with an AC 380V power supply, and the rear end of the control transformer outputs an AC 220V voltage serving as the AC 220V power supply. The system guarantees the punching precision of the press and the quality of a punched part, improves the punching efficiency, and can be used in the control of the press.

Owner:YANGLI GRP CORP LTD

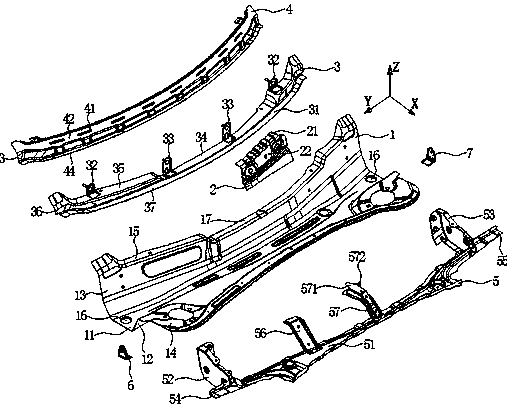

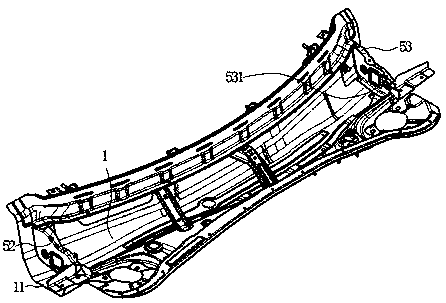

Automobile gutter channel assembly

The invention relates to an automobile gutter channel assembly which comprises a gutter channel. The gutter channel comprises a first bent part, a bottom board and a second bent part, all of which aresequentially connected and are each in a U shape. The upper end of the first bent part is connected with a first flanging part extending to the outer side of the gutter channel, and the upper end ofthe second bent part is connected with a second flanging part extending to the outer side of the gutter channel. The bottom board is in a shape with the middle portion higher than the two ends, drainholes are formed in the two ends of the bottom board, a downward-recessed section is arranged on the middle portion of the first flanging part, the two ends of the second flanging part are connected with a right gas supporting rod support component and a left gas supporting rod support component, the second flanging part is further connected with a gutter channel crossbeam assembly, the upper sideof the first flanging part is sequentially connected with a front windshield lower crossbeam connecting board assembly and a front windshield lower crossbeam upwards, and the face, facing the outer side of the gutter channel, of the first bent part is connected with a pedal tubular beam installation support component. By the adoption of the automobile gutter channel assembly, the problem of partrusting caused by bad accumulated water flow guidance is solved effectively, the rigidity and the rigidity of a whole automobile after the whole automobile is connected can be effectively guaranteed,and the automobile gutter channel assembly can be conveniently connected with other parts of the whole automobile.

Owner:力帆科技(集团)股份有限公司

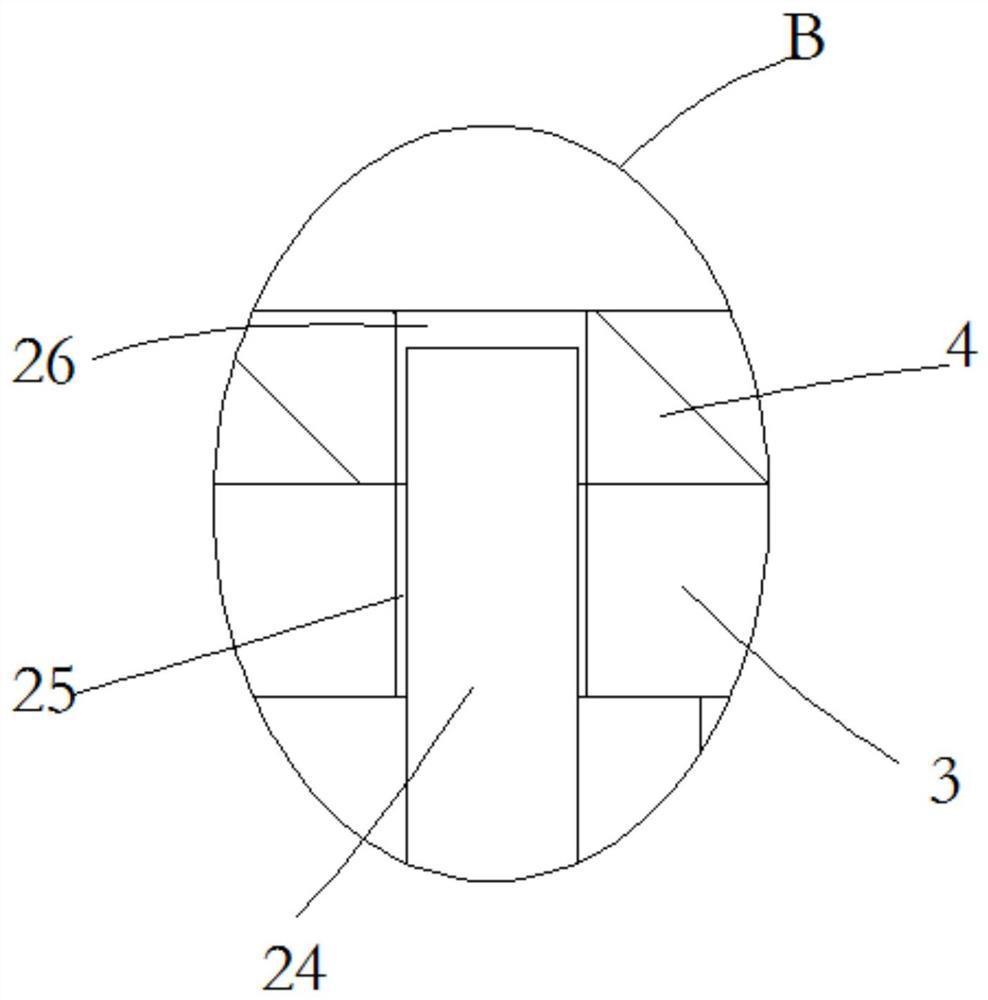

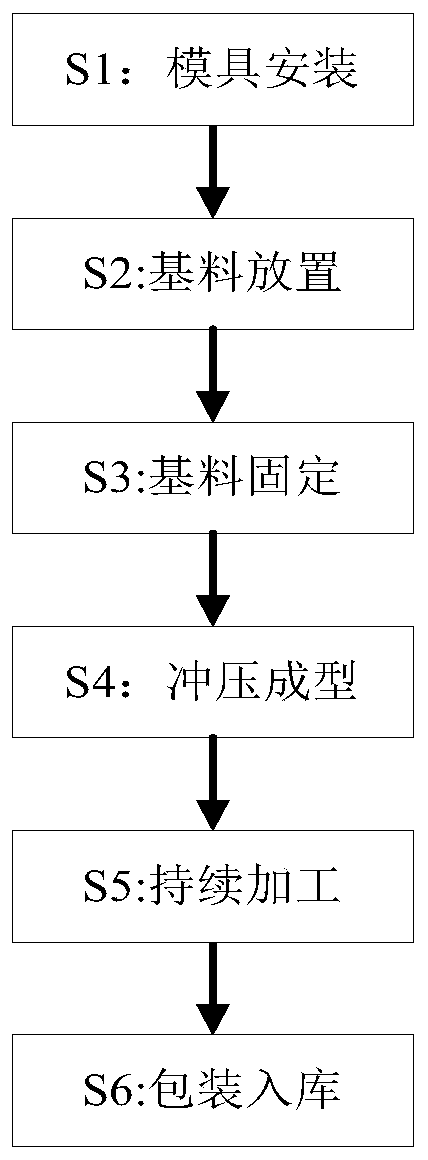

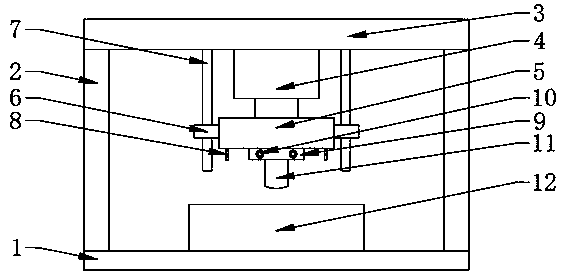

Stamping die control method

ActiveCN104289578AGuarantee stamping qualityPlay the role of automatic safe unloadingShaping toolsMetal-working feeding devicesEngineering

The invention relates to a stamping die control method. The lower end of a locating rod (39) is sleeved with a compression spring (391), the upper end of the compression spring (391) is connected with a T-shaped supporting plate (392), a through hole is formed in the vertical portion of the T-shaped supporting plate (392), the locating rod (39) penetrates through the through hole, and the horizontal portion of the T-shaped supporting plate (392) is used for supporting a stamping part; columnar storing grooves (394) are formed in the upper end of the locating rod (39) in the axial direction, the upper ends or the lower ends of the storing grooves (394) are connected with connecting shafts (395), the two ends of each connecting shaft (395) are fixed on the walls of the storing grooves (394), elastic stop rods (393) are connected with the connecting shafts (395) and are rotatable, and the included angle between each elastic stop rod (393) and the locating rod (39) changes within 0-90 degrees. A stamping part pressing and limiting mechanism has a discharging function, arrangement space in a die is saved, and stamping efficiency is improved.

Owner:东莞市盈德精密五金有限公司

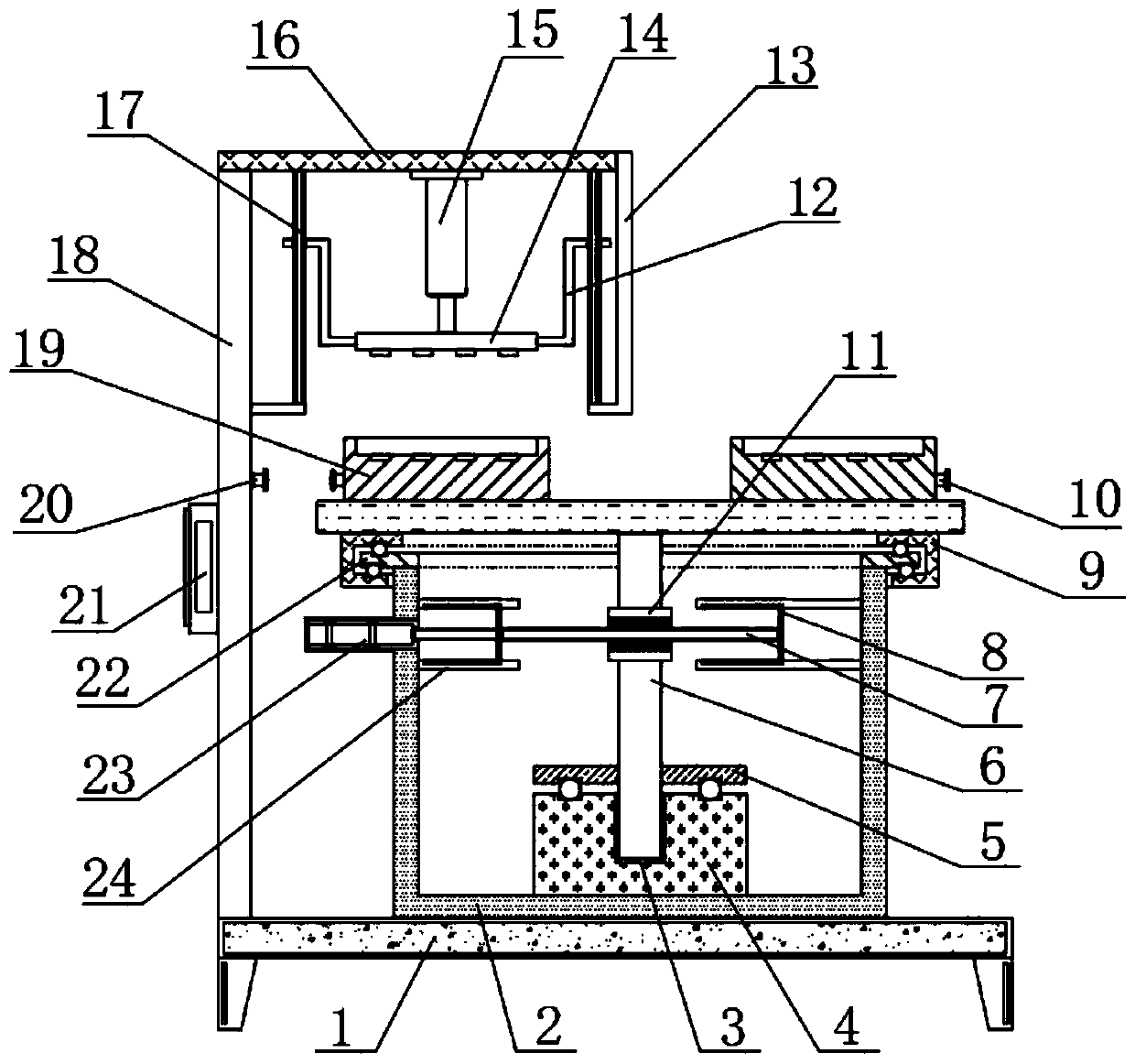

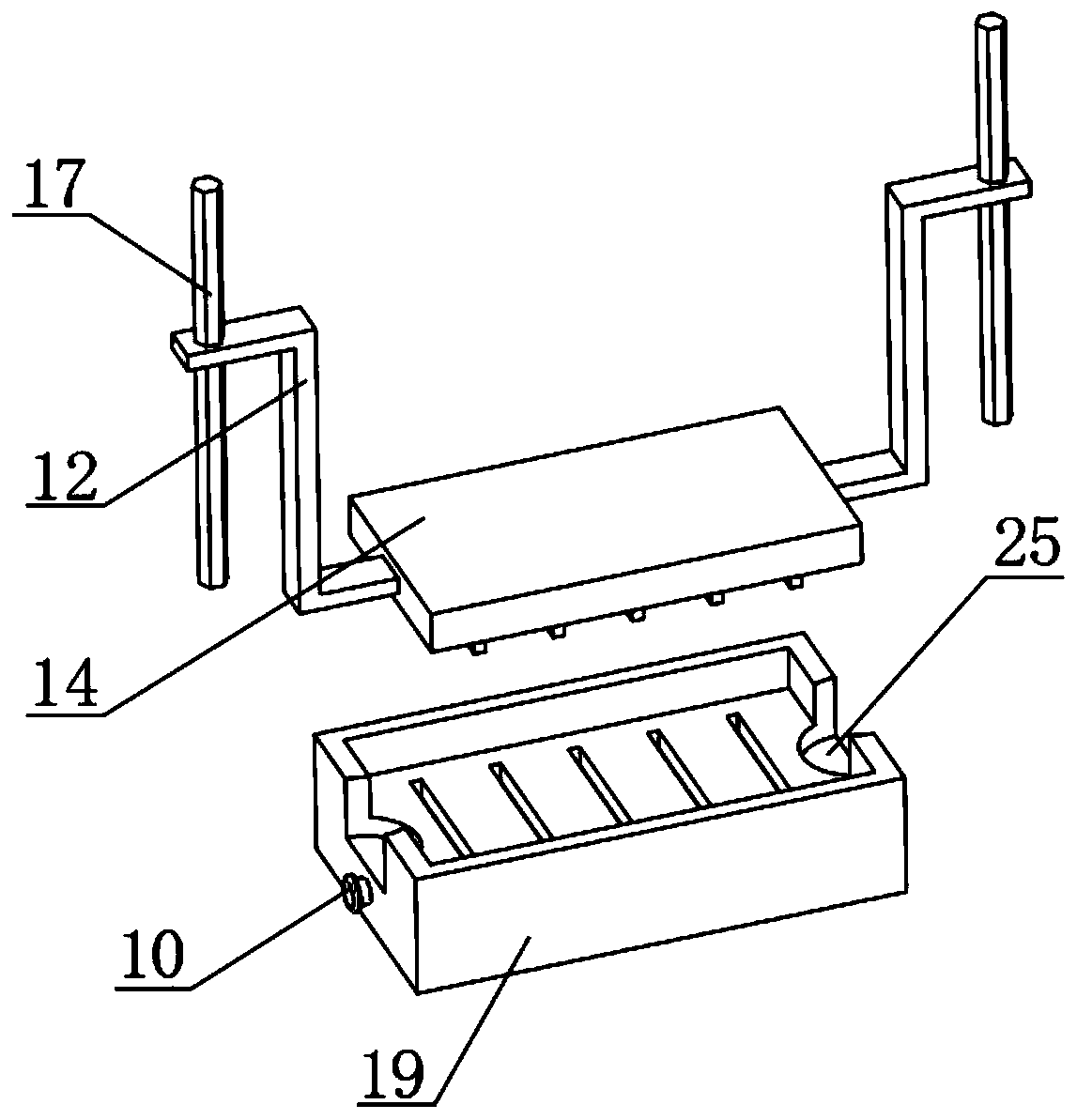

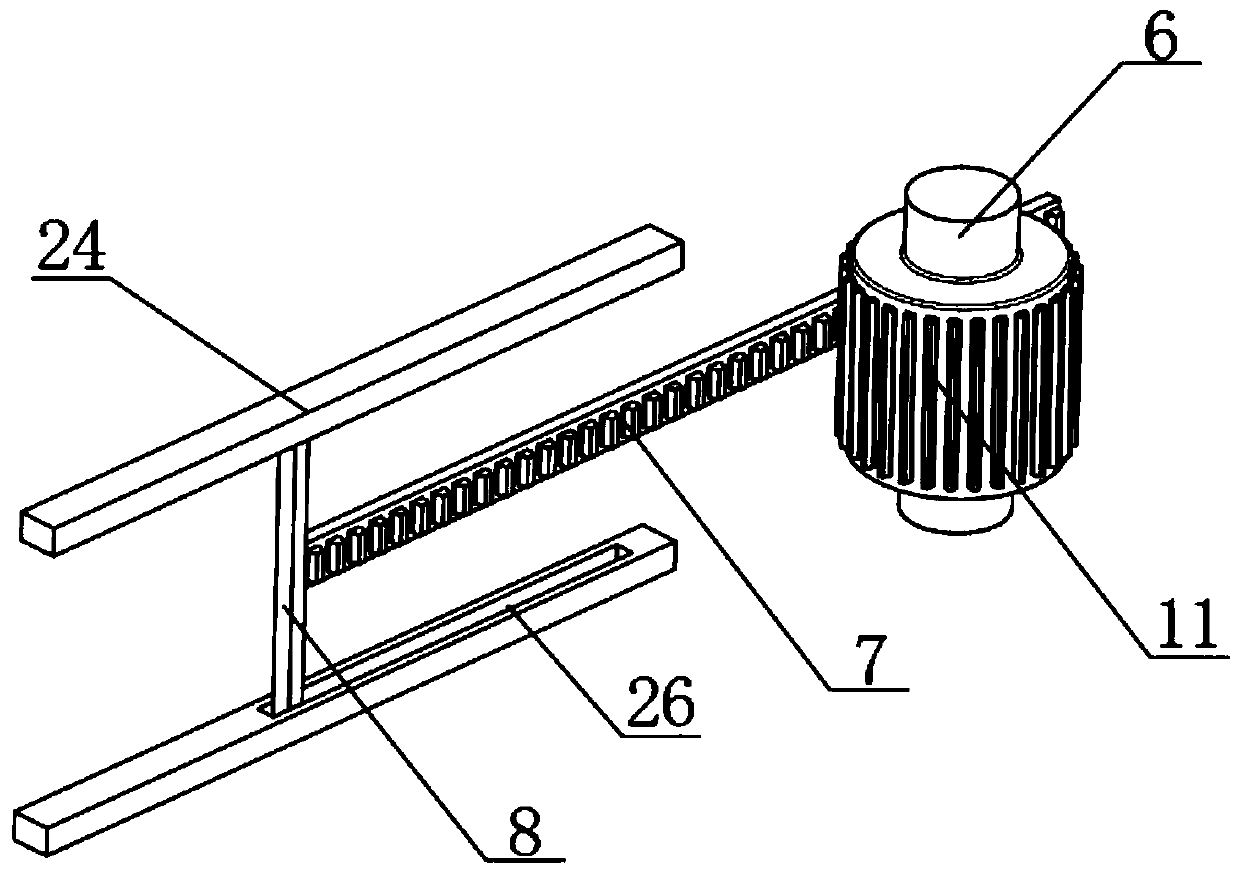

Magnesium alloy plate stamping device

PendingCN112170623AQuick placementPlace stableShaping toolsMetal-working feeding devicesStampingStructural engineering

The invention relates to the technical field of magnesium alloy plate stamping, and discloses a magnesium alloy plate stamping device. The magnesium alloy plate stamping device comprises a base, a plurality of supporting blocks are symmetrically and fixedly connected to the upper end of the base, the upper ends of the supporting blocks are fixedly connected with the same support plate, the upper end of the support plate is fixedly connected with a lower die, and two die grooves are formed in the upper end of the lower die in a front-back symmetrical mode; two electric sliding rails are fixedlyconnected to the upper end of the base in a bilateral symmetry mode, sliding blocks on the two electric sliding rails are fixedly connected with the same U-shaped supporting plate, two air cylindersare symmetrically and fixedly connected to the upper end of the horizontal portion of the U-shaped supporting plate, and output shafts at the lower ends of the two air cylinders penetrate through thelower end of the horizontal portion of the U-shaped supporting plate and are fixedly connected with the same stamping plate; and a plurality of stamping heads are uniformly and fixedly connected to the lower end of the p stamping plate. The magnesium alloy plate stamping device has the advantages that continuous stamping operation can be achieved, the production efficiency is improved, people canconduct feeding and discharging operation conveniently, and the feeding and discharging safety is guaranteed.

Owner:巢湖云海镁业有限公司

Punching device of board press for bamboo chip test

InactiveCN105128122AGuaranteed stabilityFully stampedWood working apparatusFlat articlesTest efficiencyPunching

The invention discloses a punching device of a board press for a bamboo chip test. The punching device comprises a vertical punching plate arranged above the center part of a working face of the board press, and a die groove formed in the working face and at the position under the punching plate; clamps are arranged on the left side and the right side of the die groove; a to-be-molded bamboo board is placed between the punching plate and the clamps to be subjected to extrusion molding; the punching plate is a rectangular punching block; and protection devices are respectively arranged outside the two side surfaces of the punching plate in the length direction. The punching device is simple in structure, is higher in degree of automation, improves the efficiency of mounting the bamboo board on the board press for bamboo chips and dismounting the bamboo board from the board press for bamboo chips, the efficiency of punching the bamboo chips into the bamboo board, and the test efficiency of the board press, ensures the punching quality of the tested bamboo board promptly, efficiently and accurately, and obtains corresponding measuring parameters of the board press conveniently.

Owner:ANHUI HONGYU BAMBOO IND TECH

New energy automobile power battery pack shell stamping device

InactiveCN113770221AIncrease punch pressureStamping fully efficientShaping toolsMetal-working feeding devicesPower batteryNew energy

The invention provides a new energy automobile power battery pack shell stamping device. The device comprises a supporting base, a special-shaped supporting frame, a mold supporting frame, a lower mold frame, grooving limiting plates and the like. The special-shaped supporting frame is fixedly connected to the top of the supporting base, the mold supporting frame is fixedly connected to the top of the special-shaped supporting frame, the lower mold frame is fixedly connected into the mold supporting frame, and the grooving limiting plates are fixedly connected to the left side and the right side of the mold supporting frame. In the stamping process, a push-out frame can move downwards, when stamping is completed, the push-out frame can move upwards and push out stamped new energy automobile power battery pack shells, an automatic demolding effect is achieved, other equipment can conveniently take out the new energy automobile power battery pack shells, the stamped new energy automobile power battery pack shells can be prevented from deforming, and the aim of automatically demolding the stamped new energy automobile power battery pack shells is achieved.

