Glass annealing and linear expansion coefficient integrated test device, and method

A technology of linear expansion coefficient and testing device, which is applied in the direction of material thermal expansion coefficient, etc., can solve the problems of secondary damage, inaccurate measurement results, and inability to measure in time to achieve the effect of ensuring control accuracy and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in further detail below in conjunction with accompanying drawing:

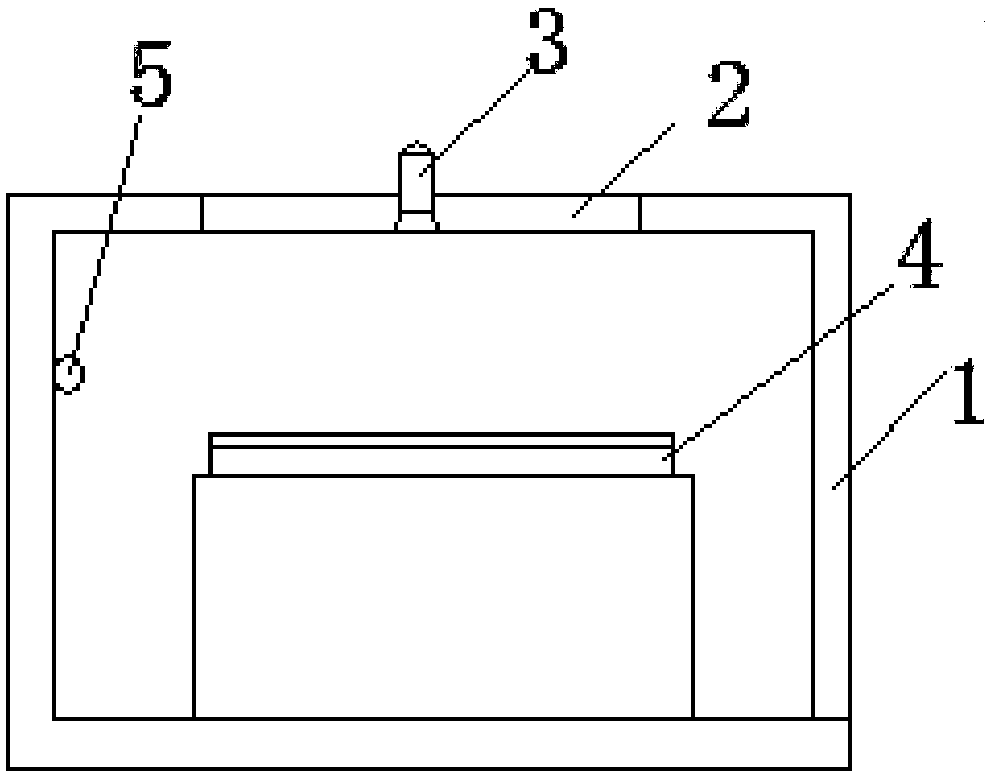

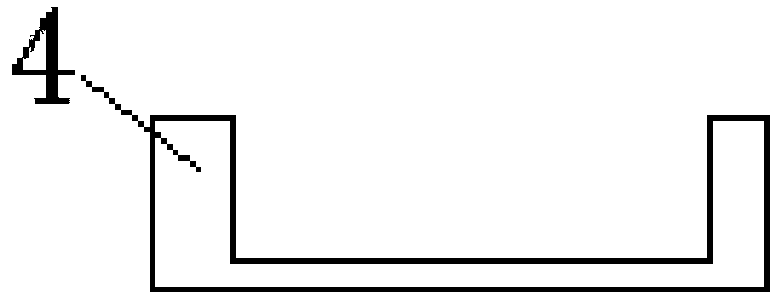

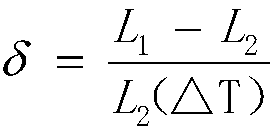

[0029] Such as figure 1 As shown, a glass annealing and linear expansion coefficient integrated testing device includes a high-temperature heating furnace 1. The upper end of the high-temperature heating furnace 1 is provided with a discharge port. A high-definition camera 3 is arranged on the transparent glass 2, and a shelving table is arranged in the high-temperature heating furnace 1. The shelving table is used to place a sample shelf 4. The sample shelf 4 is provided with a scale network cable. To test the sample, the lens of the high-definition camera 3 is aimed at the upper surface of the sample shelf 4, and when the test starts, the side line of the sample to be tested is flush with the scale grid line.

[0030] The sample rack 4 is a high-temperature-resistant material; the high-temperature heating furnace 1 is provided with a temperature sensor 5 and a heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com