Presplitting drum brake

A brake drum and pre-cracking technology, which is applied in the direction of brake drums, etc., can solve problems such as cracks on the inner wall of brake drums, deterioration of high-temperature mechanical properties of materials, and reduction of fatigue strength, so as to improve structural strength and mechanical properties, and enhance tensile strength The effect of strength and variable stiffness, enhancing the characteristics of damping impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

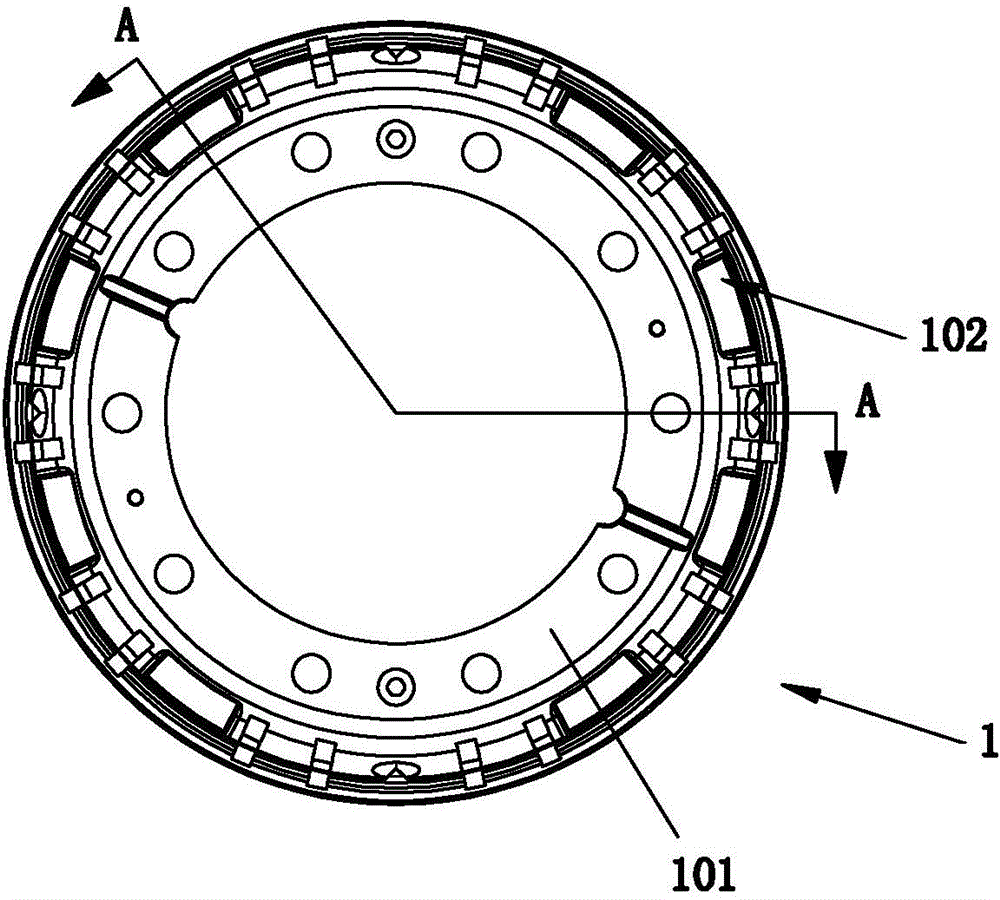

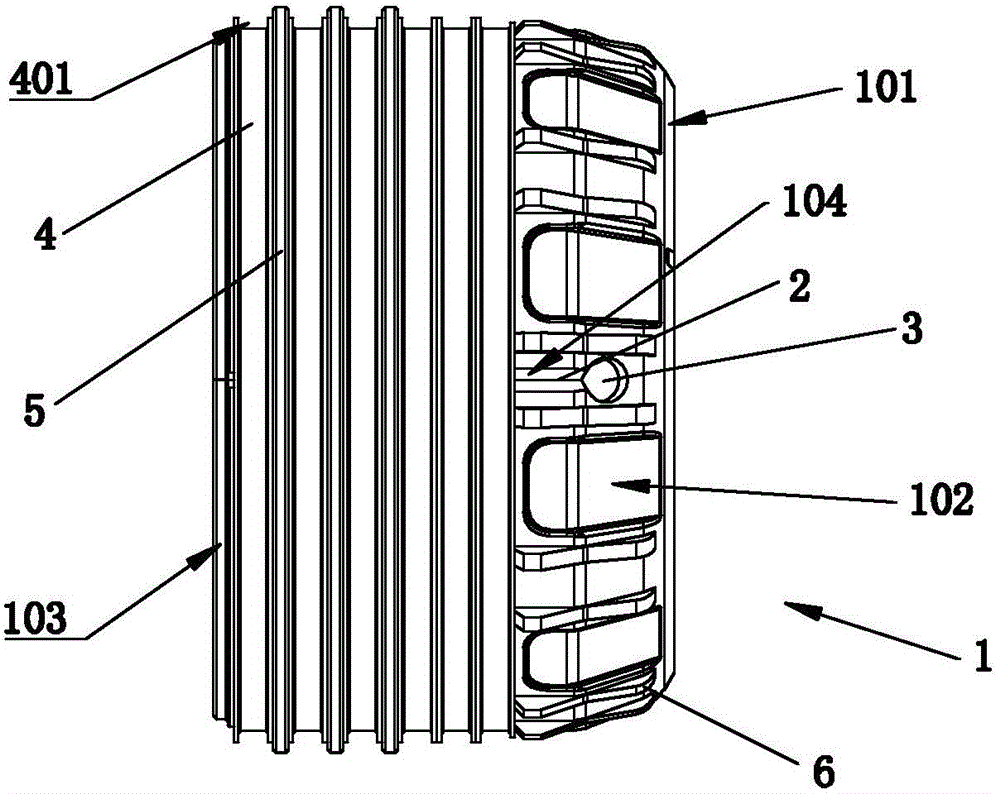

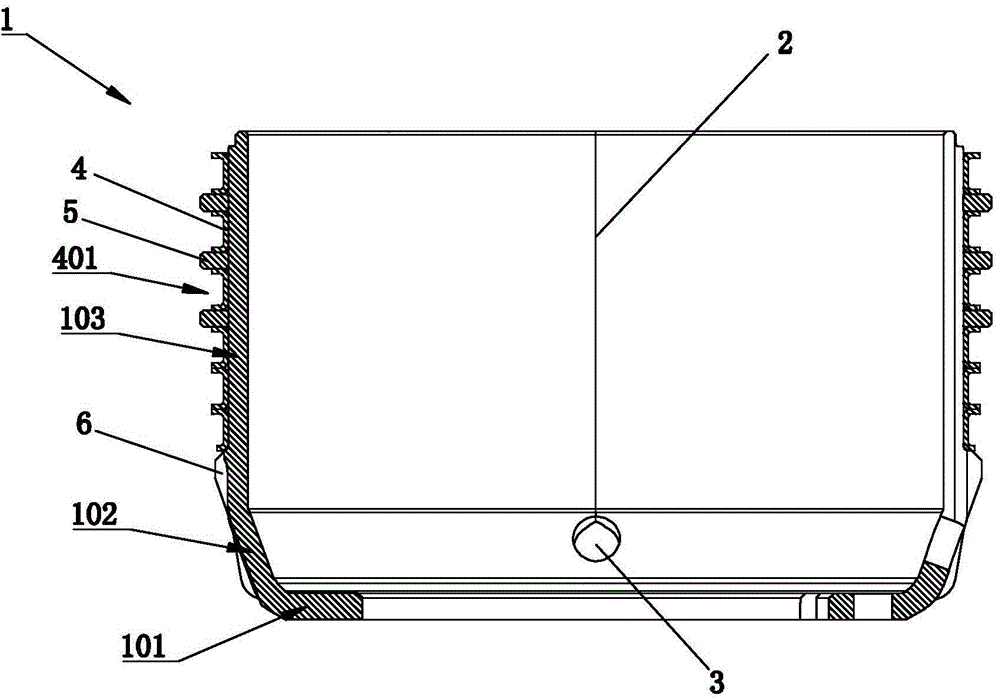

[0038] like Figure 1 to Figure 3 Commonly shown, the pre-split brake drum includes a cast brake drum body 1, which includes a mounting portion 101 for connecting with a wheel and a braking portion 103 for cooperating with a brake shoe , the installation part 101 is a flange; a transition connection part 102 is provided between the installation part 101 and the brake part 103, and the outer diameter of the end of the transition connection part 102 close to the brake part 103 is larger than the outer diameter of the brake part 103 ;

[0039] There are several slits 2 penetrating through the wall thickness of the braking portion 103 in an annular array on the braking portion 103, and the slits 2 extend from one end away from the transitional connection portion 102 to the transitional connection portion 102, corresponding to each crack 2 A through hole 3 is provided on the transition connection part 102, and the through hole 3 communicates with the crack 2;

[0040] The outer p...

Embodiment 2

