Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Guaranteed stamping accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

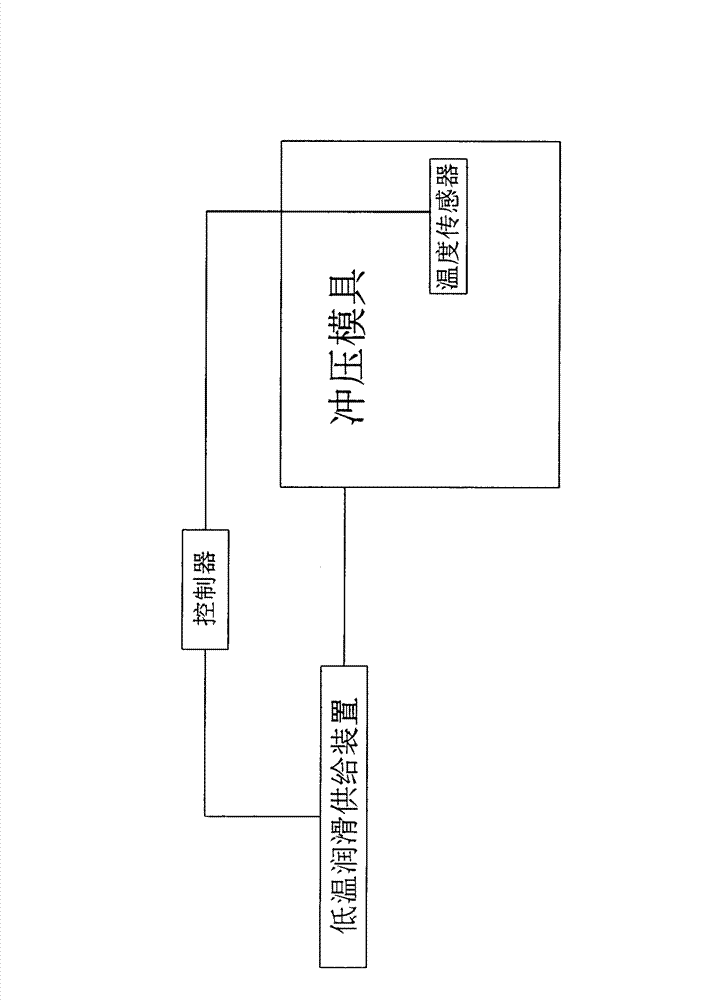

High speed stamping die with cooling structure

InactiveCN102233385AReduce the temperatureGuaranteed stamping accuracyShaping toolsEngineeringStamping process

The invention discloses a high speed stamping die with a cooling structure. The high speed stamping die is internally equipped with a cooling pipeline; a cooling liquid circulates in the cooling pipeline, the initial end of the cooling pipeline is a cooling liquid inlet, and the terminal end of the cooling pipeline is a cooling liquid outlet; and the high speed stamping die is also internally equipped with a temperature sensor for monitoring the temperature in the high speed stamping die. In the invention, the cooling liquid in the cooling pipeline can immediately conduct heat generated during the stamping process out of the high speed stamping die by utilizing a heat exchange mode so as to lower the temperature in the high speed stamping die; and a control device controls an infusion pump to adjust flow of the cooling liquid according to temperature information monitored by the temperature sensor so as to keep the temperature in the high speed stamping die within a certain range. Therefore, the high speed stamping die has the beneficial effects that the deformation and damage of the high speed stamping die are reduced and the service life of the high speed stamping die is prolonged while the stamping precision and production efficiency are ensured.

Owner:KUNSHAN JIAHUA ELECTRONICS

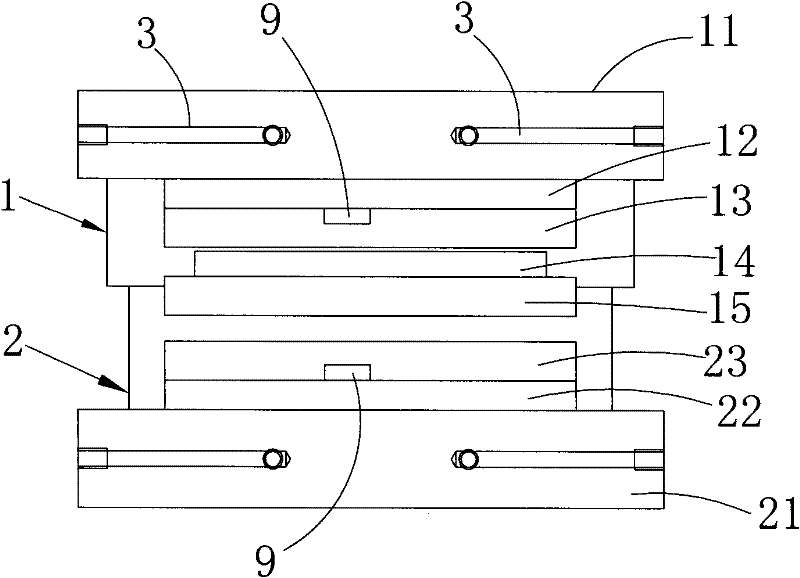

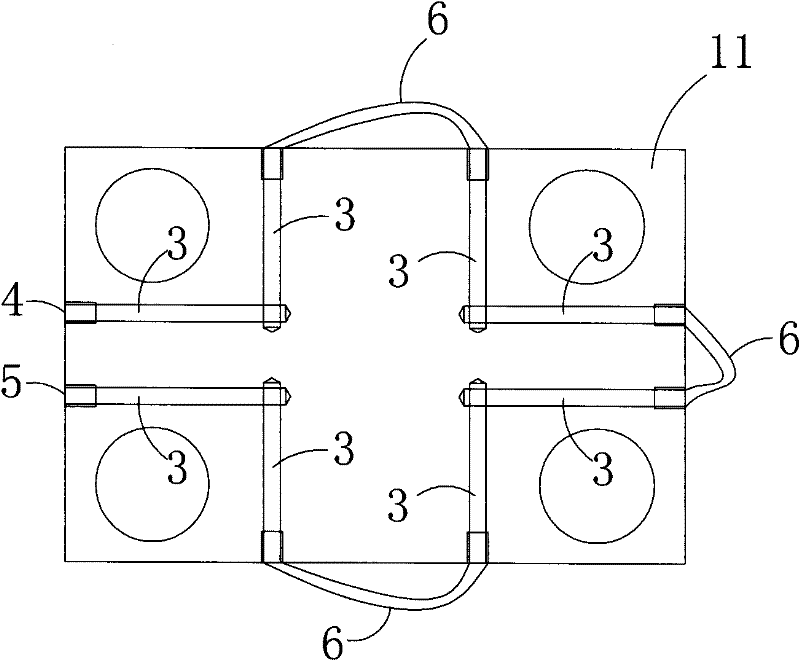

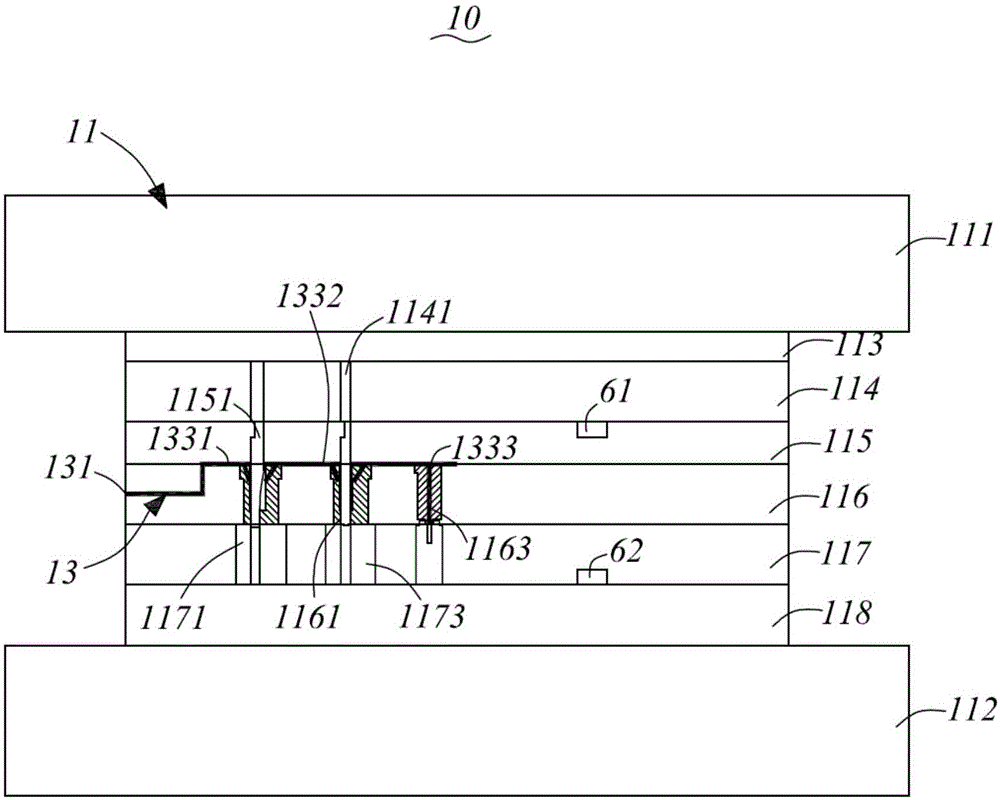

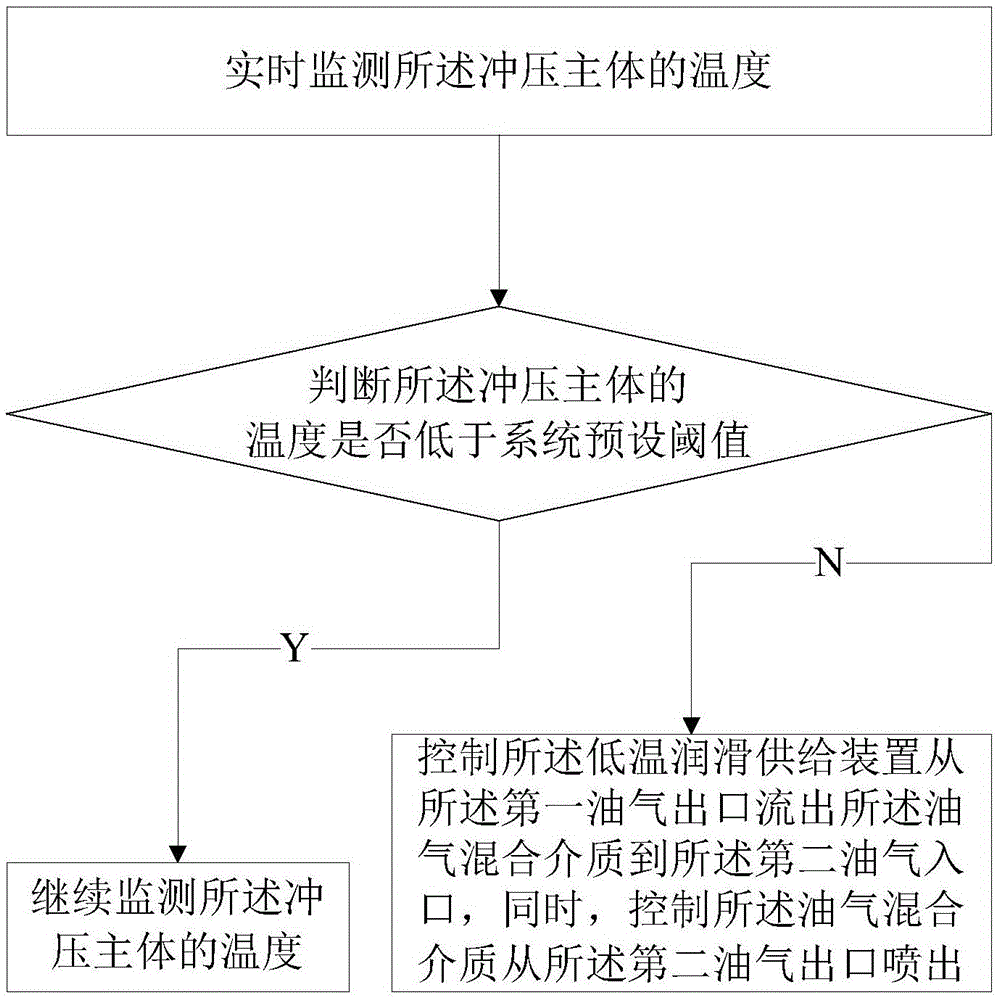

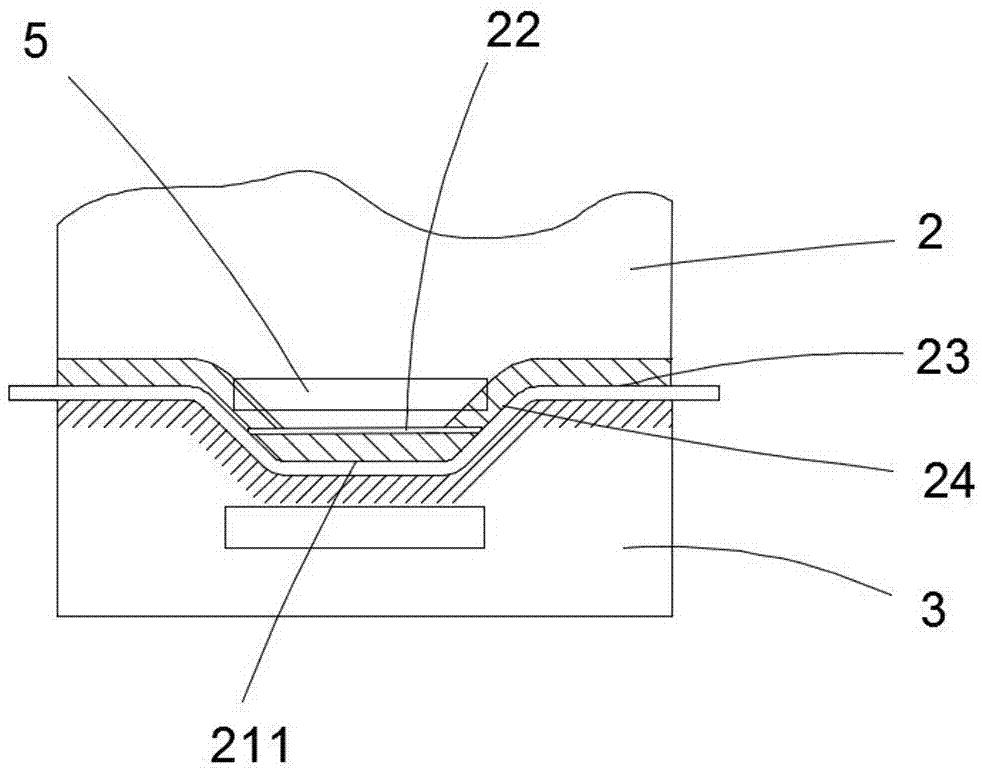

High speed stamping die with low temperature lubricating structure

InactiveCN102921818AReduce deformation or damageExtended service lifeShaping toolsStamping processLubrication

The invention provides a high speed stamping die with a low temperature lubricating structure and belongs to the technical field of dies. The invention solves the problems of bad cooling effect, bad lubricating effect and short service life of the current stamping die. The high speed stamping die with the low temperature lubricating structure comprises an upper die holder and a lower die holder, wherein a forming plate group composed of an upper die lining plate, a punch fixing plate, a discharge lining plate, a discharging plate, a lower template and a lower die lining plate is arranged between the upper die holder and the lower die holder, a forming assembly is arranged in the forming plate group, an oil gas path communicated with the forming assembly is arranged between the forming plate groups, and the inlet of the oil gas path is connected with a low temperature lubrication feeding device. The low temperature lubrication feeding device mixes and atomizes low temperature compressed air and micro-lubricating oil to form low temperature gas-liquid two-phase stream, and the low temperature gas-liquid two-phase stream is jetted to a stamping processing region through a gas channel so as to permeate the low temperature cold air to a stamping processing contact interface with oil particles atomized by the micro-lubricating oil to play a lubricating effect and effectively take away the heat generated during the stamping process.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

