Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38 results about "Antenna fabrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

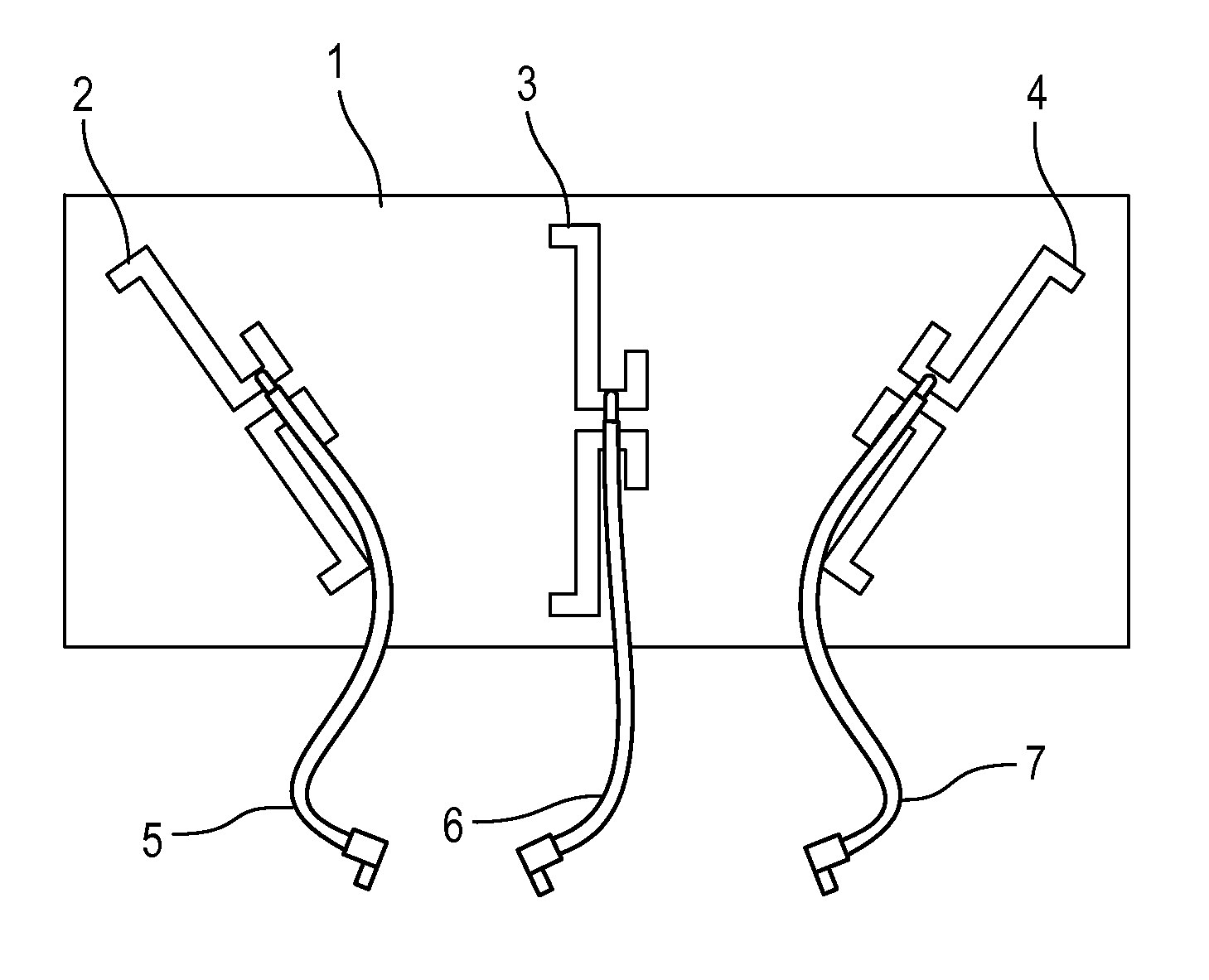

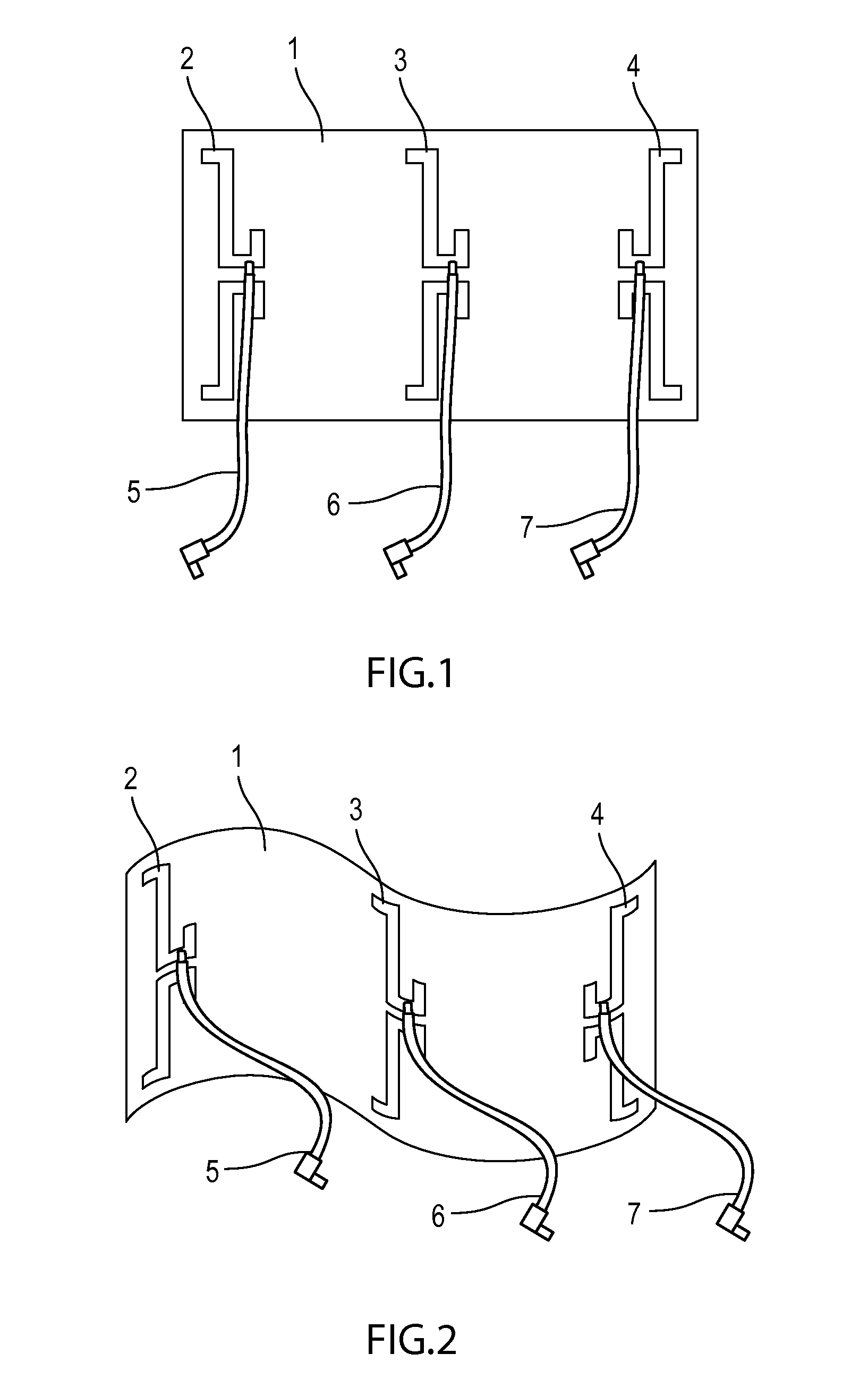

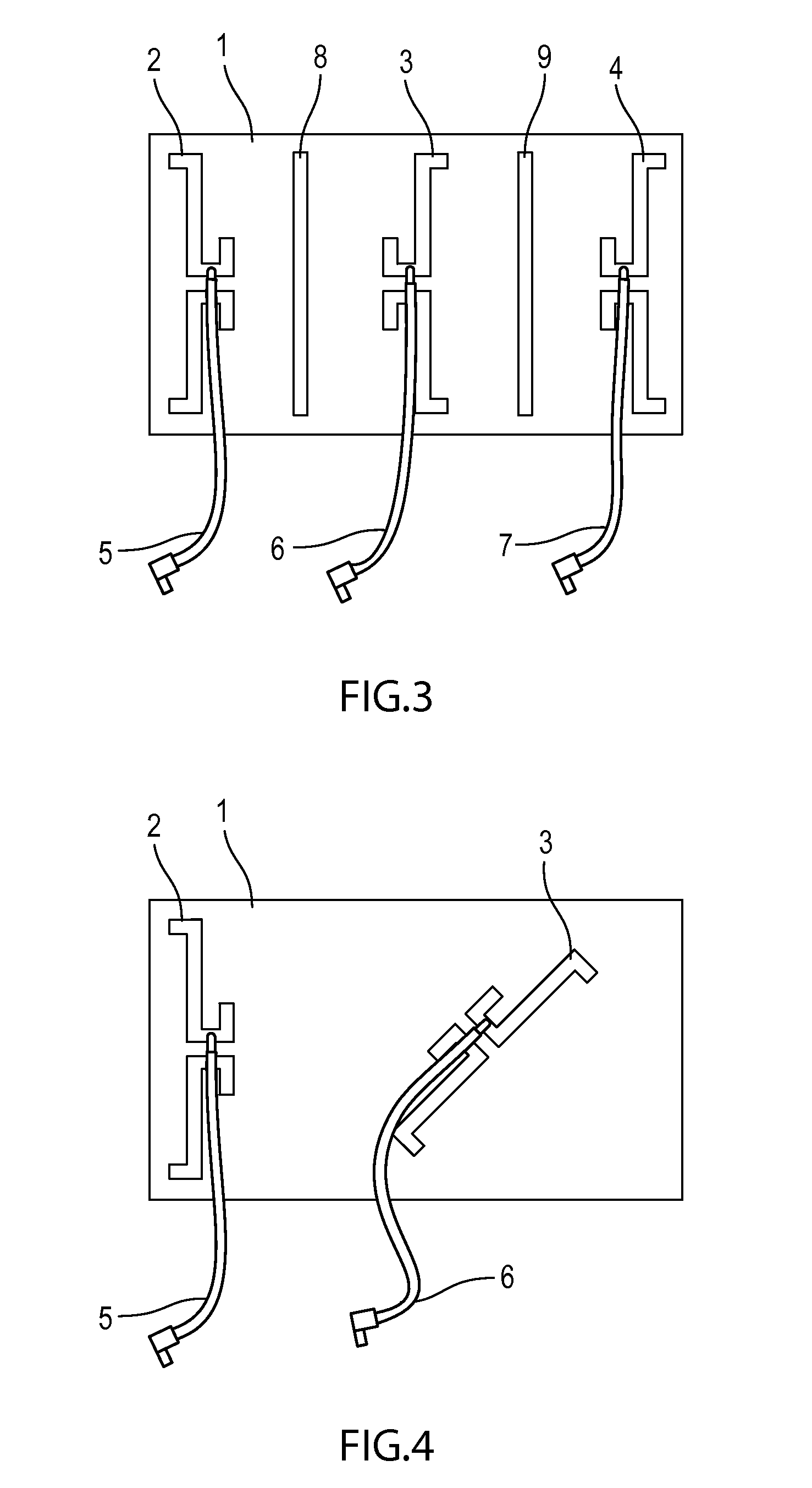

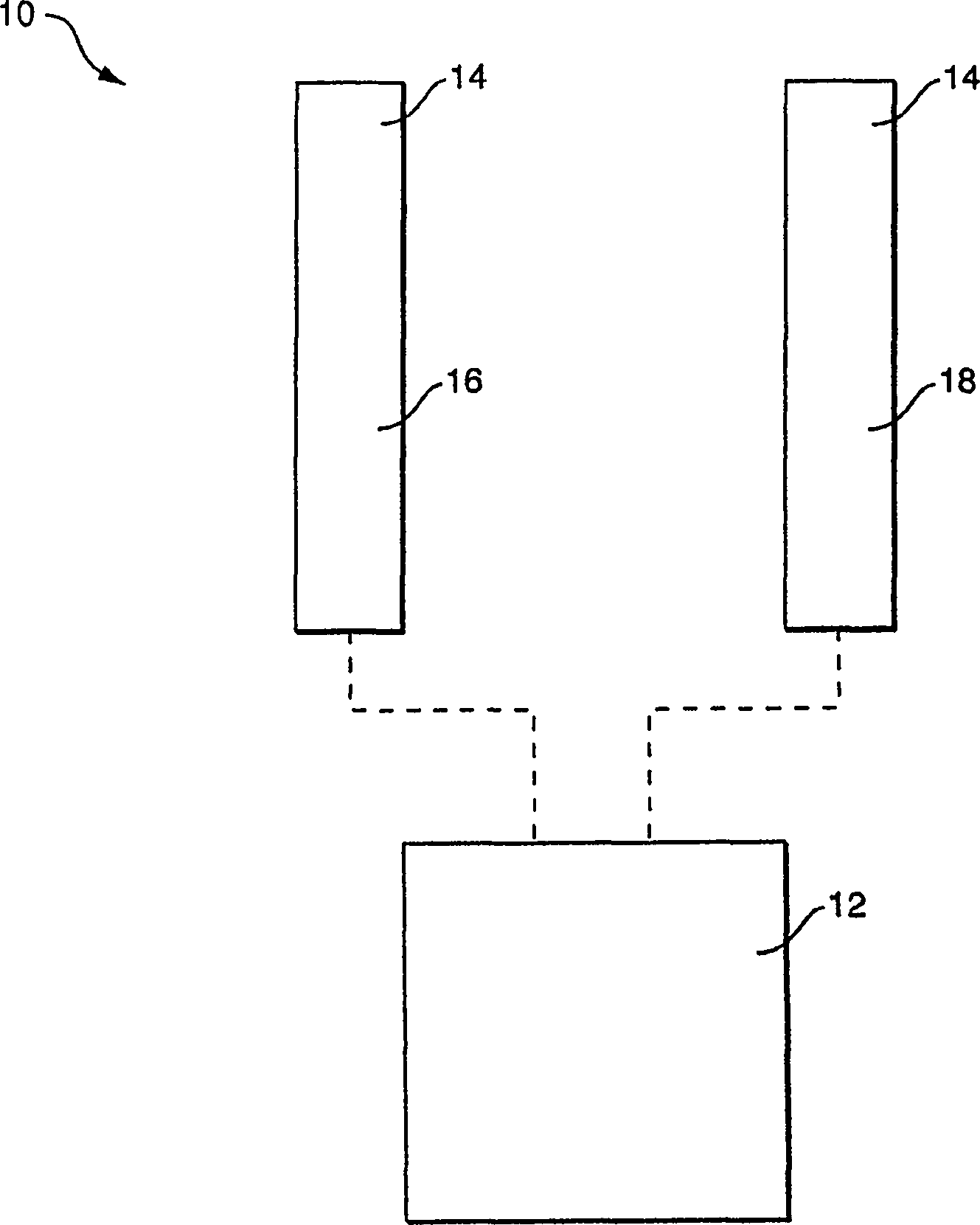

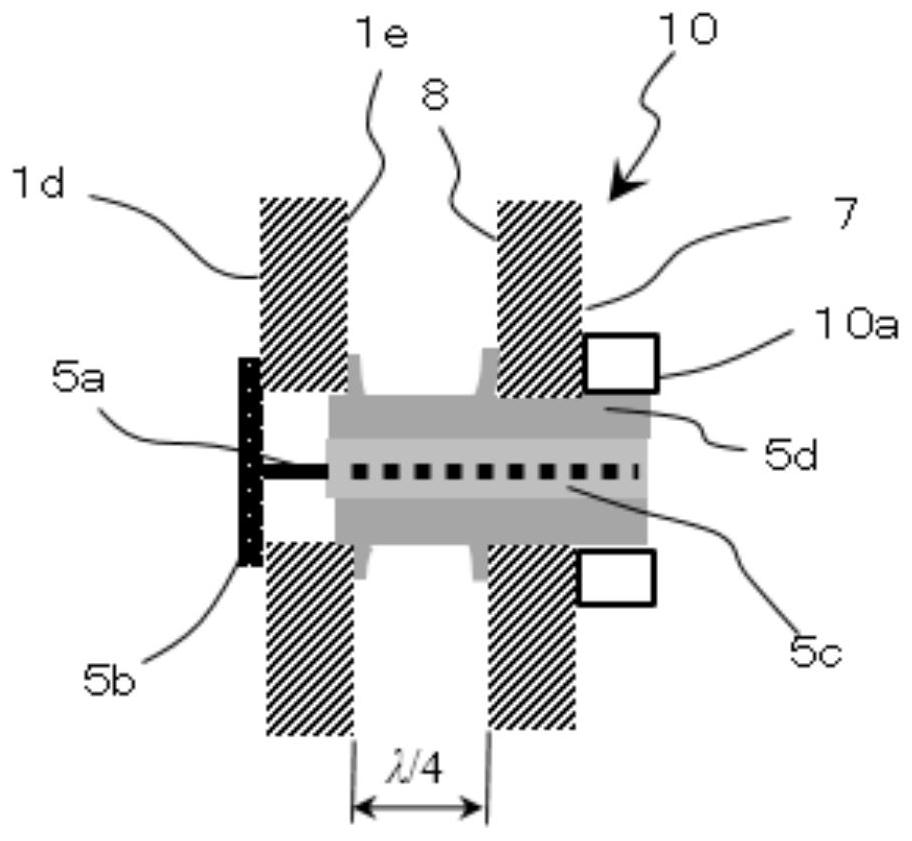

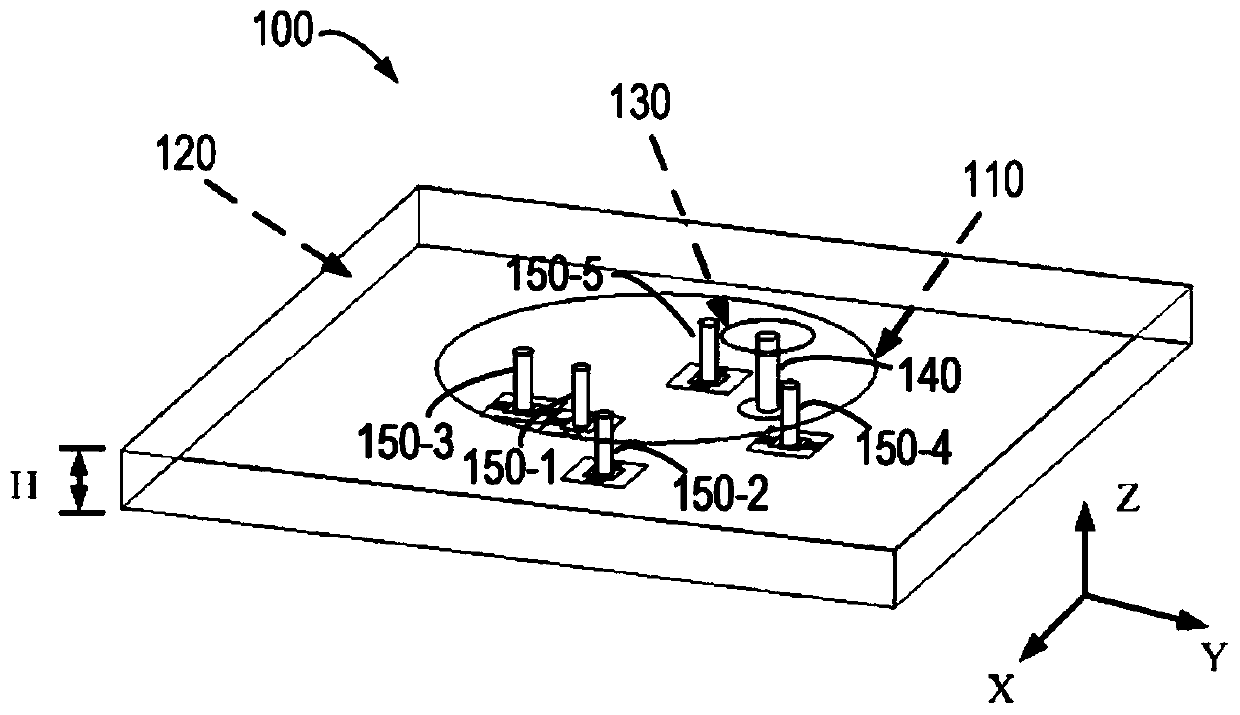

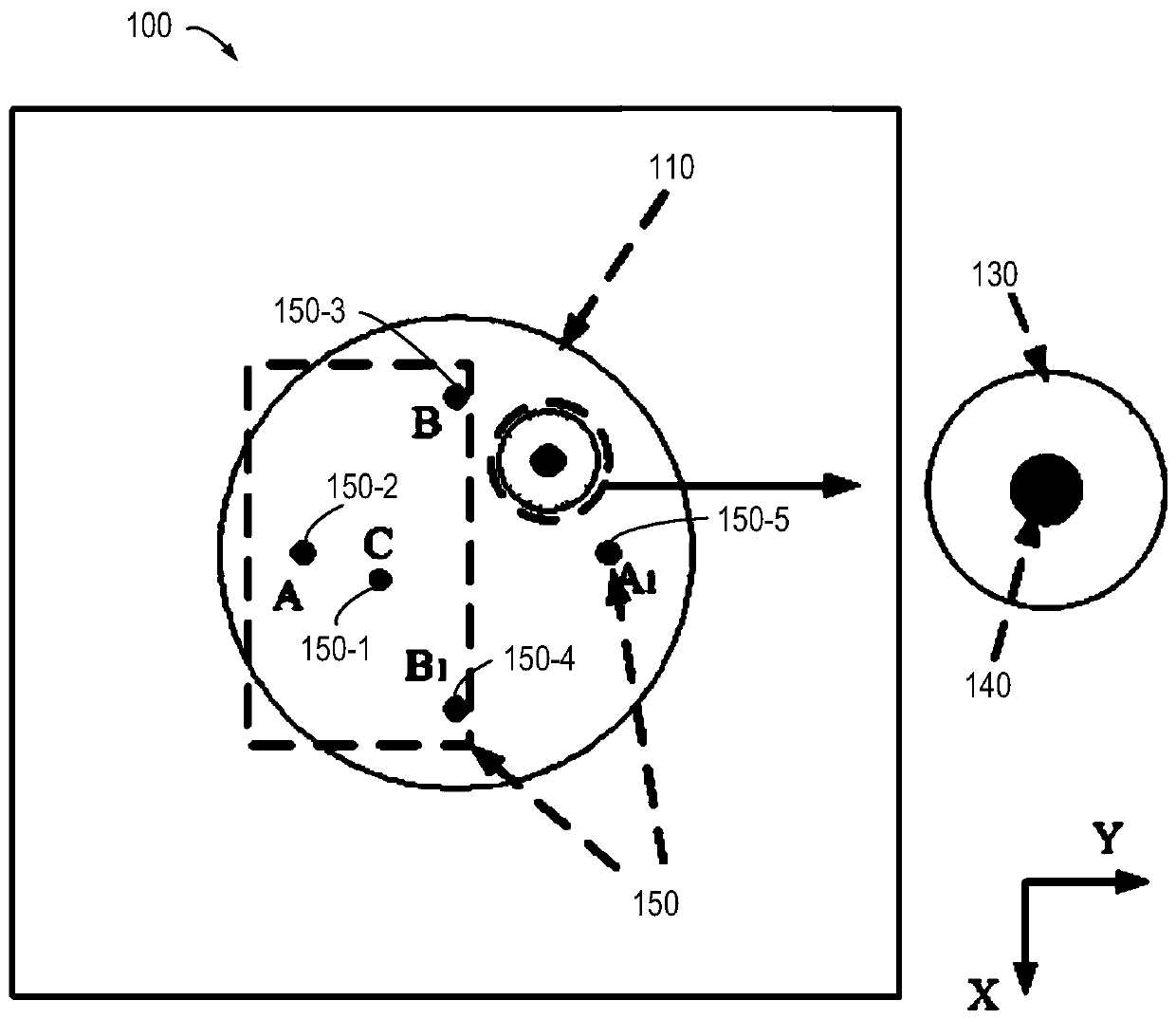

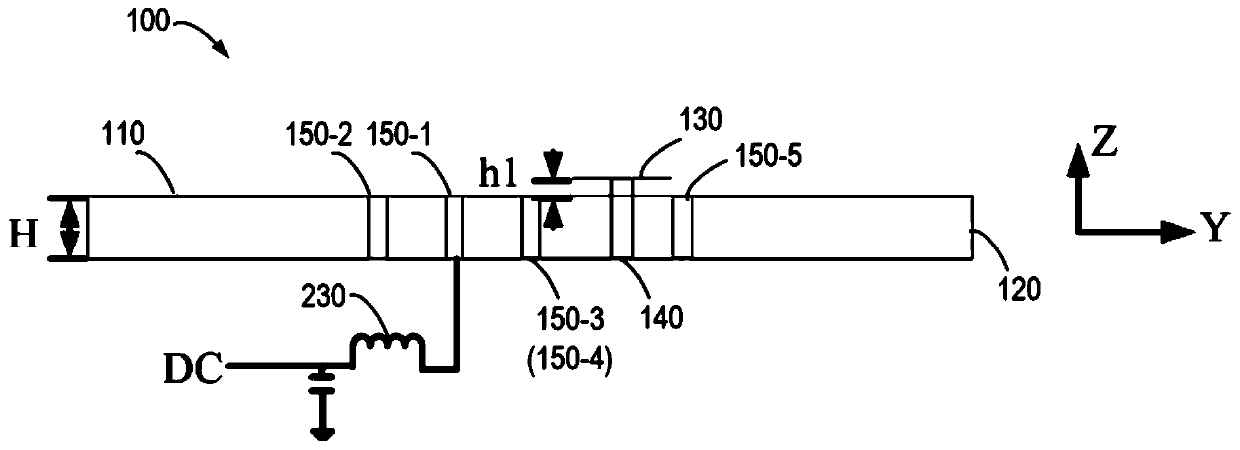

Integrated MIMO antenna system

ActiveUS20130321240A1High precisionEasy to controlThin/thick film capacitorElectrolytic capacitorsMimo antennaAntenna fabrication

An integrated MIMO antenna system is described wherein multiple antennas are fabricated on a single substrate. Antenna spacing and alignment is enhanced and controlled to a finer degree than with conventional discrete antenna fabrication techniques. Rotation of one or multiple antennas in relation to the other antennas in the system can be performed to within the accuracy of current photo-etching techniques. Metalized traces can be designed and etched on the single substrate and positioned between antenna elements to enhance inter-element isolation. The integrated MIMO antenna system can be fabricated on flexible printed circuit (FPC) material, or can be fabricated on rigid metallized substrate such as common FR4 materials. Portions of one or multiple antenna elements can be photo-etched on opposite sides of the substrate to provide an additional degree of freedom in terms of antenna placement, spacing, and rotation angle.