Owner:杭州巍枫减速机械有限公司

Motorcycle fitting stamping die

InactiveCN108526324AImprove work efficiencyIncrease pick-up speedShaping toolsMetal-working feeding devicesEngineering

The invention relates to the technical field stamping dies and particularly discloses a motorcycle fitting stamping die which comprises a rack; the rack is fixedly provided with a press machine and alower die seat; an upper die seat is connected to the output end of the press machine; first springs and two fixed blocks are connected to the lower die seat; a push plate is connected to the first springs; a first forming die and a second forming die are hinged to the two fixed blocks respectively; second springs are connected to the lower die seat; a moving block is connected to the second springs; a die core is connected to the moving block, is matched with a die cavity and is provided with a T-shaped sliding pipe in a sleeved manner; the T-shaped sliding pipe is provided with a third spring; a cross rod is connected to the end, far away from the fixed block, of the T-shaped sliding pipe and is connected to the moving block in a sliding manner; a cylinder is rotationally connected to the cross rod; a vertical plate and a push rod are connected to the upper die seat; a wedged block is hinged to the vertical plate; a fourth spring is connected between the wedged block and the verticalplate; and the vertical plate is connected with a limiting plate. By means of the motorcycle fitting stamping die, a stamped piece is automatically taken after stamping, the workload is reduced, andthe stamping working efficiency is improved.

Owner:重庆市璧山区合成机械制造有限公司

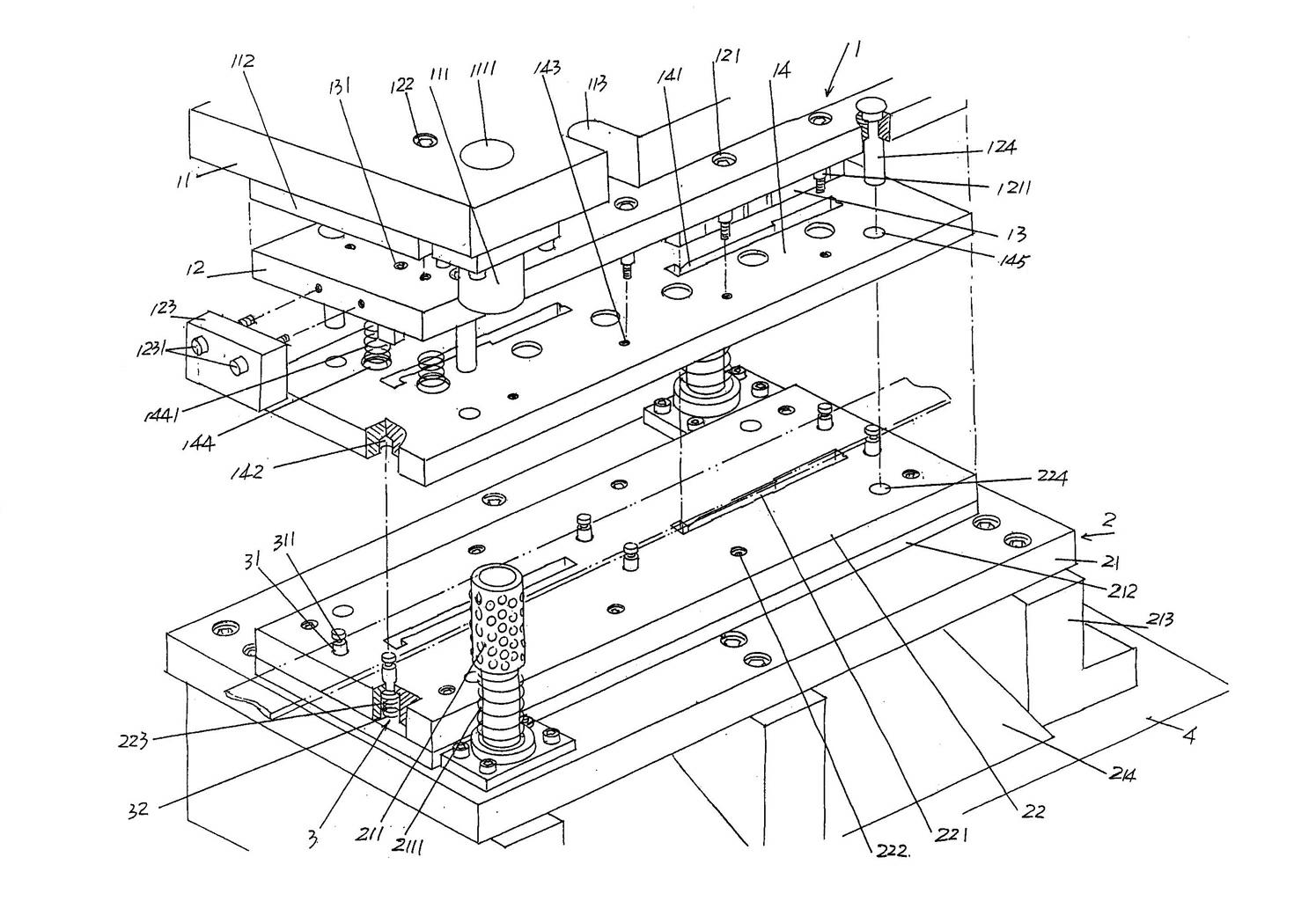

Needle bed insert blank body punching mould

InactiveCN102672053AQuality assuranceImprove stampingShaping toolsMetal-working feeding devicesPunchingEngineering

A needle bed insert blank body punching mould belongs to the technical field of moulds. The needle bed insert blank body punching mould comprises an upper mould mechanism and a lower mould mechanism, wherein the upper mould mechanism comprises an upper mould plate rack, an upper mould plate and an insert embossing mould; a lower mould mechanism comprises a lower mould plate rack and a lower mould plate; the needle bed insert blank body punching mould is characterized in that: one end of the insert embossing mould facing to one side of the lower mould plate is higher than the other end thereof; the height difference between the higher end and the lower end is equal to the thickness of a needle bed insert blank body to be punched and moulded; the upper mould mechanism also comprises a material pressing plate; the material pressing plate is connected with one side of the upper mould plate; a guiding mould hole is formed on the material pressing plate; a group of thin steel strip guiding and limiting mechanisms is arranged on one side of the lower mould plate; a material guiding rod hole is formed on one side of the material pressing plate; thin steel strip guiding and limiting mechanism installing holes are formed on the lower mould plate; each of the thin steel strip guiding and limiting mechanisms comprises a material guiding rod and a spring; and a material guiding groove is formed at one end of the material guiding rod. The needle bed insert blank body punching mould has the advantages that: the quality of the needle bed insert blank body is ensured; equipment investment can be reduced; and deviation of a thin steel strip can be avoided.

Owner:常熟市尚湖镇冶塘伟东模具厂

Medicine bottle cap punch

InactiveCN107413921ASimple structureEasy to operateShaping toolsMetal-working feeding devicesPunchingMedicine bottle cap

The invention relates to the field of bottle cap processing, in particular to a punching machine for medicine bottle caps. A punching machine for medicine bottle caps, comprising a tray rack, a punching frame, and a punching mechanism, a feeding mechanism, and a blanking mechanism arranged on the punching frame; the punching mechanism includes a punching motor, an eccentric shaft and a punching shaft, and the eccentric The two ends of the shaft are positioned on the punching frame through bearings, and the punching frame is provided with a punching cavity, and the eccentric part of the eccentric shaft is located in the upper end of the punching cavity, and the output end of the punching motor is connected to the eccentric shaft through a transmission assembly; The mechanism includes a lubricating roller group, a feeding roller group and a pressing plate group sequentially arranged between the tray frame and the punching station; the medicine bottle cap punching machine has a novel structure, is easy to control, and the quality of the punched product is better.

Owner:浙江冠利新材料股份有限公司

Die for lateral hole flanging of upper cross plate of automobile seat backrest

ActiveCN104338829AIngenious structureHigh concentricityPerforating toolsMetal-working feeding devicesPunchingEngineering

The invention discloses a die for lateral hole flanging of an upper cross plate of an automobile seat bracket. The die comprises a lower die base arranged on a working table, wherein a first punch is arranged on the lower die base; a first concave die and a second concave die are sequentially and correspondingly arranged on the working table and one the same side of the first punch; a cavity of the first concave die and a cavity of the second die right face the first punch; a lower cavity is arranged between the first concave die and the second concave die; a punch guide through hole is formed in the upper part of the lower cavity; a second punch penetrates through the punch guide through hole and right faces the first punch; and orientations of the second punch and the first punch are consistent. The die has the remarkable effects as follows: the two punches are used for punching, so that the stroke of a single punch is reduced, the punch stability is improved, hole flanging concentricity is high, the punch quality is stable, and the qualified rate of a product is high; and besides, a punch return device is arranged ingeniously, and the structure is compact.

Owner:CHONGQING YANFENG ADIENT AUTOMOTIVE COMPONENTS CO LTD

Stamping device for processing new energy automobile parts

InactiveCN110918747AImprove processing efficiencyAvoid placingShaping toolsMetal-working feeding devicesHand partsNew energy

The invention belongs to the technical field of processing of automobile parts, in particular to a stamping device for processing new energy automobile parts. Aiming at the problems that the processing efficiency of a traditional stamping device is not high and certain potential safety hazards exist, the following scheme is provided, the stamping device comprises a base and a workbench, support legs are welded at four corners of the outer wall of the bottom of the base, a fixing box is fixed on the outer wall of the top of the base through bolts, an annular plate and an annular supporting discare respectively welded on the opposite sides of the fixing box and the workbench, first annular grooves are formed in opposite sides of the annular plate and the annular supporting disc, and the inner walls corresponding to the two first annular grooves are in rolling connection with balls I distributed at equal distances. Due to the arrangement of two lower dies, feeding and discharging can becarried out on one lower die in the stamping process of the other lower die, the processing efficiency of the parts is greatly improved, in the feeding process, hands of operators are prevented from being placed below the stamping mechanism, and the safety of the device is improved.

Owner:东营瑞尔泰机电科技有限公司

Stamping equipment for medicine bottle cap

InactiveCN107335708ASimple structureEasy to operateMetal-working feeding devicesClosure capsPunch pressMedicine bottle cap

The invention relates to the field of bottle cap processing. The medicine bottle cap punching equipment includes a punching mechanism and a feeding mechanism; the punching mechanism includes a punching motor, an eccentric shaft and a punching shaft, and the two ends of the eccentric shaft are positioned on the punching frame through bearings. The output end of the stamping motor is connected to the eccentric shaft through a transmission assembly; the feeding mechanism includes a lubricating roller group, a feeding roller group and a pressing plate group arranged sequentially between the tray frame and the punching station; the feeding roller The set includes a base, and a driving feeding roller and a driven feeding roller positioned on the base, and the other end of the driving feeding roller is linked with the stamping part through a swing arm assembly. The stamping mechanism of the medicine bottle cap stamping equipment has a novel structure, is easy to control and has high stability; in addition, the feeding roller group is linked with the stamping mechanism to ensure the synchronization of the stamping work and the feeding work, to ensure the quality of the stamping, and to facilitate the control of a single The length of the sheet to be fed is conducive to improving the utilization rate of raw aluminum sheets.

Owner:浙江冠利新材料股份有限公司

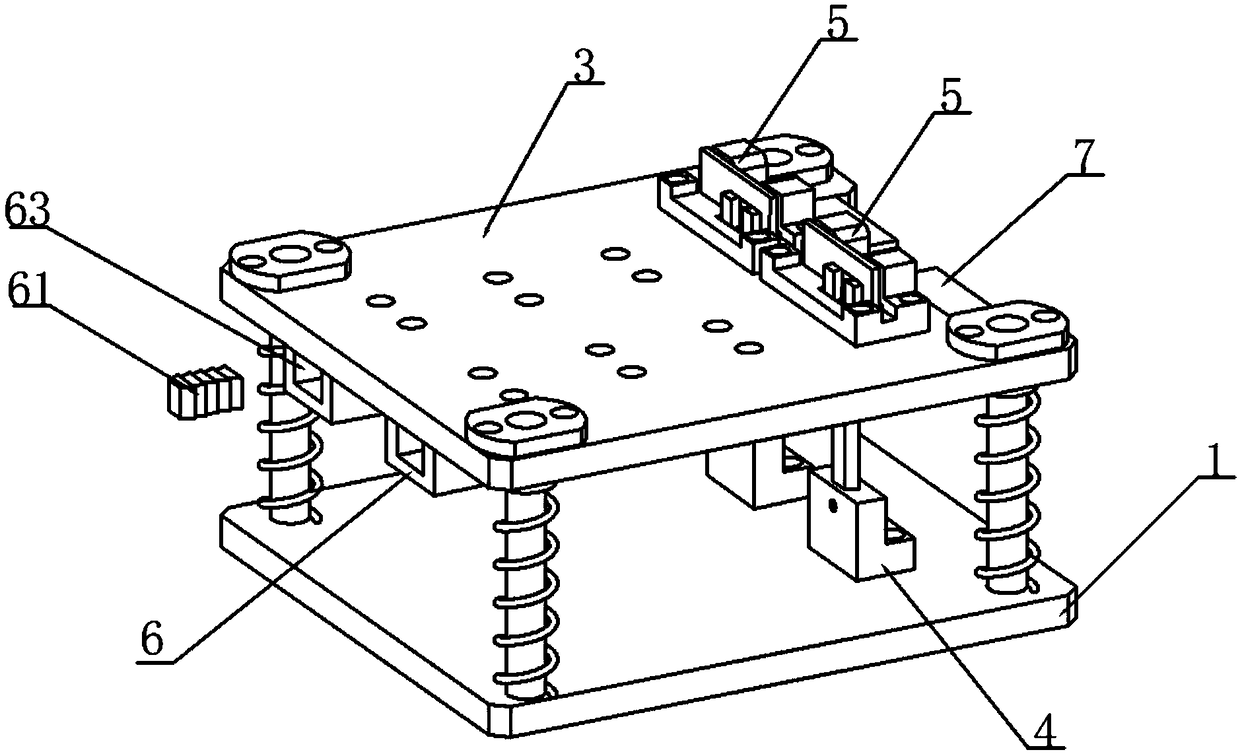

Magnet assembly jig

PendingCN109396794AIncrease productivityGuarantee stamping qualityWork holdersMetal working apparatusPunchingEngineering

The invention discloses a magnet assembly jig. The magnet assembly jig comprises an upper plate and a lower plate, wherein the upper plate and the lower plate are arranged in a manner of being capableof relatively moving. Ejector rods are arranged on the lower plate. Product locating parts used for containing products are fixedly arranged on the upper surface of the upper plate. A through hole isformed in the upper surface of each product locating part. The bottom of the upper plate is fixedly connected with channels. The inner side wall of each channel is in sliding connection with a magnet. An ejector rod groove is formed in the outer side wall of each channel. Openings used for allowing the magnets to enter therein are formed in the first ends of the channels, and force application parts used for driving the magnets to move are arranged at the second ends of the channels. According to the magnet assembly jig, the upper plate is driven by a punching machine to be pressed down, andtherefore the ejector rods press the magnets in the channels into the products; and an iron block is arranged on one side of each channel, only the iron blocks in the whole jig are made of irony materials, the magnets can move only through attraction of the iron blocks, the iron blocks attract the magnets in the channels into the ejector rod grooves, automatic conveying is completed, and thereforethe production efficiency is improved.