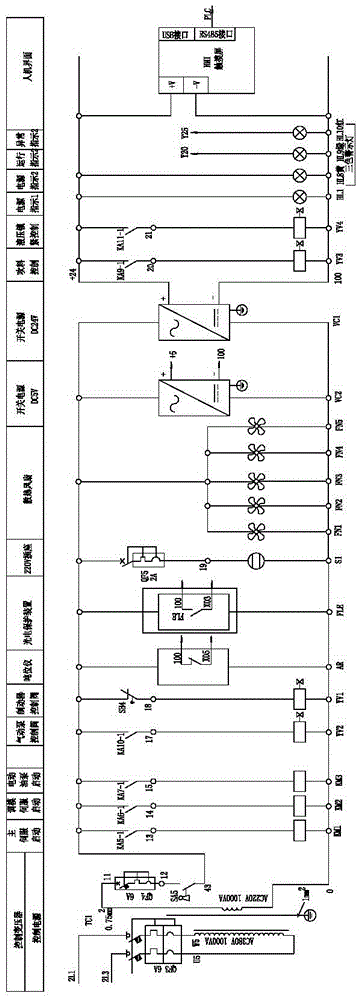

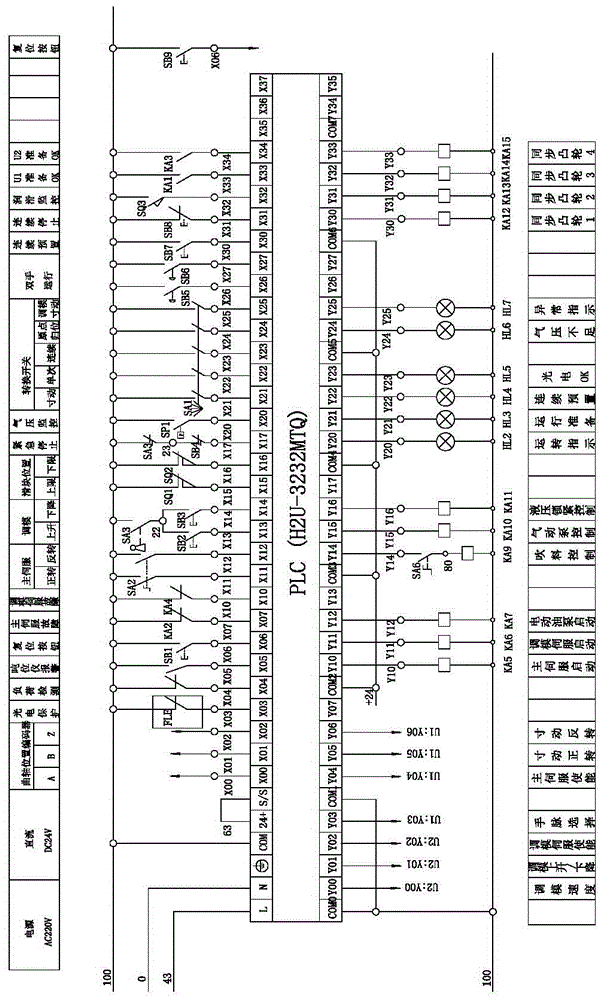

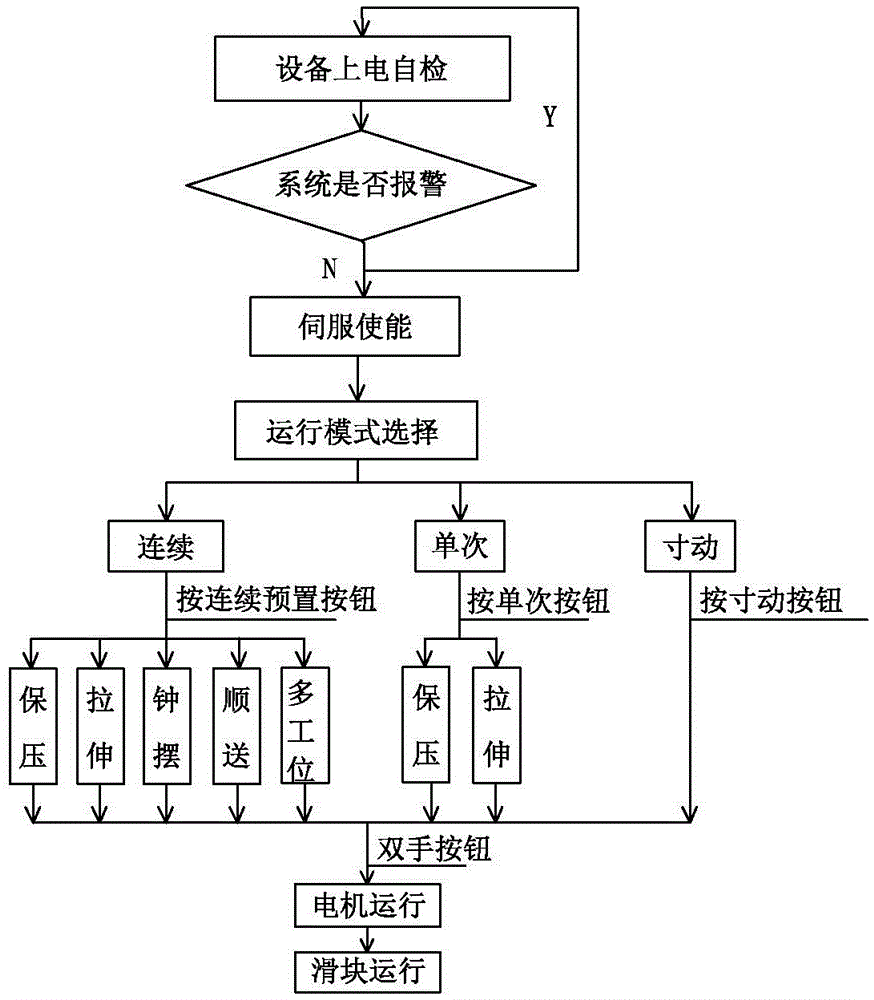

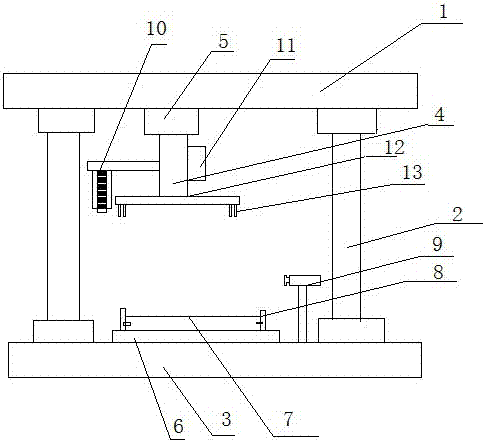

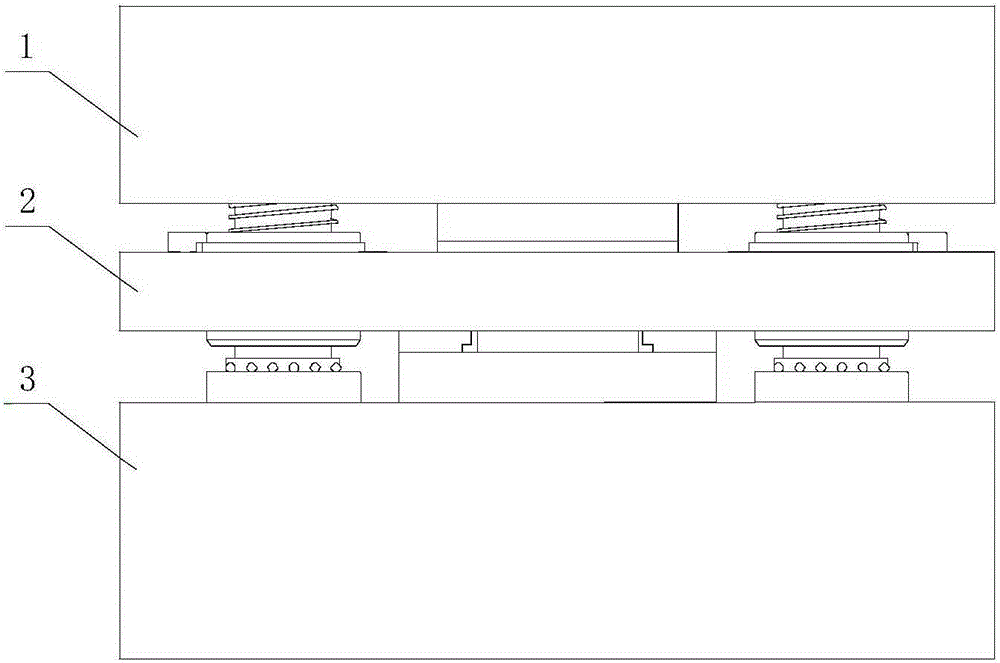

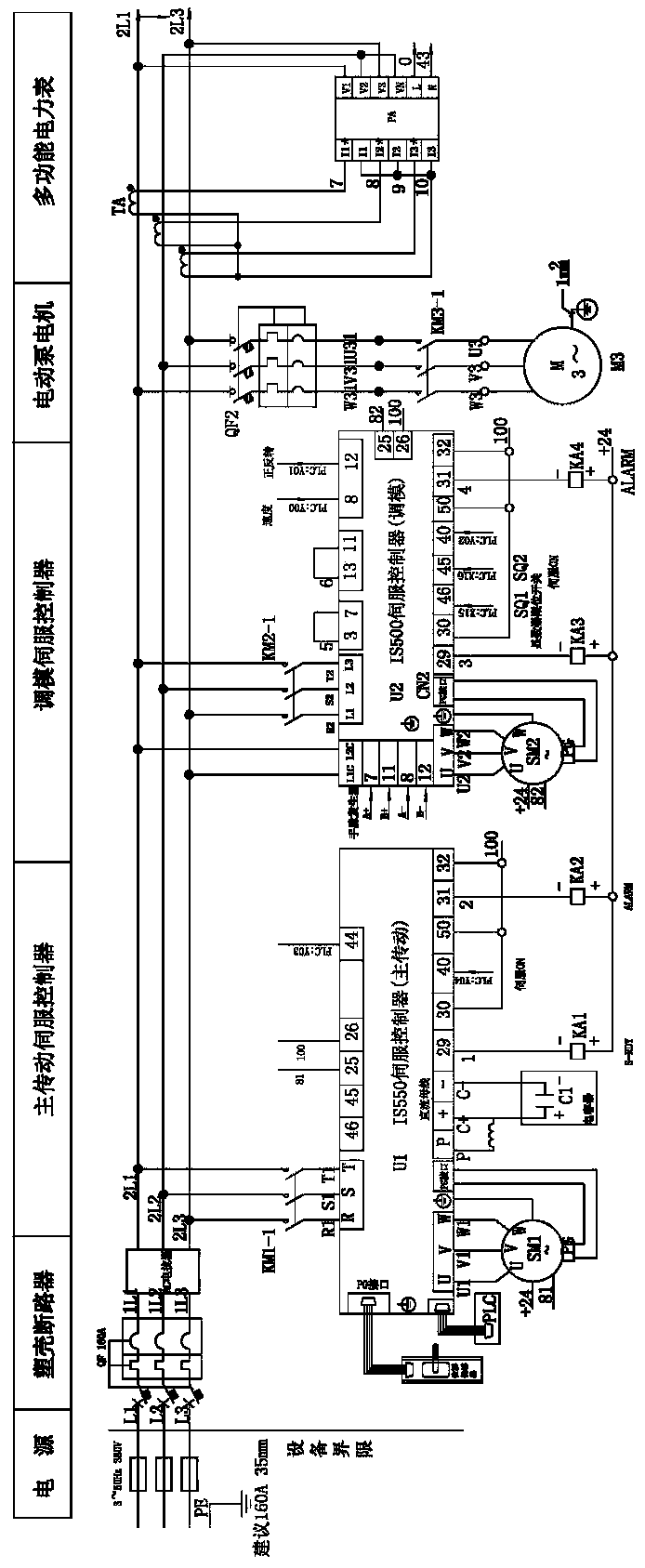

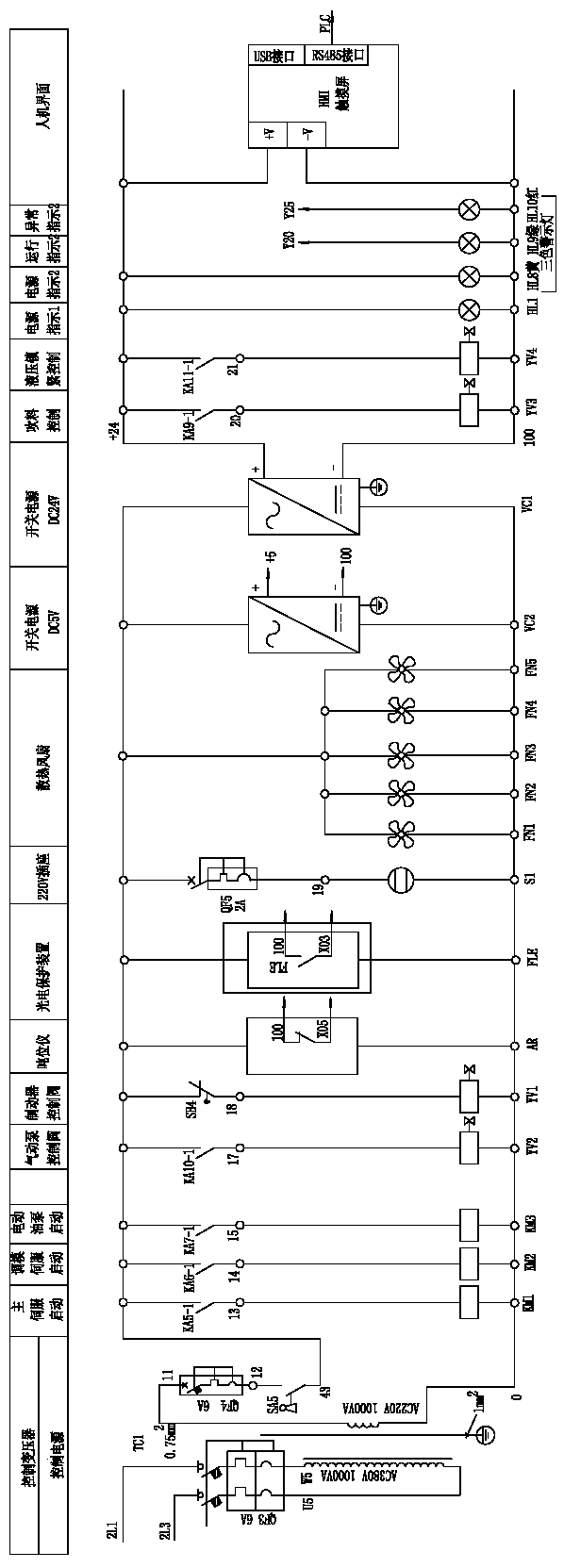

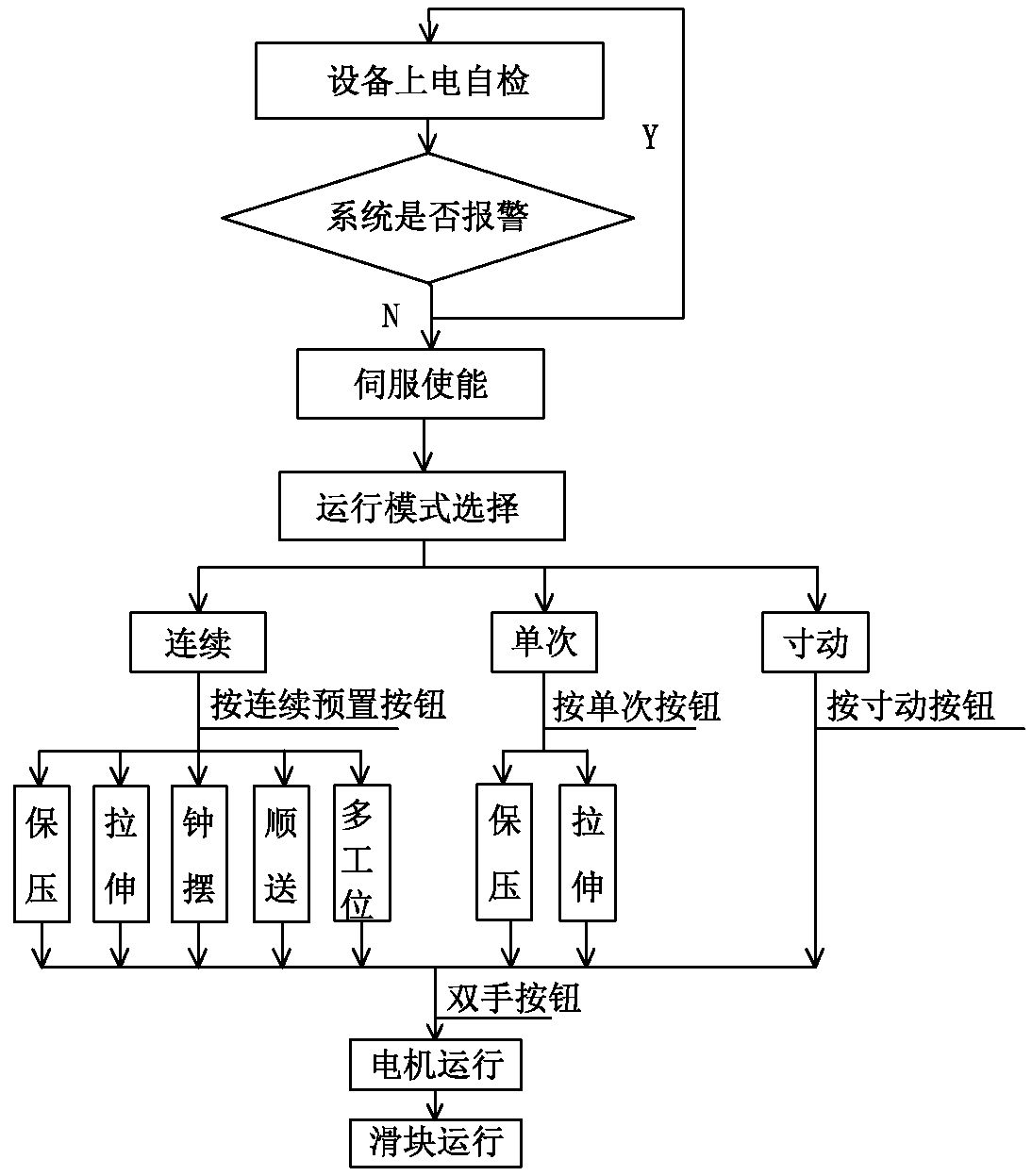

Control system and method for intelligent-type servo press

ActiveCN105700453AGuaranteed stamping accuracyGuarantee stamping qualityProgramme control in sequence/logic controllersPunchingControl power

The invention discloses a control system for an intelligent-type servo press, and the system comprises a servo drive unit, a PLC control unit, and a control power unit. The servo drive unit comprises a main drive servo controller, a mold adjustment servo controller, an electric pump motor, and a multifunction power meter, wherein the main drive servo controller, the mold adjustment servo controller, the electric pump motor and the multifunction power meter are connected to a three-phase power supply. The PLC control unit comprises a PLC, and a drive power end of the PLC is connected with an AC 220V power supply. A control power end of the PLC is connected with a DC 24V power supply, and the PLC collects the operation signals of all corresponding devices, and transmits the control signals for controlling the corresponding devices. The control power unit comprises a control transformer, wherein the front end of the control transformer is connected with an AC 380V power supply, and the rear end of the control transformer outputs an AC 220V voltage serving as the AC 220V power supply. The system guarantees the punching precision of the press and the quality of a punched part, improves the punching efficiency, and can be used in the control of the press.

