Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62results about How to "Guaranteed to be centered" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

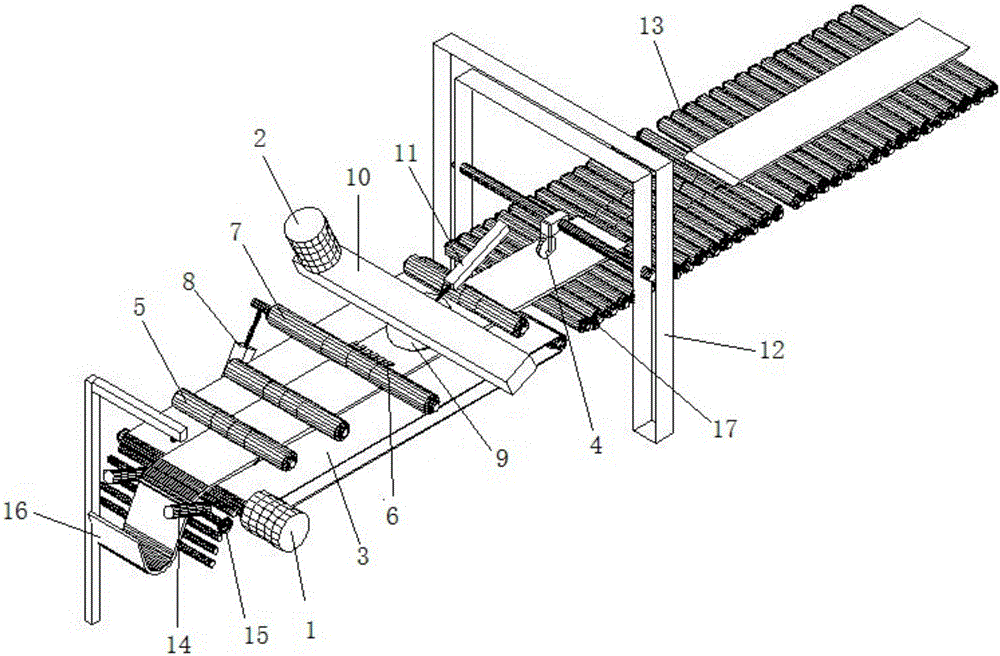

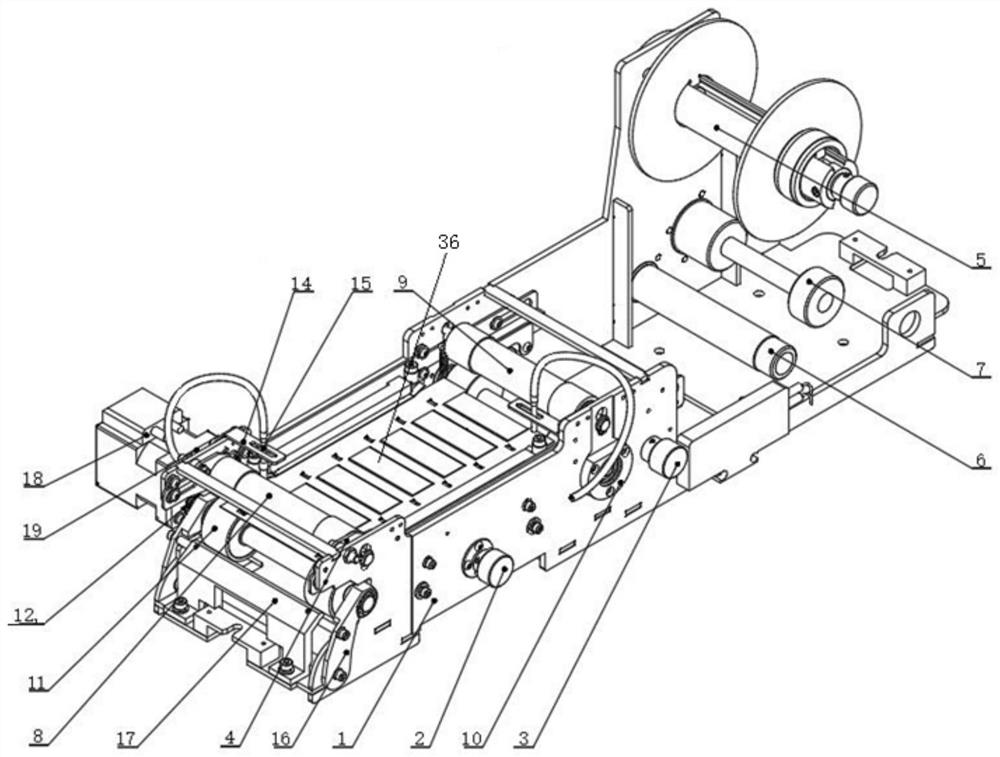

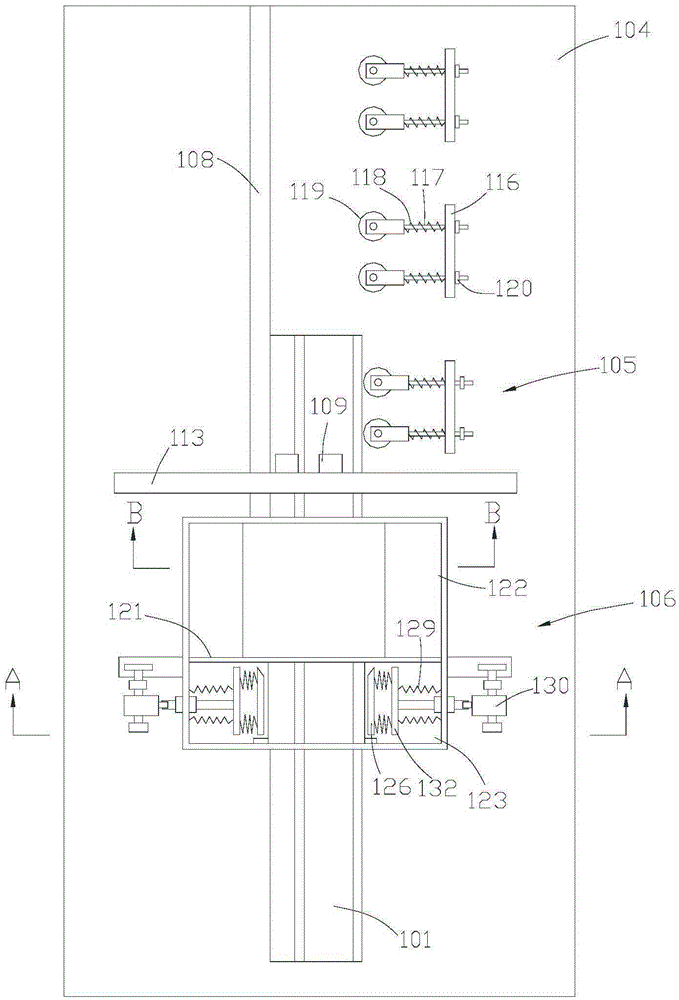

Method for fixed-length cutting of tire tread

ActiveCN106217433AGuaranteed flatnessGuaranteed to be centeredTyresMetal working apparatusControl systemEngineering

The invention relates to a tire forming device and especially relates to a conveying device capable of fixed-length cutting of a tire tread. The conveying device capable of the fixed-length cutting of the tire tread comprises a first servo motor, a second servo motor, a first servo drive, a second servo drive, a conveying belt, a cutter device, a length-counting encoder, a distance measurement sensor and a PLC control system. The device provided by the invention has the effects that (1) through coordination between guide rollers and pressing rollers, the tire tread can be kept smooth and centralized on the conveying belt in front of the cutter, and errors caused by deflection of the tire tread position can be reduced; (2) the laser distance measurement sensor detects a gradient of a cutting mouth, so that measurement errors caused by inaccurate detection can be effectively reduced; (3) by pressing feet of the cutter, the tire tread position can be kept steady during cutting; (4) by the novel detection method, accuracy for a cutting length can be increased; and (5) by the length-counting encoder, influences brought by sliding between the tire tread and the conveying belt can be reduced.

Owner:HANGZHOU CHAOYANG RUBBER

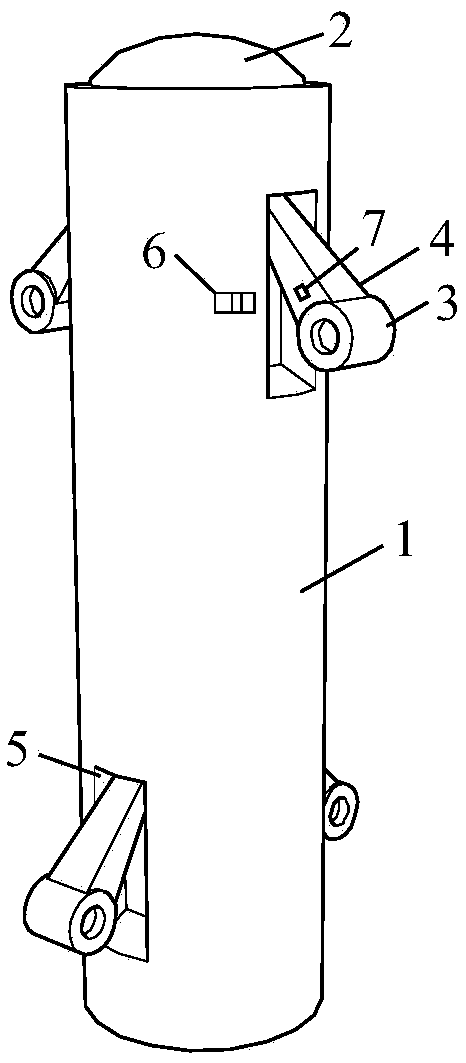

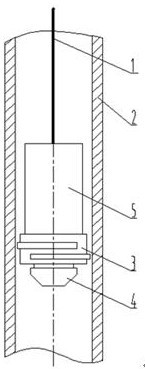

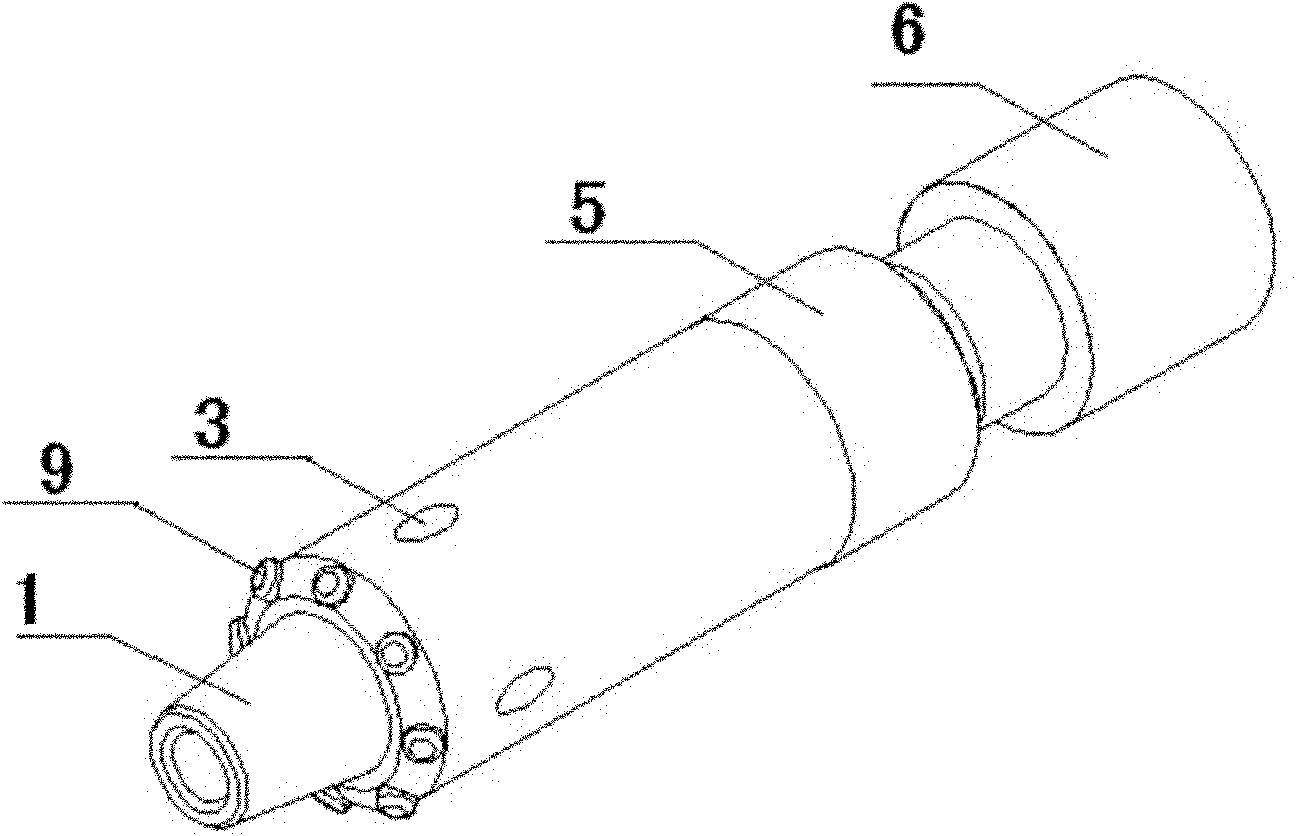

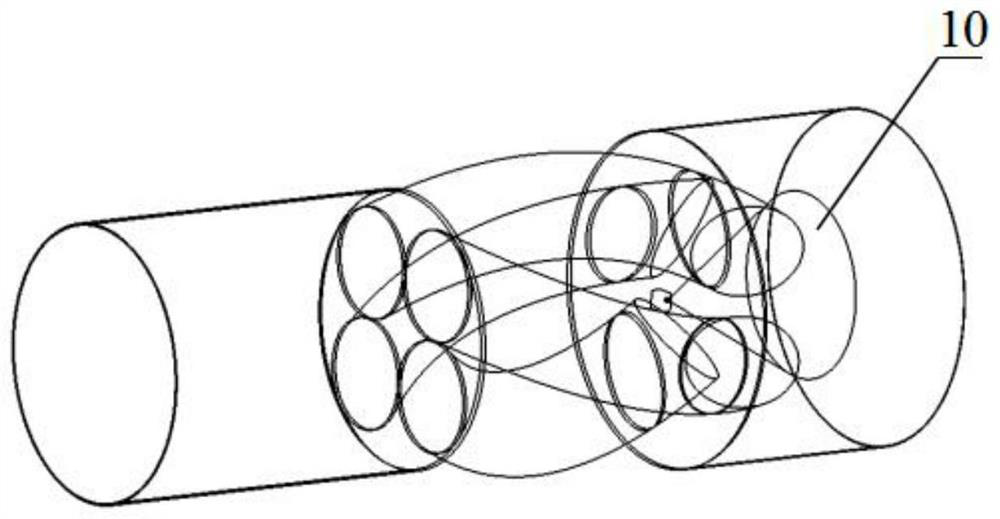

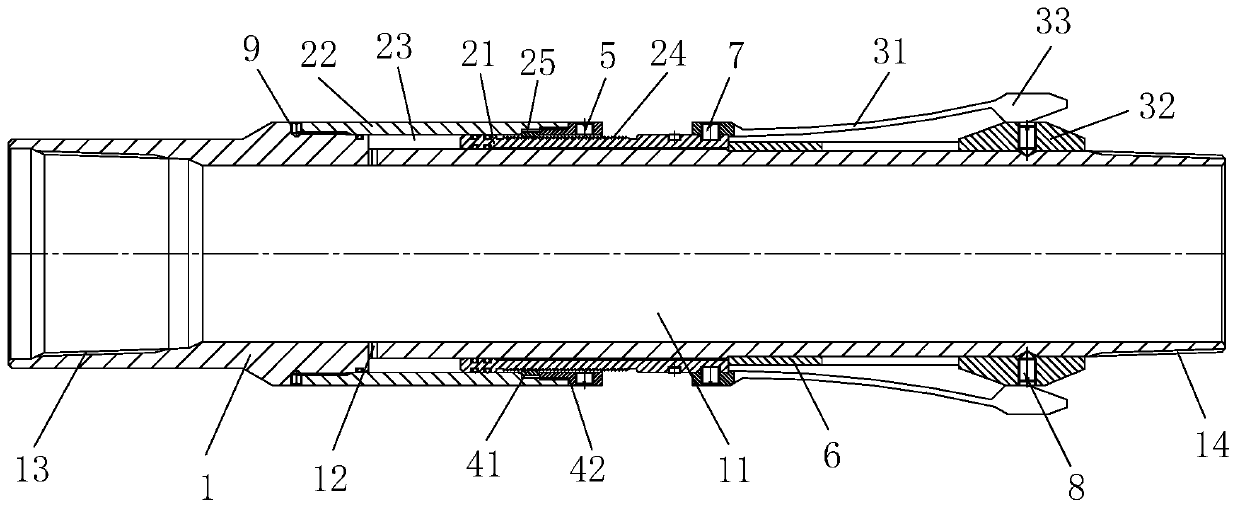

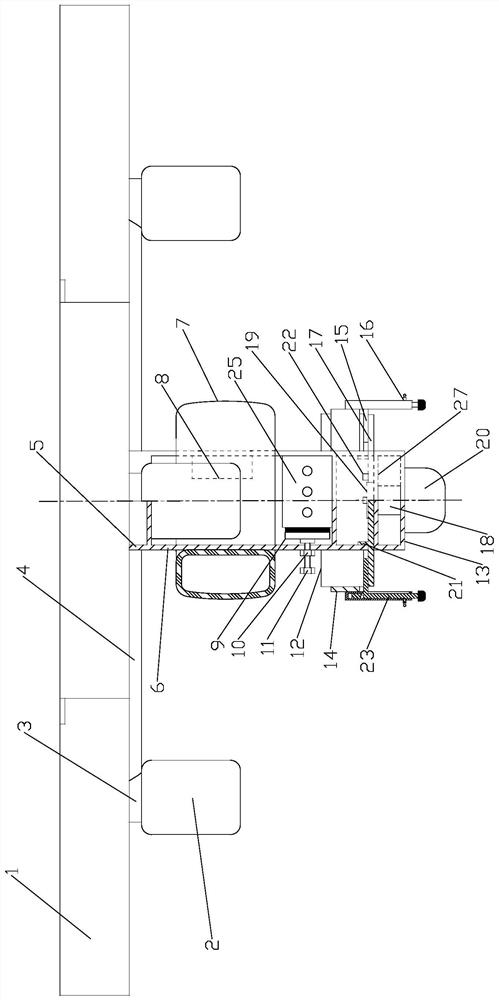

Self-propelled peeping probe adapted to different diameters of drill holes and peeping method thereof

The invention discloses a self-propelled peeping probe adapted to different diameters of drill holes and a peeping method thereof. The probe comprises a peeping probe body, a camera, walking wheels, rocker arms connected to the walking wheels, and an operating host. The rock arms can achieve a certain angle of damping opening and closing under the effects of internal torsion springs and gas springs and have alarm functions, and the rocker arms can be fixed in grooves of a peeping probe side through locking holes and locking blocks. The self-propelled function of the peeping probe in a drill hole can be achieved through an internal power supply, a driving motor, a video processing module, a control module, a WIFI module and the external operating host. The peeping probe has the advantages of centered drill hole, self-propelling and less workers in operation in a drilling peeping operation process, the complexity in a conventional drilling peeping operation is reduced, a push rod and a video transmission line are removed, auxiliary accessories are greatly reduced, and a new solution is provided for determining the fracture of a rock mass through drilling peeping in underground engineering.

Owner:CHINA UNIV OF MINING & TECH

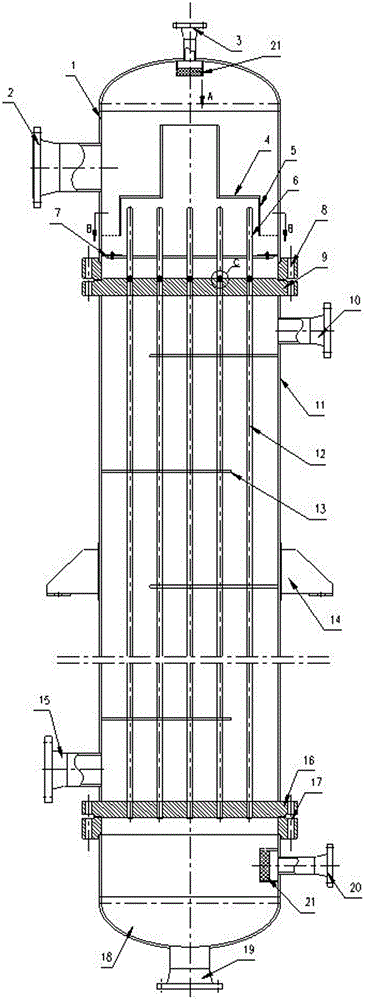

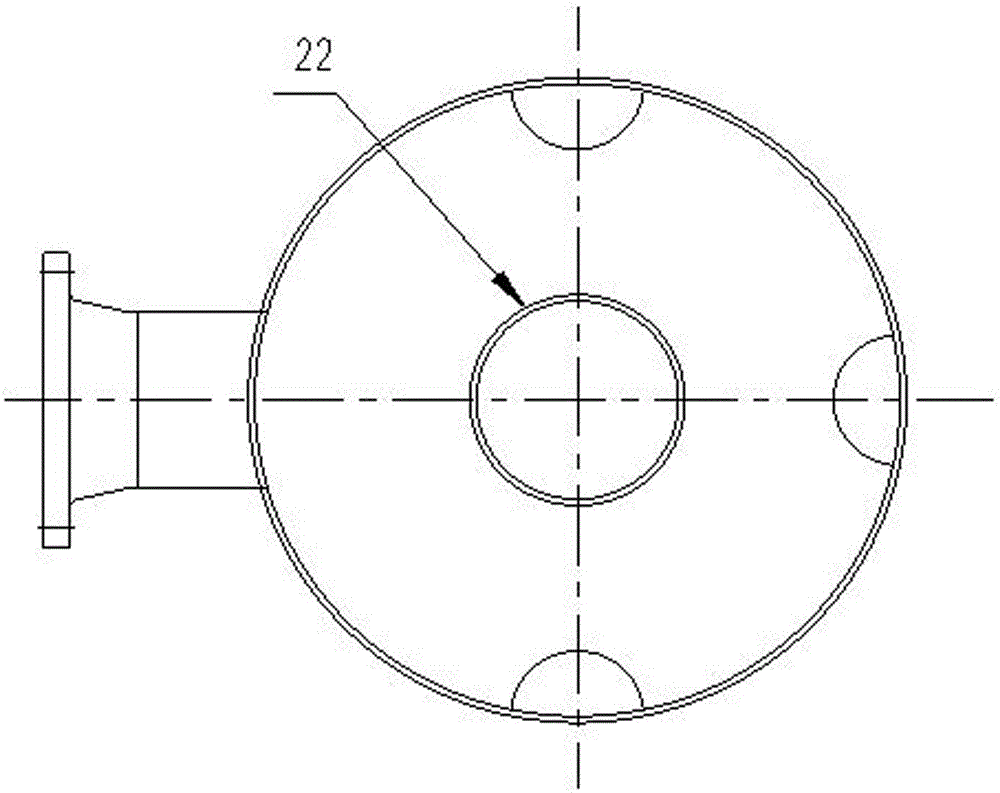

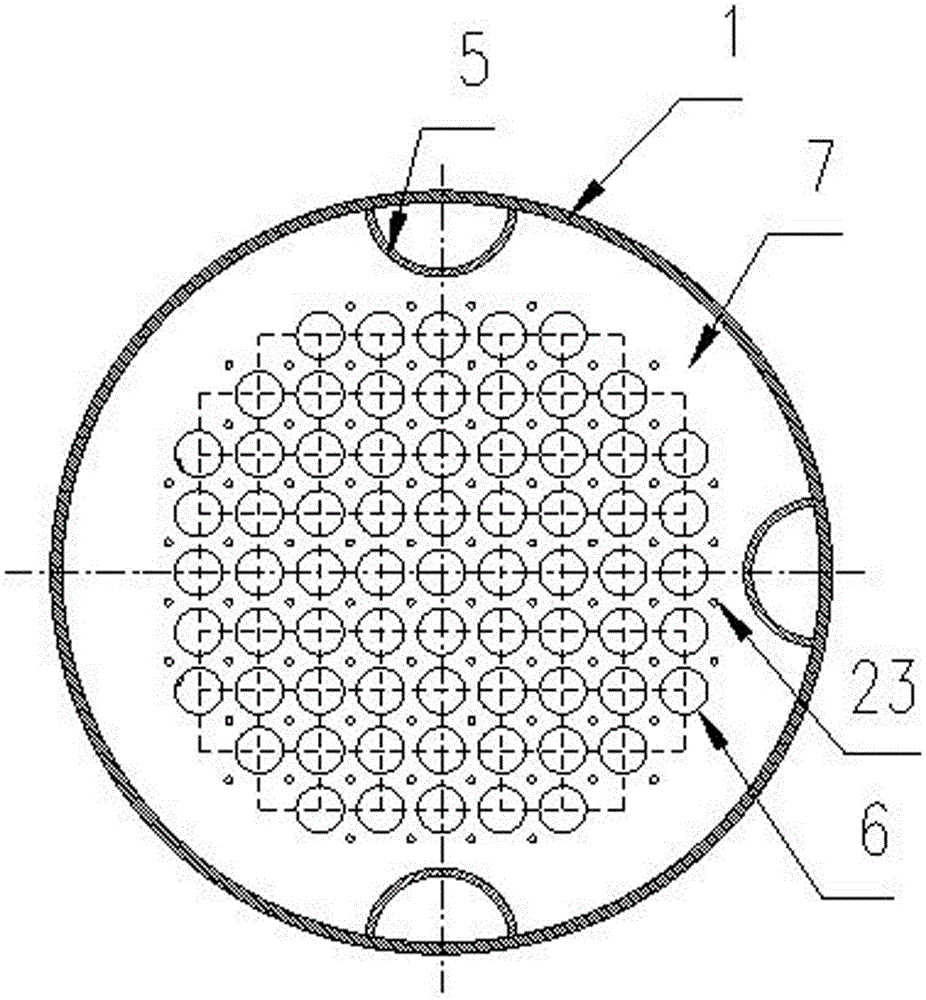

Vertical tube type falling-film evaporator

ActiveCN106178557AGuaranteed centralityHigh recovery rateGeneral water supply conservationEvaporators with vertical tubesVertical tubeEngineering

