Foam line starching device

A line and foam technology, applied in the field of foam line scraping device, can solve the problem of easy dropping of mortar, and achieve the effect of easy production, uniform thickness and powerful function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

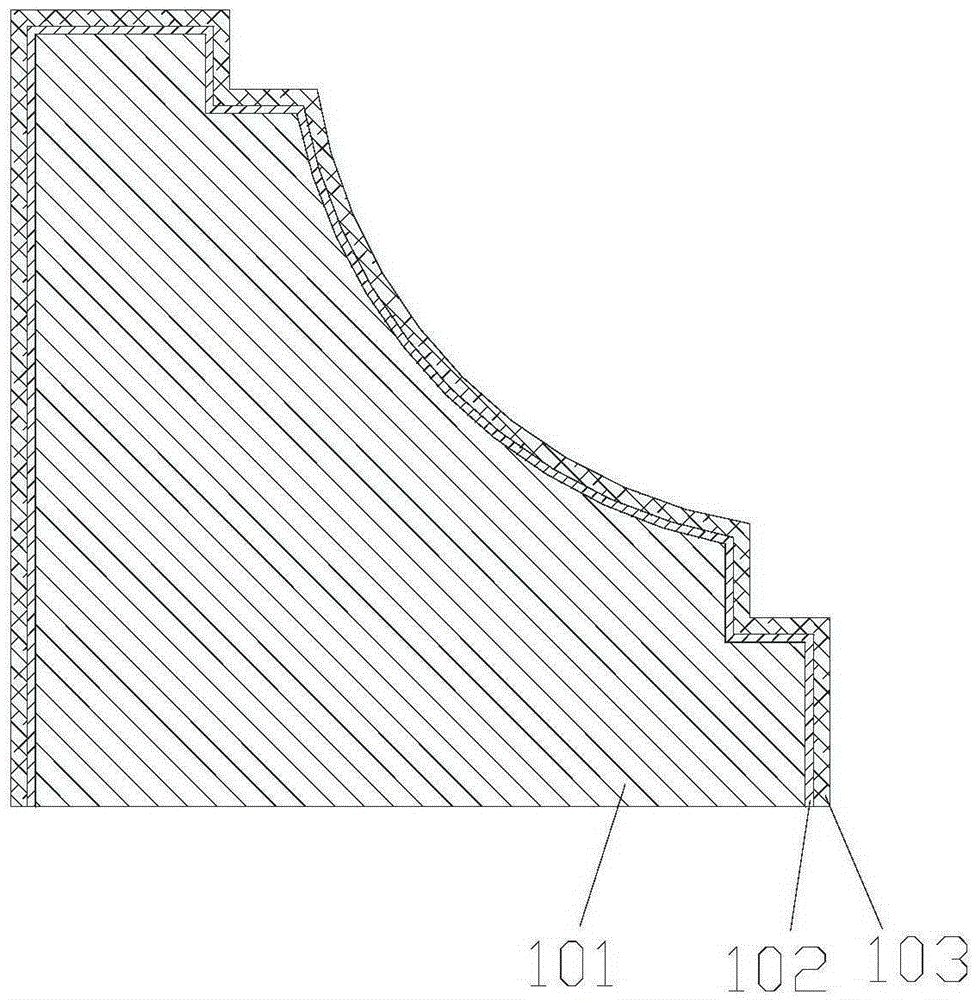

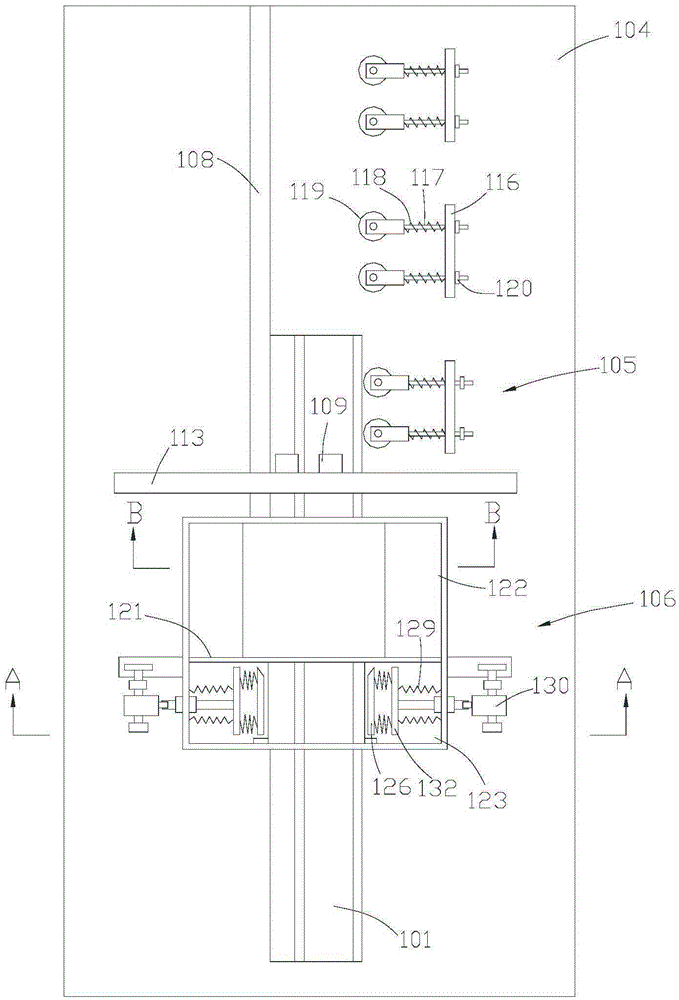

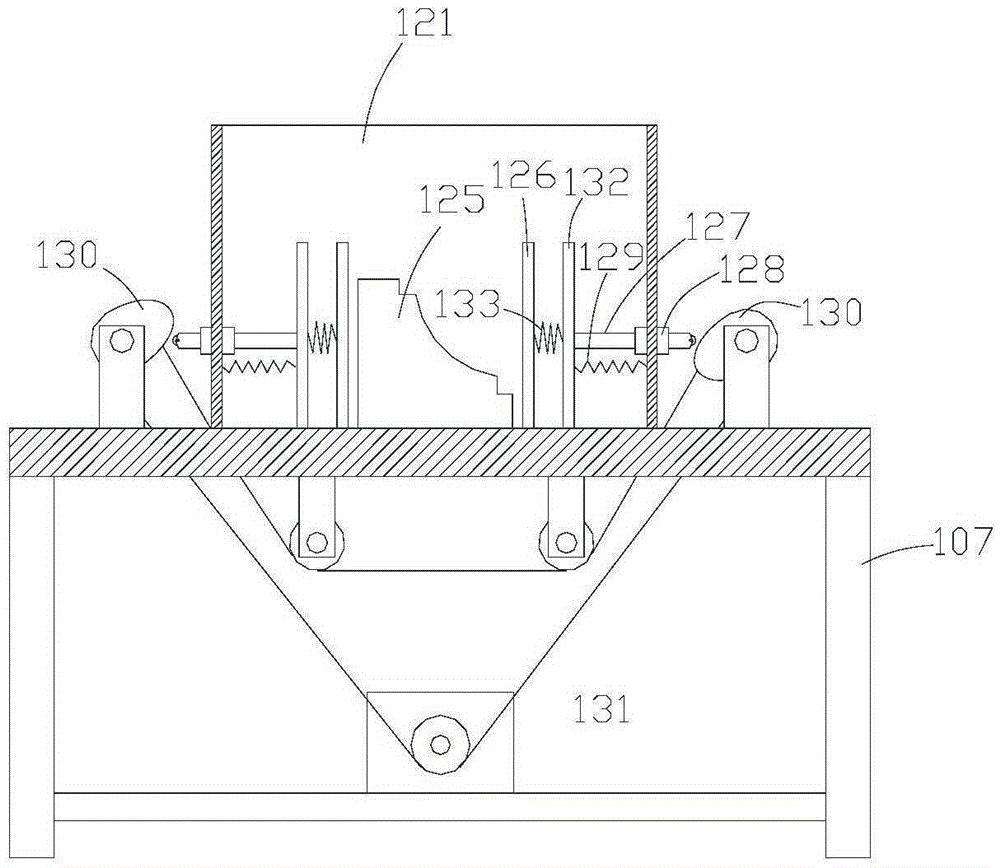

[0045] Example 1, see Figure 2 to Figure 5 .

[0046] This embodiment provides a foam line scraping device, including a workbench 104 , a positioning guide device 105 and a scraping device 106 .

[0047] Support feet 107 are fixed on the bottom of the workbench 104, and the workbench 104 has a horizontal working surface. When the mortar 103 is coated, the bottom surface of the foam line 101 moves linearly against the working surface. Of course, to make the foam lines move in a straight line, you have to rely on a positioning guide.

[0048] The positioning guide device includes a vertical extruding mechanism for pressing the foam line on the workbench, a positioning plate and a transverse extruding mechanism for respectively extruding the foam line from both sides. The positioning plate is fixedly connected with the workbench, and the side wall of the positioning plate has a smooth surface for bonding foam lines. The vertical extrusion mechanism presses the top surface of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com