Owner:YANGLI GRP CORP LTD

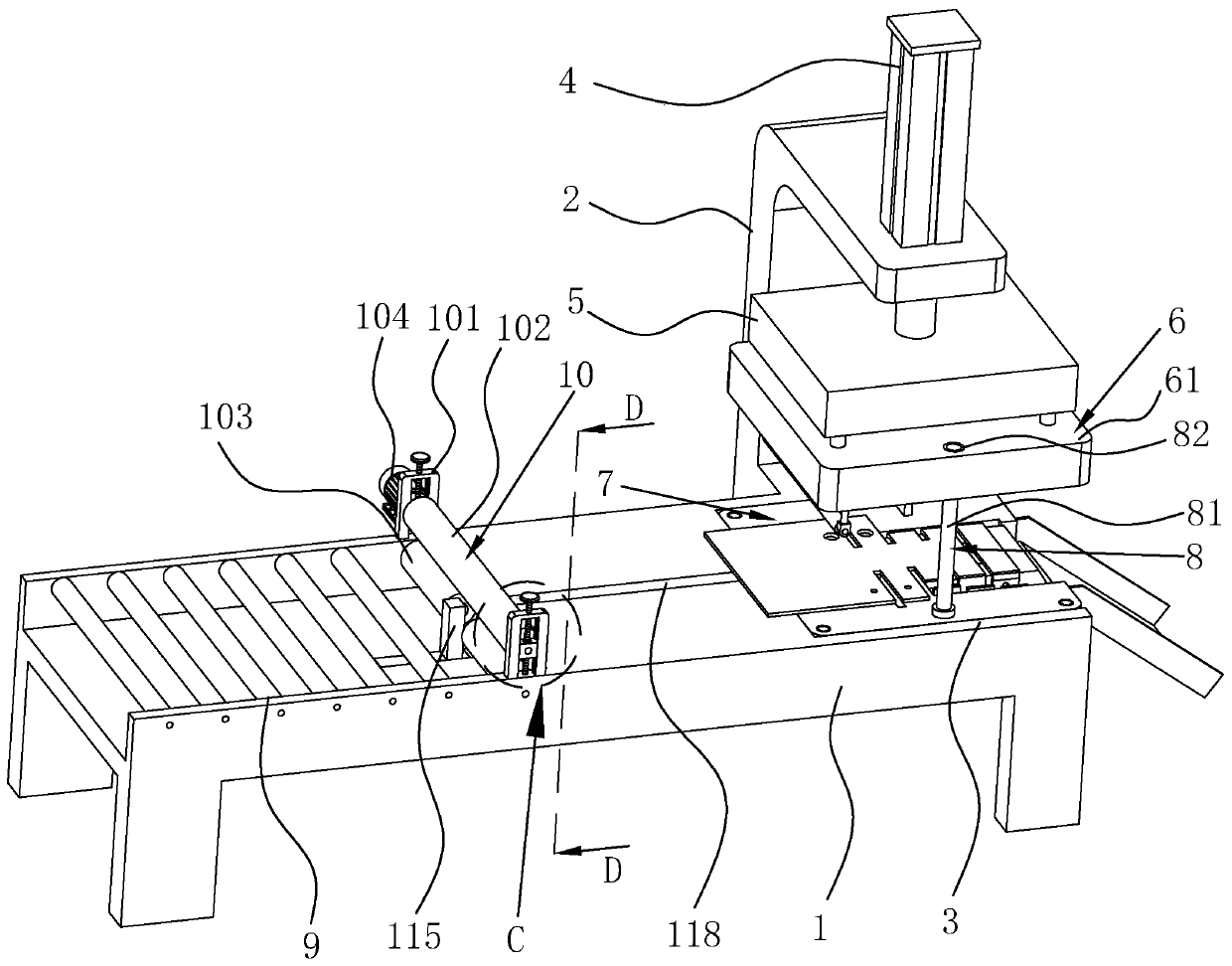

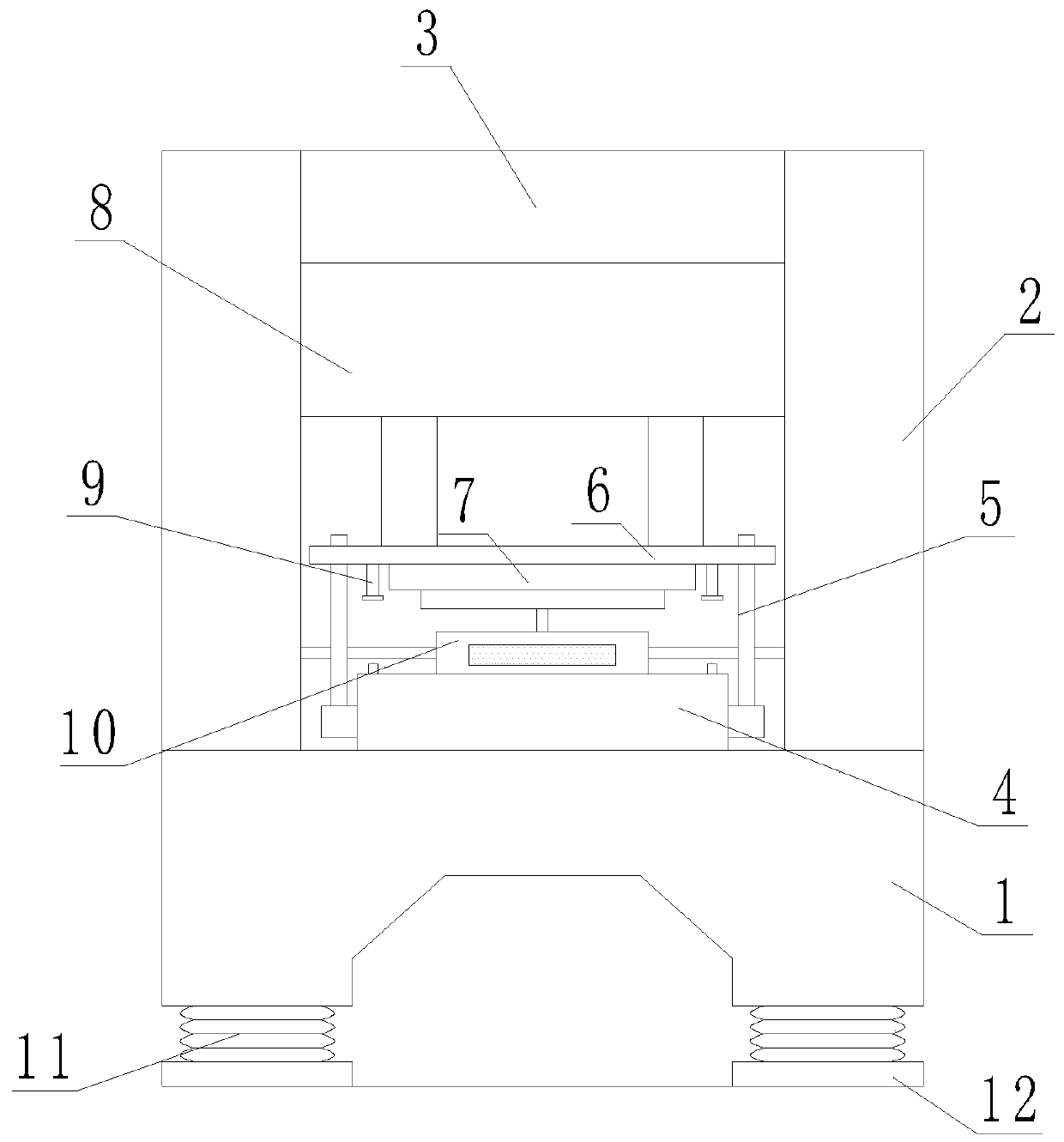

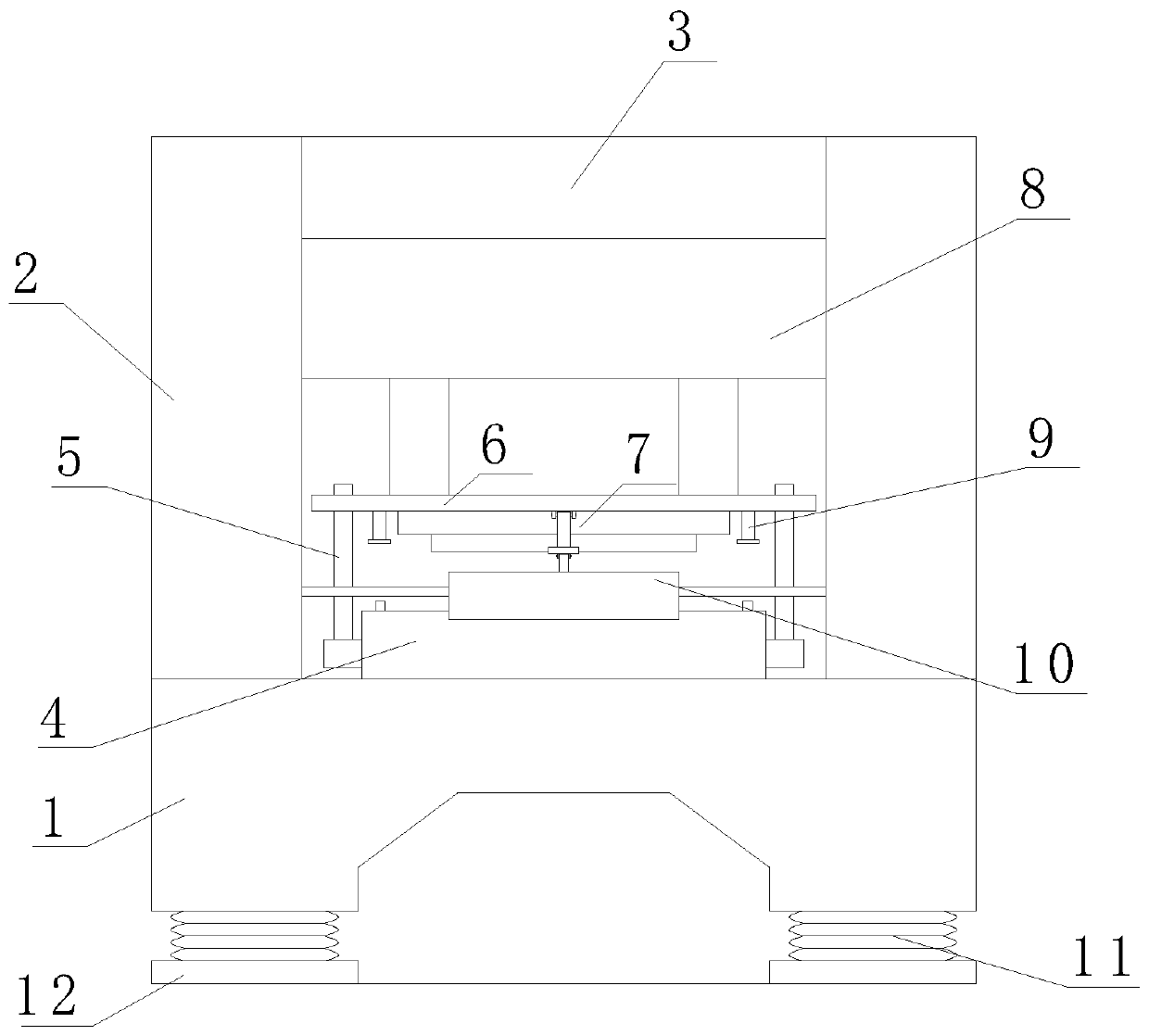

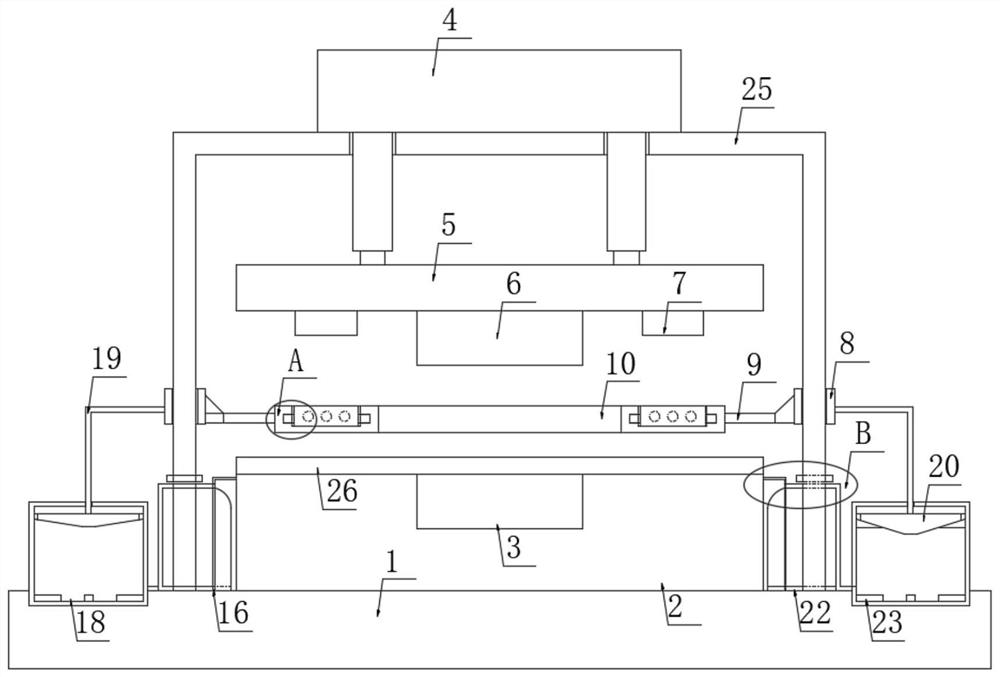

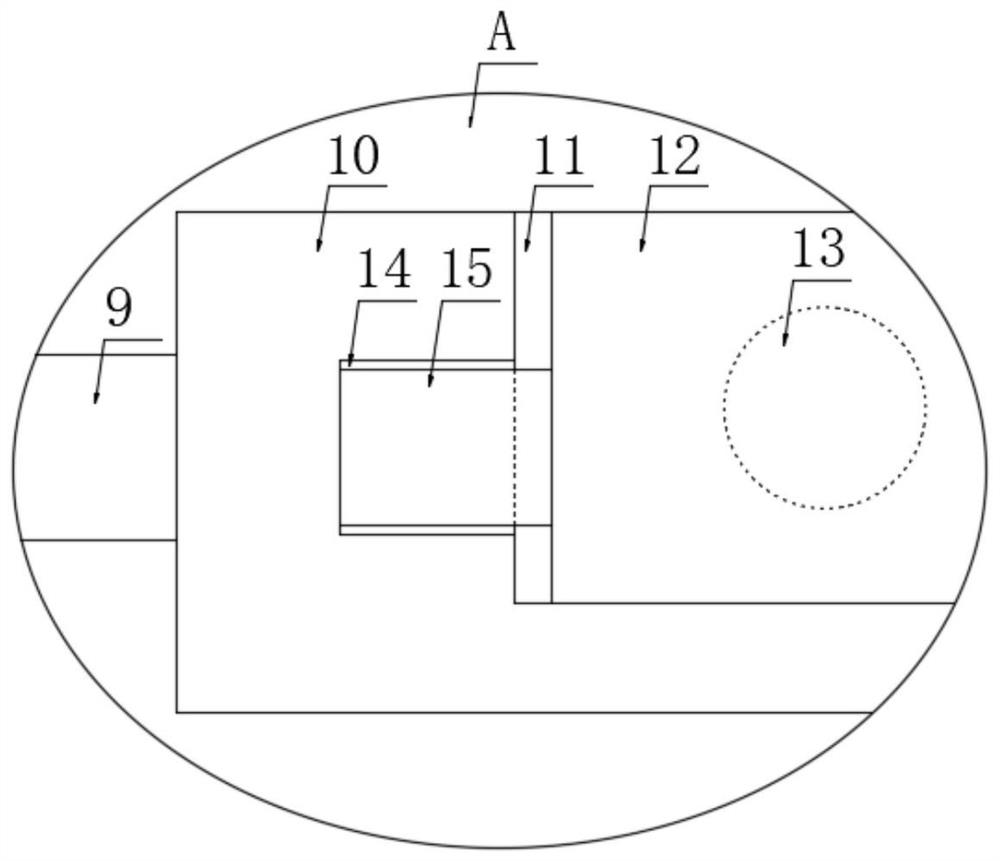

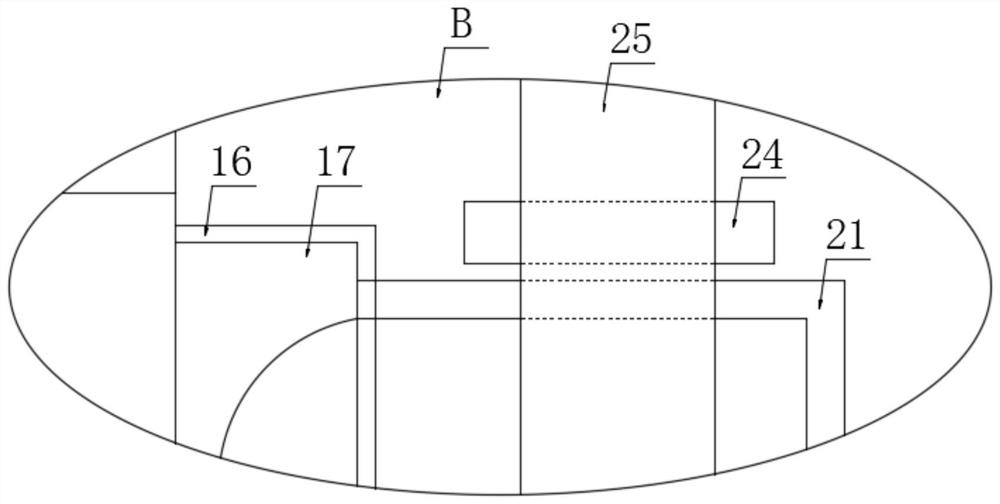

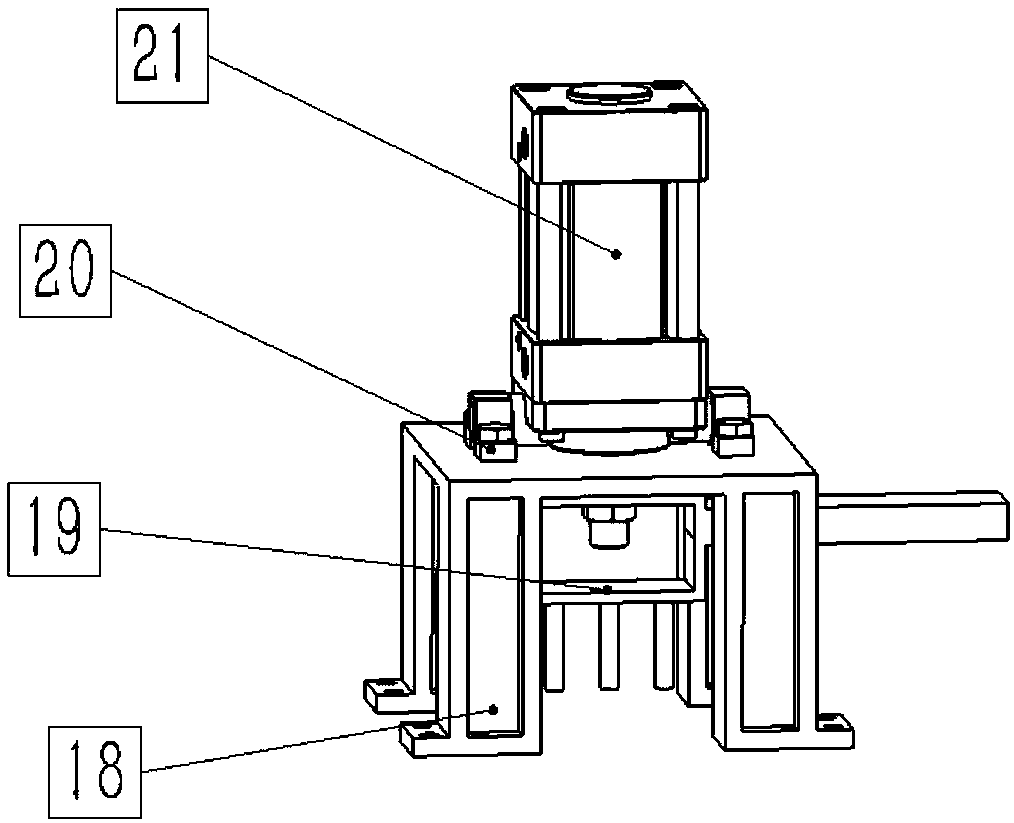

Stamping device capable of automatically correcting stamping workpieces and working method of stamping device

InactiveCN107377796AReasonable structural designGuaranteed stamping accuracyMetal-working feeding devicesPositioning devicesStamping processEngineering

The invention discloses a stamping device capable of automatically correcting stamping workpieces and working method of the stamping device. The stamping device comprises an upper die holder, a guide column, a lower die holder, a punch, a punch fixing seat, a stamping worktable, a forming die, a die locking device, a product correcting device, a monitoring component and a monitoring terminal, the upper die holder is connected with the lower die holder the through the guide column, the punch is arranged on the upper die holder through the punch fixing seat, the monitoring component is arranged on the punch fixing seat and electrically connected with the monitoring terminal, the stamping worktable is arranged on the lower die holder, the forming die is fixed on the stamping worktable through the die locking device, the product correcting device is arranged on the right side of the forming die, an in-place sensor is arranged on the forming die, a stamping control device is arranged on the punch, an output end of the in-place sensor is connected with the stamping control device, and the stamping control device controls the punch to rise, fall and stop. The stamping device is reasonable in structure design, stamping process can be monitored in real time, monitoring information is transmitted to the monitoring terminal and viewed through the monitoring terminal, stamping states do not need to be observed by standing in front of the stamping device, and the stamping device is convenient and practical.

Owner:太仓市华天冲压五金制品厂

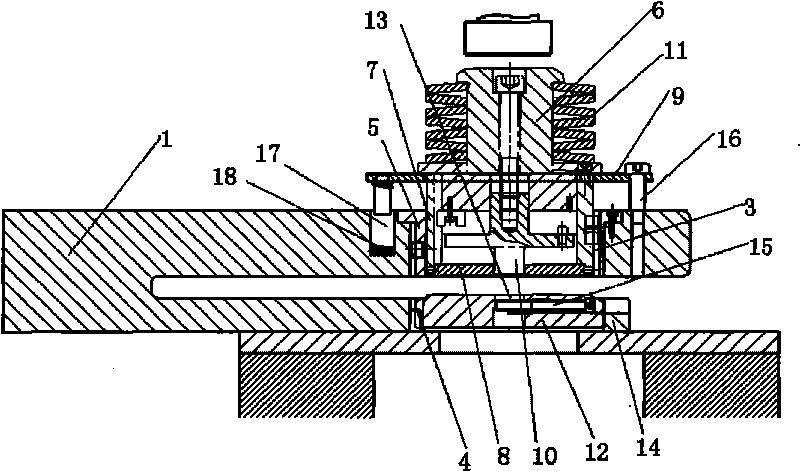

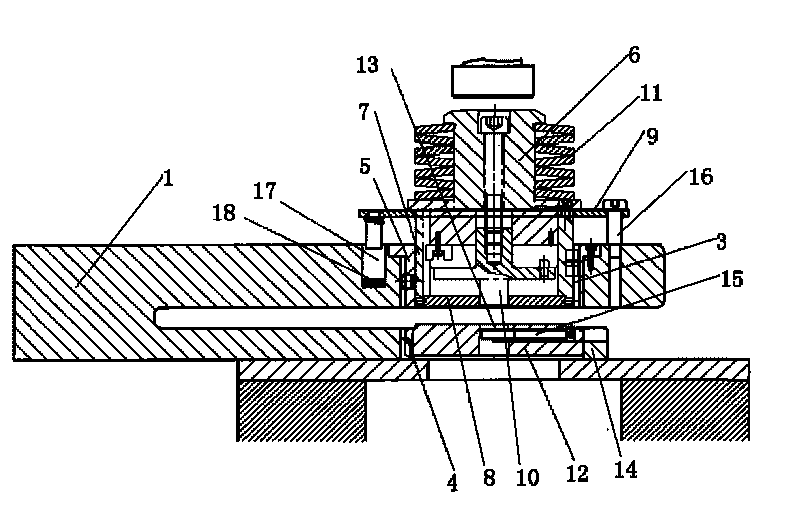

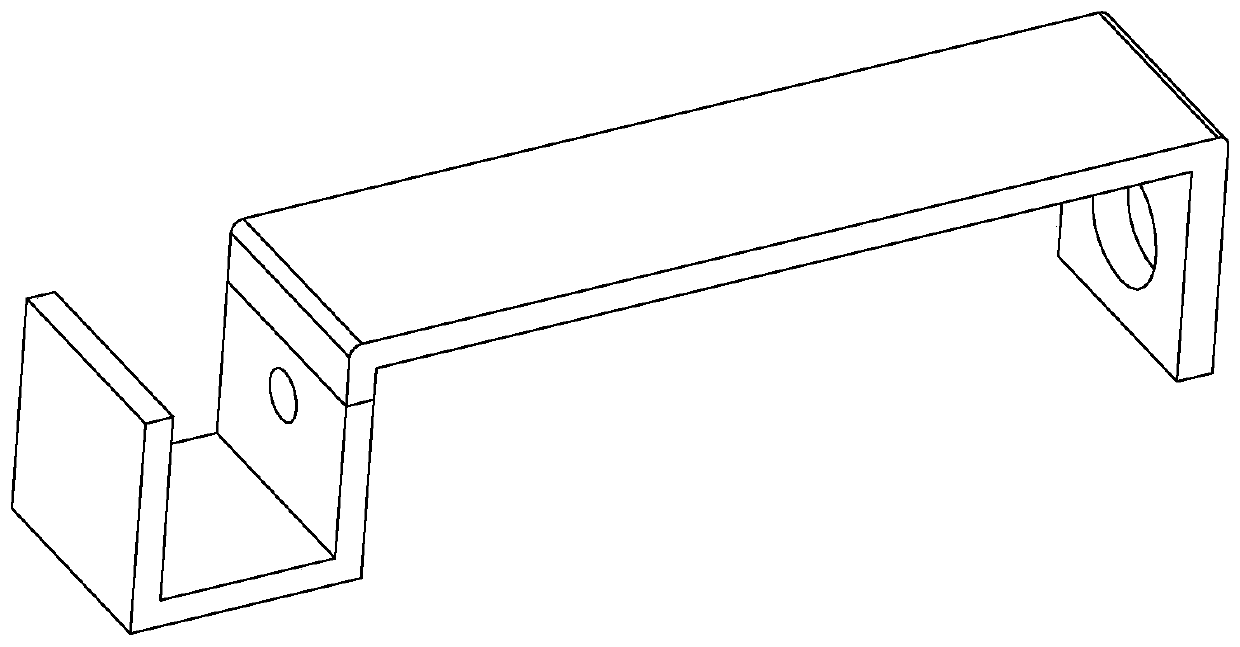

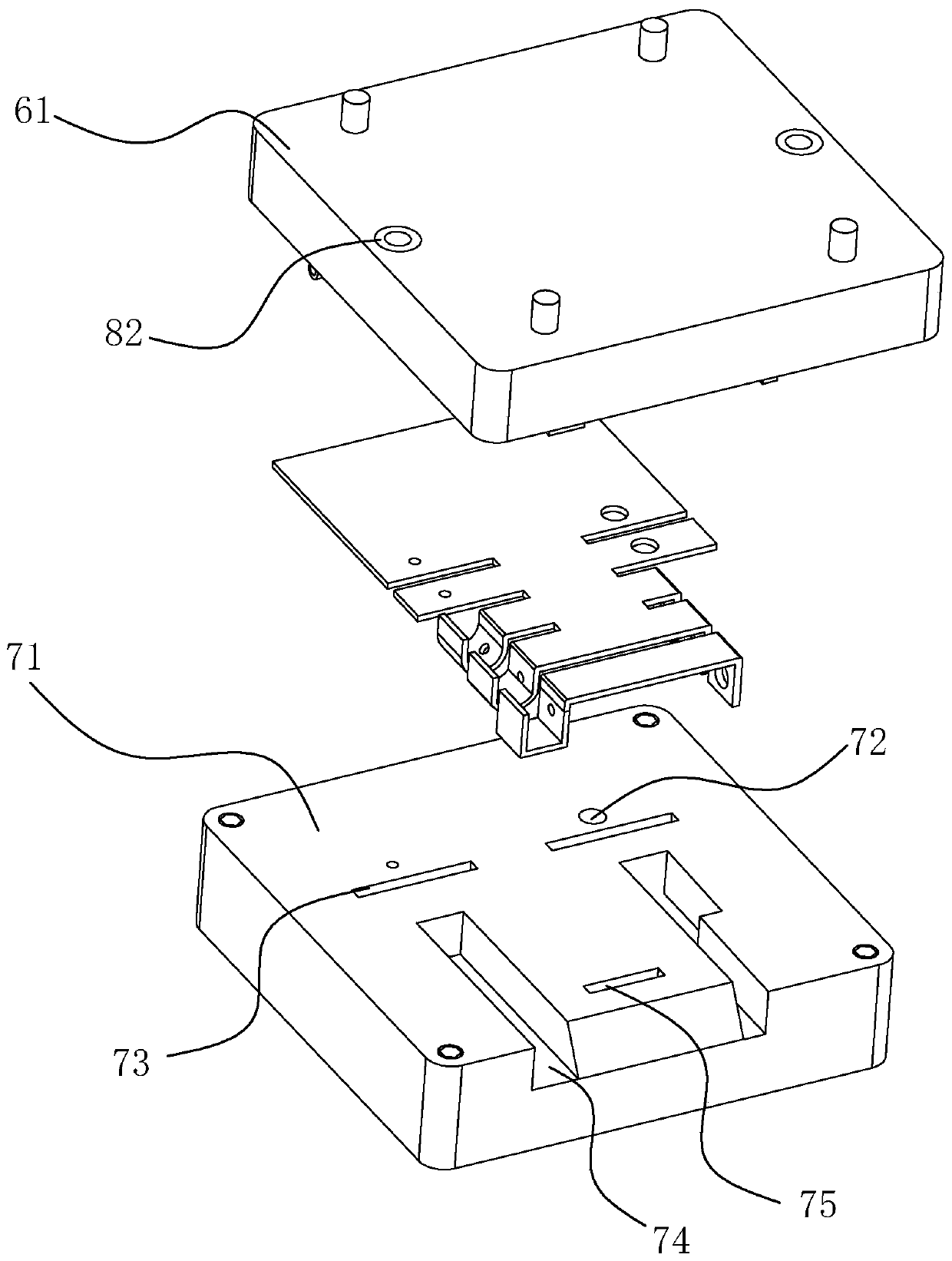

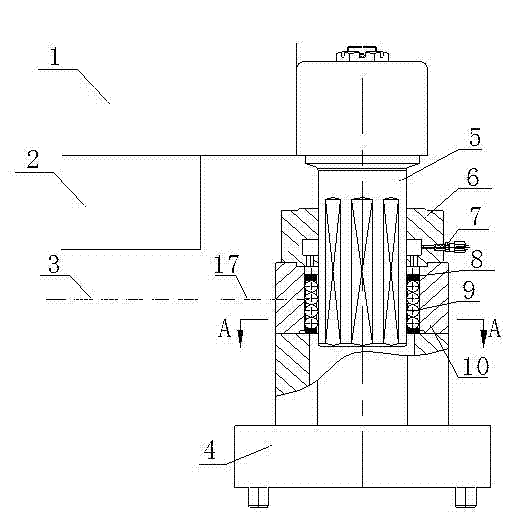

Filter case stretching material falling device

ActiveCN104226812AEasy to operateEasy to implement mechanicallyShaping toolsStripping-off devicesPunchingEngineering

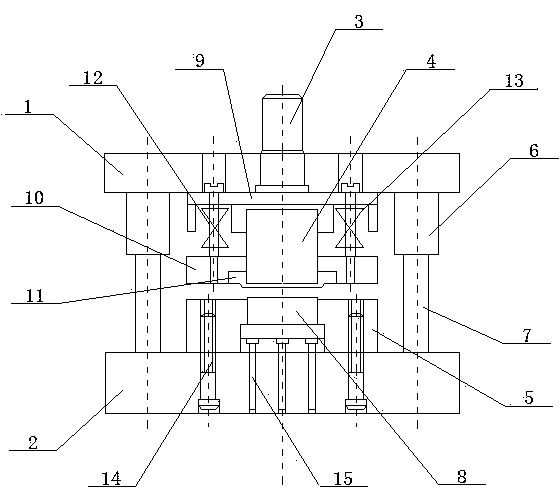

The invention discloses a filter case stretching material falling device, which comprises an upper template (1) and a lower template (14), wherein a lower mold support frame (11) and a material pushing flat plate (10) are arranged on the lower template (14), a mold frame (9) is arranged on the material pushing flat plate (10), a material falling female mold (7) and a material falling male mold (6) are sequentially arranged on the mold frame (9) through a female mold positioning plate (8), the material falling male mold (6) is connected with the upper template (1) through a material falling connecting block (4), and material falling positioning blocks (3) are also arranged between the material falling male mold (6) and the upper template (1). The filter case stretching material falling device has the advantages that the operation is convenient, the mechanization and the automation can be easily realized, the filter case stretching material falling device is suitable for mass production of filter case parts, the production efficiency can be improved, the processing period can be shortened, the quality and the punching precision of products are ensured, in addition, the labor cost and the production cost are greatly reduced, a great amount of labor can be saved, and the rejection rate is reduced.