The invention relates to a vertical tube type falling-film evaporator. The vertical tube type falling-film evaporator comprises an upper tube box, a lower tube box, a casing, multiple heat exchange tubes, an upper tube plate and a lower tube plate, wherein a solution inlet and a secondary steam outlet I are arranged at the upper tube box, a concentrated liquid outlet and a secondary steam outlet II are arranged at the lower tube box, a steam inlet is arranged at the upper part of the casing, and a condensed water outlet is arranged at the lower part of the casing; a film distributing device used for distributing a solution on the inner walls of the heat exchange tubes is arranged in the upper tube box; the film distributing device comprises a liquid bearing plate, a liquid feeding plate, a liquid distributing plate and liquid guiding tubes. By means of a steam stripping effect generated by secondary steam and liquid films, the heat transferring push force and the evaporation efficiency are increased. The liquid films can be uniformly distributed by the film distributing device, the film forming is stable, the wall drying phenomenon is avoided, the recovery rate of secondary steam produced in an evaporator is high, the recovery is convenient, and the heat transferring efficiency is improved.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

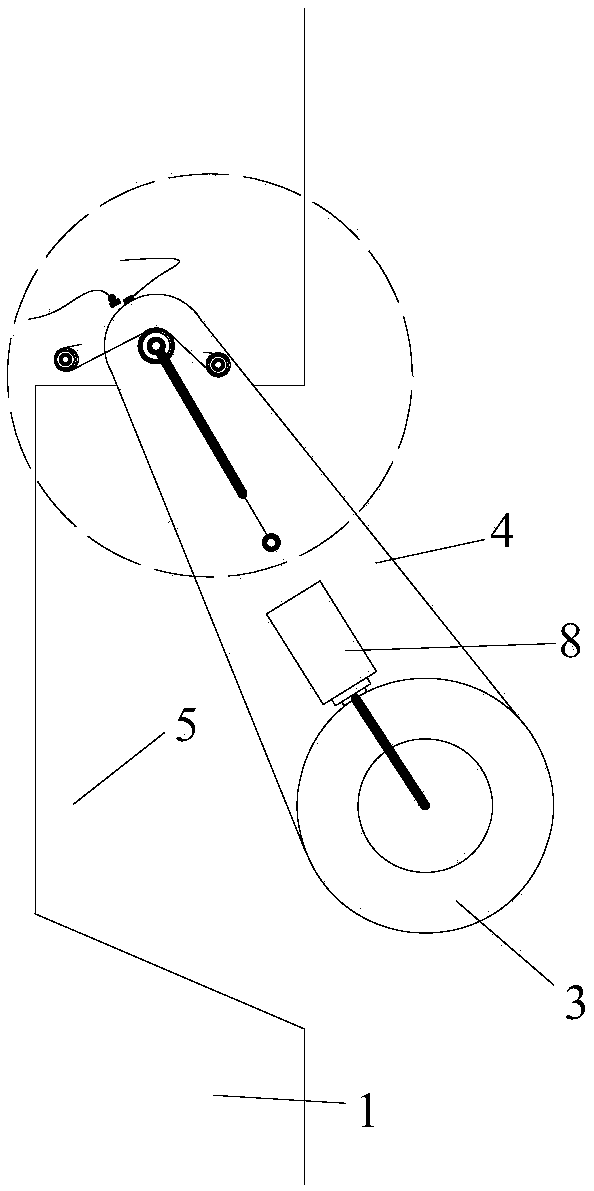

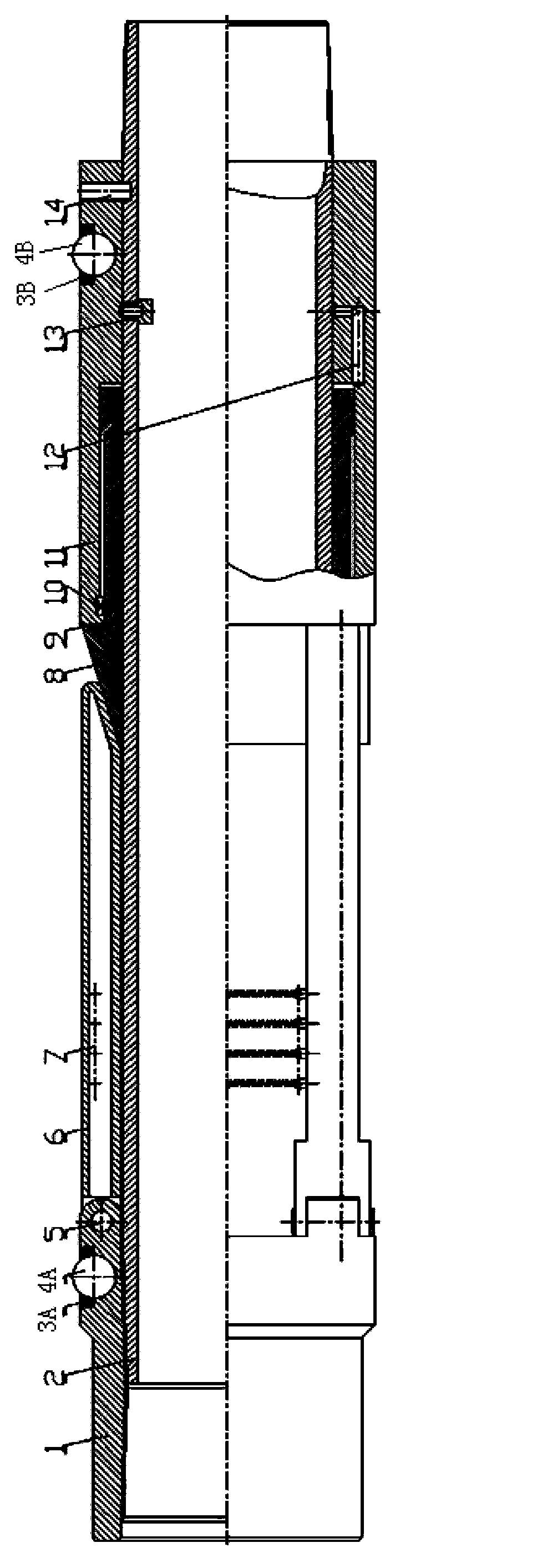

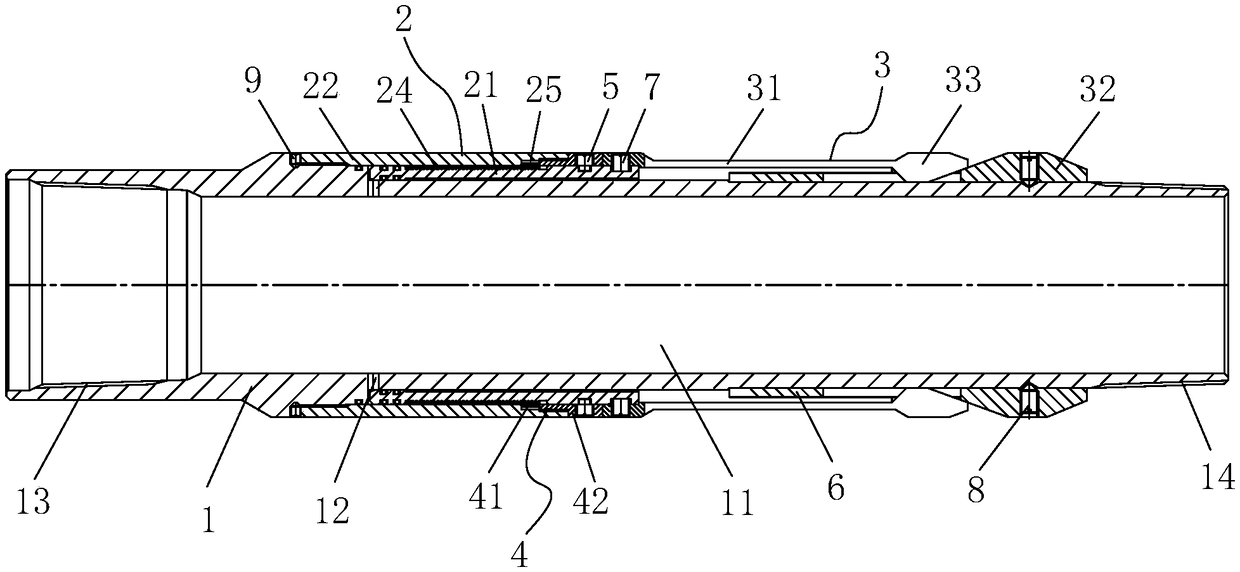

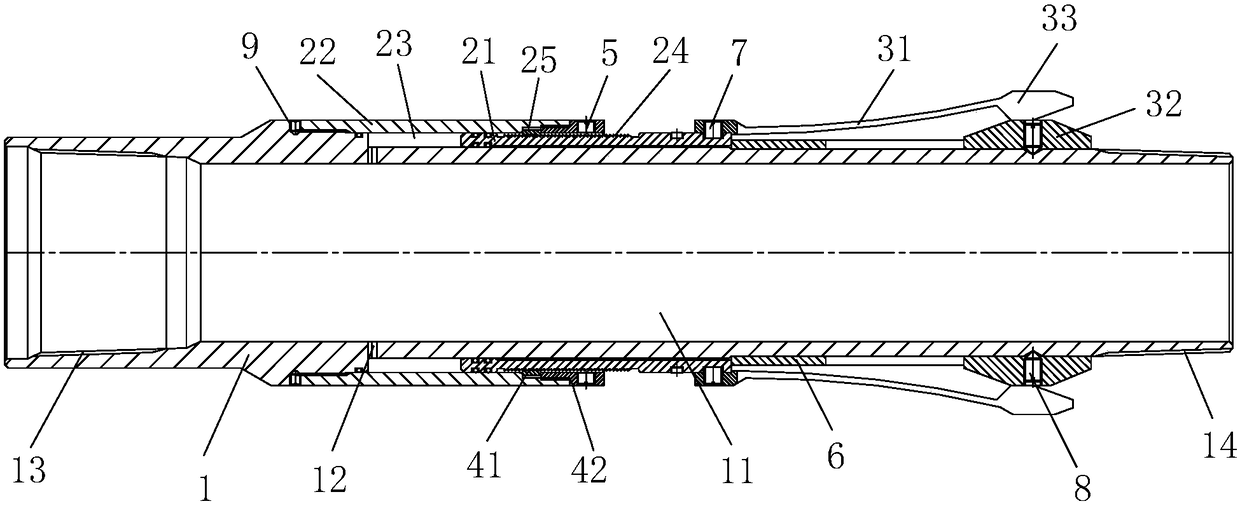

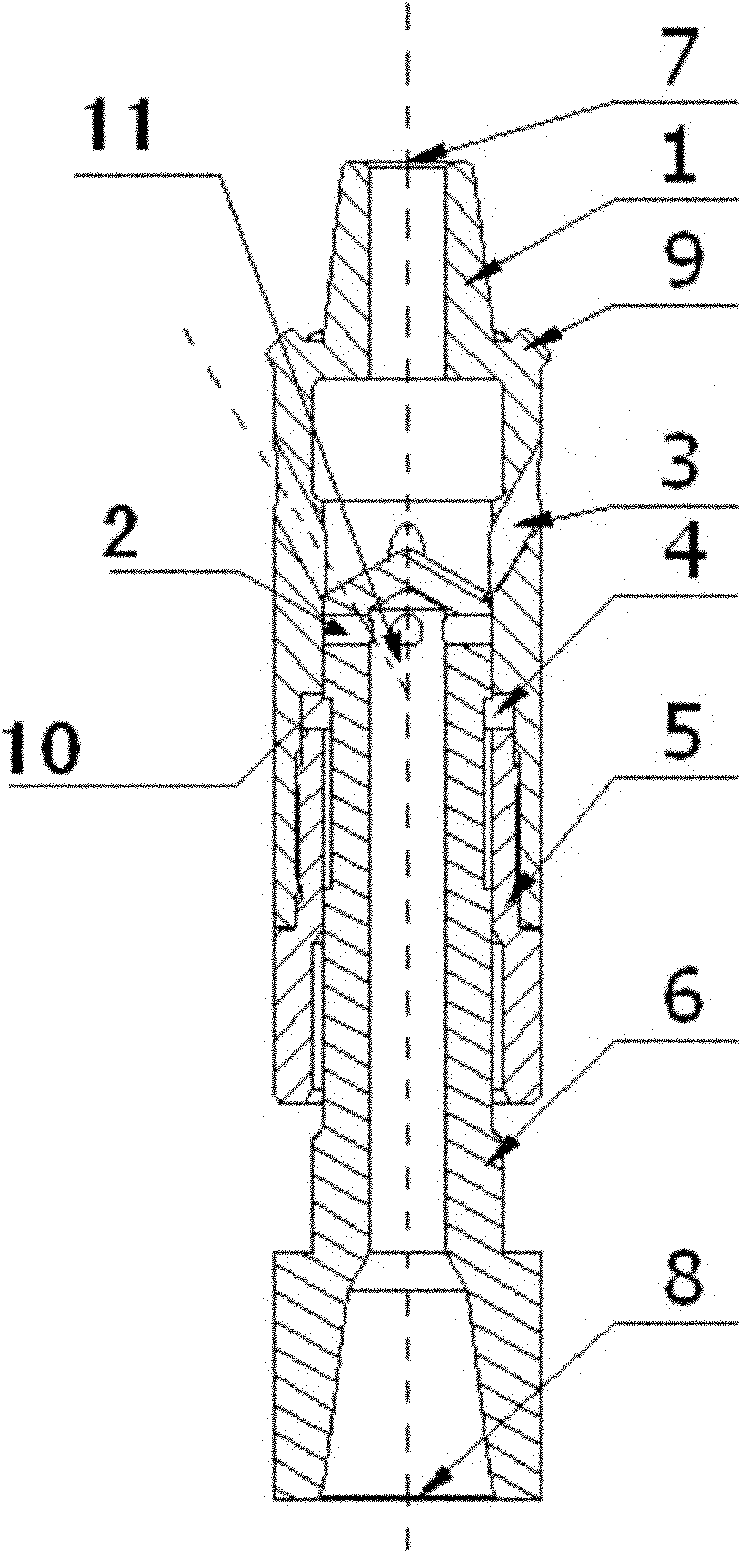

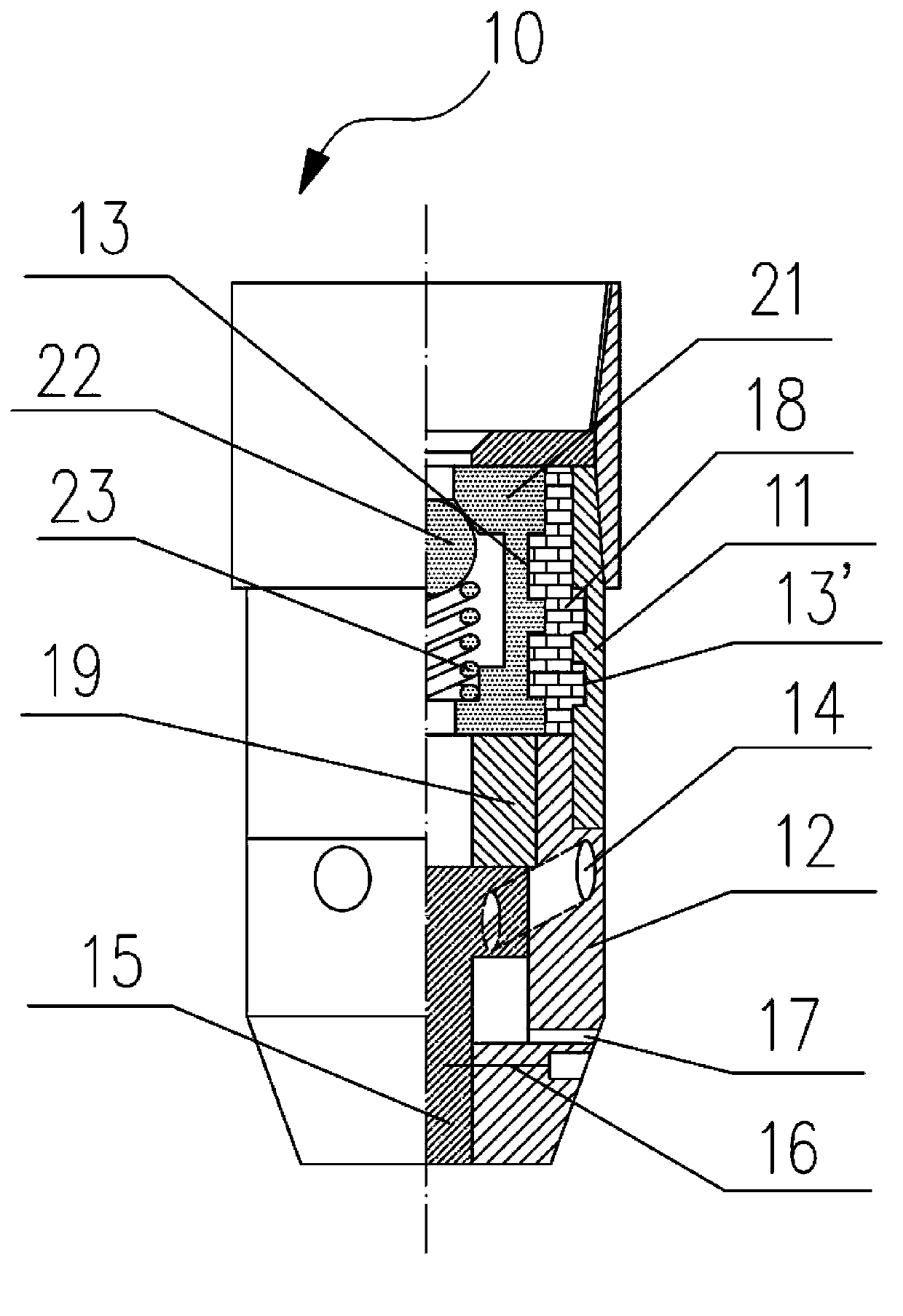

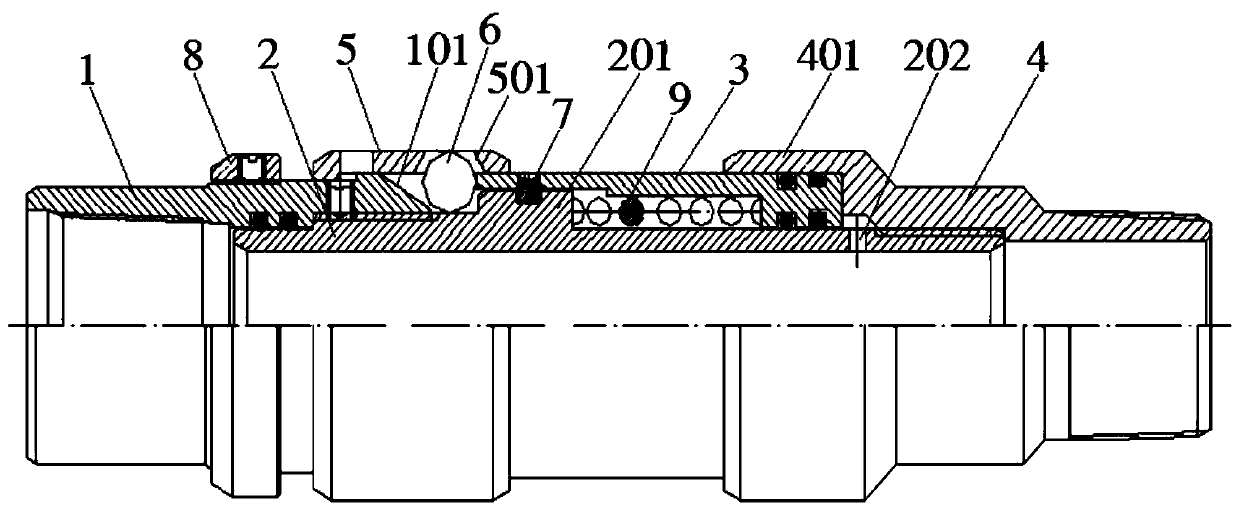

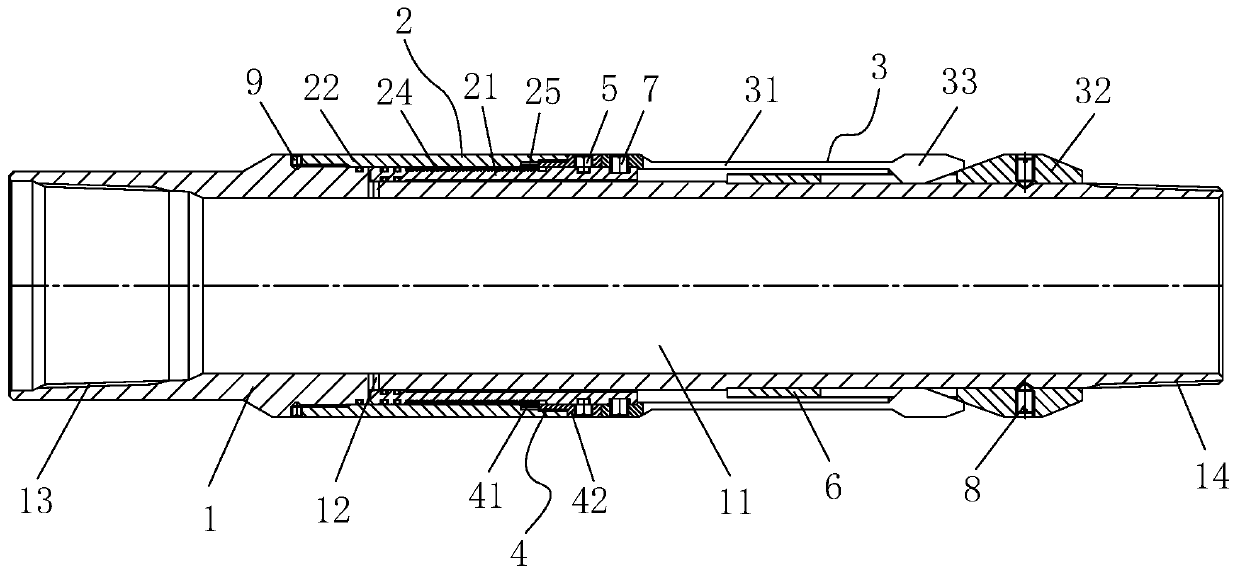

Hydraulic casing centralizer

ActiveCN103670297AGuaranteed to be centeredUniform cement sheathDrilling rodsDrilling casingsCasing stringPetroleum