Owner:SUZHOU BENTENG PLASTIC

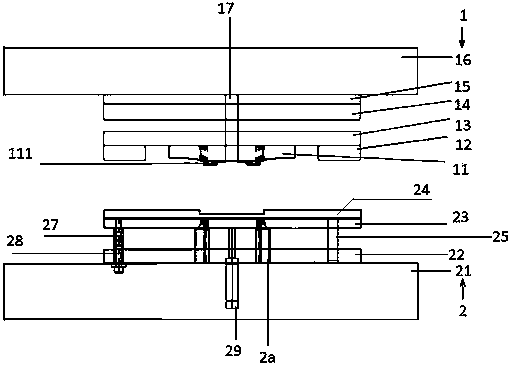

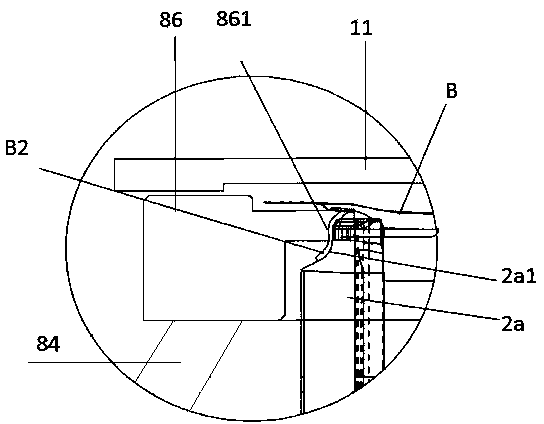

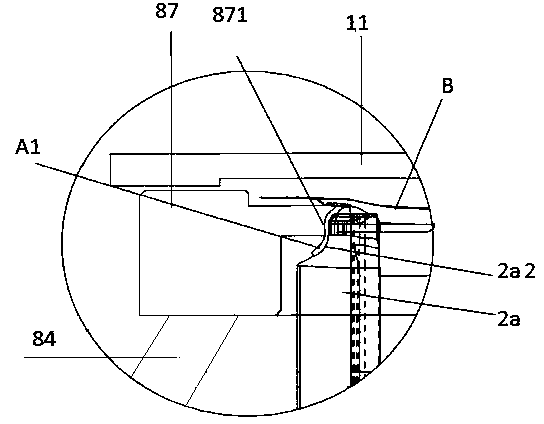

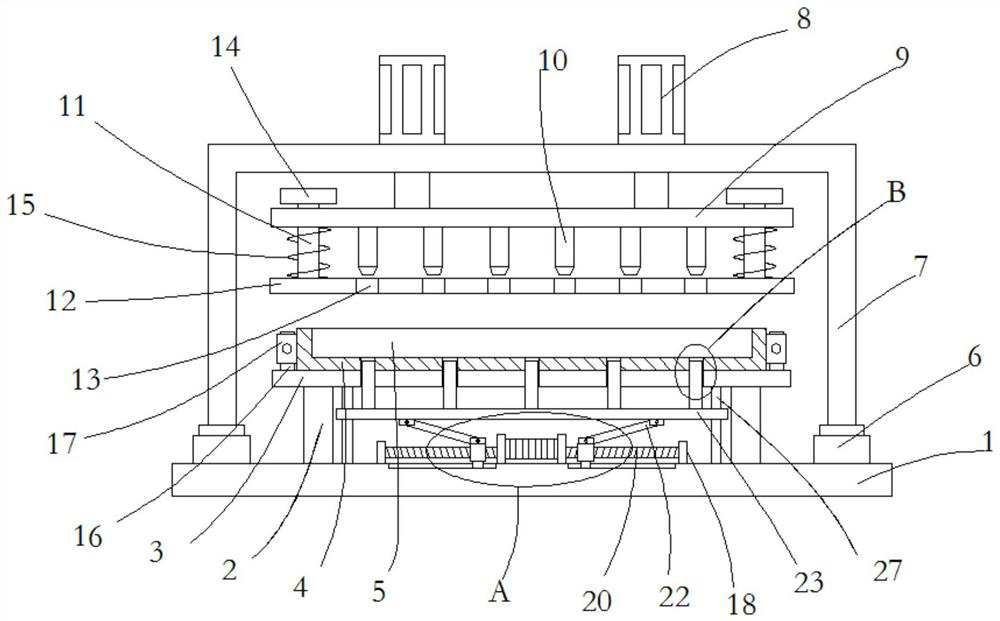

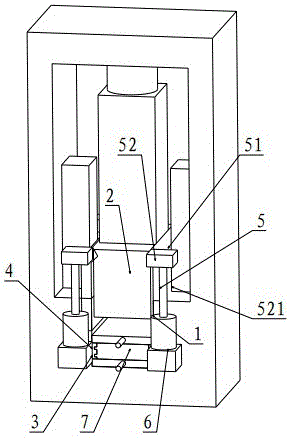

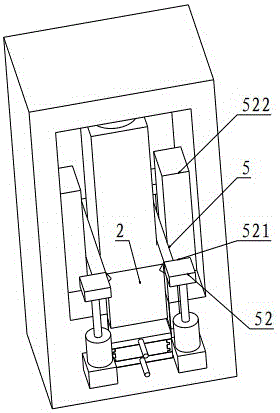

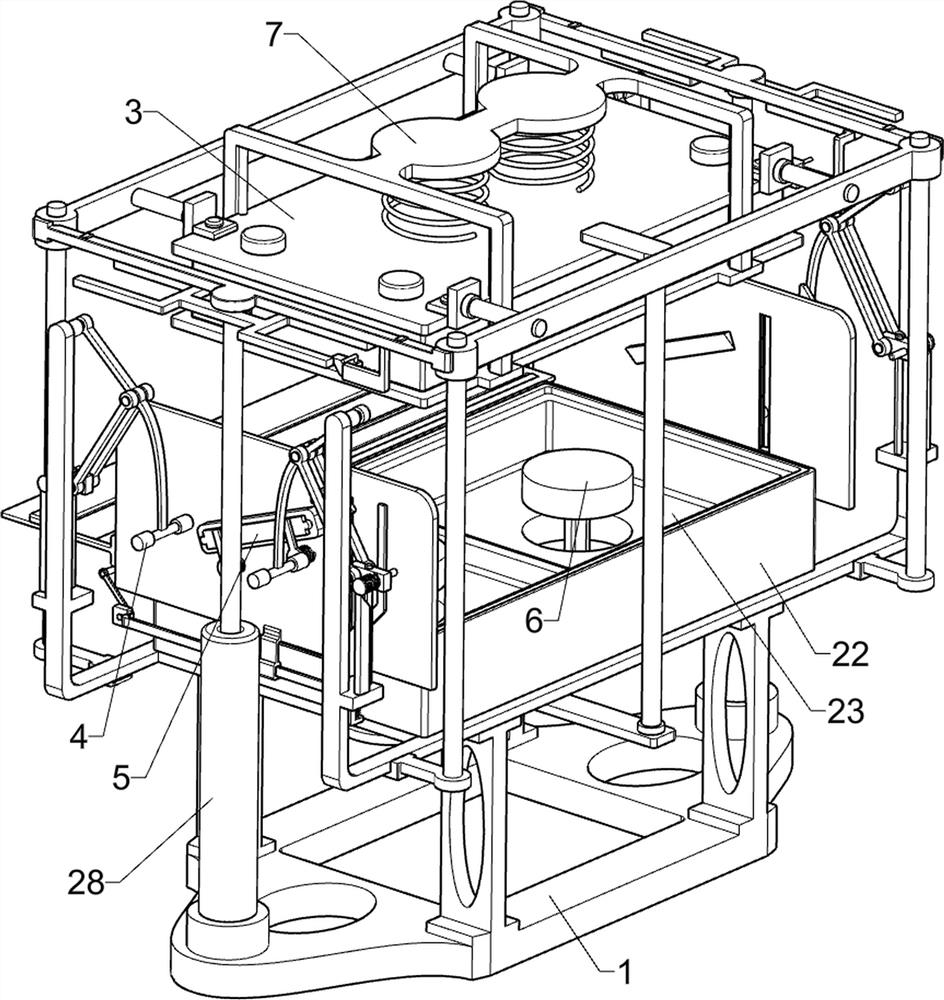

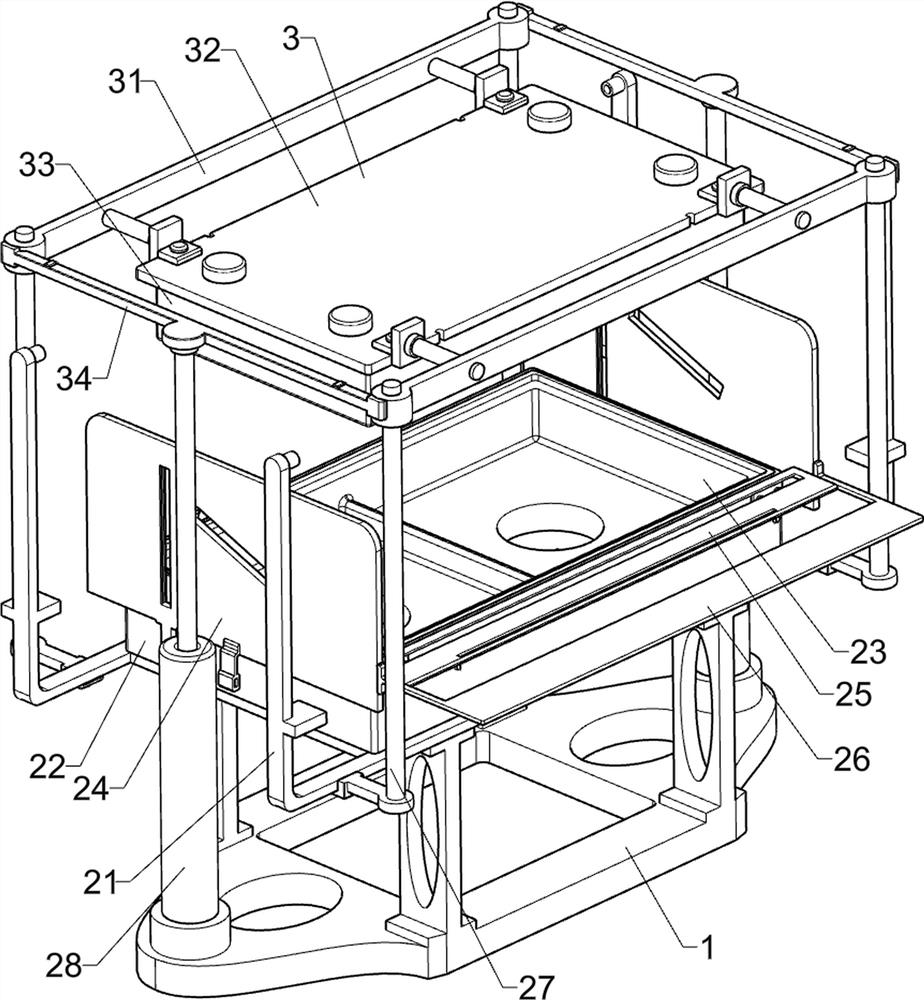

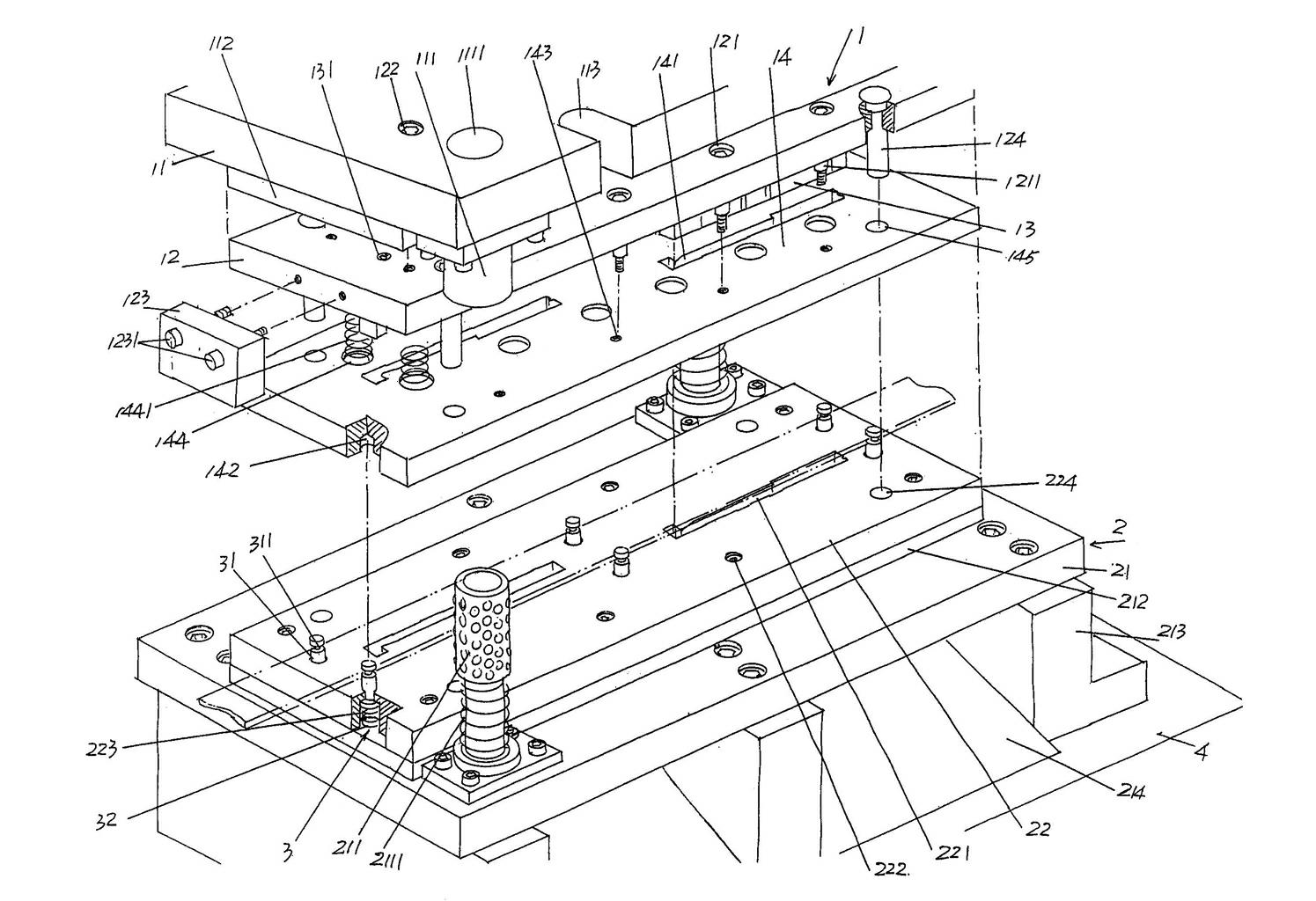

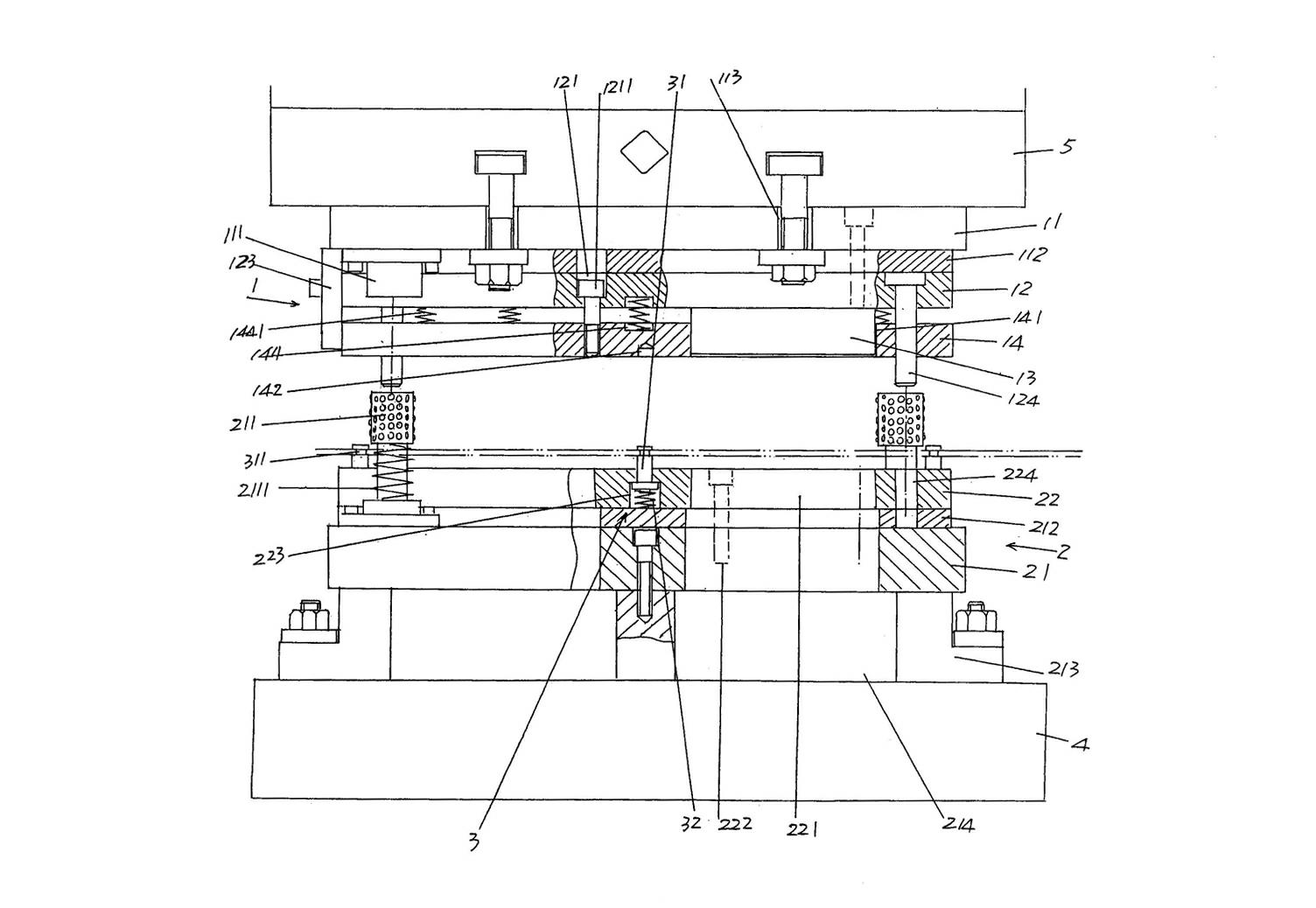

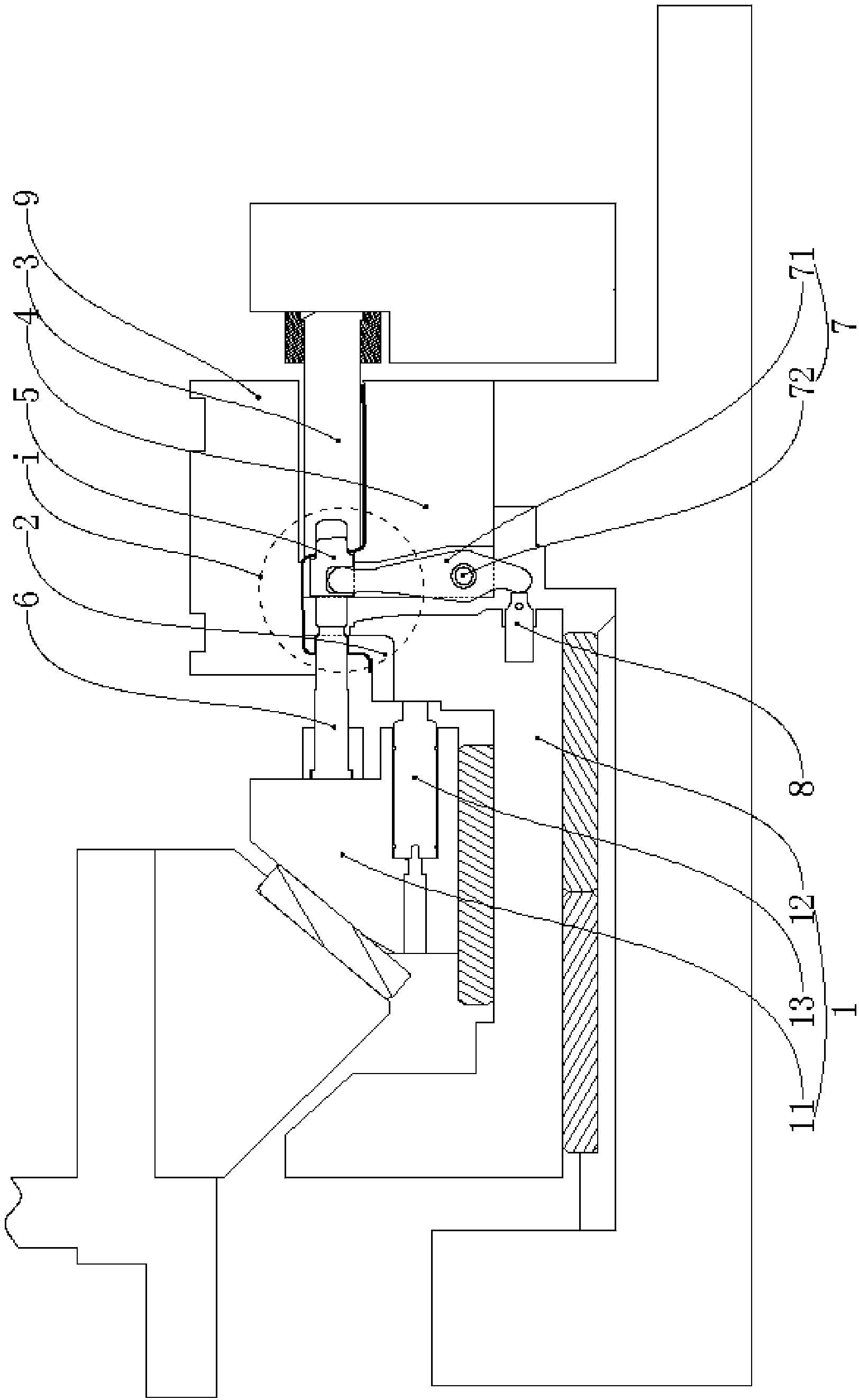

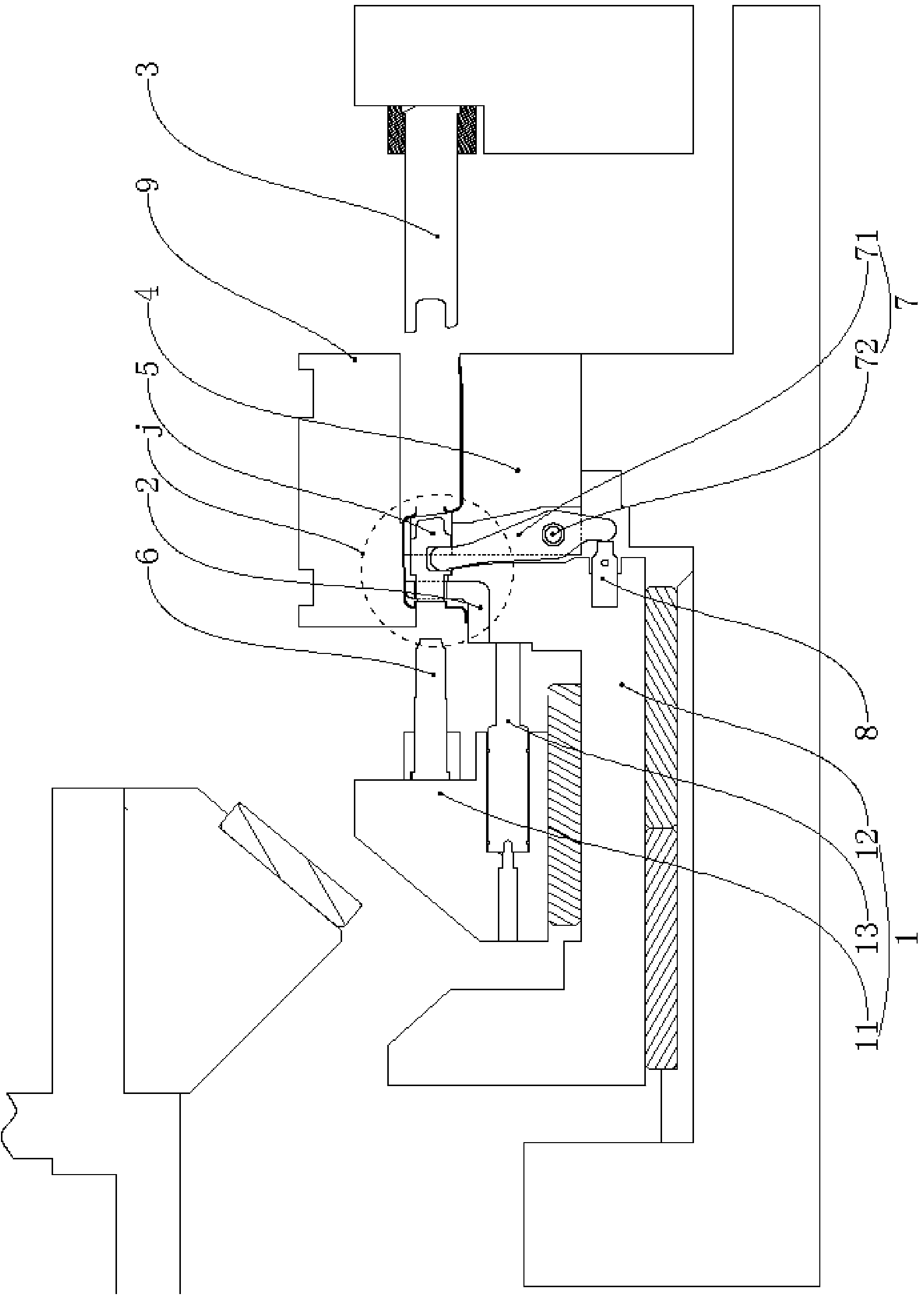

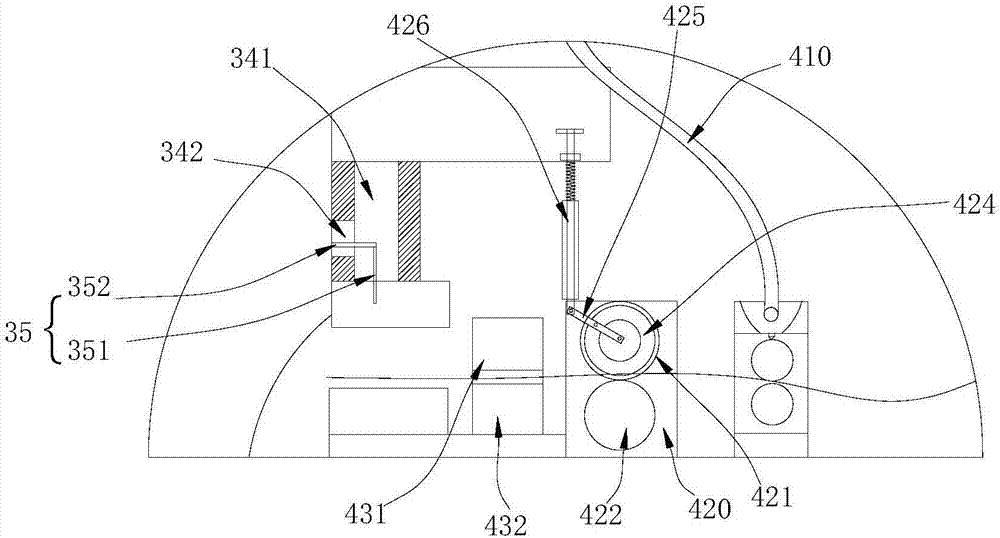

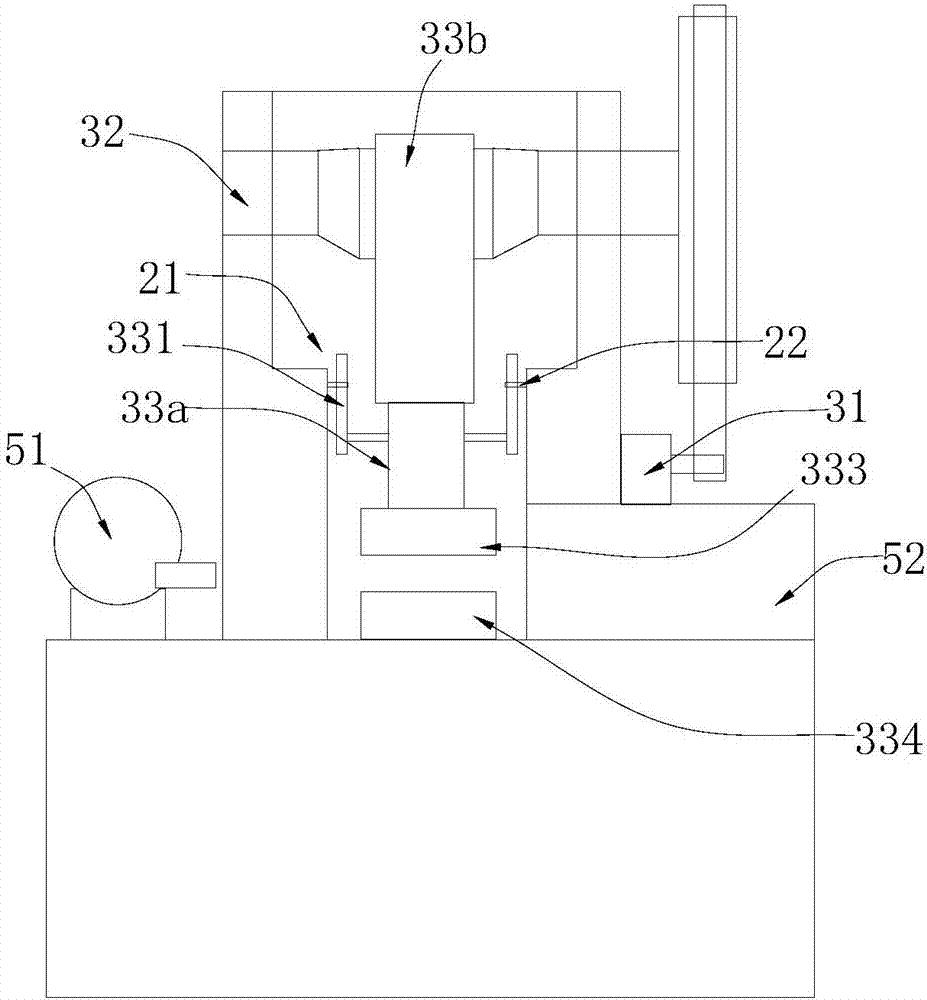

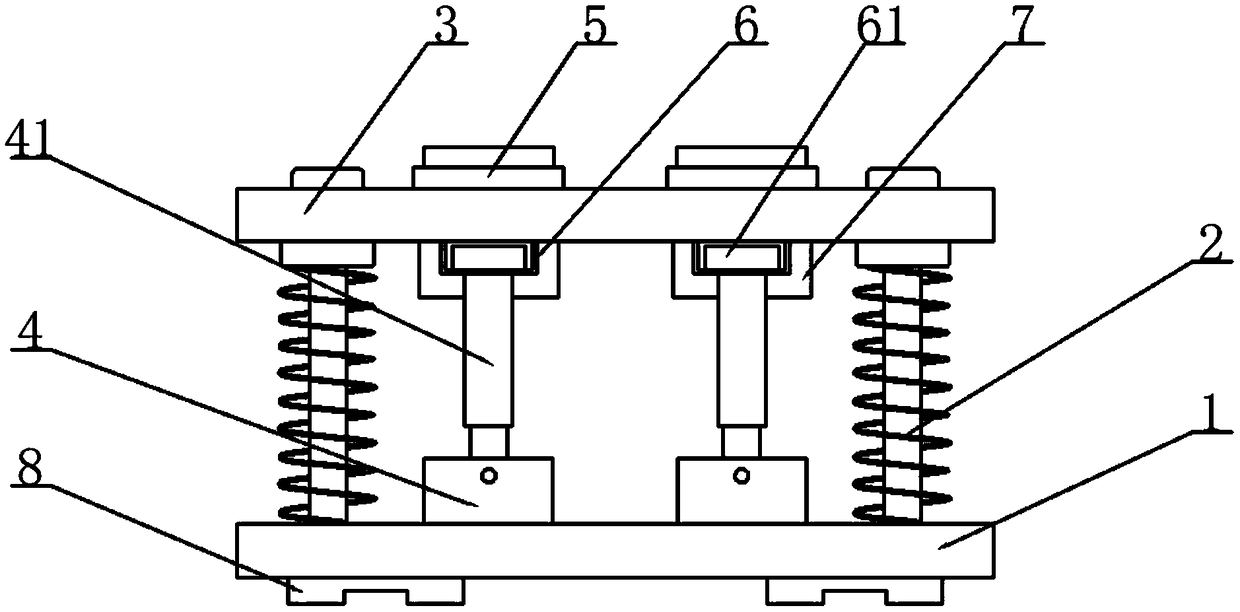

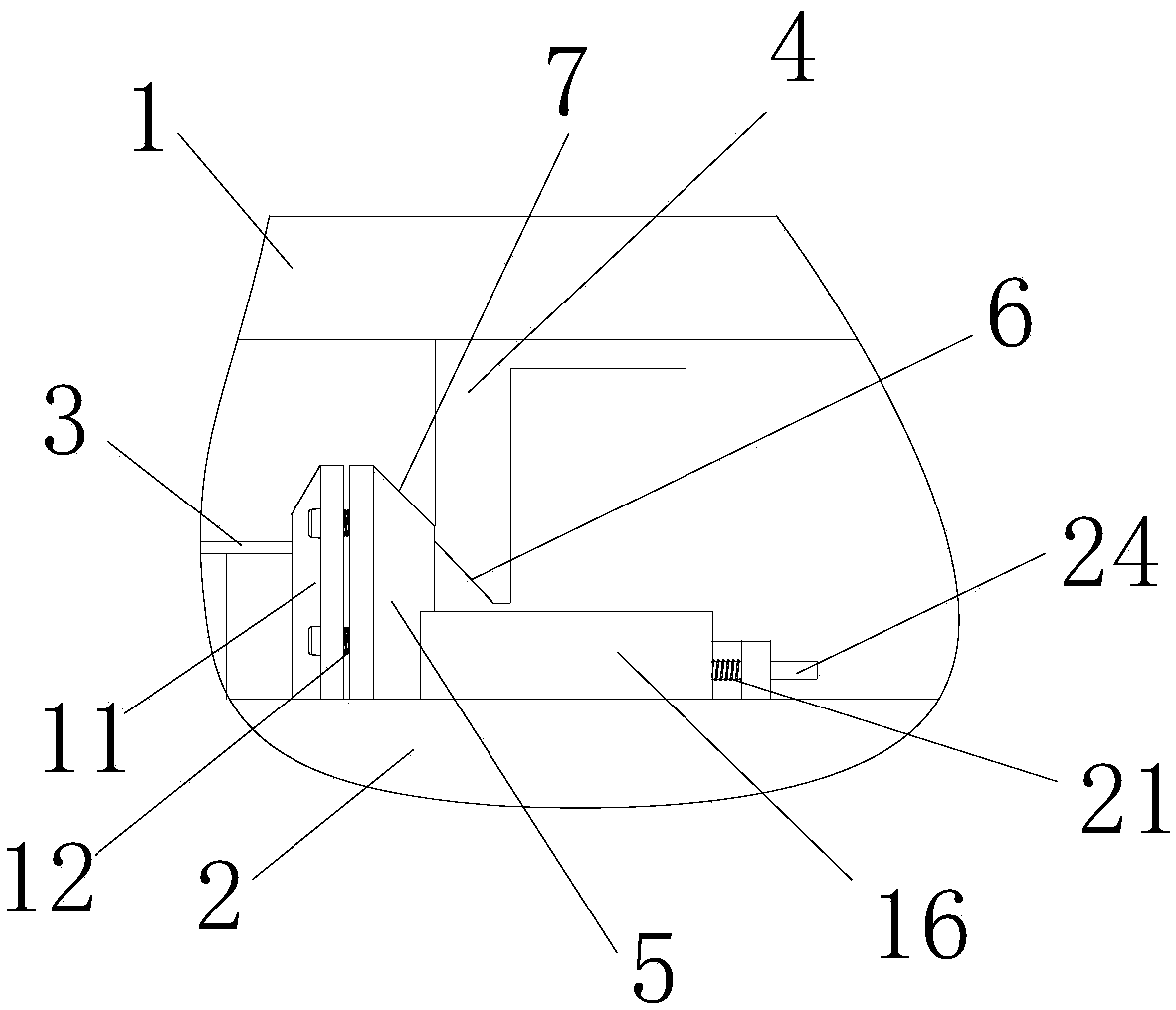

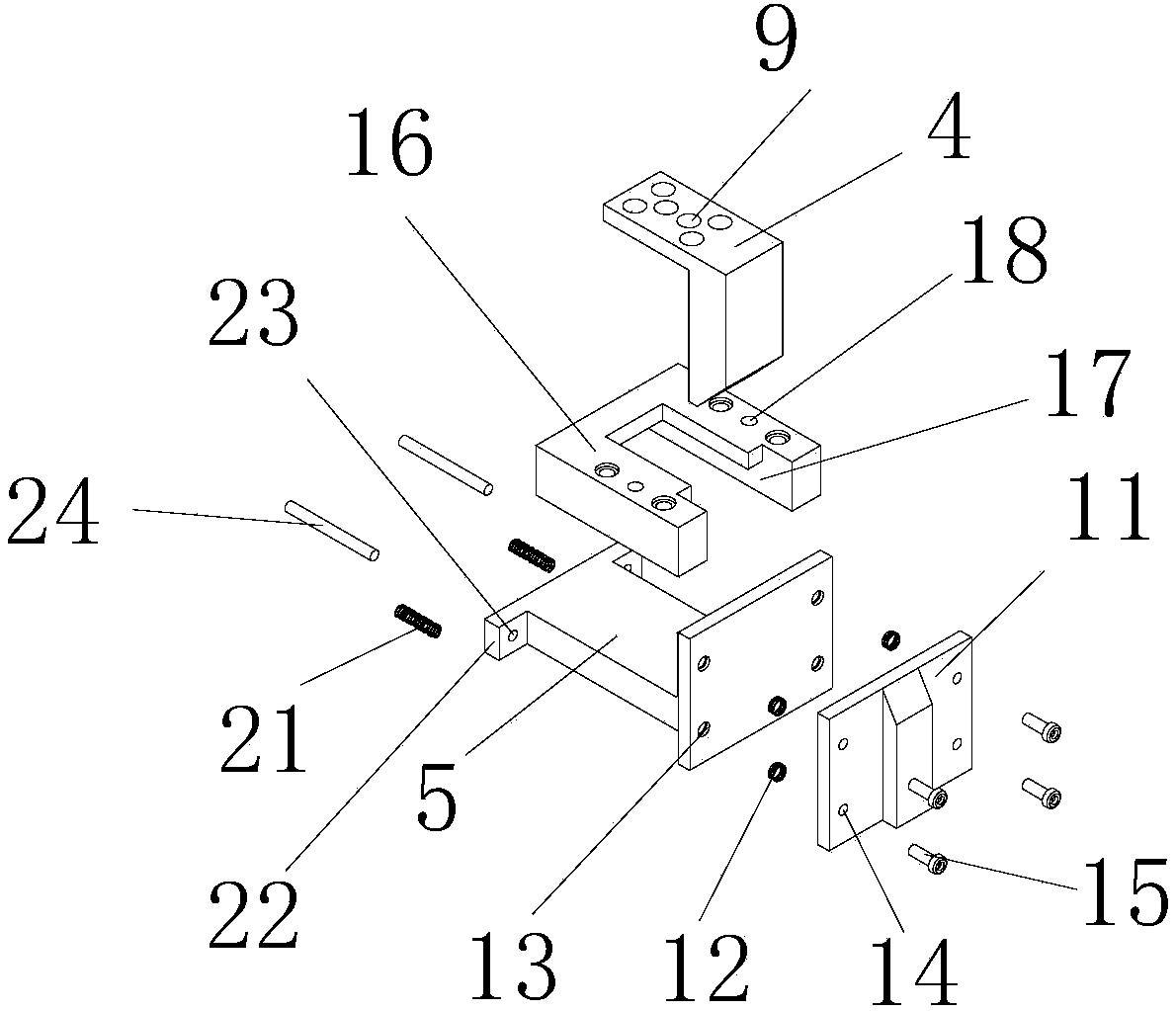

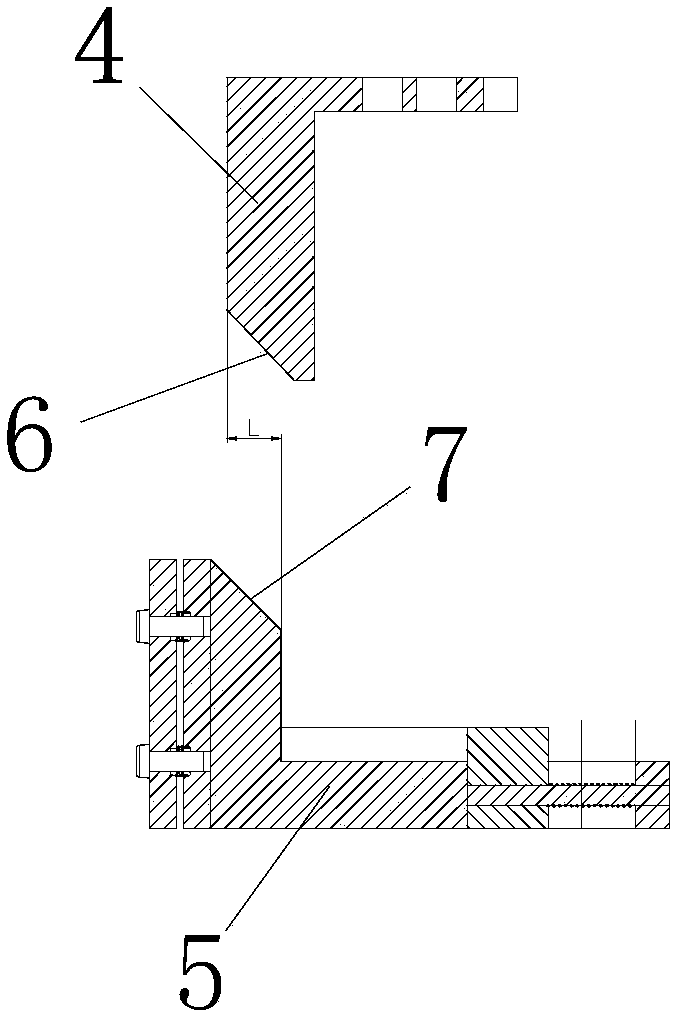

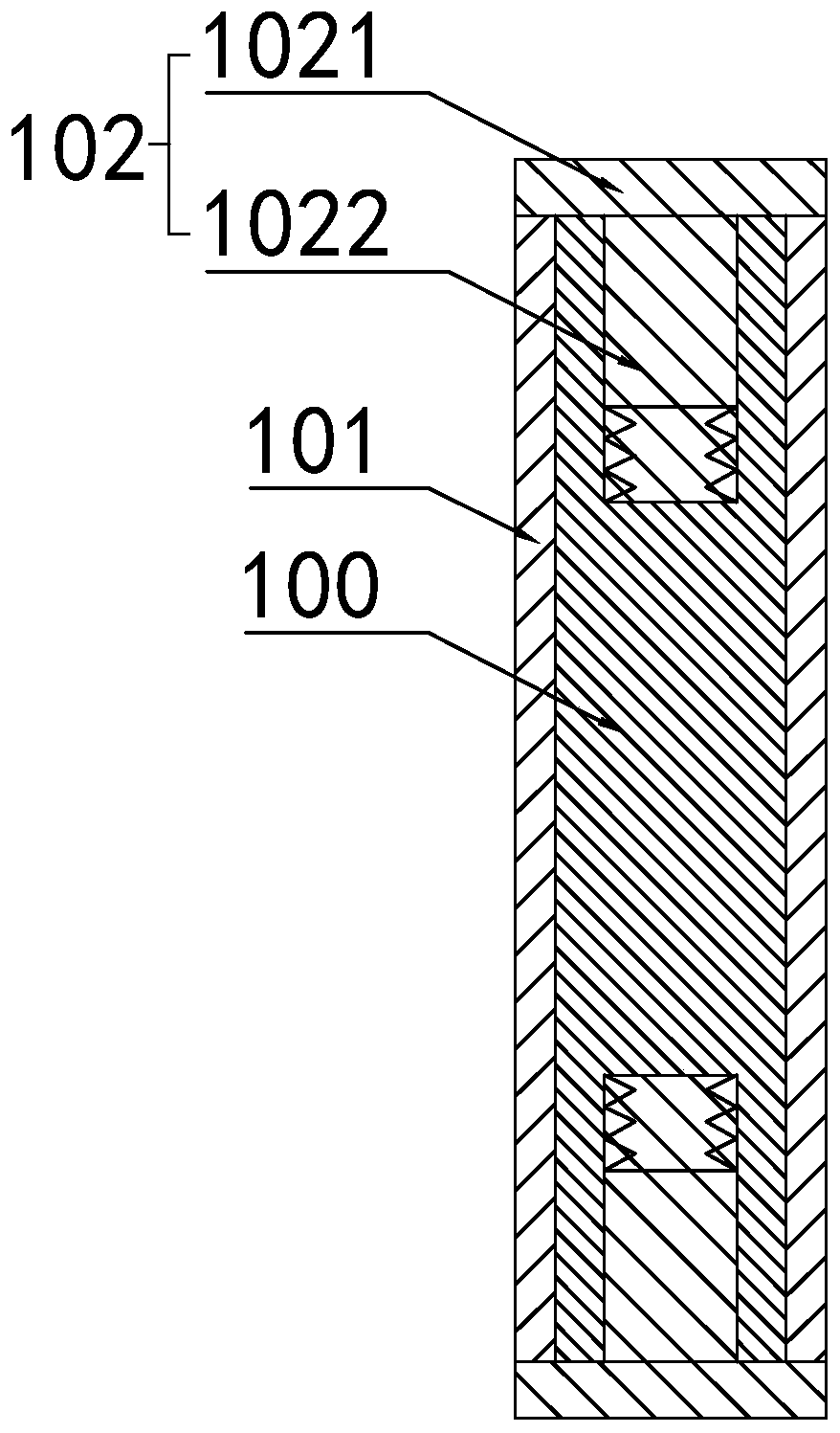

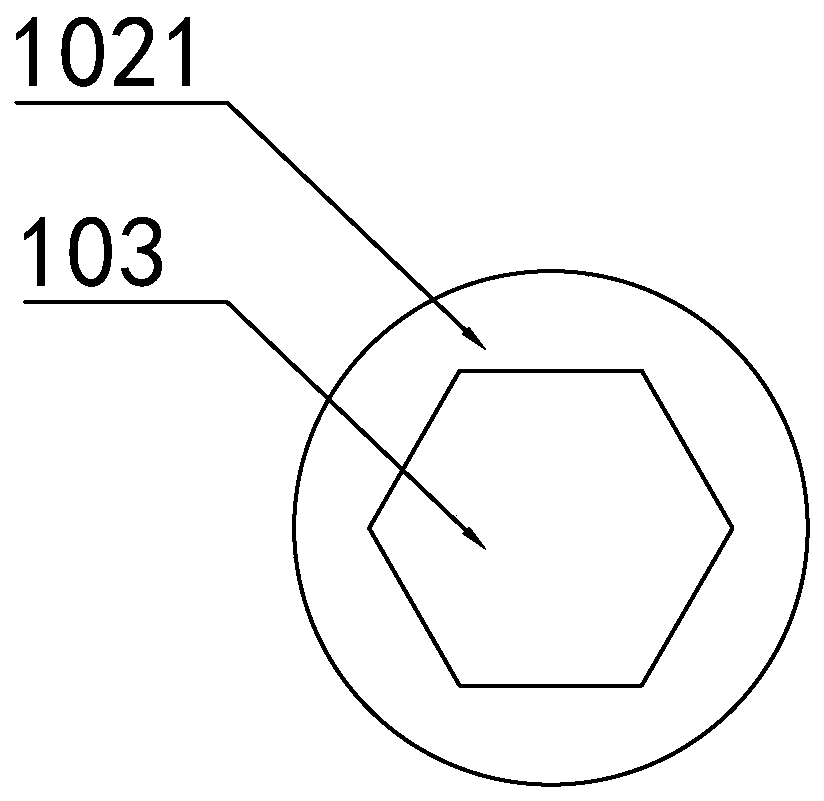

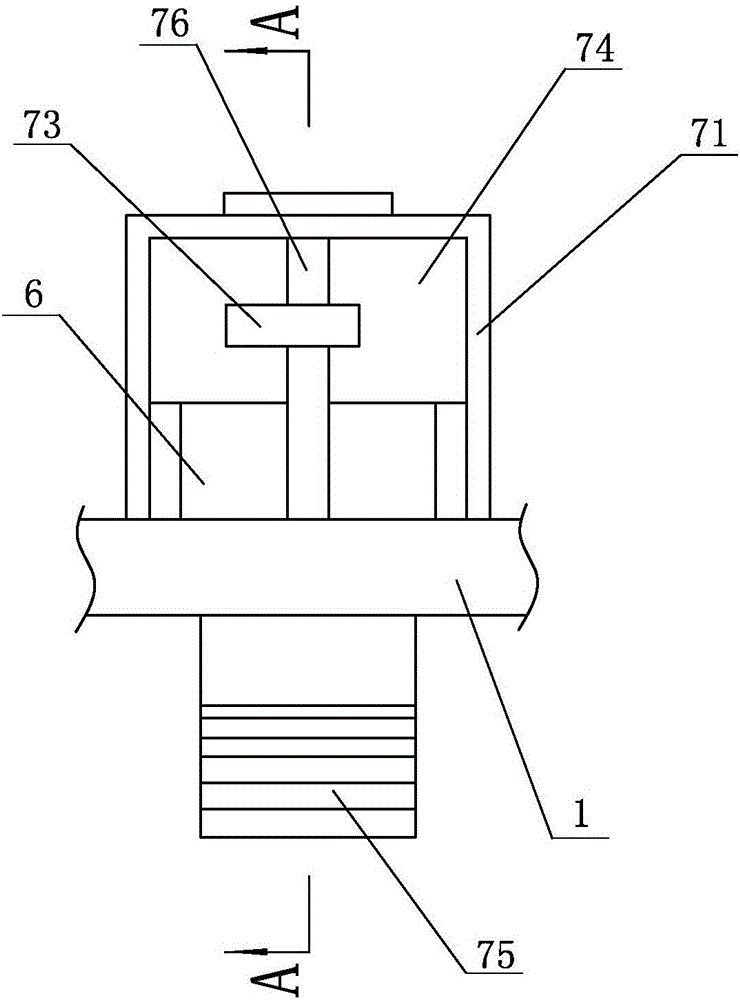

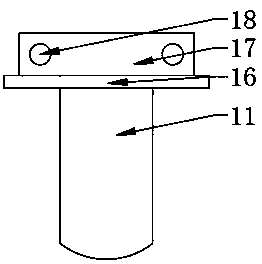

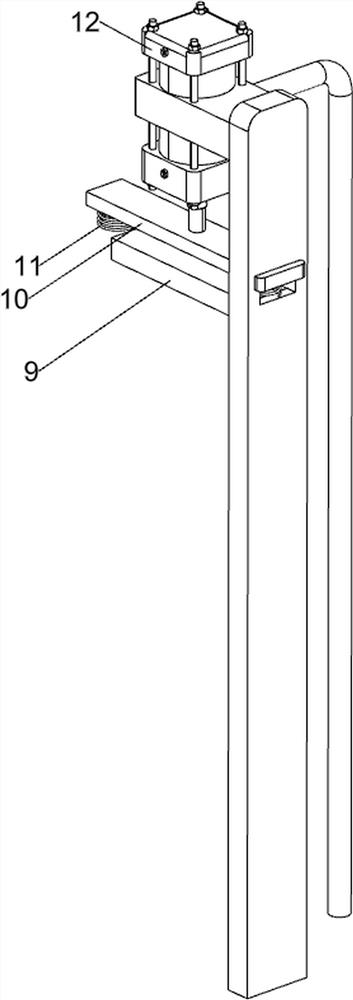

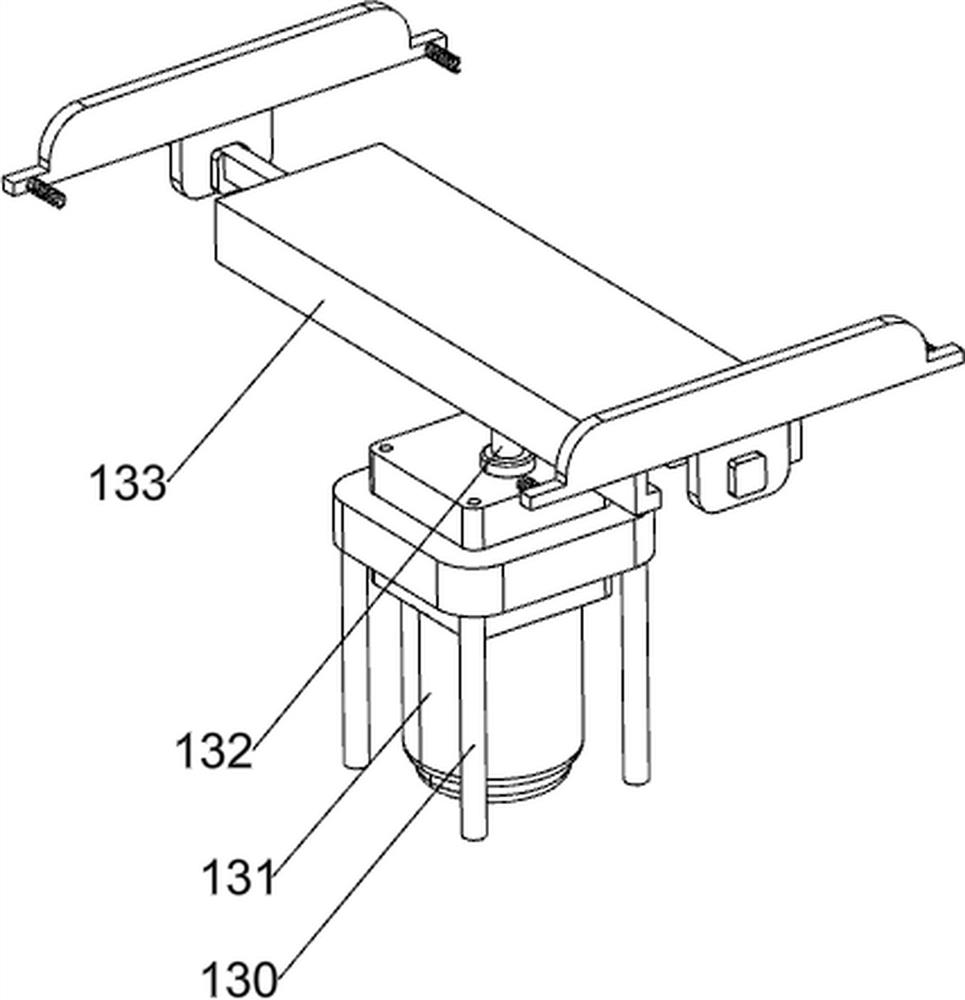

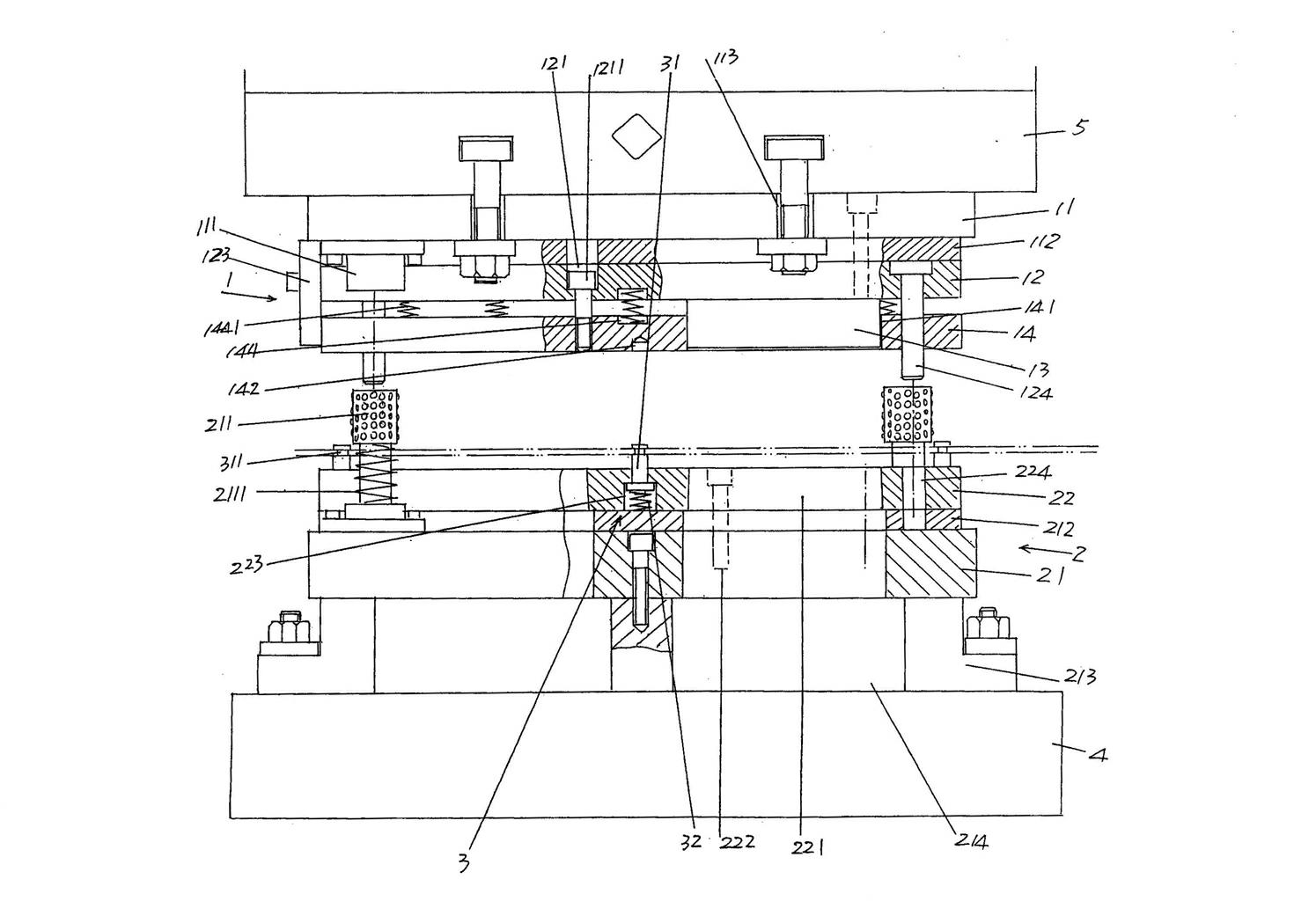

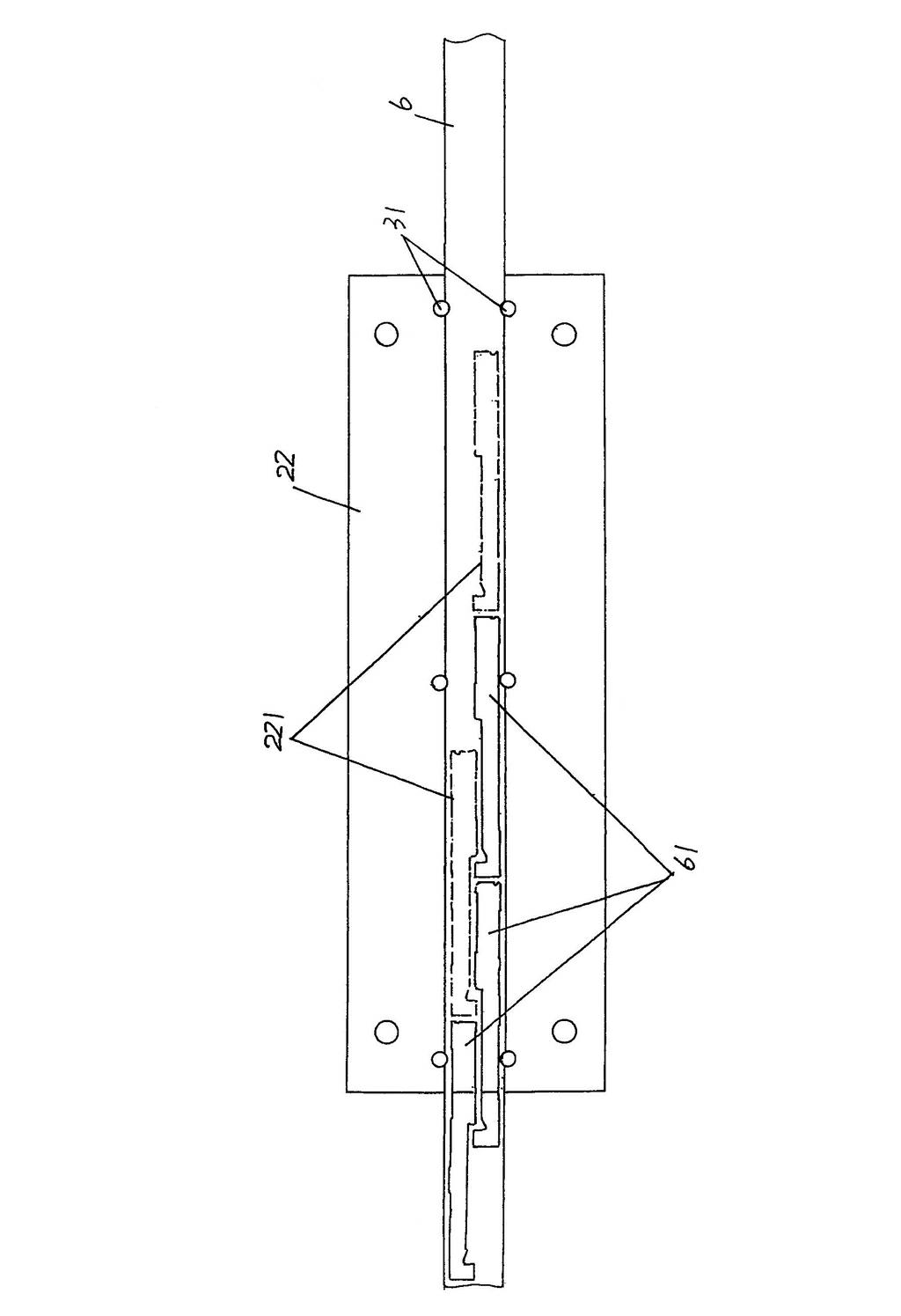

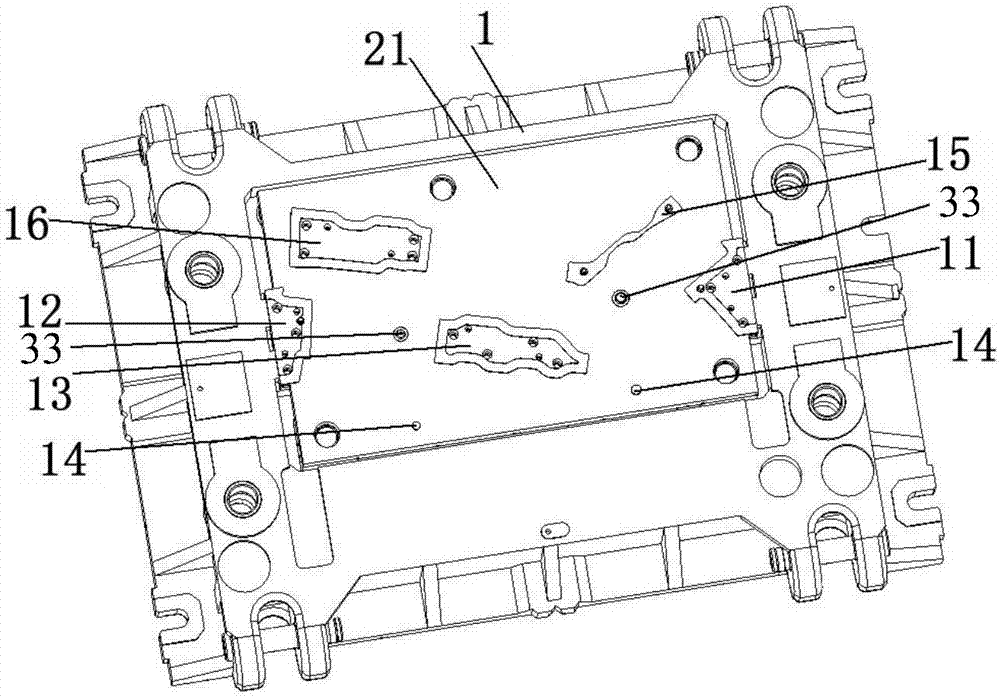

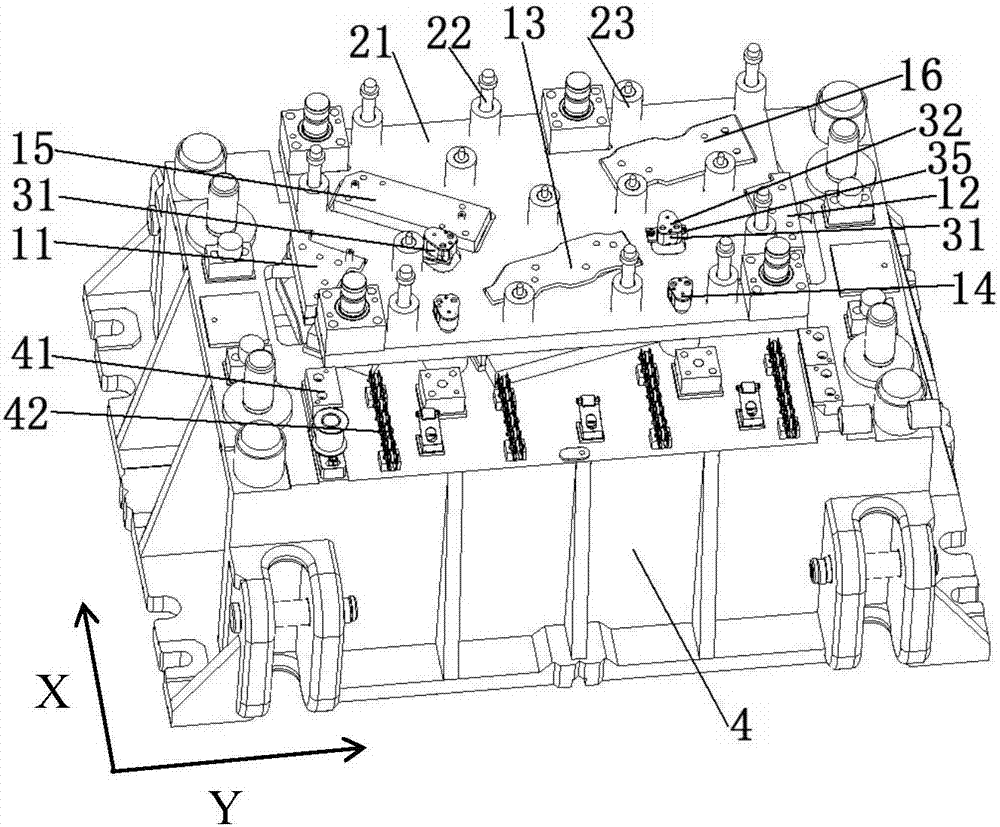

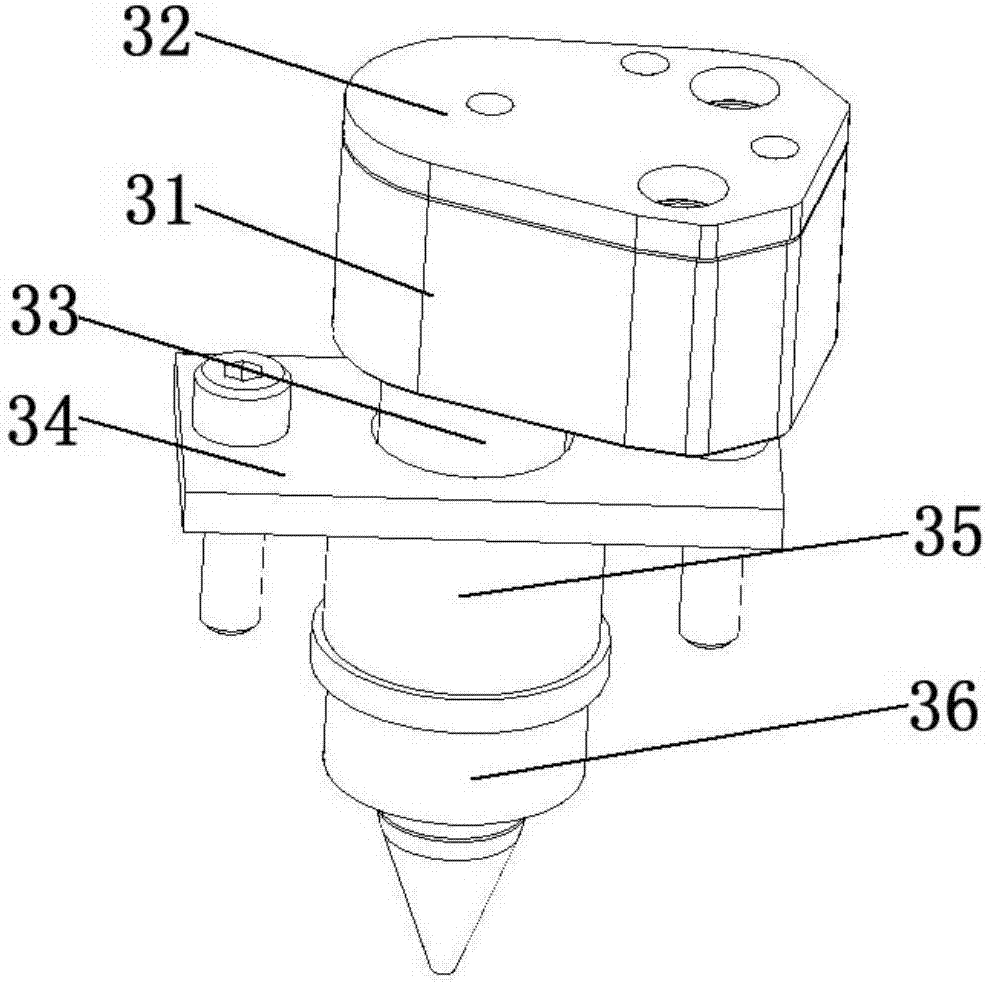

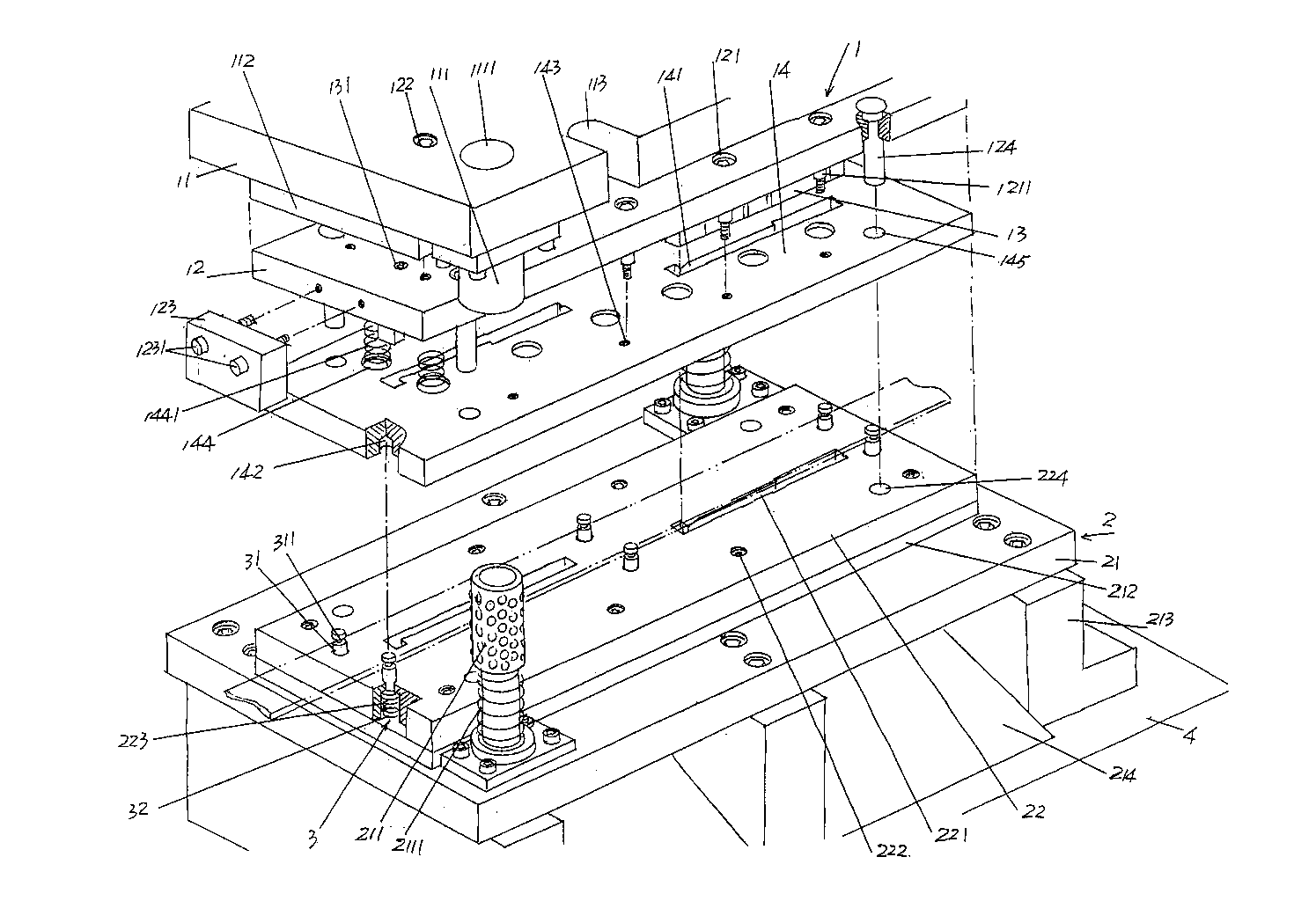

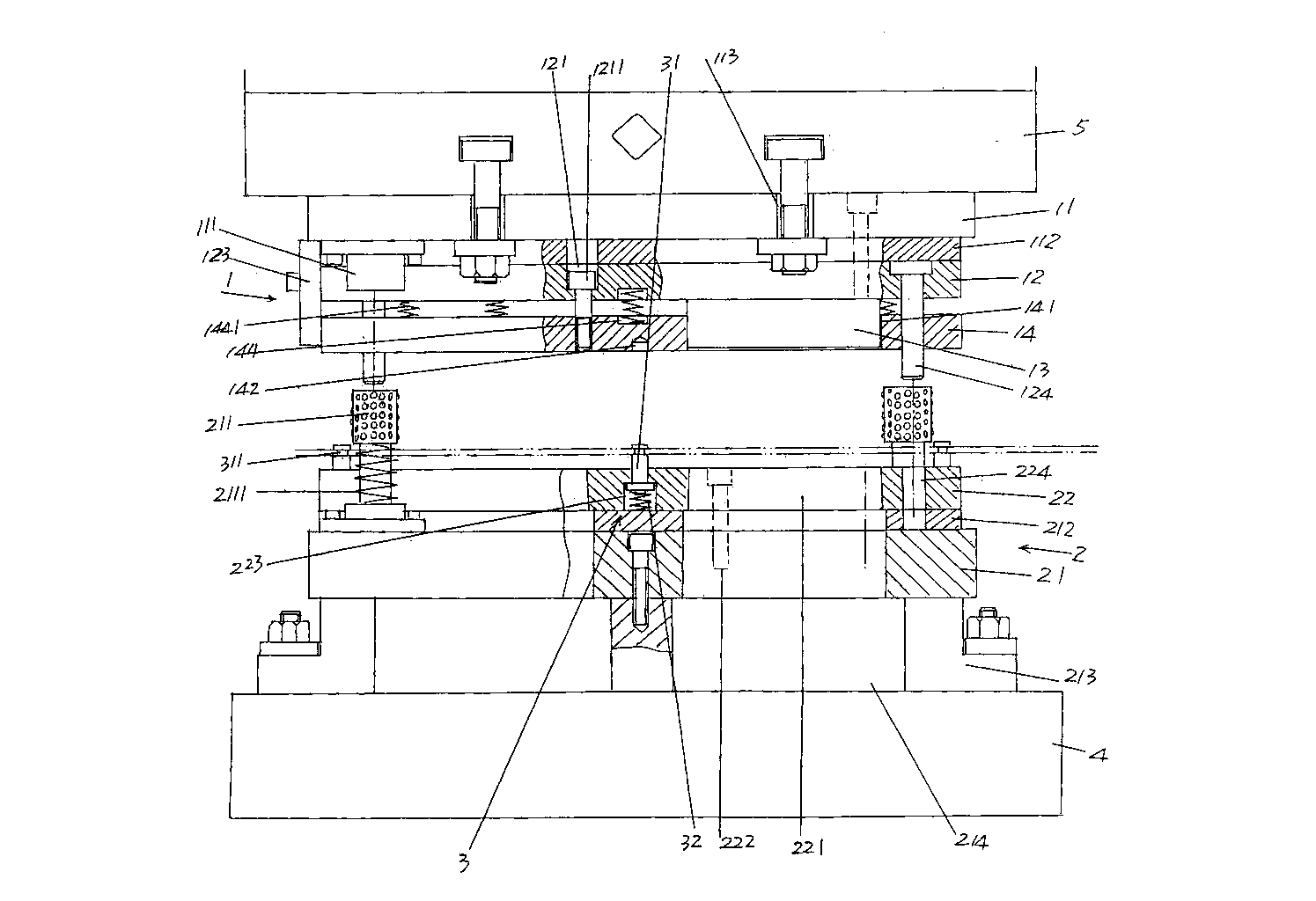

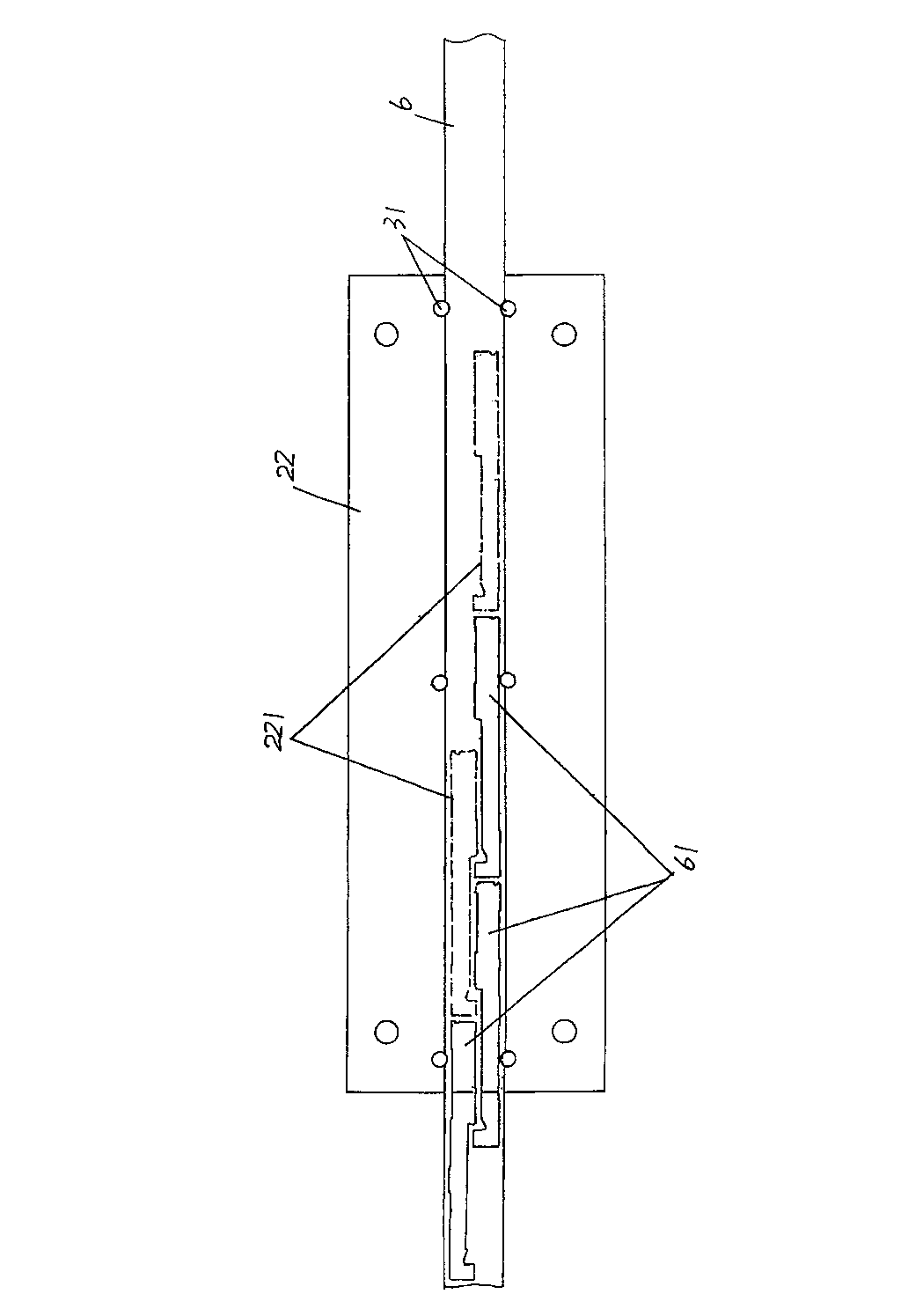

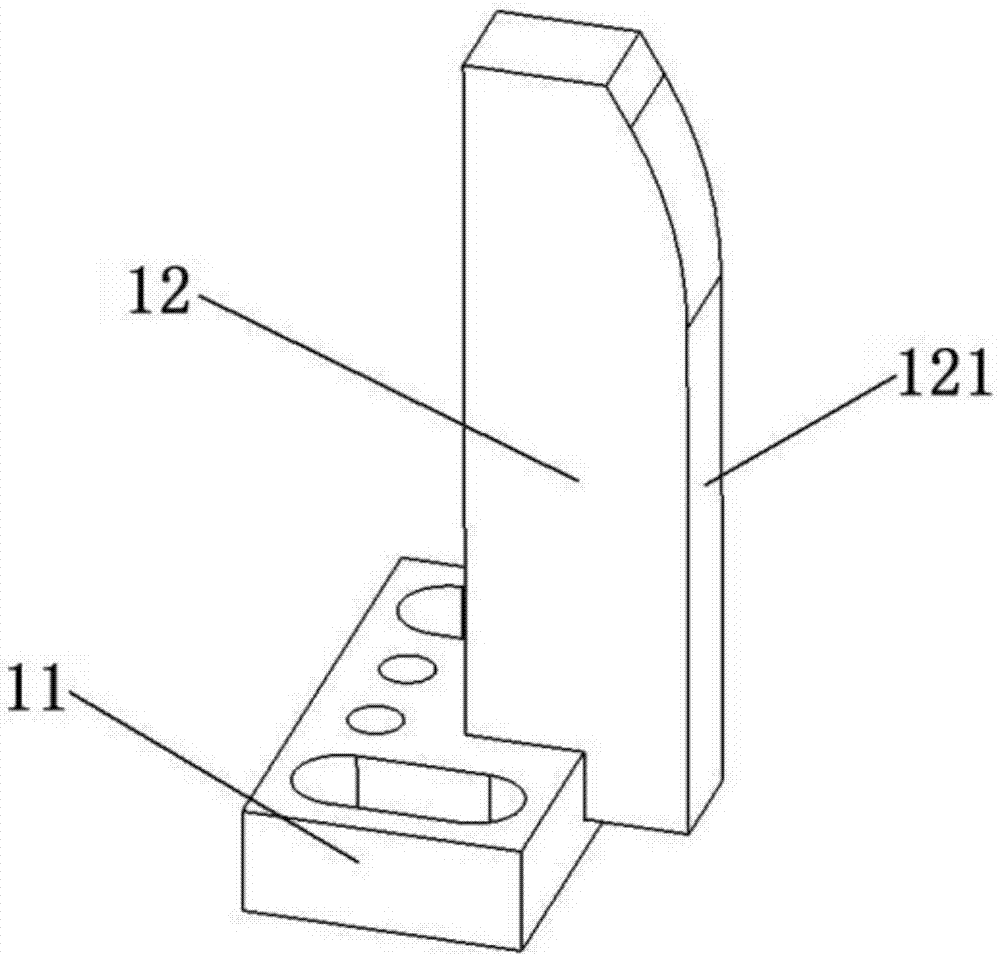

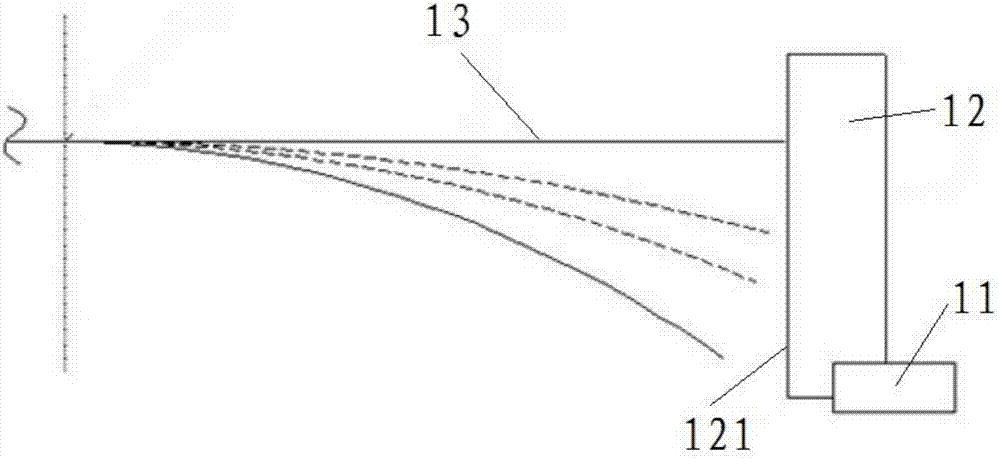

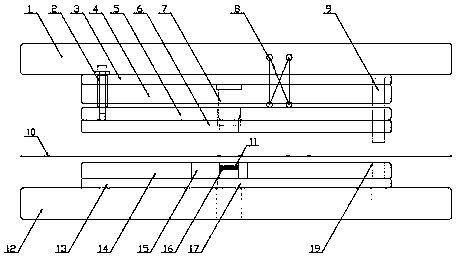

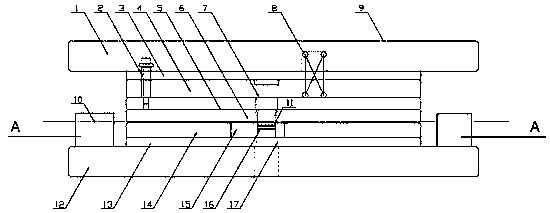

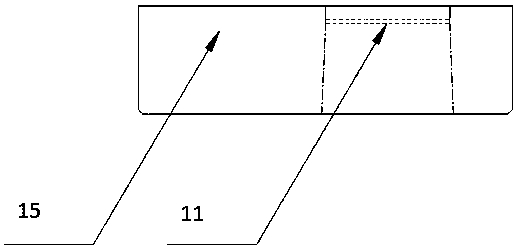

Positioning device and metal plate automatic production line