Owner:ZHEJIANG UNIVERSE FILTER

High-precision stamping mould

The invention discloses a high-precision stamping mould, comprising a mould frame body, wherein, one side of the mould frame body is provided with a transverse feeding blind groove the upper part of which is provided with an upper die installation hole, and the lower part thereof is provided with a lower die installation hole; a guide die sleeve is arranged in the upper die installation hole; a material pressing device is arranged in the guide die sleeve in a sliding manner; the upper end of a sliding sleeve is provided with an upper die plate; a punch head is arranged in the sliding sleeve; the lower end of the punch head penetrates through the material pressing plate; the upper end of the punch head penetrates through the upper die plate and is provided with a strike post the top of which is provided with steps; a compression spring is sheathed on the strike post; the lower die is arranged in the lower die installation hole; and the lower die is provided with a die cavity matched with the punch head. The high-precision stamping mould of the invention can meet the requirements of stamping clearance of an open mould being smaller than 0.1, centering, orientation and guiding precision in high-precision stamping process of porous combination punching and the like, commonly uses a numerical control turret punch press mould, and ensures normal operation of the mould high-precisionstamping process, and the operation is simple.

Owner:MAANSHAN CHENXING MACHINERY MFG

Curtain rod metal piece stamping stepping die

ActiveCN111250599AImprove work efficiencySave spaceShaping toolsMetal-working feeding devicesStampingElectric machinery

The invention discloses a curtain rod metal piece stamping stepping die and relates to the technical field of metal stamping. The curtain rod metal piece stamping stepping die comprises a machine station, a base and a stamping cylinder arranged on the machine station, an upper die holder arranged at the bottom of the stamping cylinder, an upper die component arranged at the bottom of the upper dieholder, and a lower die component arranged above the base, wherein a stamping passage is formed between the upper die component and the lower die component; a feeding mechanism is arranged on one side of the machine station and comprises a transferring table, a transferring roller set arranged on the transferring table, and a pushing component arranged on the side, close to the machine station, of the transferring roller set; the transferring roller set comprises vertical frames arranged on the two sides of the transferring table, an upper transferring roller and a lower transferring roller rotatably connected between the vertical frames, and a transmission motor coaxially connected at the end part of the upper transferring roller or the lower transferring roller; and a sheet metal transferring passage is formed between the upper transferring roller and the lower transferring roller and is as high as the stamping passage. The curtain rod metal piece stamping stepping die has the benefits of carrying out continuous stamping on the sheet metal longer than the lower die component, feeding without halt and being high in working efficiency.

Owner:ZHEJIANG QIANGWEI HARDWARE

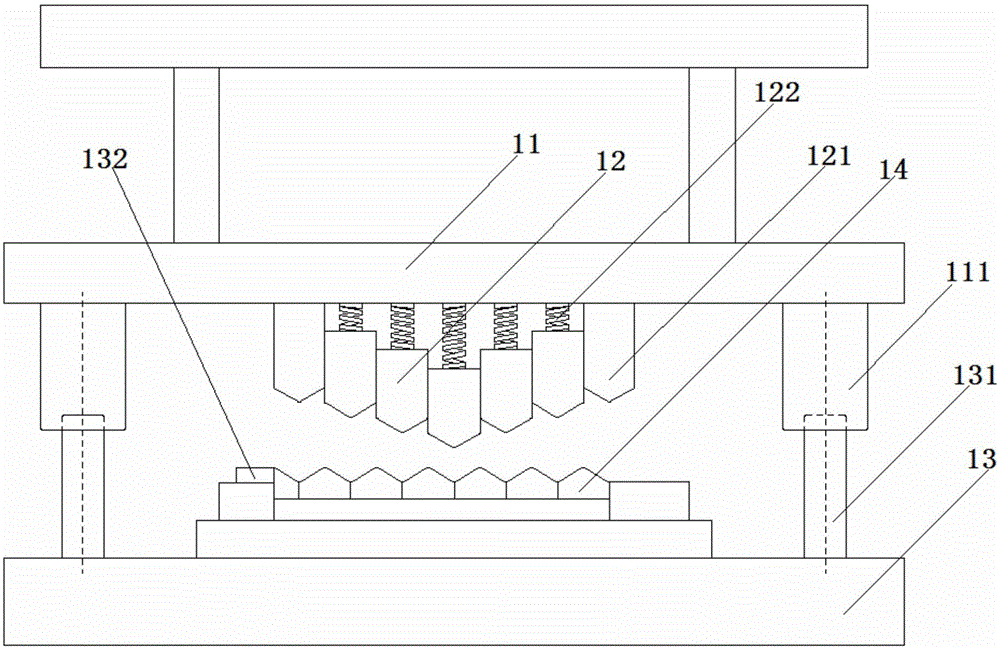

Machining process of corrugated plate for machining AP1000 steam generator dryer

The invention discloses a machining process of a corrugated plate for machining an AP1000 steam generator dryer. In the machining process, a corrugation stamping device used for stamping base plate corrugations and a tailhook stamping device used for stamping a tailhook are adopted, and a water baffle stamping device used for stamping water baffles and a supporting member stamping device used for stamping supporting members are further adopted. In the machining process of the corrugation plate, a base plate of the corrugation plate, the water baffles and the supporting members are respectively machined through dies and fixed into a whole through a welding mode, wherein tool arrays of the corrugation stamping device used for machining the corrugations on the base plate sequentially abut against a base plate template in a pressed mode before formal stamping, and therefore the positioning accuracy of the base plate is guaranteed; after the base plate is completely pressed, the corrugated plate is formed by conducting the stamping again. The machining efficiency is improved, and the machining accuracy is guaranteed.

Owner:SHANGHAI EAST SEA PRESSURE VESSEL MFG

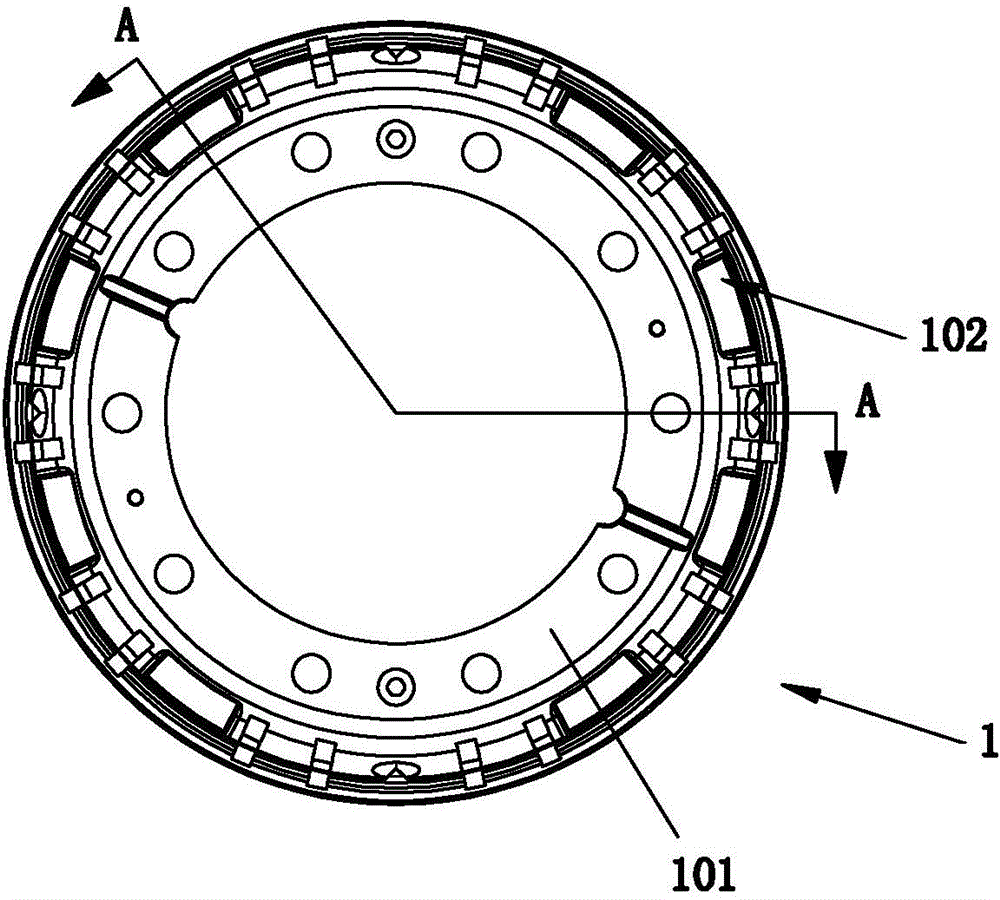

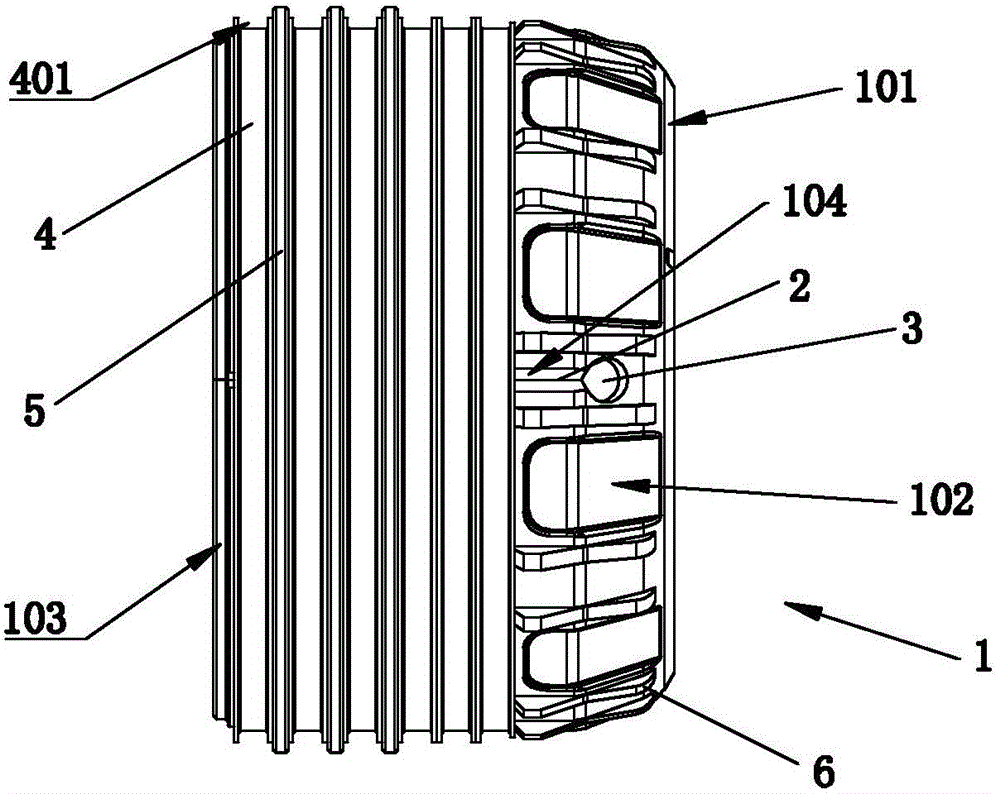

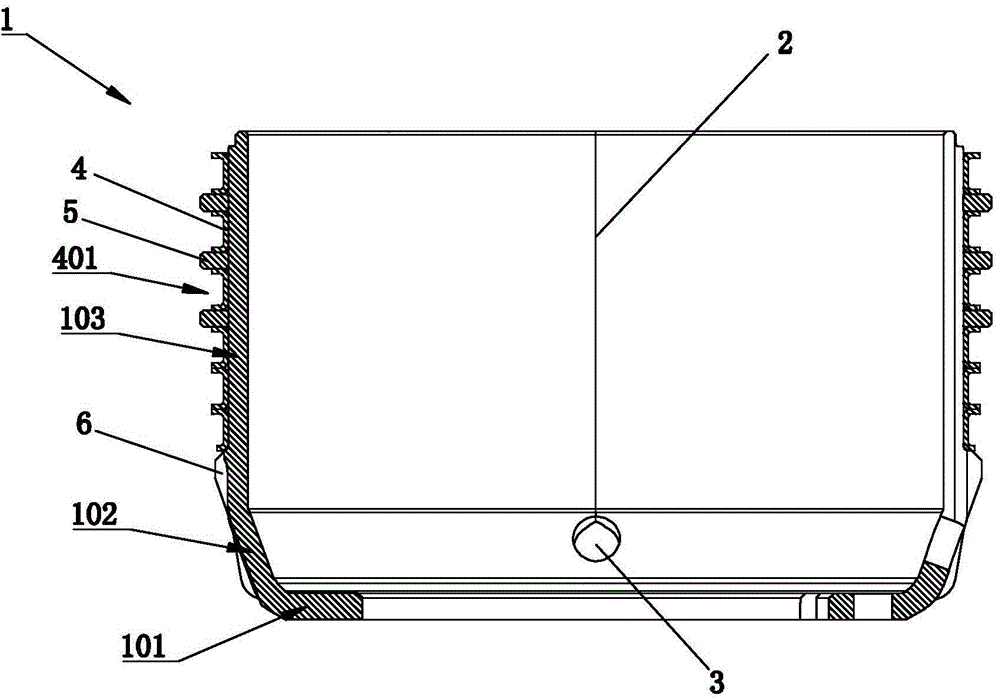

Presplitting drum brake

ActiveCN104595393AReduced inner surface axial crackingReduced axial crackingBraking drumsElastomerInterference fit

The invention discloses a presplitting drum brake, which comprises a drum brake body which is molded by casting, wherein the drum brake body comprises a mounting part and a braking part; a transition connection part is arranged between the mounting part and the braking part; a crack which penetrates through the wall thickness of the braking part is arranged on the braking part; the crack extends from one end part which is far away from the transition connection part to the transition connection part; a plurality of steel hoops which are axially arrayed and are in interference fit with the braking part sleeve the periphery of the braking part. The drum brake body is presplit by the crack to form an elastomer, the stress effect is improved, and the resistance buffering impact force is enhanced; meanwhile, the drum brake body only bears the rotation friction braking force; when the drum brake body is heated and strong tension force acts, the crack is capable of eliminating the expansion stress in time, and the fracturing phenomenon is reduced. The brake tension force is borne by the steel hoops, and the strength of extension and the anti-deformation rigidity of the drum brake are enhanced. Due to the adoption of the drum brake, the structural intensity and the mechanical performance are improved, the service life of the drum brake is prolonged, the radiating performance is good, and the use safety is high.

Owner:SHANDONG HAOXIN MACHINERY

Plate material punching machine

InactiveCN111842595AConvenient loading and unloading processNo damageMetal-working feeding devicesShaping safety devicesPunchingElectric machinery

The invention relates to the technical field of punching machines, in particular to a plate material punching machine. The plate material punching machine comprises a punching rack, a punching mechanism, a correcting mechanism and a conveying mechanism, wherein the upper side of the punching rack is provided with the conveying mechanism, the middle portion of the punching rack is provided with thepunching mechanism, the punching mechanism is provided with the correcting mechanism, the punching rack comprises a rectangle frame, a balance weight bottom frame, a first vertical plate, a second vertical plate, a third vertical plate, a first steel channel and a second steel channel, and the balance weight bottom frame is arranged below the rectangle frame. According to the plate material punching machine, a second motor drives a transmission roller to rotate, plate materials on the upper side of the transmission roller can be driven to run depending on friction force, workers do not need to operate at a punching station, the operation safety is guaranteed, the plate material loading and unloading procedure is also facilitated, a punching plate and a bottom mold plate are driven to perform combination punching by adopting a method of a first motor being in engaging transmission with a first engaging plate and a second engaging plate, and the punching process and the transmission process can be separated effectively.

