Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

308 results about "Sheet metal stamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

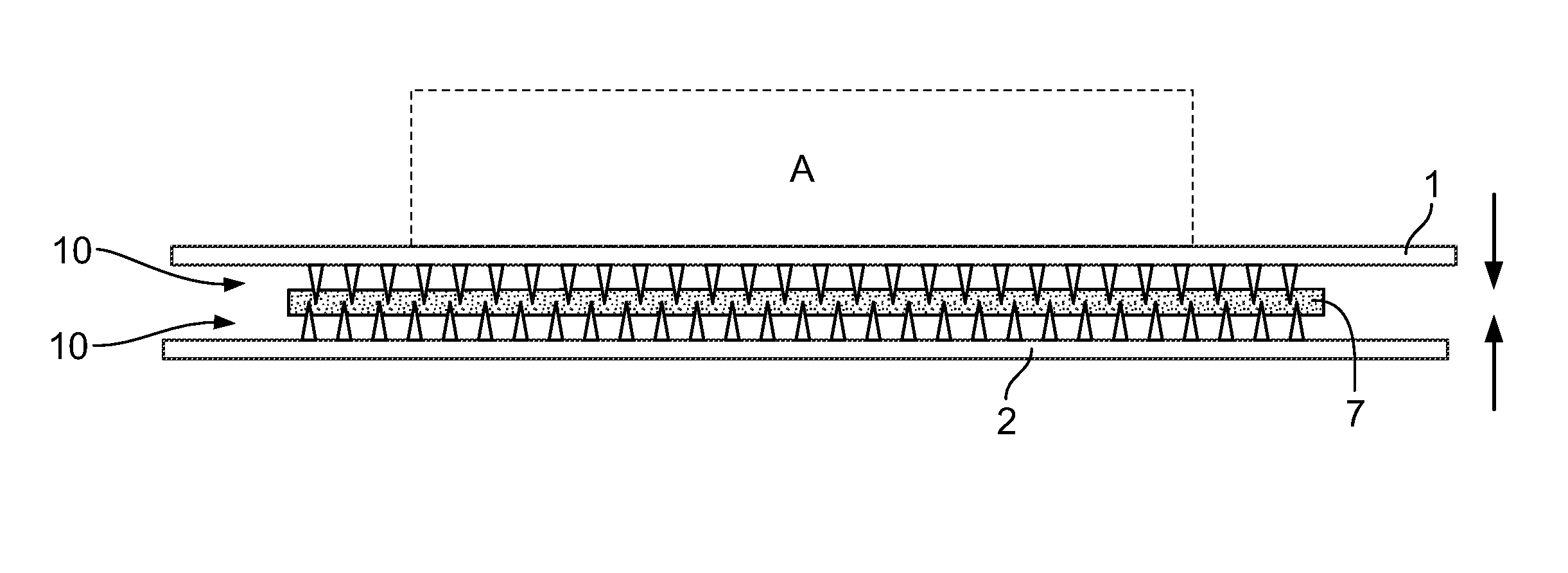

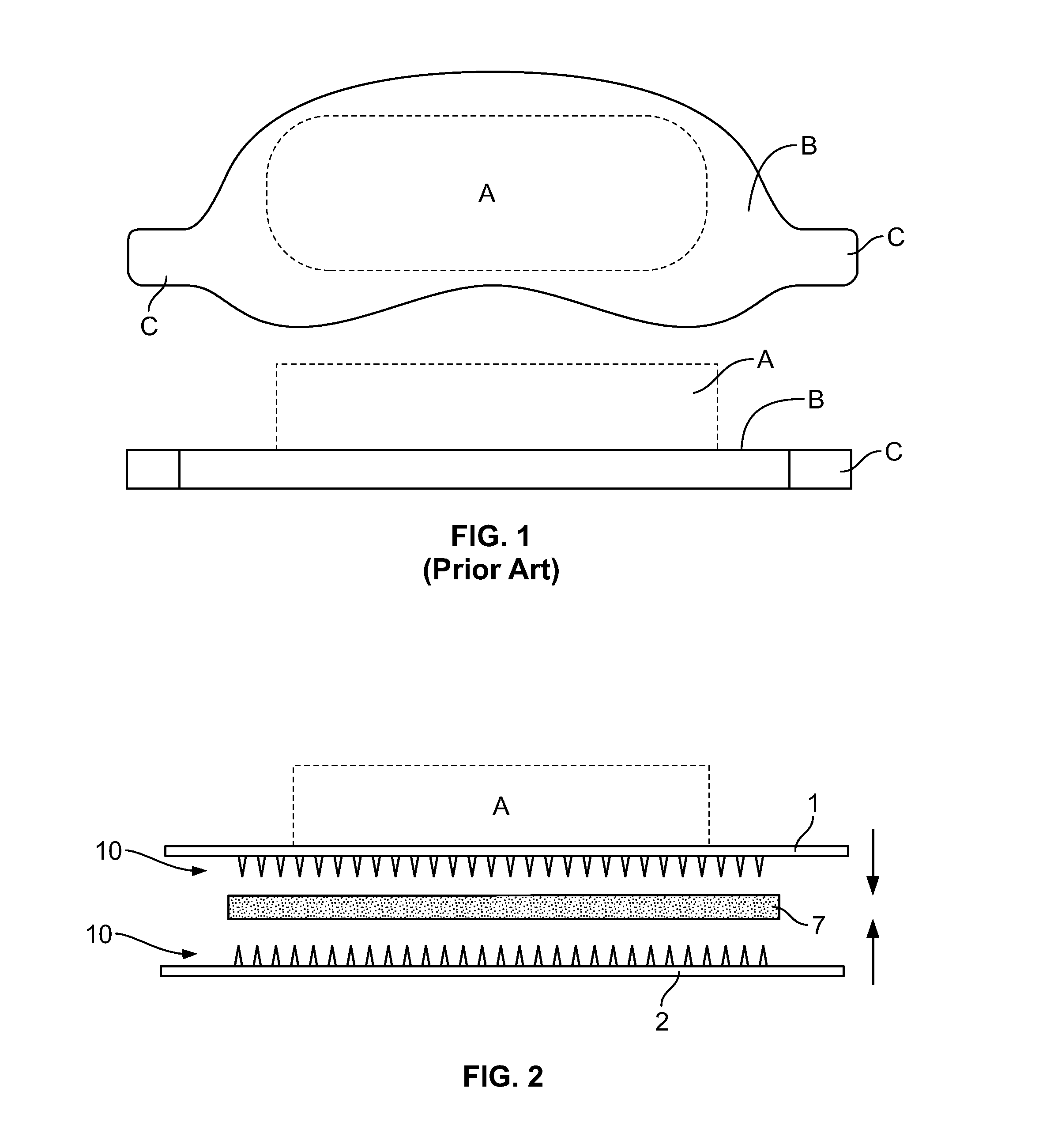

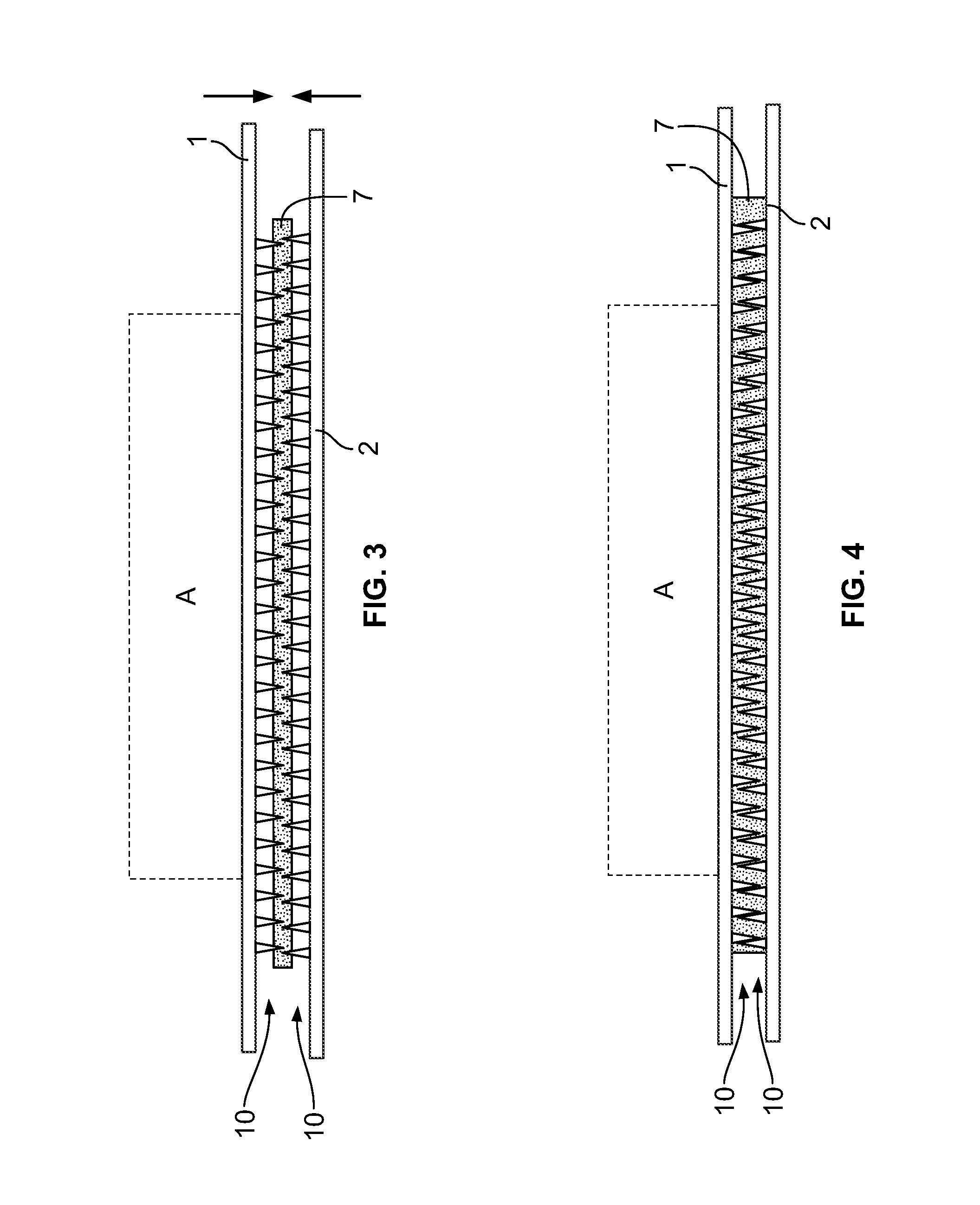

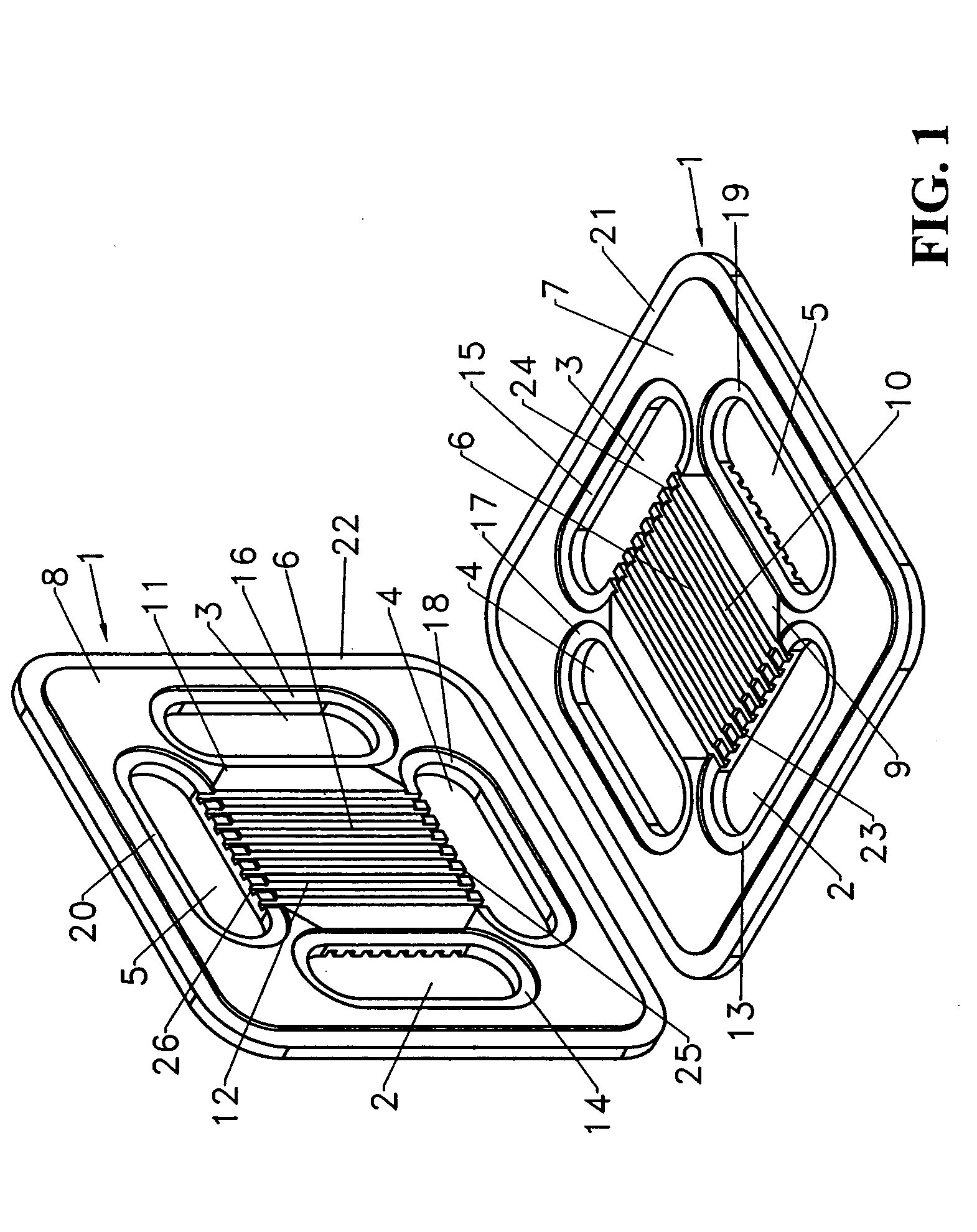

