Horizontal well automatic anchor release hydraulic righting device

A horizontal well and hydraulic technology, applied in the direction of drilling equipment, wellbore/well components, production fluid, etc., can solve the problems of large shrinkage diameter, unsuitable casing deformation, scaling, etc., to achieve convenient withdrawal and reduce accidents The effect of card risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

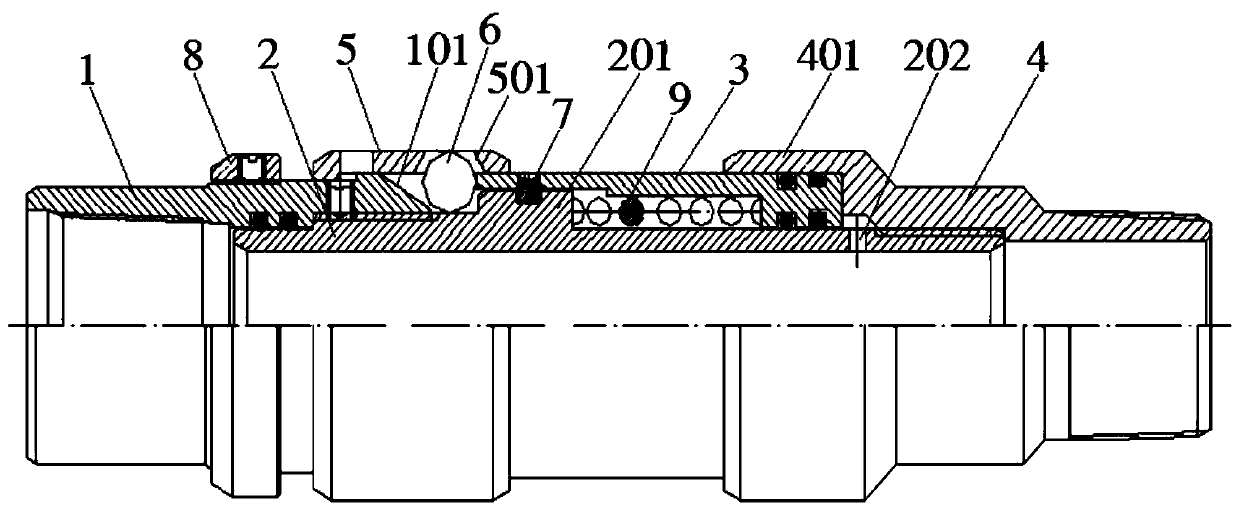

[0024] reference figure 1 The self-unlocking hydraulic centralizing device for horizontal wells of the present invention includes a front joint 1, a central tube 2, a piston tube 3, a rear joint 4, and a centralizing sleeve 5. The rear end of the front joint 1 is provided with a ring cone 101; The front end is connected with the inner side of the rear end of the front joint 1 through an external thread. A shoulder 201 is provided in the middle of the center tube 2; the piston tube 3 is slidingly sleeved on the center tube 2, and the rear end of the piston tube 2 is a necked end. Both the inner and outer side walls of the end are provided with a sealing groove, and an O-ring is fitted in the sealing groove. The front end of the piston tube 2 is slidingly fitted with the shaft shoulder 201, and the rear end is slidingly fitted with the wall of the central tube 2, and the rear of the piston tube 3 A spring 9 is arranged between the inner ring surface of the end and the shaft shoul...

Embodiment 2

[0027] On the basis of Example 1, refer to figure 1 A start pin 7 is provided between the front end of the piston tube 3 and the shaft shoulder 201. The start pin 7 can fix the piston tube 3 so that it can withstand a high pressure of 4MPa. When the pipe string is lowered to the designed position, the piston tube 3 will not be easily moved forward by the joint 1 due to external force, causing the device to be stuck in the casing. After the pipe string is set, high-pressure water is introduced into the pipe string to make the internal high pressure of the central pipe 2 exceed 4MPa, the high-pressure water pushes the piston pipe 3 to the front end, and the piston pipe 3 cuts off the start pin 7 and continues to the forward joint 1. Movement, at this time, the ball 6 protrudes from the through hole 501 on the centralizing sleeve 6 to realize the centralization of the pipe string.

Embodiment 3

[0029] On the basis of Example 1, refer to figure 1 , The front joint 1 is threadedly connected with a parallel cap 8, and a pin is connected between the cap 8 and the front joint 1. The piston tube 3 moves forward to the joint 1 under the pressure inside the center tube 2, and the roller 6 rolls in the direction of the forward joint 1 along the tapered surface 101 of the front joint 1, and at the same time, drives the centralizing sleeve 5 to the forward joint through the through hole 501 1 movement, the cap 8 fixed on the front joint 1 by a pin can limit the position of the centralizing sleeve 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com