Owner:淮南威凯机械设备有限公司

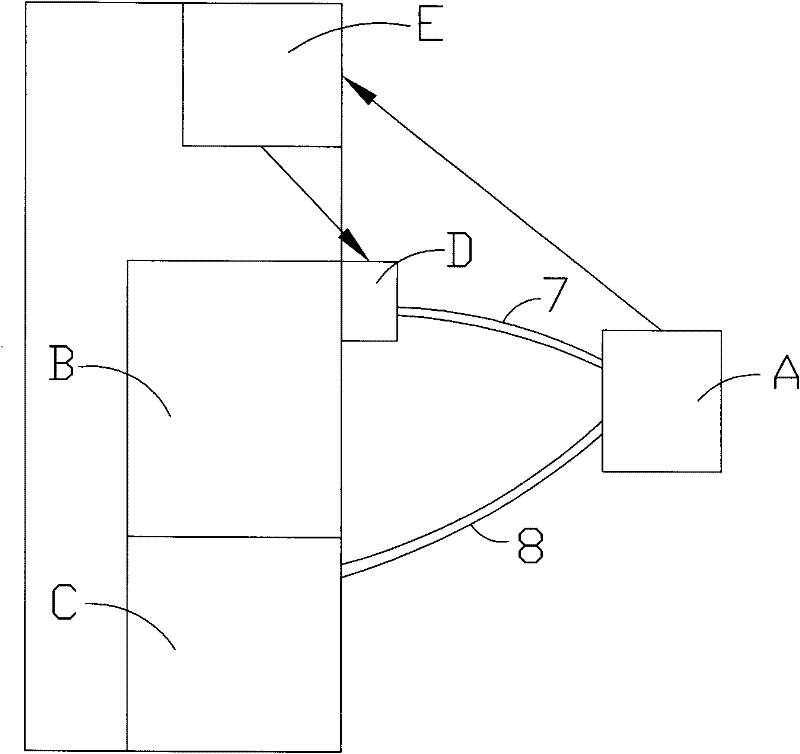

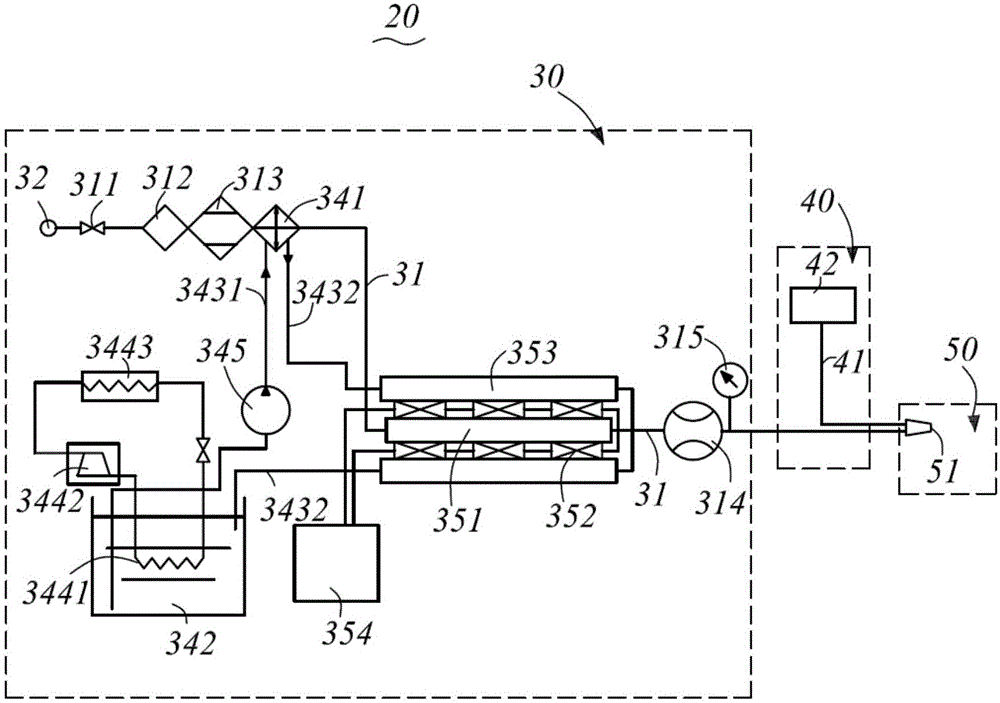

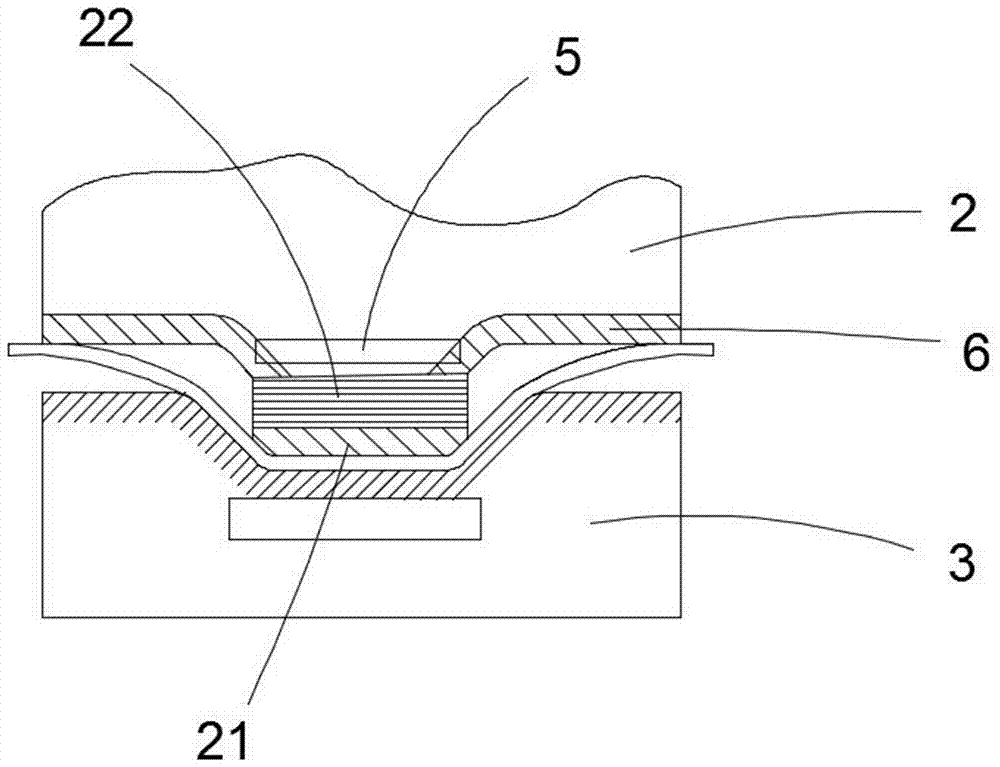

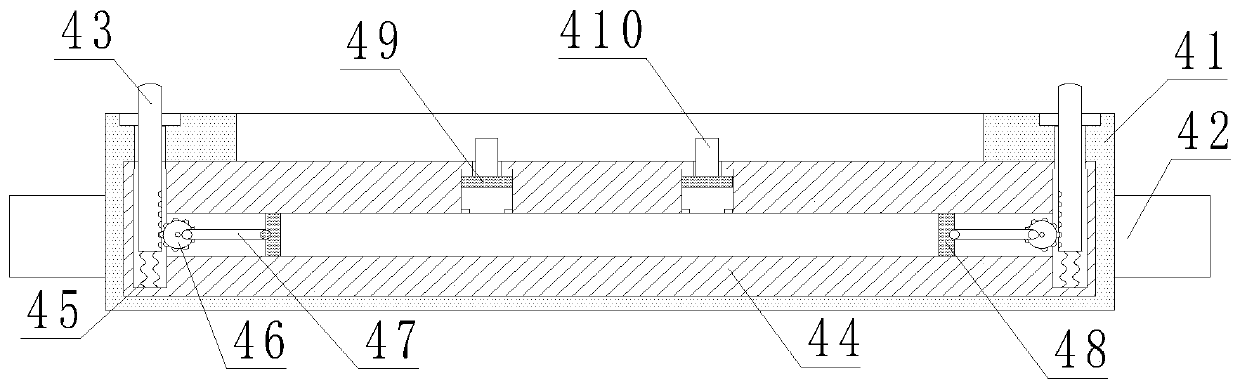

Low-temperature lubricating supply device, high-speed stamping die with same and control method thereof

InactiveCN105033073AReduce wearExtended service lifeShaping toolsLubrication elementsProcess engineeringPhase change

The invention provides a low-temperature lubricating supply device, a high-speed stamping die with the same and a control method thereof. The low-temperature lubricating supply device comprises a gas supply part for conveying gas, an oil supply part for conveying lubricating oil and an oil-gas mixing part simultaneously communicated with the gas supply part and the oil supply part. The oil-gas mixing part is used for conveying an oil-gas mixed medium formed after the mixing of the gas and the lubricating oil. The gas supply part comprises a gas supply main pipeline. The gas supply part further comprises a vapor compression refrigeration device and a semiconductor refrigeration device which are partially arranged on the gas supply main pipeline and sequentially cool the gas supply main pipeline. According to the low-temperature lubricating supply device, by utilizing forced convection of low-temperature cold gas and phase-change heat exchange of the lubricating oil in the oil-gas mixed medium, heat generated in the working process of a stamping machining area and heat generated during part machining are taken away timely, and the abrasion to the high-speed stamping die is reduced through a lubricating film formed by the lubricating oil.

Owner:苏州明和行新材料科技有限公司

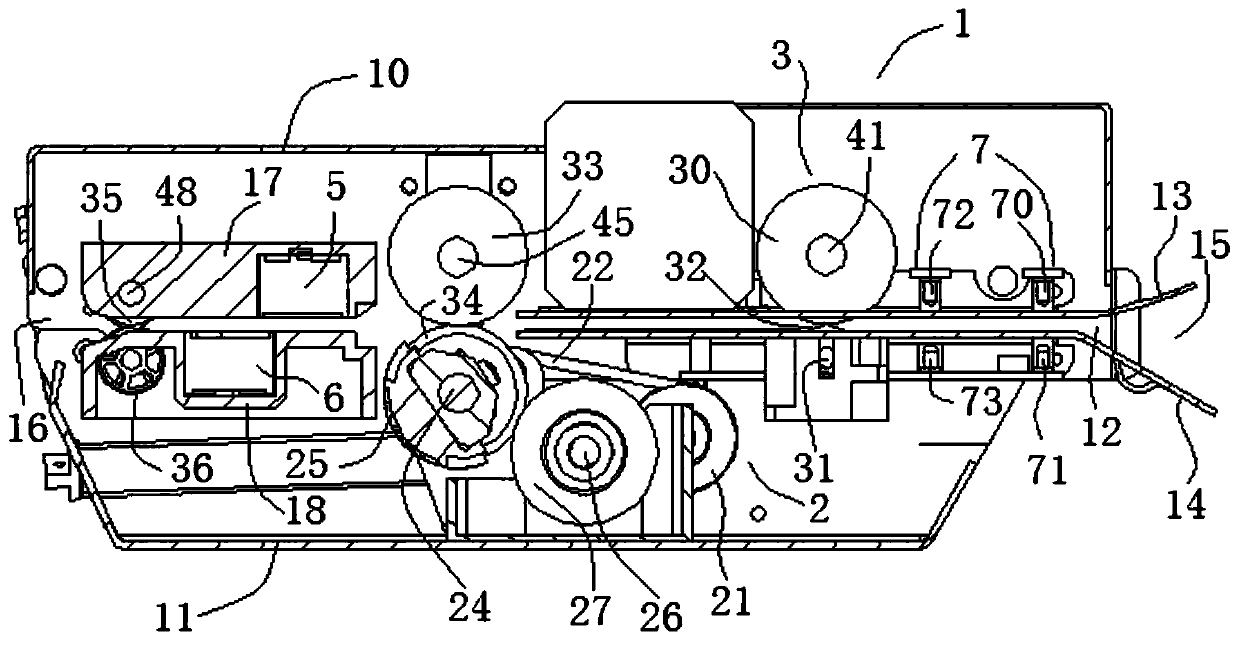

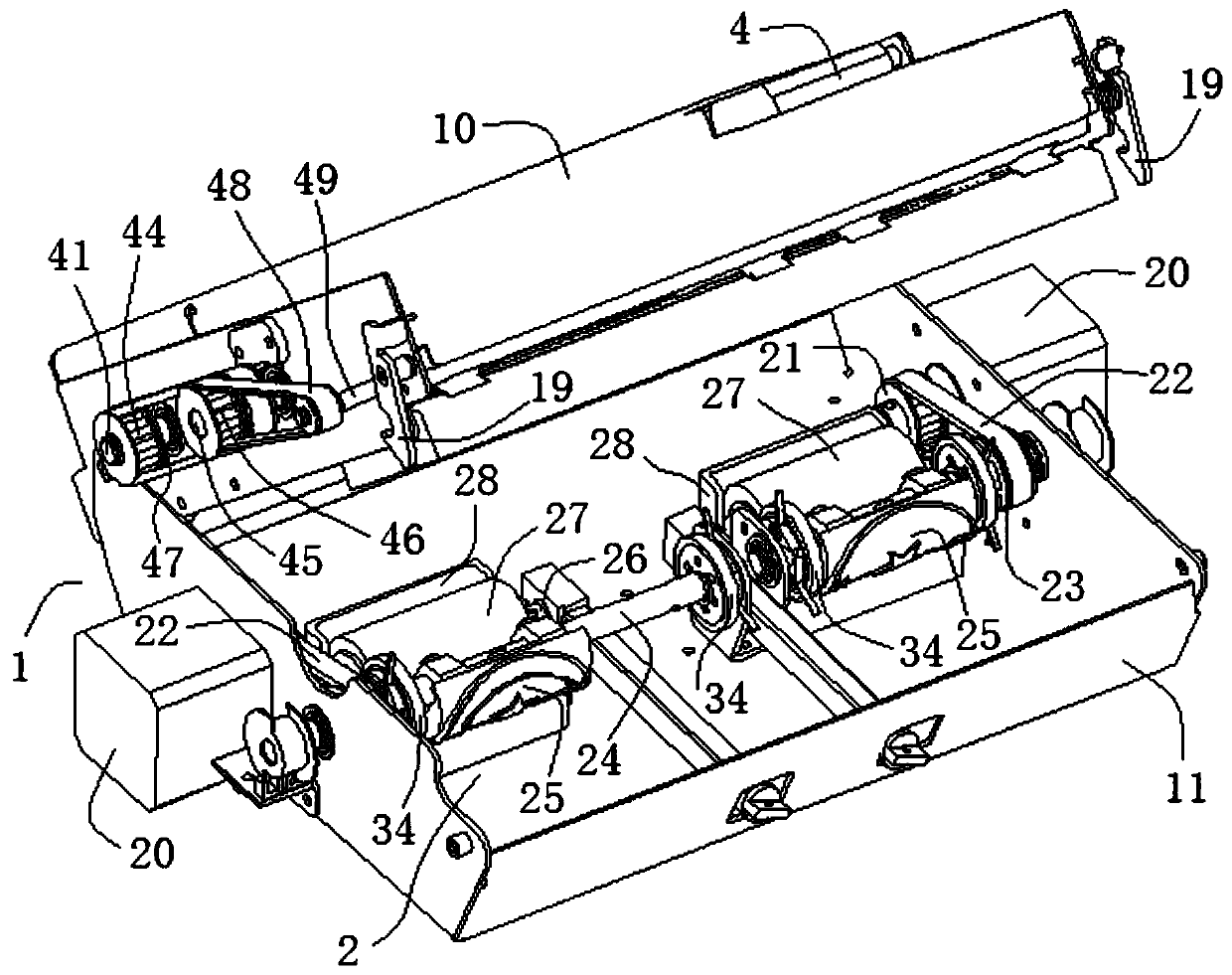

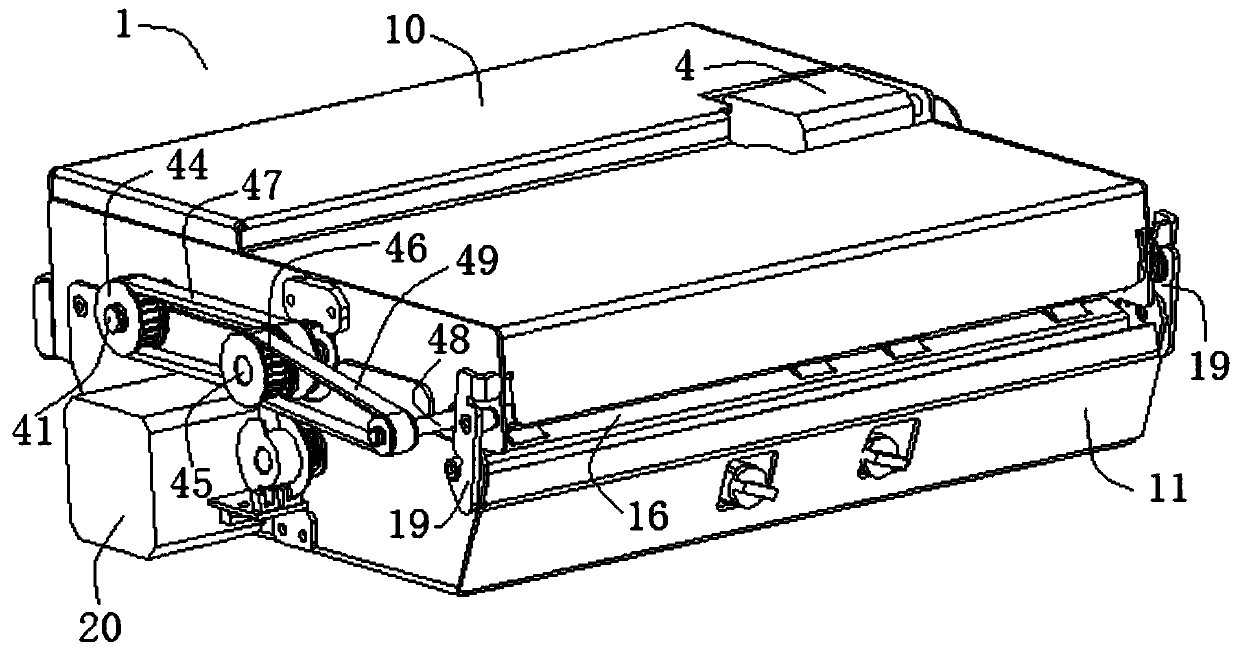

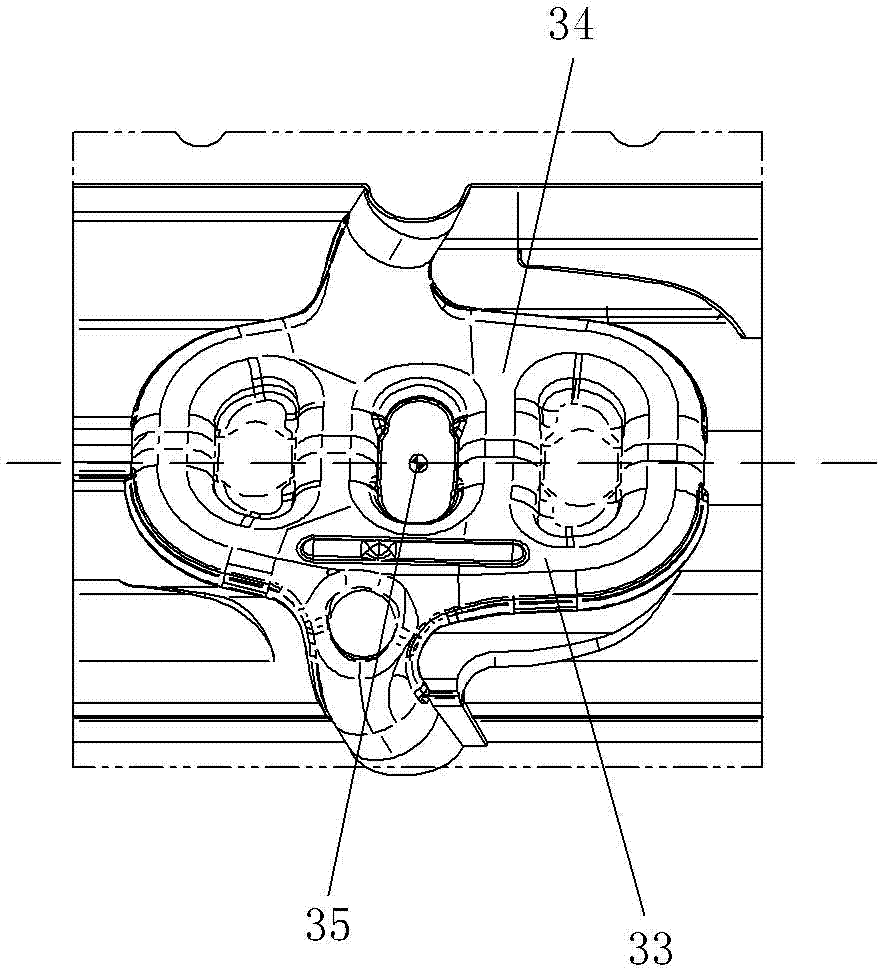

Stamping and scanning integrated device

PendingCN111447338AEasy to scanEasy to moveStampingPictoral communicationIndustrial engineeringPaper sheet

The invention discloses a stamping and scanning integrated device, and belongs to the technical field of office equipment. The printer comprises a shell which is provided with a paper inlet and a paper outlet; the paper feeding channel is arranged in the shell, the paper feeding channel is provided with a paper inlet end and a paper outlet end, the paper inlet end is communicated with the paper inlet, and the paper outlet end is communicated with the paper outlet; the paper feeding driving wheel set is used for driving paper to move in the paper feeding channel and sending out the paper from the paper outlet, and wheel surfaces of the paper feeding driving wheel set extend into the paper feeding channel; the seal stamping device is used for stamping the paper and is installed on the upperside or the lower side of the paper feeding channel, and a seal arranged on the seal stamping device extends into the paper feeding channel; the scanning device is close to the paper outlet end, installed in the shell and located on the upper side and / or the lower side of the paper feeding channel. According to the stamping and scanning integrated device, paper can be stamped and scanned, and theapplicability of the stamping and scanning integrated device is improved.