The invention discloses a hydraulic casing centralizer and belongs to the field of petroleum and gas development. The centralizer comprises a center pipe, a centralizing connector, a first ball, a pin shaft, a first fixing cover, a liquid cylinder, a fixing screw, a second ball, a second fixing cover, a piston, a hydraulic channel, a valve, a screwed plug, a centralizing arm, an oblique plate and a tension spring. One end of the center pipe is connected with the centralizing connector in a sleeved mode. The other end of the center pipe is connected with the liquid cylinder in a sleeved mode. The piston is arranged between the liquid cylinder and the center pipe. The centralizing arm and the oblique plate are arranged between the centralizing connector and the liquid cylinder in sequence. According to the hydraulic casing centralizer, after cement injection, pressure accumulating is carried out in a casing, the piston pushes the oblique plate to move, the centralizing arm is pushed forcibly to move outwards to be supported to a well wall by moving of the oblique plate, a casing string is forced to be in the center, the fact that the horizontal well casing is centered is effectively guaranteed, cement ring uniformity between the casing and a well hole is guaranteed, accordingly, well cementation quality is improved, in addition, the hydraulic casing centralizer is convenient to mount and easy to use, extra construction equipment is of no need, and therefore wide application prospect is achieved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

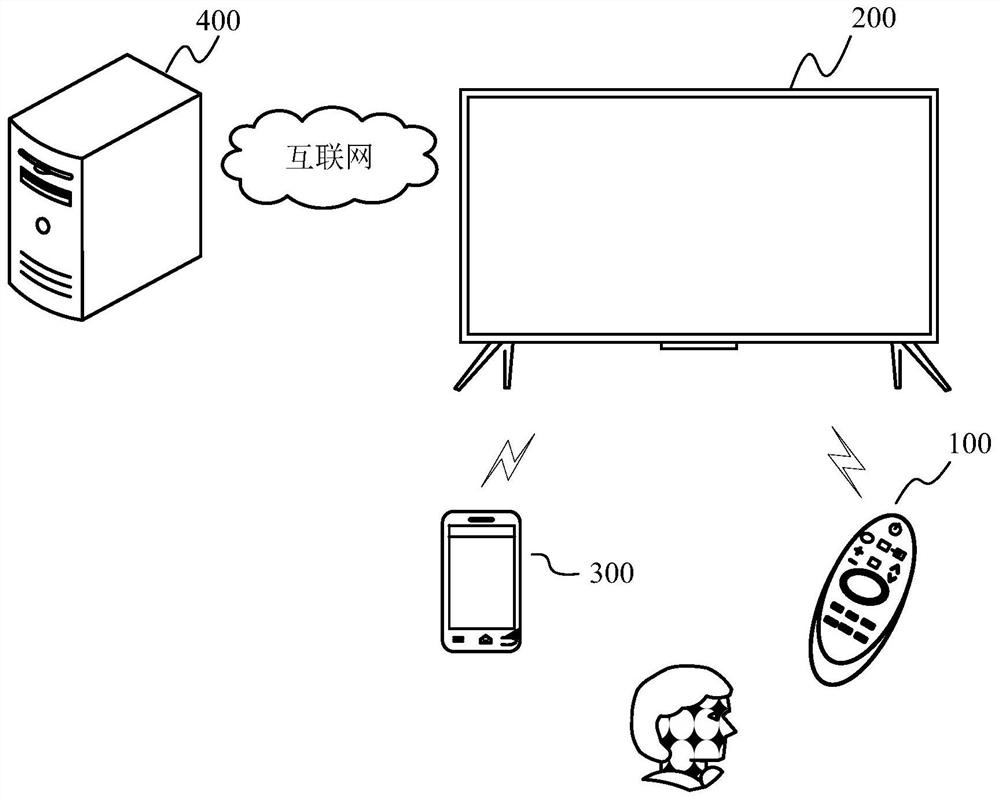

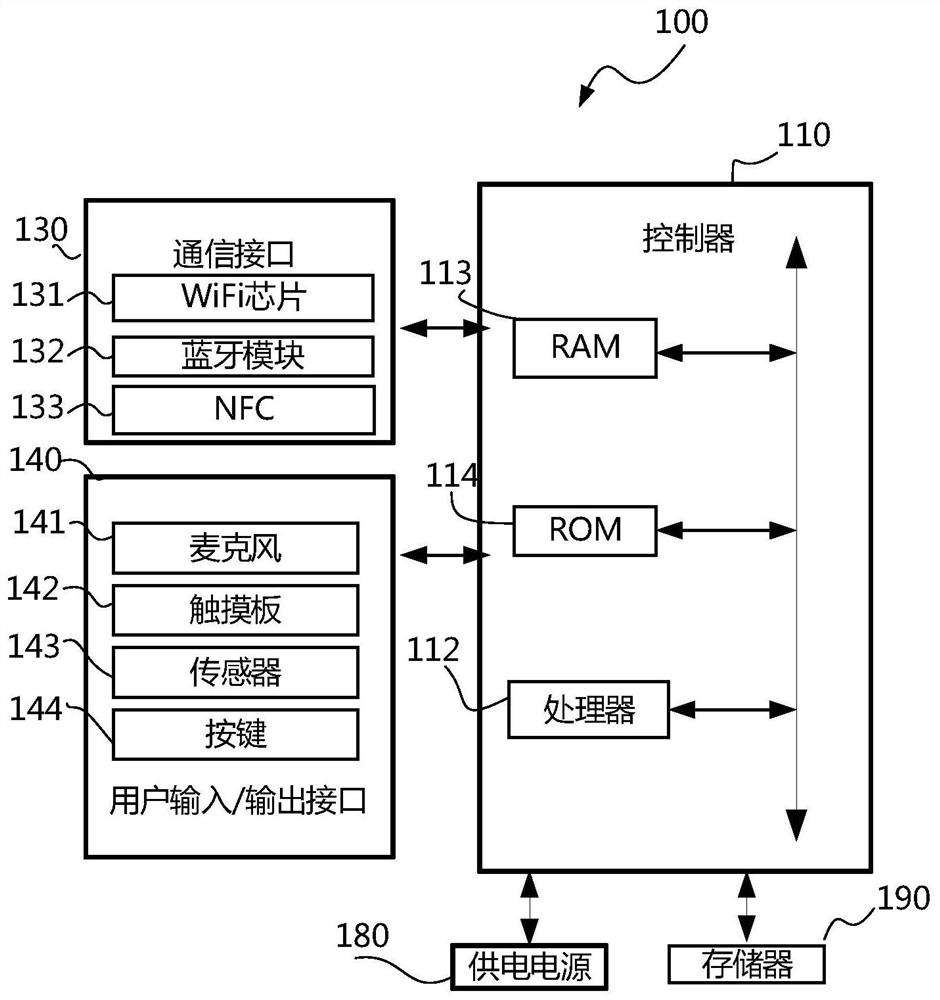

Camera control method and display equipment

InactiveCN111669508AGuaranteed to be centeredTelevision system detailsColor television detailsCamera controlCamera image

The invention discloses a camera control method and display equipment, and the method comprises the steps: enabling a controller to carry out the recognition of a specified image collected by a camera, ing a portrait region position, and calculating the azimuth distance between the region center of the portrait region position and the image center of the specified image; if the azimuth distance exceeds an azimuth set threshold, calculating a target adjustment angle of the camera according to the azimuth distance and shooting parameters of the camera; and adjusting the shooting angle of the camera based on the target adjustment angle of the camera, so as to enable the portrait of the person to be located in the central area of the specified image acquired by the camera. Visibly, according to the method and the display equipment, character position information is accurately recognized through camera image detection, the portrait position is automatically focused and positioned, the shooting angle of the camera is finely adjusted from the horizontal direction and the vertical direction, the portrait of the character is located in the center of the image shot by the camera, and therefore it is guaranteed that the character in the displayer image is centered.

Owner:HISENSE VISUAL TECH CO LTD

Hydraulic casing centering device

ActiveCN108316866ASolve the problem of difficult entryLarge outer diameter of rightingDrilling rodsDrilling casingsWell cementingEngineering

Disclosed is a hydraulic casing centering device used for centering a casing in a well cementing and completion technology. The hydraulic casing centering device comprises a body, a driving mechanismand a centering mechanism, wherein the body is a tubular structural piece provided with a central hole and connected to the casing; the driving mechanism comprises a piston and a piston cylinder sleeve, the piston cylinder sleeve is mounted on the body in a sleeving mode and fixedly connected with the body, an accommodating cavity is formed between the piston cylinder sleeve and the body, the piston is mounted on the body and located in the accommodating cavity, the body is provided with a liquid inlet hole, and the liquid inlet hole communicates with the central hole and the accommodating cavity; and the centering mechanism is mounted on the body and comprises a centering device body and a taper sleeve, one end of the centering device body is connected with the piston, the other end of the centering device body abuts against the taper sleeve, and the taper sleeve is fixed to the body, and the centering device body can climb upwards along the outer conical surface of the taper sleeve.

Owner:STARSE ENERGY & TECH GROUP

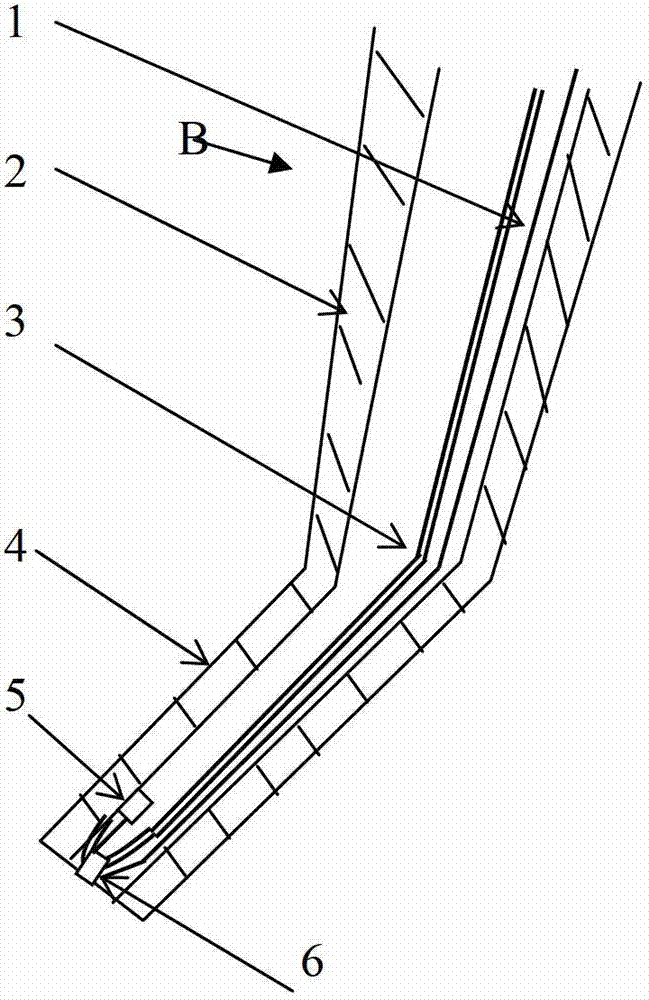

Coal mine roof panel deep hole pre-splitting blasting method

InactiveCN109470100ASolve the problem of missing medicineTroubleshooting Groove Alignment IssuesBlastingDetonatorEngineering

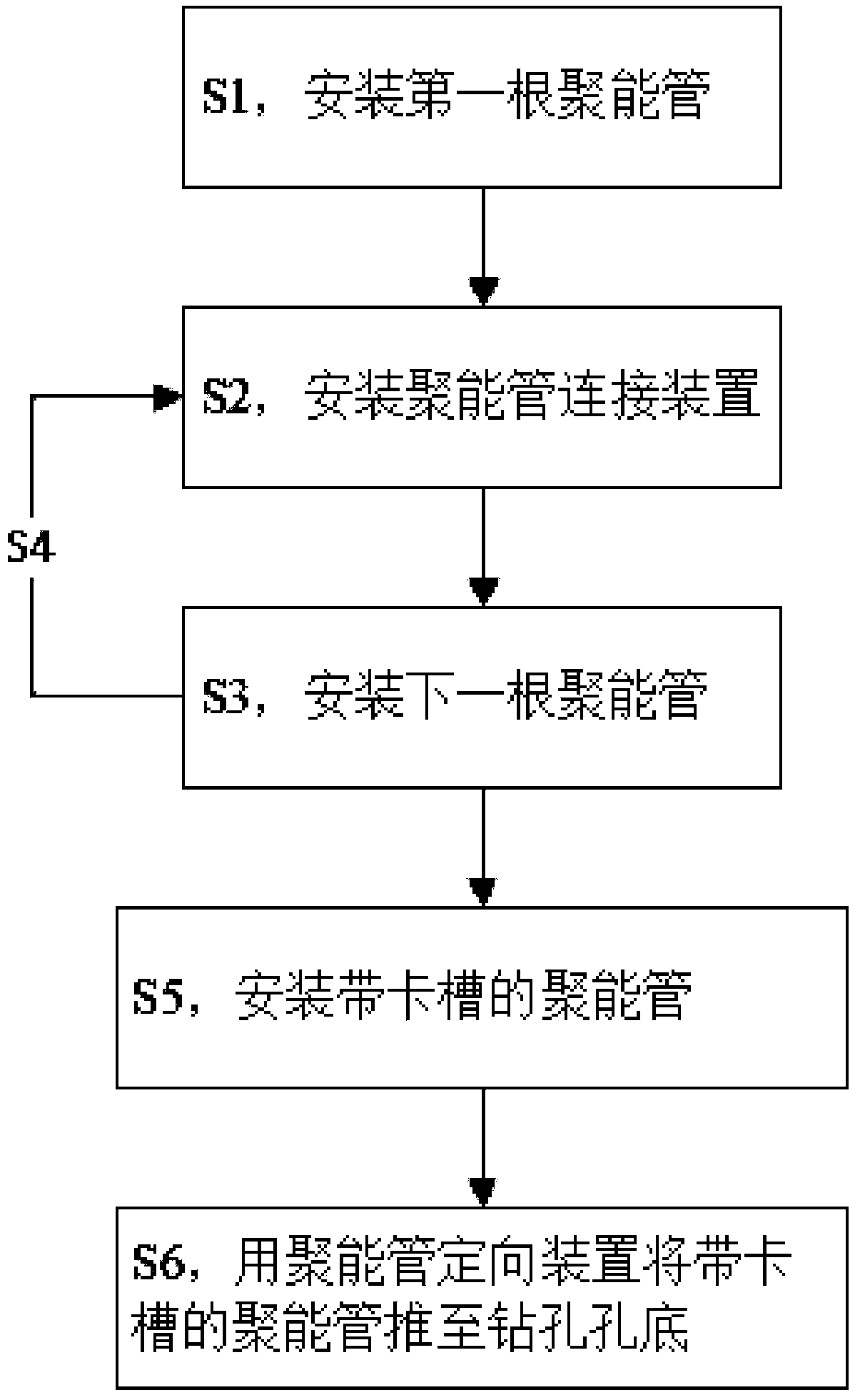

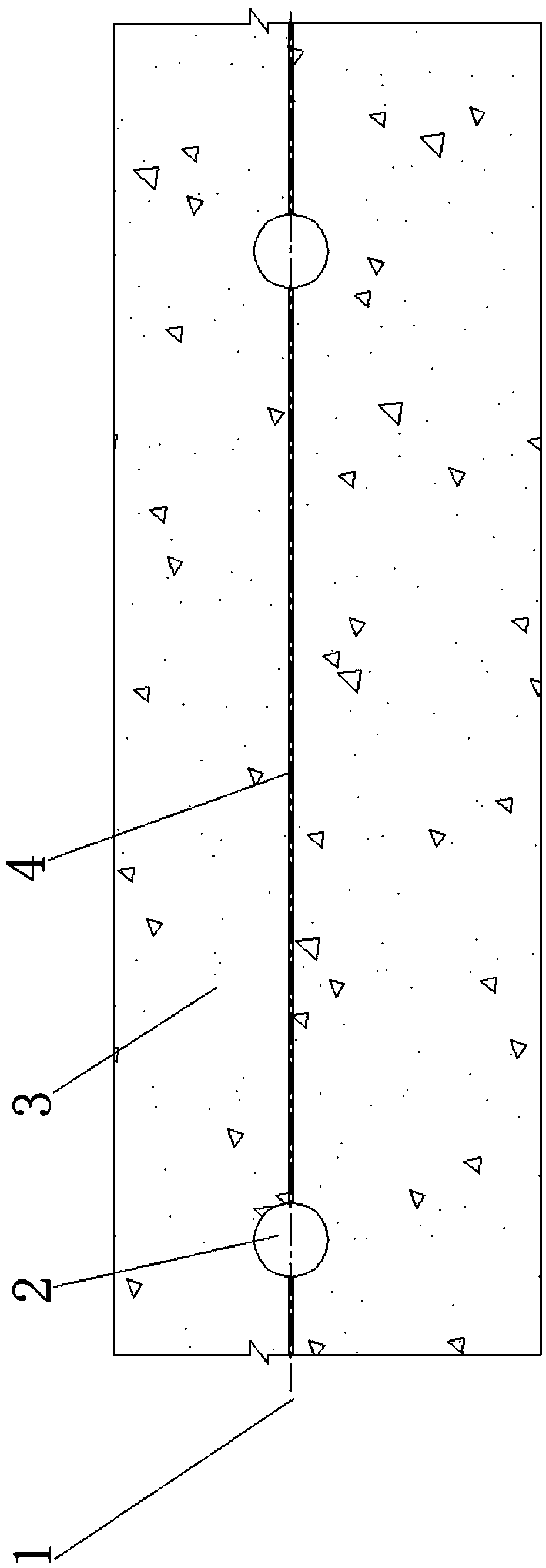

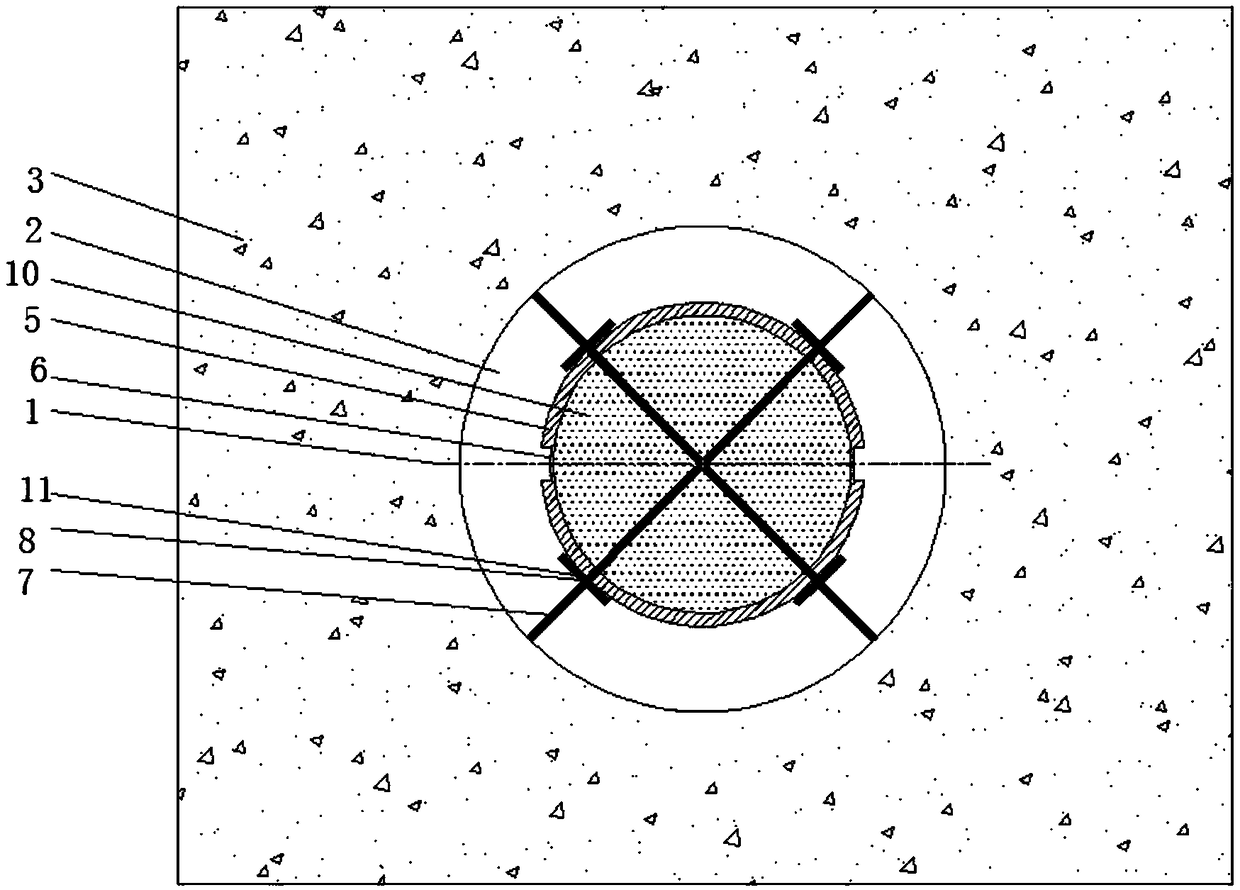

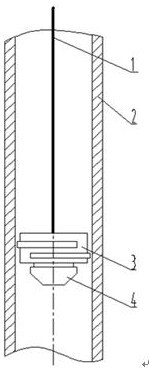

The invention discloses a coal mine roof panel deep hole pre-splitting blasting method. The coal mine roof panel deep hole pre-splitting blasting method comprises a step of installing a plurality of energy-gathered tubes which are full of explosives inside a deep drill hole of a roof panel; and the step comprises the following steps of: (S1) installing a first energy-gathered tube; (S2) installingan energy-gathered tube connecting device; (S3) installing a next energy-gathered tube; (S4) repeating the step (S2) and the step (S3), and installing the other middle energy-gathered tubes; (S5) installing the last energy-gathered tube provided with a clamping slot, repeating the step (S2) and the step (S3), installing detonators and connecting detonating cords; and (S6) pushing the energy-gathered tube provided with the clamping slot to the bottom of the drill hole by using an energy-gathered tube orienting device. The invention provides a coal mine roof panel cutting method which can effectively solve the problem about suspension of a roof panel; the suspended roof panel becomes broke waste rocks; and the problem about roof panel rotation pressure caused by suspension of the roof panelis effectively solved.

