Motorcycle fitting stamping die

A technology for stamping dies and motorcycles, which is applied in the field of stamping dies, can solve the problems of heavy workload of manual pick-up and low stamping work efficiency, and achieve the effects of eliminating potential safety hazards, improving work efficiency, and increasing pick-up speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Further detailed explanation through specific implementation mode below:

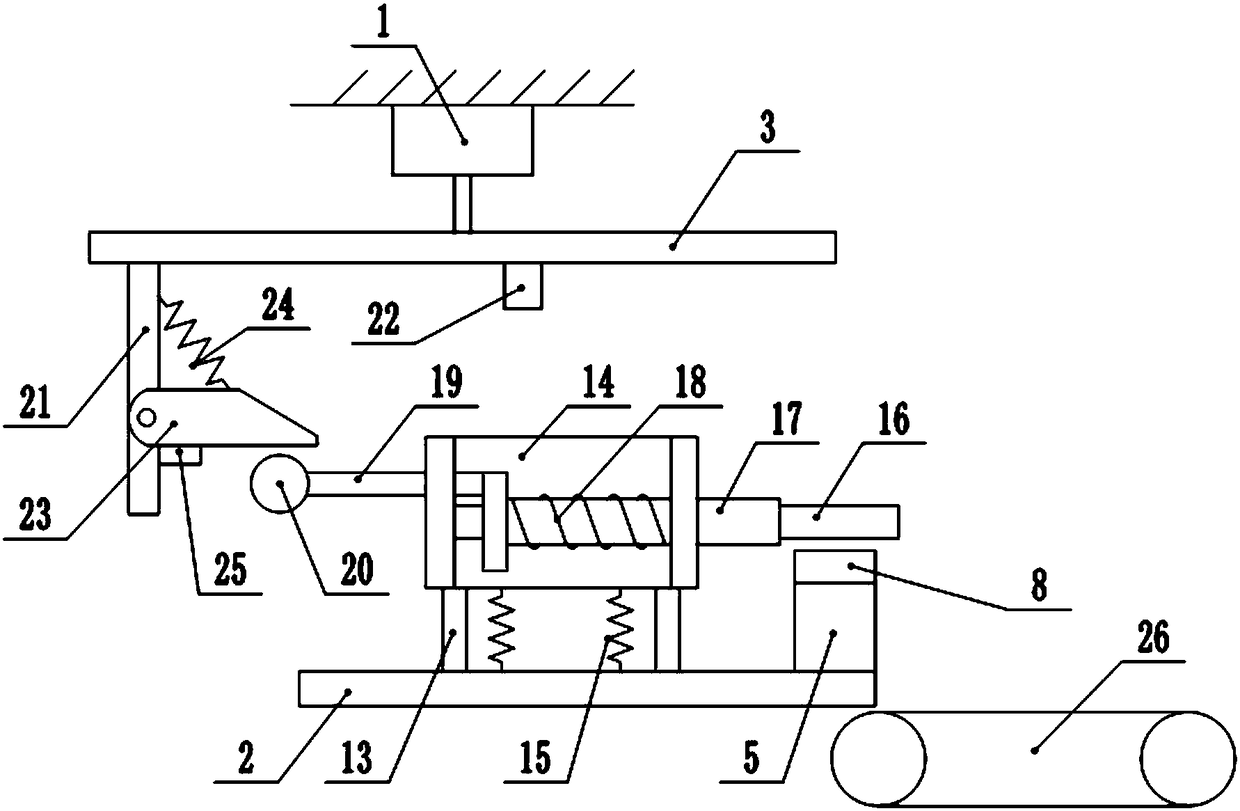

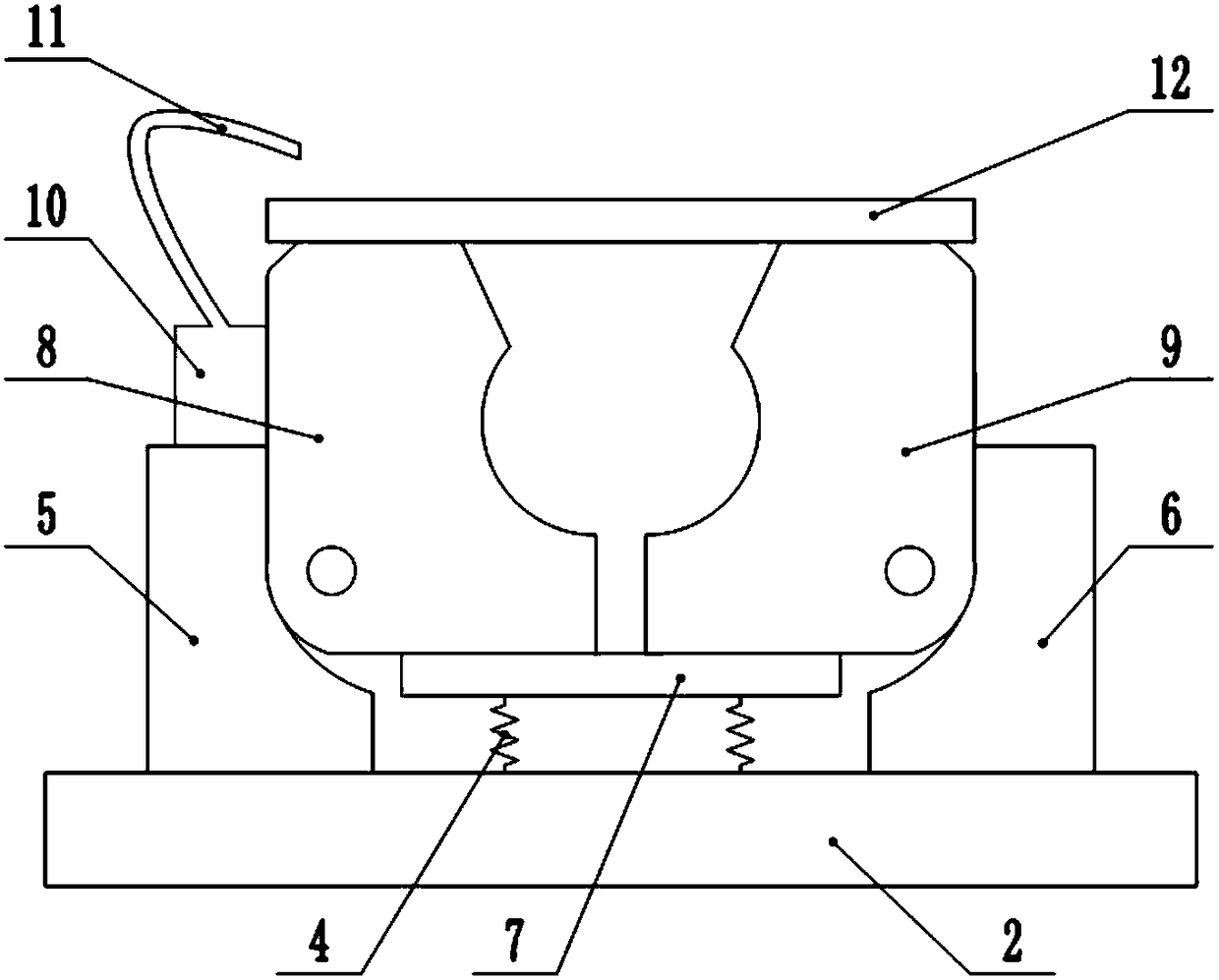

[0018] The reference signs in the accompanying drawings of the description include: press machine 1, lower mold base 2, upper mold base 3, first spring 4, first fixed block 5, second fixed block 6, push plate 7, first molding die 8 , second molding die 9, hot air blower 10, air outlet pipe 11, workpiece to be stamped 12, pillar 13, moving block 14, second spring 15, mold core 16, T-shaped sliding pipe 17, third spring 18, cross bar 19 , cylinder 20, riser 21, push rod 22, wedge block 23, fourth spring 24, limit block 25, conveyor belt 26.

[0019] This embodiment is basically as figure 1 As shown, the motorcycle parts stamping die includes a frame, the frame is fixedly installed with a press 1 and a lower mold base 2, and the output end of the press 1 is fixedly connected with an upper mold base 3 . combine figure 2 As shown, the lower mold base 2 is fixedly connected with the first spring 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com