Owner:BEIJING C&W ELECTRONICS GRP

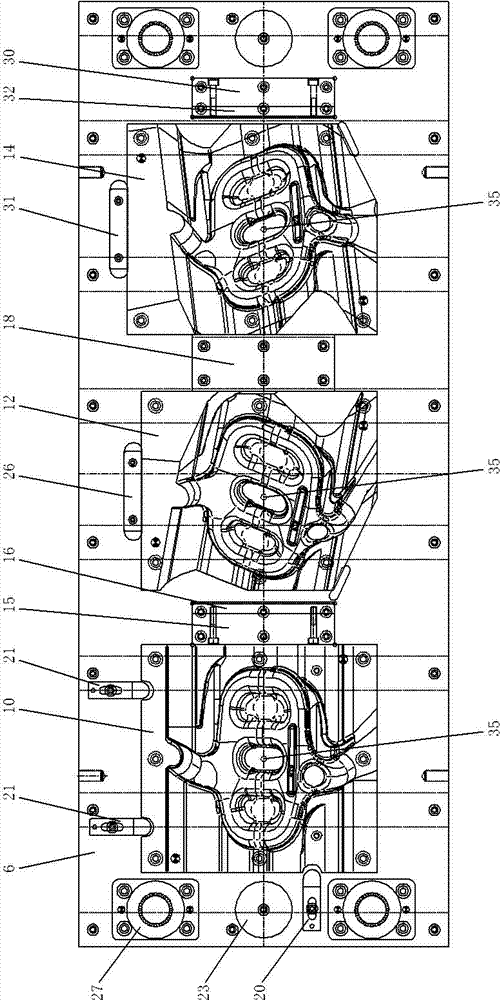

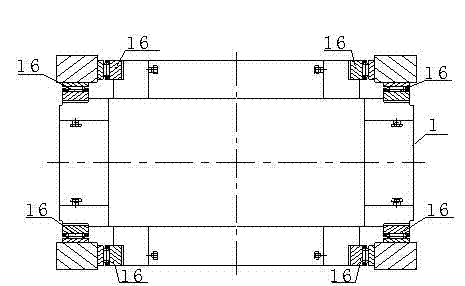

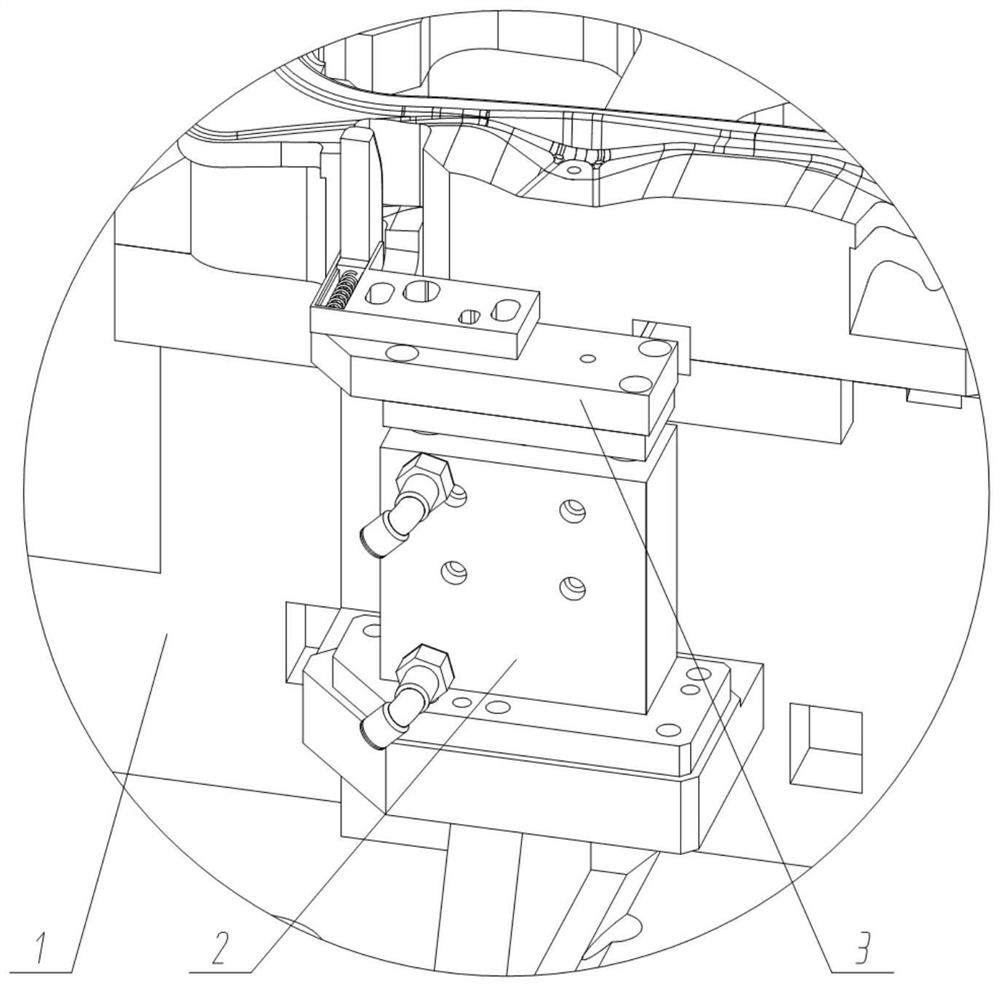

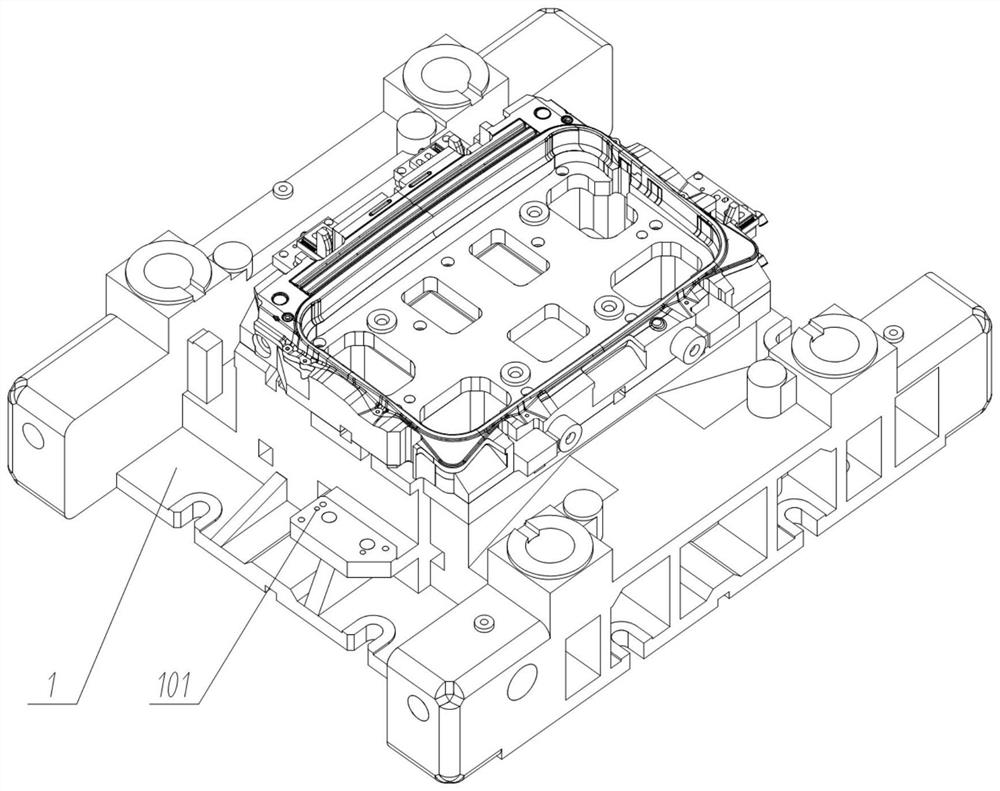

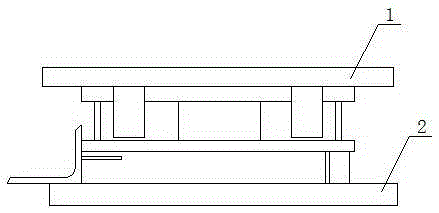

Forming and shaping die for air inlet manifold of automobile engine exhaust system

The invention provides a forming and shaping die for an air inlet manifold of an automobile engine exhaust system. The forming and shaping die has the advantages that the cost of production equipment can be effectively reduced and the production efficiency is increased. The forming and shaping die comprises an upper die plate and a lower die plate, wherein an upper mounting plate is mounted above the upper die plate through an upper die pin, a lower mounting plate is mounted below the lower die plate through a lower die pin, and the upper die plate and the lower die plate are in guiding connection through guide members which roll independently. The forming and shaping die is characterized by further comprising an integral forming module, an upper shell portion shaping module and a lower shell portion shaping module, wherein the integral forming module, the upper shell portion shaping module and the lower shell portion shaping module are mounted between the upper die plate and the lower die plate side by side along the transverse direction.

Owner:邝记(清新)环保排气系统有限公司

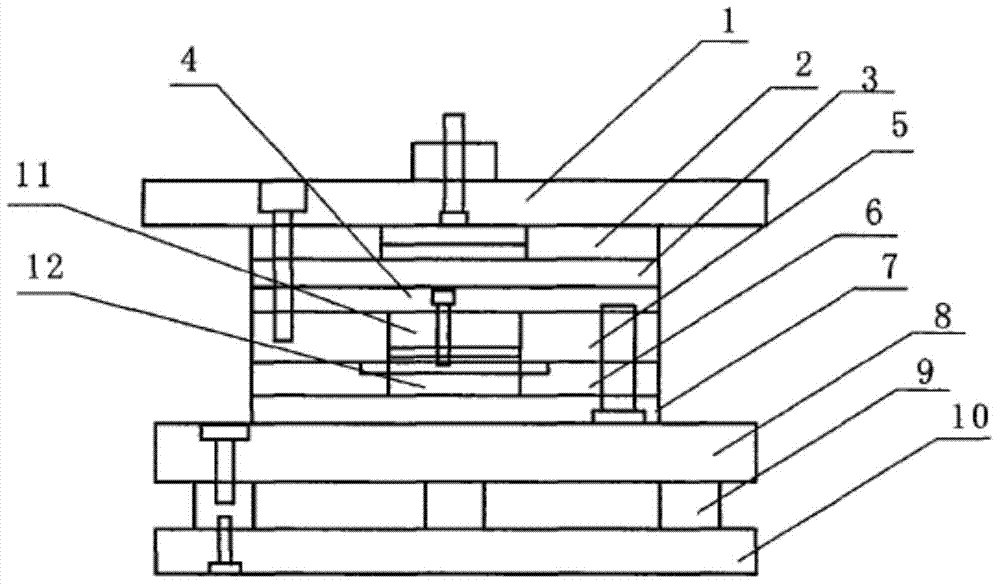

Stamping die provided with guide pillar

InactiveCN103537548AEnsure correct orientationGuaranteed stamping accuracyShaping toolsPunchingEngineering

The invention discloses a stamping die provided with a guide pillar. The stamping die provided with the guide pillar comprises a blanking-punching die and a forming die. The stamping die provided with the guide pillar is characterized in that the blanking-punching die comprises an upper die base, a lower die base, an upper base plate, a lower base plate and a lower bearing plate; a hollow base plate is arranged between the upper die base and the upper base plate; an upper clamping plate is arranged at the lower end of the upper base plate; an upper template is arranged at the lower end of the upper base plate; the upper end of the lower die base is connected with the lower base plate; an outer stripping plate is arranged at the upper end of the lower base plate; an inner stripping plate and a concave-convex die are arranged in the upper template and the outer stripping plate respectively. The forming die comprises an upper die base, a lower die base, a lower base plate and a lower bearing plate; the bottom of the upper die base is connected with an upper clamping plate; the upper clamping plate is at least provided with the guide pillar; a punch is arranged in the middle portion of the upper die base and the upper clamping plate; the upper end of the lower die base is connected with a second lower base plate and a first lower base plate; the first lower base plate is connected with a lower template. The stamping die provided with the guide pillar is simple in manufacturing procedure, stamped products are stable in size, and precision is high.

Owner:ANHUI PRINTING MECHANICAL & ELECTRICAL

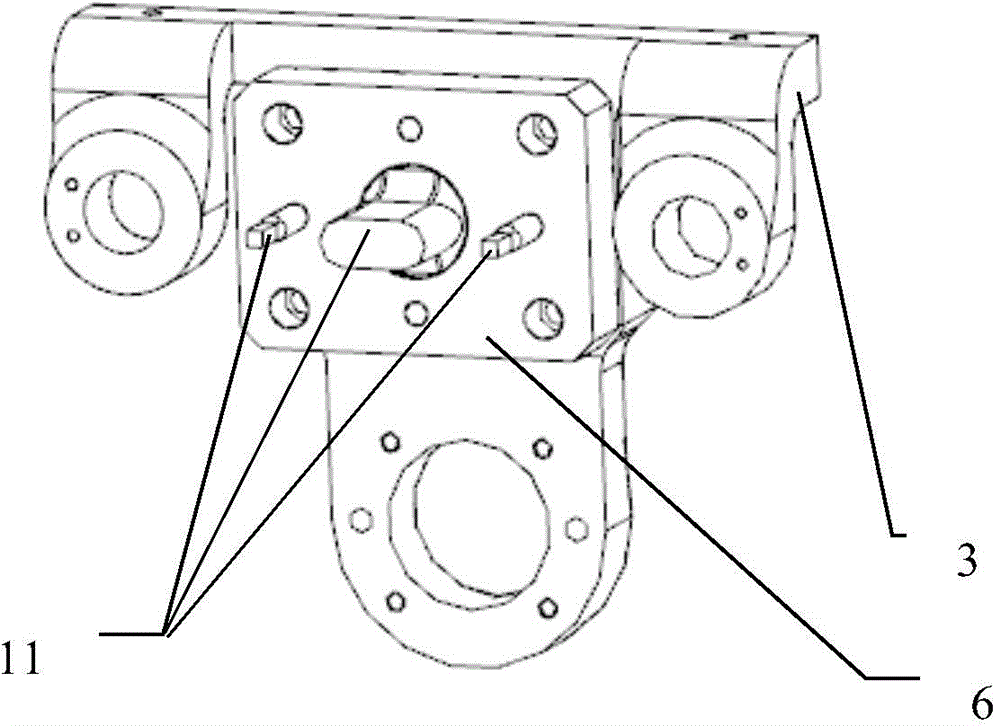

Press slide guide

Owner:JDM JINGDA MASCH (NINGBO) CO LTD

Air cylinder type floating device for stamping machining

PendingCN112170674AGuaranteed to be centeredEasy to unloadMetal-working feeding devicesPositioning devicesStructural engineeringSheet metal stamping

The invention discloses an air cylinder type floating device for stamping machining, relates to the technical field of stamping equipment, and solves the problems that in existing stamping machining,the position of a metal plate can be correctly placed only by manually and repeatedly adjusting the position of the metal plate, meanwhile, after stamping of the metal plate is completed, the metal plate is difficult to separate from a lower die, operation is complex, and the production efficiency is low. The air cylinder type floating device comprises a bottom die main body, wherein four air cylinders are fixedly connected to the side surface of the bottom die main body, the tops of the air cylinders are fixedly connected with material floating blocks, the tops of the floating material blocksare fixedly connected with guide plates, and the tops of the guide plates are slidably connected with guide blocks. The air cylinder type floating device has good positioning capacity, can effectively guarantee the effect that a sheet metal part is located in the middle, has excellent automatic centering performance, improves the positioning progress and the feeding speed, can separate the sheetmetal part from the bottom, facilitates discharging of the sheet metal part, reduces the discharging difficulty, improves the working efficiency and greatly facilitates stamping work.

Owner:广州鑫娄山模具有限公司

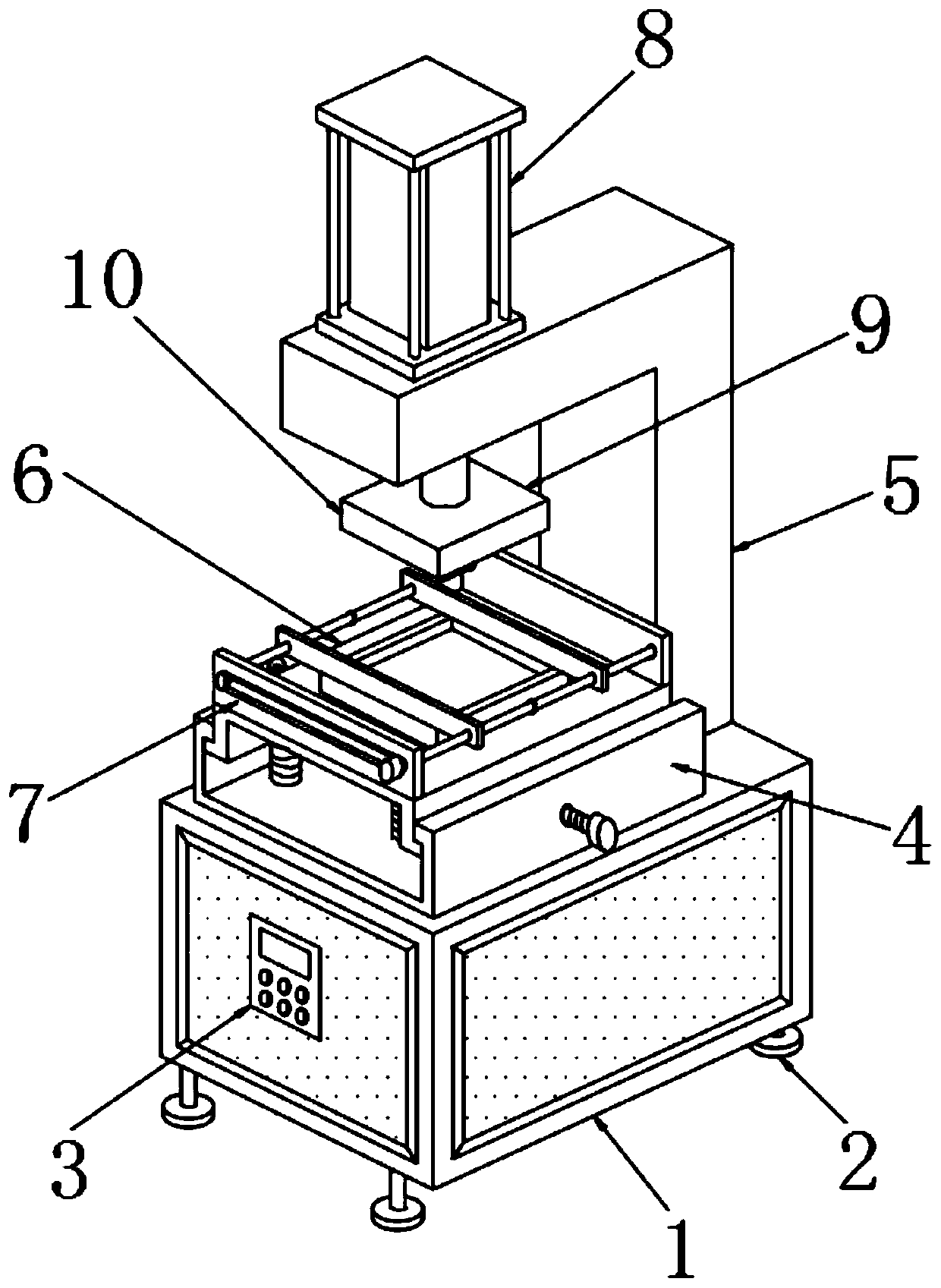

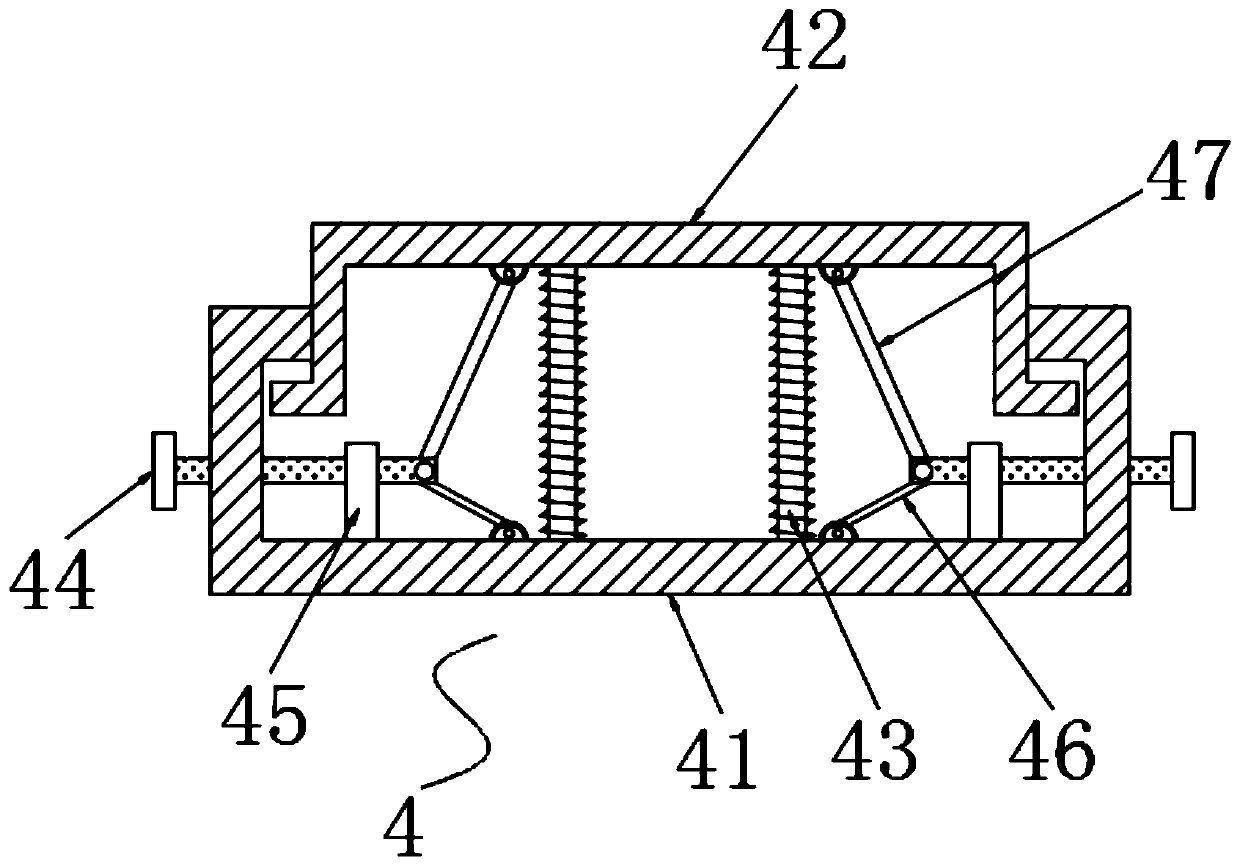

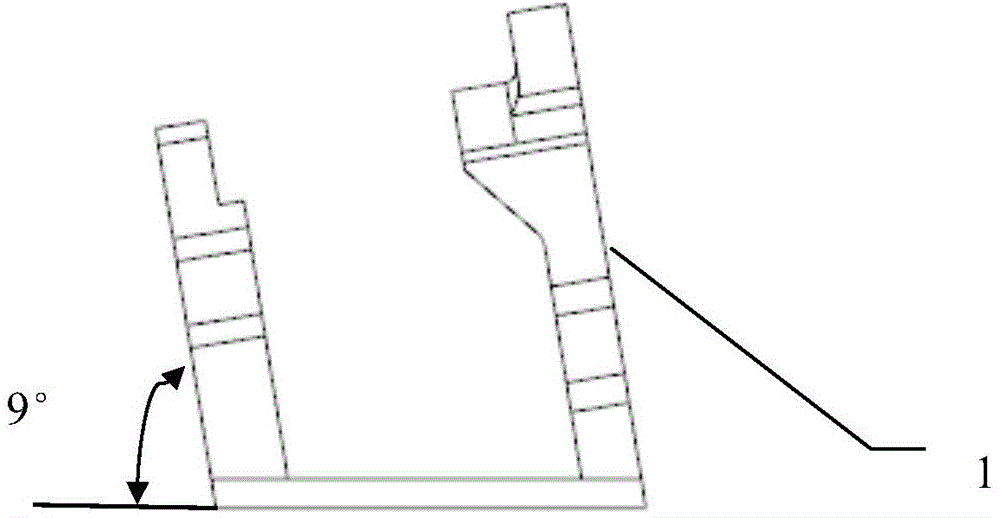

Stamping device for machining JYW800 steel material of vehicle

PendingCN111451344AGuaranteed stamping accuracyConvenient unloading workShaping toolsMetal-working feeding devicesStamping processTelescopic cylinder

The invention discloses a stamping device for machining a JYW800 steel material of a vehicle, and relates to the technical field of steel material machining, in particular to the technical field of machining of the JYW800 steel material. The stamping device comprises a machine frame, feet and a control panel. The feet are fixedly installed on the lower surface of the machine frame. The control panel is embedded in the front side of the machine frame. An adjusting base is arranged on the upper surface of the machine frame. The position, located on one side of the adjusting base, of the upper surface of the machine frame is fixedly provided with a stand column. A telescopic cylinder is fixedly installed at the top end of the stand column. The stamping device is scientific and reasonable in structure and convenient to operate; by means of the adjusting base, the height adjustment of a lower die holder can be realized, convenience is provided for stamping work of operators, and the stamping device can adapt to uses at different heights; and by means of a fixing mechanism, the to-be-machine steel material can be fixed and is prevented from displacement in the stamping process, and the stamping precision is ensured.

Owner:JINGYE STEEL CO LTD

Simple precision die

A simple precision die relates to the field of punching equipment. A die handle is arranged on an upper die holder, guide sleeves and guide posts are arranged between the upper die holder and a lower die holder, the guide posts are movably connected with the guide sleeves, a male die is arranged on the bottom of the lower die holder, a bolster is arranged between the male die and the upper die holder, a stripper plate is arranged on the lower part of the male die, the bottom of the stripper plate is provided with an annular opening, a toothed ring pressing plate is arranged in the annular opening, an ejector plate is arranged at the middle of a female die, three ejector rods are arranged on the bottom of the ejector plate, and the female die is fixed on the top of a lower die holder by a left screw and a right screw. Two stripper screws are arranged between the upper die holder, the bolster and the stripper plate, and disc springs are arranged on the stripper screws. The simple precision die can overcome the defects of the prior art, the pressure resistance of the simple precision die is enhanced, the deviation of the die is prevented, and thereby the punching precision of the die is ensured.