InactiveCN107774816AGuarantee stamping qualityAccurate locationMetal-working feeding devicesPositioning devicesProduction lineEngineering

The invention relates to a positioning device and a metal plate automatic production line. The positioning device is used for a production line die and the production line die includes an upper die and a lower die. The upper die and the lower die act jointly, to complete stamping on a workpiece on the lower die. The positioning device includes a driving block and a sliding block. The driving blockis fixedly connected with the upper die, the sliding block is movably connected to the lower die, the driving block is driven by the upper die to move and drives the sliding block to slide on the lower die, and the sliding block pushes the workpiece to move on the lower die, to adjust the position of the workpiece. The positioning device has the advantages of being reasonable in design, simple instructure and low in cost and capable of automatically correcting the workpiece on the lower die to make the position of the workpiece accurate and ensure metal plate stamping quality.

Owner:GREE ELECTRIC APPLIANCES INC

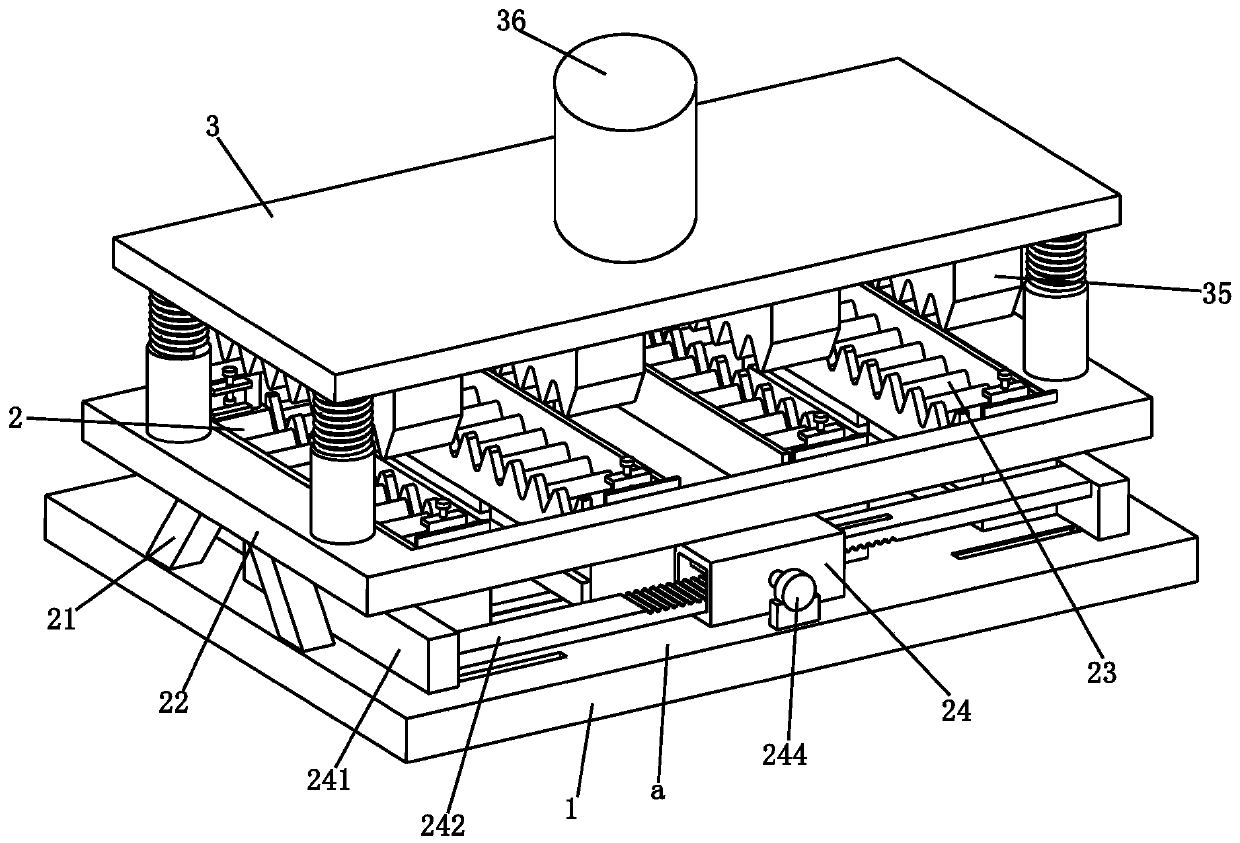

Air-conditioning condenser fin manufacturing and processing technology

ActiveCN110538940ASmall processing rangeReduce processing efficiencyShaping toolsHeat exchange apparatusEngineeringAir conditioning

The invention provides an air-conditioning condenser fin manufacturing and processing technology. A stamping die and the like are fully cooperated to complete manufacturing and processing of air-conditioning condenser fins. The problems that single-station processing is carried out on most existing equipment when the fins are processed by the