Owner:TAOGLAS GROUP HLDG LTD

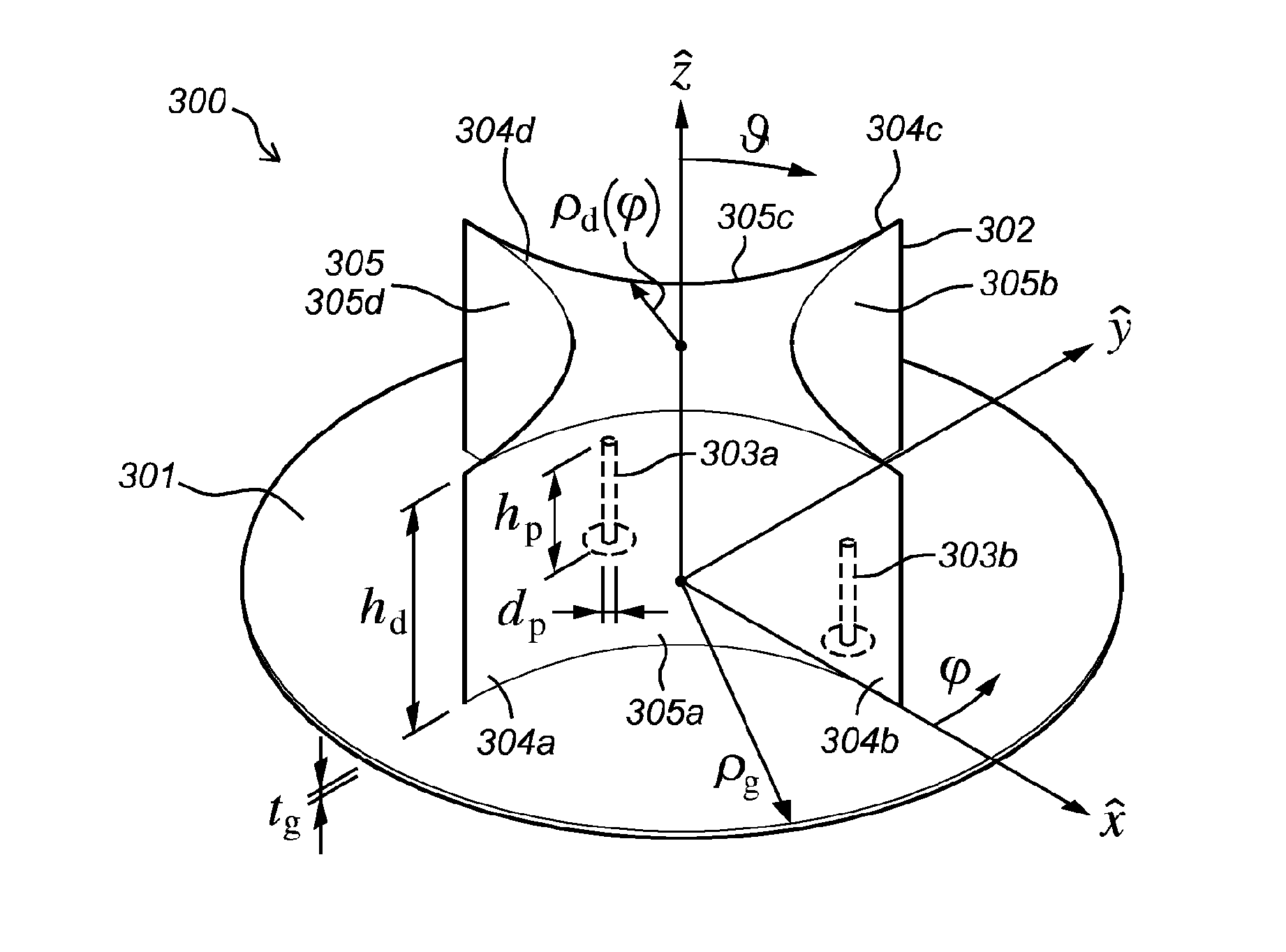

Lens Antenna, Method for Manufacturing and Using such an Antenna, and Antenna System

ActiveUS20150236428A1Increase demandEliminate the effects ofSimultaneous aerial operationsFrequency diversityTransceiverCommunication device

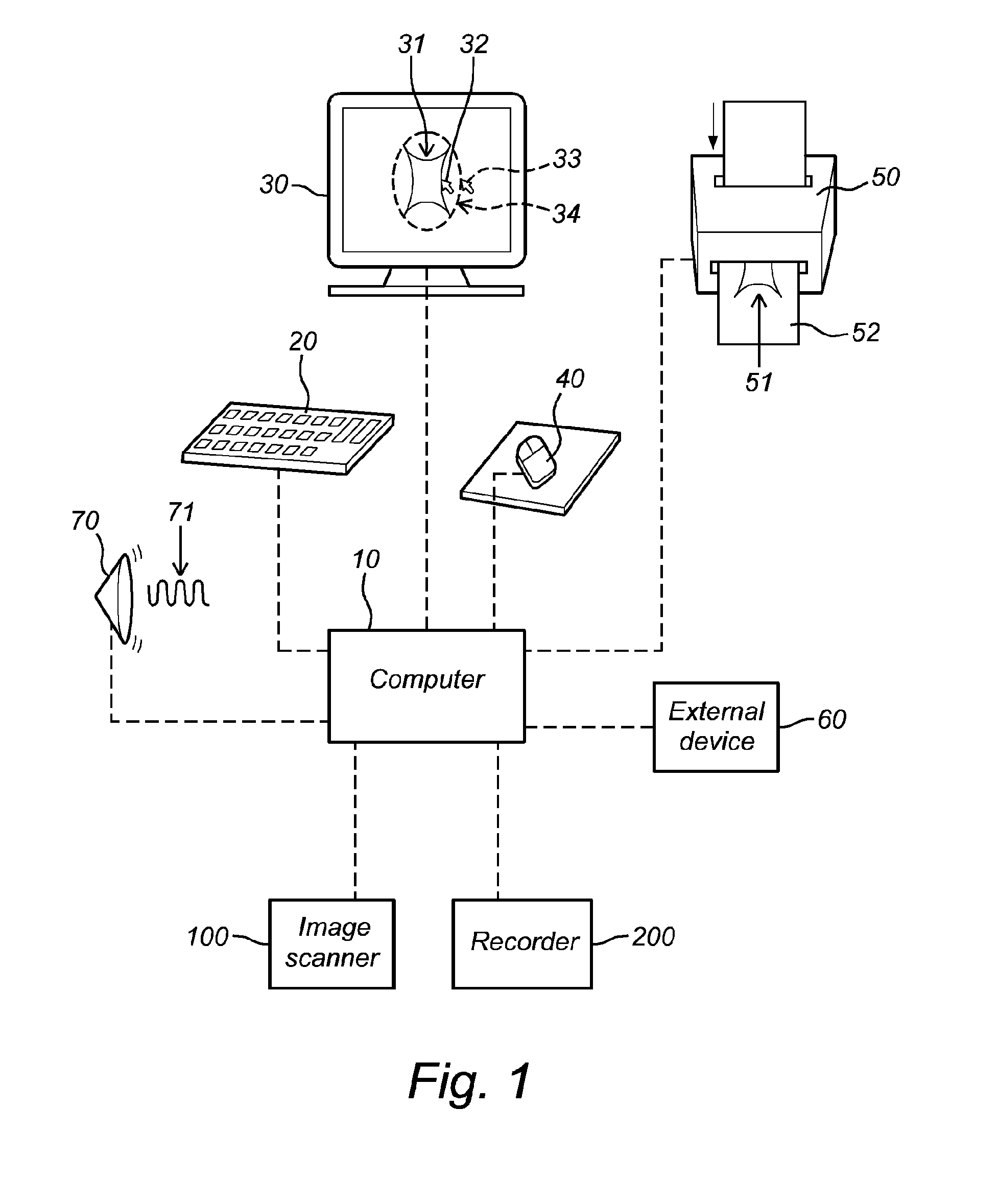

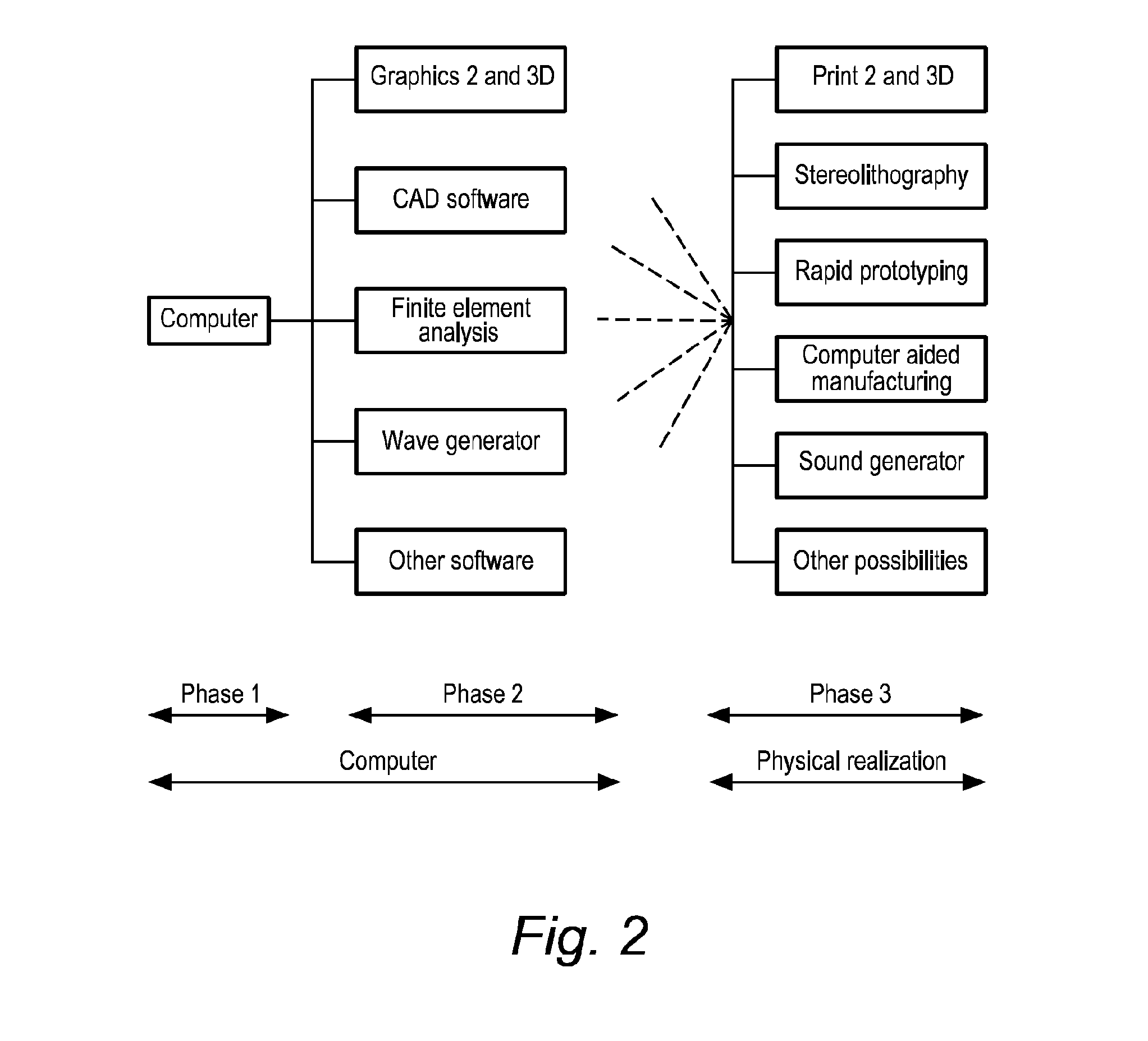

The invention relates to a lens antenna. The invention also relates to an antenna system for transmitting and receiving electromagnetic signals comprising at least one antenna according to the invention. The invention further relates to a method of manufacturing an antenna according to the invention. The invention moreover relates to a method for use in wireless communications by using an antenna according to the invention. The invention additionally relates to a RF transceiver of a wireless communications device comprising at least one antenna according to the invention. The invention further relates to an electronic device comprising an RF transceiver according to the invention.

Owner:THE ANTENNA COMPANY INT

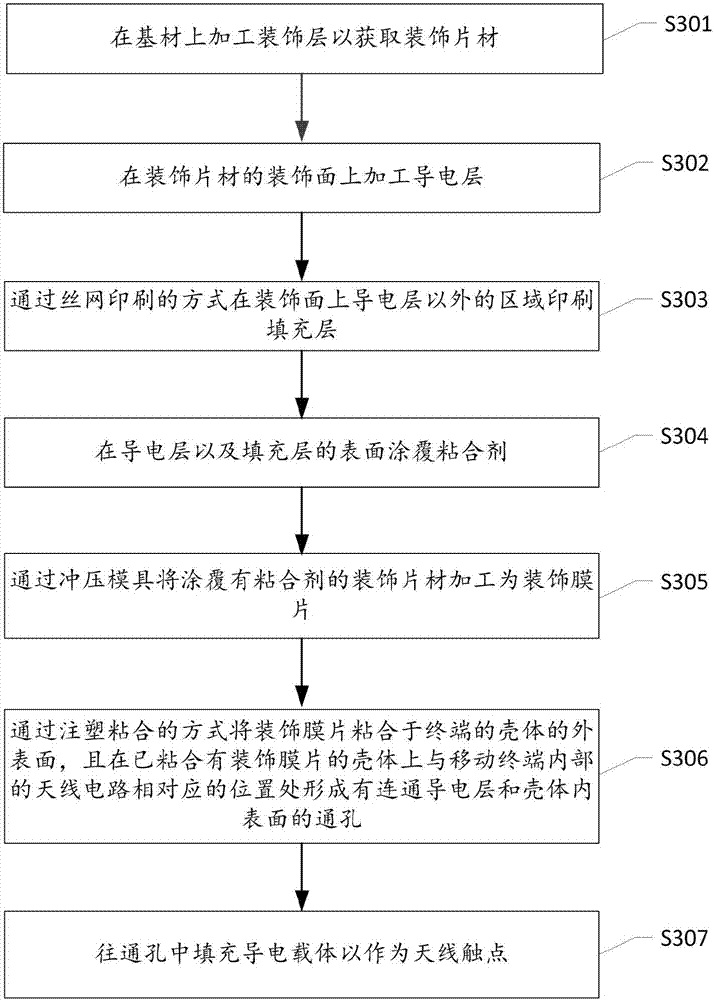

Antenna fabrication method of terminal, antenna and terminal

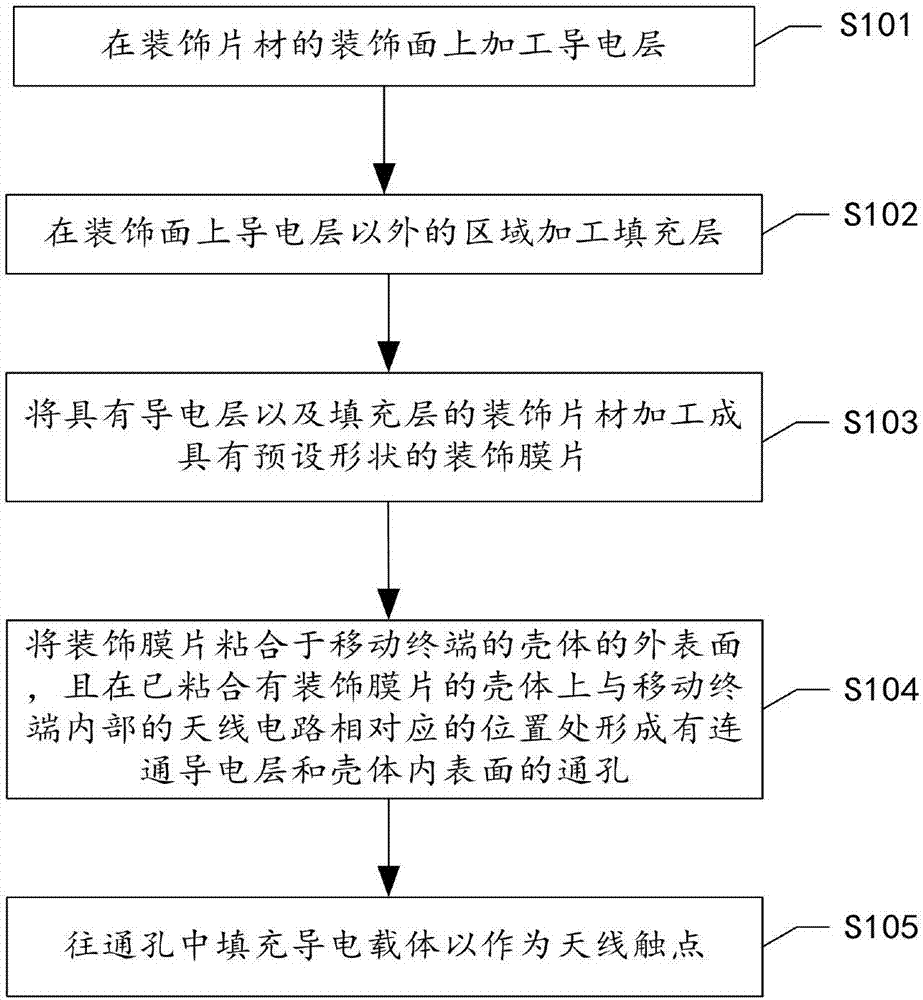

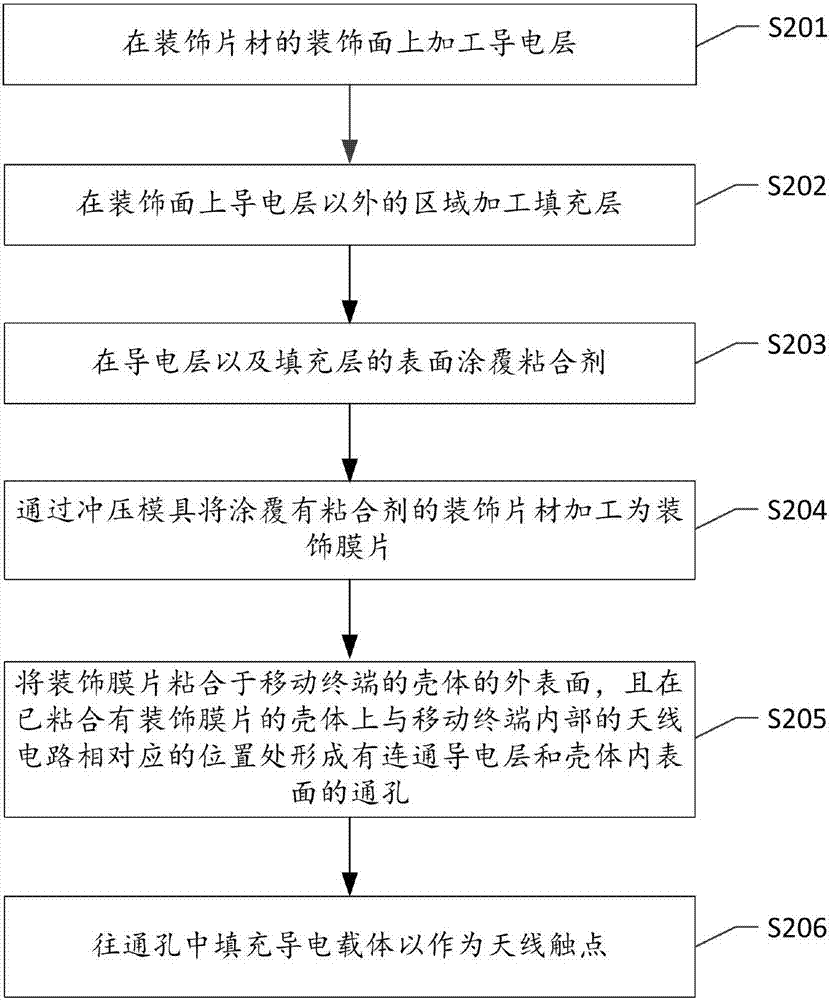

InactiveCN107146946AIncrease headroomImprove RF performanceAntenna supports/mountingsRadiating elements structural formsAntenna fabricationEngineering

The embodiment of the invention discloses an antenna fabrication method of a terminal. The antenna fabrication method comprises the steps of processing a conductive layer on decoration surface of a decoration sheet; processing filling layers on regions except the conductive layer on the decoration surface, wherein the thicknesses of the filling layers are same as the thickness of the conductive layer; processing the decoration sheet with the conductive layer and the filling layers to form a decoration membrane with a preset shape; pasting the decoration membrane on an outer surface of a shell of the terminal, wherein a through hole is formed in a position, corresponding to an antenna circuit in the terminal, on the shell pasted with the decoration membrane and is used for communicating the conductive layer and an inner surface of the shell; and filling the through hole with a conductive carrier to be used as an antenna contact.

Owner:SHENZHEN GIONEE COMM EQUIP

Antenna oscillator utilizing plastic as main material and manufacturing method of antenna oscillator

InactiveCN102904010AReduce manufacturing costLight in massRadiating elements structural formsTinningCopper coating

The invention relates to an antenna oscillator and a manufacturing method thereof and particularly relates to an antenna oscillator utilizing plastic as a main material and a manufacturing method of the antenna oscillator. The antenna oscillator is characterized in that a main body is a plastic body which is formed by injection molding and has the structure and size of the antenna oscillator; a copper coating with the thickness of 3-25mu m is electroplated on the external surface of the plastic body; and a silver coating or tin coating with the thickness of 2-20mu m is electroplated on the copper coating. The manufacturing method comprises injection molding, electroplating and welding. According to the invention, the plastic is used for replacing steel, the plastic oscillator is electroplated and welded at a low temperature, and then is installed in an antenna; in all tests, the original aluminum oscillator standards can be achieved; and the manufacturing cost and the whole mass of the antenna are greatly lowered.

