Workpiece stamping process for electronic product machining

A technology for electronic products and workpieces, which is applied in the field of stamping technology for workpieces used in electronic product processing. It can solve problems such as inability to meet customer requirements for finished product precision, complex process design, and lack of rationality, so as to avoid mechanical crushing and simplify the process flow. , Guarantee the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

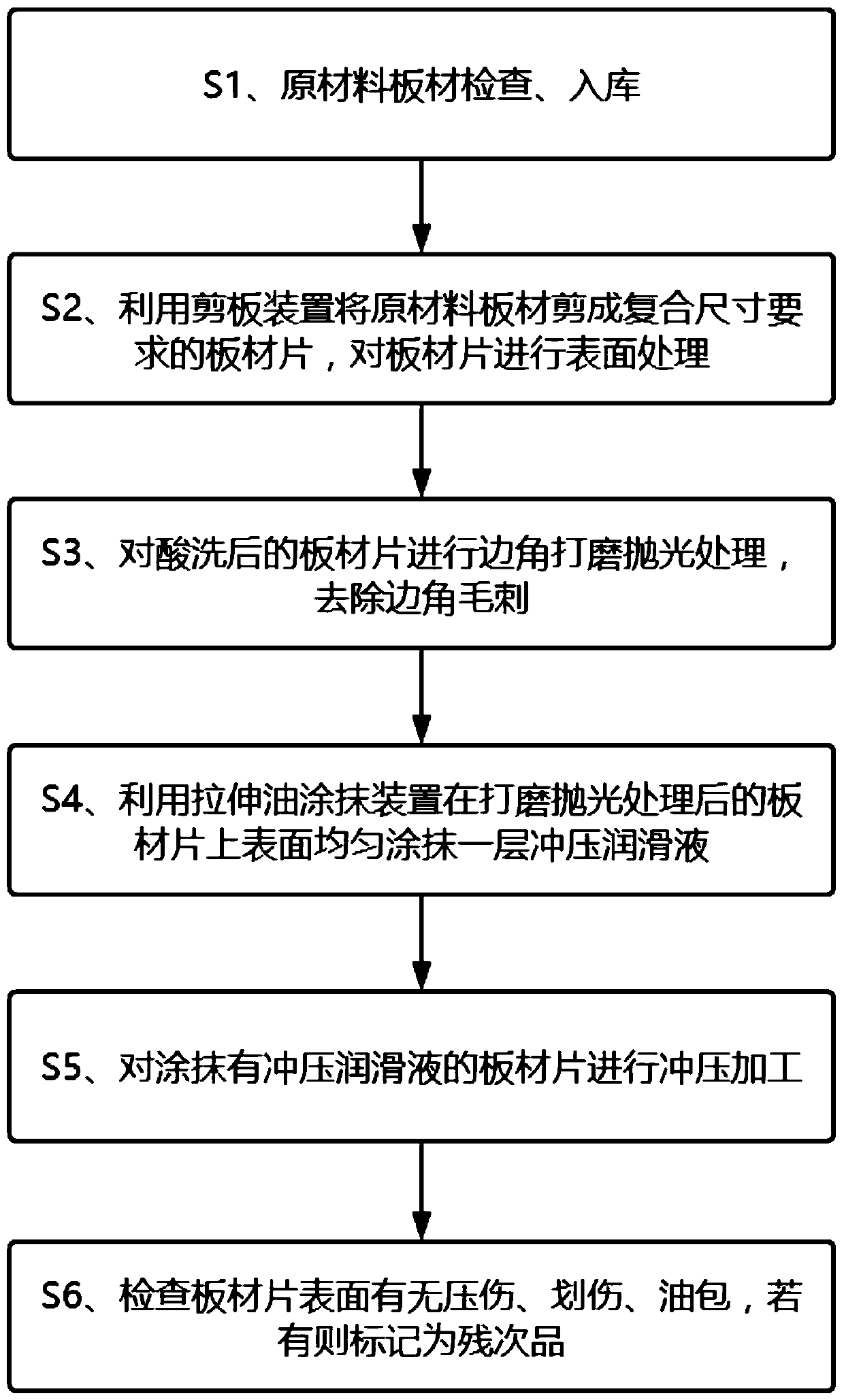

[0044] see figure 1 , a workpiece stamping process for processing electronic products, comprising the following steps:

[0045] S1. Inspection and storage of raw materials and plates;

[0046] S2. Use the shearing device to cut the raw material sheet into a sheet with a composite size requirement, and perform surface treatment on the sheet;

[0047] In S2, surface treatment includes the following steps:

[0048] S21. Pickling treatment: put the sheet into the pickling tank, add pickling liquid into the pickling tank, pickle at 30°C for 120-150min, and clean the sheet after the pickling;

[0049] S22. Passivation treatment: put the pickled sheet into a passivation tank, add a passivation solution to the passivation tank, and passivate the sheet at 20°C for 30 minutes;

[0050] S23. Cleaning and drying: the passivation-treated sheet is rinsed three times under a high-pressure water gun, and dried to complete the surface treatment.

[0051] Wherein, the pickling solution incl...

Embodiment 2

[0064] see figure 1 , a workpiece stamping process for processing electronic products, comprising the following steps:

[0065] S1. Inspection and storage of raw materials and plates;

[0066] S2. Use the shearing device to cut the raw material sheet into a sheet with a composite size requirement, and perform surface treatment on the sheet;

[0067] In S2, surface treatment includes the following steps:

[0068] S21. Pickling treatment: put the sheet into the pickling tank, add pickling liquid into the pickling tank, pickle at 35°C for 120-150min, and clean the sheet after the pickling;

[0069] S22. Passivation treatment: put the pickled sheet into a passivation tank, add a passivation solution to the passivation tank, and passivate the sheet at 25°C for 40 minutes;

[0070] S23. Cleaning and drying: wash the passivated sheet under a high-pressure water gun for 4 times, and dry to complete the surface treatment.

[0071] Wherein, the pickling solution includes the followi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com