Grillwork for pressurized water reactor fuel assembly

A technology for fuel assemblies and pressurized water reactors, which is applied to reactor fuel elements, reactors, and greenhouse gas reduction, etc., can solve the problems of inability to limit internal strips, poor structural rigidity, poor strength, and thicker plate thickness, so as to avoid cracks. and deformation, increased stiffness, high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The grid frame in the prior art is composed of inner strips and outer strips, and the inner strips are interlaced and surrounded by the outer strips. Both the inner strip and the outer strip are formed by pressure processing of metal plates, and the inner strips, the inner strip and the outer strip are connected by welding; the disadvantages are:

[0035] Both the inner strip and the outer strip are processed by pressure from metal plates; the pressure processing is prone to cracks and springback, so there are many defects, the process is complicated, and the processing efficiency is low; in addition, the protrusions on the inner strip and the outer strip Because it is formed by pressure processing, it will cause local plate thinning, which affects the local stiffness and strength of the strip.

[0036] In view of the above problems, the present invention provides a grid for PWR fuel assemblies.

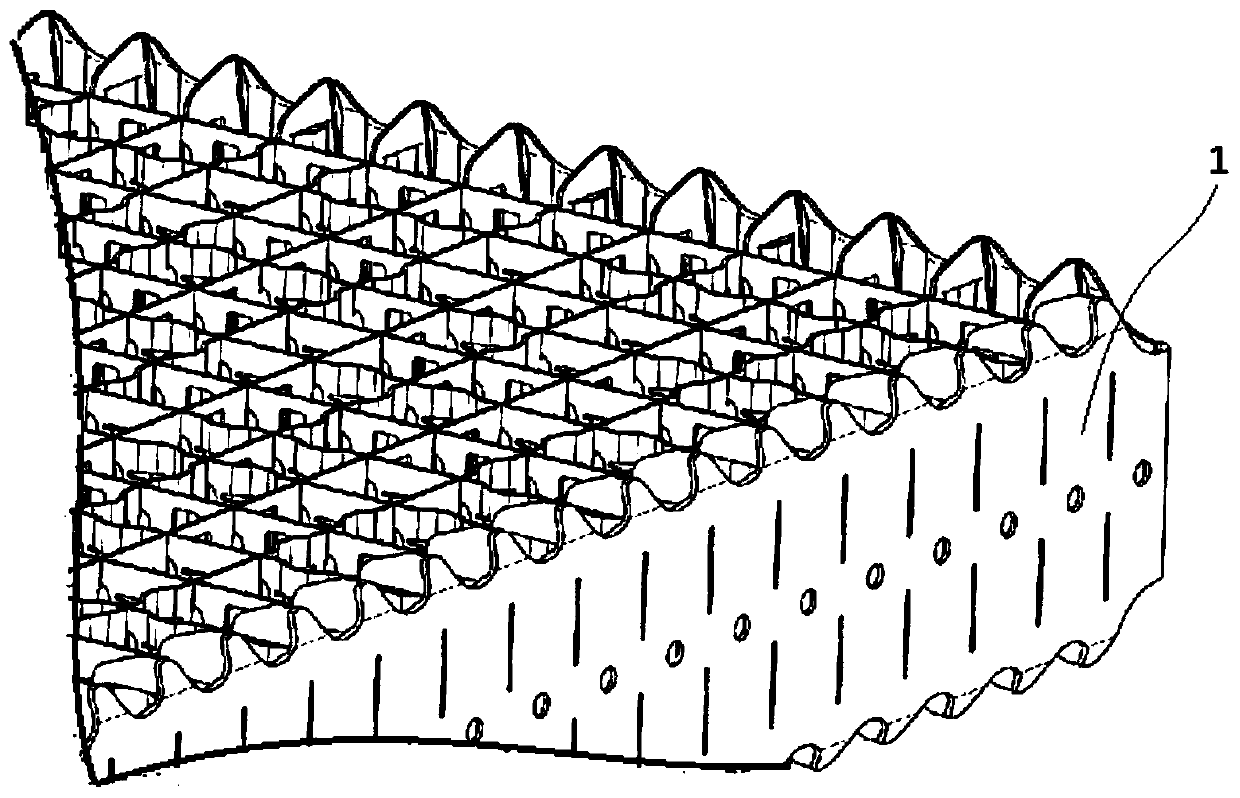

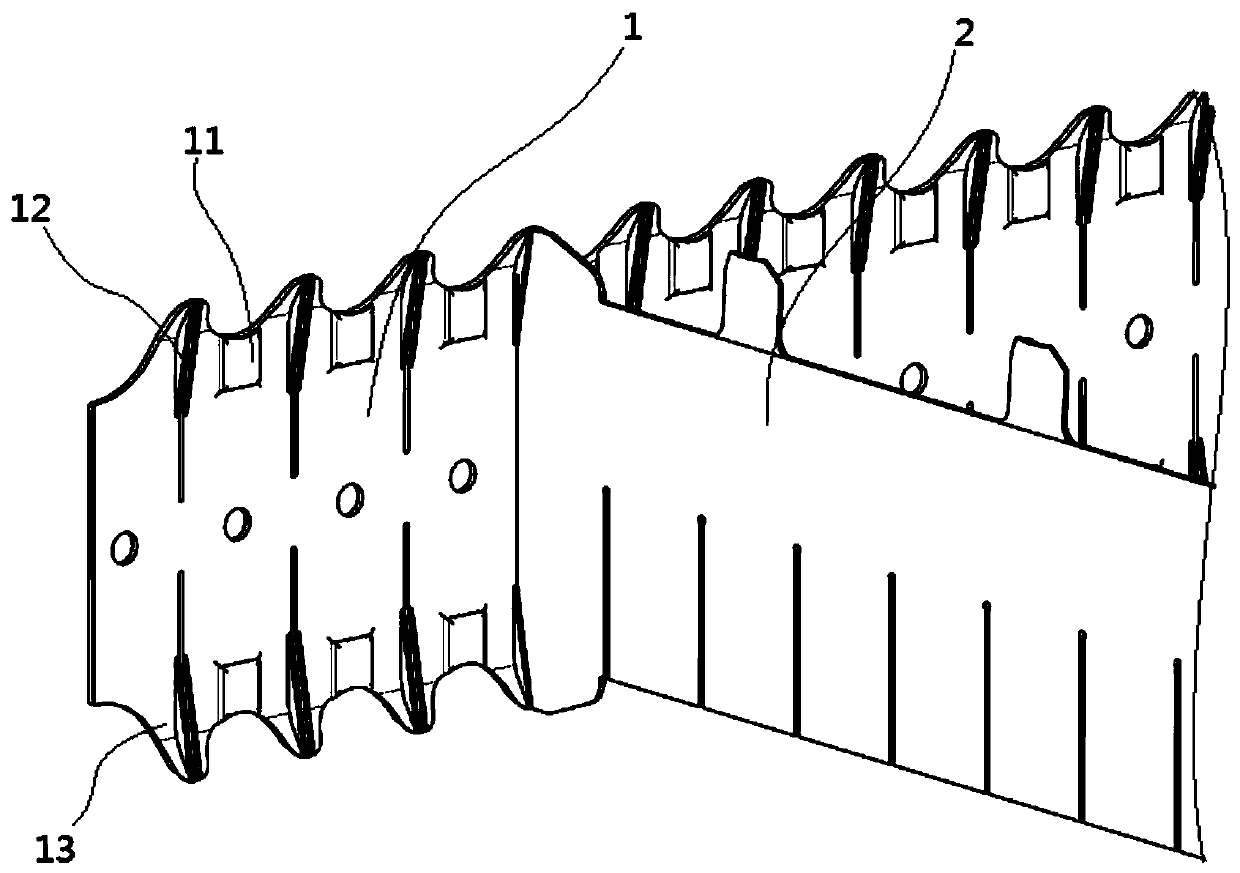

[0037] Specific as figure 1 with figure 2 As shown, a grid for PWR fu...

Embodiment 2

[0045] The embodiment of the present invention is further limited on the basis of embodiment 1.

[0046] In the prior art grid, the guide fins of the outer strips are also bent inwards to reduce the risk of the adjacent components being caught during loading and unloading, but the guide fins bent inwards in the vertical direction Rigidity will be reduced, and it is easy to deform in the vertical direction when the assembly is loaded and unloaded.