Owner:NANJING HUAGE ELECTRONICS & AUTOMOBILE PLASTIC IND

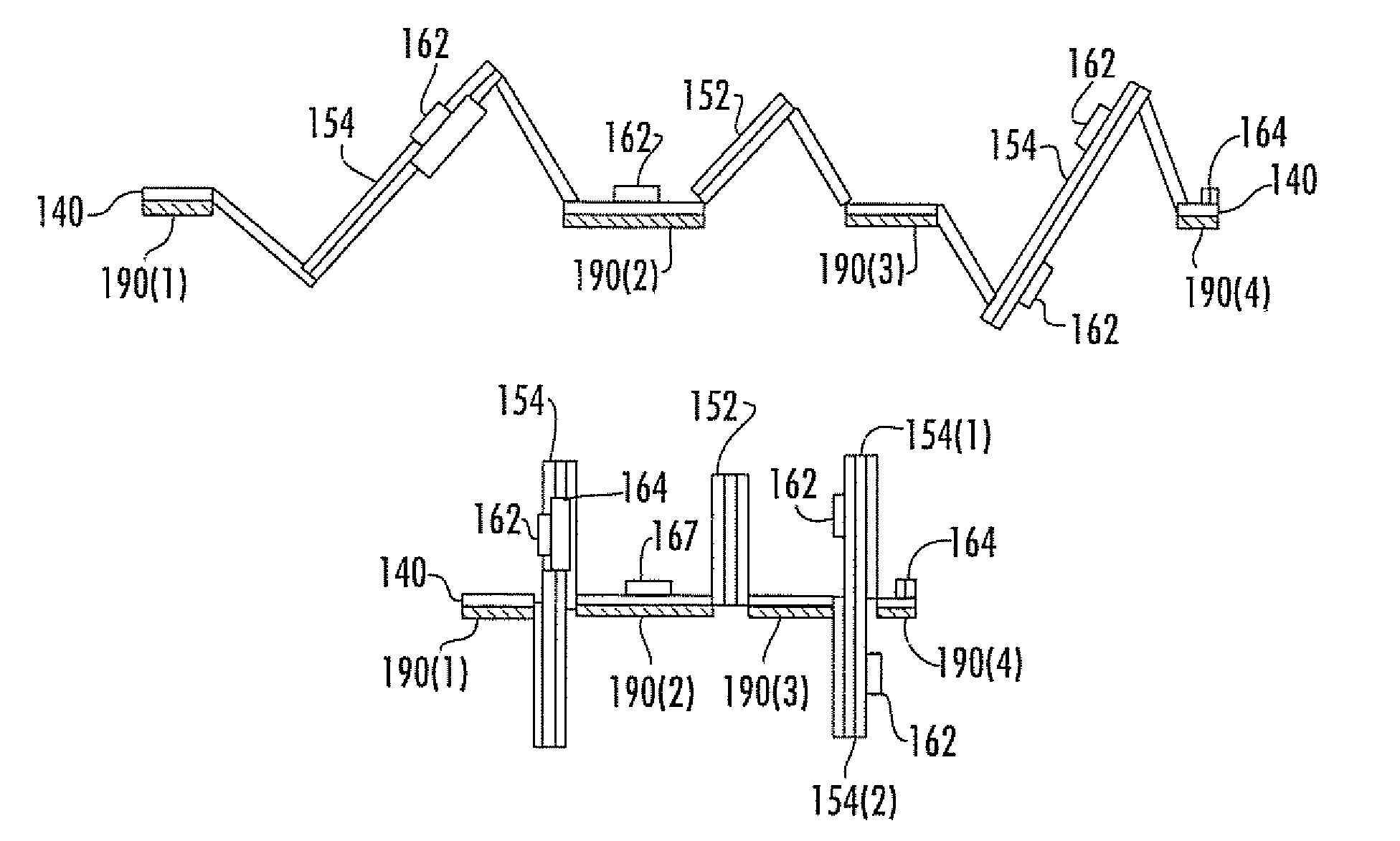

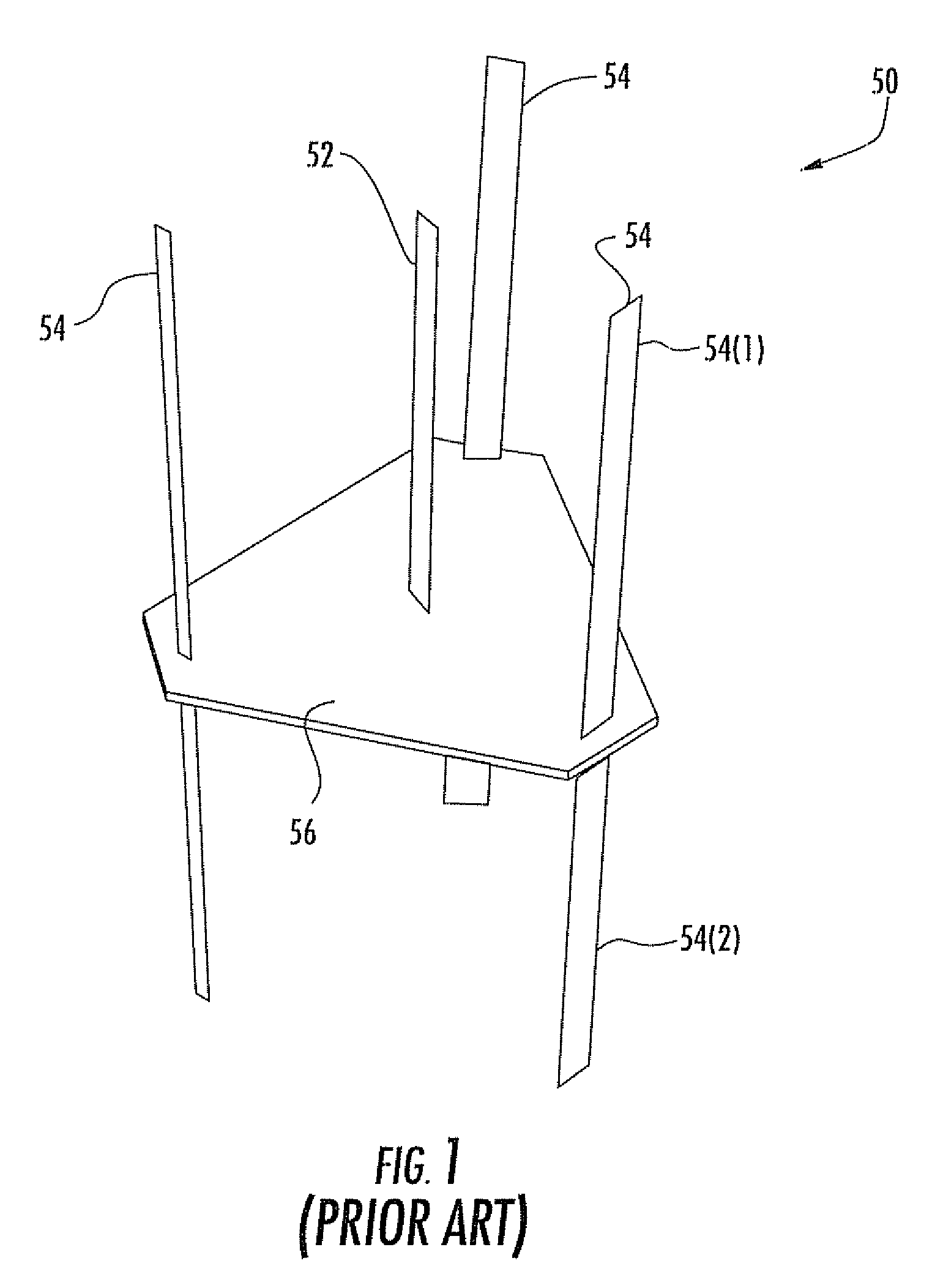

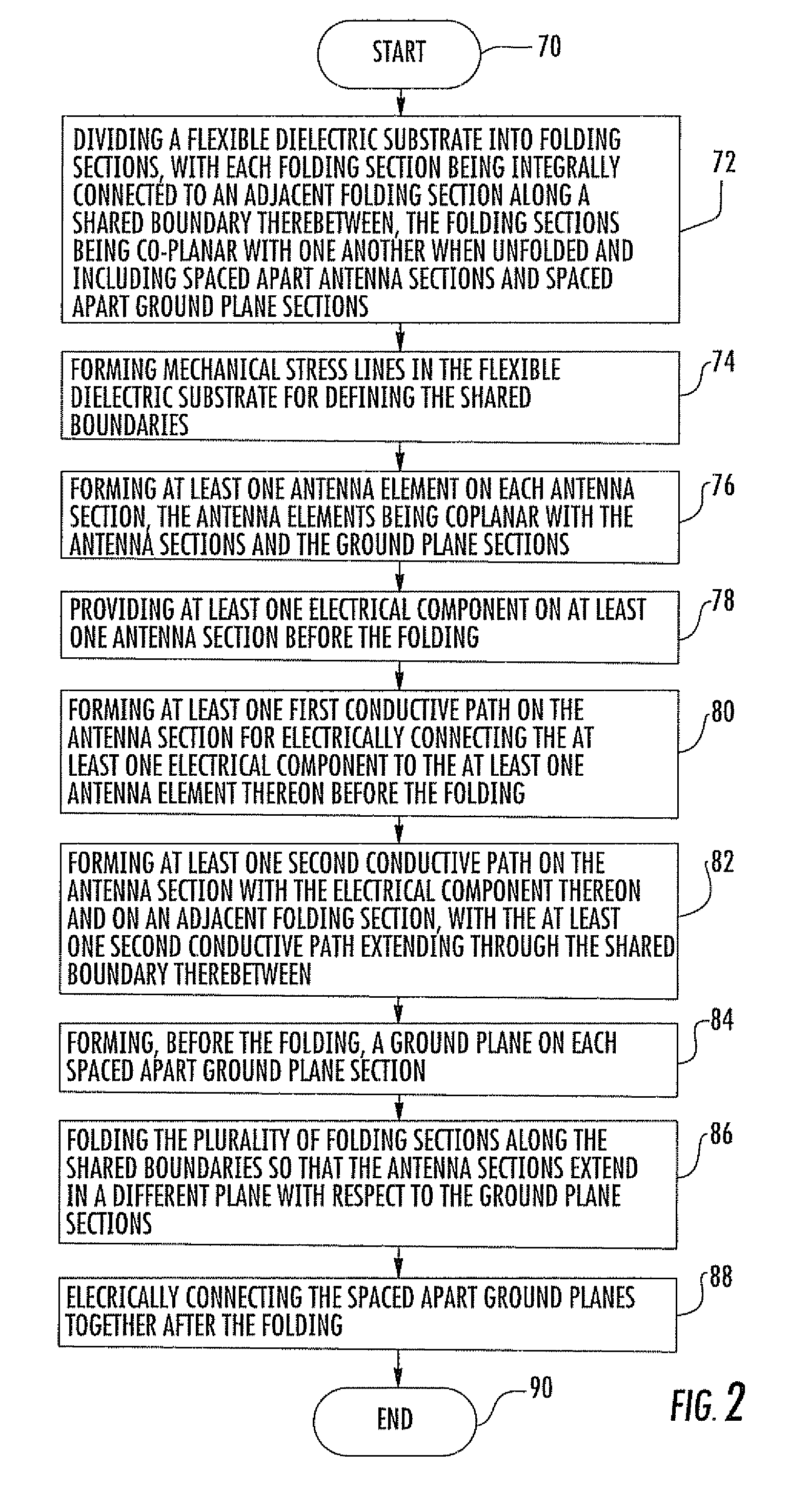

Three-dimensional antenna fabrication from a two-dimensional structure

InactiveUS7602348B2Fast and inexpensiveCollapsable antennas meansAntenna arraysDielectric substrateAntenna fabrication

A method for making an antenna array includes dividing a flexible dielectric substrate into a plurality of folding sections, with each folding section being integrally connected to an adjacent folding section along a shared boundary therebetween. The folding sections are co-planar with one another when unfolded and include spaced apart antenna sections, spaced apart ground plane sections and connecting sections therebetween. An antenna element is formed on each antenna section. The antenna elements are coplanar with the antenna sections, the ground plane sections and the connecting sections. The folding sections of the flexible dielectric substrate are folded along the shared boundaries so that the antenna sections extend in a different plane with respect to the ground plane sections.

Owner:INTERDIGITAL TECH CORP

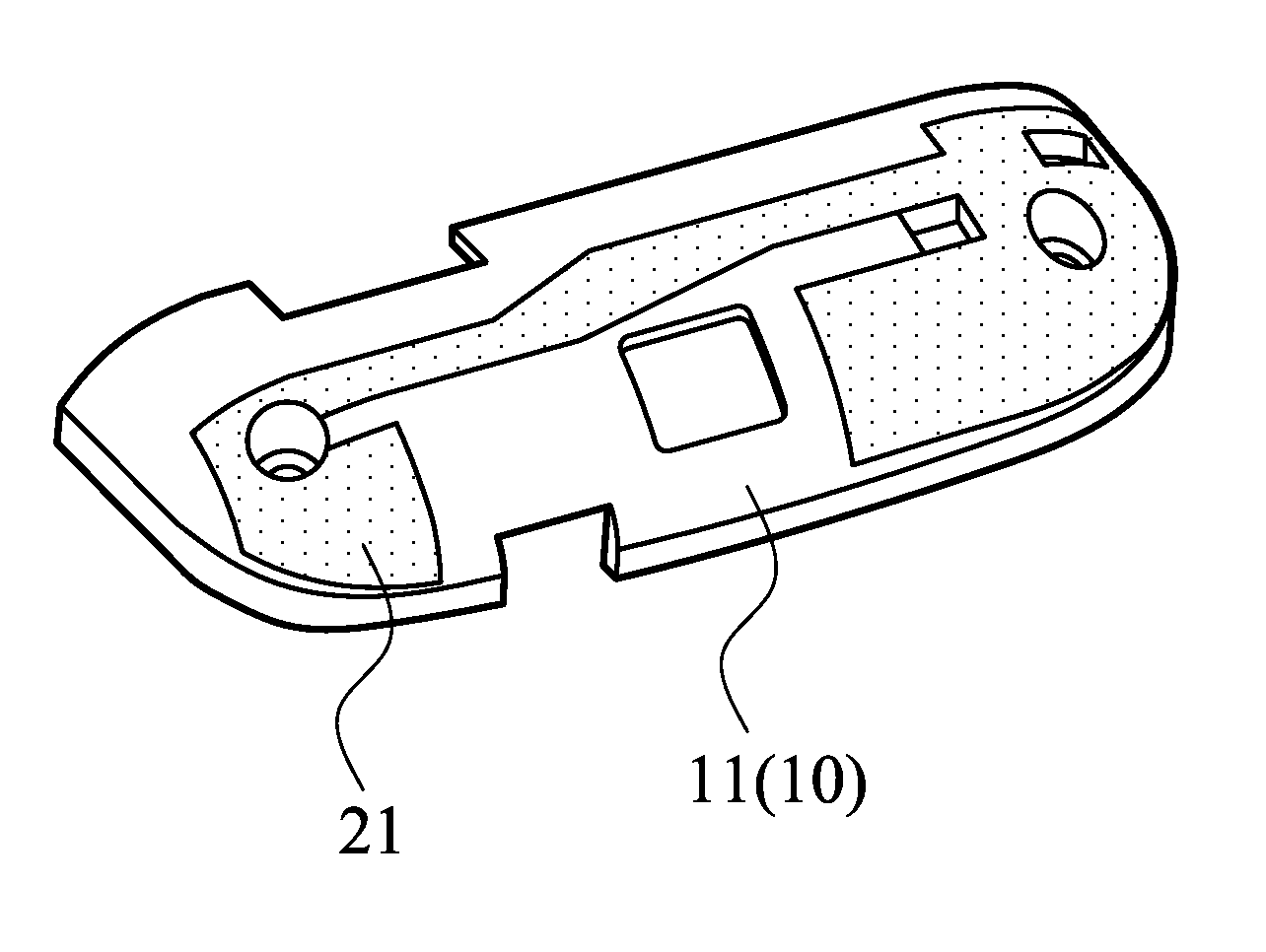

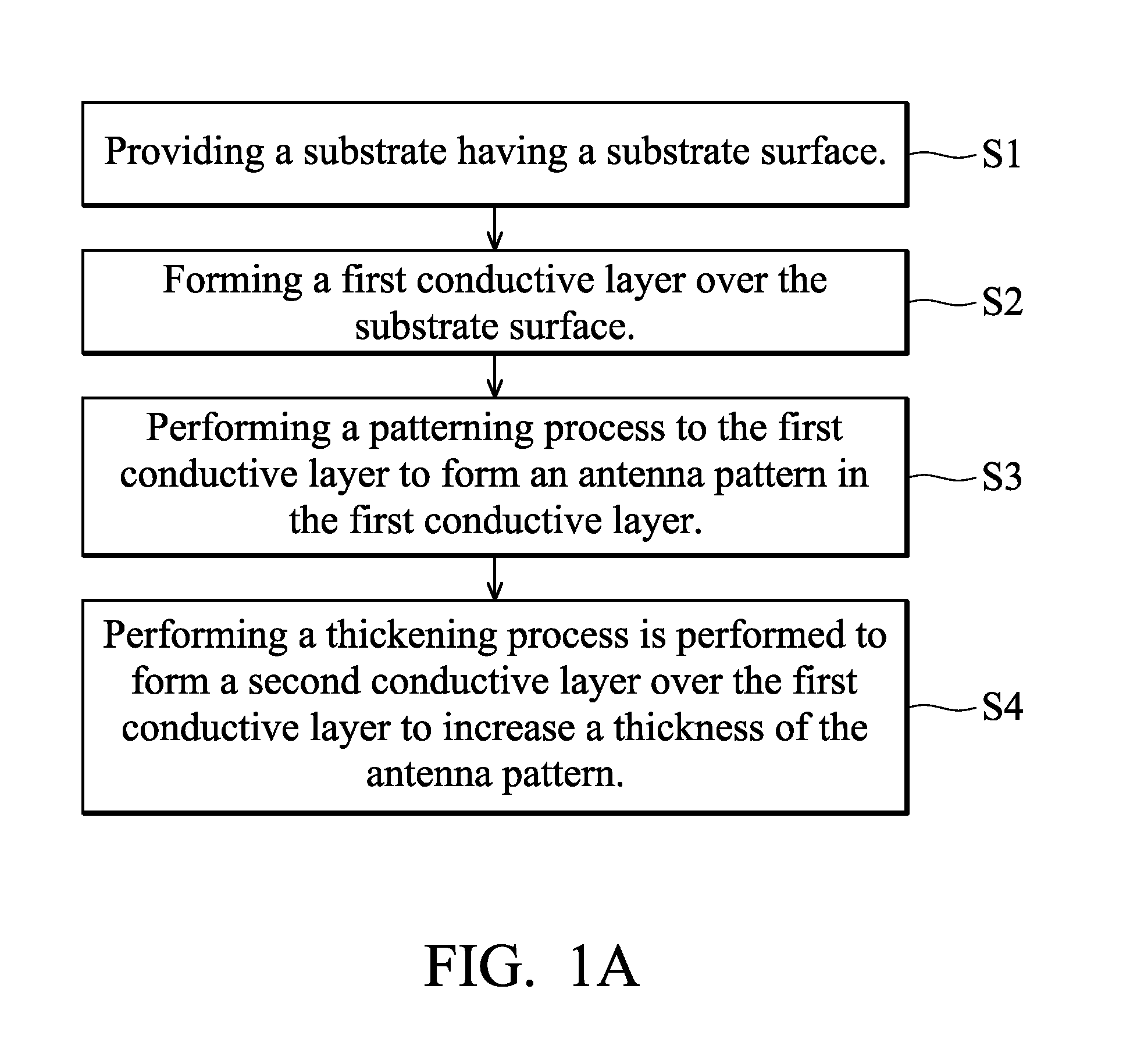

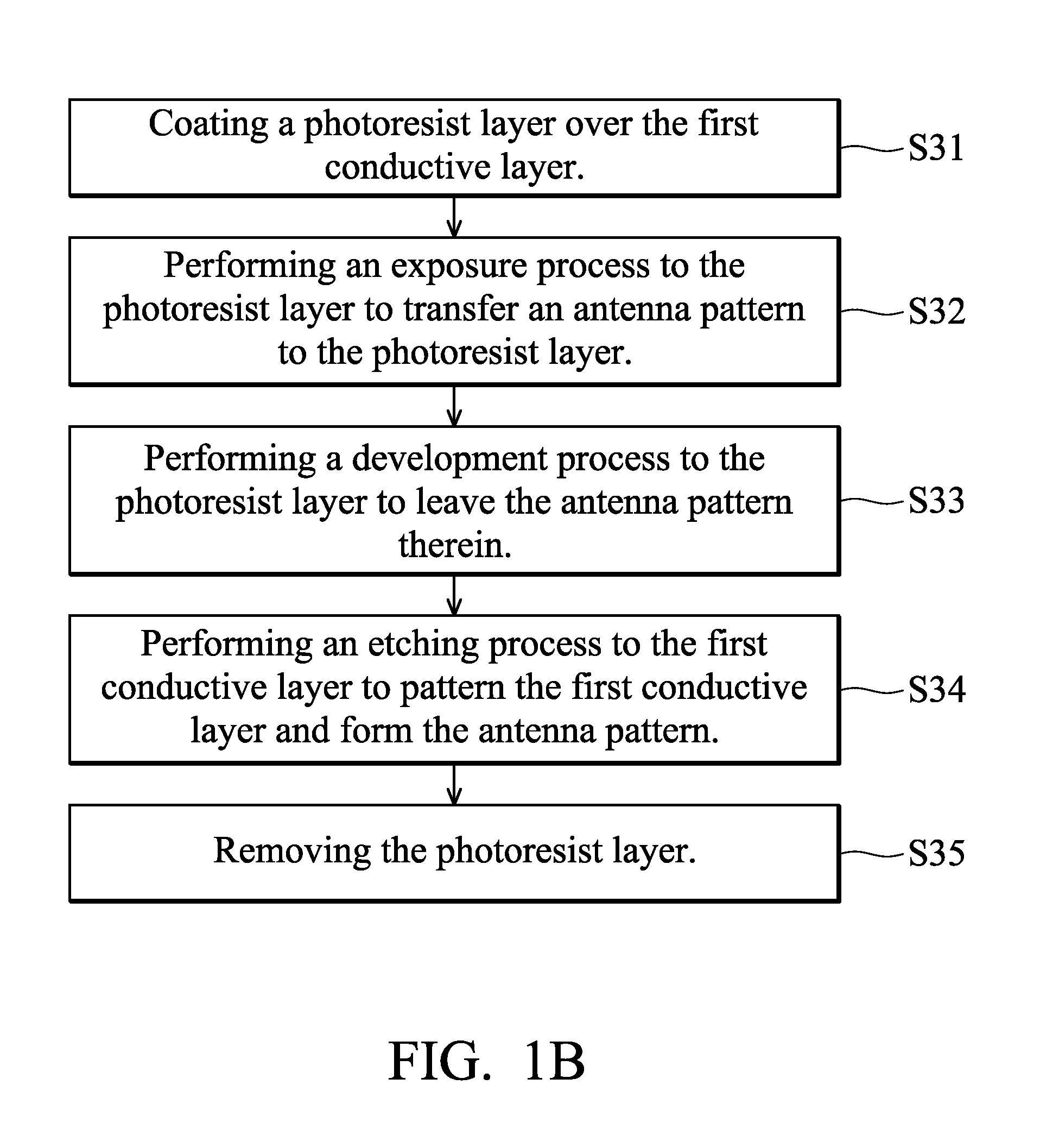

Portable electronic device, antenna structure, and antenna producing process thereof

InactiveUS20130044041A1Increasing the thicknessSimultaneous aerial operationsAntenna supports/mountingsSputteringChemical plating

An antenna structure is provided, comprising: a first conductive layer, wherein the first conductive layer is formed by vacuum sputtering; and a second conductive layer formed over the first conductive layer, wherein the second conductive layer is formed by chemical plating, electroplating or printing.

Owner:WISTRON NEWEB

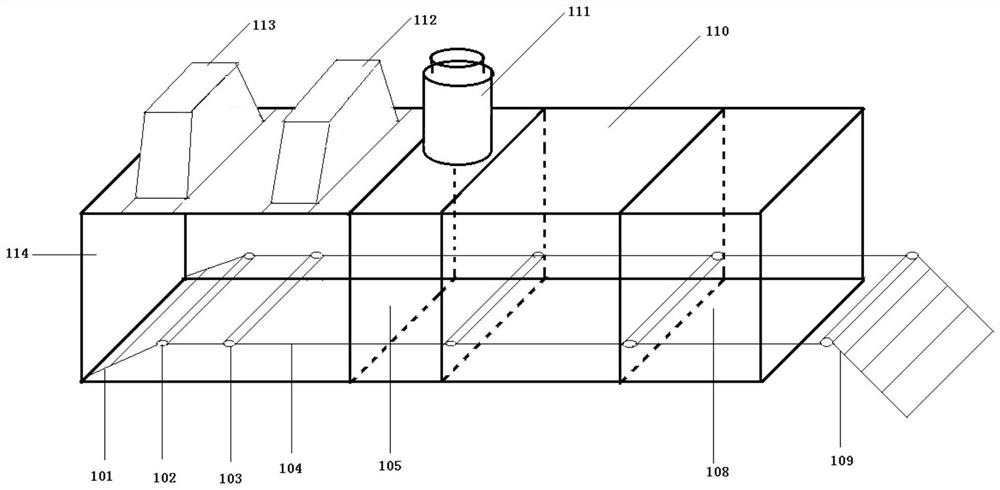

Integrated conformal manufacturing method of multilayer interconnected three-dimensional circuit and product

ActiveCN111613888ARealize vertical interconnectionEasy to print directlyAdditive manufacturing apparatusRadiating elements structural formsAntenna fabricationHemt circuits

The invention discloses an integrated conformal manufacturing method of a multilayer interconnected three-dimensional circuit and a product, and belongs to the field of multilayer antenna manufacturing. The method comprises the steps of S1, preparing a supporting structure base body in a 3D printing mode; S2, preparing an activation pattern with catalytic capability on the surface of the supporting structure base body obtained in the step S1; S3, depositing metal on the activation pattern, obtaining a metal pattern layer consistent with the activation pattern, wherein the metal pattern prepared for the first time is a first metal pattern layer; S4, preparing a dielectric layer used for isolating two adjacent metal pattern layers, wherein the dielectric layer prepared for the first time isa first dielectric layer; S5, preparing a vertical interconnection through hole penetrating through the dielectric layer, wherein the vertical interconnection through hole has conductivity so as to interconnect the two adjacent metal pattern layers; and S6, preparing a second metal pattern layer on the first dielectric layer. The method provided by the invention can realize rapid, high-quality andlow-cost preparation of the multilayer interconnected three-dimensional circuit.

Owner:HUAZHONG UNIV OF SCI & TECH

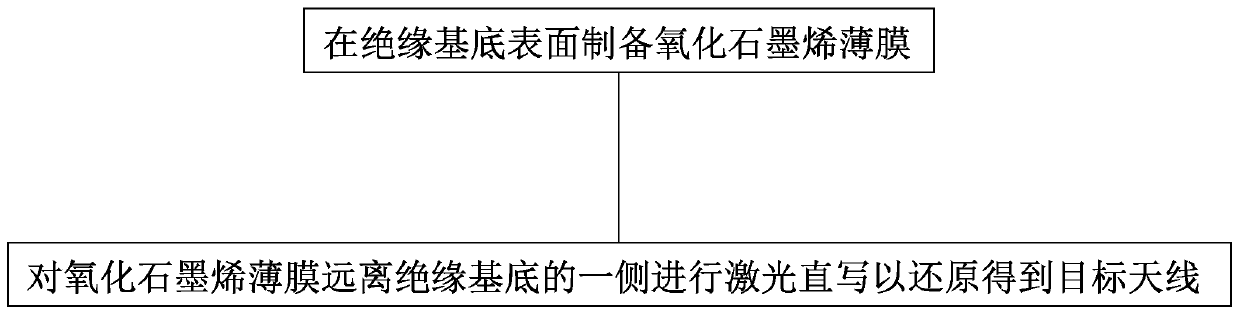

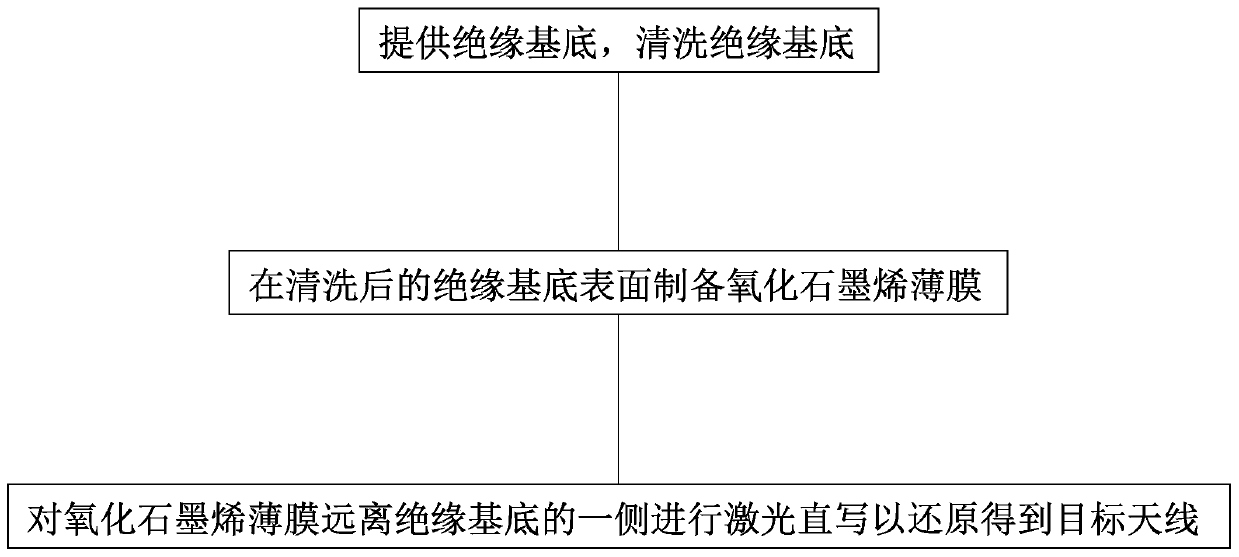

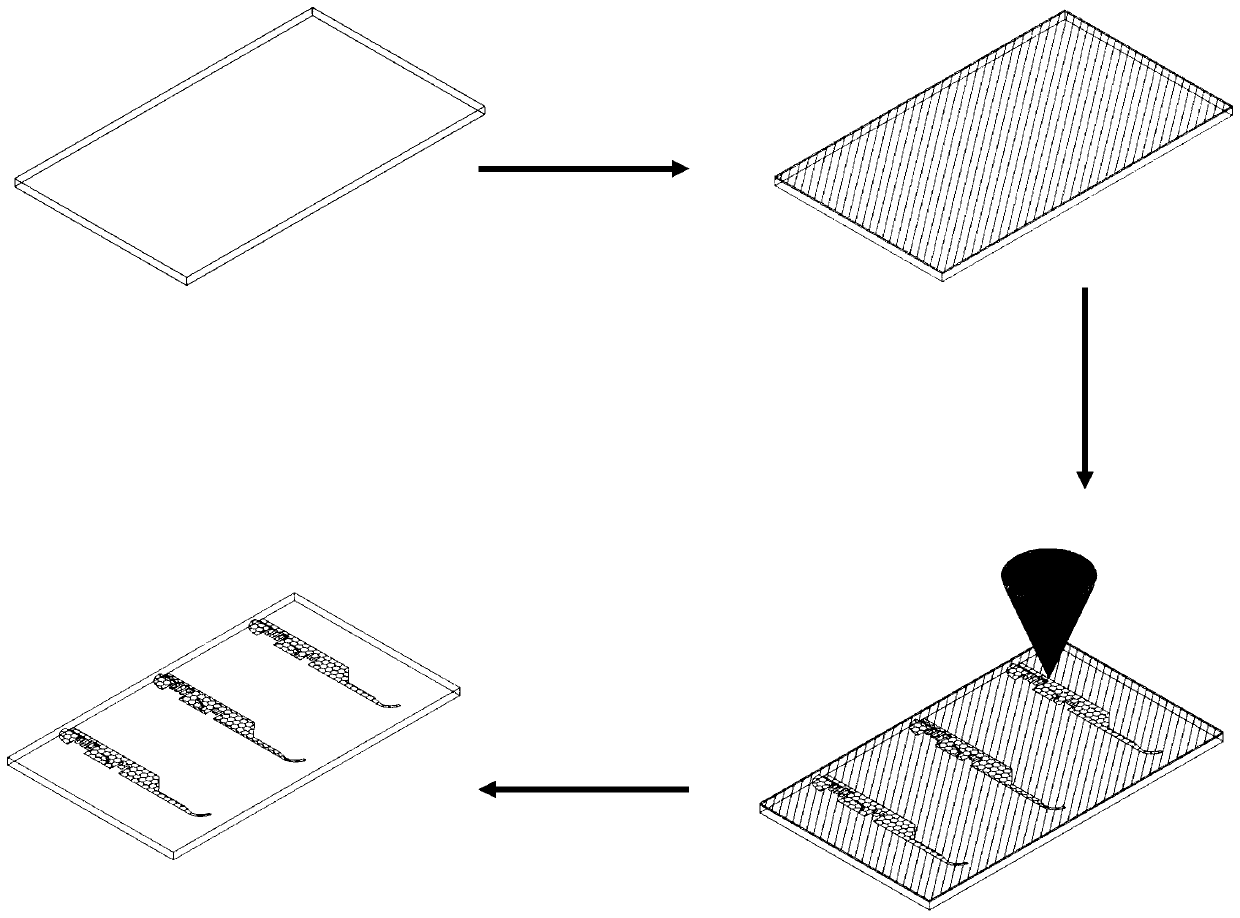

Antenna fabrication method and antenna with same

The invention relates to an antenna fabrication method and an antenna with the same. The method comprises the following steps of fabricating a graphene oxide thin film on a surface of an insulation substrate; and performing laser direct-writing on one side, far away from the insulation substrate, of the graphene thin film so as to reduce to obtain a target antenna. The fabrication method belongs to a material increasing mode to fabricate the antenna and is suitable for antenna fabrication on a plane and a curve surface, antennas with a planar structure or a curve-surface structure can be fabricated, and a high-flexible antenna also can be fabricated. The antenna with same preset pattern can be fabricated in one step by laser direct writing; and compared with a process of growing graphene on the metal substrate under a vacuum environment, transferring the graphene to a transparent substrate from the metal substrate and obtaining a graphene target pattern by laser cutting material reduction mode, the method is simple and is low in cost, and resources are saved.

