A hydraulic casing centralizer

A technology of centralizer and casing, applied in casing, drill pipe, drill pipe, etc., can solve the problems of poor applicability, easy peeling, collapse, insufficient bearing capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

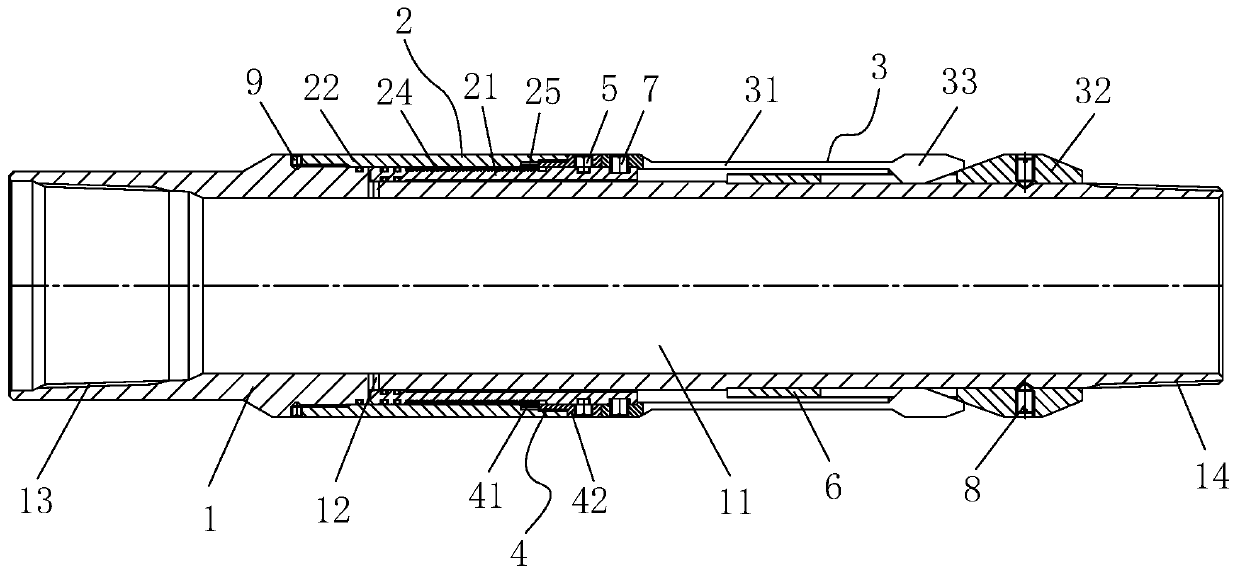

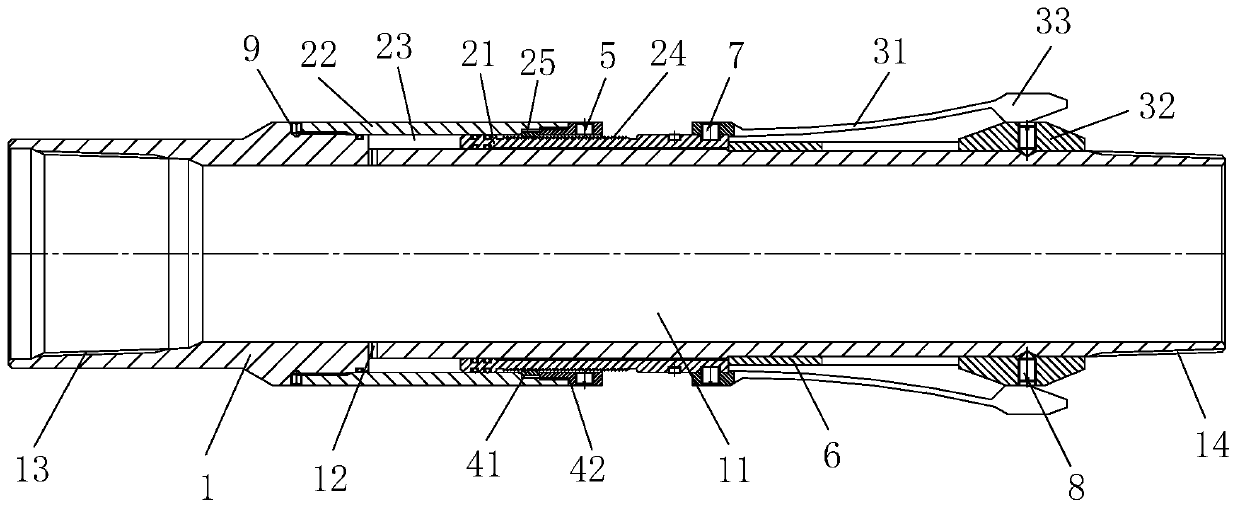

[0060] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

[0061] see figure 1 , figure 1It is a structural schematic diagram of an embodiment of the present invention. The hydraulic casing centralizer of the present invention is used for centering and centralizing the casing in the cementing and completion process, comprising: a body 1, a tubular structural member with a central hole 11, connected to the casing (not shown), preferably The upper end of the body 1 is provided with a female thread 13, and the lower end of the body 1 is provided with a male thread 14, which are respectively used to connect the sleeves at the upper end and the lower end; the driving mechanism 2 includes a piston 21 and a piston cylinder sleeve 22. The piston cylinder liner 22 is set on the body 1 and is fixedly connected with the body 1. There is an accommodating cavity 23 between the piston liner 22 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com