Owner:中矿科创(北京)煤炭技术有限公司

Plasma cutting device and method for underground oil casing

PendingCN112443286AReal-timeRealize regulationDrilling rodsDrilling casingsEngineeringElectric cables

The invention discloses a plasma cutting device and method for an underground oil casing. The plasma cutting device comprises an electrode, an electrode feeding mechanism and a guide shoe, the electrode is fixed to the electrode feeding mechanism, the electrode is arranged outwards in the radial direction, the guide shoe is connected to the axial lower end of the electrode feeding mechanism, and the electrode and the electrode feeding mechanism are both connected with a cable; the upper end of the electrode feeding mechanism is connected with a rotating mechanism; the upper end of the rotatingmechanism is connected with an upper centering mechanism; and a lower centering mechanism is further connected between the guide shoe and the electrode feeding mechanism. Strings are cut, the cuttingefficiency is high, and the success rate is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

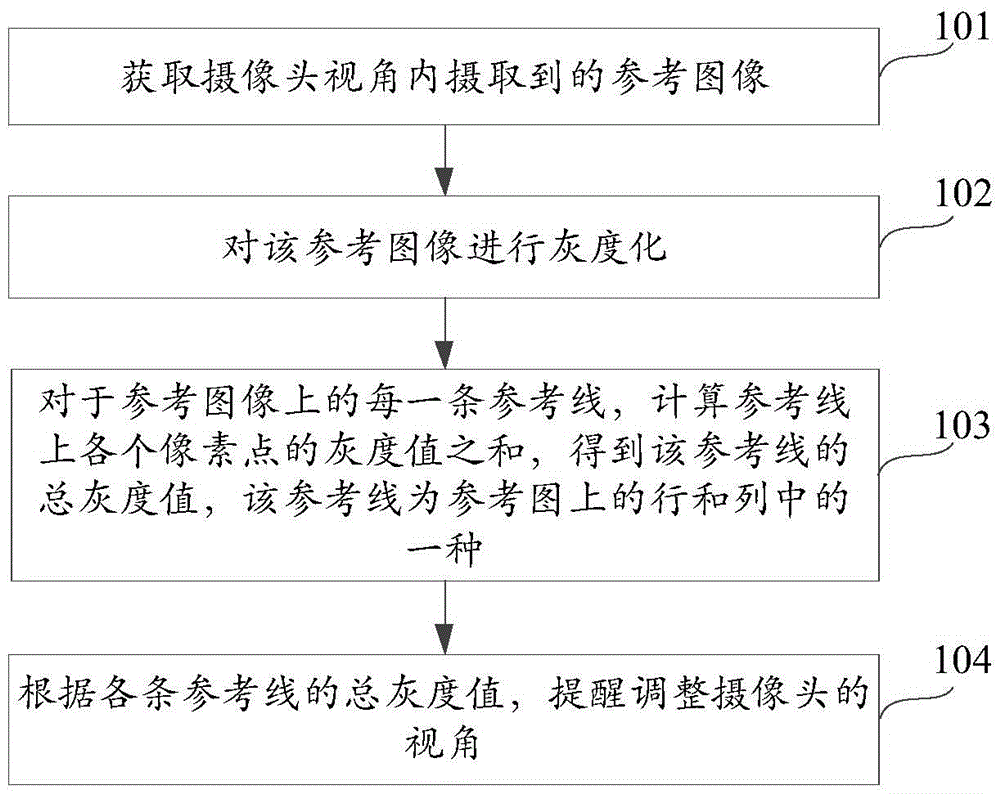

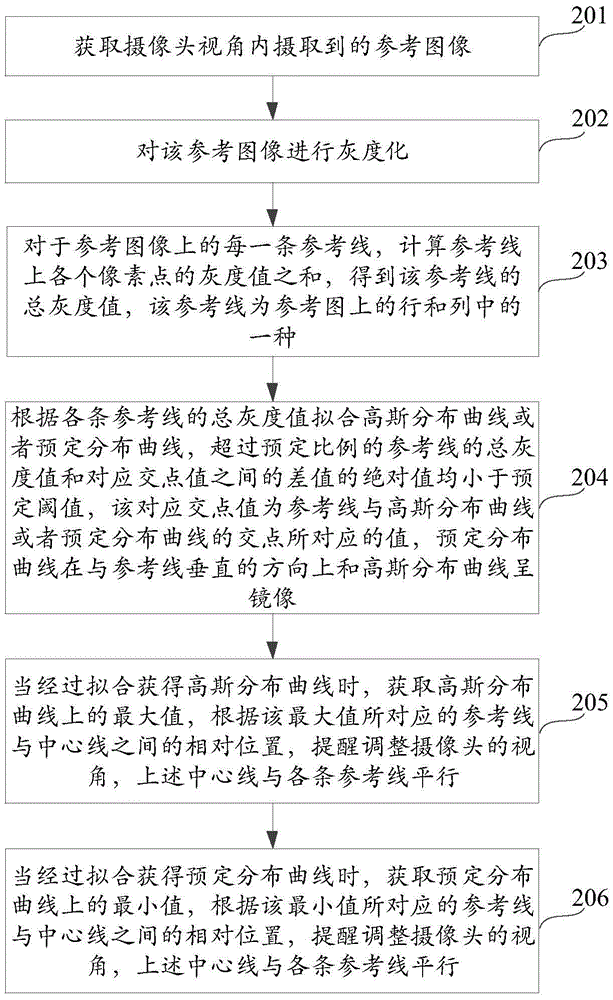

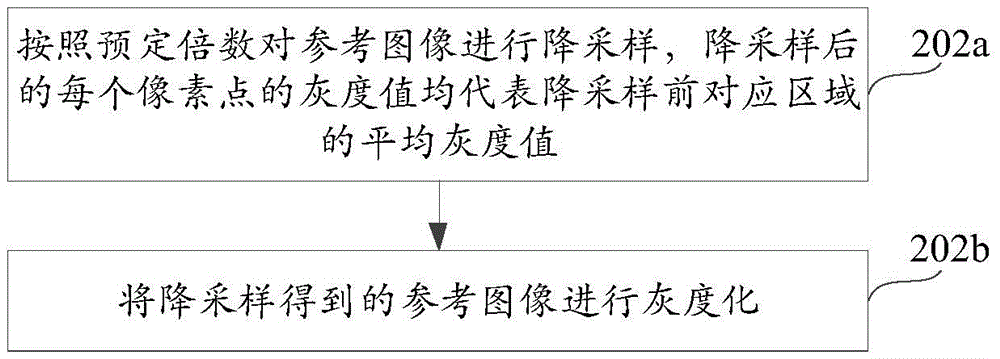

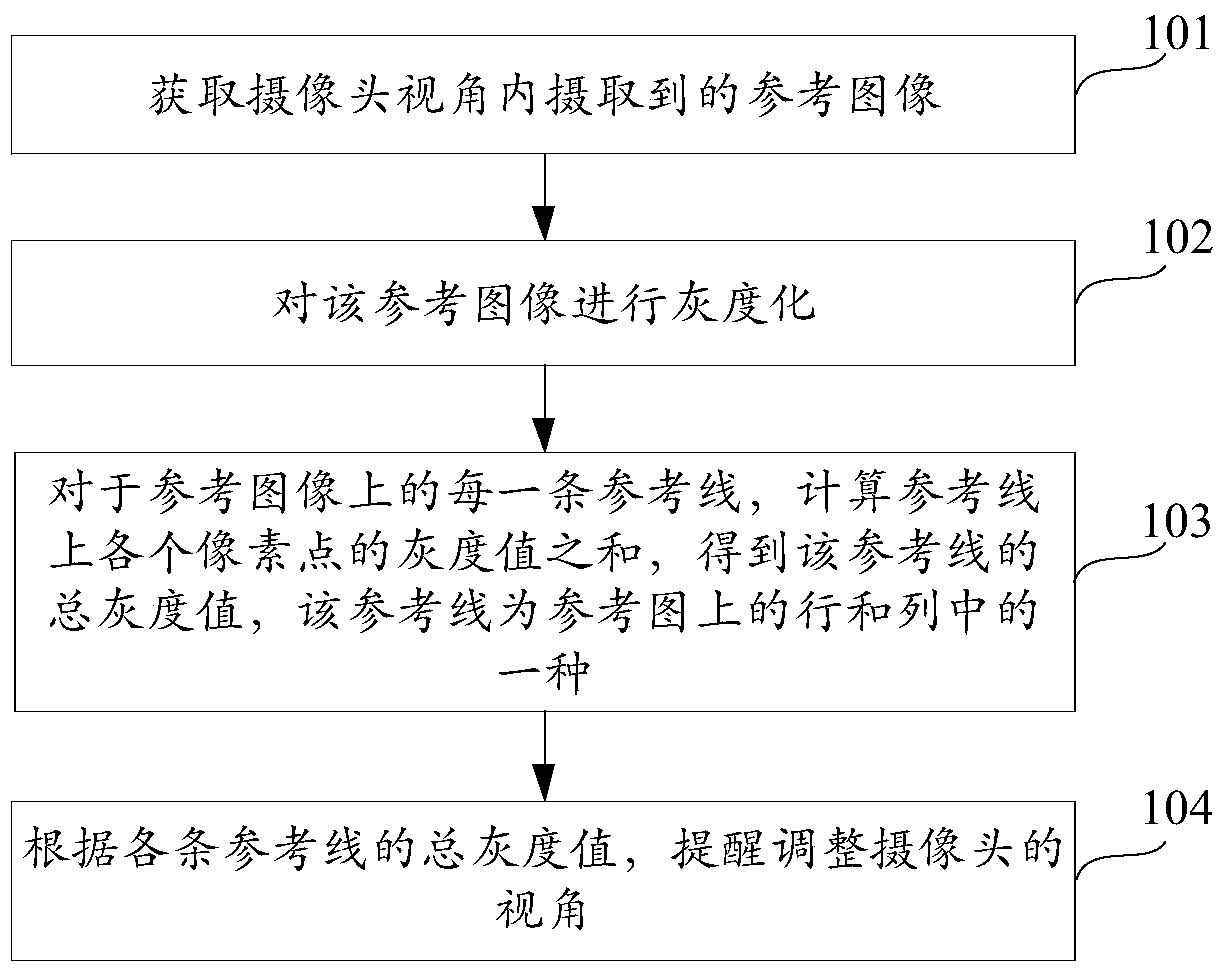

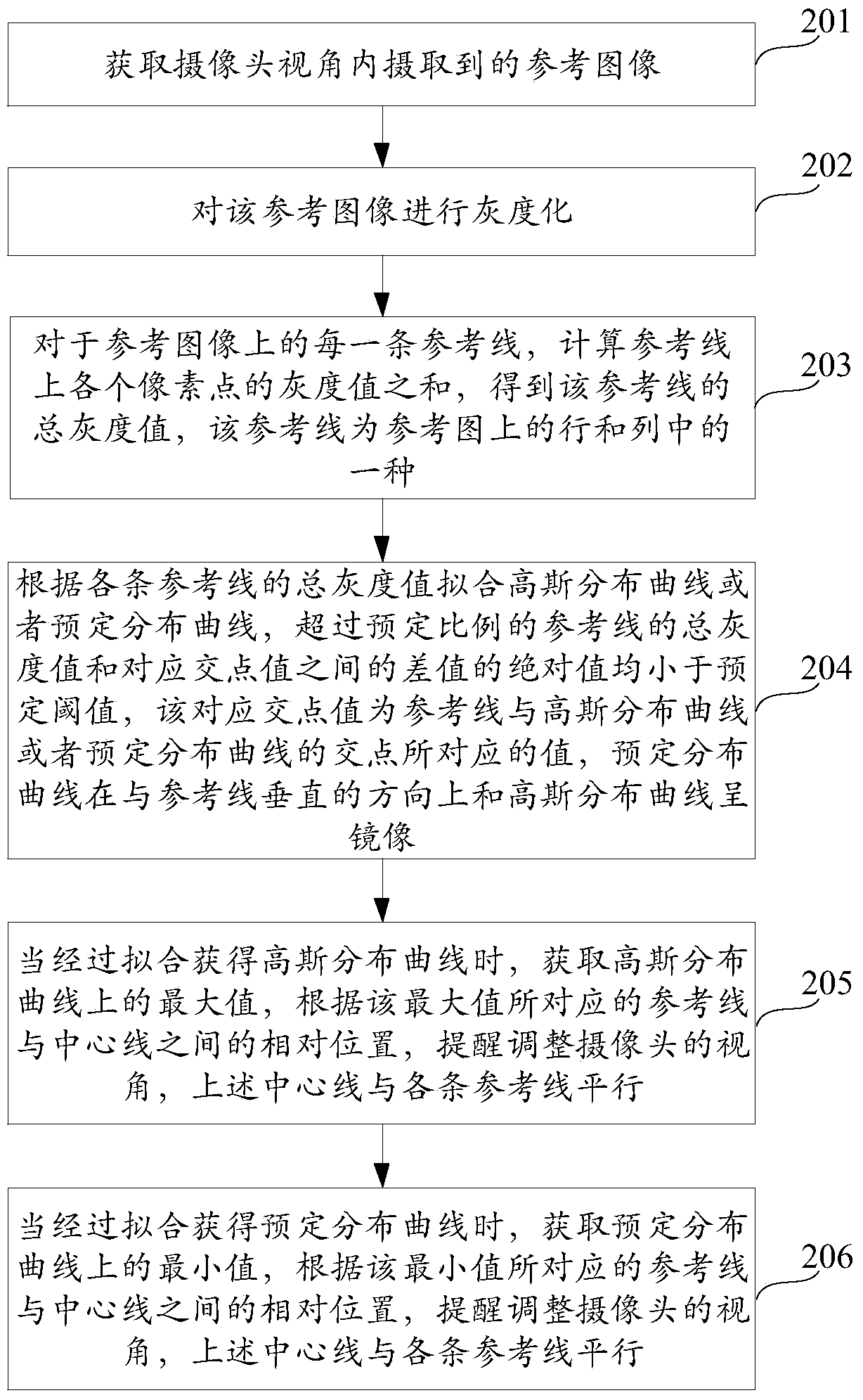

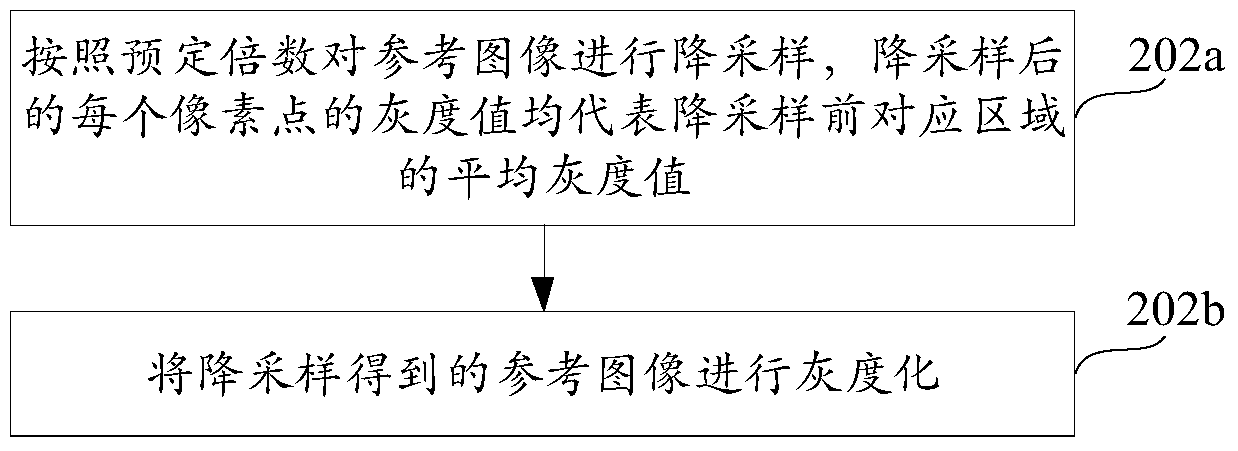

Pick-up head visual angle adjusting method and apparatus

ActiveCN105635573AGuaranteed to be centeredAvoid multiple adjustmentsTelevision system detailsColor television detailsImaging processingReference image

The invention relates to a pick-up head visual angle adjusting method and apparatus, and belongs to the technical field of image processing. The method comprises the following steps: obtaining a reference image shot within a visual angle of a pick-up head; performing graying on the reference image; for each reference line on the reference image, calculating the sum of a gray value of each pixel point on the reference line, and obtaining a total gray value of the reference line, wherein the reference line is one from a row and a column on the reference image; and according to the total gray value of each reference line, prompting to adjust the visual angle of the pick-up head. According to the invention, the problem of unreasonable composition existing in an image obtained when a user adjusts the shooting visual angle of the pick-up head according to his own feeling is solved; and the effects of improving user experience by prompting the user to adjust the visual angle of the pick-up head when the composition of the image shot by use of the pick-up head is unreasonable.