Owner:INST OF FLEXIBLE ELECTRONICS TECH OF THU ZHEJIANG +1

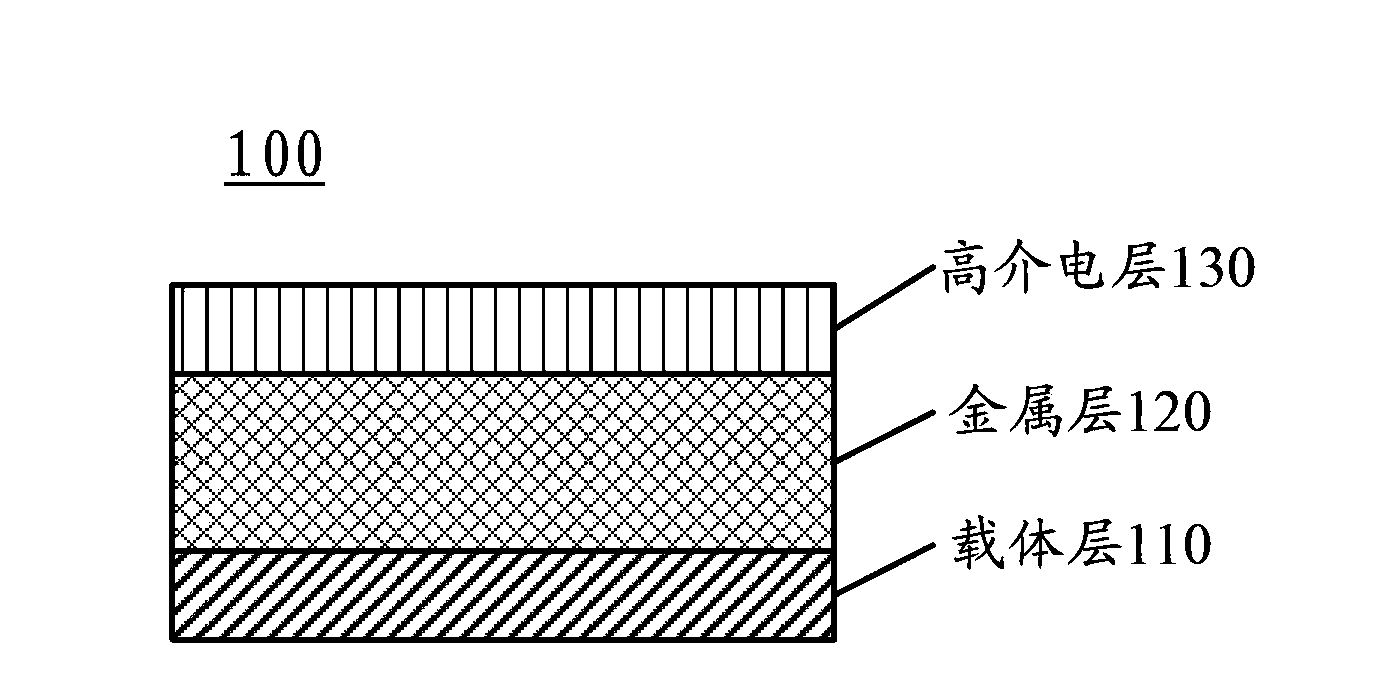

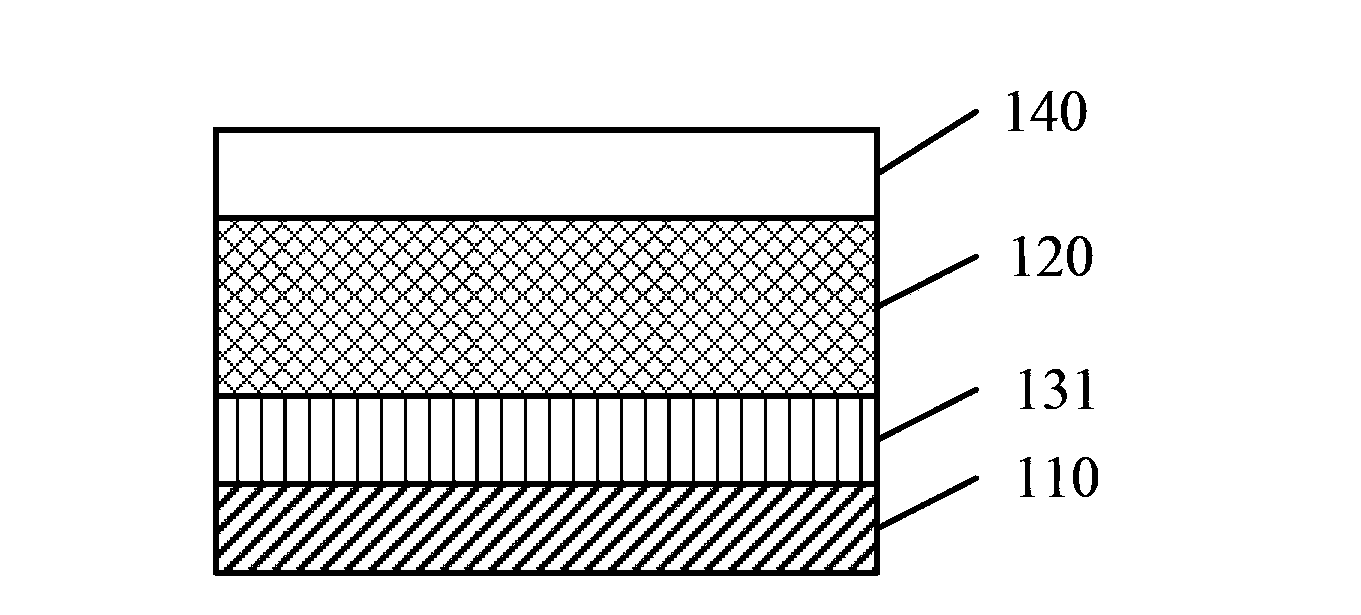

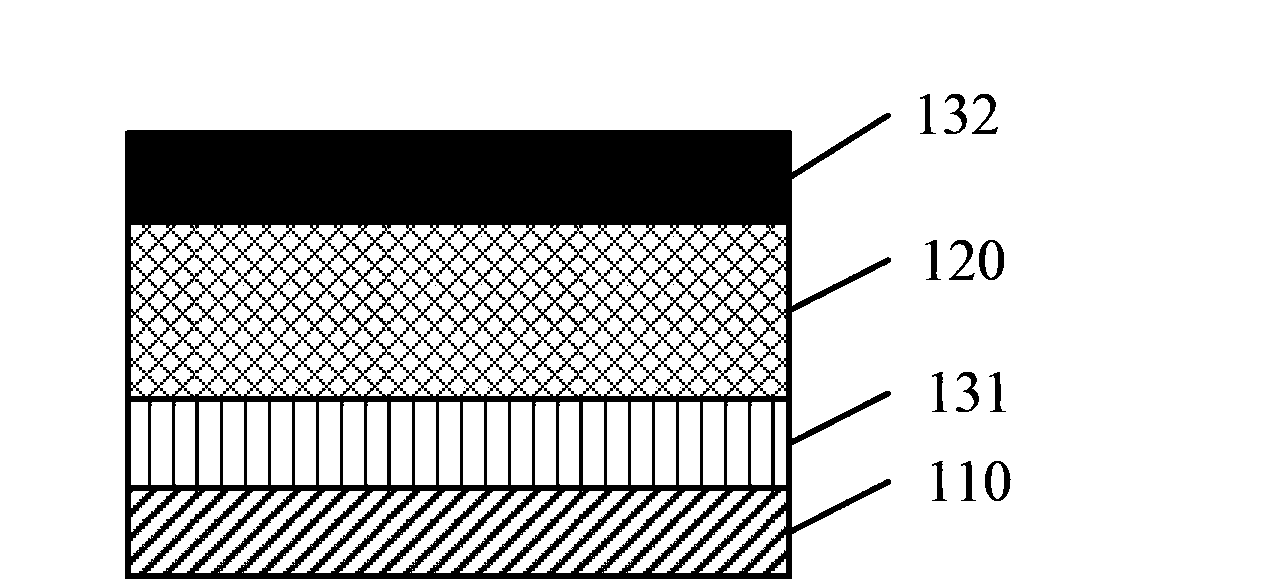

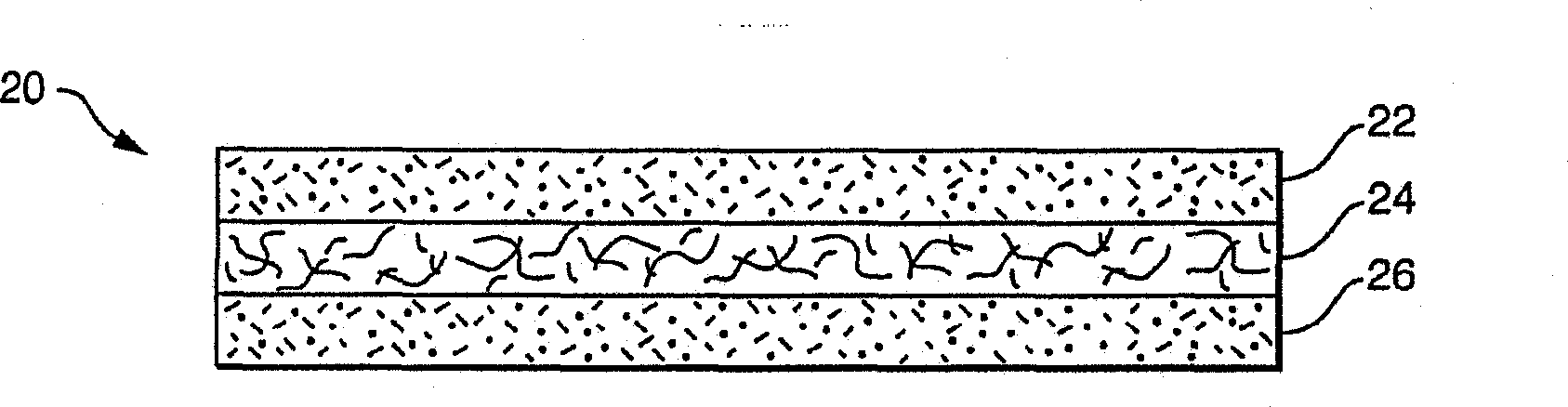

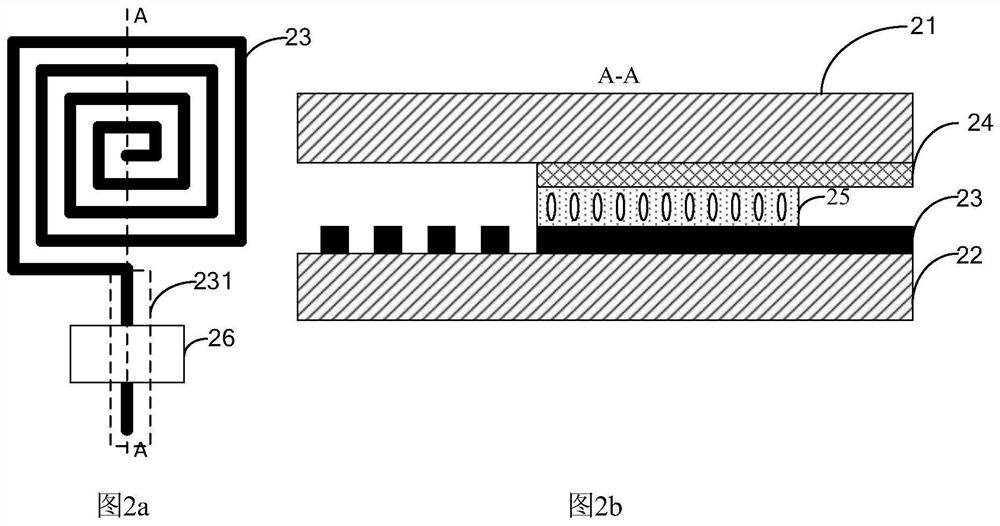

Antenna device and antenna fabrication method

ActiveCN103904422ASmall footprintRadiating elements structural formsProtective material radiating elementsElectricityAntenna fabrication

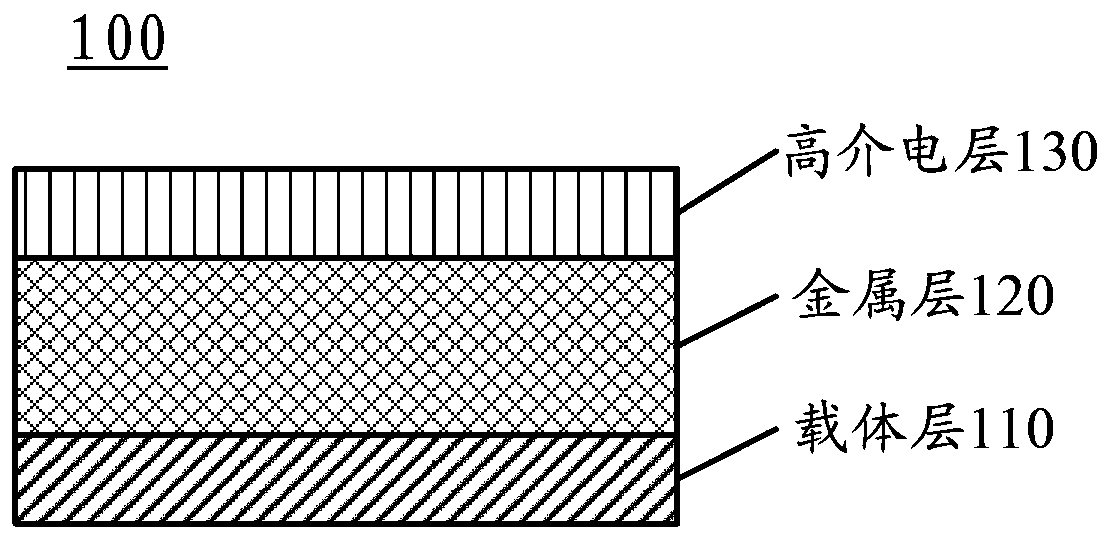

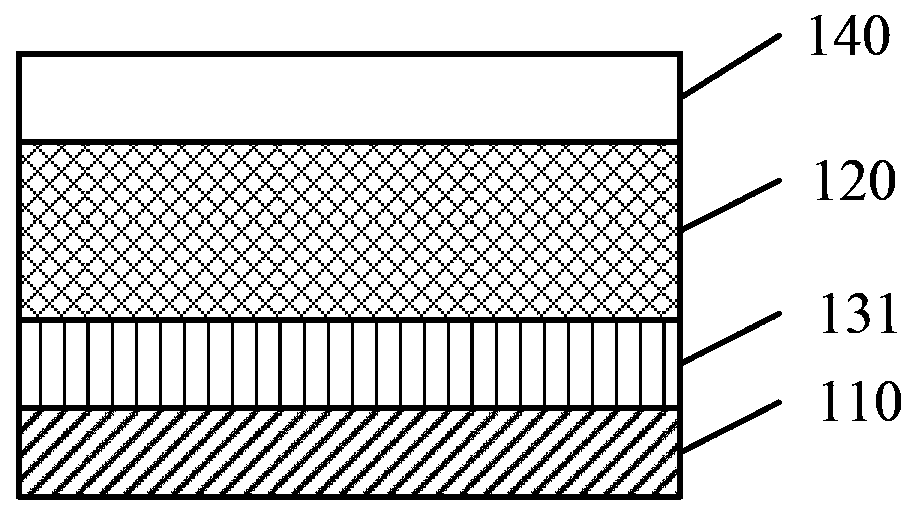

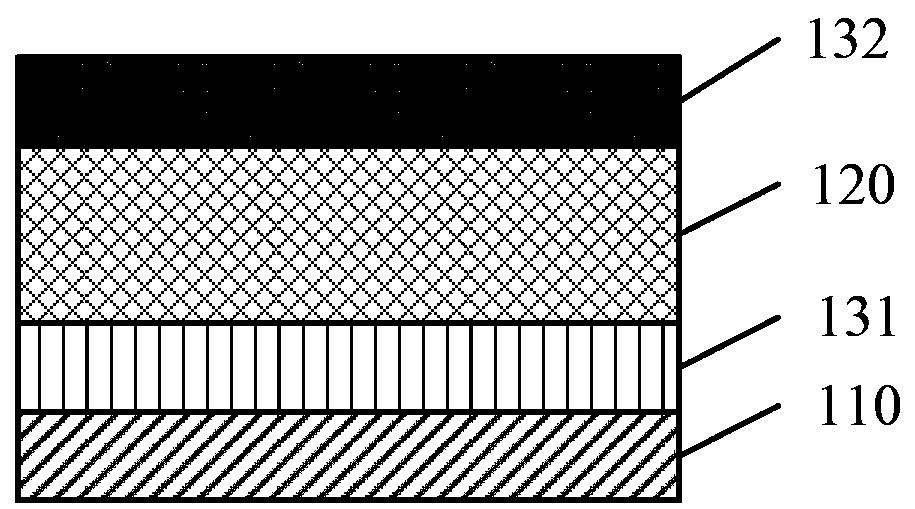

The invention provides an antenna device and an antenna fabrication method. The antenna device comprises: a carrier layer which is the base carrier of the antenna device; a metal layer which is located on the carrier layer and used as an radiating body to transmitting and receiving signals; and a high-dielectric layer which is in contact with the metal layer directly and mode from a high-dielectric material of which the dielectric constant is greater than a preset threshold. In the technical scheme of the antenna device and the antenna fabrication method according to the embodiments of the invention, by arranging the high-dielectric layer which is in contact with the metal layer directly, the occupied space of the antenna can be reduced.

Owner:LENOVO (BEIJING) LTD

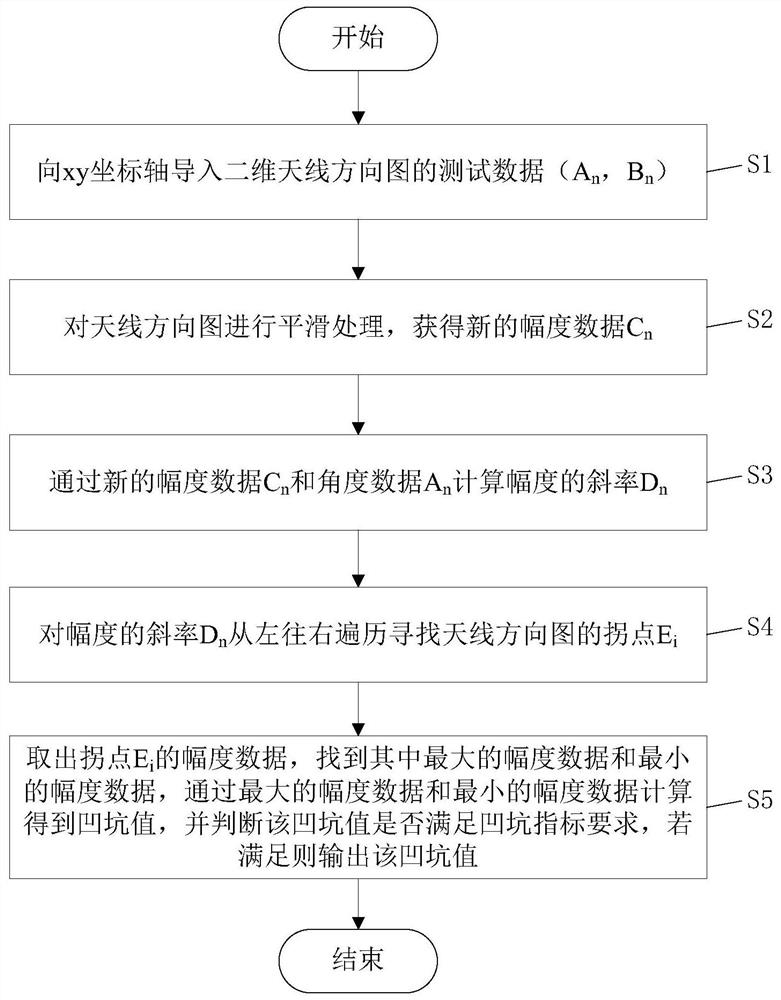

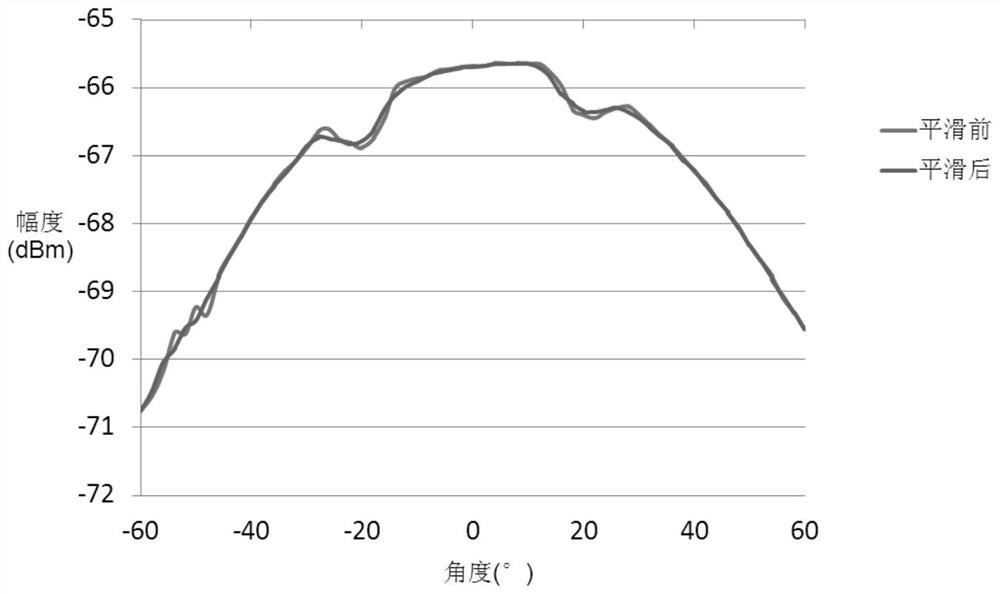

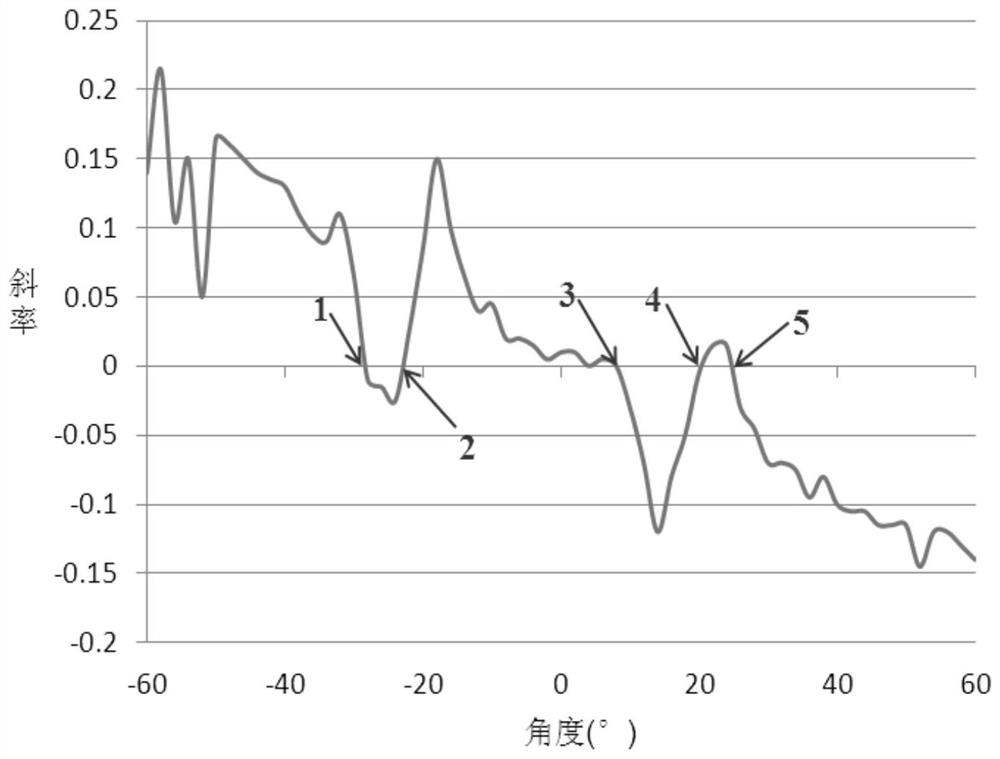

Method for automatically identifying and calculating antenna pattern pits

ActiveCN112348793AEliminate distractionsThe recognition effect is accurateImage enhancementImage analysisAlgorithmAntenna fabrication

The invention discloses a method for automatically identifying and calculating antenna pattern pits. The invention provides a special algorithm, and the algorithm can eliminate the interference, caused by a test environment error, of directional diagram small sawteeth on pit recognition, and carries out the precise recognition and calculation of pits. Meanwhile, the calculation process is simple and clear, data processing efficiency is high, and software implementation is facilitated. At present, when engineering application is achieved, the pit processing period in the antenna manufacturing process is shortened by 96%, and the pit recognition efficiency and quality are remarkably improved.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