Owner:KUNSHAN PANTRATEQ

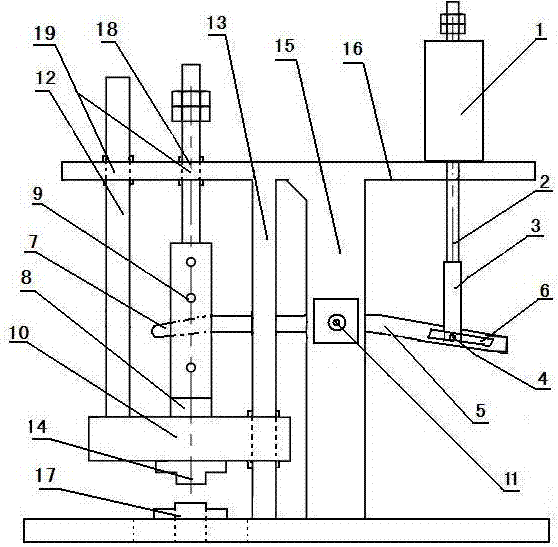

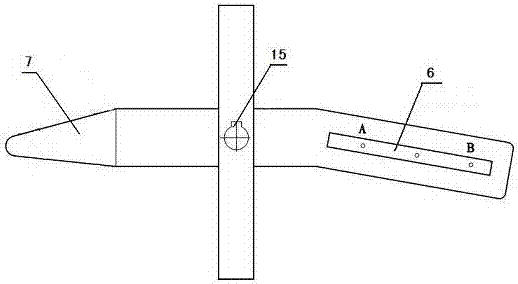

Punching machine

The invention discloses a punching machine. A shuttlecock feather piece pneumatic punching machine comprises an air pump, a punching machine main frame, a lever system and a lower module; the air pump, the lever system and the lower module are mounted on the punching machine main frame; the lever system consists of an air pump extension rod, a rolling pressure rod, a lever, a force balance bracket, a vertical lifting mechanism and an upper module; the air pump is fixedly connected with the air pump extension rod; one end of the rolling pressure rod is connected with the air pump extension rod, and the other end of the rolling pressure rod is movably connected to a chute in one end of the lever; the lever uses the force balance bracket as a support point; and the other end of the lever lifts a slide way for improving the shearing matching between the upper module and the lower module of the vertical lifting mechanism. The punching machine is pushed by the air pump, is low in noise and energy consumption, and is the shuttlecock feather piece pneumatic punching machine with high shearing precision, low mold damage, low overall noise and low energy consumption.

Owner:宁波澳玛特高精冲压机床股份有限公司

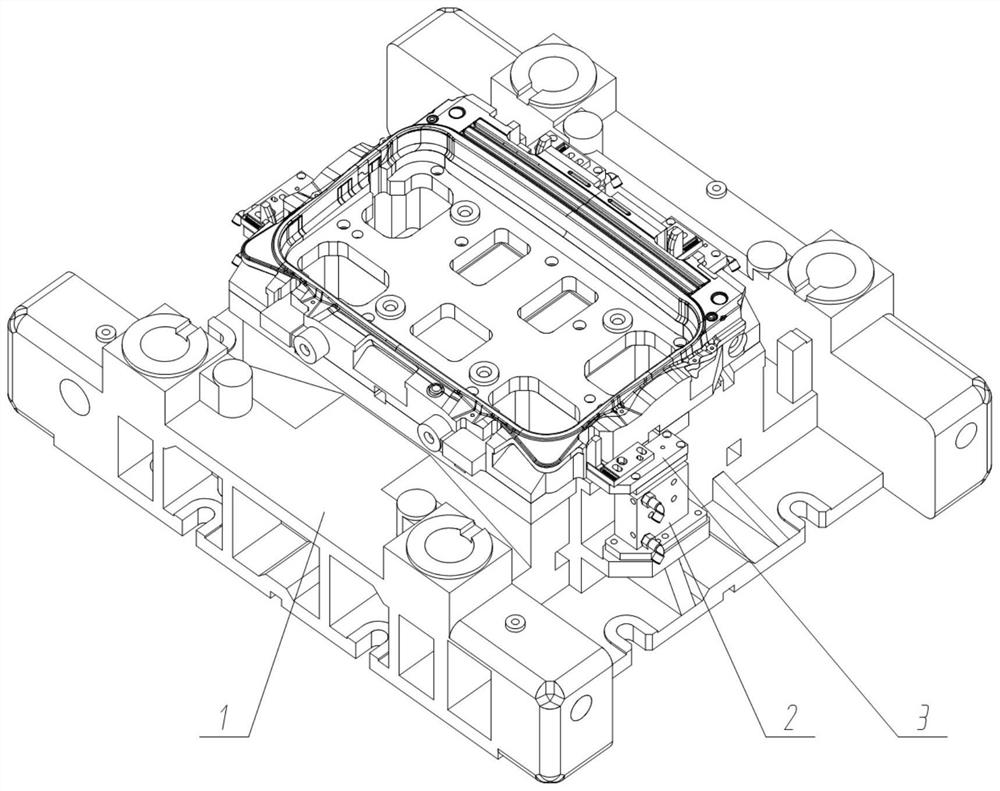

Stamping auxiliary device capable of machining high-precision protrusion part

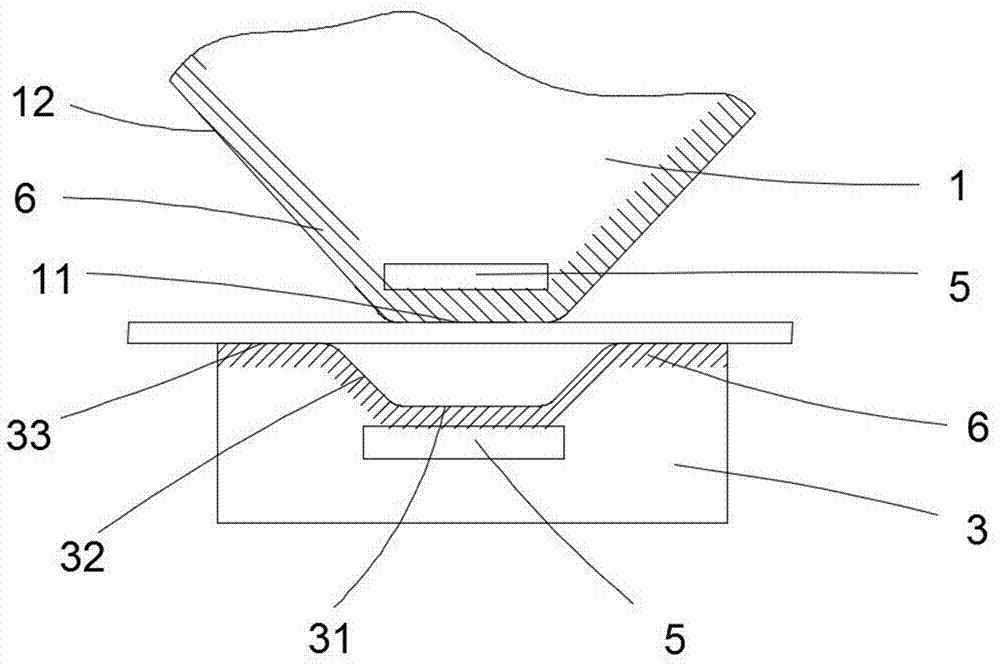

ActiveCN107335709AStretch smoothlyGuaranteed stamping accuracyShaping toolsMetal-working feeding devicesEngineeringMechanical engineering

The invention discloses a stamping auxiliary device capable of machining a high-precision protrusion part. The stamping auxiliary device comprises a first stamping die, a second stamping die and an auxiliary device body; a sinking part matched with the workpiece protrusion part in shape is formed in the auxiliary device body, the end of the fist stamping die and the end of the workpiece protrusion part are matched in shape, a telescopic pressing block is arranged at the end of the second stamping die, after the pressing block is shortened, the whole shape of the second stamping die is matched with the shape of the workpiece protrusion part, and the first stamping die, the second stamping die and the auxiliary device body are each provided with a heating device. The dies and the workpiece can be heated, after the workpiece is heated, the workpiece is more easily stretched evenly, stamping precision is ensured, deformation is not prone to generation, after the workpiece is stamped, the workpiece is attached to the auxiliary device body, and the high-precision requirement of the workpiece protrusion part an be ensured.

Owner:太仓市华天冲压五金制品厂

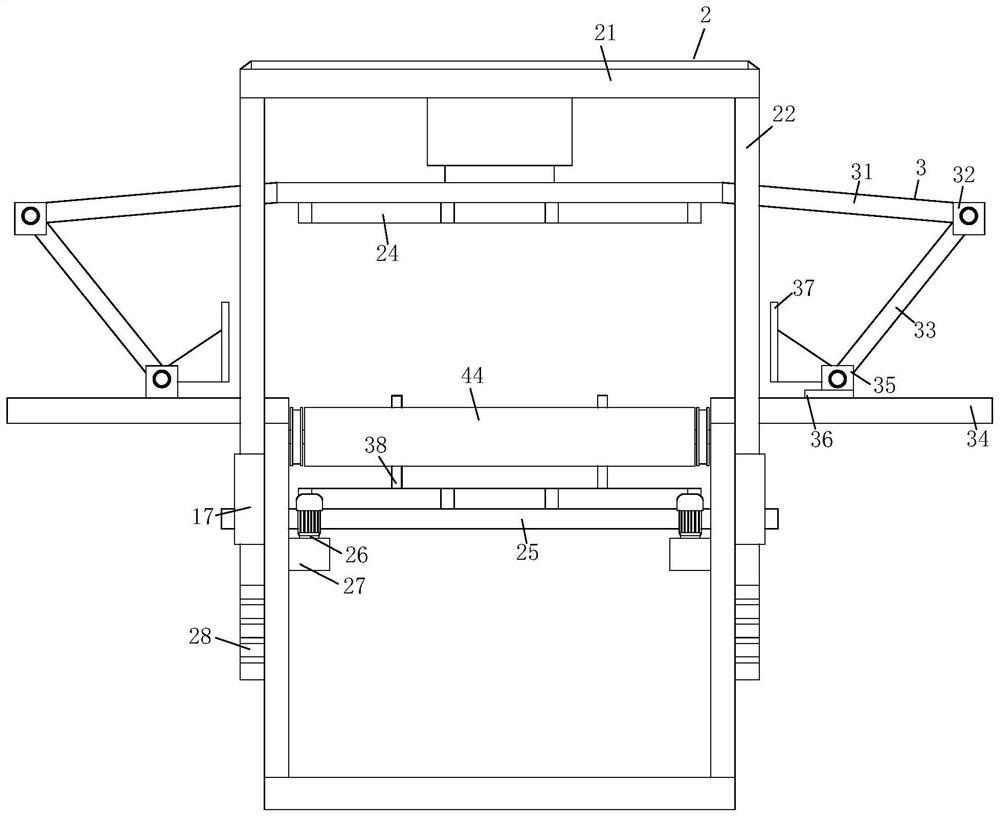

Refrigerator bottom plate forming die provided with automatic demoulding device

ActiveCN109732839AEasy to demouldSolve difficult demouldingDomestic articlesHydraulic cylinderEngineering

The invention relates to the technical field of automatic demoulding equipment of refrigerator bottom plate forming dies and provides a refrigerator bottom plate forming die provided with an automaticdemoulding device. The refrigerator bottom plate forming die comprises a base, two symmetrical support arms connected with the upper end of the base, and a top beam connected between the two supportarms, wherein a concave die is arranged at the upper end of the base and comprises a die set; two symmetrical connecting blocks are connected with the two ends of the die set; a limiting sliding rod is connected with the upper ends of the connecting blocks; a rectangular groove is formed in the inner bottom wall of the die set; a hydraulic cylinder is connected into the first rectangular groove; an H-shaped groove is formed in the cavity of the hydraulic cylinder; and two symmetrical rack bars. The refrigerator bottom plate forming die overcomes the defects in the prior art, is reasonable in design and compact in structure, solves the problem that the existing refrigerator bottom plate is difficult in demoulding after punch forming, adopts the simple structural combination, facilitates demoulding of the formed refrigerator bottom plate, improves the working efficiency and has high practicality.

Owner:滁州市锴模装备模具制造有限公司

Hydraulic punching device

The invention discloses a hydraulic punching device. The hydraulic punching device comprises a base, a connection plate, a transmission assembly and a hydraulic cylinder. The transmission assembly comprises a first transmission shaft, a second transmission shaft and a third transmission shaft which are arranged in parallel. The first transmission shaft and the second transmission shaft are both connected with one side of the base in a sliding mode. The two ends of the third transmission shaft are fixed to the two sides of the base respectively. One end of the first transmission shaft and the end of the second transmission shaft are each fixed to the connection plate. The connection plate is connected with the third transmission shaft in a sliding mode. A female die is arranged on the other side of the base. An indented part is formed in the female die. A punching assembly is fixed to the connection plate and comprises a male die, an elastic pressing block and a punch. The elastic pressing block abuts against a part. Transmission is conducted through the three shafts by means of first-stage main guide and second-stage auxiliary guide, deviation of the punch is reduced, and the punching accuracy is ensured. Meanwhile, a traditional punching die is replaced with hydraulic punching, and the problems that cost is high and the period is long are solved.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

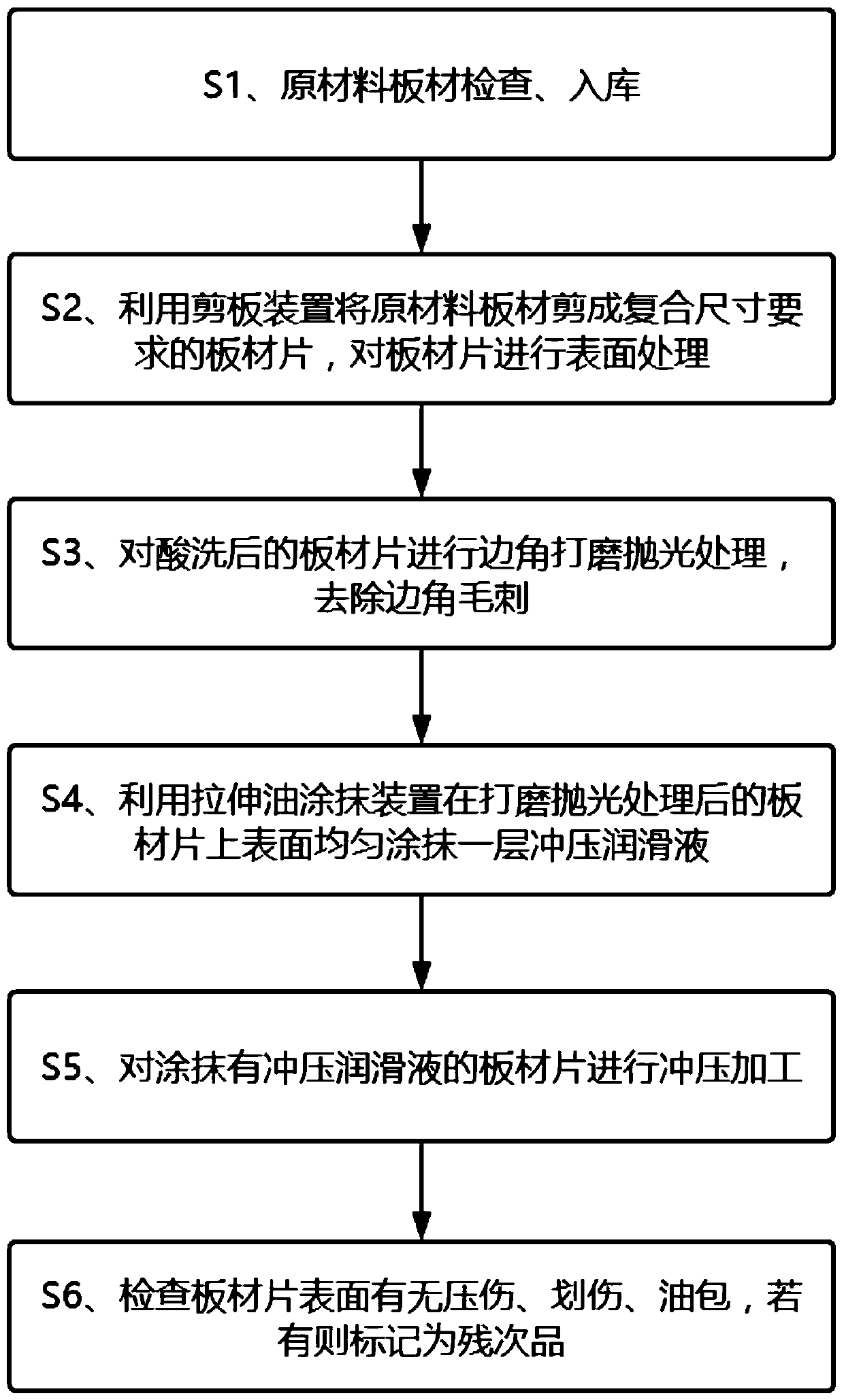

Workpiece stamping process for electronic product machining

InactiveCN111571136ASimple processEasy to operateEdge grinding machinesShaping toolsManufactured materialProcess engineering

The invention discloses a workpiece stamping process for electronic product machining, and belongs to the technical field of electronic product production. The workpiece stamping process for electronic product machining comprises the procedures of raw material plate inspection, storage, plate shearing treatment and surface treatment, grinding and polishing treatment, surface lubricating treatment,stamping machining, final inspection and the like. The workpiece stamping process for electronic product machining comprises the procedures of surface treatment, grinding and polishing treatment, lubricating and smearing treatment, stamping treatment and the like, the technological process is simple, and operation is easy; and the yield of stamping can be effectively increased, the stamping efficiency can be improved, the production cost is reduced, time is saved, and the workpiece stamping process is suitable for large-scale industrial production.

Owner:昆山久茂电子科技有限公司

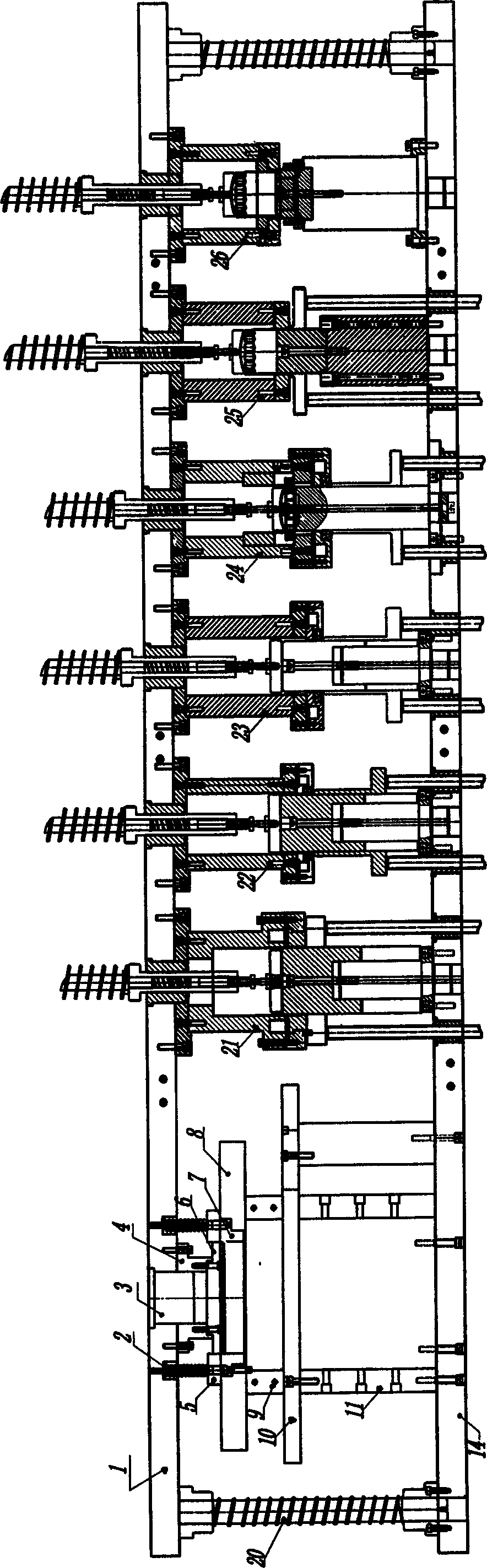

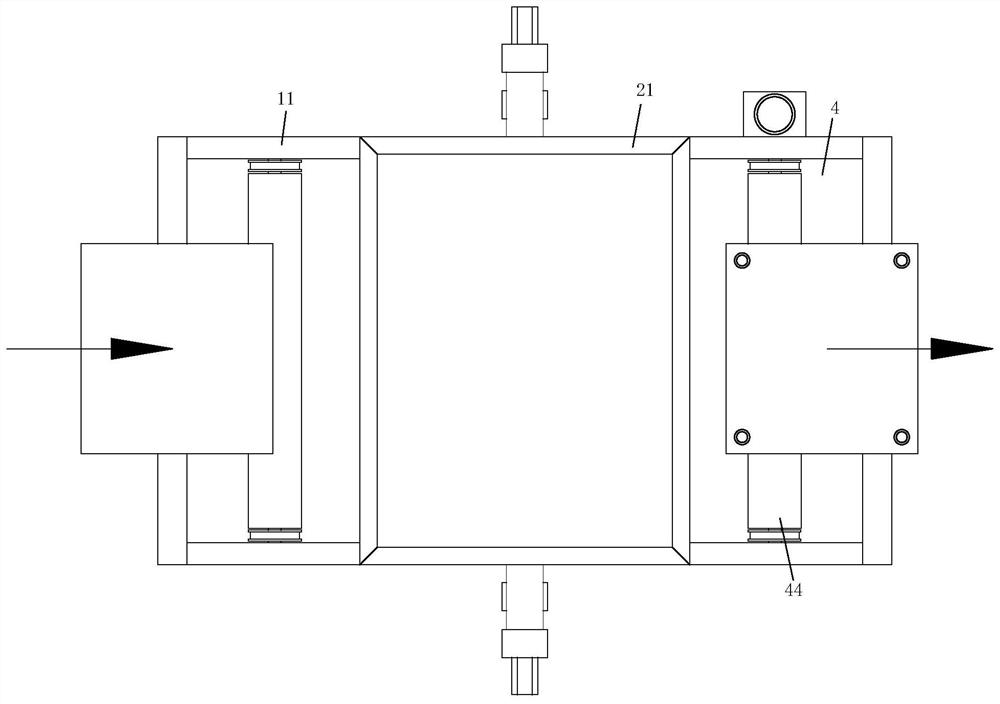

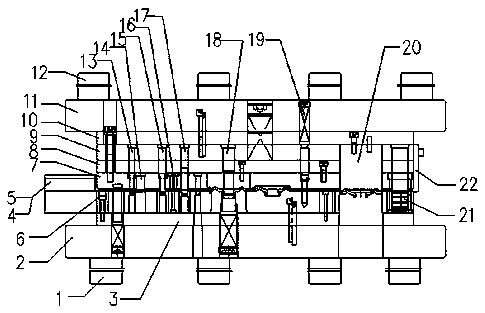

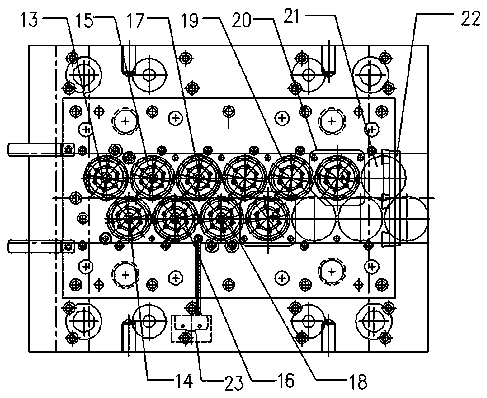

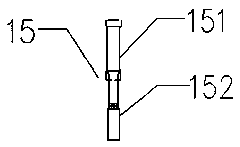

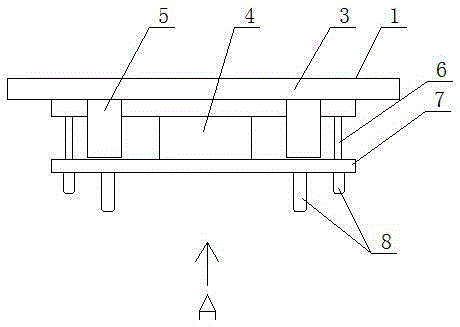

Continuous stepping device for screw plate of filter

InactiveCN105562515AEasy to moveSave production costShaping toolsPerforating toolsPunchingEngineering

The invention discloses a continuous stepping device for a screw plate of a filter. The continuous stepping device comprises a rack which is sequentially provided with lower pad iron, a lower die plate, a lower base plate, a concave die plate, a discharging plate, a discharging backing plate, a fixing plate, an upper base plate, an upper die plate and upper pad iron from bottom to top. A plate conveying device is arranged between the concave die plate and the discharging plate. A first material guiding block and a second material guiding block are arranged at the front end of the plate conveying device. A phi 6 punching assembly, a phi 13 forming die assembly, a phi 8.05 punching assembly, a budding die assembly, a phi 9 punching assembly, a forming die assembly, a blanking die assembly, an inner guide sleeve assembly and a cutting assembly are sequentially arranged between the upper die plate and the lower die plate from left to right according to the corresponding processes. Compared with the prior art, the continuous stepping device for the screw plate of the filter has the following advantages that relevant machining modules for manufacturing the screw plate are equipped on one device, by combining the stepping conveying device, material movement of the screw plate is achieved according to the set step pitch, and therefore automatic machining is completed, the production cost and the maintenance cost are reduced, production benefits of enterprises are increased, and popularizing is convenient.