Owner:XIAOMI INC

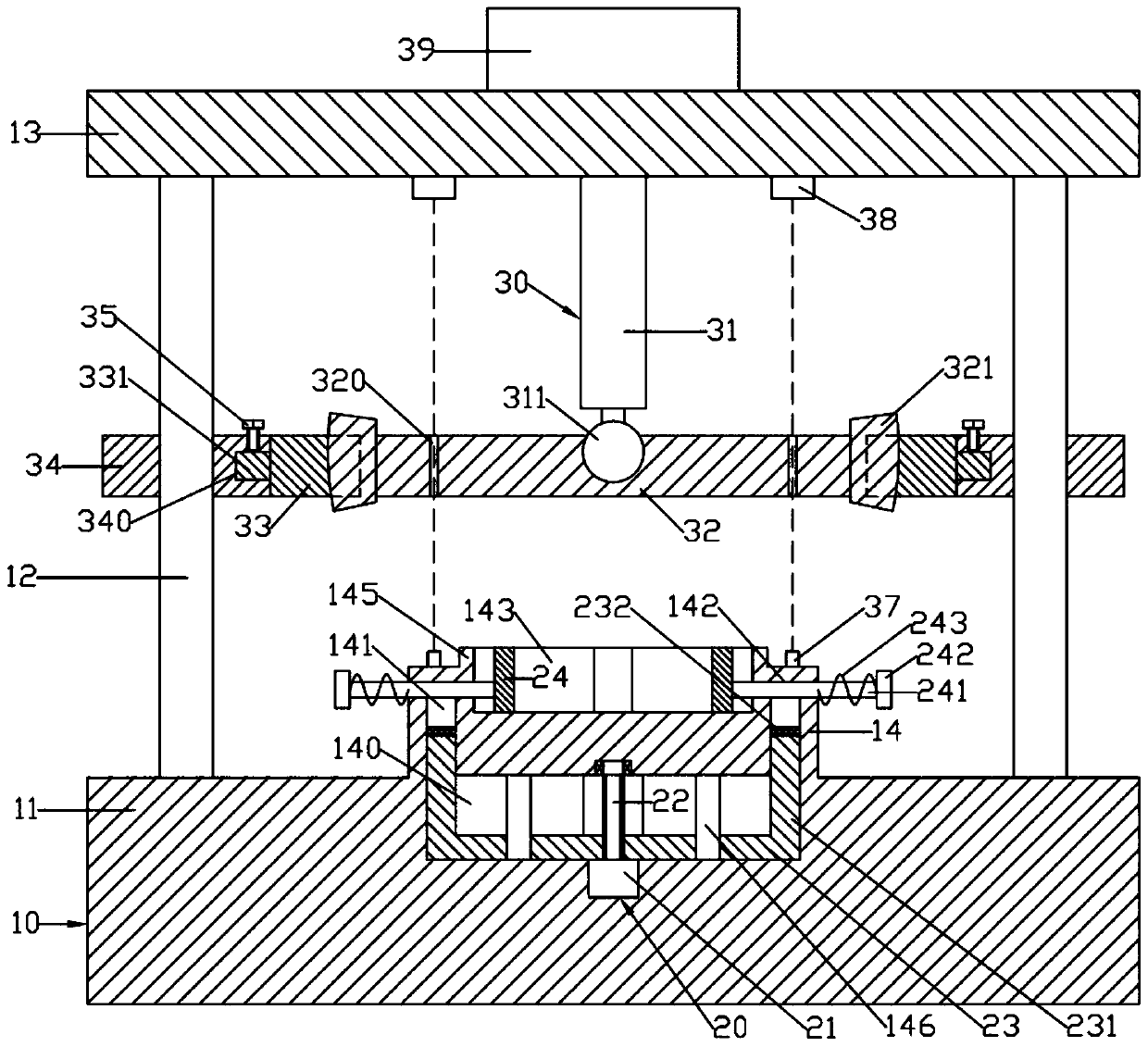

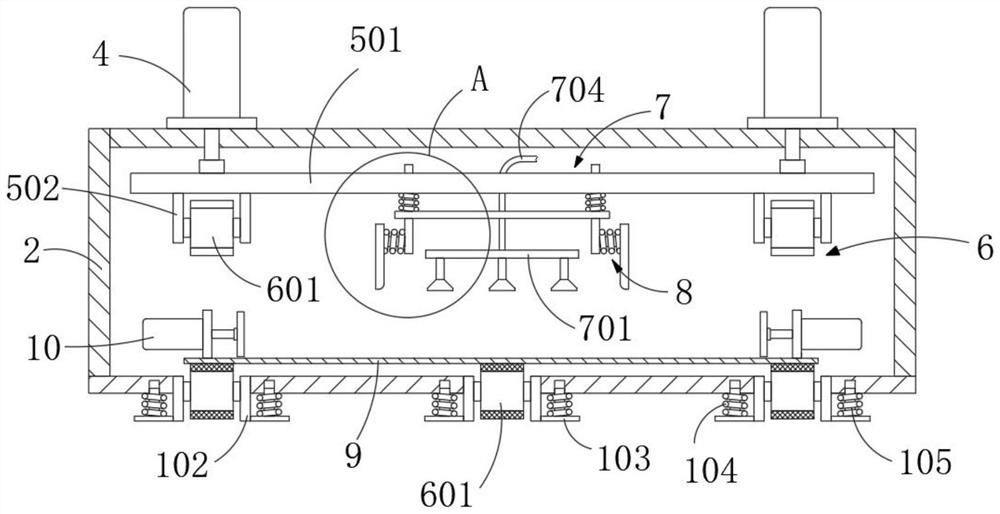

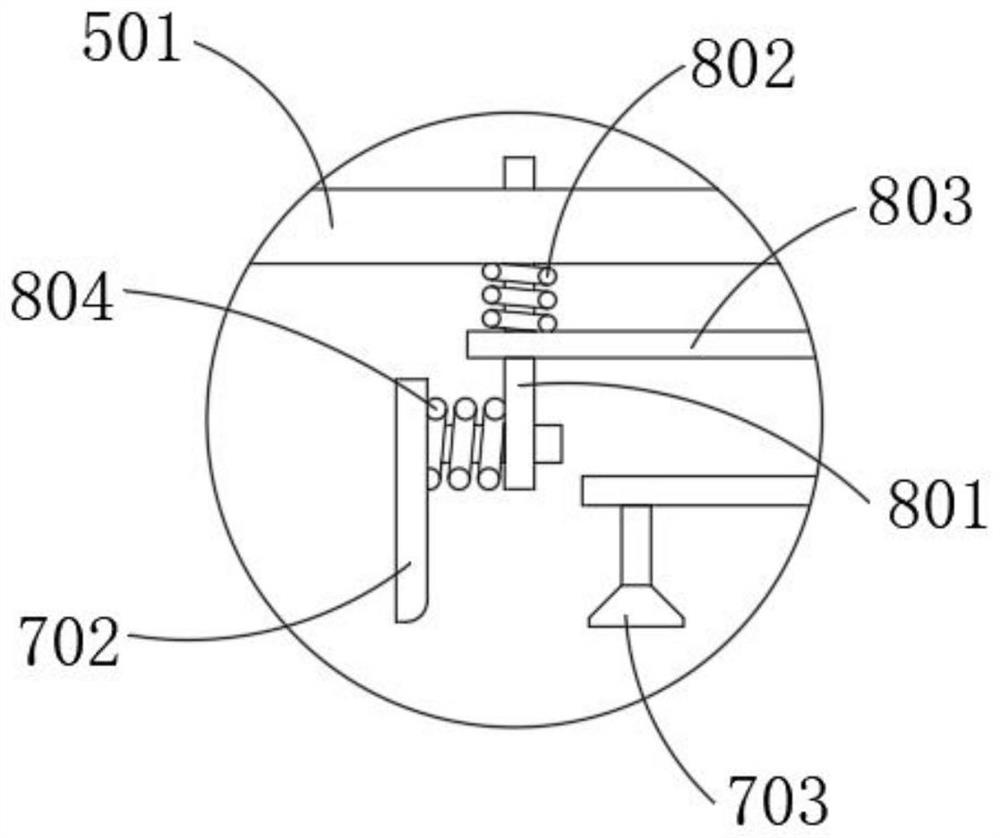

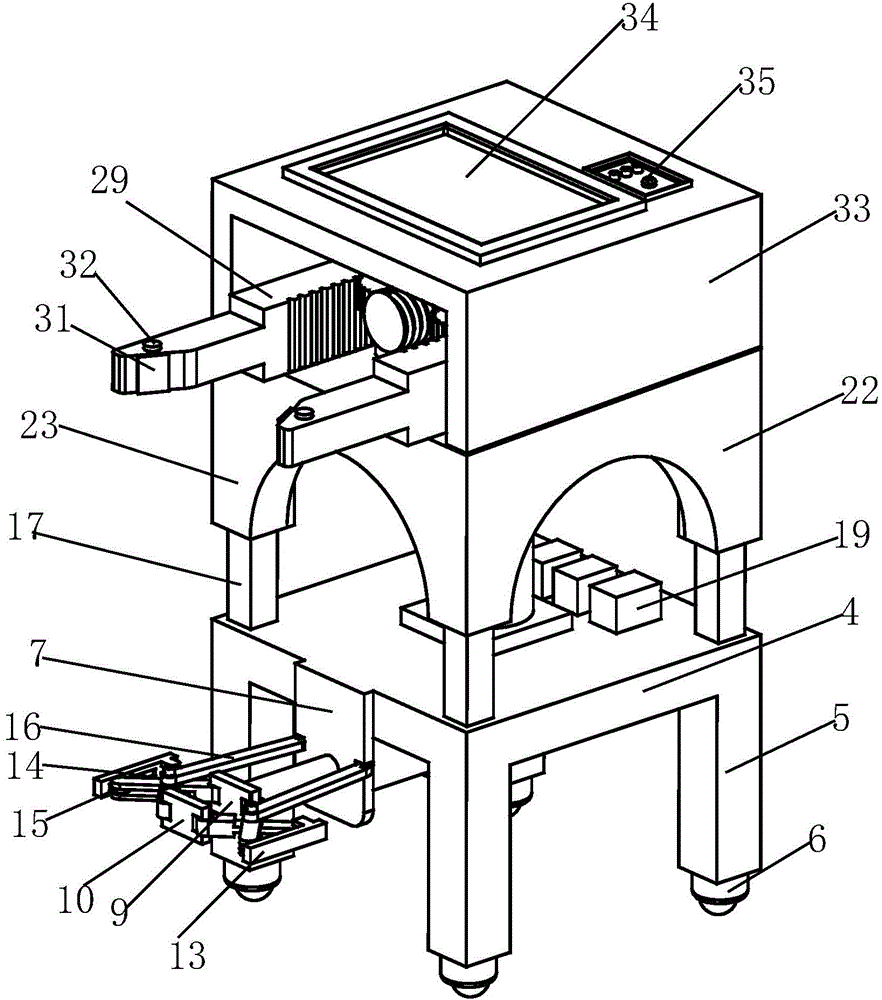

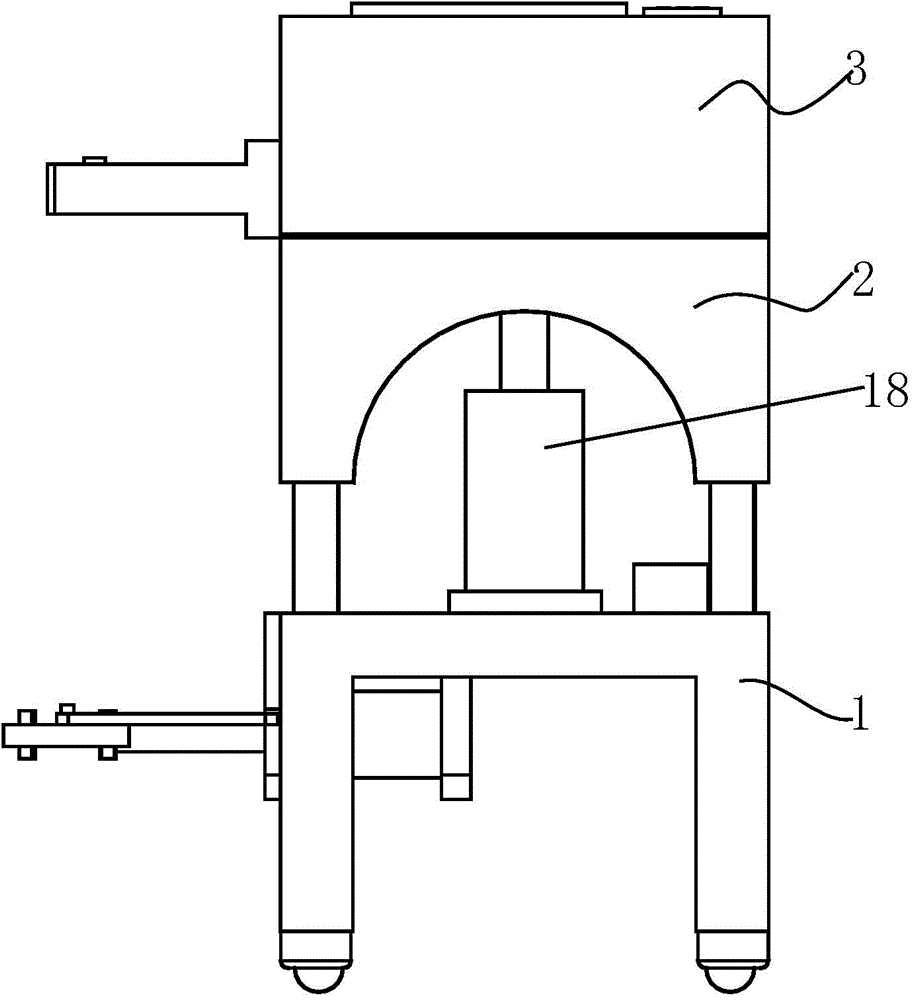

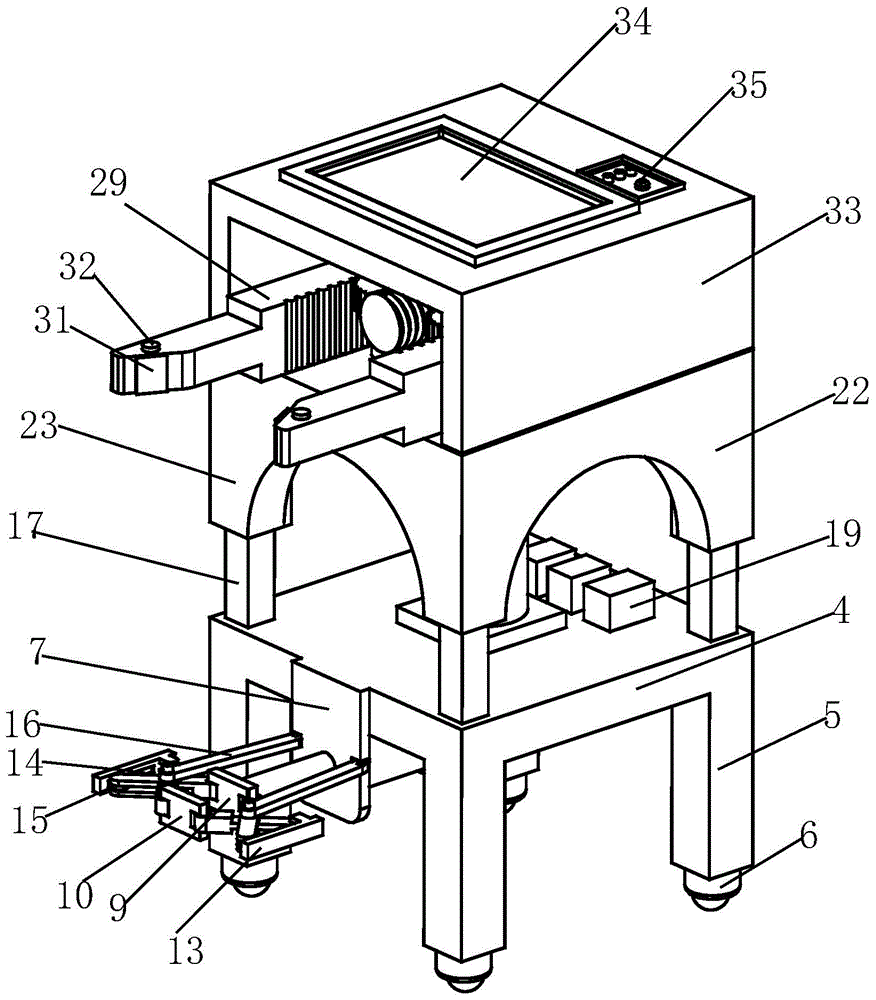

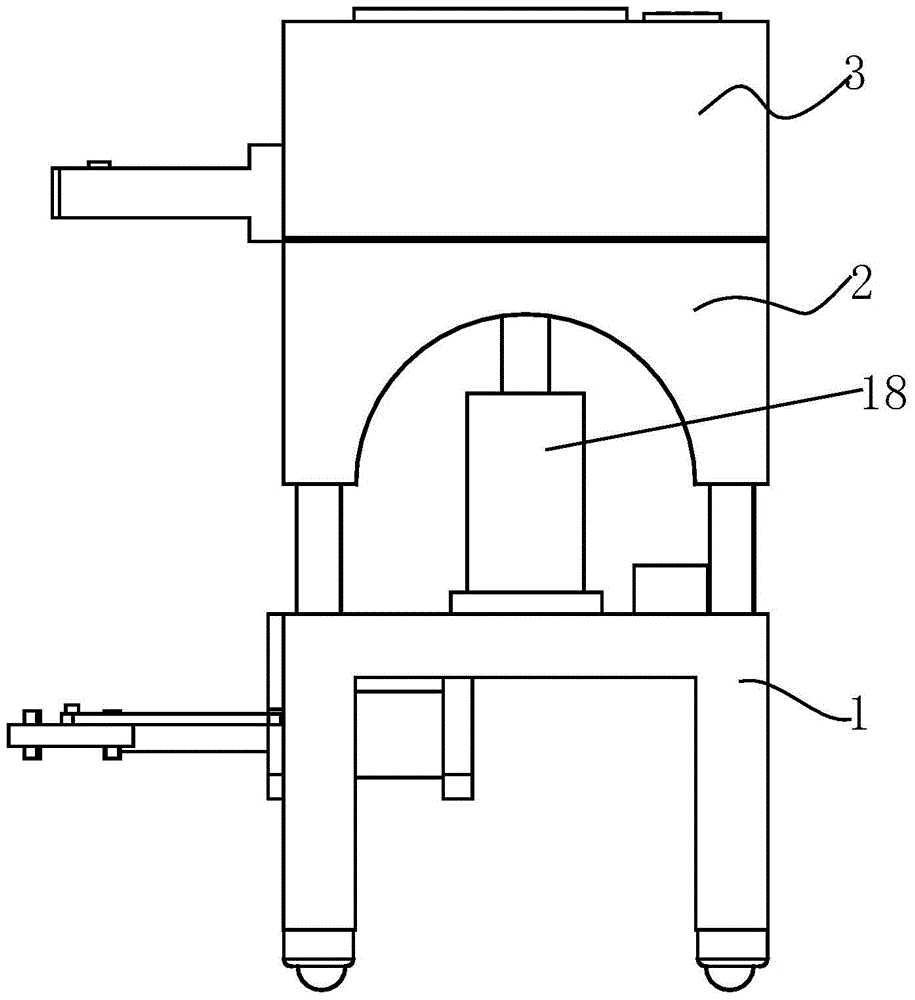

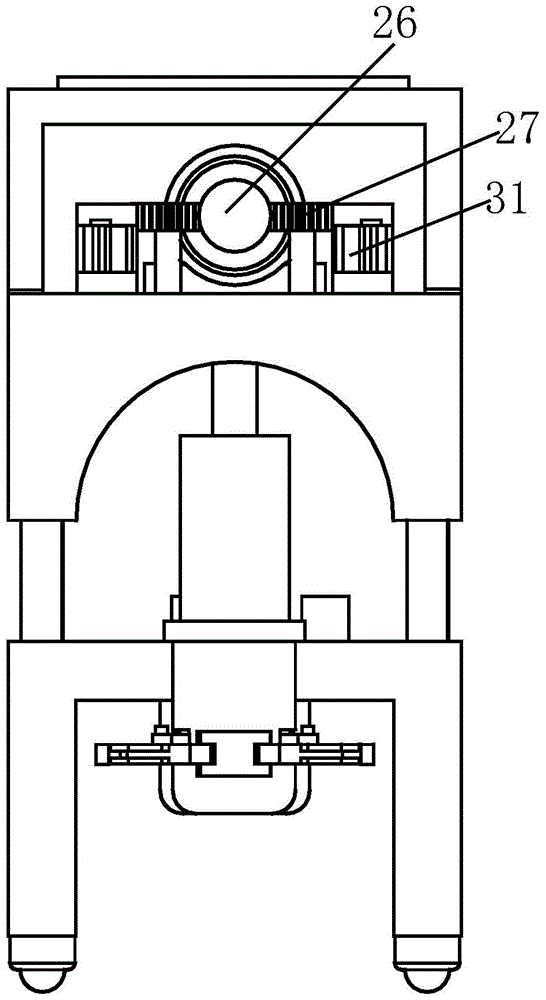

Press machine for bearing installation

ActiveCN110919331AGuaranteed to be centeredGuaranteed levelMetal working apparatusStructural engineeringMachine

The invention discloses a press machine for bearing installation. A cuboid-shaped lower supporting seat is formed at the center of the upper end surface of a supporting base, a rectangular-groove-shaped workpiece placement groove is formed in the upper end surface of the lower supporting seat, and telescopic holes penetrating inside and outside are formed perpendicularly in the middle parts of thefour side walls of the workpiece placement groove; a rectangular-groove-shaped lifting groove is formed in the lower end of the lower supporting seat; vertical-upward vertical moving grooves are formed in the middle parts of the peripheries of the upper side wall of the lifting groove correspondingly; the upper ends of the vertical moving grooves are in communication with the telescopic holes; aworkpiece limiting device includes a limiting lifting block, the limiting lifting block is arranged in the lifting groove in lifting-lowering modes, and four limiting press blocks matched with the vertical moving grooves are formed on the upper end surface of the limiting lifting block; and telescopic connecting rods are movably arranged in the telescopic holes, spring limiting plates are formed at the outer ends of the telescopic connecting rods, and workpiece limiting plates are formed at the inner ends of the telescopic connecting rods.