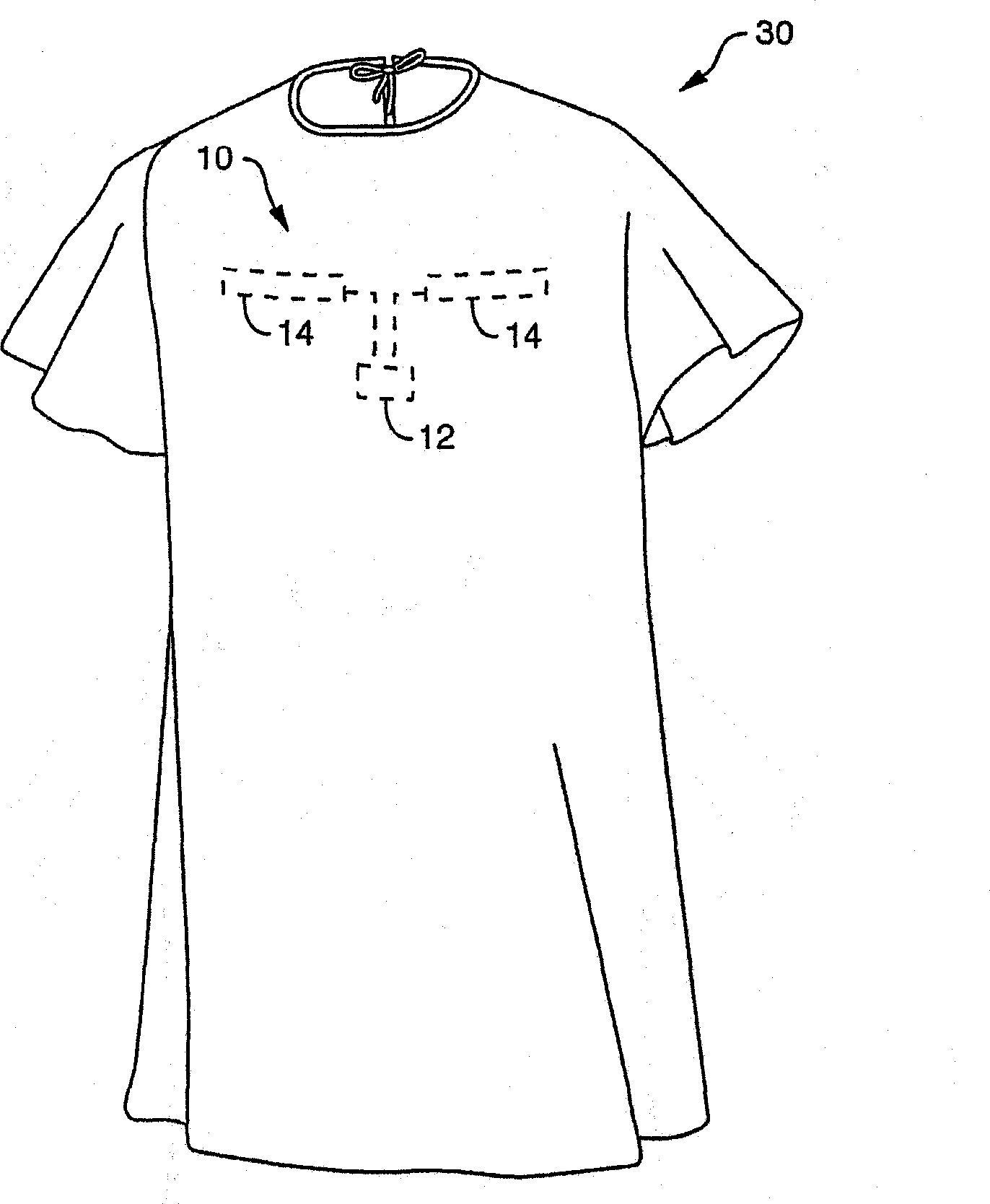

Radiating element for a signal emitting apparatus

Owner:KIMBERLY-CLARK WORLDWIDE INC

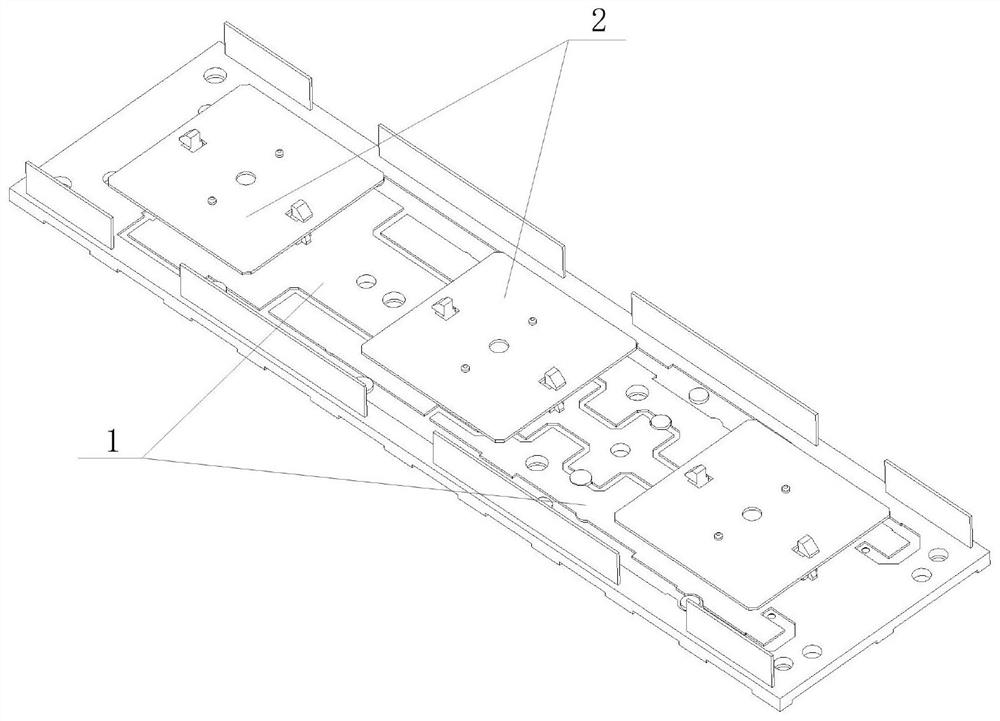

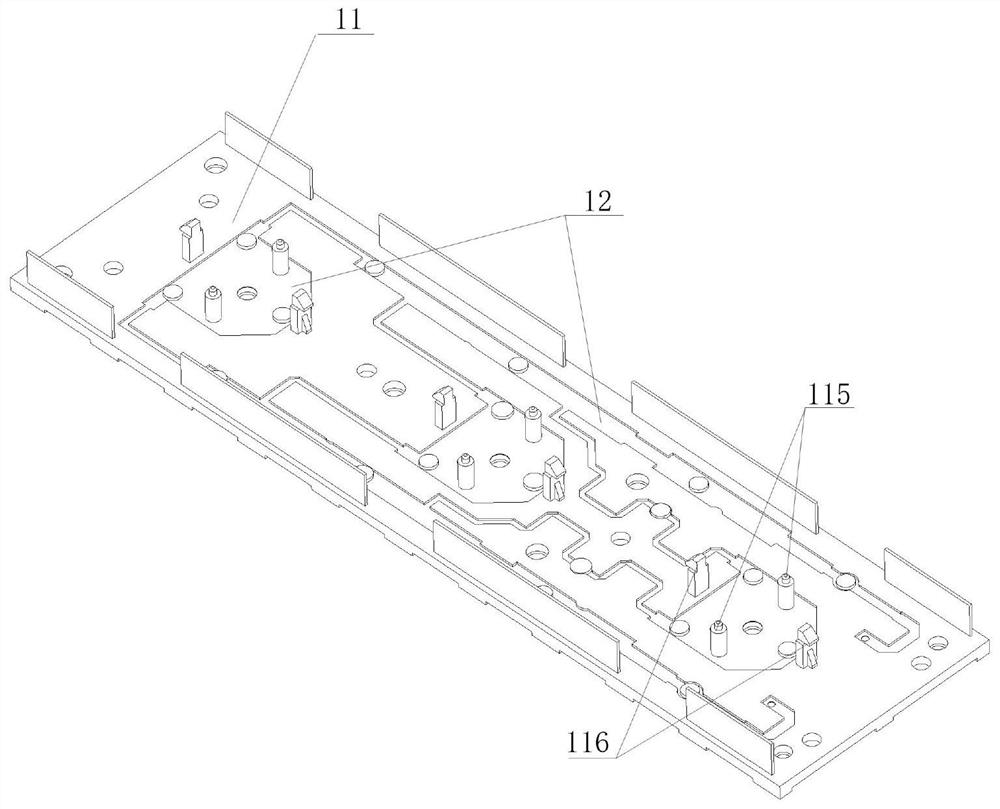

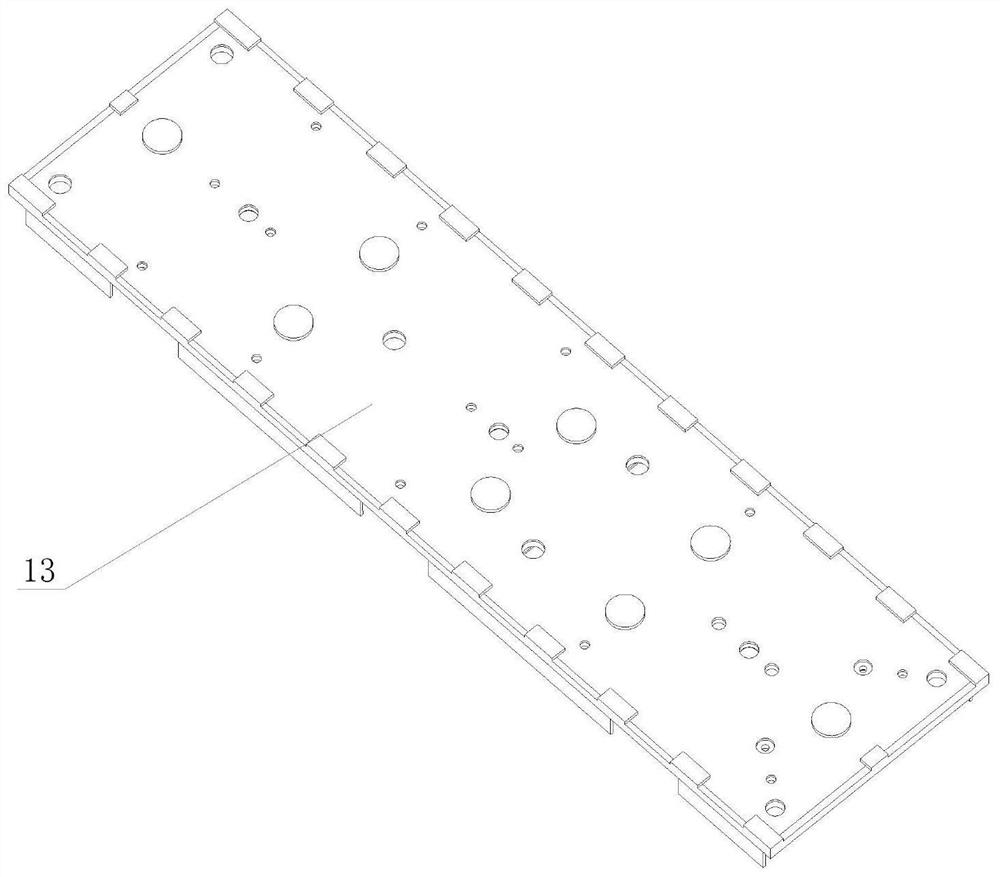

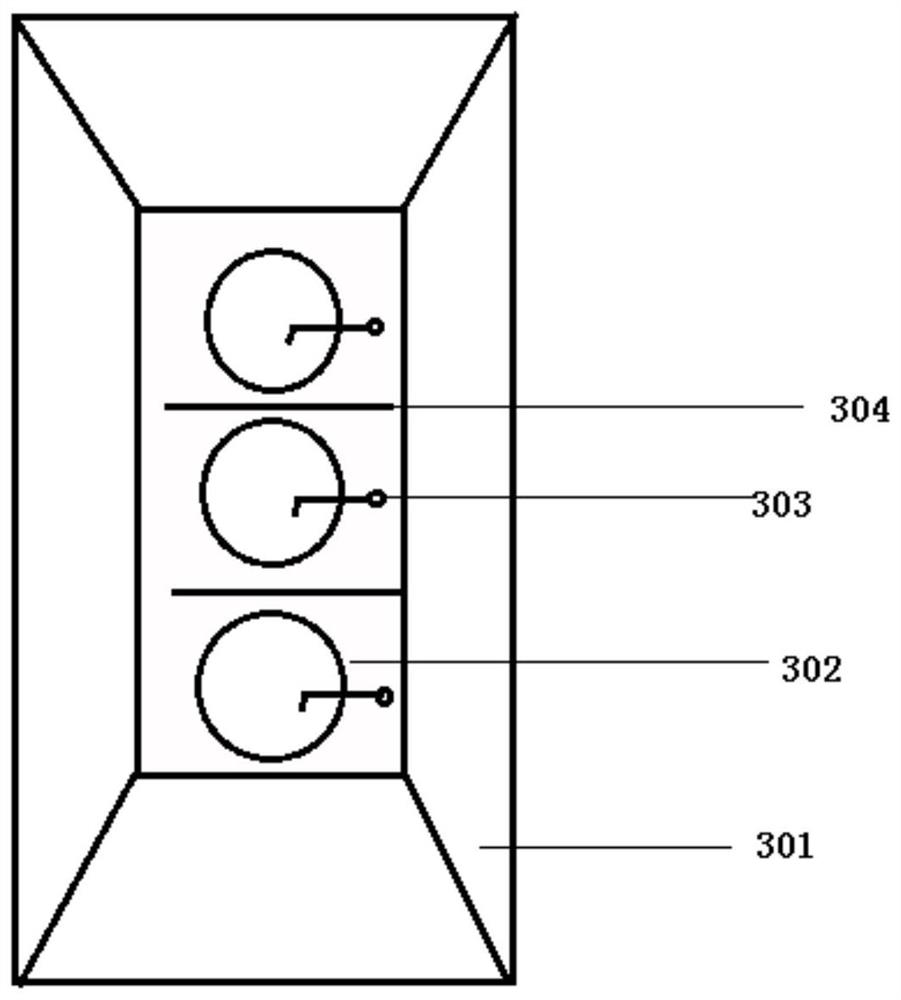

Integrated antenna assembly and antenna array

PendingCN113097717AFew partsSimple structureParticular array feeding systemsAntenna supports/mountingsAntenna fabricationEngineering

The invention relates to the technical field of base station antenna manufacturing, and provides an integrated antenna assembly and an antenna array, and the integrated antenna assembly comprises a feed network module and an antenna unit radiation fin. The feed network module comprises a bracket, a feed network elastic sheet and a reflecting plate elastic piece; the two sides of the reflecting plate elastic piece are provided with separating walls perpendicular to the reflecting plate elastic piece. A groove with the same shape as the feed network elastic sheet is formed in one surface of the bracket, the feed network elastic sheet is arranged in the groove in an attached mode, and the depth of the groove is larger than the thickness of the feed network elastic sheet; the reflecting plate elastic piece is arranged on the other surface of the bracket; the feed network elastic sheet, the reflecting plate elastic piece and the bracket are integrally formed through injection molding. The integrated antenna assembly provided by the embodiment of the invention is few in required parts, simple in structure, convenient to assemble, free of welding, easy to automation, low in production cost and suitable for large-scale efficient production.

Owner:苏州硕贝德创新技术研究有限公司

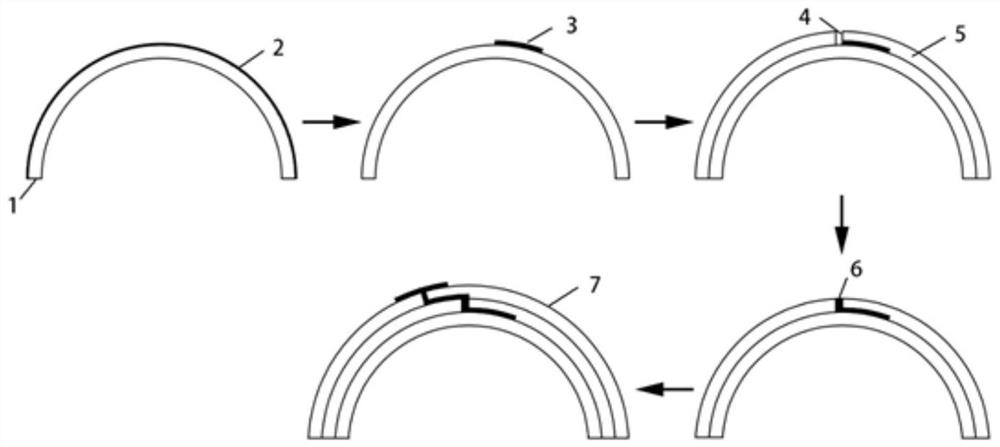

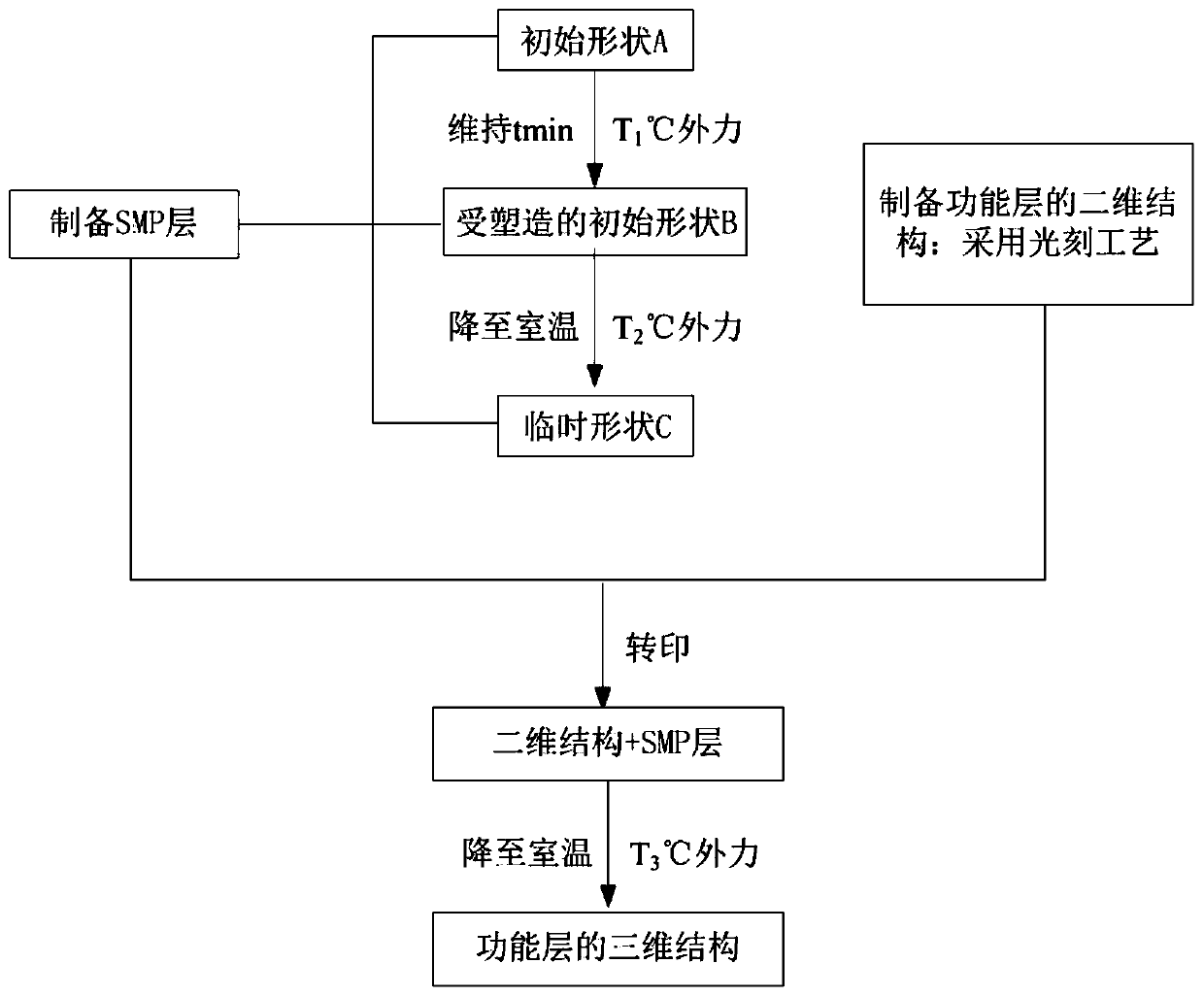

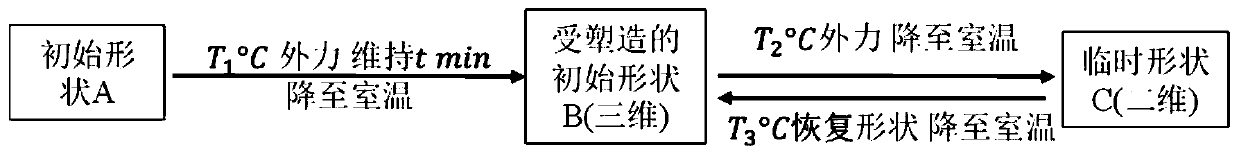

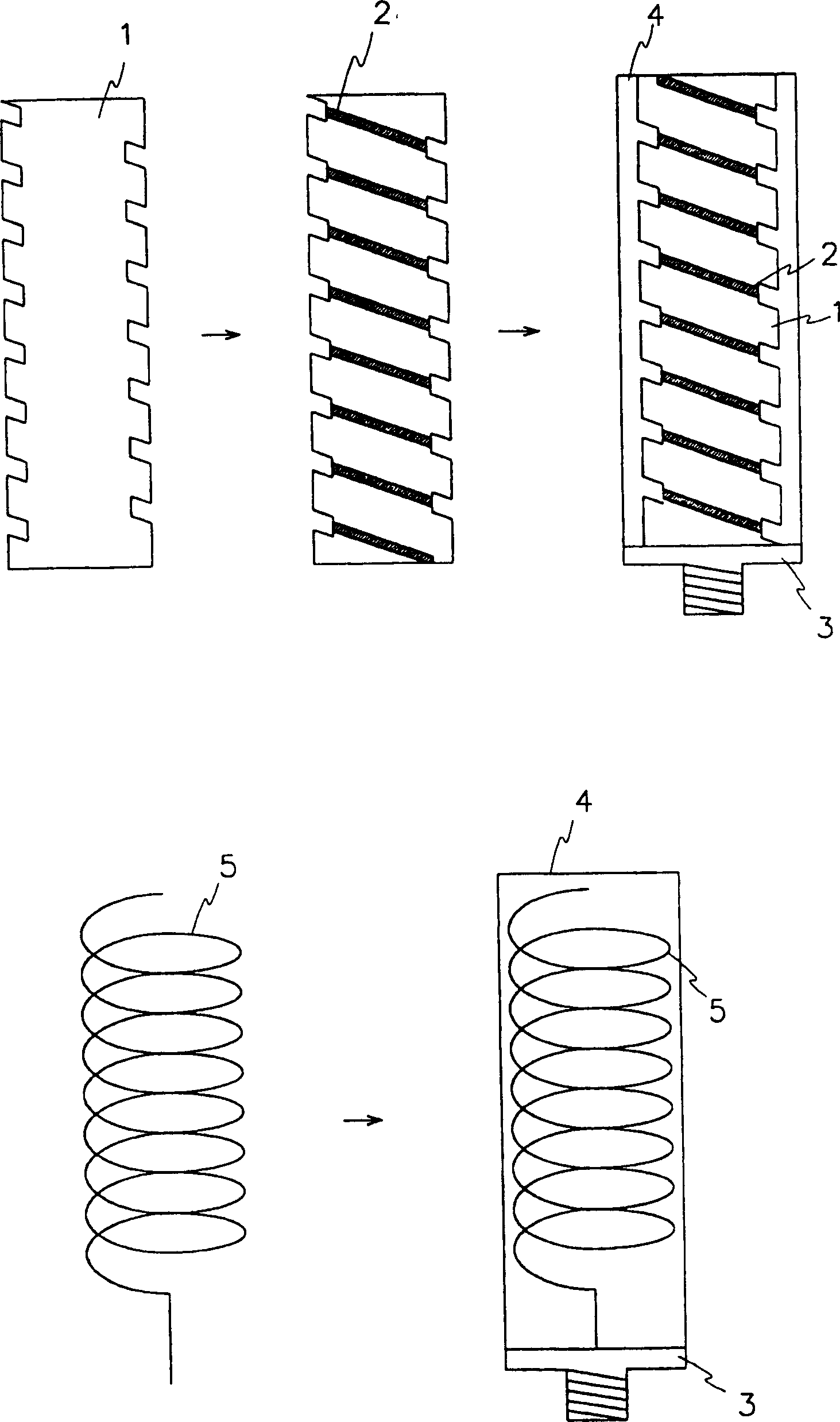

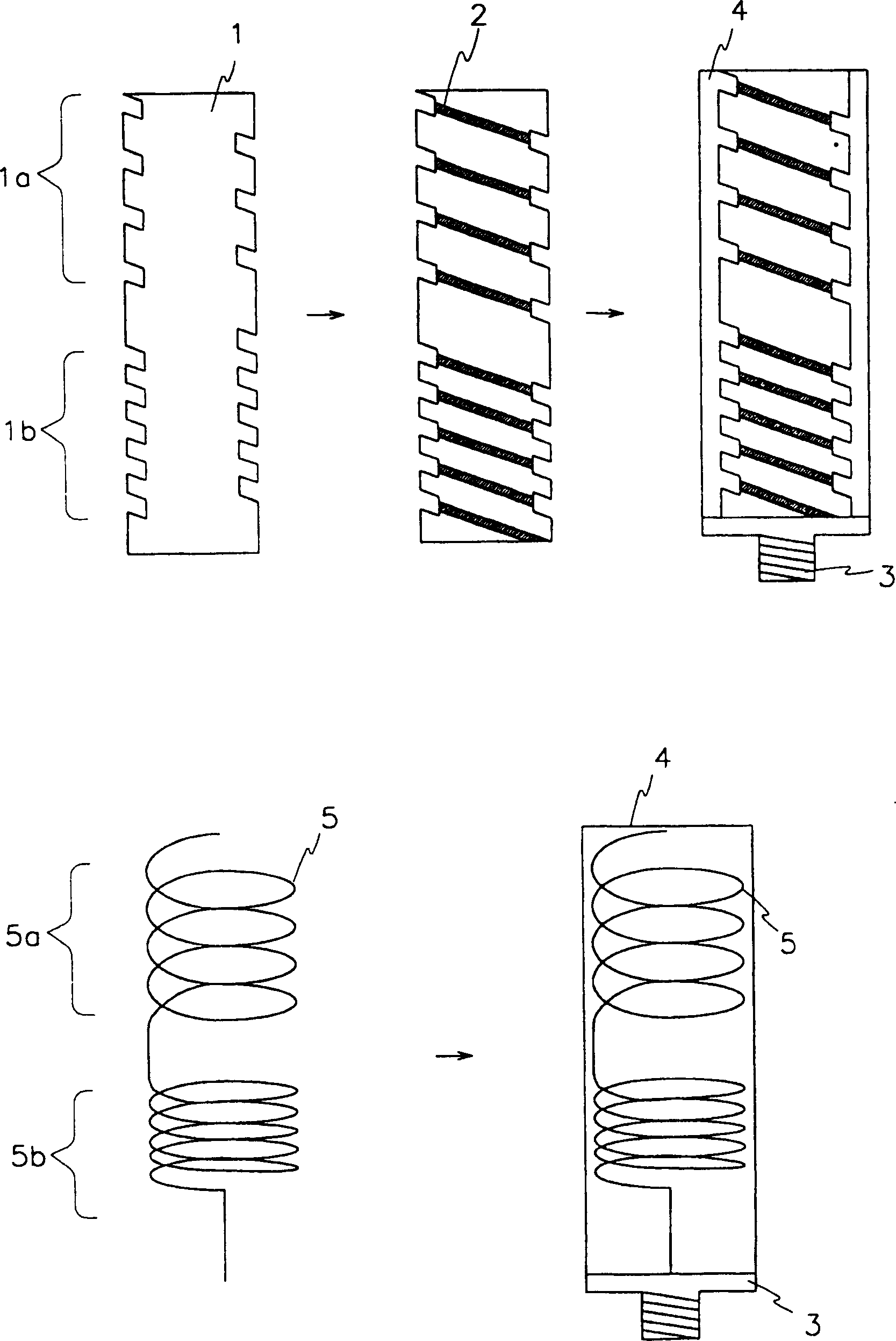

Three-dimensional antenna manufacturing method based on shape memory polymer and three-dimensional antenna

ActiveCN110676564AEasy to manufactureLow costRadiating elements structural formsAntenna fabricationMechanical engineering

The invention provides a three-dimensional antenna manufacturing method based on a shape memory polymer and a three-dimensional antenna. The three-dimensional antenna comprises a functional layer anda shape memory polymer layer. The functional layer has a three-dimensional structure when the three-dimensional antenna is in a use state. The manufacturing method comprises the following steps: providing a shape memory polymer layer with a three-dimensional shaped initial shape; converting the shape memory polymer layer having the shaped initial shape into a shape memory polymer layer having a two-dimensional temporary shape; combining the functional layer with the two-dimensional structure with the shape memory polymer layer with the temporary shape; and changing the shape memory polymer layer combined with the functional layer with the two-dimensional structure to have a shaped initial shape, and driving the functional layer with the two-dimensional structure to deform to form a three-dimensional structure. The method intelligently, simply and conveniently realizes manufacturing of the three-dimensional antenna, and is relatively low in cost, relatively wide in application range andsuitable for manufacturing of the flexible antenna.