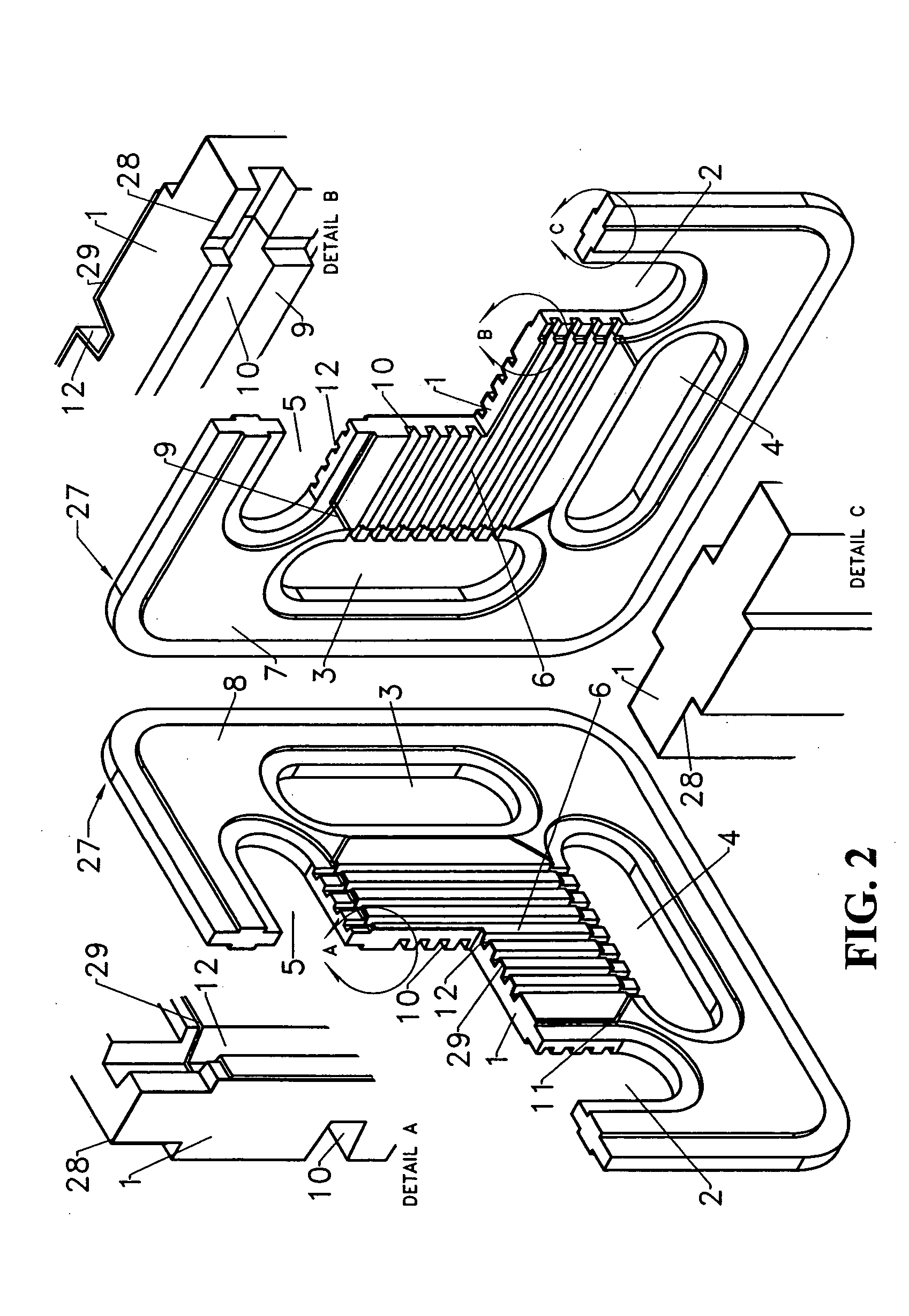

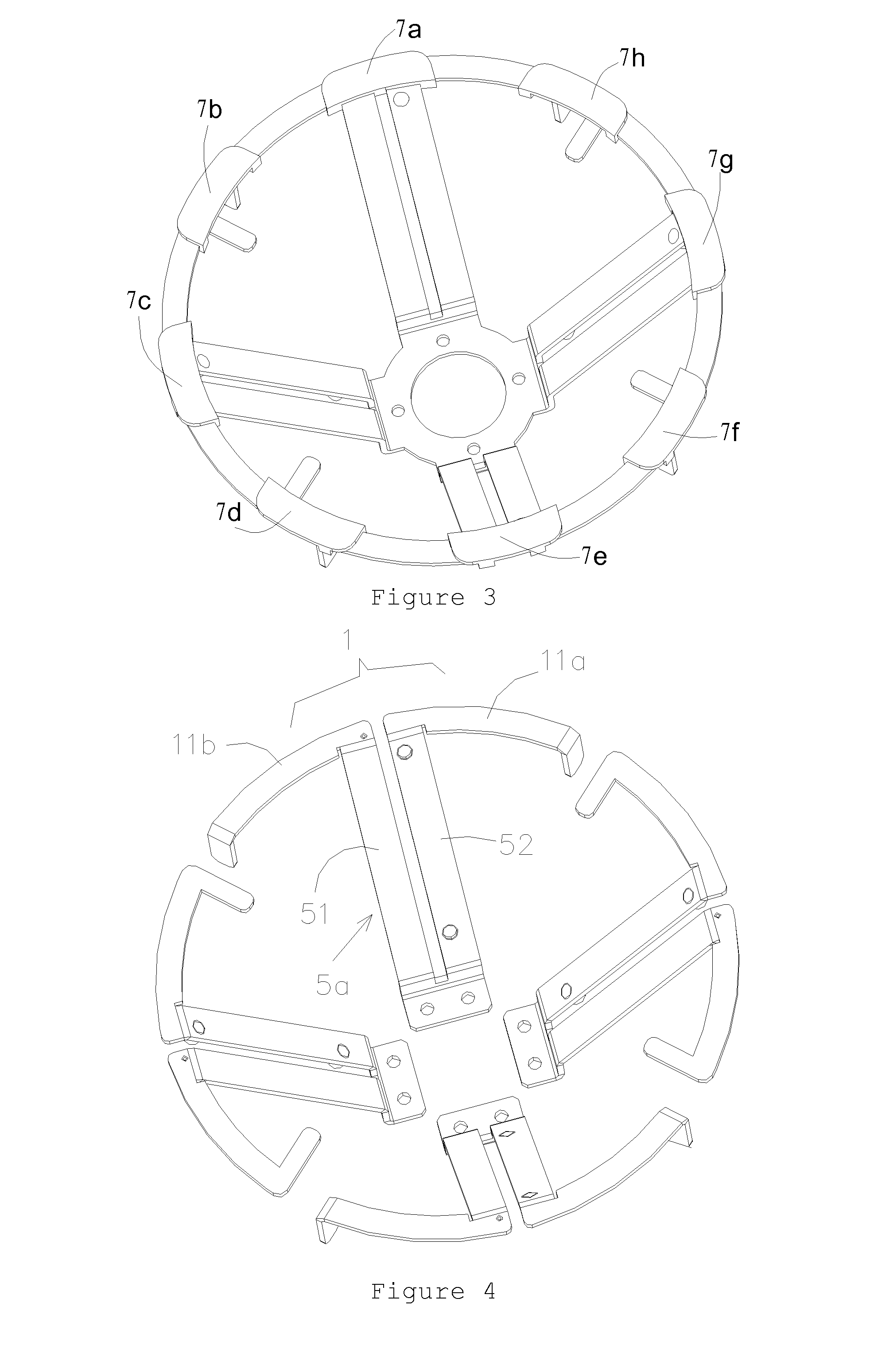

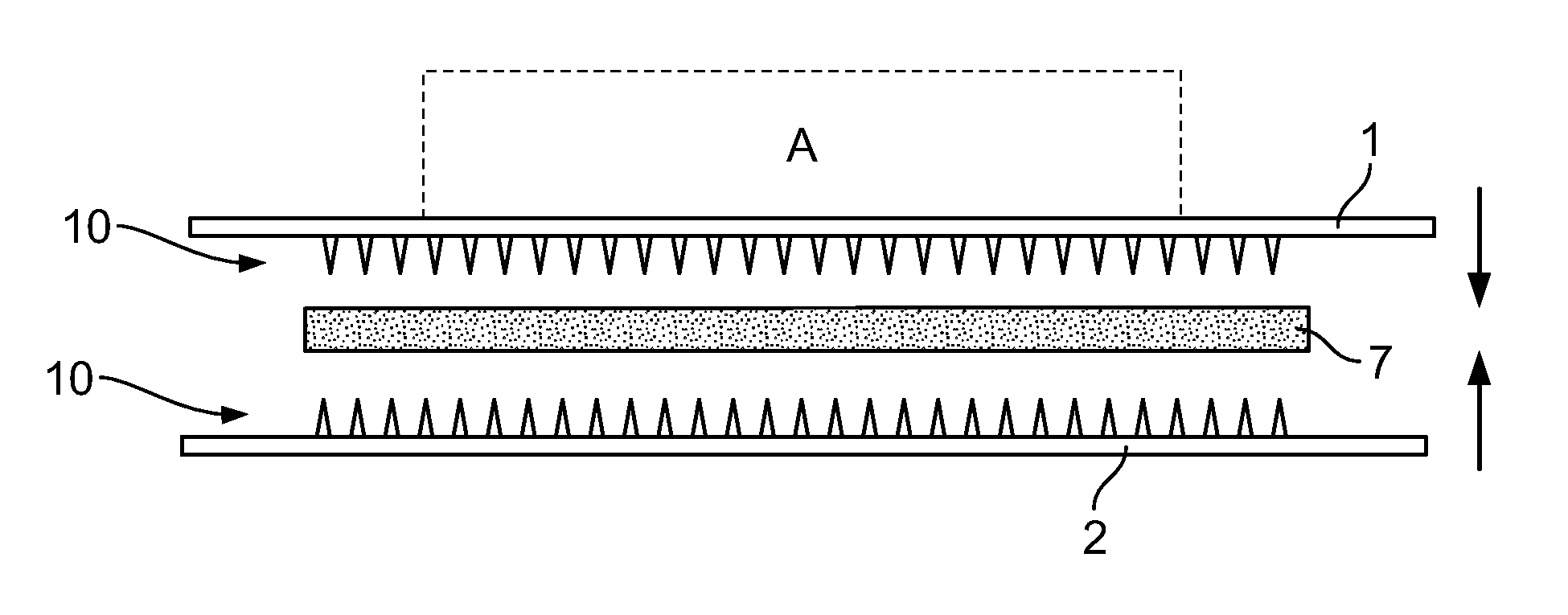