equipment, different dies need to be replaced when thedifferent-size fins are processed, the processing range is small, and the processing efficiency is low; meanwhile, when the existing equipment is used for processing the fins, due to influences of special structures of the fins, the processed fins are tightly attached to the dies, and material taking after processing is not convenient to achieve; and raw materials can be stressed to retract back in the processing process of the fins, due to the improper restriction manner of the fins, the fins can offset during processing, and the fins deform and are broken after the fins are processed are solved.

Owner:SHANDONG MODERN LION AIR CONDITIONING EQUIP

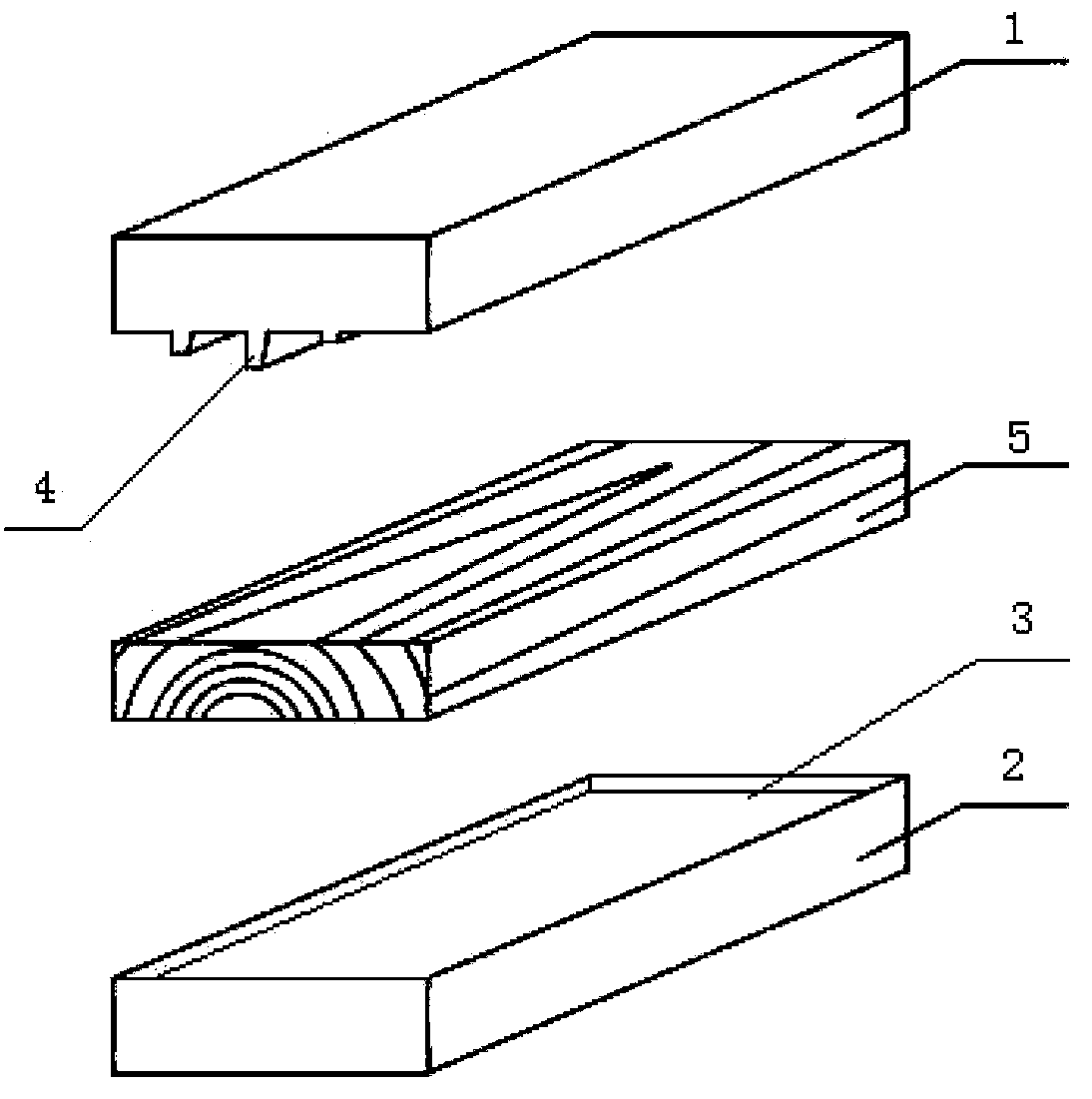

Hot pressing die for wood embossing

InactiveCN103358792AGuaranteed working temperatureGuarantee stamping qualityEmbossing decorationsPunchingEmbossing

The invention relates to a hot pressing die for wood embossing. The hot pressing die comprises a pressing template and a bearing plate matched with the pressing template, wherein the pressing template is parallel to the bearing plate; two opposite surfaces of the pressing template and the bearing plate are respectively a pressing template working surface and a bearing plate working surface; a working region for accommodating wood is arranged on the bearing plate working surface; a convex die for embossing patterns is arranged on the pressing template working surface. By the mode, the invention provides the hot pressing die for the wood embossing; figures or the patterns on the surface of the wood are formed and processed by a die-pressing mode. The hot pressing die comprises the pressing template