Owner:TSINGHUA UNIV

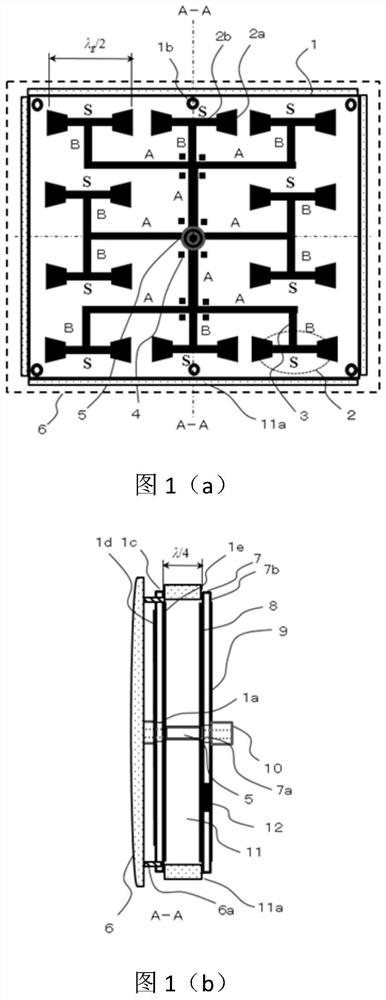

Antenna device

PendingCN114374072AMitigate constant variationAntennas earthing switches associationPlanar substrateDielectric substrate

The invention relates to the technical field of antenna manufacturing, in particular to an antenna device which is small in size, compact in structure and capable of forming an antenna loop on a planar substrate, antenna characteristics of the antenna device do not change along with dramatic changes of environment temperature, and the antenna device comprises a first dielectric substrate which is provided with an antenna part. The high-power microstrip antenna is characterized in that a heating part is arranged on the surface, facing the back face of the first dielectric substrate, of the second dielectric substrate, and an air heat preservation layer is formed between the first dielectric substrate and the second dielectric substrate; the first dielectric substrate and the second dielectric substrate are oppositely arranged, and a heat preservation wall surrounding the air heat preservation layer is arranged between the first dielectric substrate and the second dielectric substrate. According to the antenna device provided by the invention, the heat preservation wall covering the space between the first dielectric substrate carrying the antenna and the second dielectric substrate oppositely arranged is arranged, and the heating part for adjusting the temperature in the space is arranged; therefore, the present invention has an effect of reducing a component constant change accompanying a change in the environment of the antenna portion.

Owner:SHANDONG HUALING ELECTRONICS

Television antenna fabrication process

InactiveCN108736143ALow costImprove antenna performanceRadiating elements structural formsMolding machineAntenna fabrication

The invention discloses a television antenna fabrication process. The television antenna fabrication process is characterized by comprising the following steps of (1) selecting a ferromagnetic material workpiece; (2) fabricating an antenna shape from the ferromagnetic material workpiece by a forming machine; (3) arranging a conductive layer on the ferromagnetic material workpiece in the antenna shape by a compression machine; (4) printing a layer of chemical medium facilitating copper or aluminum adhesion onto an outer surface of the ferromagnetic material workpiece; and (5) printing corrosion-resistant ink onto a copper-coated foil or an aluminum-coated foil according to the antenna shape. By the fabrication process, the cost is reduced, and the antenna performance can be improved.

Owner:丹阳市遥控天线厂

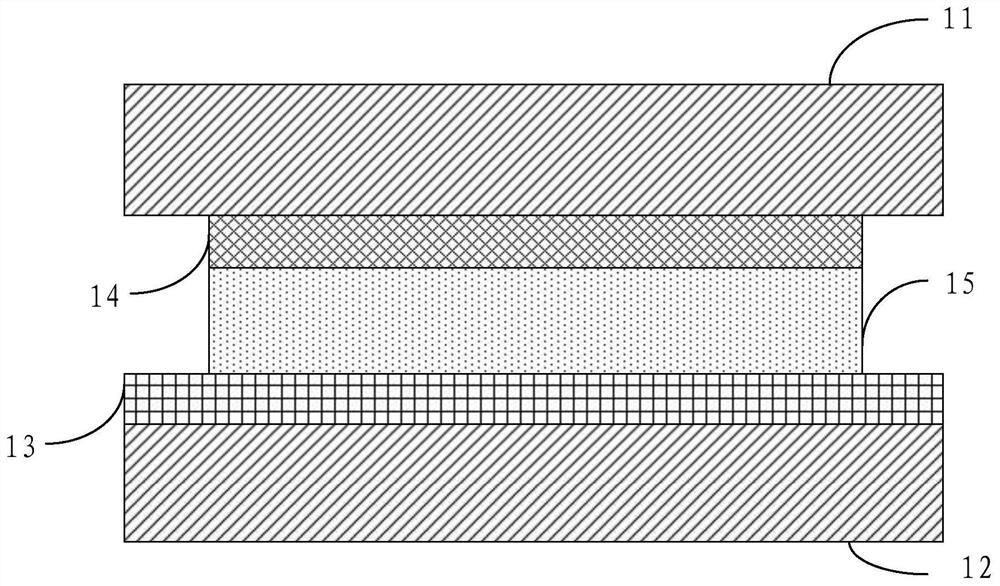

A frequency tunable antenna and its manufacturing method

ActiveCN108711669BAvoid the defects of changing the manufacturing processIn line with the processSimultaneous aerial operationsAntenna supports/mountingsCapacitanceAntenna fabrication

Embodiments of the present invention provide a frequency-tunable antenna and a manufacturing method thereof, which relate to the field of antenna manufacturing. The liquid crystal layer can be used as a capacitor to complete the inductive impedance adjustment of the frequency-tunable antenna without drilling holes, so that the frequency can be adjusted. Adjust the transmitting and receiving frequency of the antenna to change. The first substrate and the second substrate facing each other, the antenna electrode disposed on the second substrate close to the first substrate, and the liquid crystal driving electrode disposed on the first substrate close to the second substrate side; wherein, the antenna electrode and the A liquid crystal layer is arranged between the liquid crystal driving electrodes; the antenna electrodes and the liquid crystal driving electrodes are used to adjust the transmitting and receiving frequency of the antenna by controlling the arrangement of liquid crystals in the liquid crystal layer.

Owner:BOE TECH GRP CO LTD +1

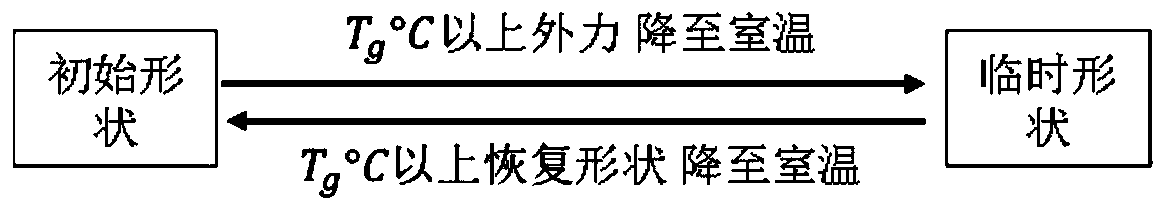

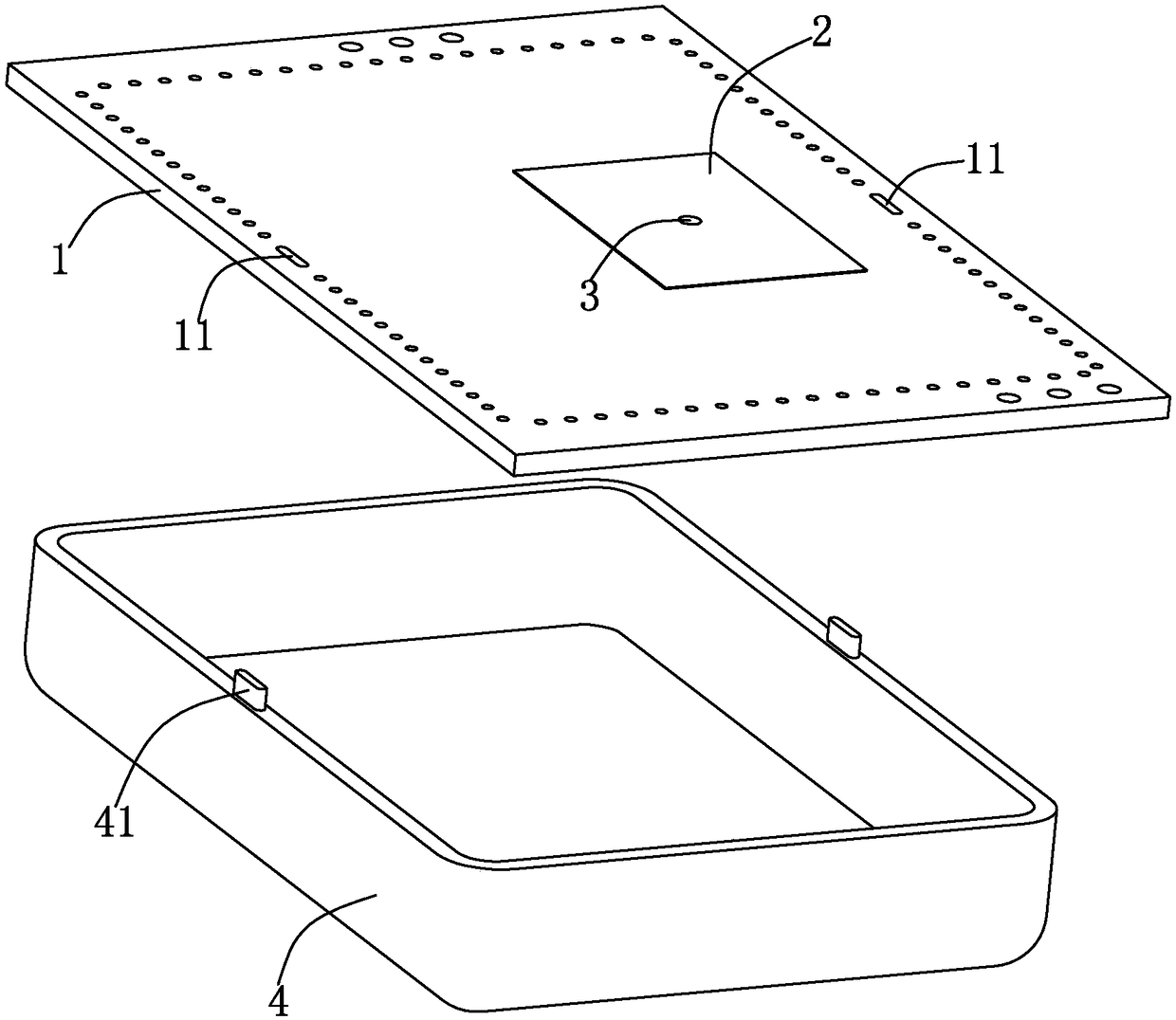

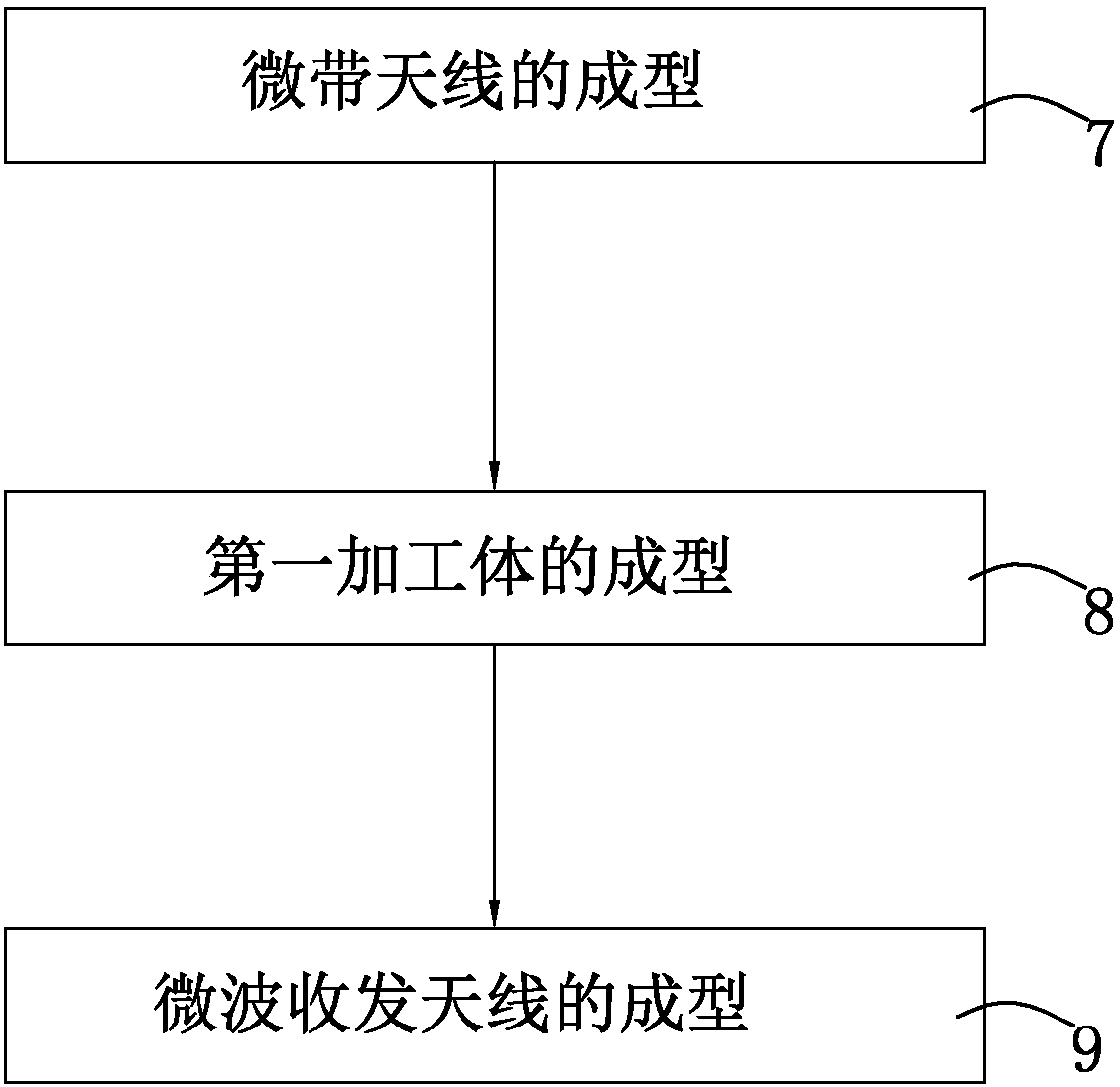

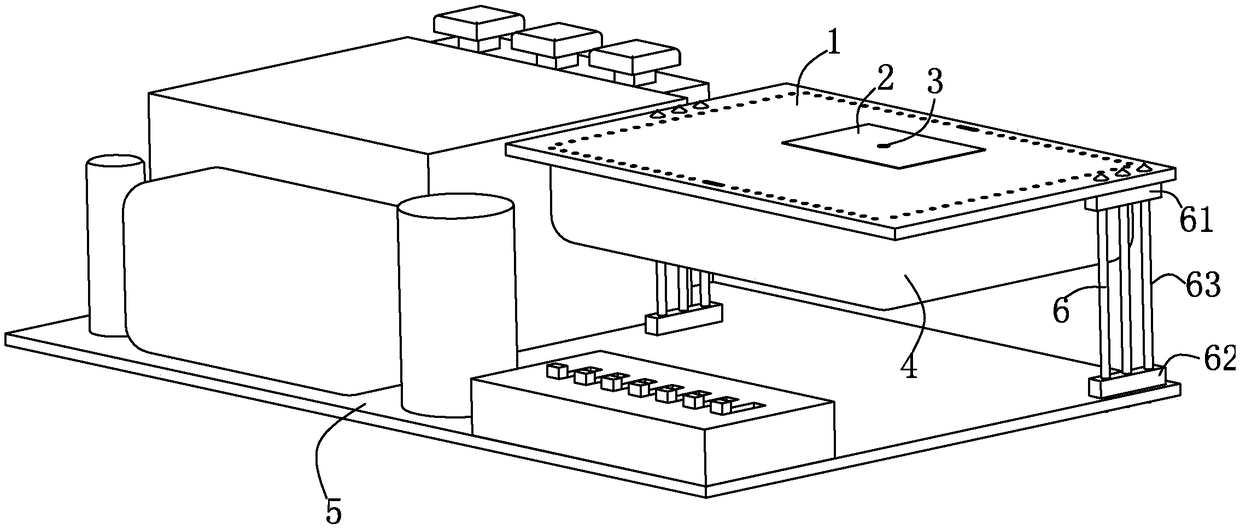

Microwave receiving and transmitting antenna, control module group, intelligent lamp, and antenna manufacturing method

PendingCN108346848ASmall footprintLow costAntenna supports/mountingsElectric circuit arrangementsMicrostrip antennaCost savings

The invention relates to a microwave receiving and transmitting antenna, a control module group, an intelligent lamp, and an antenna manufacturing method. The microwave receiving and transmitting antenna comprises a first circuit board and a first working circuit disposed on one side surface of the first circuit board. A laminar microstrip antenna is disposed on the first circuit board and is located on an opposite surface of the first working circuit. The microstrip antenna is electrically connected with the first working circuit. Through the advantages that the microstrip antenna is small inoccupied space, is convenient to produce and saves the cost, the control module group and the intelligent lamp which comprise the microwave receiving and transmitting antenna are advantageous in small occupied space and cost saving. Meanwhile, the intelligent lamp also can be enabled to save energy.