Owner:TAIZHOU ZSON BEARING TECH CO LTD

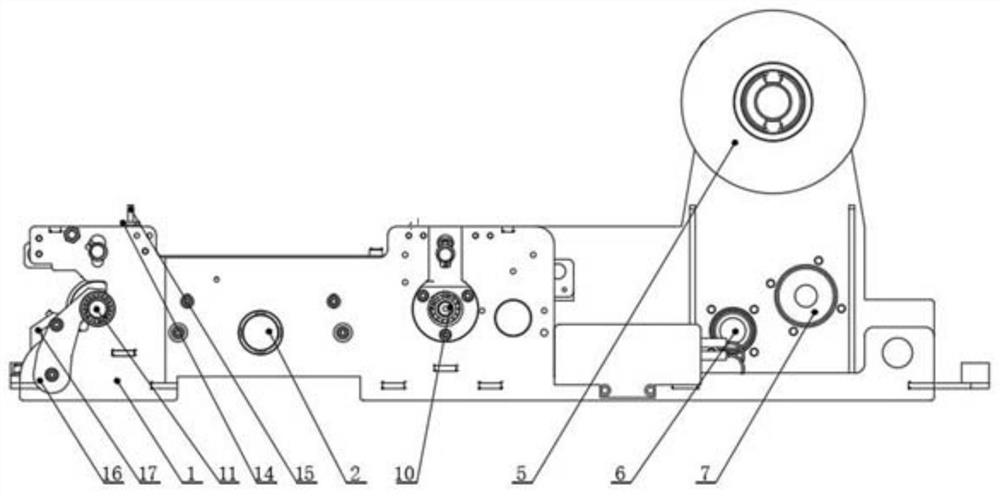

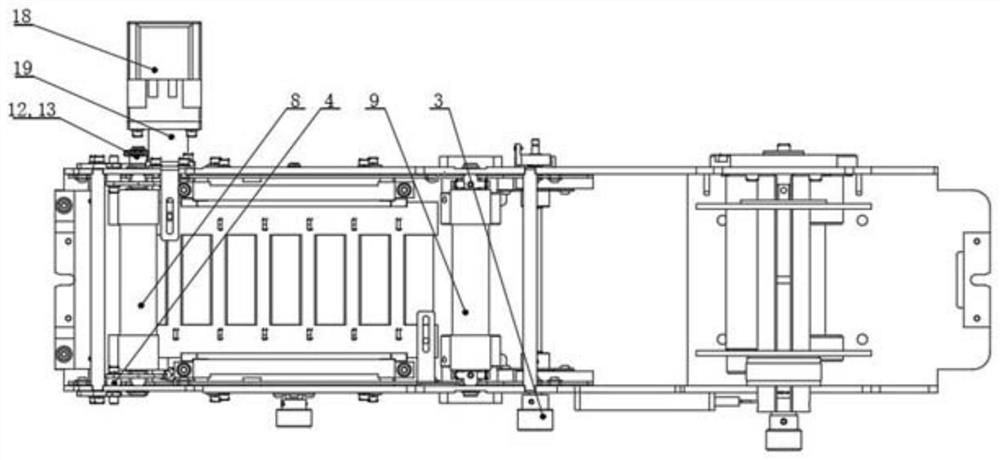

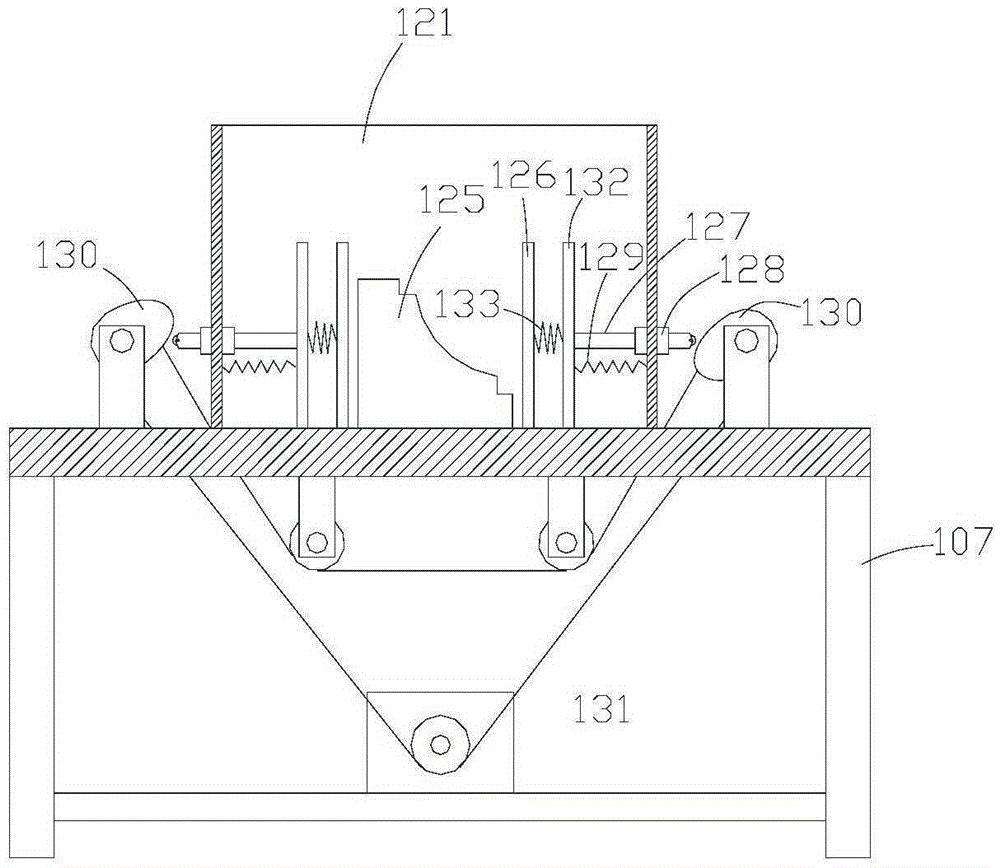

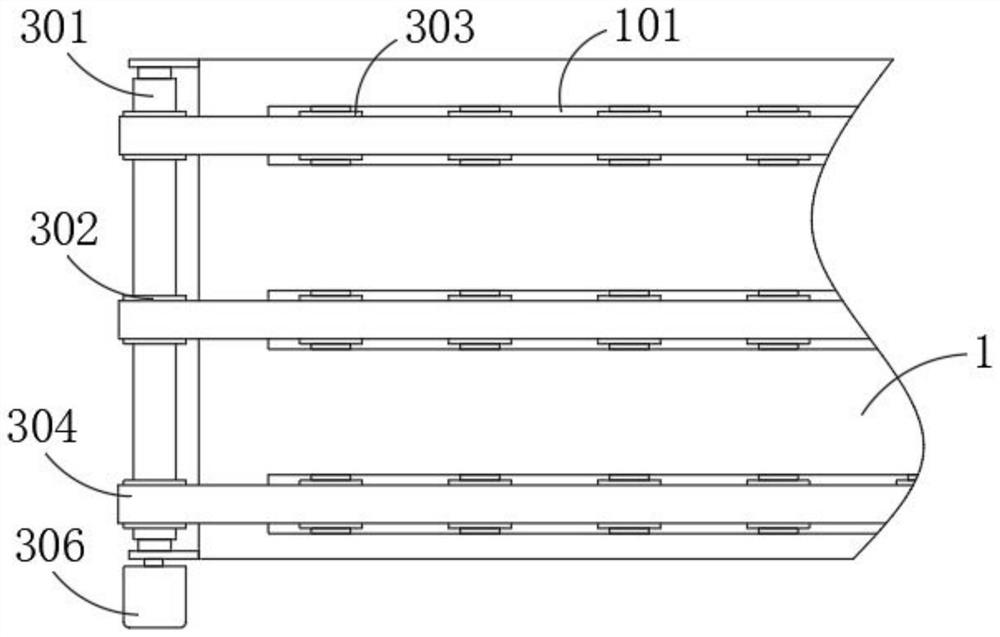

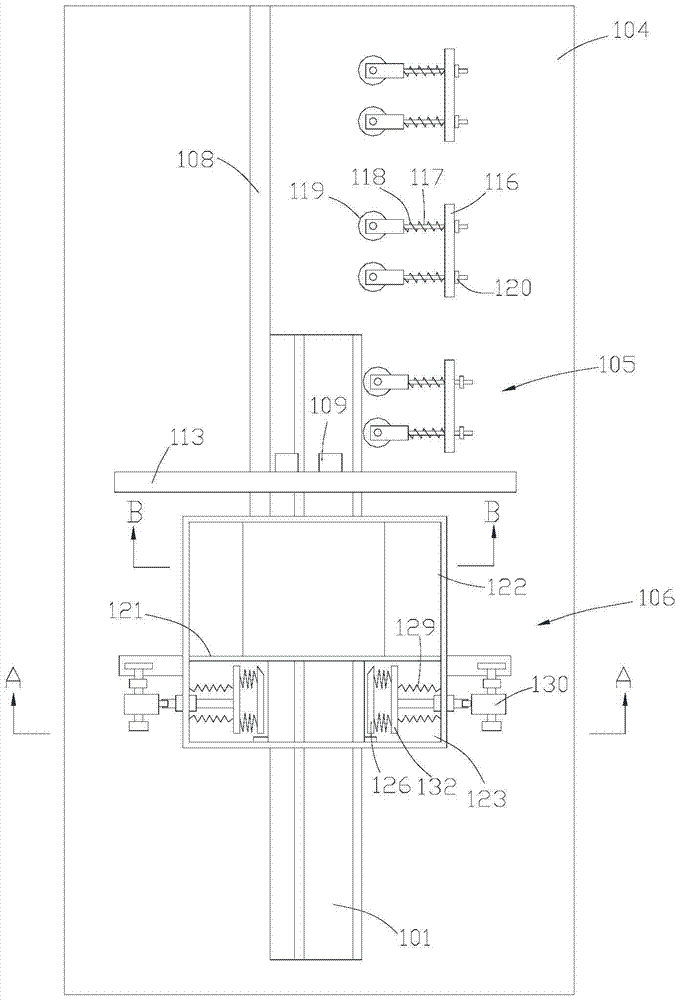

Marked coil stock feeding device

ActiveCN112320428AGuaranteed to be centeredTransmission position is accurateWebs handlingDrive wheelDrive shaft

The invention relates to a marked coil stock feeding device. A guide centering device is mounted below a marked coil stock, a jacking mechanism is mounted in the middle of a rack, a drive wheel shaftis mounted on a side plate at one end of a main rack, a front roller pressing device is located at the end of the drive wheel shaft, a driven wheel is mounted in the middle of the rack, a driving wheel shaft C is mounted below the driven wheel, a main transmission shaft, a main shaft pressing device and a movable plate pressing block are installed on the inner side of the main rack, a coil stock main shaft is mounted on a side plate at the other end of the main rack, a guide shaft and a guide shaft C are mounted below the coil stock main shaft, a feeding motor is mounted on a motor base, the motor base is mounted on the main rack, an output shaft of the feeding motor is connected with a feeding motor gear, the feeding motor gear meshes with a transmission shaft gear, a lateral sensor fixing plate is mounted on a lateral plate of the main rack, and a positioning sensor is fixed on the lateral sensor fixing plate. According to the device, the stable operation of marked coil stock transmission can be ensured, the transmission position is accurate, and the transmission distance is controllable.

Owner:WUHAN ZHONGGU POWER SUPPLY DEVICE

Combined drilling device

InactiveCN101949262ALimit Skew DirectionGuaranteed hole inclination controlDrilling rodsBorehole drivesPetroleum engineeringDrill pipe

The invention discloses a combined drilling device. The combined drilling device comprises a connectable drill rod and a downhole air hammer, wherein the downhole air hammer is sequentially connected with a back flushing grinding device and a centering device, and then connected with the drill rod; and a drill rod extension part connected after the downhole air hammer is sequentially connected with the back flushing grinding device and the centering device is at least connected with a group of centering devices. The combined drilling device grinds rock flour deposited in a back flushing hole, probe stones which fall on rock masses and are attached to a hole wall and large rock masses, so that the problems of drill clamping and drill burying of a large-diameter drilling tool are solved; and the centering device has the advantages of ensuring that the drilling tool is in the middle of a pore cannel, meeting the requirement on drilling accuracy, enhancing pore-forming quality and solving the problems of drill clamping and drill burying due to large outer diameter under the combination effect of the back flushing grinding device. Due to the combination effect of the device, drilling efficiency is improved and pore-forming quality is enhanced.

Owner:CHENGDU HYDRO ELECTRIC ENG CONSTR OF SINOHYDRO BUREAU 7

Foam line starching device

InactiveCN105328786ASimple structureEasy to manufactureSurface layering apparatusLinear motionEngineering

The invention provides a foam line starching device, belonging to the field of production equipment of architectural decoration lines. The foam line starching device comprises a workbench, a positioning guide device and a scraping device, wherein the workbench is provided with a horizontal working surface; the positioning guide device comprises a vertical extrusion mechanism, a positioning plate and a transverse extrusion mechanism, the vertical extrusion mechanism is used for pressing a foam line on the workbench, and the positioning plate and the transverse extrusion mechanism are used for extruding the foam line from the two sides; the positioning guide device can enable the foam lines to keep linear motion, and the thickness of coated mortar is uniform; the scraping device comprises a mortar groove and a material pressing mechanism, the mortar groove is used for coating mortar on the surface of the foam line, and the material pressing mechanism is used for compacting the mortar coated on the surface of the foam line. When passing through the mortar groove, the foam line orderly passes through a feeding inlet, a feeding outlet and a material pressing outlet of which the sizes are orderly increased; after the foam line passes through the feeding outlet, the surface of the foam line is coated with thick mortar; after the foam line is extruded by the material pressing mechanism, the mortar on the two sides of the foam line becomes thinner and more compact and is not easy to fall off.

Owner:广州市卓基新材料科技有限公司

NFC antenna assembly equipment

PendingCN114055119AImprove work efficiencySolve the defects of manual alignmentAntenna supports/mountingsArticle unpackingAntenna fabricationElectrical and Electronics engineering

The invention relates to the field of NFC antenna manufacturing, in particular to NFC antenna assembling equipment which comprises a platform and a portal frame, the portal frame is fixedly installed on the upper surface of the platform, three sets of conveying assemblies are arrayed on the upper surface of the platform at equal intervals, air cylinders are symmetrically installed at the top of the portal frame, and supports are fixedly installed at the telescopic rod ends of the air cylinders; and two floating roller rows are symmetrically arranged on the lower surface of the support and located over the conveying assembly, and a coil hoisting assembly is arranged between the two floating roller rows. The conveying assembly comprises a driving roller, driving wheels and floating wheels which are arrayed in the platform at equal intervals, the driving wheels are fixedly connected through keys and arrayed on the surface of the driving roller at equal intervals, a transmission assembly is arranged on the platform and used for conveying the NFC antenna jig plate, the working efficiency is improved, the defects of manual alignment are overcome, and the operation time is shortened; and through the two sets of limiting plates, it can be guaranteed that the coil is centered during adsorption, and displacement can be prevented when the coil and the jig plate are combined.

Owner:东莞市海联科技有限公司

Rotational flow shoe

ActiveCN103967412AAvoid destructionConducive to centeringDrilling machines and methodsDifferential pressureMechanical engineering

The invention relates to a rotational flow shoe which comprises a hollow shell, a hollow connecting pipe is detachably mounted at the downstream end part of the shell to form a fluid passage, a rotational flow passage penetrating through the side wall of the connecting pipe is also formed in the connecting pipe, a differential pressure type valve capable of cutting off or communicating the fluid passage is fixedly arranged inside the shell, and a bearing slide block which can move in the axial direction and cover the rotational flow passage is arranged inside the connecting pipe and is connected with the connecting pipe through a cutting pin. The rotational flow shoe has the benefits that the pressure resistance is higher, and the rotational flow shoe is not affected by the cleanness of well fluid.

Owner:CHINA PETROLEUM & CHEM CORP +1

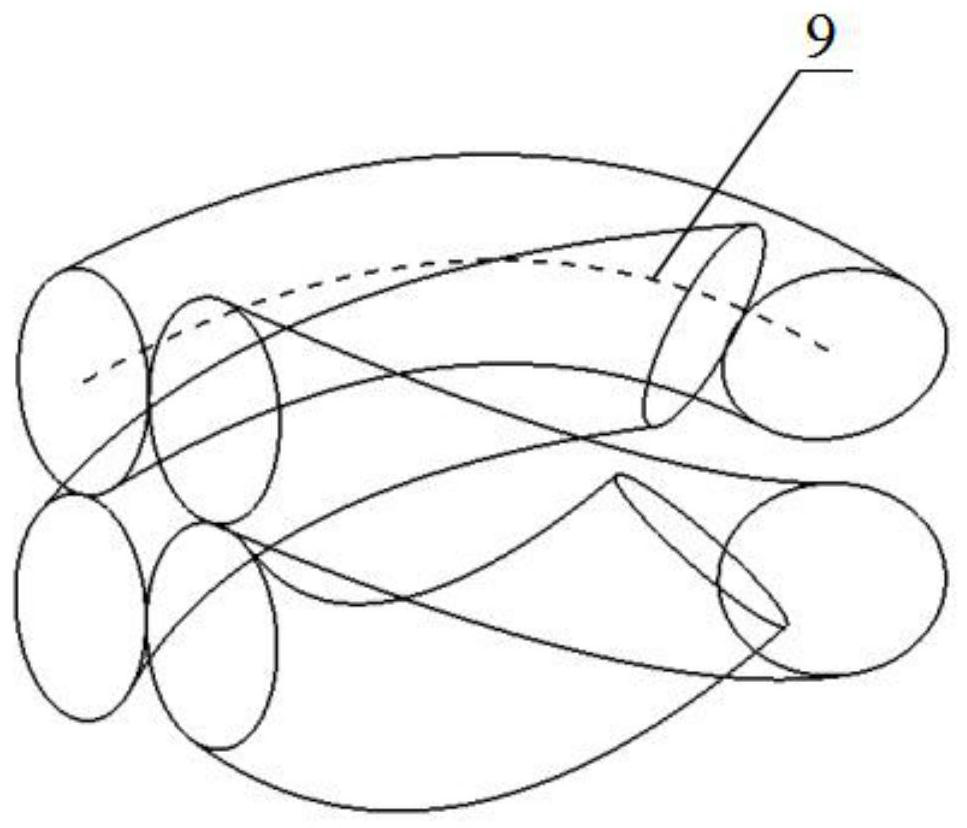

Linear arm plate spring linear compressor

ActiveCN111336088ASimple efficiencyImprove efficiencyPositive displacement pump componentsPiston pumpsLinear compressorElectric machine

The invention discloses a linear arm plate spring linear compressor. The compressor efficiency of an existing linear compressor is reduced due to the fact that the position of a compressor piston is prone to radial displacement caused by low radial rigidity of a plate spring. The linear arm plate spring linear compressor includes a compressor assembly, a magnetic field assembly, an alternating current motor assembly, and a plate spring assembly; the compressor assembly includes a box body, a machine frame and a cylinder; the magnetic field assembly includes a permanent magnet and a yoke; the alternating current motor assembly includes an alternating current coil and a supporting frame; the plate spring assembly includes a plate spring base and a plate spring group; and the plate spring group includes 2-5 pieces of linear plate springs, the adjacent linear plate springs are separated by washers, the linear plate springs are in a disc shape, three or four olive-shaped through holes are symmetrically formed, and elastic beams are arranged between the adjacent two through holes. A simple linear arm plate spring structure is adopted, the mass of the spring is reduced, the elastic coefficient is unchanged, the resonance frequency of the spring and a system is increased, the compressor is operated at a higher frequency, and the efficiency of the compressor is improved.

Owner:HANGZHOU DIANZI UNIV

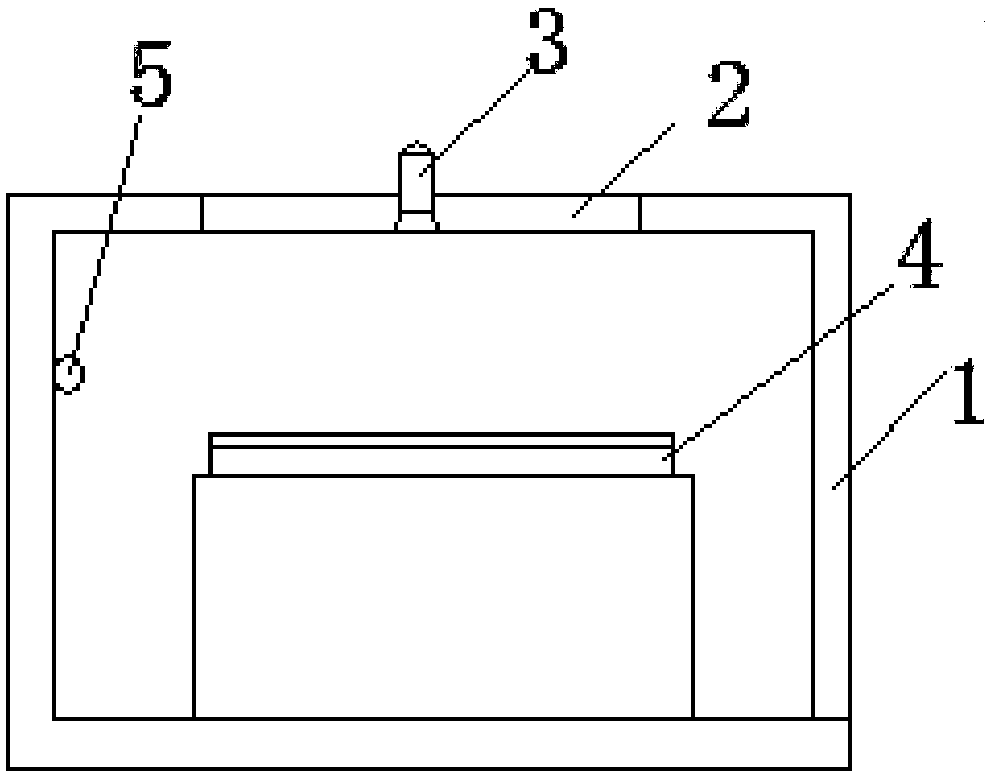

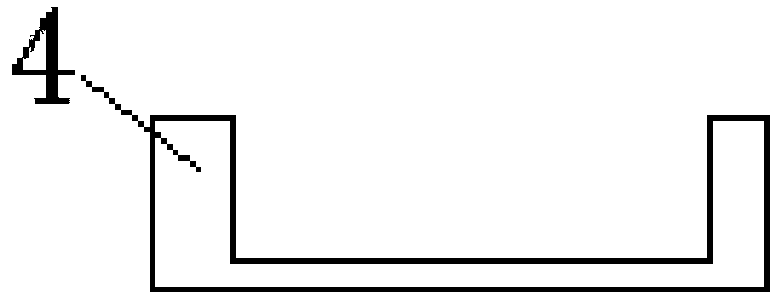

Glass annealing and linear expansion coefficient integrated test device, and method

InactiveCN108254404AAccurately observe changesGuaranteed accuracyMaterial thermal coefficient of expansionFree coolingThermal expansion

The invention discloses a glass annealing and linear expansion coefficient integrated test device, and a test method. According to the test method, a discharge port of a high temperature heating furnace is sealed with high temperature resistant transparent glass, a high definition camera is arranged on the high temperature resistant transparent glass, a sample to be tested is placed on a sample support which is used for supporting the sample to be tested and is arranged in the high temperature heating furnace, the sample support is provided with scale lines for recording of the change of the size of the sample, the high temperature heating furnace is used for annealing processing of the sample to be tested, natural cooling is carried out, moving of the sample to be tested is not needed, sothat secondary destroy or influences by the external environment are avoided, and at the same time, the thermal expansion coefficient of the sample is measured in the high temperature heating furnace, the high definition camera is used for real-time recording of the change of the size of the sample to be tested, so that accurate observing of the change situations of the sample to be tested is realized, and test result accuracy is ensured.

