SCR rotational flow mixing pipe

A technology of swirling mixing and mixing tubes, which is applied in exhaust gas treatment, mechanical equipment, engine components, etc., can solve the problems of slow decomposition rate, uneven distribution, and high risk of crystallization of urea, so as to avoid wall contact crystallization and improve uniform distribution The effect of guaranteeing the uniformity of distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

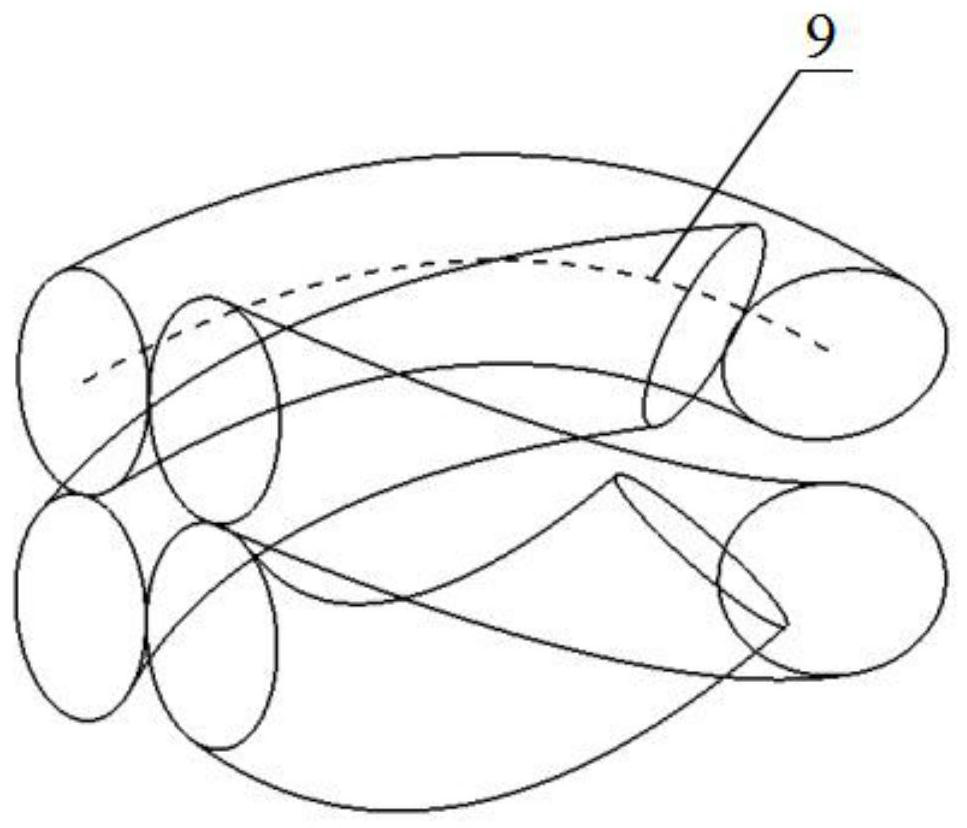

[0047] like Figure 1-4 As shown, a SCR swirl mixing tube is characterized in that: a spiral tube 2 is added between the intake pipe 1 and the mixing tube 4, and a space is generated in the front section of the mixing tube 4, and a urea injector 3 can be installed; the spiral tube 2 makes the discharge The air rotates, creating turbulence. Then it is rectified by the post-mixer 5 to improve the distribution uniformity of urea and its decomposition products again. Finally, the mixed gas undergoes NOx reduction reaction on the SCR catalyst 7 in the reactor barrel 6, and the treated exhaust gas finally passes through the Exhaust pipe 8 discharges.

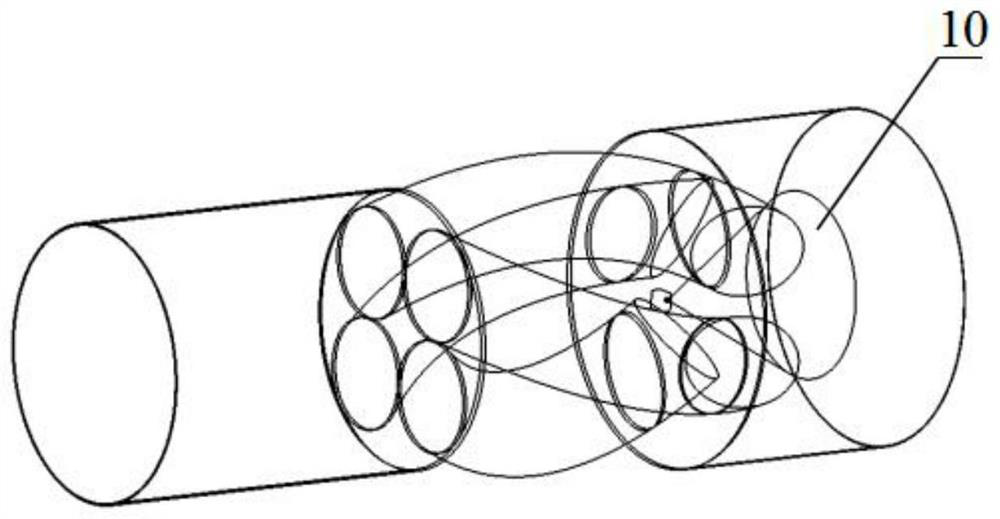

[0048] By using the spiral tube 2, an installation space is created on the front section of the mixing tube 4, and the urea injector 3 and its control lines can be arranged. This structure can make the urea evenly sprayed into the mixing tube 4, and the cylindrical urea spray mist beam 10 and The circular mixing tube 4 is optimally ...

Embodiment 2

[0057] The device is the same as in Embodiment 1, except that the distance D=400mm between the urea injection point and the front end face of the mixing tube 4, as Figure 5 shown.

[0058] Now only a small part of the swirling air flow will directly act on the urea spray mist beam 10, most of the swirling air flow directly generates a protective air flow on the wall of the mixing tube 4, the urea injection position moves backward, and the position where the urea spray may touch the wall also Correspondingly move back, the position of contacting the wall after the move back has better protective airflow, stronger swirling airflow can better carry away the urea sprayed to the wall of the mixing tube, and the anti-crystallization ability is stronger.

Embodiment 3

[0060] The device is the same as in Embodiment 1, except that the distance D=800mm between the urea injection point and the front end face of the mixing tube 4, as Image 6 shown.

[0061] At this time, all the swirling airflows directly generate protective airflows on the walls of the mixing tube 4, and no swirling airflows directly act on the urea spray mist beam 10. The possible wall-touching position of the urea spraying moves backwards with the urea injection point, and the wall-touching position after the backward movement A large number of protective airflows are formed at the position, and the strong swirling airflow can directly carry away the urea sprayed to the inner wall of the mixing tube 4, and has strong anti-crystallization ability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com