Owner:瑞德探测技术(深圳)有限公司

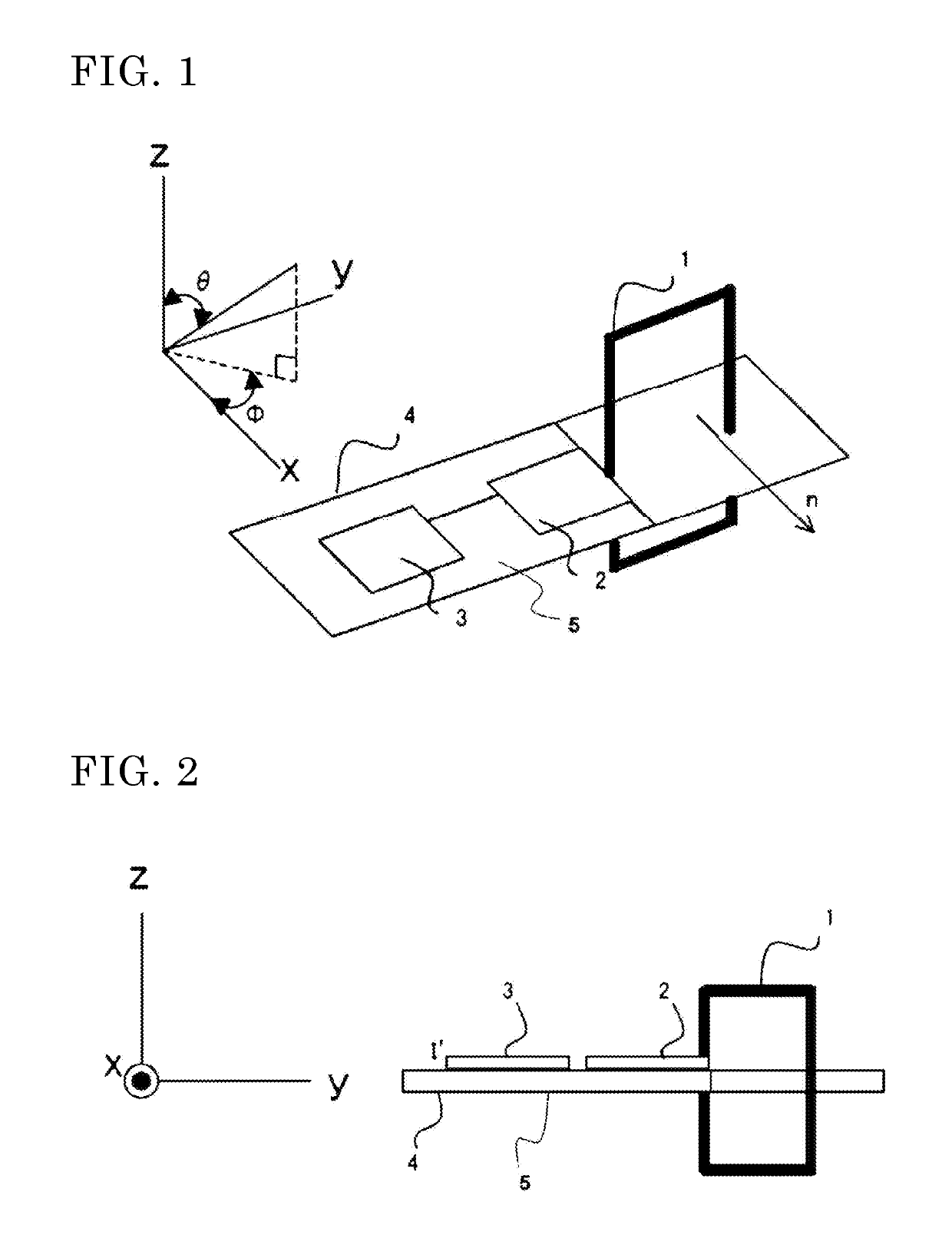

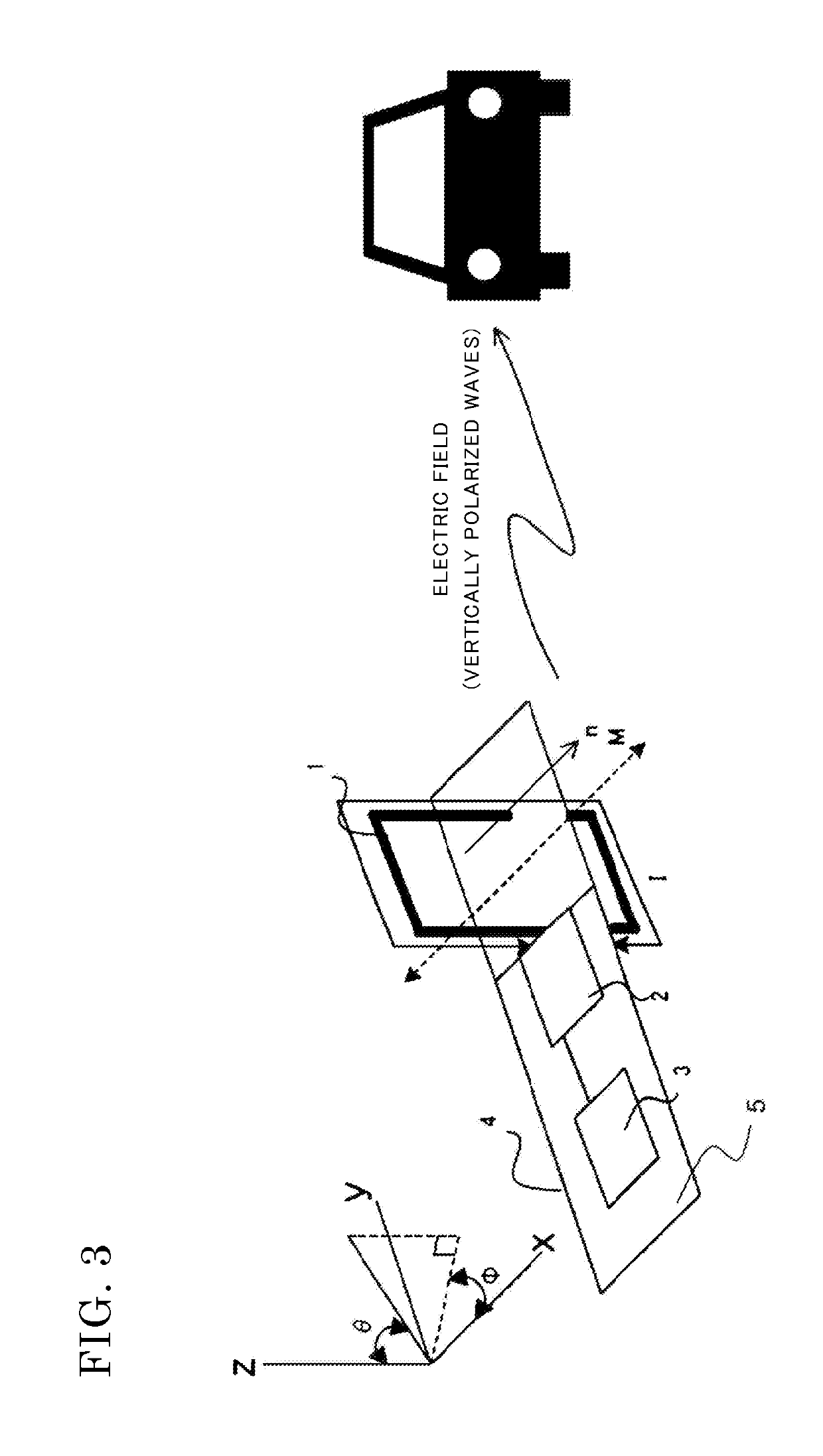

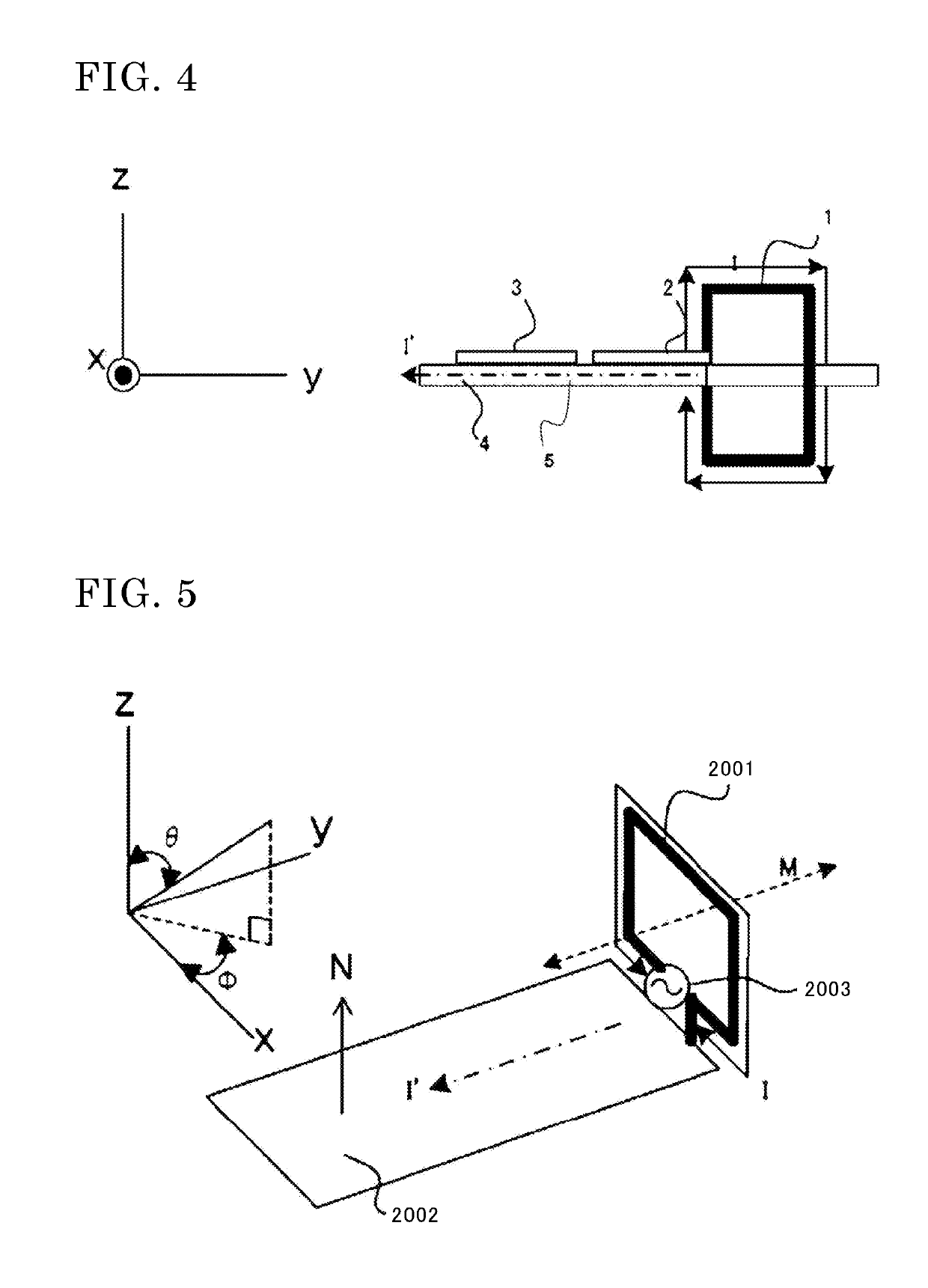

Antenna device and antenna manufacturing method

ActiveUS10243256B2Reduce power lossReduce lossesAntenna supports/mountingsAntenna adaptation in movable bodiesElectrical conductorAntenna fabrication

Owner:MITSUBISHI ELECTRIC CORP

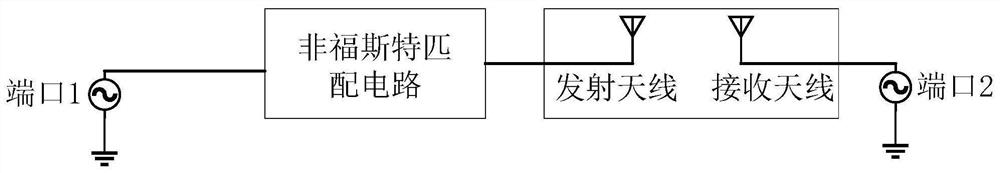

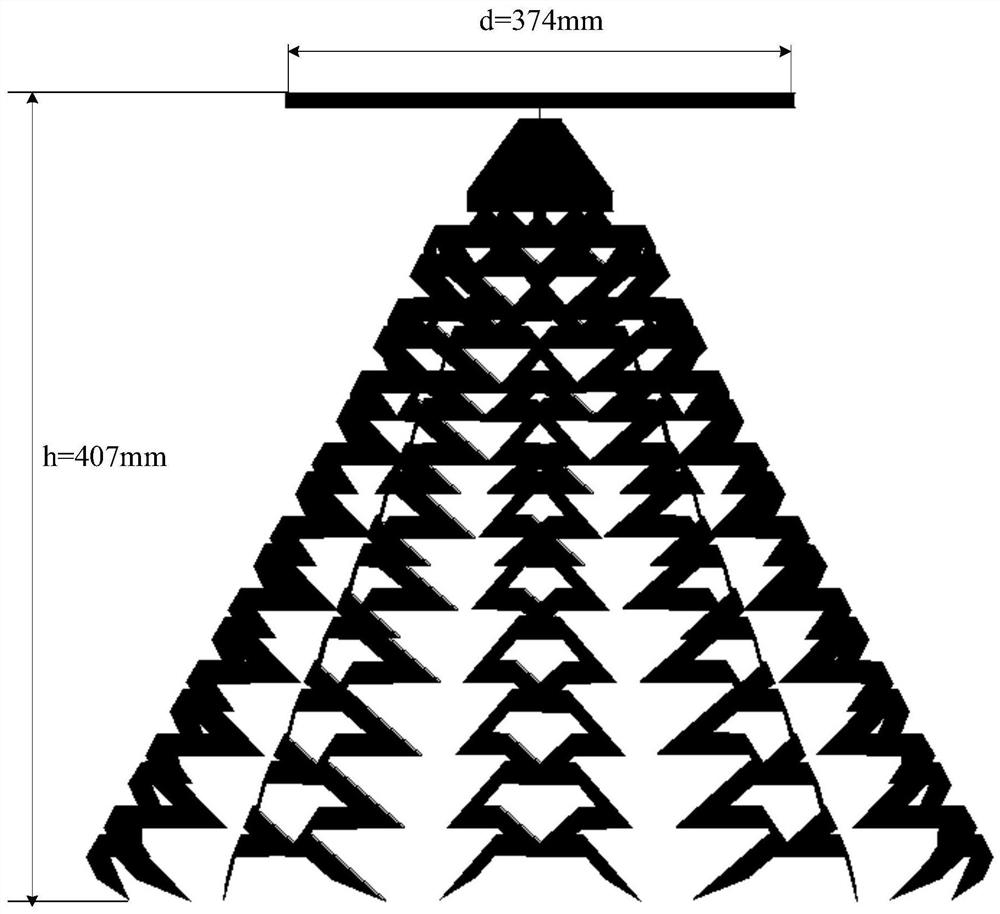

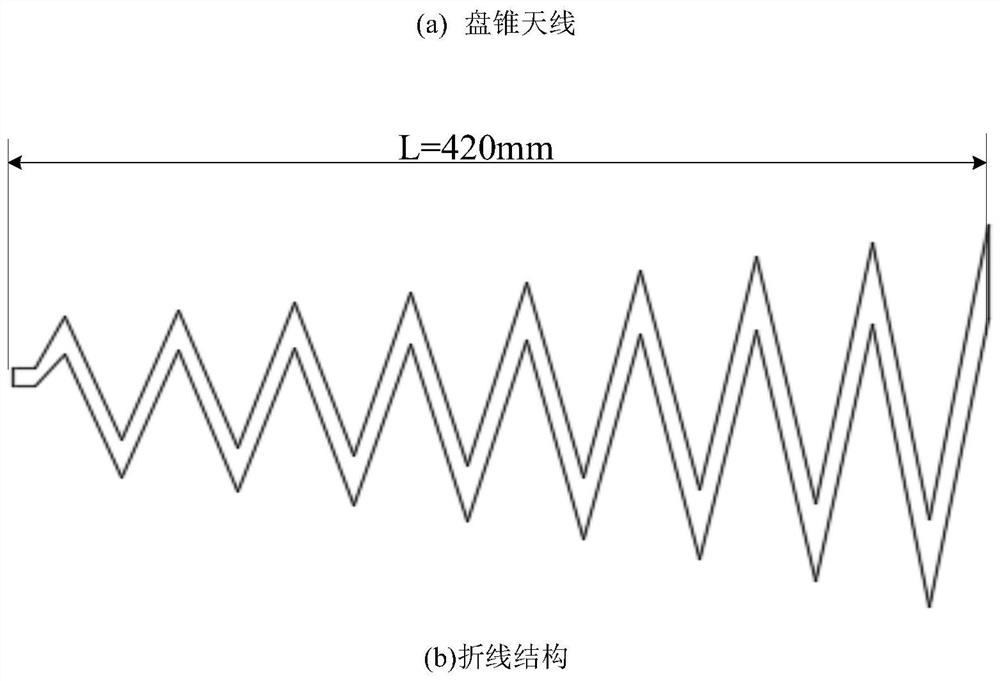

Miniaturized Discocone Antenna Based on Non-Foster Matching Circuit

ActiveCN111146574BSolve the problem that it is difficult to realize broadband miniaturization designResolve interferenceRadiating elements structural formsVibration dampingTelecommunicationsBone structure

The present invention claims a miniaturized disc-cone antenna based on a non-Foster matching circuit. The whole design includes a miniaturized disc-cone antenna and a non-Foster matching circuit. The non-Foster matching circuit includes a negative impedance converter, a transformer and The buffer circuit uses a broken line structure to replace the rib structure of the traditional disc cone antenna, which makes the antenna miniaturized, and on this basis, a non-Foster matching circuit is added to improve the performance of the antenna. The broken line structure increases the current path without increasing the size of the antenna, reduces the size of the antenna, introduces a non-Foster matching circuit to reduce the reflection coefficient of the antenna, and improves the transmission coefficient of the antenna. The invention can effectively solve the problem of excessive size of the antenna in the ultrashort wave communication, help reduce the cost of manufacturing and erecting the antenna in the ultrashort wave communication, and improve the radiation efficiency of the antenna.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

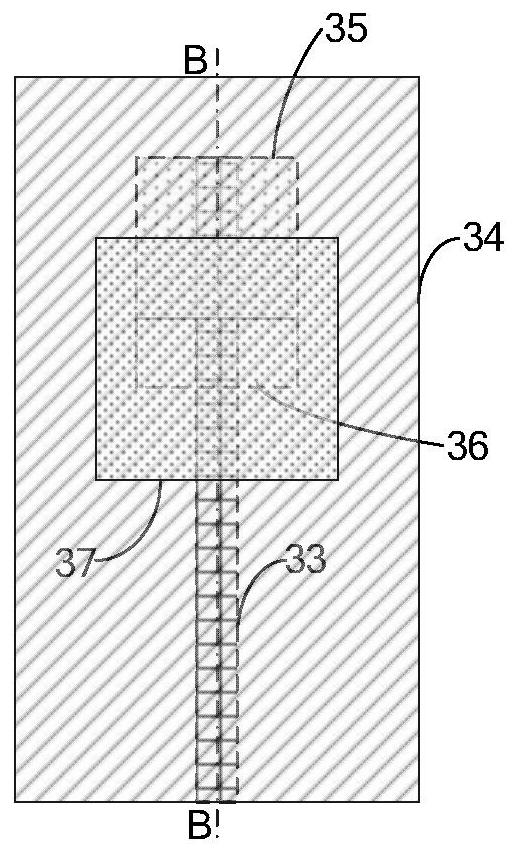

Polygonal loop antenna, communication device and antenna manufacturing method

ActiveCN107968264BWorking bandwidthSmall radiation stateLoop antennasAntennas earthing switches associationTelecommunicationsAntenna fabrication

Embodiments of the present disclosure relate to a polygonal loop antenna, a communication device and a method for manufacturing an antenna. For example, a polygonal loop antenna comprises: a radiation element, including a plurality of radiation units, each of the radiation units forming one side of the antenna; a plurality of capacitive elements, an even number of the capacitive elements being placed on each side of the antenna; and a plurality of feeding units, each of the feeding units is placed between two adjacent capacitive elements of the capacitive elements on each side of the antenna. Further, there is disclosed a corresponding communication device and method for manufacturing an antenna.

Owner:ALCATEL LUCENT SHANGHAI BELL CO LTD

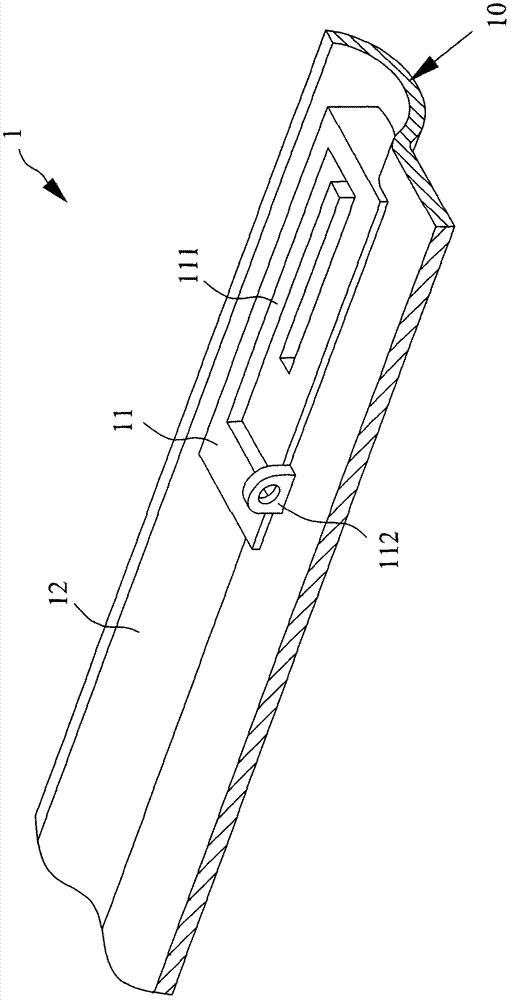

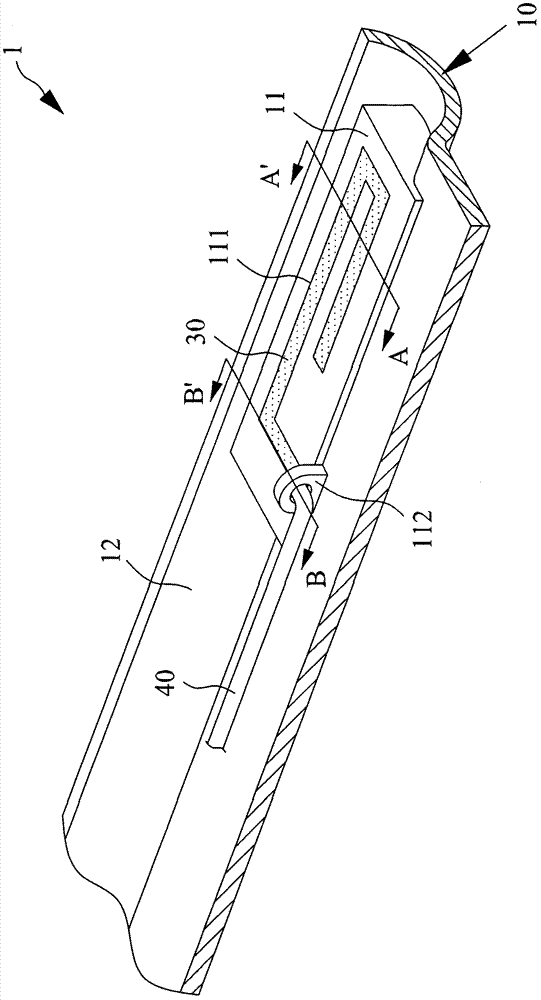

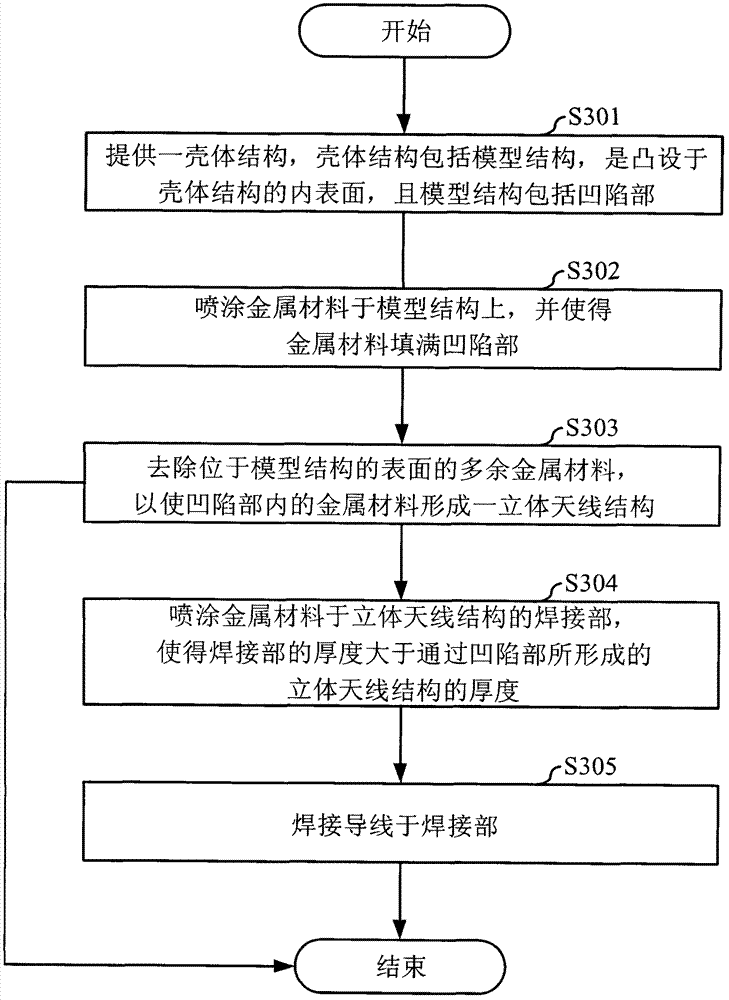

Electronic device housing integrating antenna and manufacturing method of the housing

InactiveCN103199330AReduce production processIncrease surface areaAntenna supports/mountingsTransmissionManufacturing cost reductionMetallic materials

An electronic device housing integrating an antenna and a manufacturing method of the housing. The method comprises the following steps: providing a housing including a model structure which is arranged on an inner surface of the housing in a protruding manner and includes a recessed part; spraying metal material on the model structure and enabling metal material to be filled in the recessed part; and removing redundant metal material located on the surface of the model structure, so as to enable the metal material in the recessed part to form a stereoscopic antenna structure. The invention also provides an electronic device housing manufactured by using the abovementioned manufacturing method of the electronic device housing integrating an antenna. Through the design of the electronic device housing integrating an antenna, the metal material forms an antenna in a stereoscopic form through the model structure of a housing structure, compared with an existing antenna by laser engraving, the antenna itself formed in the invention can provide an overall superficial area of a greater range by changing the depth of the recessed part, and the existing relatively complicated antenna manufacturing process can be reduced, so as to reduce manufacturing cost.

Owner:ACER INC

Antenna fabrication method

InactiveCN108281760AReduce manufacturing costReduce recycling costsRadiating elements structural formsCoatingsUltrasound deviceAntenna fabrication

The invention relates to the field of antennas, in particular to an antenna fabrication method. The antenna fabrication method comprises the steps of placing organic plastic powder and an oily solventin a container for immersion, and forming a solution after stirring; adding an additive into the solution to form paste; uniformly coating the prepared paste on a surface of a substrate, and performing drying to obtain a cured organic plastic layer; and winding the antenna onto the substrate coated with the organic plastic layer, and fixing the antenna on the organic plastic layer by ultrasonic wave equipment. The material such as paper easy to recycle is used as the substrate, and the production cost of the antenna is effectively reduced.

Owner:GUANGDONG CHUTIAN DRAGON SMART CARD

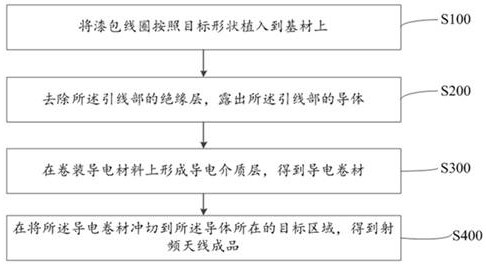

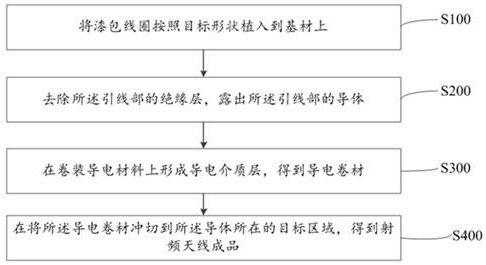

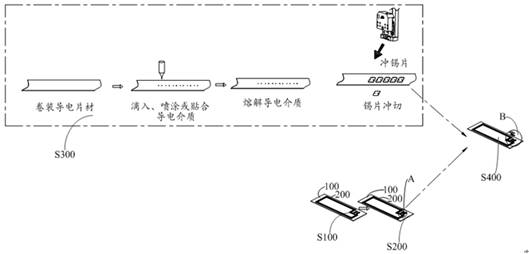

Radio frequency antenna manufacturing method and radio frequency antenna

ActiveCN114421139BSolve efficiency problemsAntenna supports/mountingsRadiating elements structural formsButt weldingAntenna fabrication

The invention relates to the technical field of antenna manufacturing, in particular to a method for manufacturing a radio frequency antenna and a radio frequency antenna. By implanting an enameled coil on a substrate according to a target shape, and then removing the insulating layer of the lead part by milling or grinding, the lead wire is exposed. Then drop a conductive medium onto the packaged conductive material to form a conductive coil, and press the conductive coil to the target area where the conductor of the lead part is located to form a structure that is electrically connected to the conductor, and let the conductor and the conductive medium The finished product of the radio frequency antenna with the layers integrally formed and electrically connected, so that the present invention no longer needs to use the touch welding method to remove the insulating layer on the enameled coil in the process of making the radio frequency antenna as in the prior art, which solves the problem of the prior art. When the insulating layer on the enameled coil is removed by the butt welding method, the base material is welded through due to the large number of solder joints, resulting in low efficiency and technical defects affecting the yield.

Owner:SHENZHEN YUANMINGJIE TECH

Wire cutting device for antenna

ActiveCN111112509BEasy to operateShorten the timeDirt cleaningCleaning using gasesAntenna fabricationTransfer mechanism

The invention relates to the technical field of antenna manufacturing, in particular to a wire cutting device for antennas, which includes a feeding assembly for feeding, a wire cutting assembly for cutting the wires, and a receiving assembly for collecting and cutting the wires; the wire cutting assembly includes Box body, transmission mechanism and cutting mechanism; there are wire inlets and outlets on the box body, and the transmission mechanism is used to transmit wires; the thread cutting mechanism includes a fixed knife and a moving knife, and the upper end of the side wall of the moving knife is connected with a connecting plate, and the connecting plate is fixed. A connecting rod is connected, and the connecting rod is slidingly connected with the box body. The end of the connecting plate away from the moving tool is connected with a sliding block. The upper end of the sliding block is provided with a cam, and four protrusions are arranged at intervals on the circumference of the cam. The four protrusions The maximum distance between the top and the outer circular surface of the cam becomes larger successively, and an elastic restoring part is arranged under the sliding block. The invention has the effects of convenient operation, shorter time for producing a single wire, and improved production efficiency.

Owner:东莞市天技实业有限公司

Rotary buckle structure, antenna plate and assembly method thereof

ActiveCN109830791BImprove versatilityGuaranteed reliabilityAntenna supports/mountingsAntenna fabricationSupport surface

The invention relates to the field of antenna manufacturing, and provides a rotating buckle structure, an antenna panel and an assembly method thereof, wherein the rotating buckle structure includes a top plate, a shaft, a clamping part and two elastic supporting surfaces; the clamping part is arranged on the shaft the first end of the shaft, and the second end of the shaft is arranged on the top plate; two support surfaces are symmetrically arranged on both sides of the shaft with respect to the axis of the shaft, and one end of each support surface is connected to one side of the top plate, and the other end is provided There is a fixed part; the fixed part faces the direction where the clamping part is located. The rotary buckle structure provided by the present invention is provided with a clamping part at one end of the shaft; and a fixed part is provided at the other end of the support surface, so that the rotary buckle structure can be clamped on the antenna plate; The supporting surface is set to be elastic, so that the rotating buckle structure can adapt to antenna plates of different thicknesses, which improves the versatility and reliability of the rotating buckle structure.

Owner:WUHAN HONGXIN TELECOMM TECH CO LTD

Antenna device and method for making antenna

ActiveCN103904422BSmall footprintRadiating elements structural formsProtective material radiating elementsAntenna fabricationDielectric layer

An antenna device and a method for making an antenna are provided. The antenna device includes: a carrier layer, which is the base carrier of the antenna device; a metal layer, located on the carrier layer, used to transmit and receive signals as a radiator; a high dielectric layer, directly contacting the metal layer , formed by a high dielectric material with a dielectric constant greater than a preset threshold. In the technical solutions of the antenna device and the method for manufacturing the antenna according to the embodiments of the present invention, by providing a high dielectric layer that is in direct contact with the metal layer, the space occupied by the antenna can be reduced.