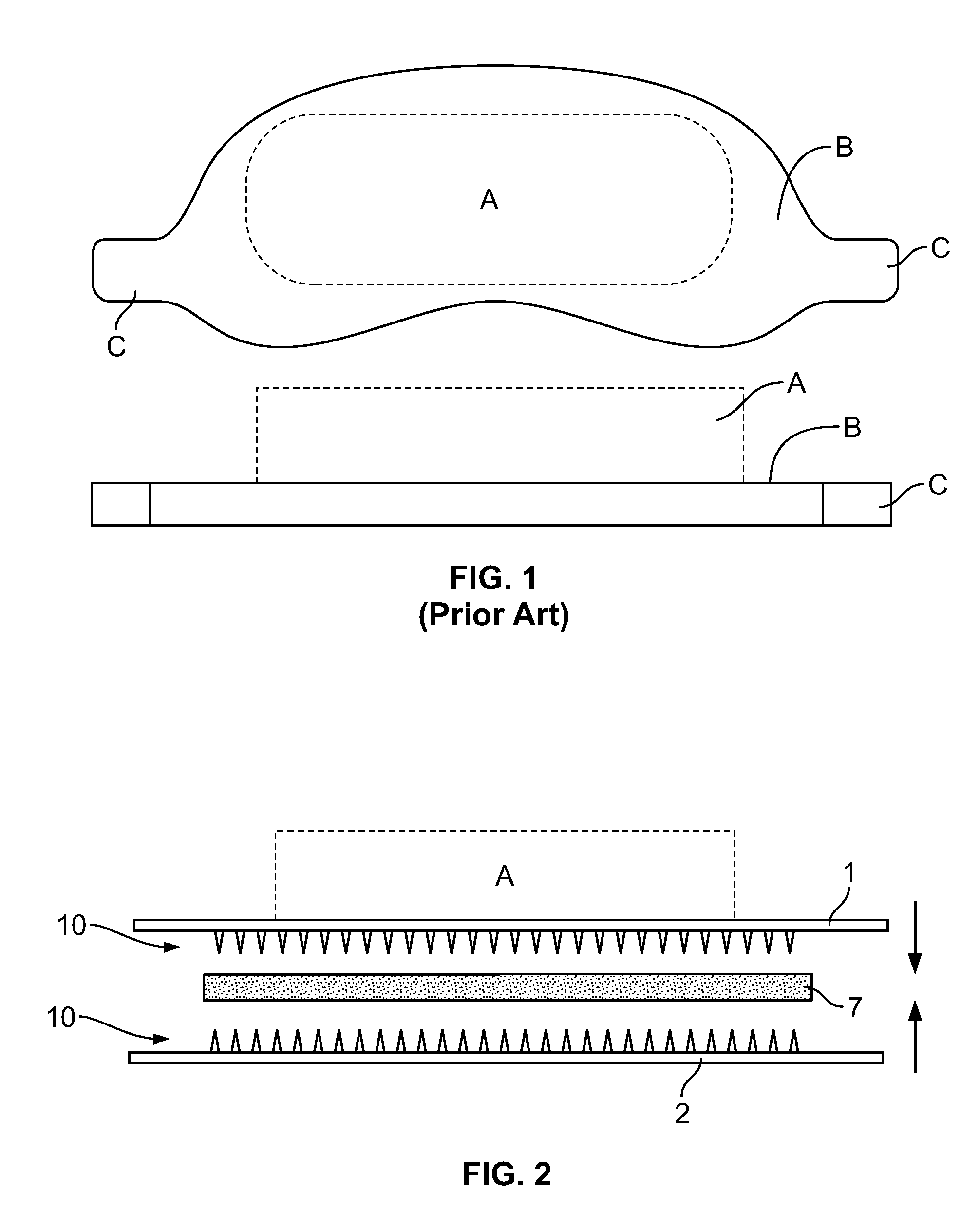

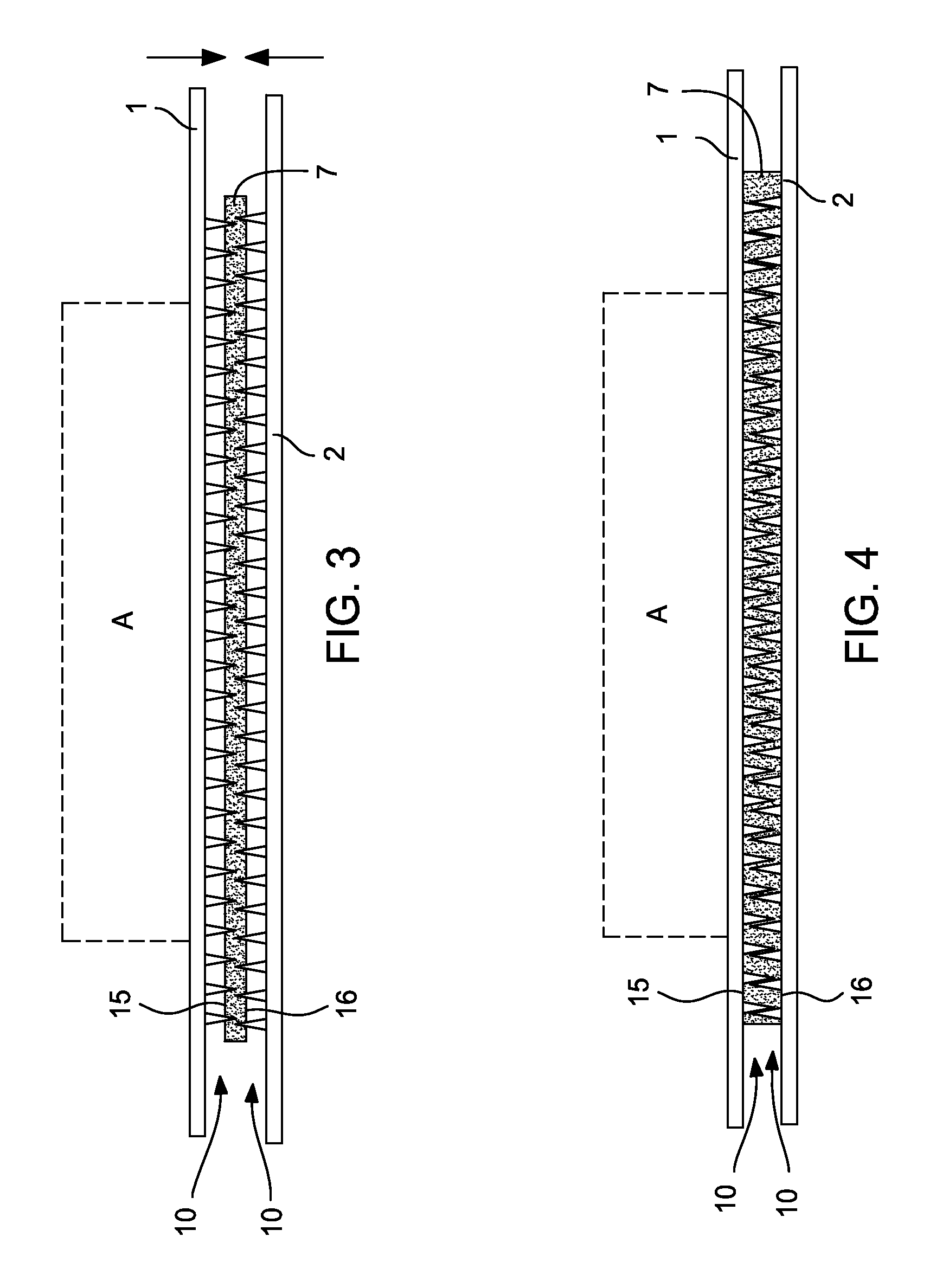

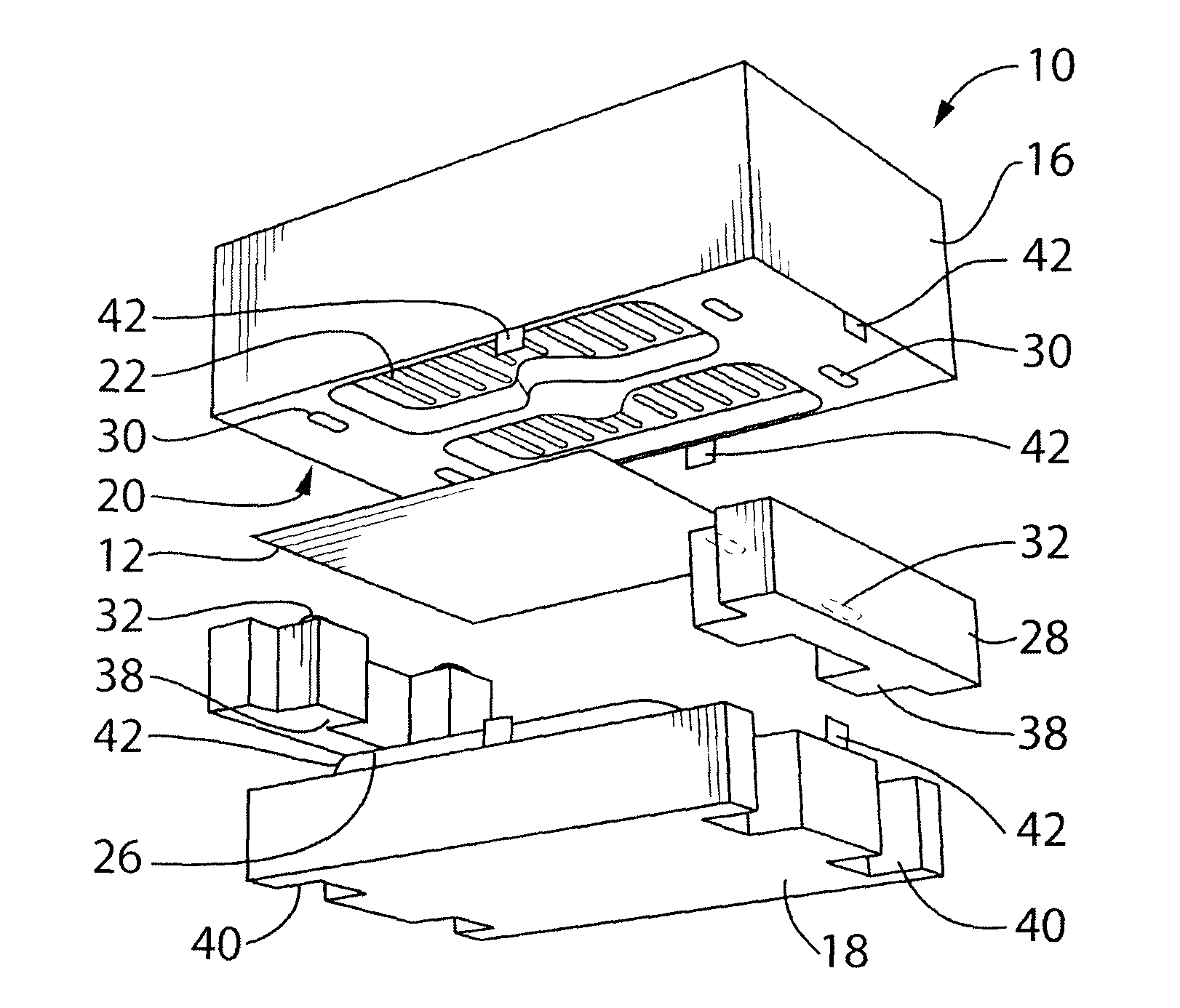

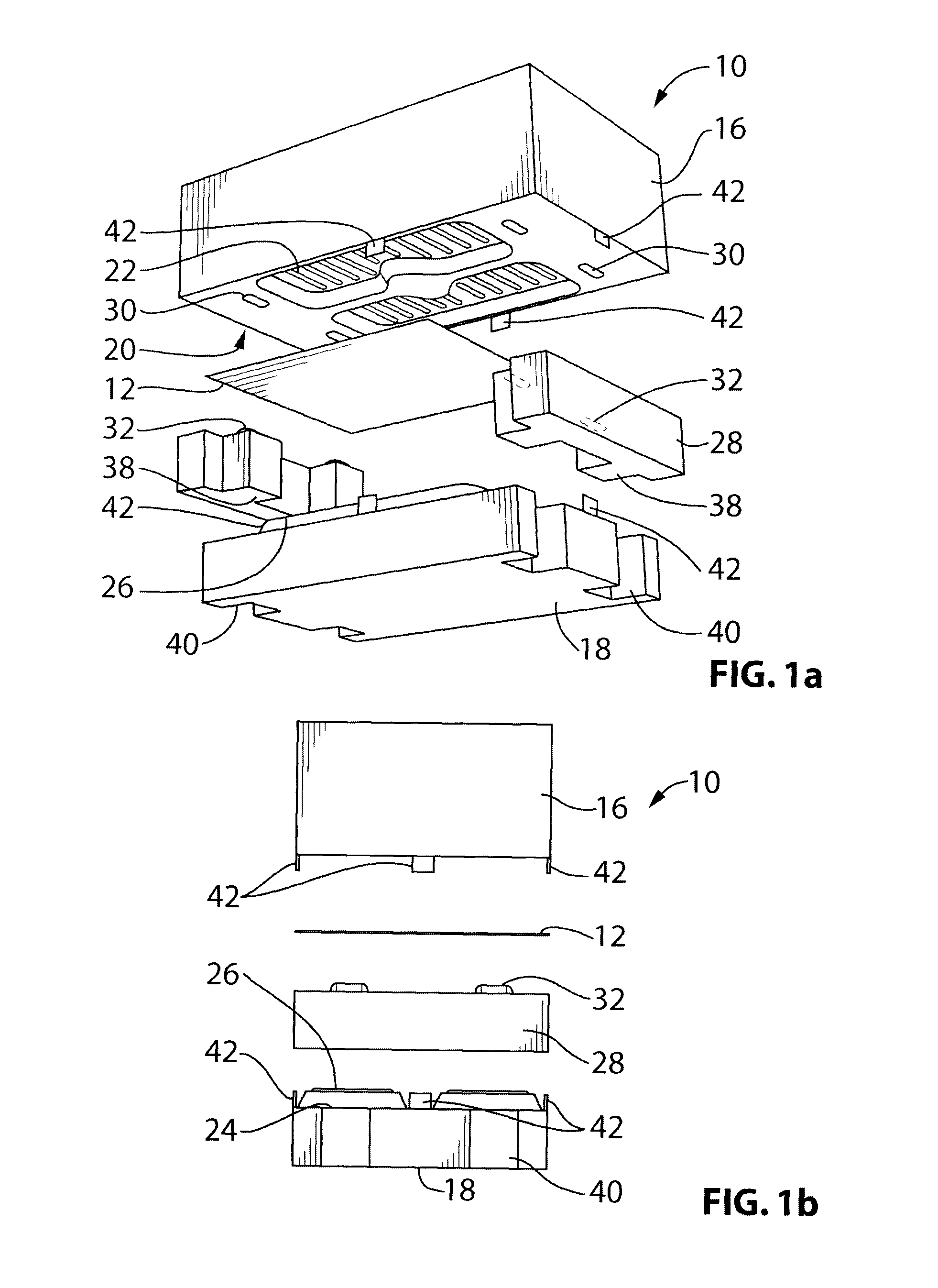