Owner:彩虹(合肥)液晶玻璃有限公司

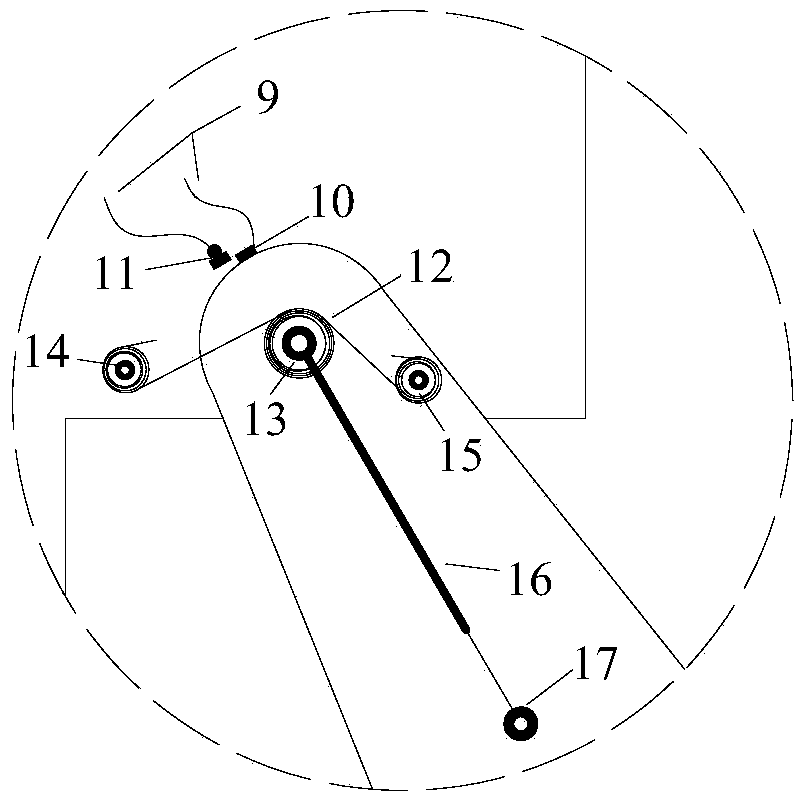

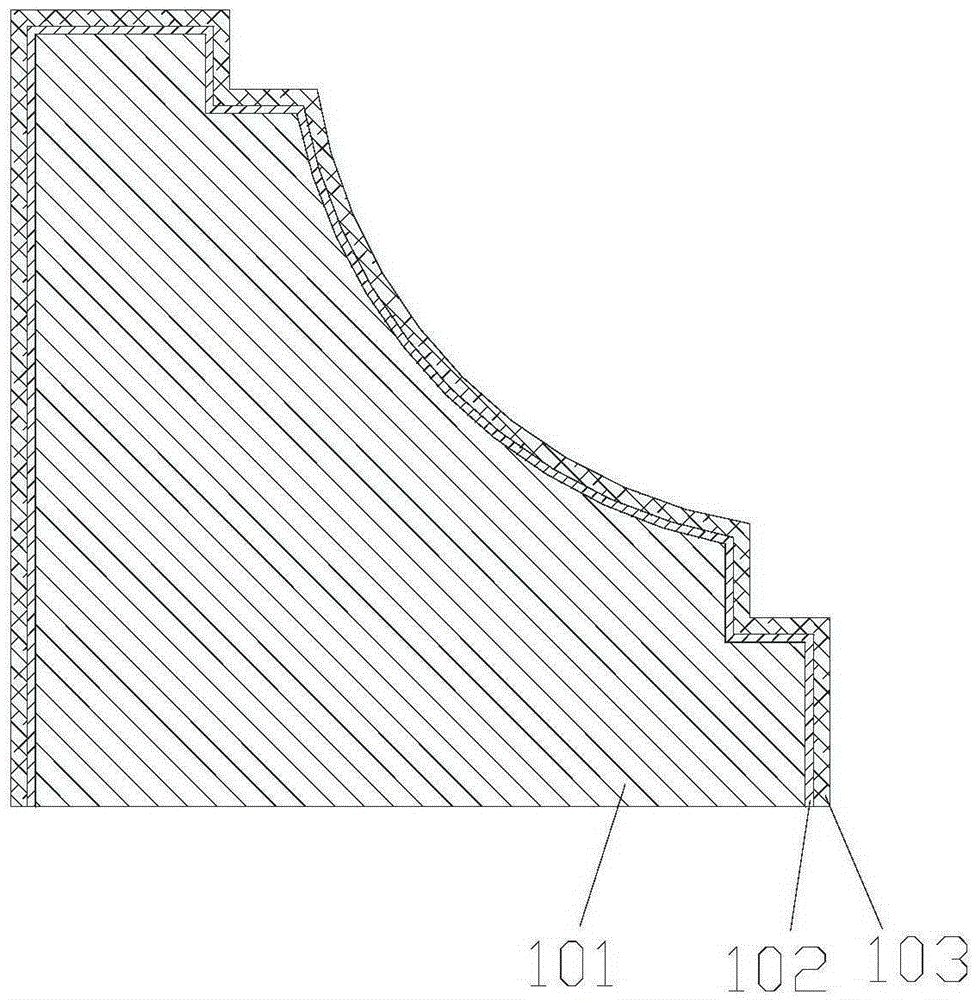

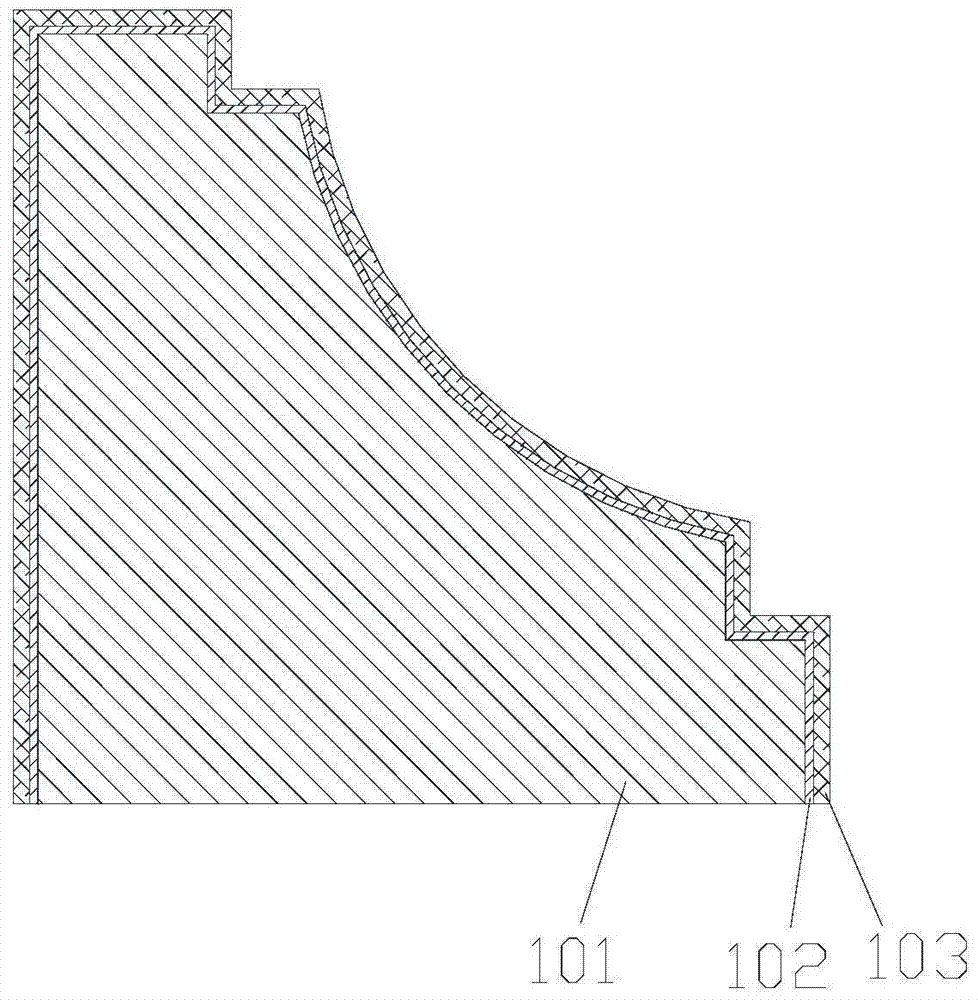

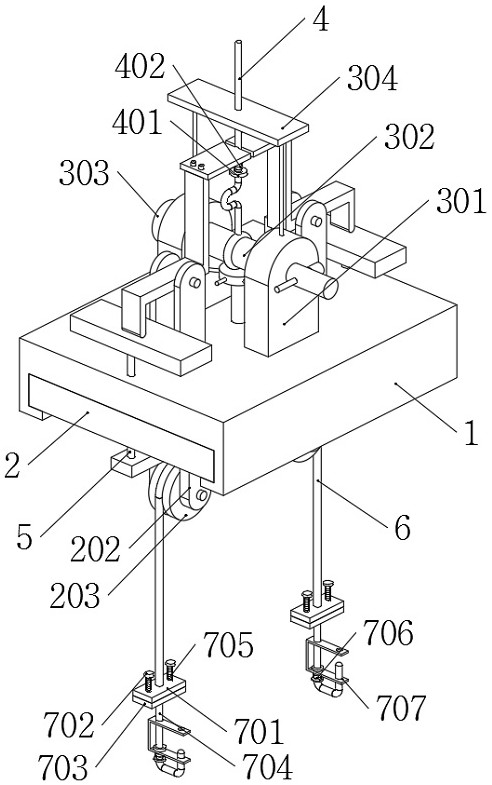

Rock core slotting tool for fracture toughness experiment and slotting method thereof

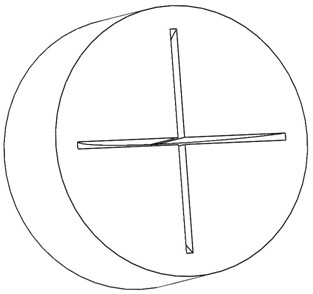

ActiveCN112903396AGuaranteed stabilityGuaranteed to be centeredPreparing sample for investigationStructural engineeringClassical mechanics

The invention relates to a rock core slotting tool for a fracture toughness experiment and a slotting method thereof. The rock core slotting tool for the fracture toughness experiment comprises a cylindrical scale, a rock core clamp, a clamp calibration tool and an abrasive wheel cutting machine combination, wherein the upper end face and the lower end face of the cylindrical scale are provided with four grooves in one-to-one correspondence, and the four grooves are uniformly arranged along the circumferential surface; the rock core clamp is an aluminum alloy frame body with a central hole, the central hole is a through hole which is formed by connecting an upper-layer round hole and a lower-layer round hole and is provided with a step, and the rock core clamp is provided with a notch; the diameter of the clamp calibration tool is equal to the inner diameter of the cylindrical scale, the height of the clamp calibration tool is equal to the height of the cylindrical scale, a cross-shaped arc-shaped groove is formed in the center of one end of the aluminum alloy cylinder and matched with the edge of the grinding wheel, and the aluminum alloy cylinder can be exactly placed in the upper-layer round hole of the rock core clamp; and the width of the arc-shaped groove is equal to the thickness of the grinding wheel. The rock core grooving position can be accurately determined, and the rock core cutting process is stable.

Owner:NORTHEAST GASOLINEEUM UNIV

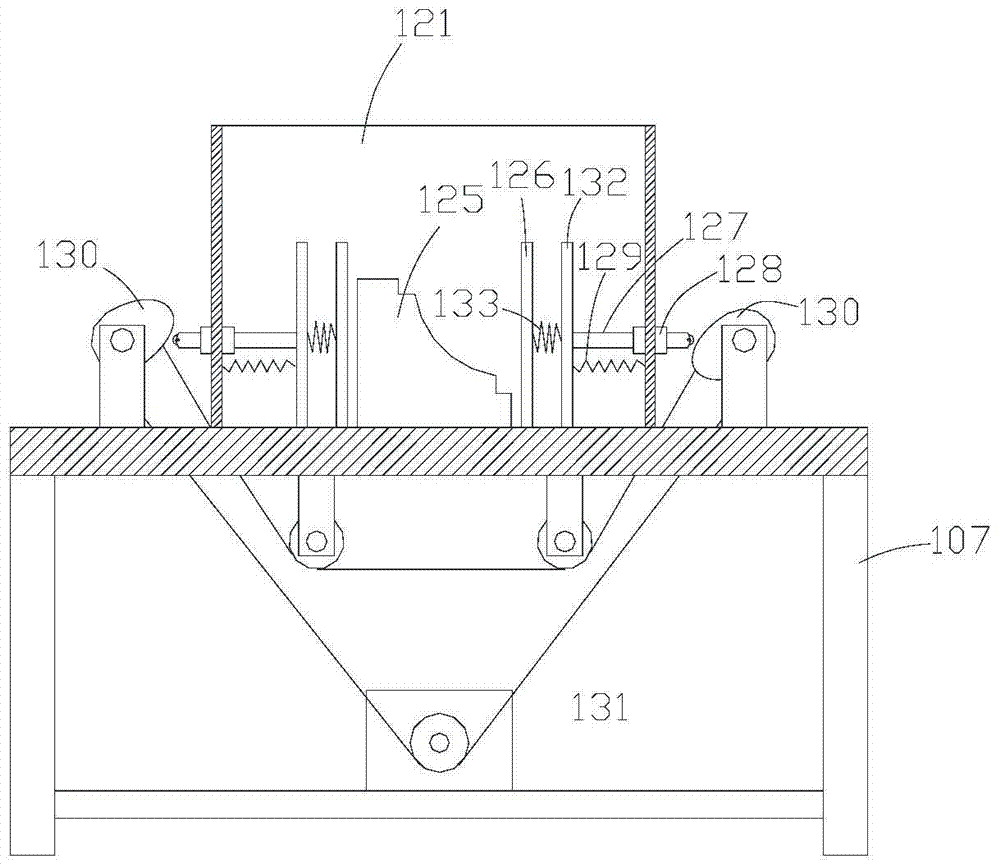

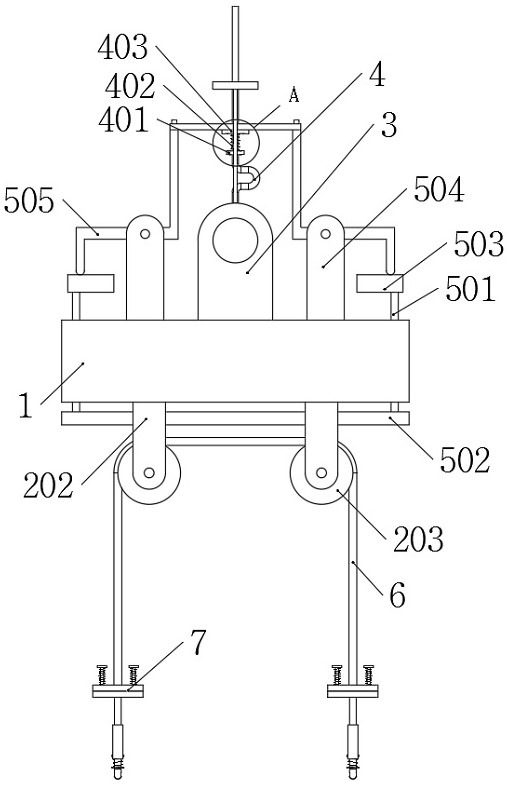

Intelligent auxiliary locating indicating car for engineering machinery assembling

ActiveCN104589046AAccurate and quick installationAvoid observationMetal working apparatusControl engineeringRolling chassis

The invention relates to an intelligent auxiliary locating indicating car for engineering machinery assembling. The intelligent auxiliary locating indicating car comprises a stretching pressing locating frame, a sensing arm telescopic frame and a moving direction indicating screen. The sensing arm telescopic frame is fixedly connected to the upper end of the stretching pressing locating frame. The moving direction indicating screen is arranged above the sensing arm telescopic frame in a covering mode. The stretching pressing locating frame comprises a base plate. Supporting legs are fixed at the lower end of the base plate. Universal balls are arranged at the lower ends of the supporting legs. An oil cylinder is fixedly arranged in the middle of the upper end face of the base plate. The sensing arm telescopic frame comprises a top plate. The moving direction indicating screen comprises an upper cover. A displaying screen and a keyboard are arranged on the upper end face of the upper cover. Manpower is replaced for detecting the up-load position of engineering machinery, direction guidance is provided for lifting assembling personnel, the problem that assembling personnel observe the position, relative to an engineering machinery bottom disc, of an up-load part of the engineering machinery beside the engineering machinery is avoided, manpower is reduced, the safety coefficient of the assembling personnel is improved, and working efficiency is improved.

Owner:WUHU YINXING AUTO PARTS

SCR rotational flow mixing pipe

ActiveCN112627951AGuaranteed uniformity of distributionGuaranteed to be centeredInternal combustion piston enginesExhaust apparatusEngineeringMechanical engineering

The invention relates to an SCR rotational flow mixing pipe, and belongs to the technical field of engine aftertreatment. The invention aims to solve the problems of non-uniform distribution after urea is sprayed into a mixing pipe, low urea decomposition rate, high crystallization risk caused by urea spray wall contact in the mixing pipe, and the like. According to a spiral pipe structure of the SCR rotational flow mixing pipe, turbulence can be formed in the mixing pipe at the rear end, so that the decomposition rate of the urea in the mixing pipe is increased, and the urea crystallization risk is reduced. Meanwhile, rotating airflow generated by the spiral pipe structure can form a large amount of rotating airflow around the inner wall of the mixing pipe, and the urea solution sprayed to the inner wall of the mixing pipe is carried away, so that the urea crystallization risk is further reduced; and urea spraying points of the SCR rotational flow mixing pipe are arranged in the middle, so that the distribution uniformity of the urea in the mixing pipe can be improved, and finally the NOX conversion efficiency of an SCR system is improved. The urea spraying points are arranged in the middle to be matched with the mixing pipe with the rear end increasing the pipe diameter, so that the urea solution can be effectively prevented from contacting the wall, and the urea crystallization risk is reduced.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Scalpel for circularly and continuously resecting anterior capsules of lenses

The invention discloses a scalpel for circularly and continuously resecting anterior capsules of lenses, which is characterized by comprising a hollow handle, wherein the front end of the handle is a tool bit which inclines outwards; a memory alloy strip which is capable of extending out of the mouth of the tool bit to form a circular track is stored in the tool bit; one end of the memory alloy strip is fixedly connected to the outer side of the mouth of the tool bit and extends from the inner side of the mouth of the tool bit towards the rear end of the handle after being bent; a sliding cutter with a blade is sheathed at the bent part; two sections of traction wires are connected onto the sliding cutter; one section is wound on a pulley which is fixedly connected to the outer side of the mouth of the tool bit while the other section is clamped in a groove at the outer side of the memory alloy strip and then extends towards the rear end of the handle; and when the memory alloy strip stored in the tool bit extends out of the mouth of the tool bit to form the circular track, the sliding cutter sheathed thereon is just located at the outer side of the mouth of the tool bit and then the sliding cutter can be driven to carry out continuous and stable circumferential movement from the outer side of the mouth of the tool bit to the inner side or from the inner side to the outer side along the circular track by contracting or releasing the tractions wires from the rear end of the handle.

Owner:西安市第四医院

A foam line scraping device

InactiveCN105328786BGuaranteed to be centeredSimple structureSurface layering apparatusLinear motionEngineering

The invention provides a foam line starching device, belonging to the field of production equipment of architectural decoration lines. The foam line starching device comprises a workbench, a positioning guide device and a scraping device, wherein the workbench is provided with a horizontal working surface; the positioning guide device comprises a vertical extrusion mechanism, a positioning plate and a transverse extrusion mechanism, the vertical extrusion mechanism is used for pressing a foam line on the workbench, and the positioning plate and the transverse extrusion mechanism are used for extruding the foam line from the two sides; the positioning guide device can enable the foam lines to keep linear motion, and the thickness of coated mortar is uniform; the scraping device comprises a mortar groove and a material pressing mechanism, the mortar groove is used for coating mortar on the surface of the foam line, and the material pressing mechanism is used for compacting the mortar coated on the surface of the foam line. When passing through the mortar groove, the foam line orderly passes through a feeding inlet, a feeding outlet and a material pressing outlet of which the sizes are orderly increased; after the foam line passes through the feeding outlet, the surface of the foam line is coated with thick mortar; after the foam line is extruded by the material pressing mechanism, the mortar on the two sides of the foam line becomes thinner and more compact and is not easy to fall off.

Owner:广州市卓基新材料科技有限公司

An intelligent auxiliary positioning and indicating vehicle for construction machinery assembly

ActiveCN104589046BAccurate and quick installationAvoid observationMetal working apparatusControl engineeringRolling chassis

The invention relates to an intelligent auxiliary locating indicating car for engineering machinery assembling. The intelligent auxiliary locating indicating car comprises a stretching pressing locating frame, a sensing arm telescopic frame and a moving direction indicating screen. The sensing arm telescopic frame is fixedly connected to the upper end of the stretching pressing locating frame. The moving direction indicating screen is arranged above the sensing arm telescopic frame in a covering mode. The stretching pressing locating frame comprises a base plate. Supporting legs are fixed at the lower end of the base plate. Universal balls are arranged at the lower ends of the supporting legs. An oil cylinder is fixedly arranged in the middle of the upper end face of the base plate. The sensing arm telescopic frame comprises a top plate. The moving direction indicating screen comprises an upper cover. A displaying screen and a keyboard are arranged on the upper end face of the upper cover. Manpower is replaced for detecting the up-load position of engineering machinery, direction guidance is provided for lifting assembling personnel, the problem that assembling personnel observe the position, relative to an engineering machinery bottom disc, of an up-load part of the engineering machinery beside the engineering machinery is avoided, manpower is reduced, the safety coefficient of the assembling personnel is improved, and working efficiency is improved.

Owner:WUHU YINXING AUTO PARTS

Horizontal well automatic anchor release hydraulic righting device

PendingCN110259392AReduced risk of getting stuckGuaranteed to be centeredDrilling rodsFluid removalUpper jointEngineering

The invention discloses a horizontal well automatic anchor release hydraulic righting device, which comprises a front joint, a center pipe, a piston pipe, a rear joint and a righting sleeve. The front end of the righting sleeve slidably sleeves the rear end of the upper joint, and the rear end of the righting sleeve slidably sleeves the front end of the piston pipe; a plurality of through holes are formed in the surface of the righting sleeve, and a plurality balls are assembled between the inner side of the righting sleeve and the center pipe; and the diameter of the balls is larger than the aperture of the through holes, and the ball surface of each ball can stretch out from the corresponding through hole. The horizontal well automatic anchor release hydraulic righting device can keep the small diameter under the normal state, supporting righting is conducted only during setting of a string, passive righting is achieved, during pulling of the string, automatic anchor release recovery can be conducted when the internal high pressure disappears or the external pressure is high, and the jamming risk of the string can further be reduced while it is ensured that the down-hole string is centered.

Owner:PETROCHINA CO LTD

Automatic clear-up packing machine

InactiveCN105398596AAvoid damageGuaranteed to be centeredRod-shaped articlesProduction lineEngineering

The invention provides an automatic clear-up packing machine. The automatic clear-up packing machine comprises a conveyor belt; the conveyor belt is sequentially provided with a first automatic separating device, a second automatic separating device, a third automatic separating device and a shaping mechanism from left to right; a blanking device is arranged on the conveyor belt, and the right side of the blanking device is provided with a clapboard which is connected with a telescoping rod; one end of a machine shell is connected with the conveyor belt, and the other end of the machine shell is connected with a slide rail, the bottom of the slide rail is provided with a baling box, and the bottom of the baling box is provided with a weighing machine. The automatic clear-up packing machine has the beneficial effects that the clear-up efficiency is high, and the labor intensity of workers is reduced, so that the production efficiency of a production line is improved; the automatic clear-up packing machine is suitable for continuous production.

Owner:TIANJIN MINGTANG ENVIRONMENTAL PROTECTION TECH

Hoisting equipment for green building assembly type prefabricated wall panel

InactiveCN114436115AAvoid breakingLatch implementationLoad-engaging elementsWall plateGreen building

The invention provides hoisting equipment for a green building assembly type prefabricated wallboard, and relates to the technical field of hoisting devices, the hoisting equipment comprises a seat body, a connecting part, an auxiliary part and a hanging part; a connecting seat A is mounted on the seat body; two rotating seats A are welded to the bottom of the connecting seat A, and each rotating seat A is rotationally connected with a rolling wheel. Each sliding block is slidably connected with two sliding rods B, the tail ends of the two sliding rods B on the left side and the tail ends of the two sliding rods B on the right side are each in threaded connection with a connecting block, and the bottom end faces of the two connecting blocks are each provided with a hook in a welded mode. Each sliding rod B is sleeved with an elastic piece B, and the elastic pieces B form a buffering structure of the hook, so that stress fracture of the hook during hanging can be prevented, and the problems that firstly, automatic locking of the hook cannot be achieved, and safety is low are solved; and secondly, automatic adjustment of the steel wire rope cannot be achieved during hoisting, and automatic locking of the steel wire rope after adjustment is achieved.