Owner:LENOVO (BEIJING) LTD

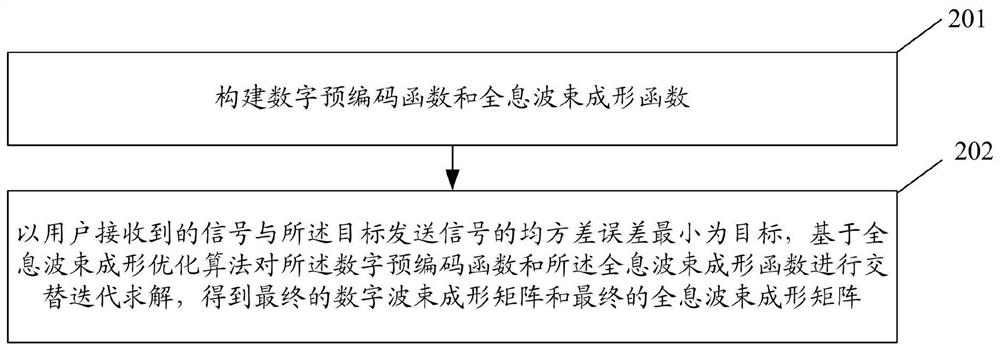

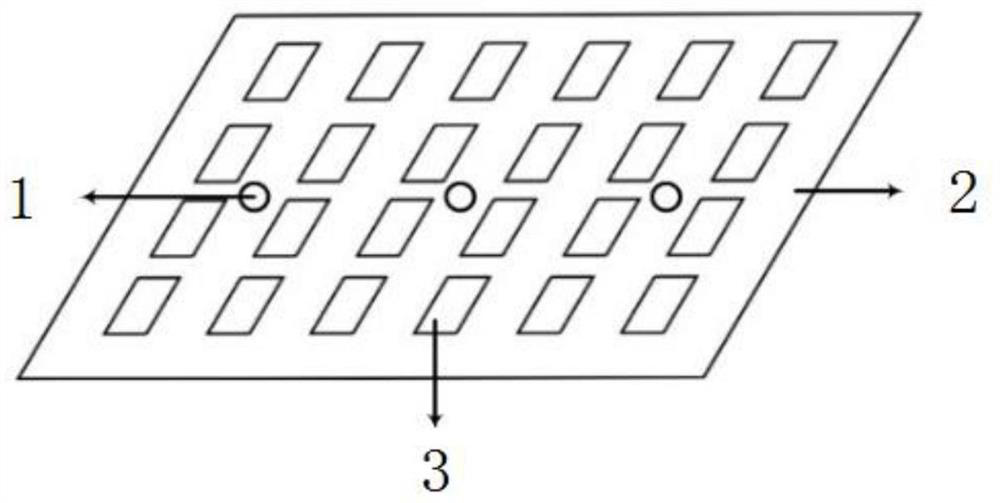

A Hybrid Precoding Method and System Based on Reconfigurable Holographic Metasurface

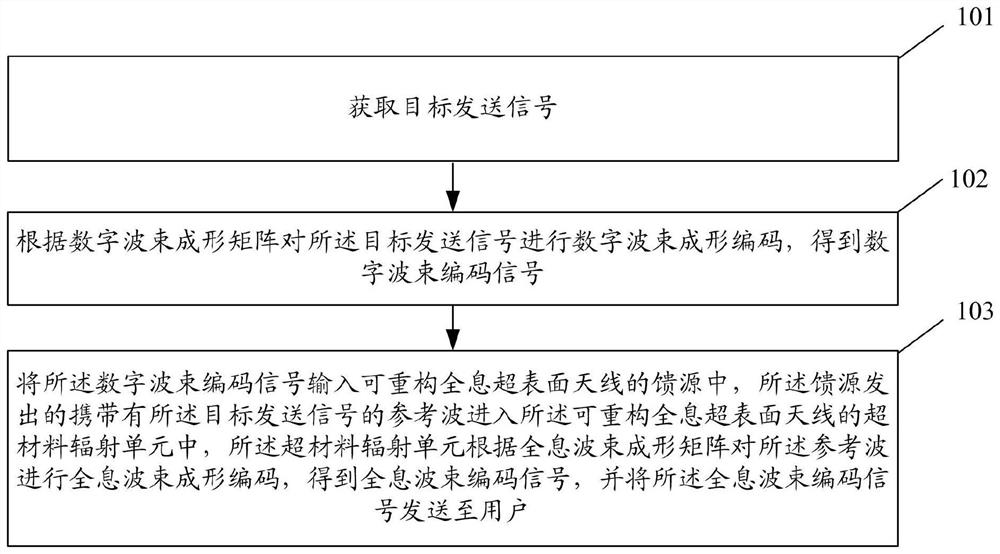

ActiveCN113595607BImprove communication qualitySpatial transmit diversityHigh level techniquesPrecodingCommunication quality

The invention discloses a hybrid precoding method and system based on a reconfigurable holographic metasurface. The method includes: performing digital beamforming encoding on the target transmission signal according to the digital beamforming matrix; inputting the digital beam encoding signal into the feed source of the reconfigurable holographic metasurface antenna, and the reference wave carrying the target transmission signal sent by the feed source Entering the metamaterial radiation unit of the reconfigurable holographic metasurface antenna, the metamaterial radiation unit performs holographic beamforming encoding on the reference wave according to the holographic beamforming matrix, and sends the holographic beam encoding signal to the user. The invention can improve the communication quality while solving the problems of high antenna manufacturing cost and large power loss in the mobile communication process.

Owner:PEKING UNIV

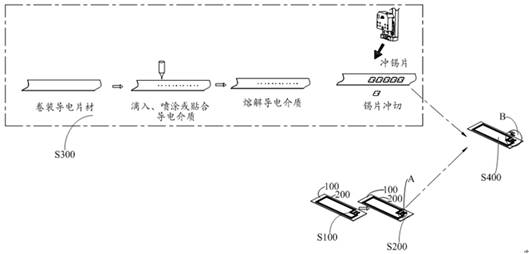

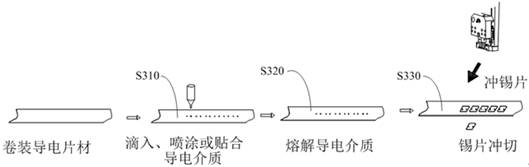

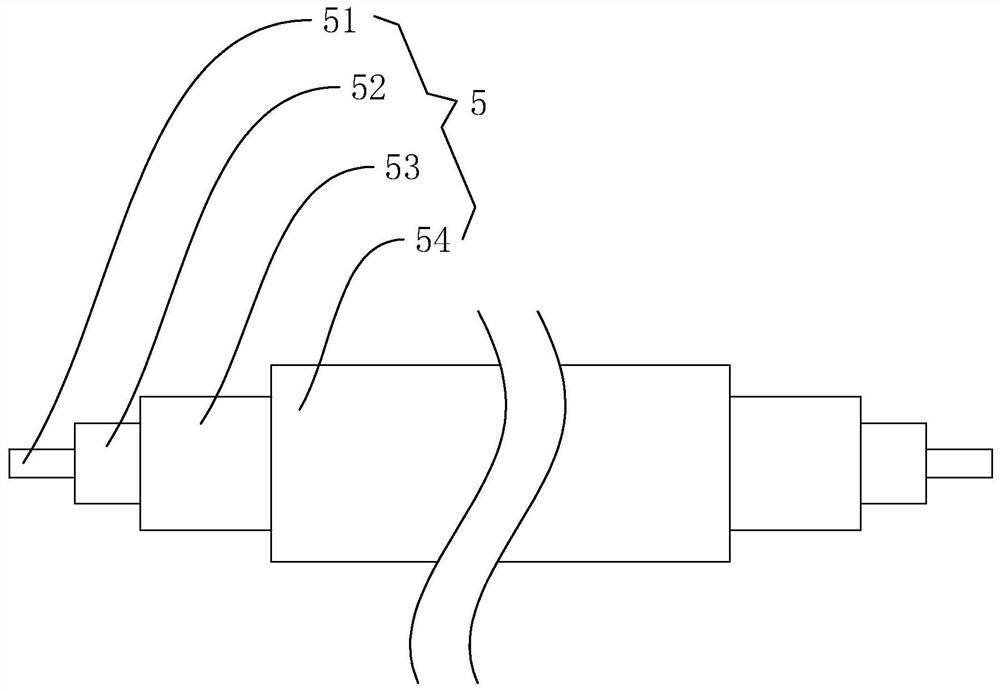

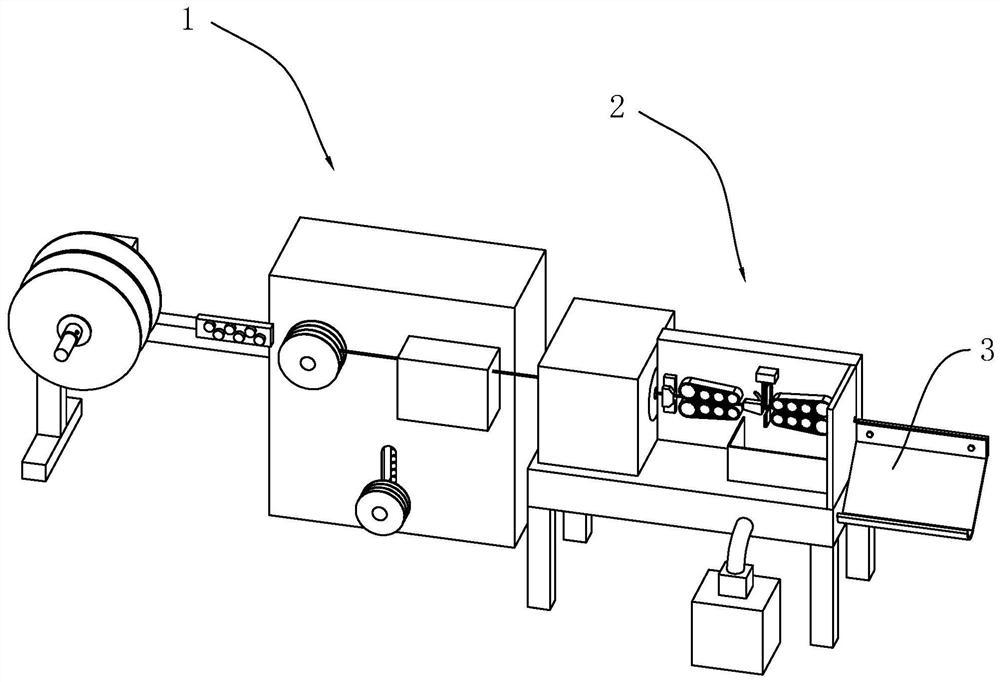

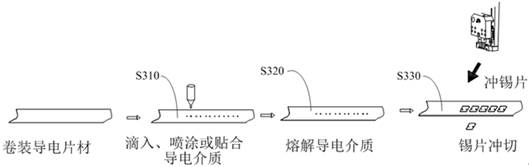

Radio frequency antenna manufacturing method and radio frequency antenna

ActiveCN114421139ASolve efficiency problemsAntenna supports/mountingsRadiating elements structural formsAntenna fabricationElectrical connection

The invention relates to the technical field of antenna manufacturing, in particular to a radio frequency antenna manufacturing method and a radio frequency antenna, an enameled coil is implanted into a base material according to a target shape, then an insulating layer of a lead part is removed by adopting a milling or polishing mode, a conductor of the lead part is exposed, and the radio frequency antenna is manufactured. Next, a conductive medium is dropped on the coiled conductive material to form a conductive coiled material, the conductive coiled material is pressed to a target area where a conductor of a lead part is located to form a structure electrically connected with the conductor, and the conductor and a conductive medium layer form a whole and are electrically connected with a radio frequency antenna finished product. Therefore, in the process of manufacturing the radio frequency antenna, it is no longer needed to remove the insulating layer on the enameled coil in a butt-welding mode like the prior art, and the problems that in the prior art, when the insulating layer on the enameled coil is removed in the butt-welding mode, a base material is welded through due to the fact that welding spots are too many; the efficiency is low; and the yield is influenced.

Owner:SHENZHEN YUANMINGJIE TECH

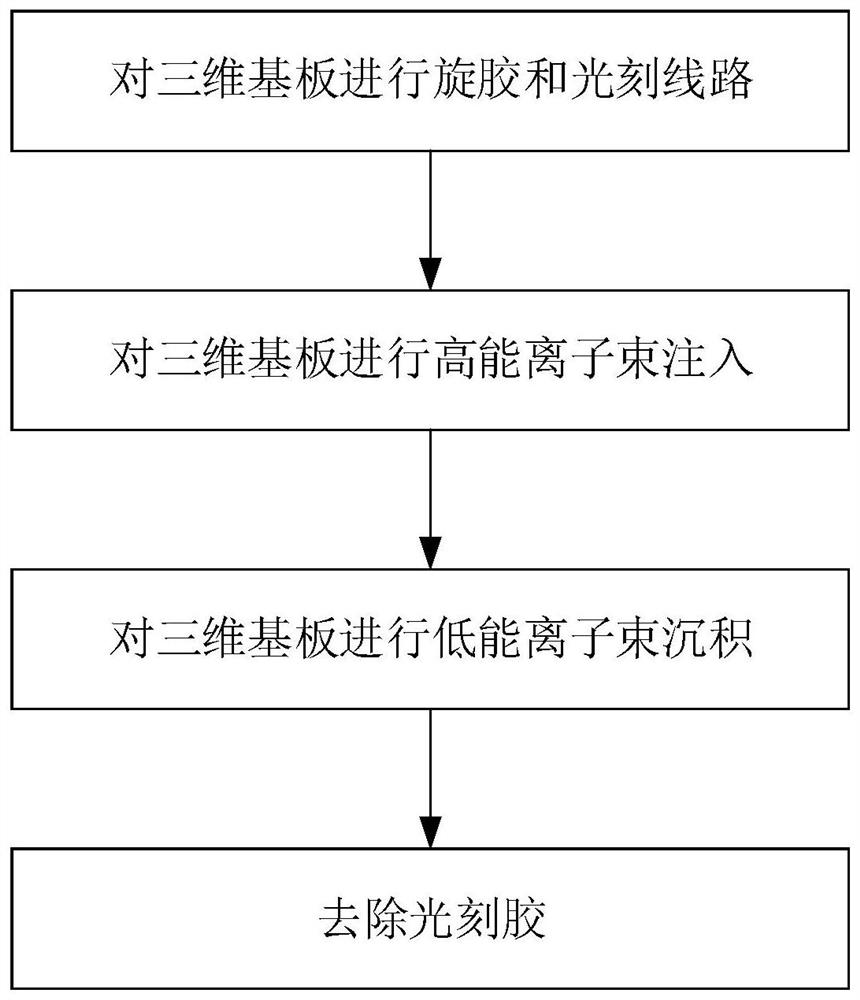

An Antenna Preparation Method Alternative to Laser Direct Structuring Technology

ActiveCN111005003BLow efficiencyLow costVacuum evaporation coatingSputtering coatingAntenna fabricationEngineering

The invention discloses an antenna preparation method which replaces the laser direct forming technology. The matrix sample enters the preparation room through a conveyor belt, and a drying system is installed in the preparation room to ensure the cleanness and drying of the sample; the matrix sample enters the pre-extraction room through the conveyor belt after drying; After the gas is completed, it enters the buffer chamber through the conveyor belt, and the buffer chamber is subjected to high vacuum pumping by a molecular pump; finally enters the processing chamber, where high-energy ion implantation and low-energy ion beam deposition operations are performed, and finally samples are collected to complete the processing process. The invention provides an antenna preparation method that replaces the laser direct forming technology. The method is based on high-energy ion beam technology, low-energy ion beam technology and related mask technology to form a metal antenna with certain functions. The antenna prepared by the method has the characteristics of low cost, no need for laser powder, good corrosion resistance, high bonding strength, good film consistency, low surface roughness, and environmental protection.

Owner:BEIJING NORMAL UNIVERSITY

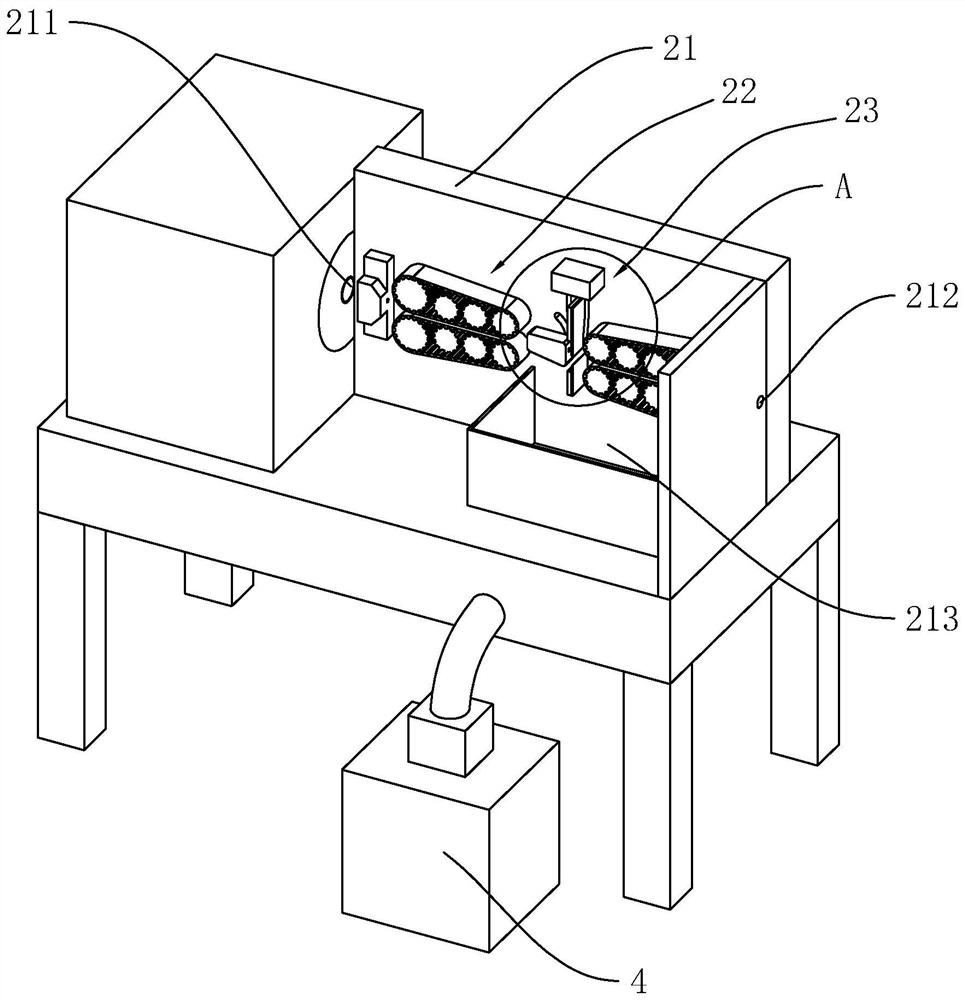

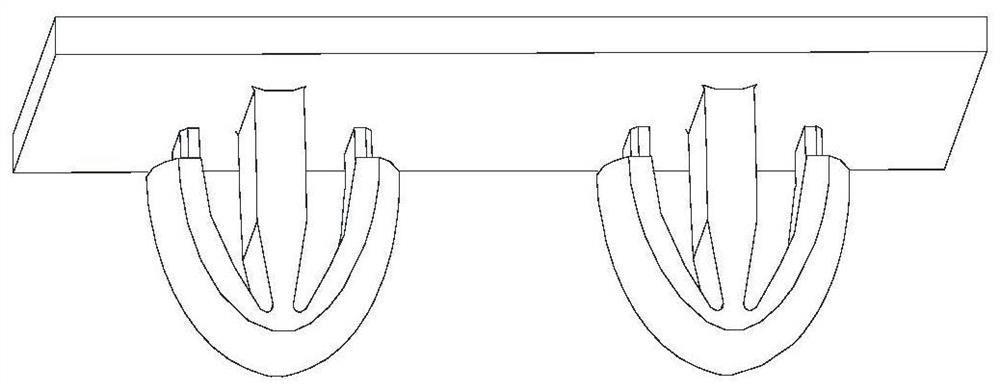

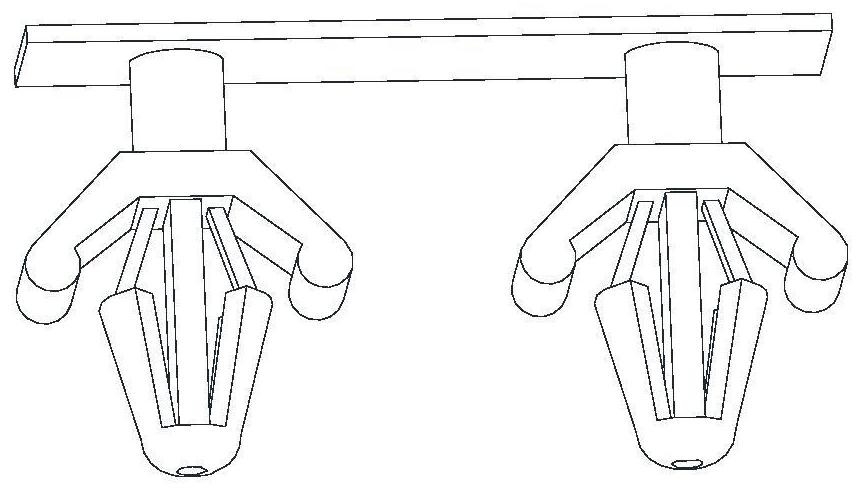

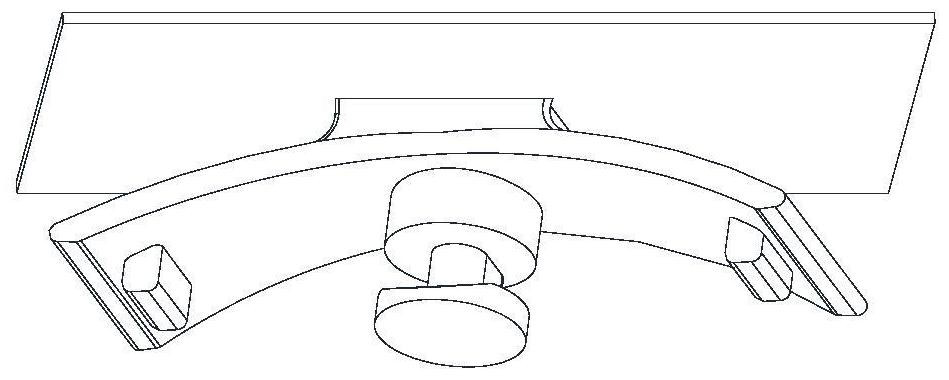

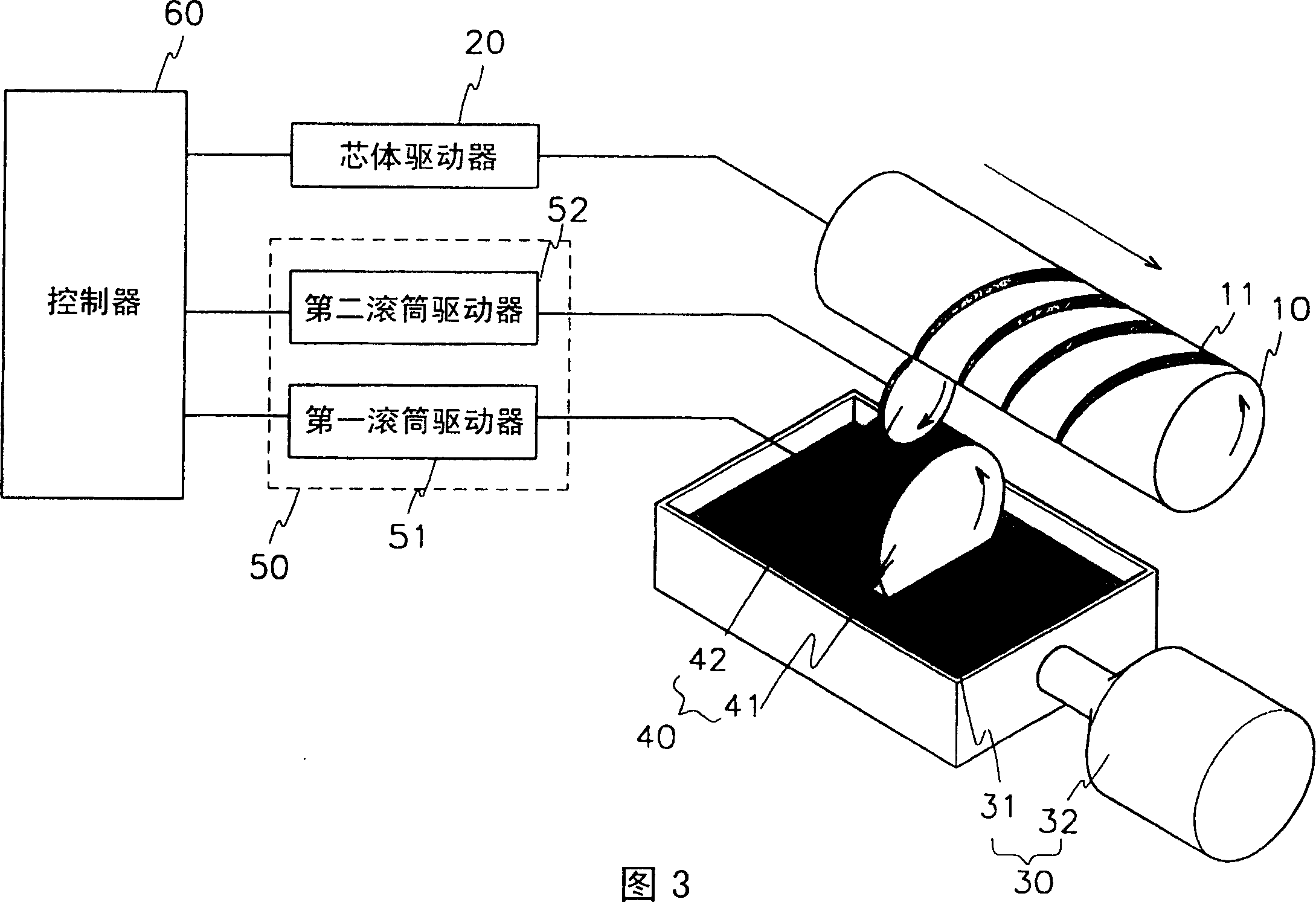

Helical antenna manufacturing apparatus and method thereof

Disclosed is a helical antenna manufacturing apparatus and method. A controller controls a core driver and a roller driver to rotate a core and a roller according to an rpm which is pre-set according to diameters of the core and the roller, and controls the core driver to move the core in a longitudinal direction according to the moving speed which is set according to working frequency bands of the antenna. When the core and the roller are contacted, they are rotated in opposite directions, and as the roller is rotated, a paste in a paste box moves together with a surface of the core and is printed on the surface of the core. As the core is rotated and moved in the longitudinal direction, a helical line is formed on the core. Pitches of the helical line formed on the core is changed according to the moving speed of the core in the longitudinal direction, and the working frequency bands of the antenna are changed according to the pitches of the helical line. Also, a helical line unit including a plurality of helical lines having different pitches printed on the surface of the core can be formed by controlling the core driver to move the core in the longitudinal direction according to the moving speeds which are set for the respective steps according to the working frequency bands of the antenna.

Owner:K CERA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com