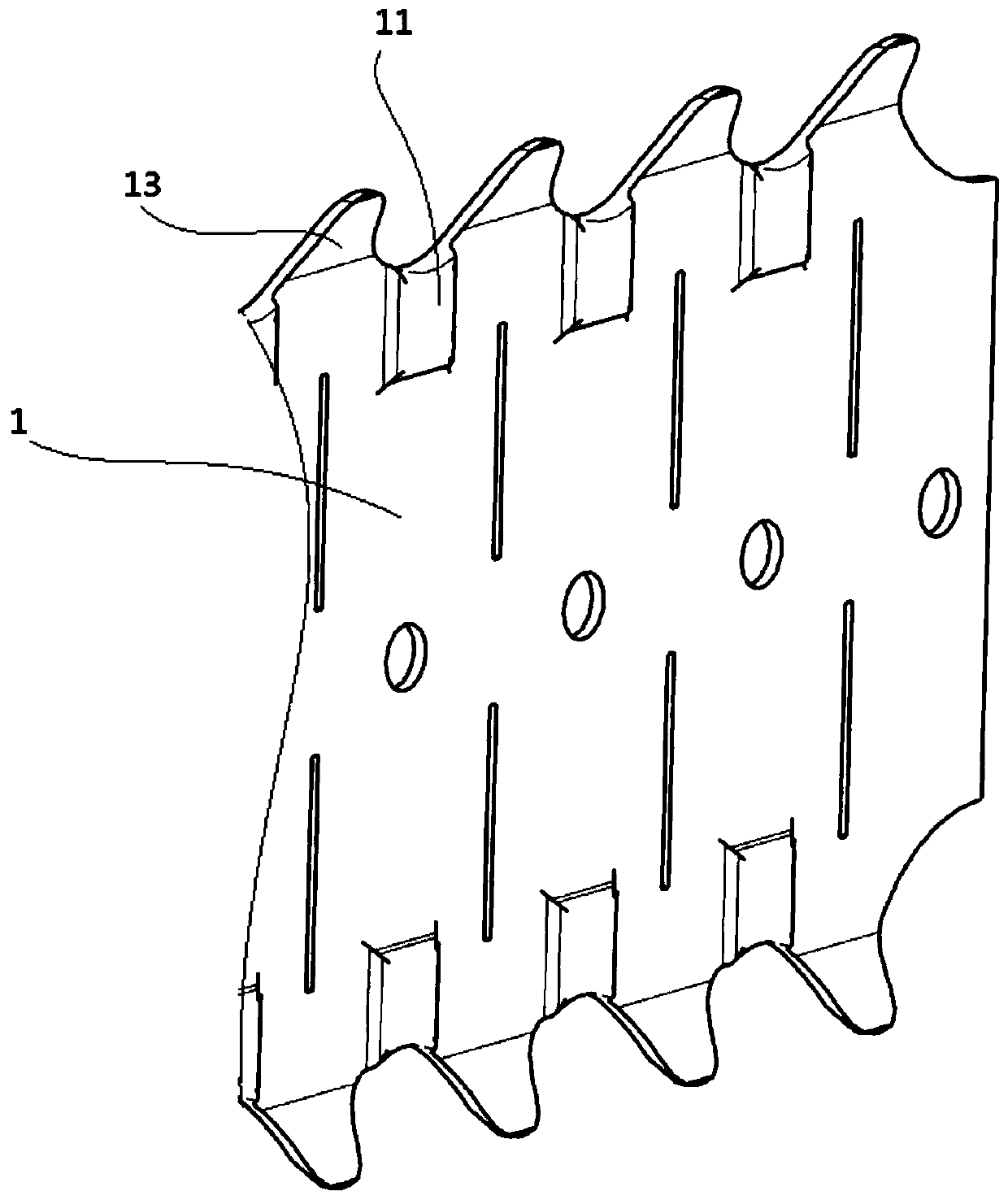

[0047] Such as Figure 4 with Figure 5 As shown, in order to increase the stiffness of the guide fins 13 in the vertical direction and reduce the risk of the adjacent components being caught during loading and unloading, a reinforcement structure is provided on the inner surface of the guide fins 13, and the reinforcement structure passes through the outer strip The limit slots provided on the belt 1 are used for position limit, and the reinforcing structure is vertically distributed with the guide fins 13 .

[0048] Furthermore...

Embodiment 3

[0052] The difference between the embodiment of the present invention and embodiment 2 only lies in:

[0053] The reinforcing structure is a reinforcing plate 14 , and an opening groove 15 is opened on the reinforcing plate 14 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com