and the bearing plate, and the pressing template and the bearing plate can be matched with each other to punch the wood. Furthermore, the working temperature of the hot pressing die can be guaranteed, so that the punching quality can be guaranteed, and processing errors are avoided.

Owner:苏州香山工坊建设有限公司

Processing equipment and processing method for grounding rod

ActiveCN110970744AHigh precisionImprove production and processing efficiencyContact member manufacturingConnection contact member materialPunchingEngineering

The invention relates to a processing method for a grounding rod. The method comprises the following steps of: turning, namely firstly, carrying out excircle machining and cutting-off on a raw material steel core and a copper sleeve so as to control the length sizes and the outer diameter sizes of the steel core and the copper sleeve; polishing, namely, polishing the outer walls of the copper sleeve and the steel core through a polishing machine; chamfering, namely, chamfering the two ends of the steel core; punching, namely, punching the steel core into the copper sleeve through a punching machine and a matched grinding tool; first sleeving spot welding, namely, enabling a first copper seat of the steel core to be connected to the copper sleeve in a sleeving mode through a sleeving machine, and welding; second-time sleeving spot welding, namely, enabling a second copper seat to be connected to the copper sleeve in a sleeving mode through the sleeving machine, and welding; and packaging, namely, packaging the machined copper sleeves in a packaging box through a packaging machine. The ground rod manufactured by the method is good in corrosion resistance.

