Combined drilling device

A technology for drilling devices and drill pipes, which is applied in the direction of driving devices, drill pipes, and drill pipes for drilling in boreholes, and can solve problems such as frequent accidents in holes, buried drilling, and difficult removal of rock dust and rock particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

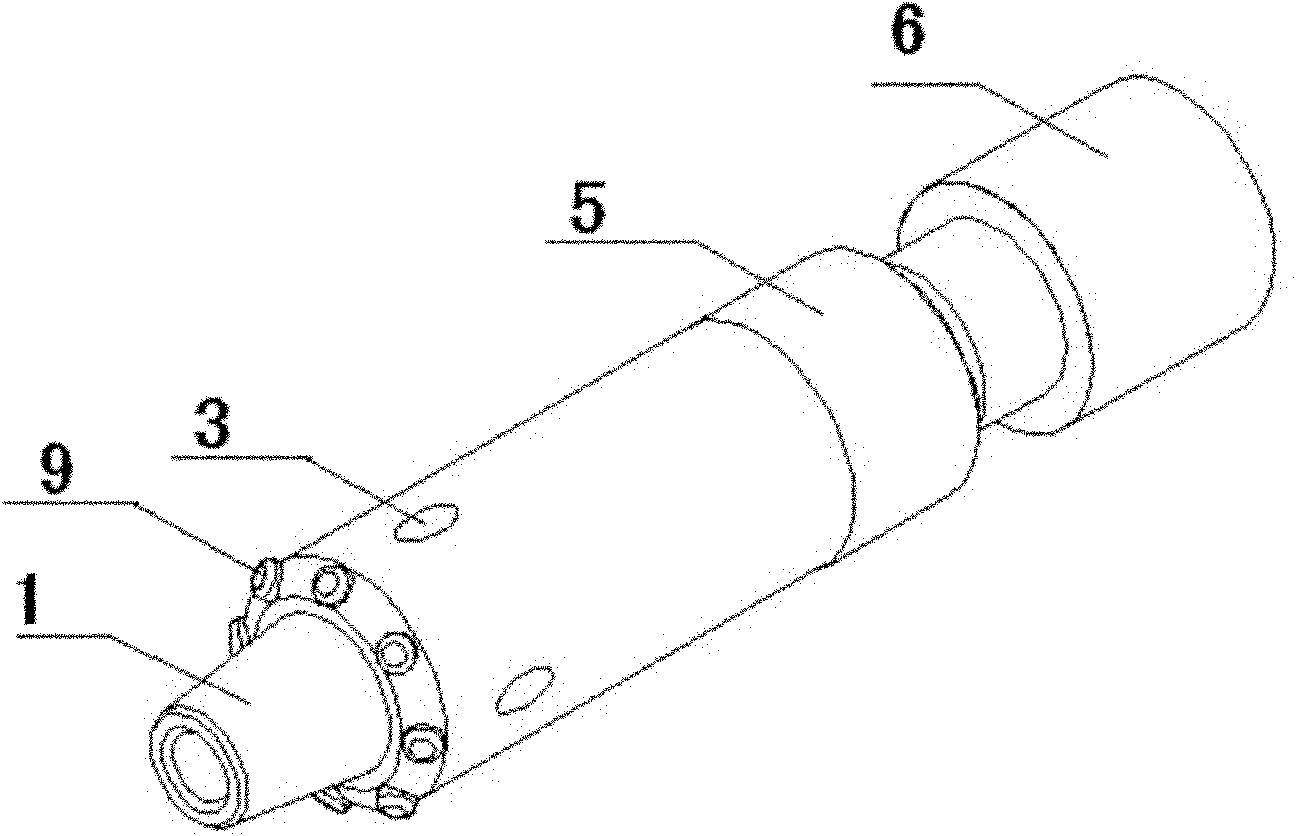

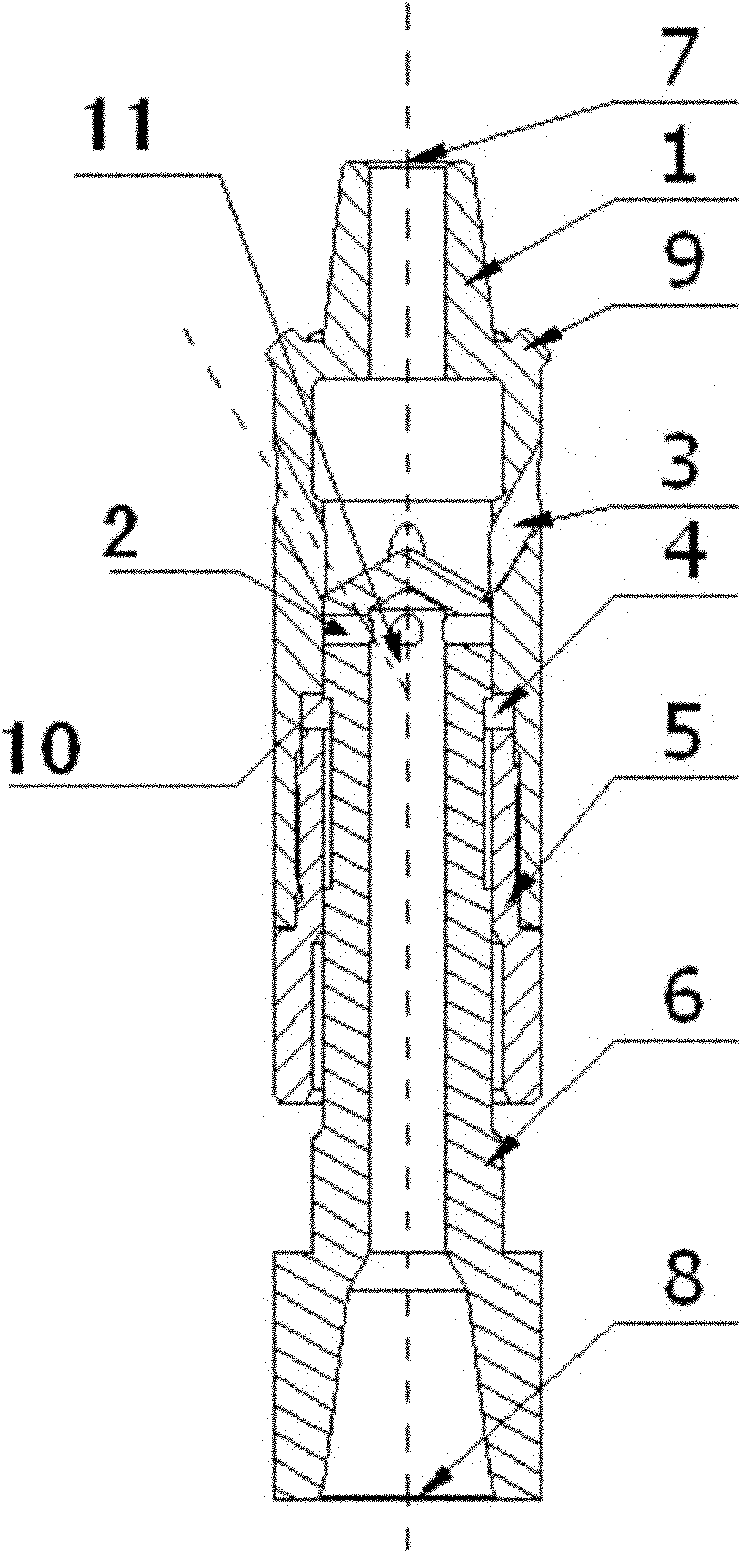

[0038] combine Figure 1 to Figure 7 .

[0039] figure 1 It is a schematic diagram of the connection structure of the device of the present invention, figure 2 It is a schematic diagram of the working state of the reverse blowing grinding device, image 3 It is a schematic diagram of the cross-sectional structure of the working state of the reverse blowing grinding device, Figure 4 It is a schematic diagram of the non-working state of the reverse blowing grinding device, Figure 5 It is a schematic diagram of the cross-sectional structure of the non-working state of the reverse blowing grinding device, Figure 6 It is a schematic diagram of the structure state of the centralizing device without edges and teeth, Figure 7 It is a schematic diagram of the cross-sectional structure of the centralizing device without ribs or teeth.

[0040] figure 1As shown: the down-the-hole impactor 21 is connected with the back blowing grinding device 22, and the back blowing grinding ...

Embodiment 2

[0051] All structures are the same as in Example 1, but the inlaid steel grains 9 can have 3, 6, 12 or 16 pieces, no matter how many inlaid steel grains 9 are there, the purpose is to utilize the grinding and crushing effect of the inlaid steel grains 9 , by grinding and crushing the falling rock blocks in the hole, under the high-pressure wind back blowing, the problems such as drill sticking can be solved, and the drilling efficiency can be improved.

Embodiment 3

[0053] All structures are identical with embodiment 1 or embodiment 2, but vent hole 3 is 6 or 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com