[0046] like Figure 4 to Figure 6 Commonly shown, the specific structure of this embodiment is the same as the structure of Embodiment 1, the difference is that: no process tank 104 is provided at the position corresponding to the crack 2, the crack 2 is a zigzag crack formed by wire cutting, and the zigzag crack The two ends respectively extend in a straight line, one end passes through the end of the braking portion 103 , and the other end communicates with the through hole 3 .

[0047]The crack 2 can also be a wave-shaped crack, or other cracks that can be realized by those skilled in the art and do not affect the normal operation of the brake drum.

Embodiment 3

[0049] like Figure 7 to Figure 9 As shown together, the specific structure of this embodiment is the same as that of the second embodiment, the difference being that no reinforcing rib 6 is provided on the transitional connection portion 102 .

[0050] In the same way, it is preferred to arrange the reinforcing ribs 6 on the transitional connection portion 102 in the first embodiment, and the reinforcing ribs 6 may not be provided.

[0051] In practical application, since the brake part 103 is provided with a crack 2 extending to the transition connection part 102, that is, the brake drum body 1 is pre-cracked to form an elastic body, which not only improves the force effect, but also enhances the The characteristics of slow resistance impact force; at the same time, the brake drum body 1 no longer bears the brake tension force, only bears the rotational friction braking force; and, compared with the brake drum of the traditional structure, the brake drum body 1 (that is: the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com