Owner:龙游龙辉电镀有限公司

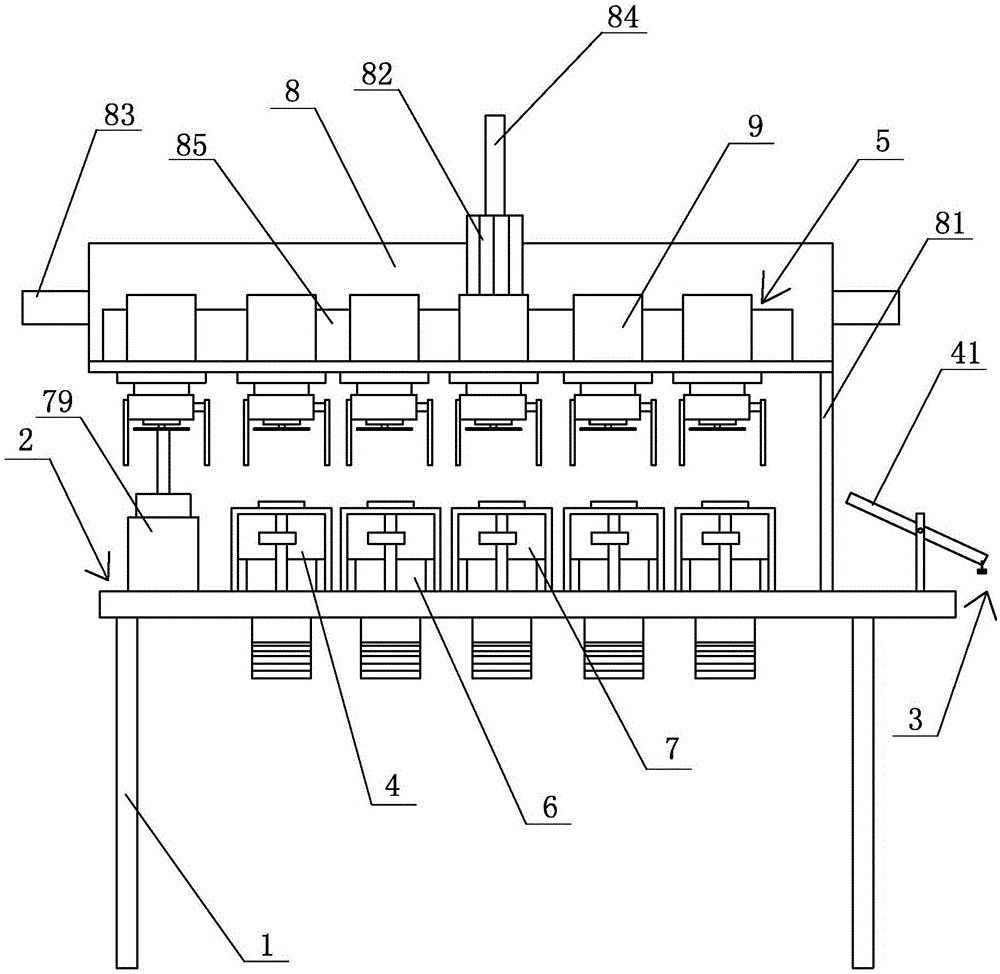

Punching device

InactiveCN106180370AReduce labor intensityAutomated Crawl AssurancePerforating toolsMetal-working feeding devicesPunchingArray data structure

The invention discloses a punching device. The punching device is characterized by comprising a rack; one end of the rack is provided with a feeding end, and the other end of the rack is provided with a discharging end; a plurality of sets of punching device bodies and a product grabbing device are arranged in the positions, between the feeding end and the discharging end, of the rack; the multiple sets of punching device bodies are arranged on the rack at intervals from left to right; each punching device body comprises a product positioning base and punching mechanisms arranged on the two sides of the product positioning base; the product grabbing device comprises a moving mechanism and a plurality of sets of material grabbing mechanisms arranged on the moving mechanism; the distance between the adjacent material grabbing mechanisms is equal to the distance between the adjacent product positioning bases; and the material grabbing mechanisms are arranged above the product positioning bases. According to the punching device, the punching efficiency and the punching quality of products are improved, and the qualified rate of the products is increased.

Owner:苏州任翔金属制品有限公司

Hardware stamping die with stamping head convenient to replace

InactiveCN110918781AGuaranteed linearityAvoid shakingShaping toolsStructural engineeringMechanical engineering

The invention discloses a hardware stamping die with a stamping head convenient to replace in the technical field of hardware stamping dies. The left and right sides of the bottom of an upper die areboth fixedly provided with locating columns. A mounting plate is fixedly welded to the bottom center of the upper die. The stamping head is fixedly in screwed connection with the bottom of the mounting plate through fastening bolts. The bottom of the mounting plate is provided with a locating groove. The sidewall of the side, far away from an opening, of the interior of the locating groove is provided with a limiting insertion groove. The front and rear sidewalls of the mounting plate are both provided with corresponding threaded through holes. A limiting plate matched with the locating grooveis fixedly welded to the top of the stamping head. An insertion block matched with the limiting insertion groove is fixedly welded to the top of the limiting plate. The front sidewall of the insertion block is provided with insertion through holes corresponding to the threaded through holes. Through the hardware stamping die with the stamping head convenient to replace, the stamping quality of the stamping head can be ensured; the stamping head can be fast and convenient to replace and dismantle, the hardware stamping die is convenient to operate, and the disassembling and assembling convenience is improved.

Owner:吴中区甪直磊鑫模具厂

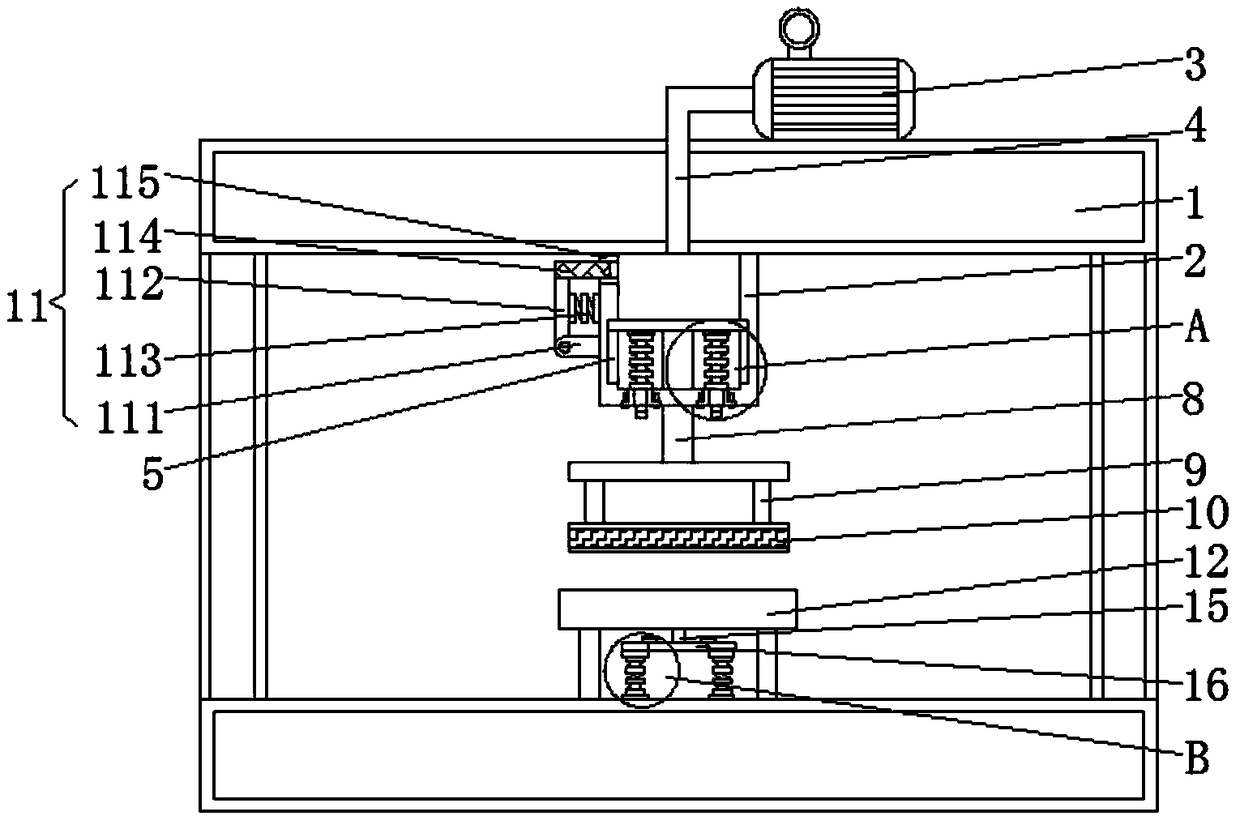

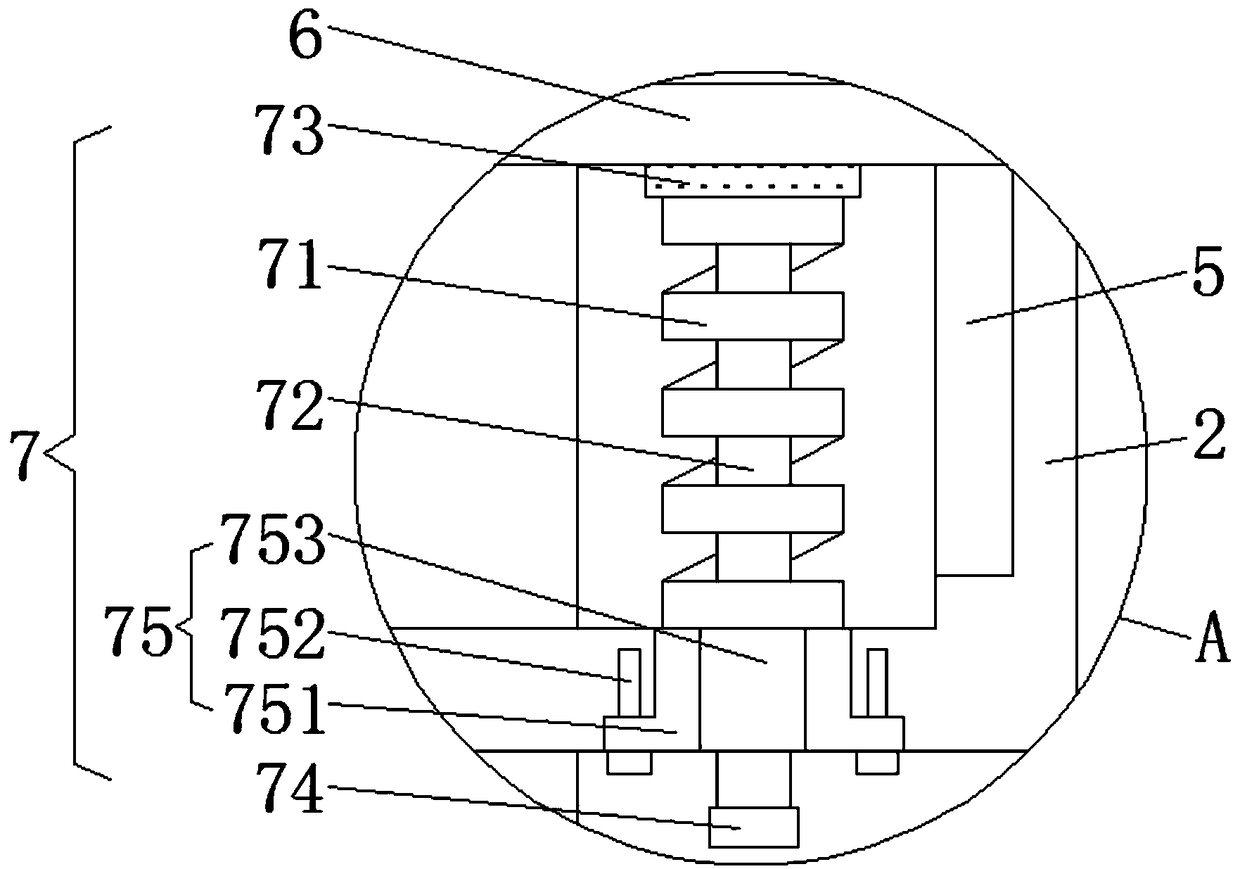

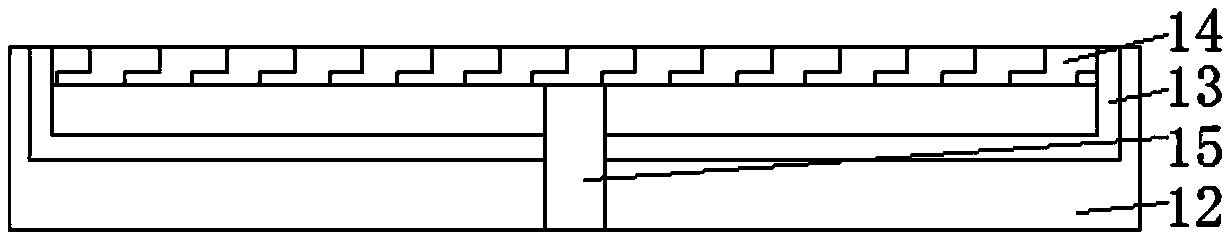

Stamping die for plastic plate applied to environment-protecting technological equipment

InactiveCN108773057AGuarantee stamping qualityEasy to replaceFlat articlesEngineeringMechanical engineering

The invention discloses a stamping die for a plastic plate applied to environment-protecting technological equipment. The stamping die comprises a frame; a shell is welded onto the inner side of the frame; an air pump is fixedly mounted on the top of the frame; an air inlet pipe is fixedly connected with the air outlet of the air pump; one end of the air inlet pipe extend into the shell; sliding grooves are formed in both sides of the inner cavity of the shell; a piston is arranged between and slidably connected with the two sliding grooves; two sides of the lower surface of the piston are respectively provided with a reset mechanism; the bottom of the piston is welded with a movable connecting rod; one end of the movable connecting rod is fixedly connected with a mounting plate; an uppermold plate is fixedly mounted on the bottom of the mounting plate; one side of the outer surface of the shell is provided with a sealing mechanism; and a lower mold plate is fixedly mounted on the lower surface of the inner cavity of the frame. According to the stamping die of the invention, a connection mechanism is arranged on the reset mechanisms, which facilitates replacement of damaged returnsprings in a later stage, and the stamping die can be normally operated and can be put into use for a long time.

Owner:桂峰

Automatic stamping die for inverse-hemming aluminum foil meal box

PendingCN113351752AEasy to moveImprove convenienceShaping toolsEnvelopes/bags making machineryStampingStructural engineering

The invention discloses an automatic stamping die for an inverse-hemming aluminum foil meal box, and belongs to the technical field of stamping dies. The automatic stamping die for the inverse-hemming aluminum foil meal box comprises a base, wherein a spring replacement assembly is arranged at the upper end of the base; a movable frame is arranged at the upper end of the spring replacement assembly; a connecting rod is arranged at the upper end of the movable frame; a stamping die core is arranged at the bottom end of the movable frame; a fixed die is arranged at the bottom end of the stamping die core; the spring replacement assembly comprises a limiting device, a fixed plate, a movable block, sleeves, limiting springs, mounting boxes and mounting insertion blocks; the sleeves are symmetrically arranged at the upper end of the base; the limiting springs are arranged in the sleeves; the mounting insertion blocks are symmetrically arranged at the two ends of the limiting springs; and the mounting boxes are arranged on the surfaces of the mounting insertion blocks. According to the automatic stamping die for the inverse-hemming aluminum foil meal box provided by the invention, by arranging the spring replacement assembly, the convenience of replacing the limiting springs is improved, the stamping quality is guaranteed, the working stability is improved, manpower resources are saved, and the working quality is improved.

Owner:江苏绿源健康铝箔科技有限公司

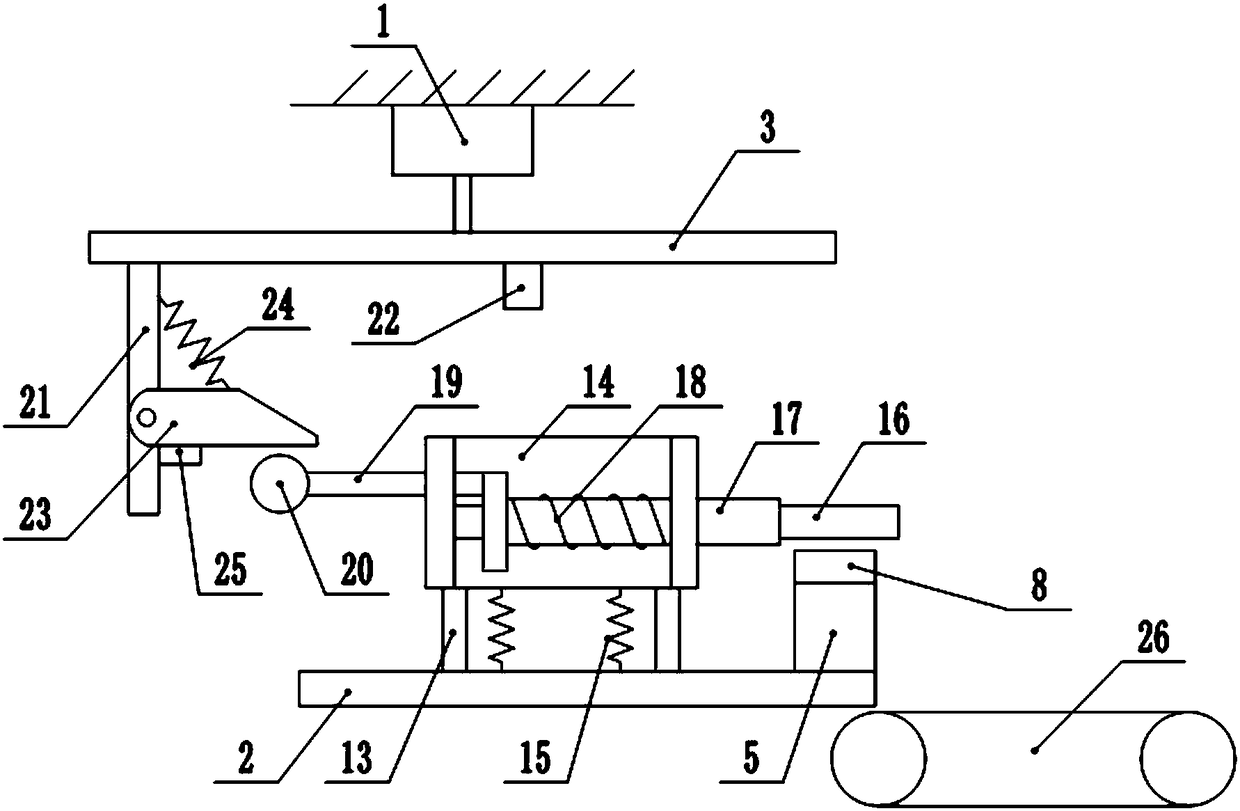

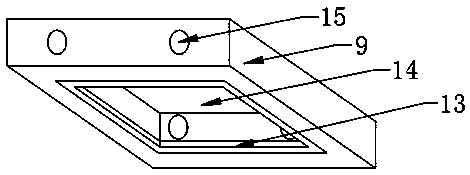

Stainless steel mesh production equipment for pet captivity

ActiveCN113182431AGuarantee stamping qualityImprove stamping efficiencyMetal-working feeding devicesClimate change adaptationSS - Stainless steelSlide plate

The invention relates to stainless steel mesh production equipment, in particular to stainless steel mesh production equipment for pet captivity. According to the stainless steel mesh production equipment for pet captivity, the machining quality can be guaranteed, the stamping efficiency is high, and the density and sizes of holes are proper. The stainless steel mesh production equipment for pet captivity comprises a base, a working platform, a placement plate, a first support plate, a first support frame, a first connecting plate and a sliding plate, wherein the first support plate is arranged at the right side of the top of the base; the placement plate is arranged between the working platform and the first support plate; the first support frame is arranged at the front side of the top of the base; the first connecting plate is arranged on the first support frame in a sliding manner; and the sliding plate is arranged on the first support frame in a sliding manner. Through cooperation of a pushing mechanism and a moving mechanism, the pushing mechanism continuously pushes a stainless steel plate front and back, and meanwhile, the moving mechanism drives a storage roller to move front and back, and therefore, the stamping quality is guaranteed.

Owner:南京市淑先科技有限公司

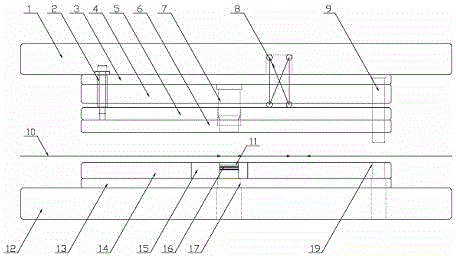

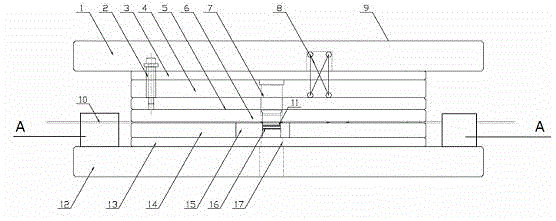

Mold for punching needle bed insert blank used in computer knitting flat knitting machine

InactiveCN102672052AAvoid interferenceRealize continuous punchingShaping toolsMetal-working feeding devicesPunchingEngineering

The invention discloses a mold for punching a needle bed insert blank used in a computer knitting flat knitting machine, belonging to the technical field of molds; the mold comprises an upper mold mechanism and a lower mold mechanism; the upper mold mechanism comprises an upper template holder, an upper template and an insert male punching mold; the lower mold mechanism comprises a lower template holder and a lower template; the mold is characterized in that the upper mold mechanism further comprises a material press plate connected with one side of the upper template; a mold guide hole is arranged on the material press plate; one side of the lower template, and two sides of a mold cavity corresponding to tool edges are provided with a group of thin steel strip guiding and limiting mechanisms for guiding and limiting the thin steel strips, respectively; each thin steel strip guiding and limiting mechanism is matched with the material press plate; a material cutter is fixed on the upper template; and the material cutter corresponds to the left end of the mold guide hole. The mold has the advantages that the mold is helpful to realize the continuous punching, so as to enhance the efficiency and satisfy the industrialization amplification production requirements; the thin steel strip is prevented from offset or up-warping, so that the punching quality is ensued, the fault is avoided so as to save materials and reduce cost; and the operation field is protected from interference.