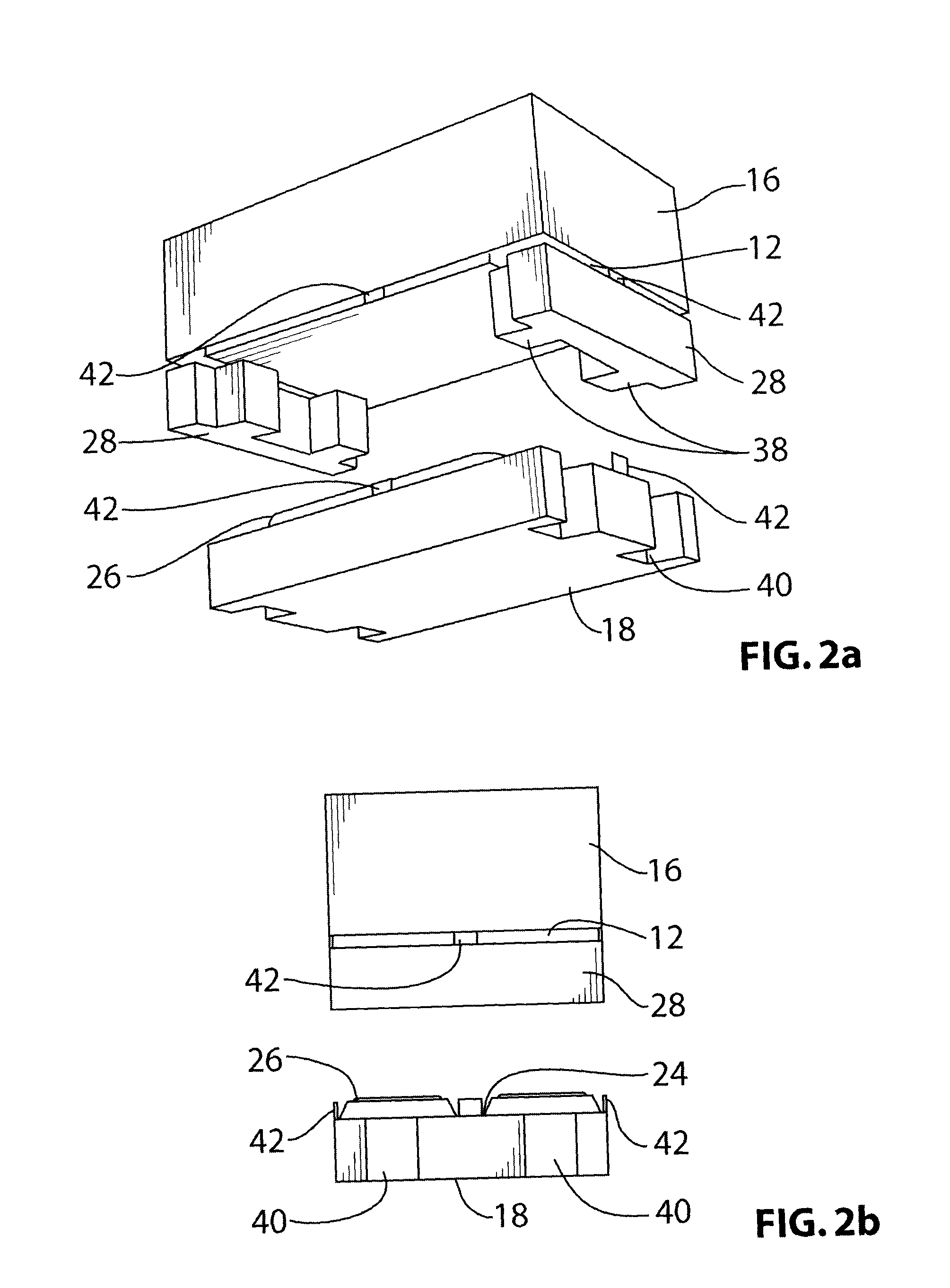

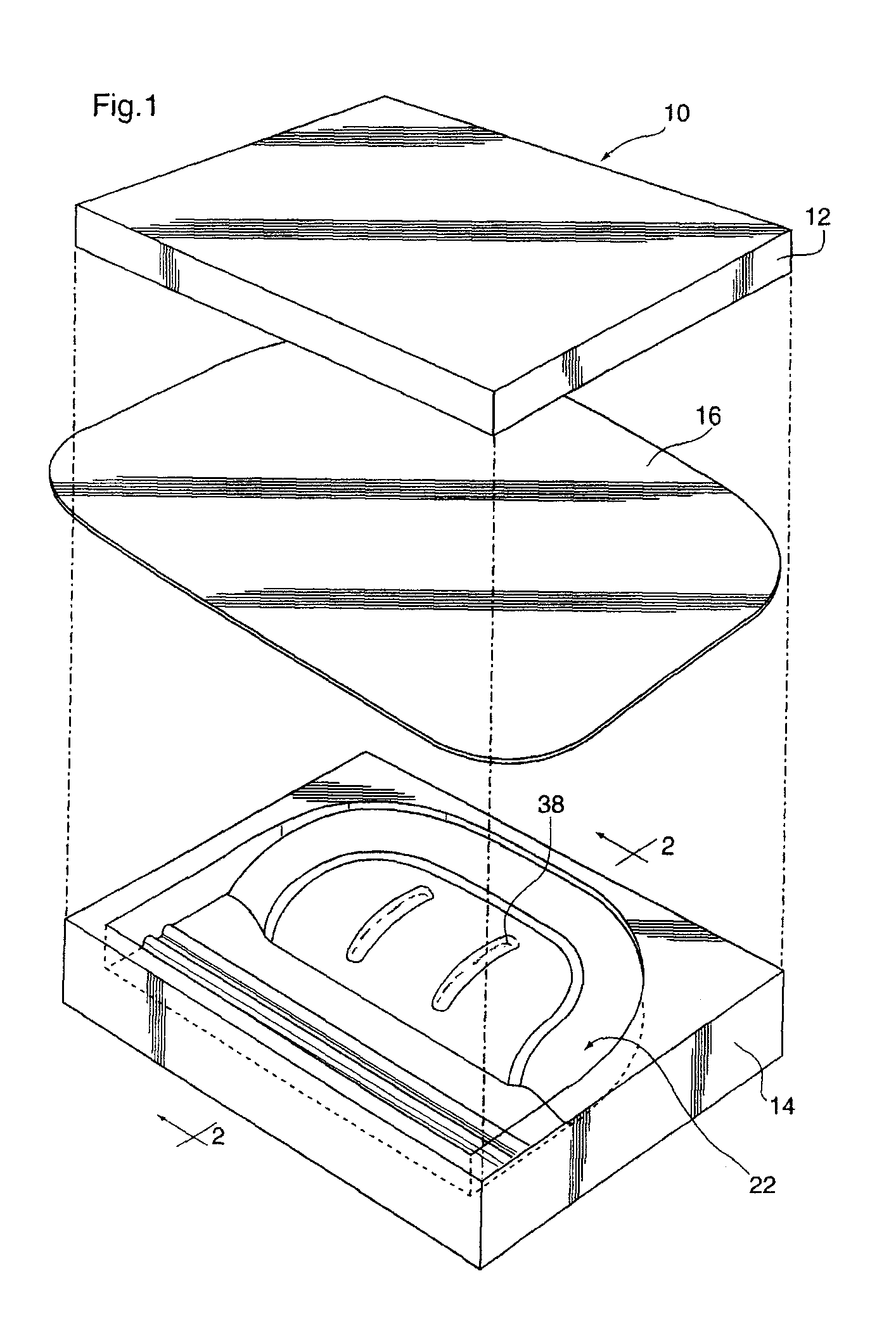

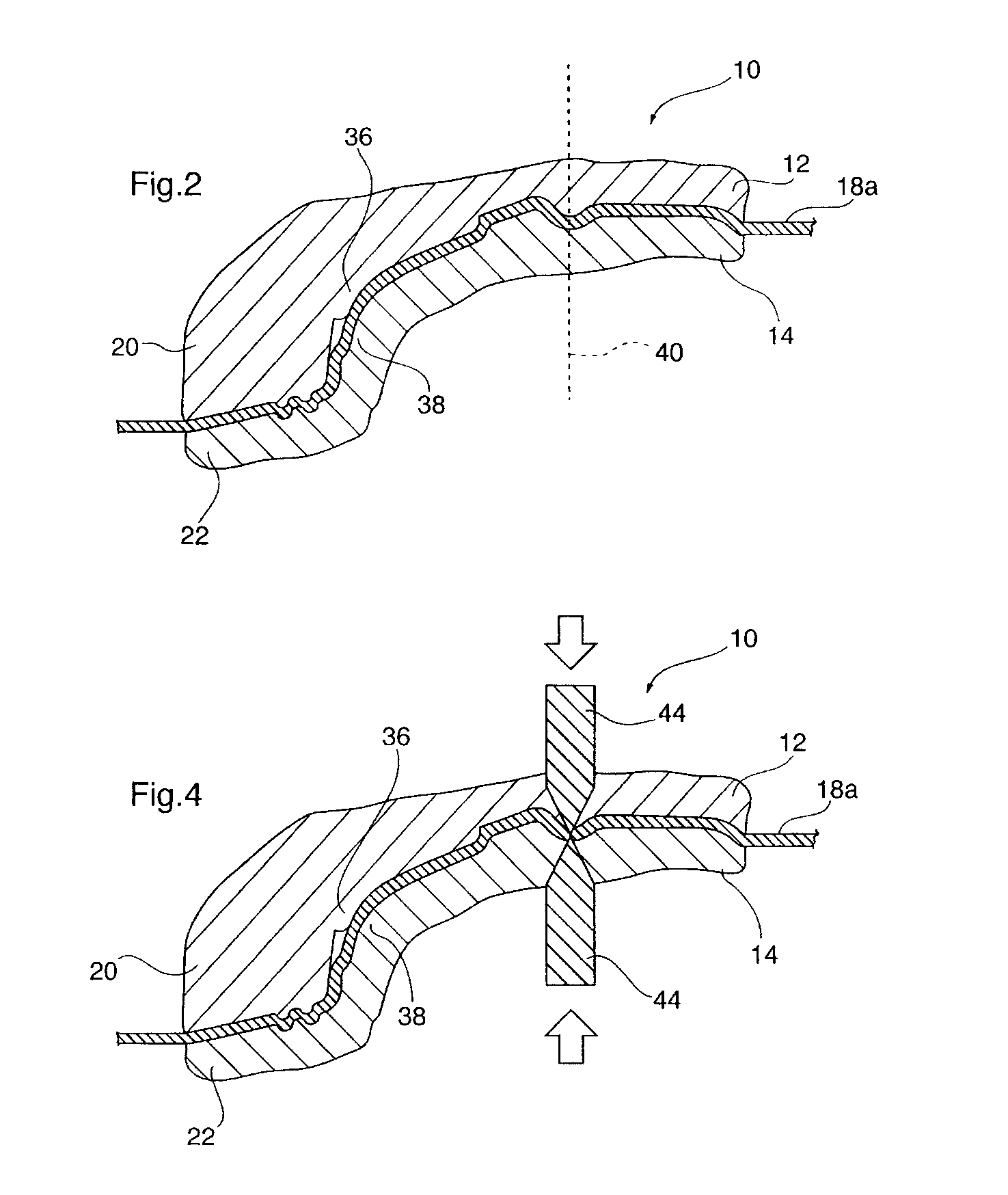

Composite disc brake backing plate

ActiveUS20150053517A1Increase stiffnessBraking elementsFriction liningSheet metal stampingMechanical engineering