Owner:代利峰

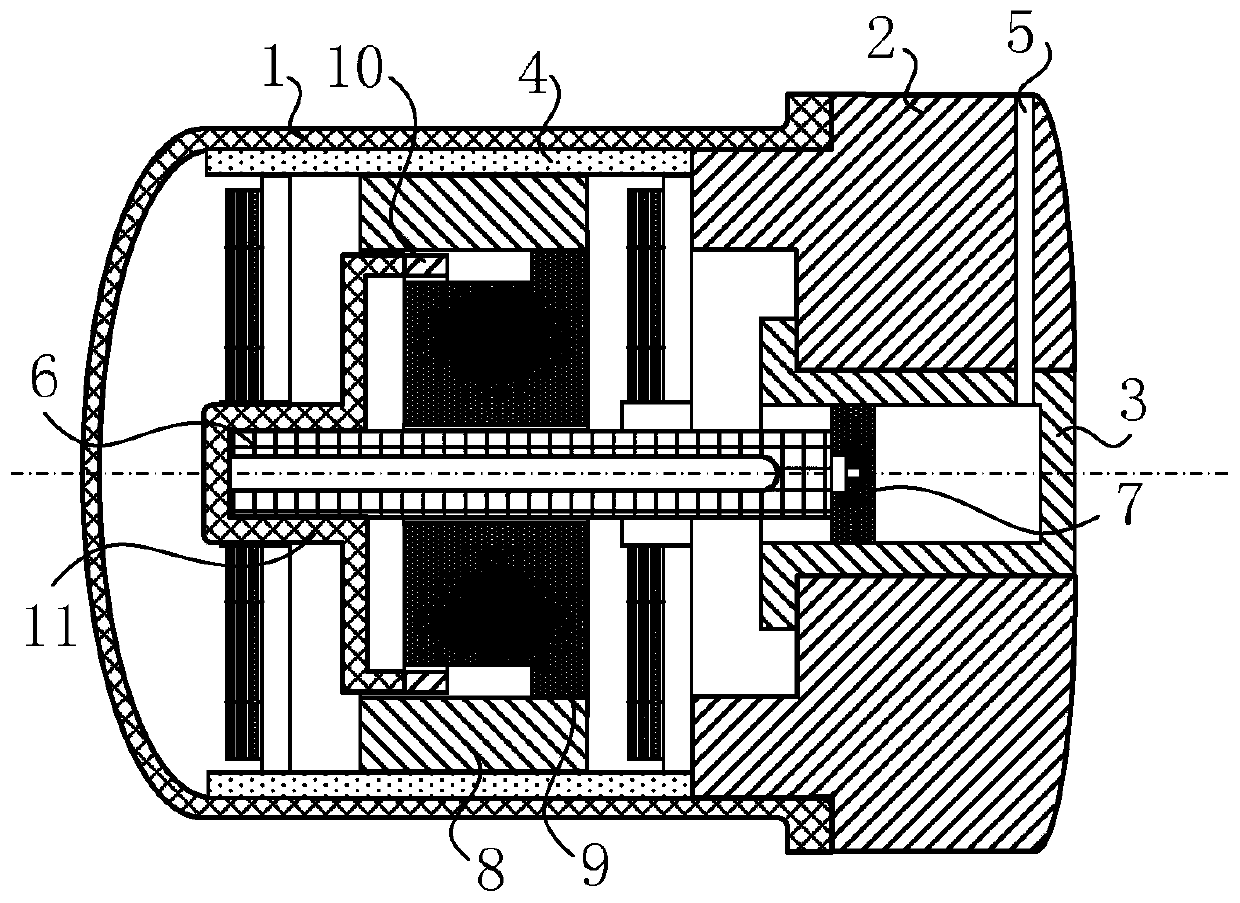

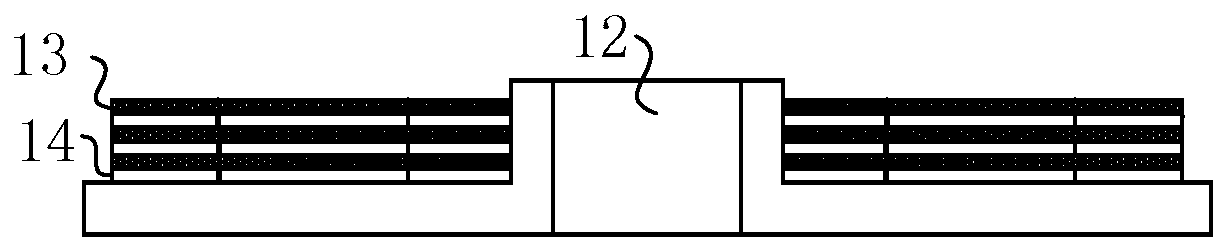

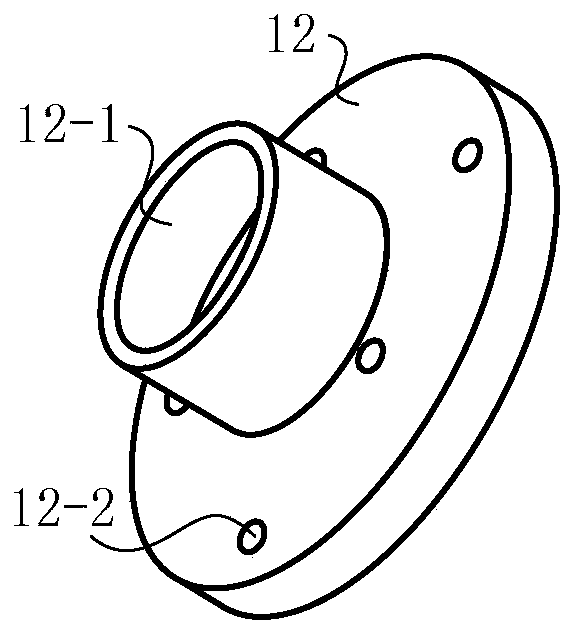

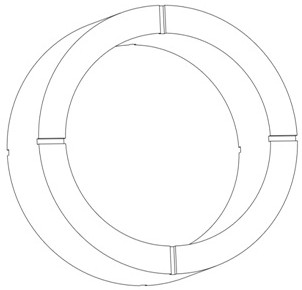

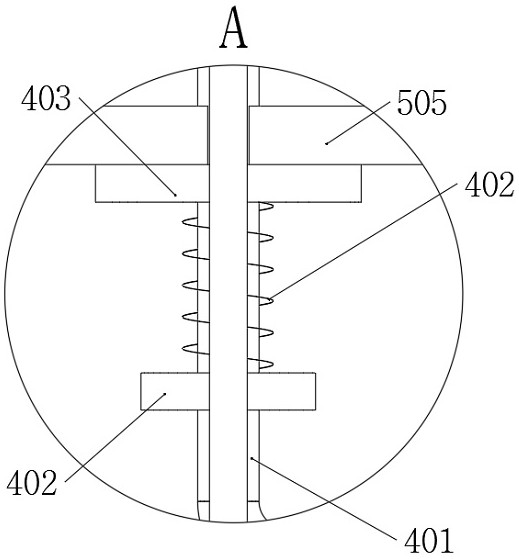

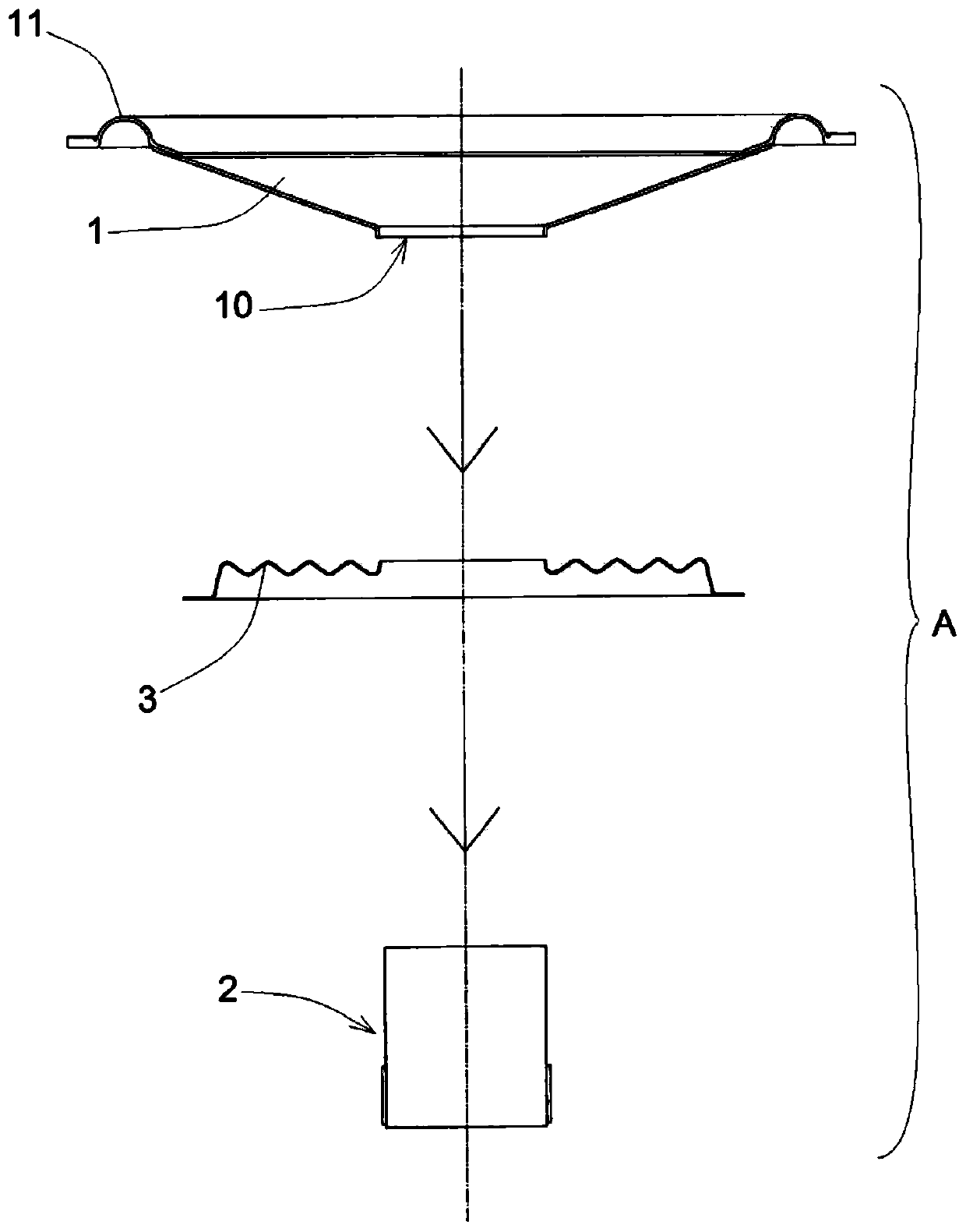

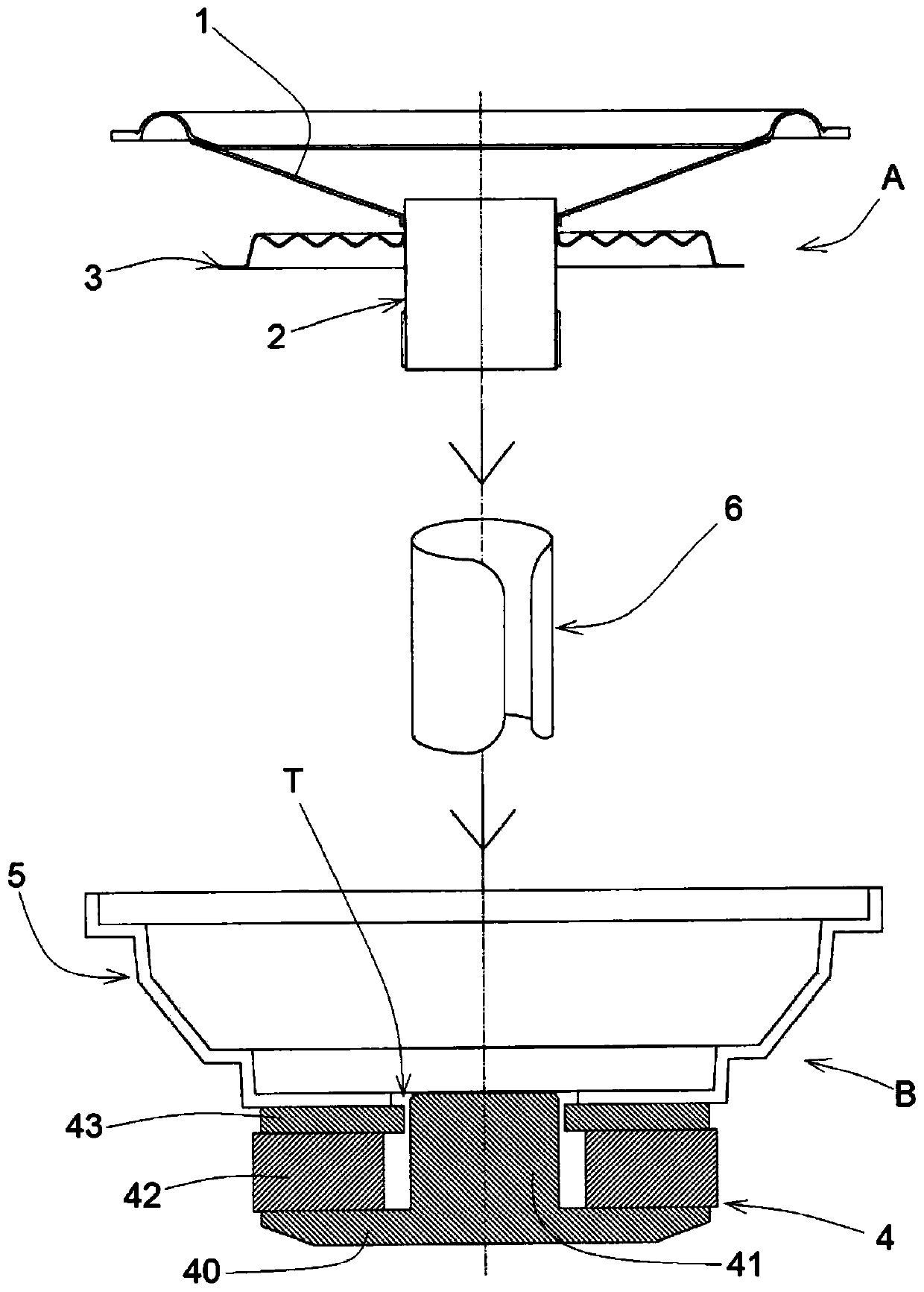

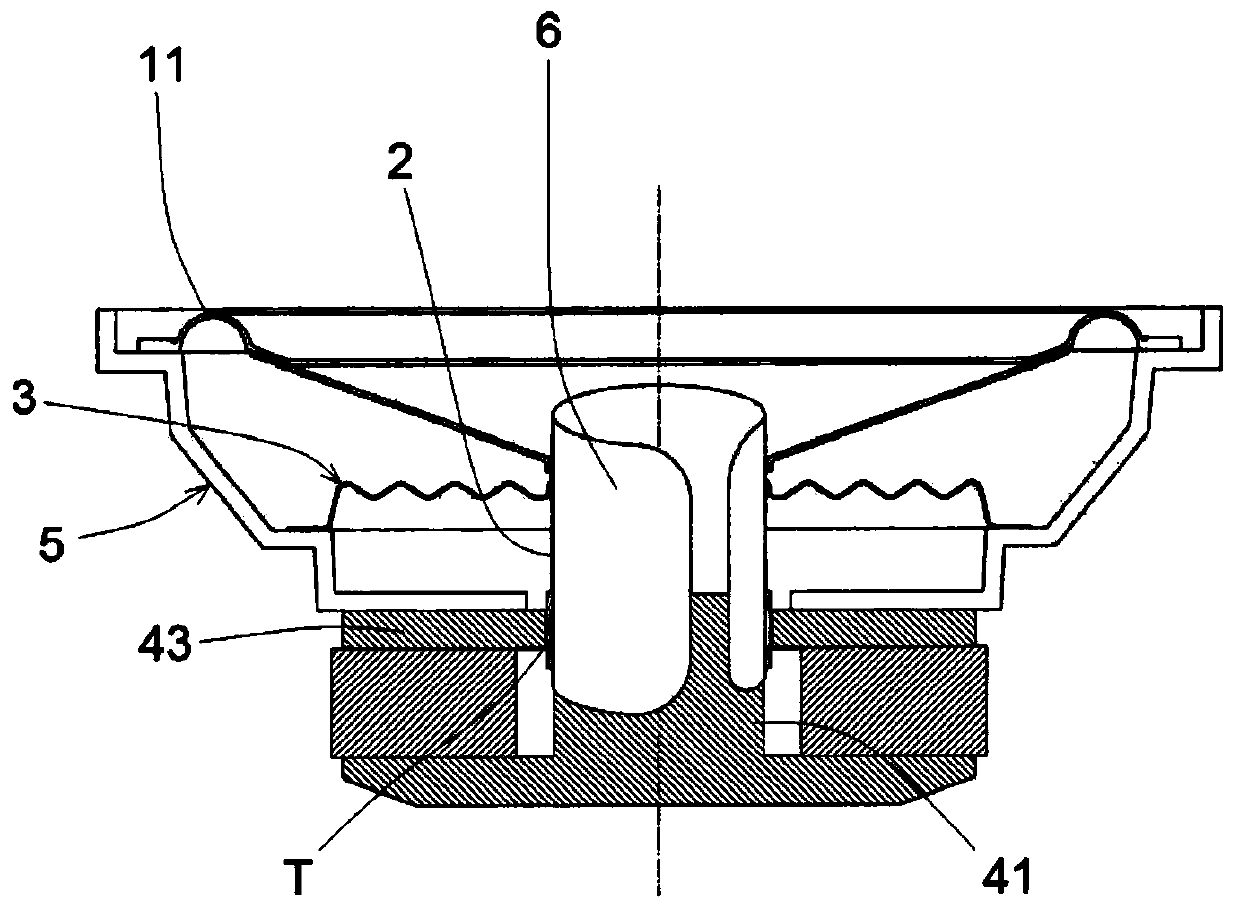

Loudspeaker with closed membrane and relative assembly method

ActiveCN109951771AGuaranteed to be centeredLoudspeakersDiaphragm mounting/tensioningLoudspeakerEngineering

An assembly method of a loudspeaker with a closed membrane comprises pre-assembling a mobile unit (A) comprising two centering devices fixed to a voice coil; pre-assembling a fixed unit (B) that comprises a basket (5) fixed to a magnetic unit (4), assembling the mobile unit in the fixed unit, by means of a centering device (6); extracting the centering device (6) and fixing a closed membrane (100)to the voice coil and to the basket (5).

Owner:ASK IND SPA

Camera viewing angle adjustment method and device

ActiveCN105635573BGuaranteed to be centeredAvoid multiple adjustmentsTelevision system detailsColor television detailsImaging processingReference image

The present disclosure relates to a camera viewing angle adjustment method and device, and belongs to the technical field of image processing. The method includes: acquiring a reference image captured within the viewing angle of the camera; graying the reference image; and calculating the gray value of each pixel on the reference line for each reference line on the reference image sum, to obtain the total gray value of the reference line, the reference line is one of the rows and columns on the reference map; according to the total gray value of each reference line, it is reminded to adjust the camera’s perspective. It solves the problem that the image obtained when the user adjusts the camera angle of view according to his own feeling still has an unreasonable composition problem; realizes that when the image composition obtained by using the camera is unreasonable, the user is reminded to adjust the camera angle of view to achieve In order to improve the effect of user experience.

Owner:XIAOMI INC

A hydraulic casing centralizer

ActiveCN108316866BSolve the problem of difficult entryLarge outer diameter of rightingDrilling rodsDrilling casingsWell cementingStructural engineering

Disclosed is a hydraulic casing centering device used for centering a casing in a well cementing and completion technology. The hydraulic casing centering device comprises a body, a driving mechanismand a centering mechanism, wherein the body is a tubular structural piece provided with a central hole and connected to the casing; the driving mechanism comprises a piston and a piston cylinder sleeve, the piston cylinder sleeve is mounted on the body in a sleeving mode and fixedly connected with the body, an accommodating cavity is formed between the piston cylinder sleeve and the body, the piston is mounted on the body and located in the accommodating cavity, the body is provided with a liquid inlet hole, and the liquid inlet hole communicates with the central hole and the accommodating cavity; and the centering mechanism is mounted on the body and comprises a centering device body and a taper sleeve, one end of the centering device body is connected with the piston, the other end of the centering device body abuts against the taper sleeve, and the taper sleeve is fixed to the body, and the centering device body can climb upwards along the outer conical surface of the taper sleeve.

Owner:STARSE ENERGY & TECH GROUP

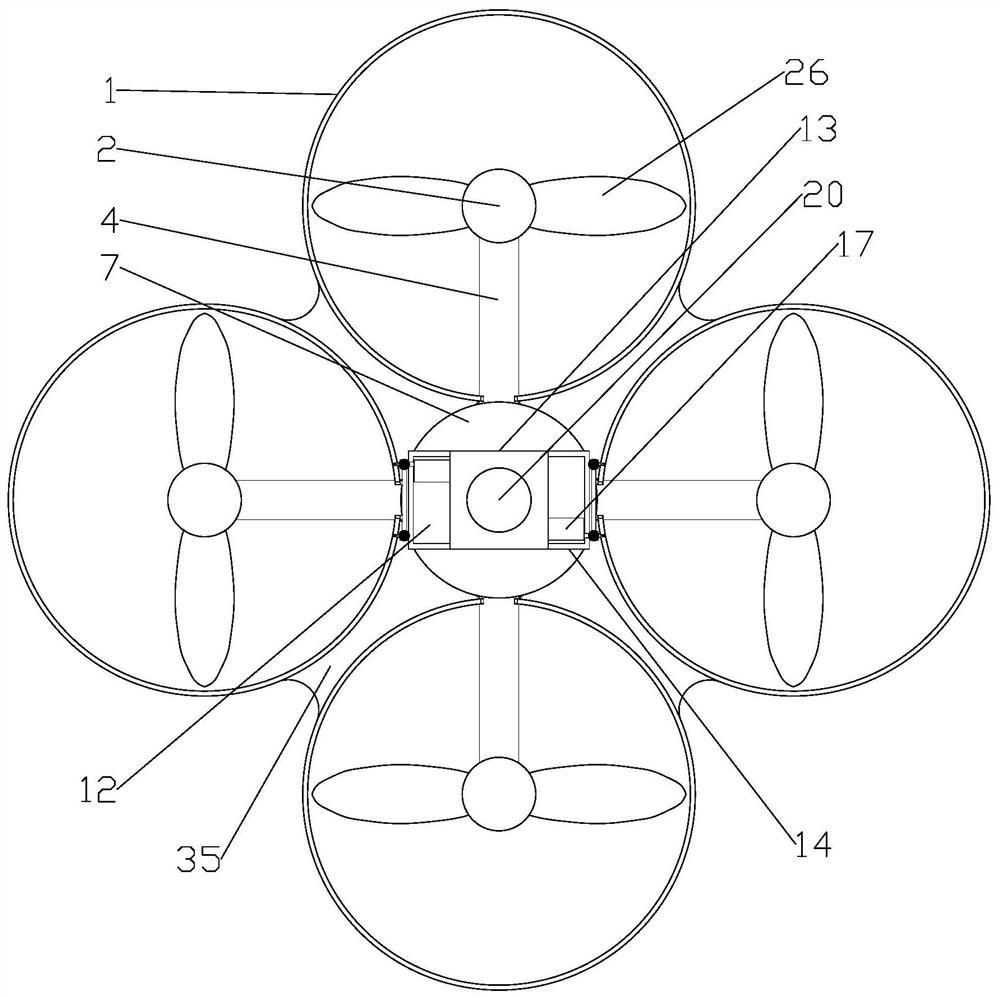

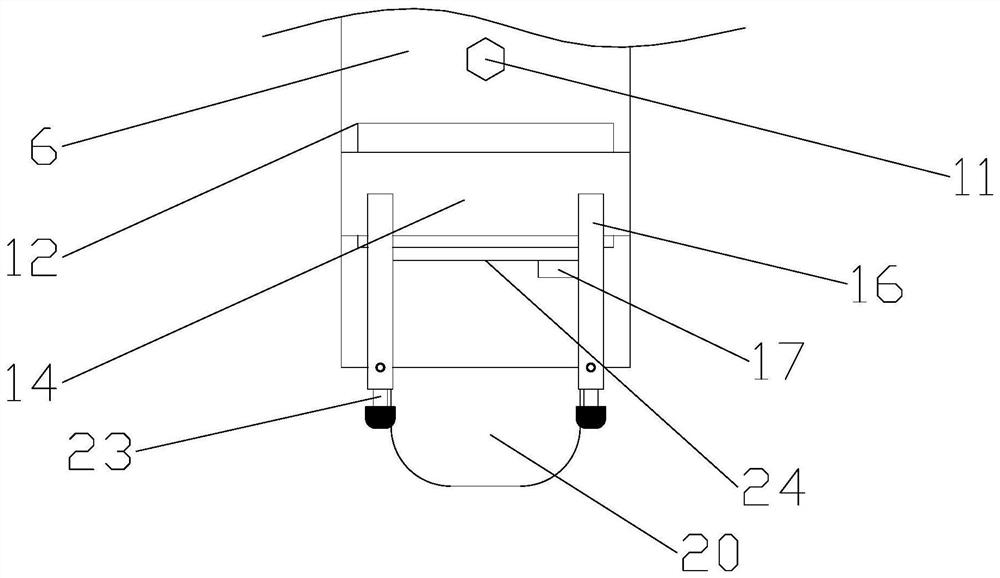

Modal switchable cross-medium environment detection platform and detection method thereof

PendingCN113173237APrevent bumping the instrumentEasy to installAircraft landing aidsUnderwater vesselsBuoyant flowAir pump

The invention discloses a modal switchable cross-medium environment detection platform and a detection method thereof. The modal switchable cross-medium environment detection platform comprises a control bin, four groups of rotor mechanisms, a floating air bag, an equipment mounting frame, a sensor mounting box, a side edge clamping mechanism, a landing supporting mechanism and a counterweight adjusting mechanism. According to the modal-switchable cross-medium environment detection platform, an air pump is used for inflating and deflating the floating air bag, so that the volume of the floating air bag is reduced and the buoyancy is greater than the gravity in the diving process, and diving is realized; the counterweight adjusting mechanism is used for releasing a counterweight after data acquisition is completed, so that the gravity is greater than the buoyancy, and floating is realized; the sensor mechanism mounting box is convenient to mount by utilizing the side edge clamping mechanism, and the sensor mechanism mounting box carrying different sensors is convenient to replace; and the landing support mechanism is linked with the counterweight adjusting mechanism, so that the landing support mechanism does not influence each sensor before data acquisition is completed, and meanwhile, the instrument is prevented from being collided during recovery and landing.

Owner:JIANGSU MARINE RESOURCES DEV RES INST LIAN YUNGANG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com