Owner:常熟市尚湖镇冶塘伟东模具厂

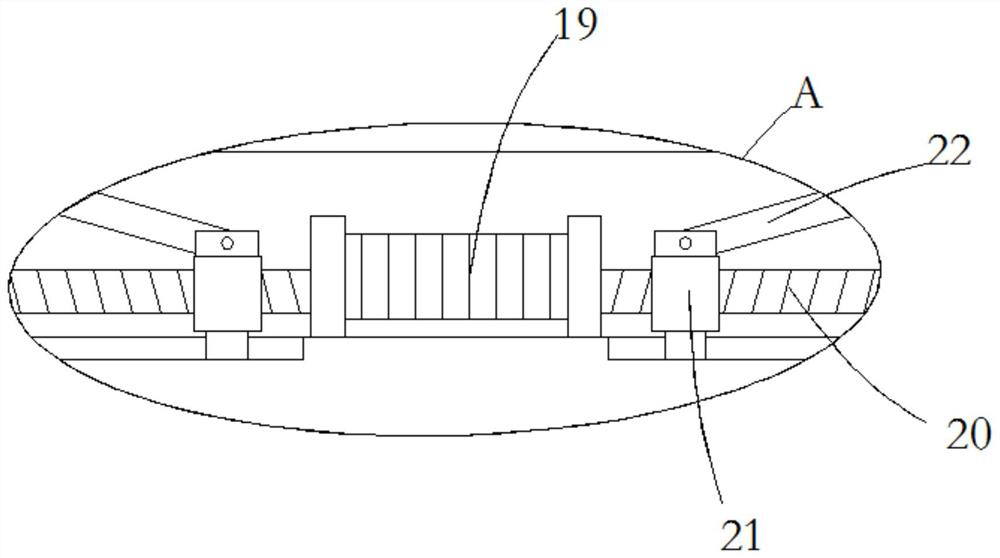

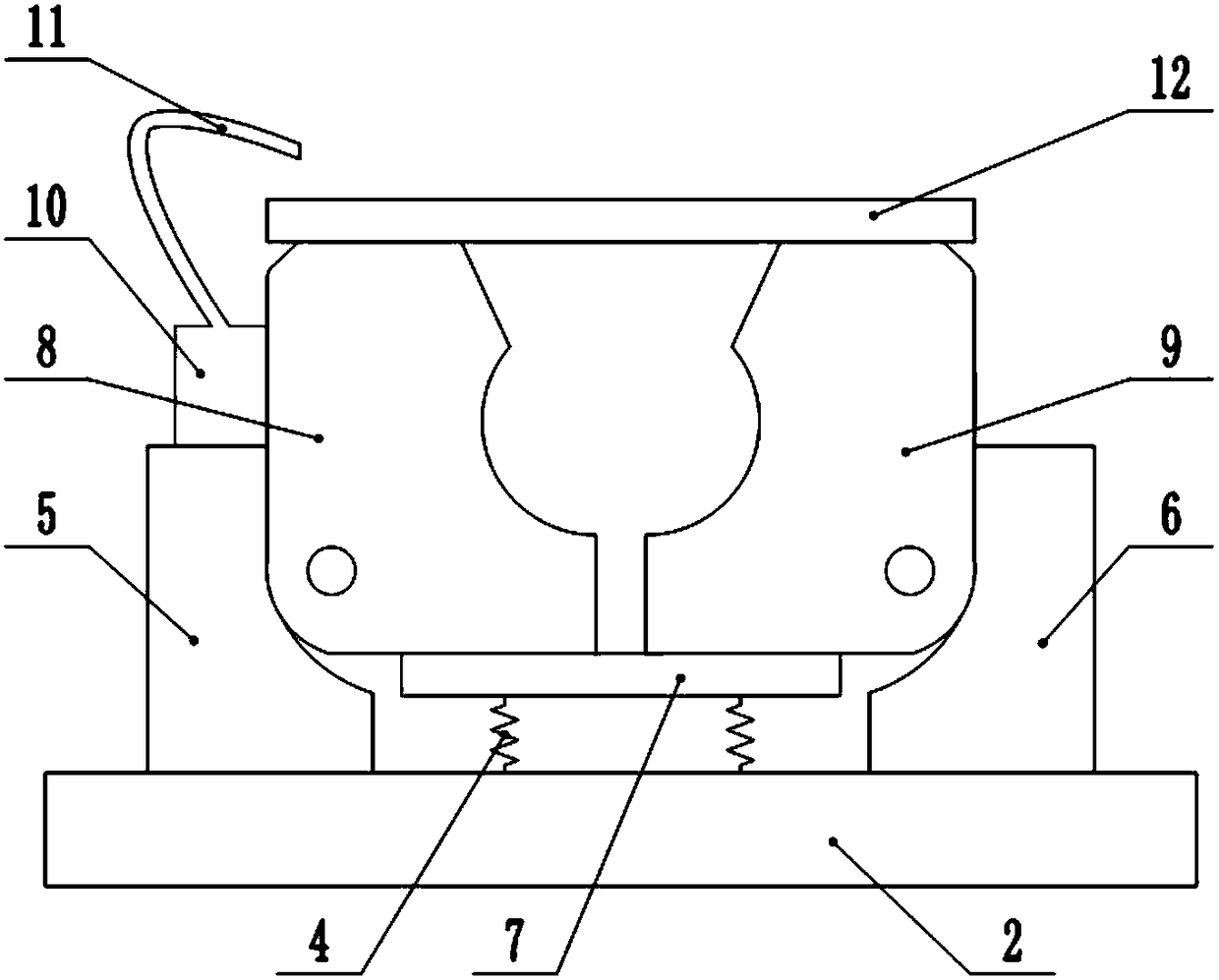

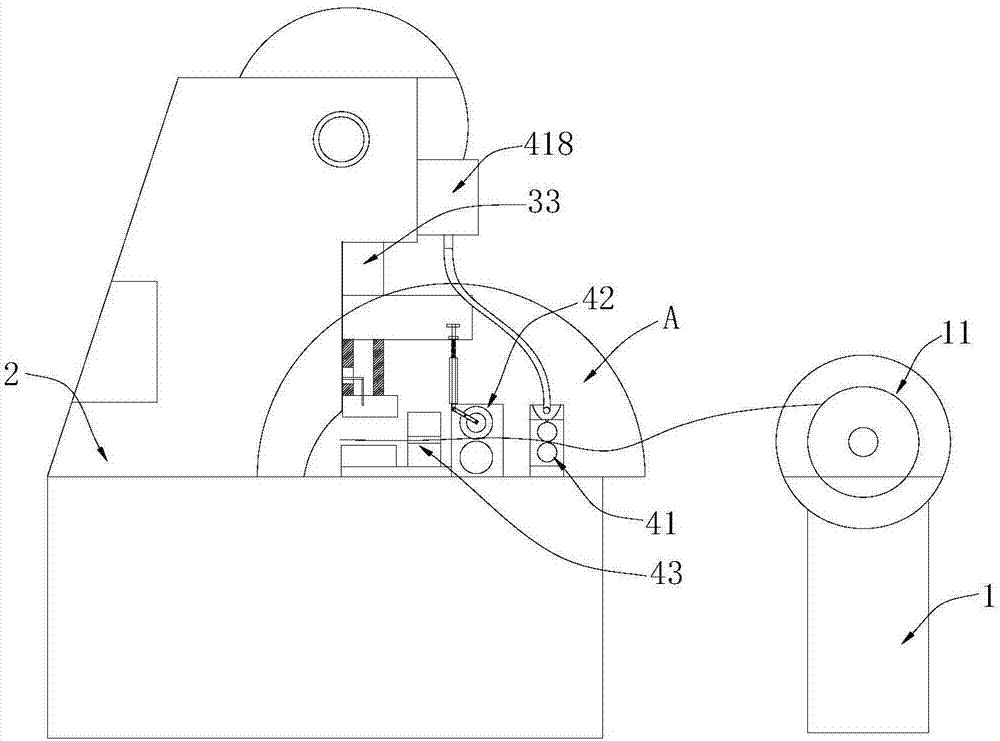

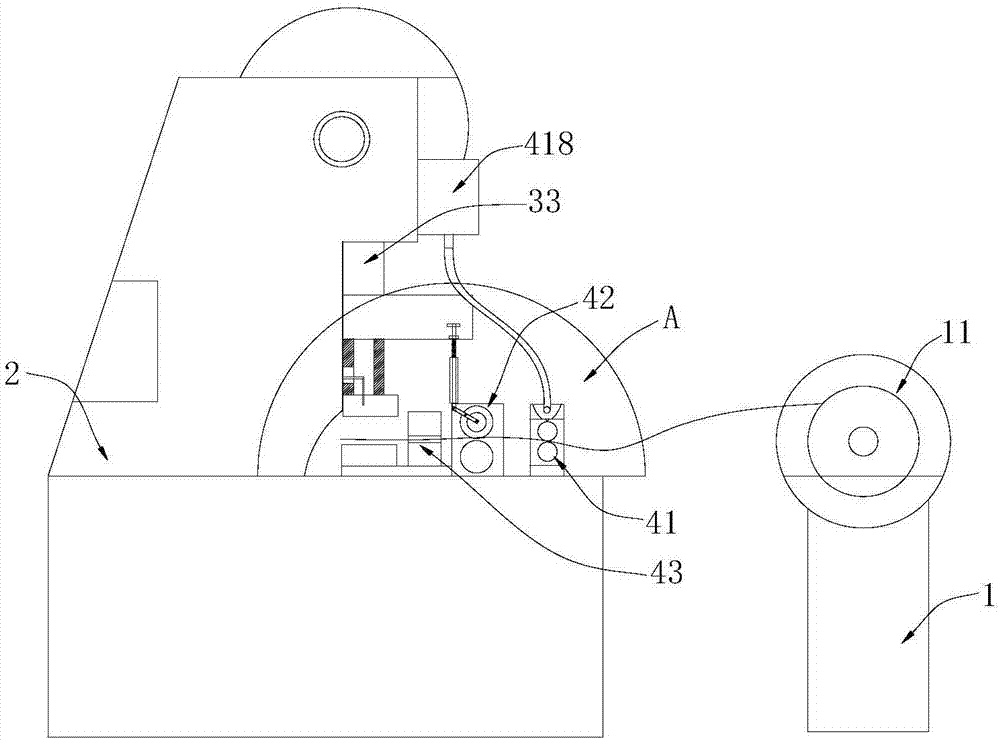

Scrap-jumping prevention stamping die stamping method

ActiveCN104438552AGuarantee stamping qualityPlay the role of automatic safe unloadingStripping-off devicesScrapEngineering

The invention relates to a scrap-jumping prevention stamping die stamping method. A blanking tool edge is provided with a blanking section in the shape of an inverted circular truncated cone. The scrap-jumping prevention stamping die stamping method is characterized in that an inlet and an outlet are each provided with a stamped part compaction limiting mechanism (A), wherein each stamped part compaction limiting mechanism (A) acts on a stamped part (10). The stamped part compaction limiting mechanisms are arranged on a lower die base, and the stamped part compaction limiting mechanisms can not only position the stamped parts but also compact the stamped parts, guarantee the stamping quality of the stamped parts, and even play an automatic safe discharge role after stamping is completed.

Owner:佛山市高明德健五金有限公司

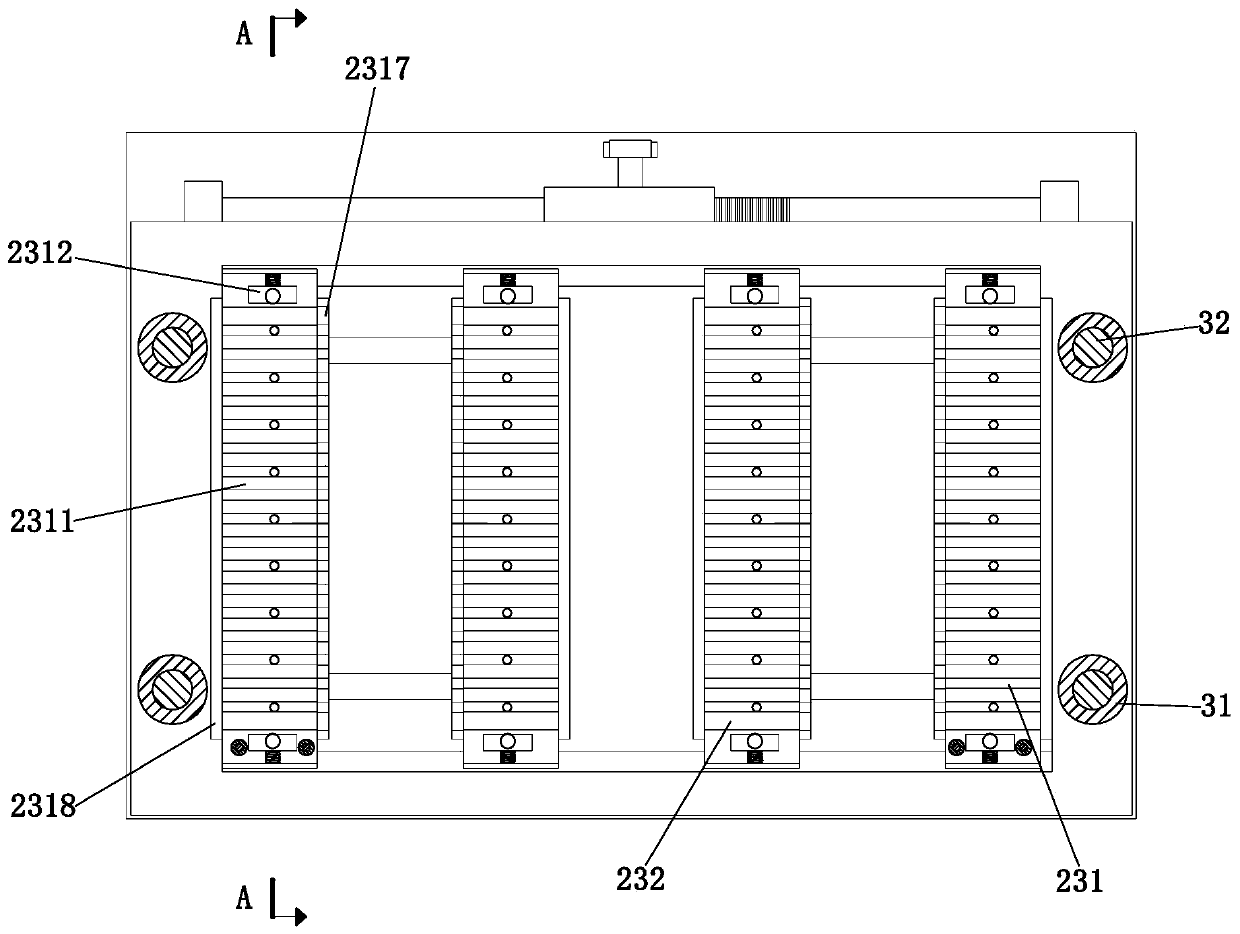

Stamping die and stamping method using same

InactiveCN106925671AAvoid deformationGuarantee stamping qualityShaping toolsPerforating toolsEngineeringMechanical engineering

The invention discloses a stamping die and a stamping method using the same. The stamping die is provided with an upper die and a lower die, wherein a plurality of upper die blocks and a plurality of lower die blocks are correspondingly arranged on the upper die and the lower die respectively; the upper die blocks and the corresponding lower die blocks form die sets; the die sets comprise edge trimming die sets, a central die set and cutting-off die sets; the edge trimming die sets are positioned on two sides in the left-right direction; the central die set is positioned between the edge trimming die sets; the cutting-off die sets are positioned on two sides in the left-right direction; in front of the edge trimming die sets and the central die set, a right cutting blade of the cutting-off die set on the left side is positioned on the right side of a left cutting blade of the central die set, and a left cutting blade of the cutting-off die set on the right side is positioned on the left side of a right cutting blade of the central die set. Continuous plate stamping forming can be realized, plates are stamped by the die sets, plate deformation caused by the reason that forces applied to plates are uneven in one-time forming is avoided, meanwhile, by the arrangement mode of the die sets, the precision of stamping is high, errors cannot be caused at joints of various substeps, and therefore, stamping quality is ensured.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

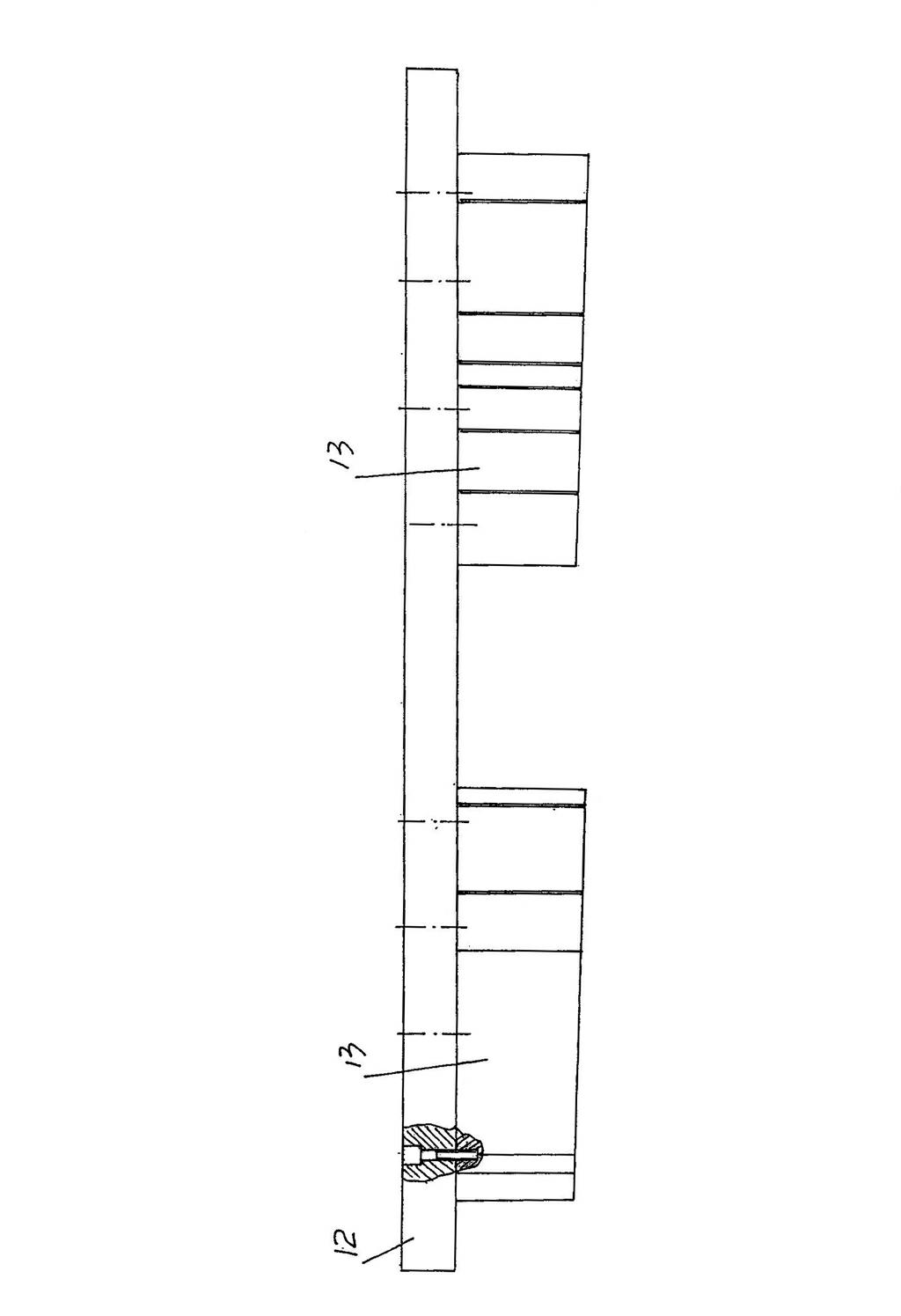

Die for forming needle bed insert blank

InactiveCN102699195AGuarantee stamping qualityLow costShaping toolsMetal-working feeding devicesStructural engineeringManufacturing engineering

The invention discloses a die for forming a needle bed insert blank and belongs to the technical field of dies. The die comprises an upper die mechanism and a lower die mechanism, wherein the upper die mechanism comprises an upper die plate frame with at least one pair of guide sleeves, an upper die plate, insert male stamping dies and a pressing plate; the lower die mechanism comprises a lower die plate frame and a lower die plate; the pressing plate is connected with one side of the upper die plate; die guiding holes are formed in the pressing plate. The die is characterized in that a group of thin steel strip guiding and limiting mechanisms are formed on one side, which faces the pressing plate, of the lower die plate; guide rod holes are formed on one side, which faces the lower die plate, of the pressing plate; thin steel strip guiding and limiting mechanism assembling holes are formed in the lower die plate opposite to the thin steel strip guiding and limiting mechanisms; each thin steel strip guiding and limiting mechanism comprises a guide rod and a spring; and guide grooves are formed at one end, which stretches out of the lower die plate, of the guide rod. Besides, the die has the advantages that the stamping quality can be guaranteed; and unqualified products cannot be manufactured, so that materials are saved, and the cost is reduced.

Owner:常熟市尚湖镇冶塘伟东模具厂

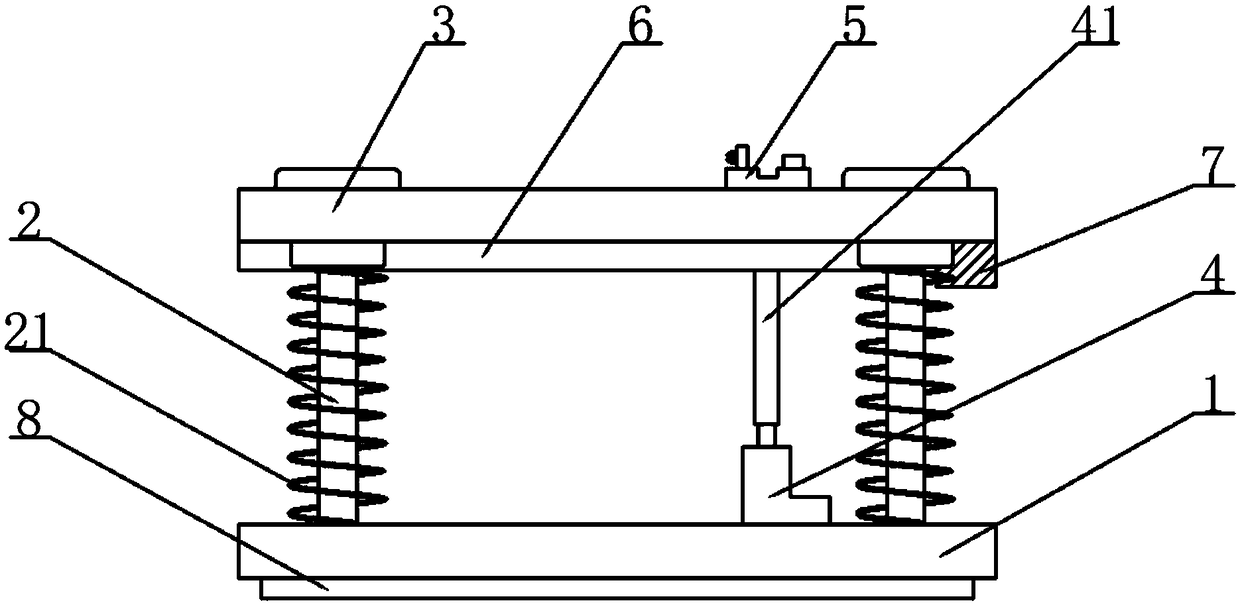

Mold telescopic positioning device

InactiveCN107297431APrecise positioningGuarantee stamping qualityShaping toolsMetal-working feeding devicesPunchingPositioning system

The invention discloses a telescopic positioning device for a mold, which comprises: a positioning plate formed with a positioning surface; a driving mechanism connected with the positioning plate to drive the positioning plate close to or away from a blank. Compared with the prior art, the present invention sets a retractable positioning plate. During the stamping process, the positioning surface is always close to the blank, and the whole process of stamping is positioned to ensure accurate positioning of the blank during the stamping process; after the stamping is completed, the The positioning surface is far away from the blank to avoid access to the stamping parts after stamping; the labor intensity is reduced, the production efficiency is improved, the stamping quality is guaranteed, and the structure is simple, which is convenient for installation and debugging.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

A control system and control method for an intelligent servo press

ActiveCN105700453BGuaranteed stamping accuracyGuarantee stamping qualityProgramme control in sequence/logic controllersControl powerPunching

The invention discloses a control system for an intelligent-type servo press, and the system comprises a servo drive unit, a PLC control unit, and a control power unit. The servo drive unit comprises a main drive servo controller, a mold adjustment servo controller, an electric pump motor, and a multifunction power meter, wherein the main drive servo controller, the mold adjustment servo controller, the electric pump motor and the multifunction power meter are connected to a three-phase power supply. The PLC control unit comprises a PLC, and a drive power end of the PLC is connected with an AC 220V power supply. A control power end of the PLC is connected with a DC 24V power supply, and the PLC collects the operation signals of all corresponding devices, and transmits the control signals for controlling the corresponding devices. The control power unit comprises a control transformer, wherein the front end of the control transformer is connected with an AC 380V power supply, and the rear end of the control transformer outputs an AC 220V voltage serving as the AC 220V power supply. The system guarantees the punching precision of the press and the quality of a punched part, improves the punching efficiency, and can be used in the control of the press.

Owner:YANGLI GRP CORP LTD

A kind of anti-jump waste stamping die

InactiveCN104289587BGuarantee stamping qualityPlay the role of automatic safe unloadingStripping-off devicesEngineeringFrustum

The invention relates to an anti-bouncing waste stamping die. A blanking knife edge is provided with an inverted-frustum-shaped blanking segment. The anti-bouncing waste stamping die is characterized in that an inlet and an outlet of the anti-bouncing waste stamping die are each provided with a stamping piece pressing limiting mechanism (A) acting on a stamping piece (10). The stamping piece pressing limiting mechanisms are arranged on a lower die base. The stamping piece pressing limiting mechanisms can not only position the stamping piece, but also press the stamping piece tightly, the stamping quality of the stamping piece is guaranteed, and even automatic safe discharging is achieved after stamping is finished.

Owner:东莞市中霸电子制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com