Owner:BENGBU CITY MINGWEI FILTER CO LTD

Stamping die for auto parts and using method thereof

ActiveCN111957835BNo reduction in impact resistanceEasy to placeShaping toolsMetal-working feeding devicesPunchingStructural engineering

The invention discloses a stamping die for auto parts and a method for using the same. block one. The method includes the following steps: S1, placing the workpiece to be punched on the lower platen, and then opening the cylinder, and the cylinder works to drive the upper platen, the boss, and the magnetic block to move downward together. The advantage is that when the first magnetic block moves downwards, the second magnetic block drives the return plate to move downwards, which can perform a pressing and fixing effect on the workpiece placed on the lower pressing plate to ensure the punching accuracy, and this part is arranged outside the lower pressing plate, and does not It will reduce the impact resistance of the lower pressing plate, and it is also convenient to take and place the workpiece; at the same time, the continued movement of the magnetic block 1 will make the two magnetic blocks 2 in the corresponding chute far away from each other, thereby further slowing down the impact force on the lower pressing plate , to avoid mold damage caused by excessive impact force.

Owner:沧州久合汽车模具有限公司

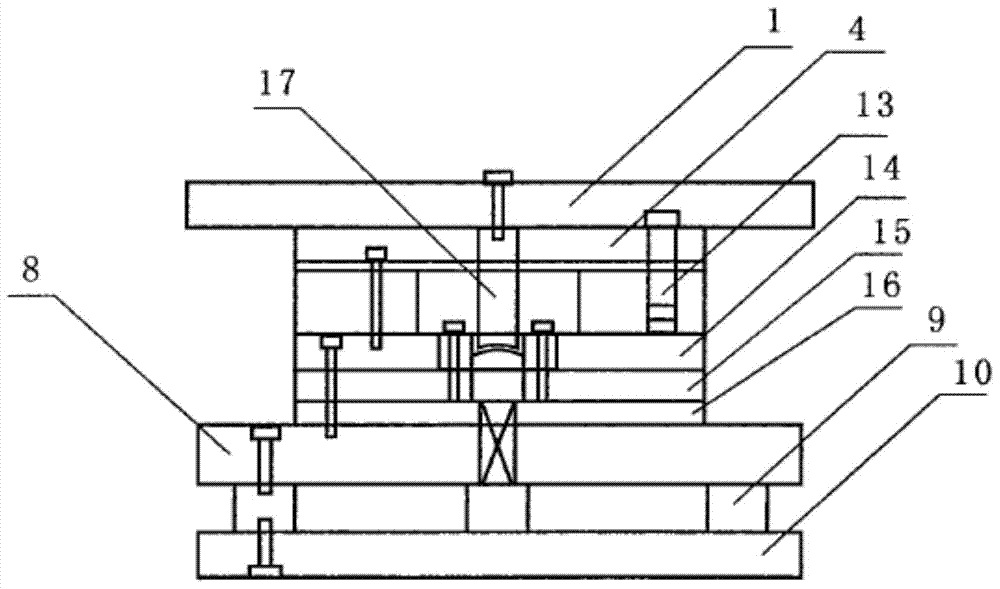

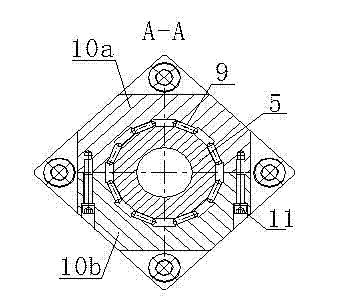

Three-plate motor iron-core progressive die

InactiveCN105234269ACorrect locationReasonable relative positionShaping toolsStripping-off devicesRetaining ringEngineering

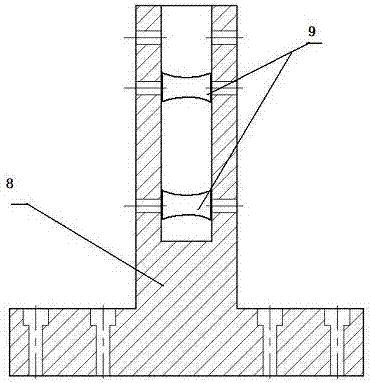

The invention discloses a three-plate motor iron-core progressive die. The three-plate motor iron-core progressive die comprises an upper die base, a discharging plate base and a lower die base matched with the upper die base. The upper die base is fixedly connected with a sliding block of a punching machine. The lower die base is fixed to the workbench surface of the punching machine. The discharging plate base is fixedly connected with the upper die base through a fixing member. The upper die base, the discharging plate base and the lower die base are sequentially arranged from top to bottom to form a three-plate structure. The upper die base is provided with a guiding device. The guiding device comprises a guide pillar, a first guide sleeve, a second guide sleeve, a first retaining ring and a second retaining ring. The upper portion of the guide pillar is fixedly connected with the upper die base. The lower portion of the guide pillar penetrates through the second guide sleeve and extents into the first guide sleeve. The first retaining ring is clamped between the first guide sleeve and the guide pillar. The first retaining ring is in interference fit with the first guide sleeve and the guide pillar through steel balls. The second retaining ring is clamped between the second guide sleeve and the guide pillar. The second retaining ring is in interference fit with the second guide sleeve and the guide pillar through steel balls. The three-plate motor iron-core progressive die has the beneficial effects that the punching precision is high; the gaps are even, and the service life of the progressive die is ensured.

Owner:NINGBO HONGDA MOTOR DIE

A control system and control method for an intelligent servo press

ActiveCN105700453BGuaranteed stamping accuracyGuarantee stamping qualityProgramme control in sequence/logic controllersControl powerPunching

The invention discloses a control system for an intelligent-type servo press, and the system comprises a servo drive unit, a PLC control unit, and a control power unit. The servo drive unit comprises a main drive servo controller, a mold adjustment servo controller, an electric pump motor, and a multifunction power meter, wherein the main drive servo controller, the mold adjustment servo controller, the electric pump motor and the multifunction power meter are connected to a three-phase power supply. The PLC control unit comprises a PLC, and a drive power end of the PLC is connected with an AC 220V power supply. A control power end of the PLC is connected with a DC 24V power supply, and the PLC collects the operation signals of all corresponding devices, and transmits the control signals for controlling the corresponding devices. The control power unit comprises a control transformer, wherein the front end of the control transformer is connected with an AC 380V power supply, and the rear end of the control transformer outputs an AC 220V voltage serving as the AC 220V power supply. The system guarantees the punching precision of the press and the quality of a punched part, improves the punching efficiency, and can be used in the control of the press.

Owner:YANGLI GRP CORP LTD

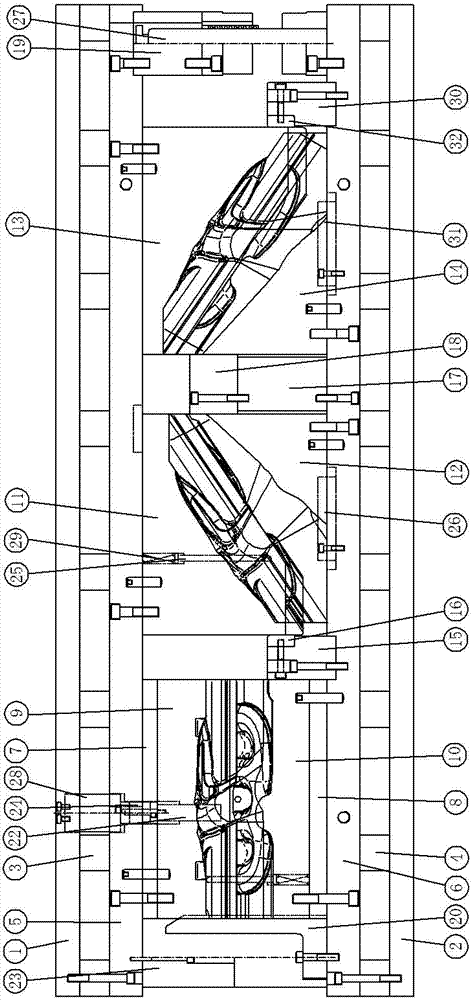

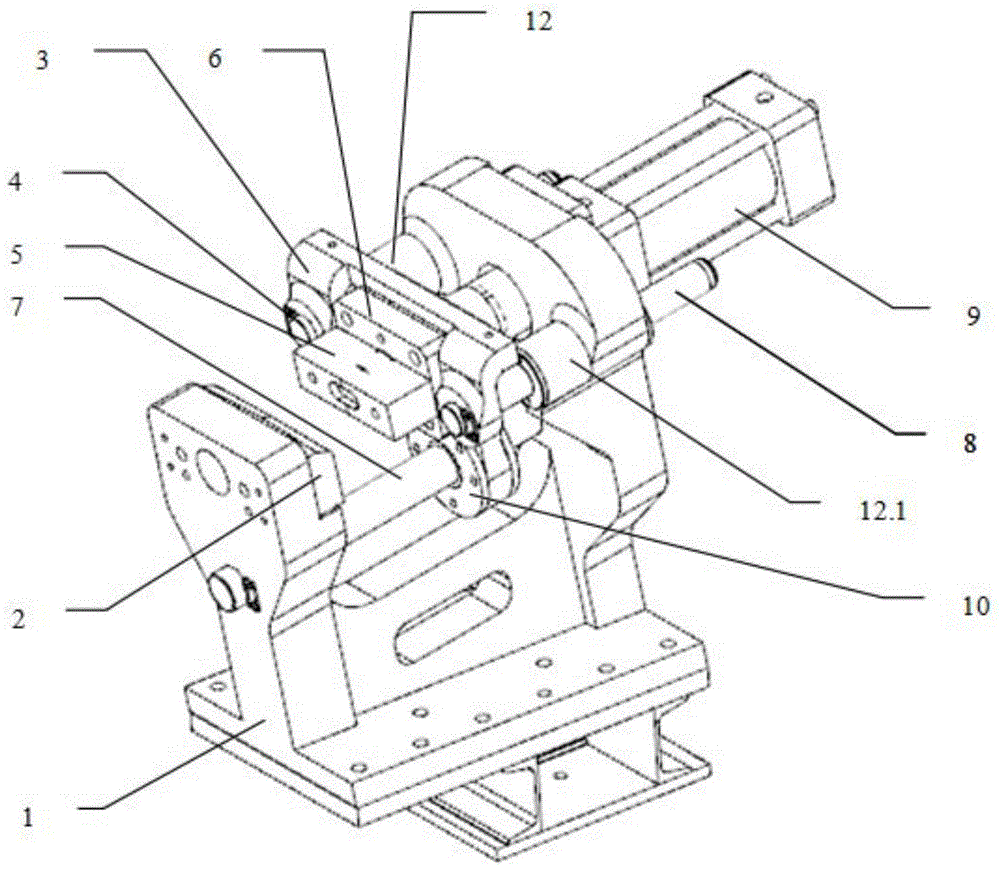

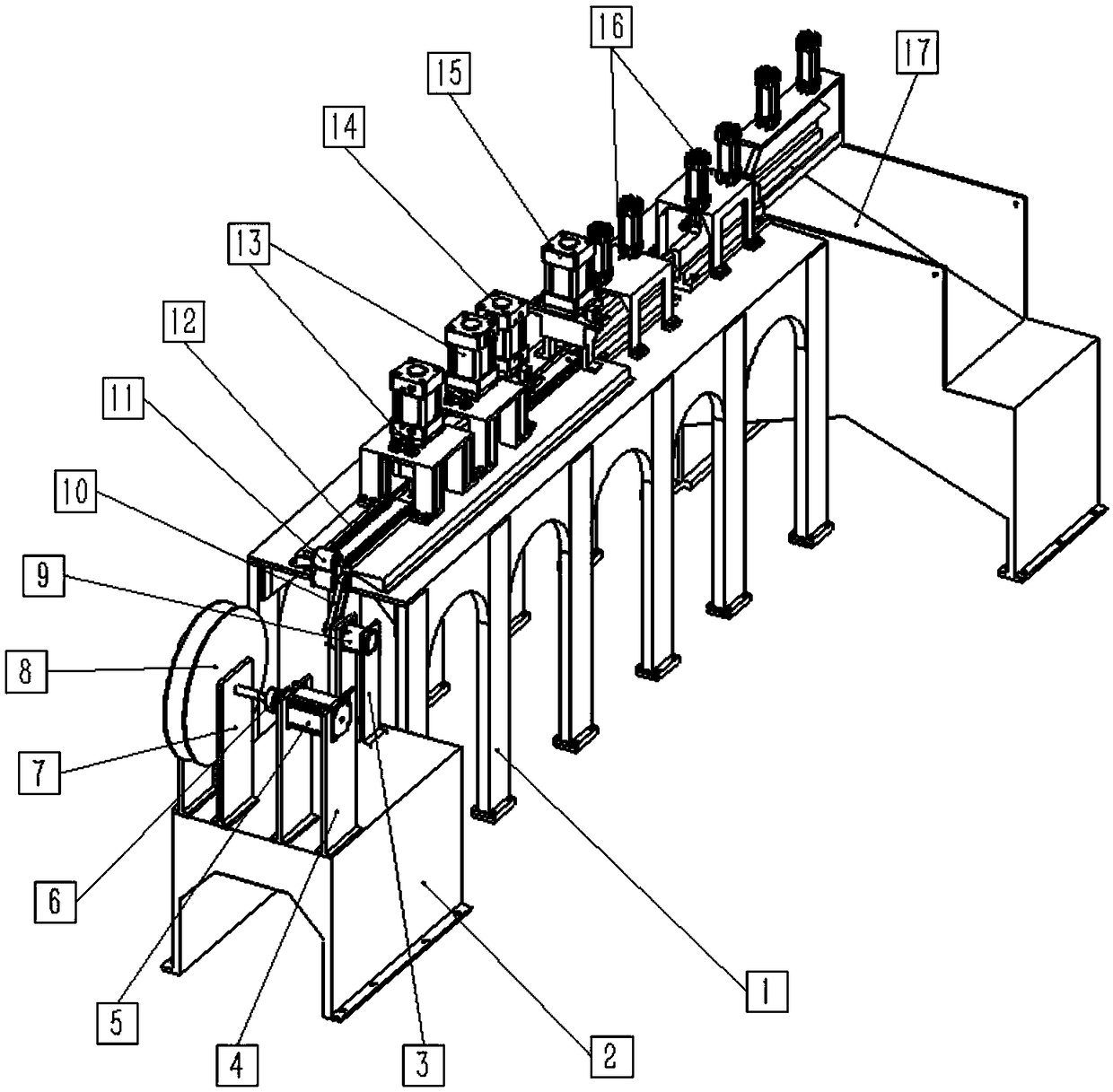

Automatic punching device of car seat sliding rail

The invention provides an automatic punching device of a car seat sliding rail, and belongs to the technical field of car production. The automatic punching device is used for achieving automation ofproduction of the car seat sliding rail. The automatic punching device is composed of a conveying support, a feeding support, a belt motor support, a reel motor support, a reel motor, a single membrane coupling, a reel support, a reel, a belt motor, a belt, a rolling wheel, a feeding rail, a punching mechanism, an edge cutting mechanism, an adjusting mechanism, bending mechanisms and a dischargingmechanism. According to the automatic punching device, a series of continuous stamping mechanisms are adopted, continuous, efficient and automatic stamping of the car seat sliding rail is achieved, feeding, machining and discharging are achieved through automation, errors caused by manmade factors are reduced to the minimum, stamping precision is guaranteed, and the labor cost is reduced. The work efficiency is improved, and meanwhile the mechanisms are simplified.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Side plate stamping die for externally-hung heater box shell

InactiveCN106694709AImprove efficiencyLow costShaping toolsMetal-working feeding devicesEngineeringMechanical engineering

The invention provides a side plate stamping die for an externally-hung heater box shell, and relates to the structure of the die. The side plate stamping die comprises an upper die body and a lower die body. The upper die body is arranged above the lower die body. The upper die body comprises an upper die holder. An upper die plate is arranged below the upper die holder. The upper die plate is connected with the upper die holder through bolts. A rubber gasket is arranged between the upper die plate and the upper die holder. Cooling hole punches, a right-angle punch, a bevel edge punch and V-shaped punches are arranged on the lower surface of the upper die plate. The lower die body comprises a lower die holder. A lower die plate is fixedly connected to the lower die holder. The upper surface of the lower die plate is provided with cooling hole grooves, a right-angle notch, a bevel edge notch and V-shaped notches. The cooling hole grooves correspond to the cooling hole punches. The right-angle notch corresponds to the right-angle punch. The bevel edge notch corresponds to the bevel edge punch. The V-shaped notches correspond to the V-shaped punches. One end of a stamped workpiece is placed between the upper die body and the lower die body to be formed at a time. After stamping is completed, the other end of the workpeice is placed between the upper die body and the lower die body to be stamped again, and therefore efficiency is high, and cost is low.

Owner:宝应县宝城低压电器厂

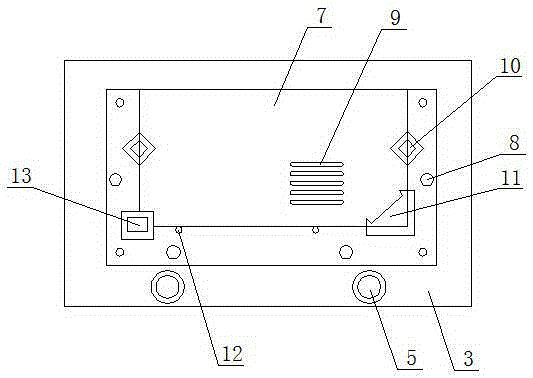

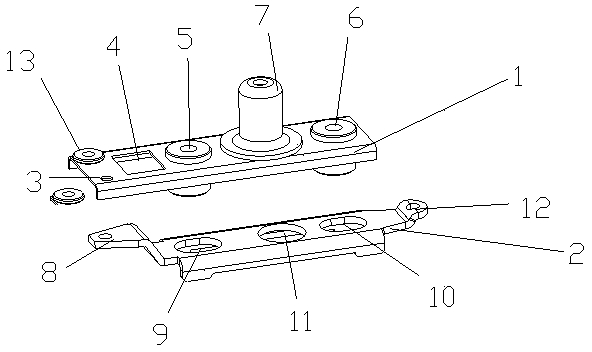

Fixed stamping deck device

ActiveCN103817249AGuaranteed stamping accuracyWon't take much timeMetal-working feeding devicesPositioning devicesEngineering

The invention discloses a fixed stamping deck device, comprising an upper deck and a lower deck; the upper deck is positioned above the lower deck; the upper deck is provided with a pair of third bolt fixing holes, a fixing hole, a fixing button, a second fixing button and a stamping drilling cap; a movable plate, a first fixing button threaded hole, a second fixing button threaded hole, a stamping through hole and a handle part are arranged on the lower deck; the movable plate is arranged at the left end of the lower deck; the first fixing button threaded hole is formed in the right end of the movable plate; the stamping through hole is formed in the right end of the first fixing button threaded hole; the handle part is arranged at the right end of the stamping through hole; the second fixing button threaded hole is formed in the position between the stamping through hole and the handle part. As when the fixing stamping deck device can ensure the stamping precision when being used for stamping a part without consuming more time, and the production efficiency is improved.

Owner:上海宝山大陆汽车配件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com