Rock core slotting tool for fracture toughness experiment and slotting method thereof

A fracture toughness and core technology, which is applied to the fracture toughness test core grooving tool and its grooving field, can solve the problems of hand-painted accuracy and inaccurate position of the grooving opening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention will be further described:

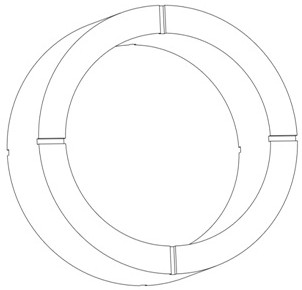

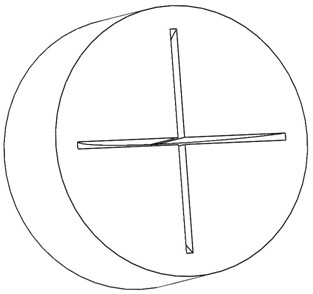

[0020] combine Figure 1-Figure 4 As shown, this fracture toughness experimental core slotting tool includes a cylindrical ruler, a core fixture, a fixture calibration tool, and a combination of a grinding wheel cutting machine. An experimental core with a diameter of 38 mm and a length of 19 mm is made by wire cutting, and the center of the experimental core is drawn using a cylindrical ruler. Cutting line, use the jig calibration tool to determine the relative position of the core jig and cutting saw blade, take out the jig calibration tool, put in the experimental core, use the grinding wheel cutting machine to cut and slot, accurately determine the slot position of the core, the core cutting process is stable and accurate, The problem of the accuracy of the experimental rock core slotting is solved, and the problem of the cutting stability of the rock core slotting is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com