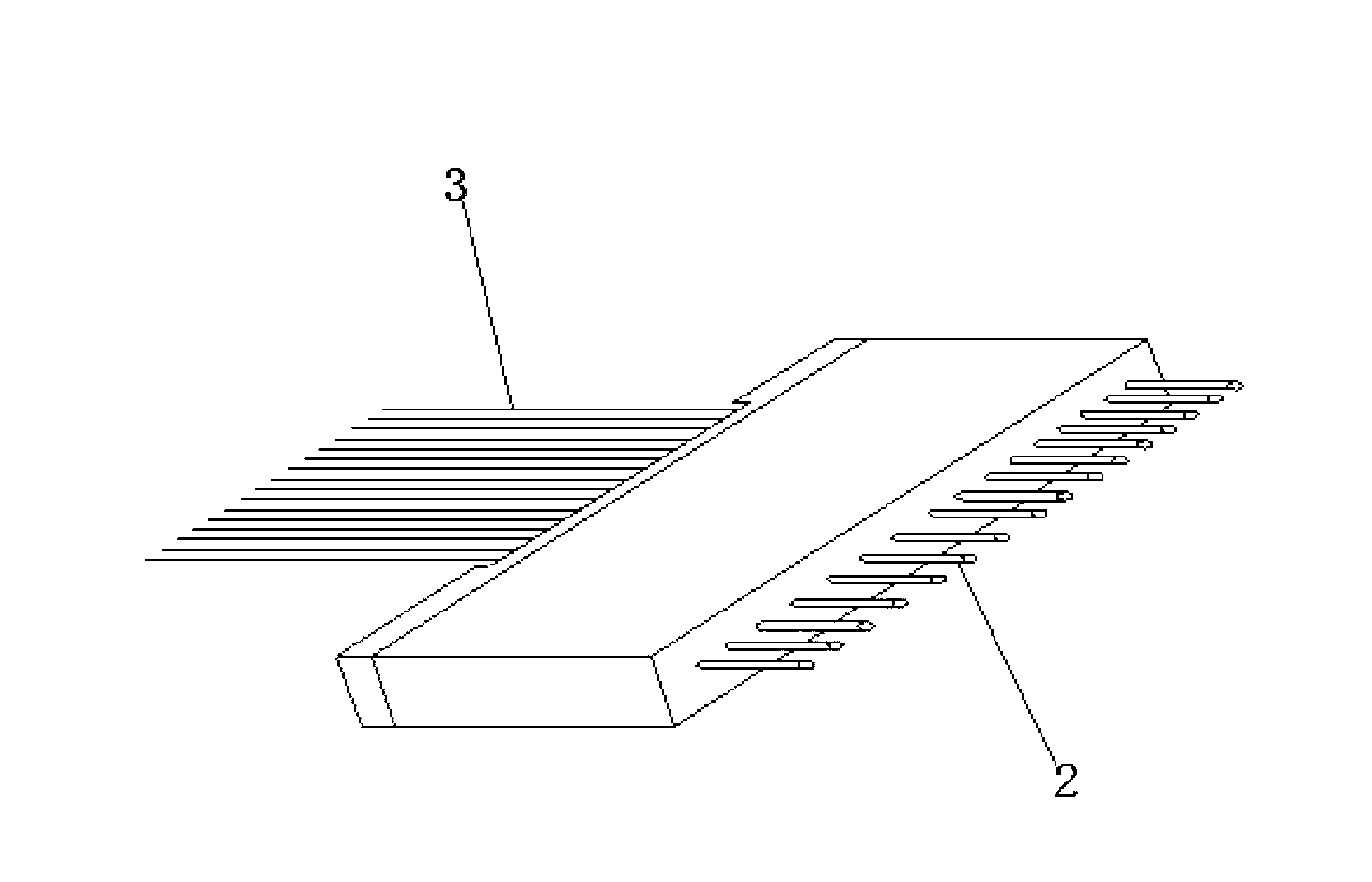

A brake backing plate is provided in which a non-compressible core material is sandwiched between two sheet metal stampings to make a lightweight, composite brake backing plate. Each of the stampings has a textured face with a plurality of integrally formed piercing members. By rolling or pressing, the piercing members of the textured faces are fully embedded in the core material, and thus lock the stampings and the core material together.

Owner:GRIPMETAL LTD

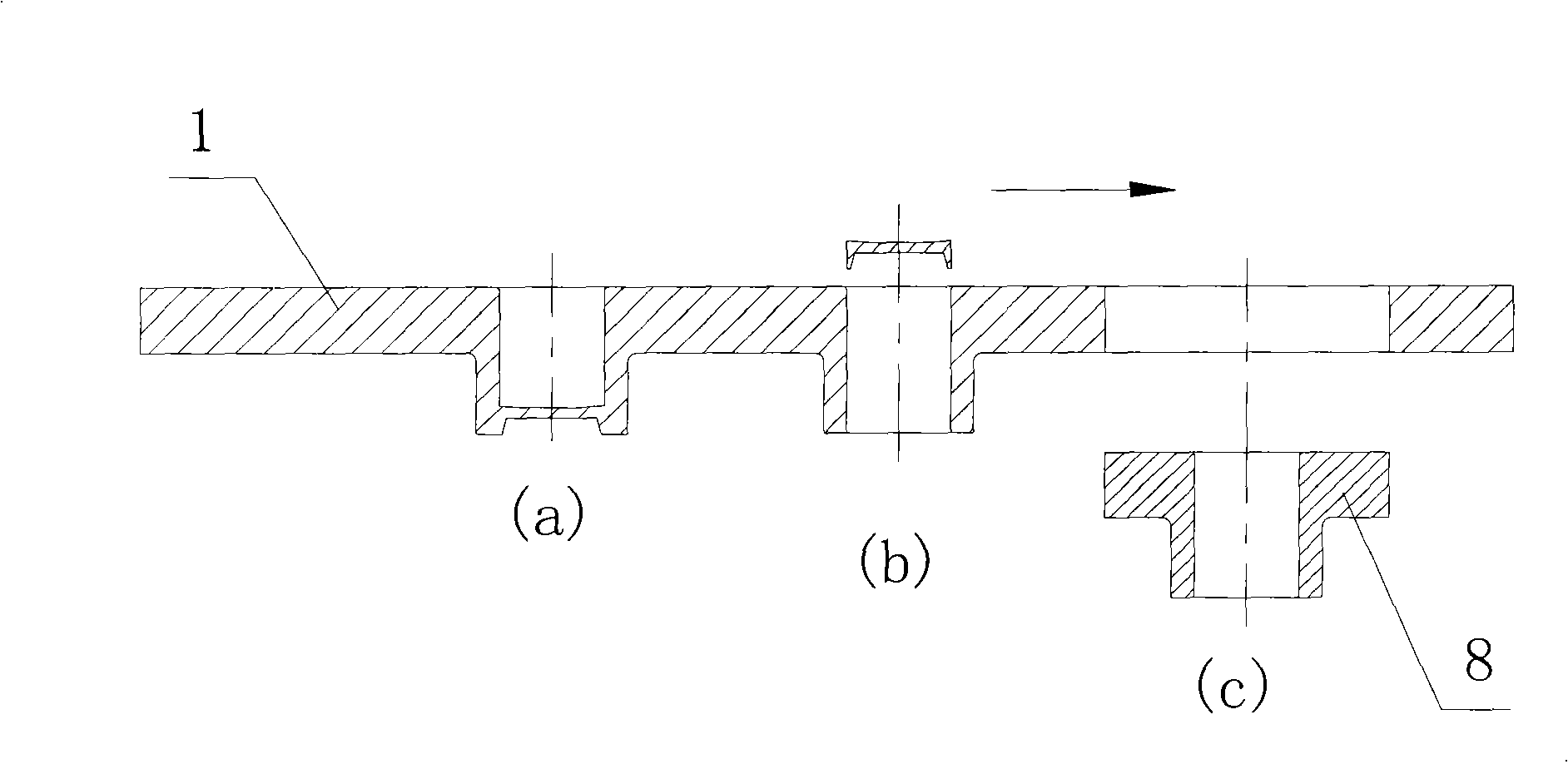

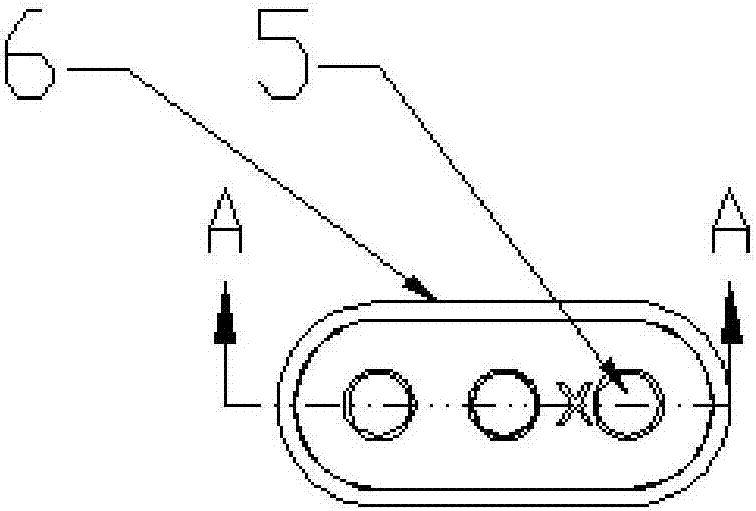

Forming technique for sheet metal stamping cold forging and fine blanking composite boss part

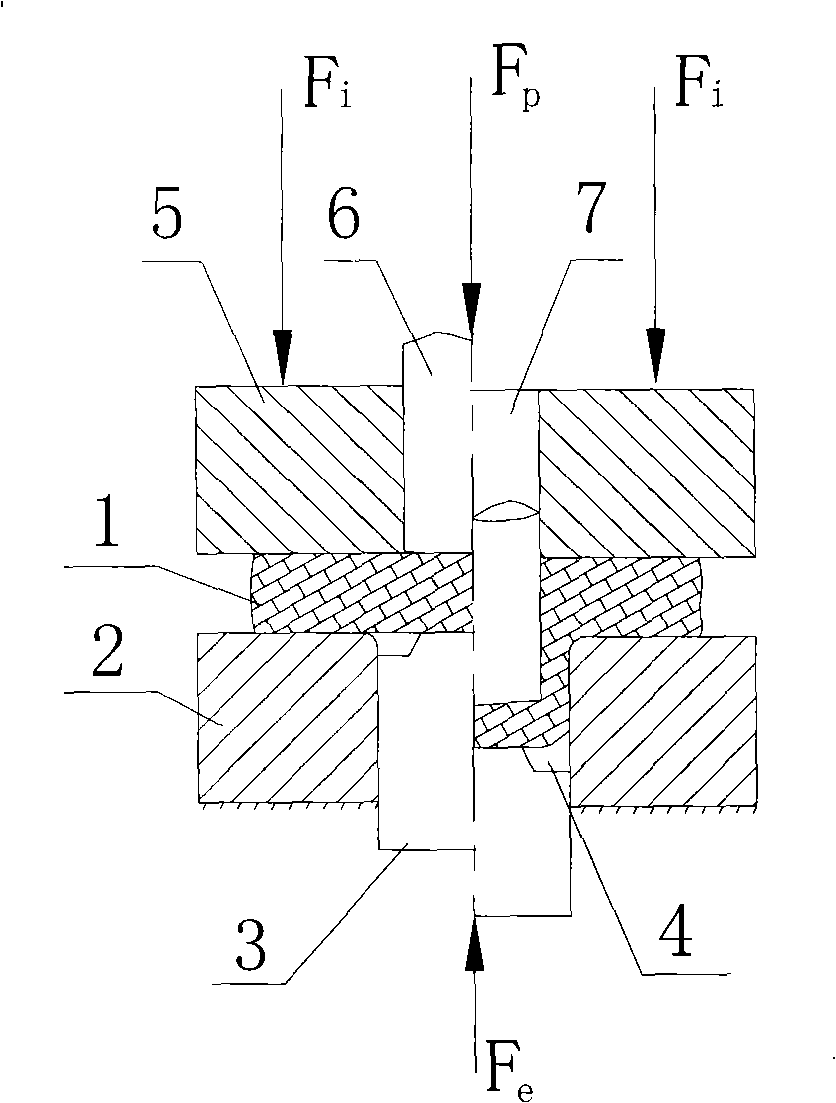

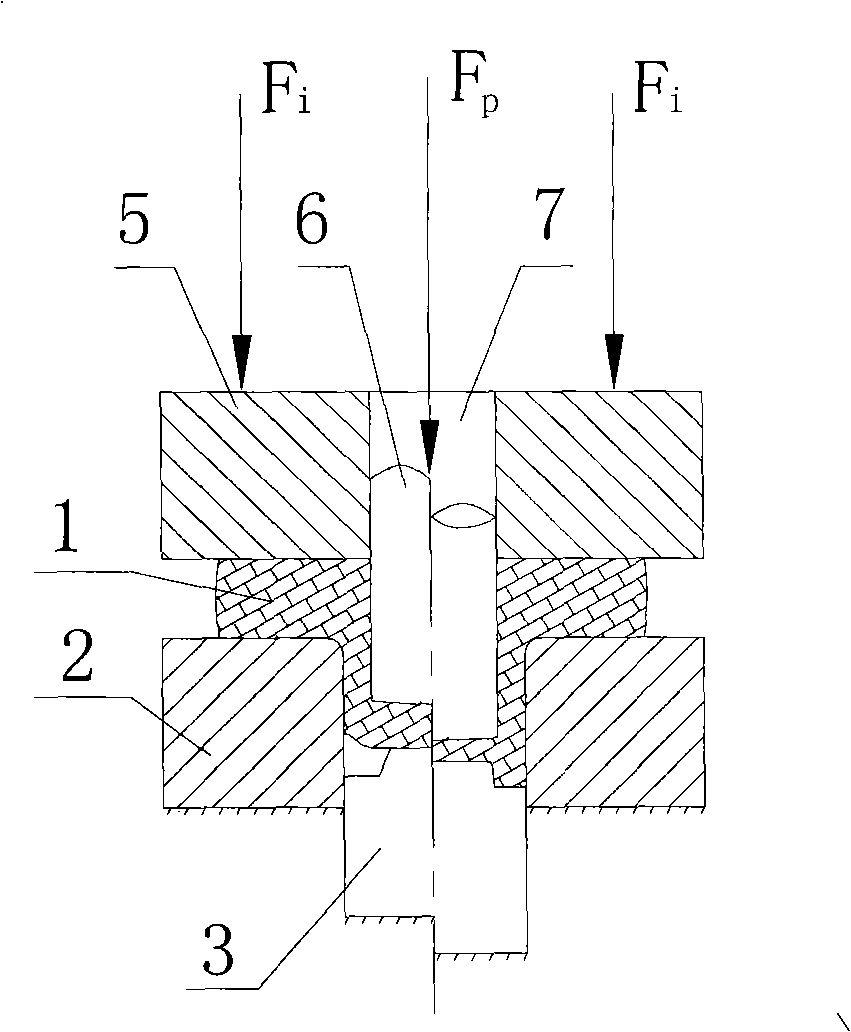

The invention relates to a forming process of a lug boss part. A shaping technique of a panel punching forge cold and fine punching compound lug boss part is characterized in including the following steps: 1) the lug boss is pre-shaped on the punching forge cold of the panel; a metal panel (1) is arranged on a cavity die (2) and pressed by using a holding pad (5); a punching force plug (6) drives a squeezing force plug (3) to move downwards under the action of punching pressure to lead the material of the metal panel (1) below the punching force plug (6) to flow into a die space; when the punching force plug (6) moves downwards to reach the lug boss shaping height of the lug boss part, the squeezing force plug is restrained to move; the punching force plug continuously moves downwards; the materials between the punching force plug (6) and the squeezing force plug (3) are squeezed so as to be filled with the die space and pre-shape the lug boss on the metal panel; 2) recoiling recess; 3) finely the profile of the lug boss part is punched to lead the lug boss part to be separated from the metal panel to obtain the lug boss part. The process can obtain the lug boss part with the high precision, the good quality and the low cost.

Owner:WUHAN UNIV OF TECH

Perimeter trim clip for suspended ceilings

ActiveUS9187898B1The process is fast and accurateLow costCeilingsFriction grip releasable fasteningsFree edgeEngineering

A perimeter trim attachment clip formed as a single piece sheet metal stamping, the clip having a base, top and bottom rearwardly extending trim engaging grips on the base, the grips having a free edge distal from the base adapted to engage respective top and bottom hems of a perimeter trim channel, a standoff projecting rearwardly of the base beyond the grip edges, the standoff being adapted to abut the side of a grid runner extending parallel along the periphery of a free edge of a ceiling, a squaring tab connected to the base and configured to extend over the parallel extending grid runner and be attached to a reinforcing bulb of a grid runner intersecting the parallel grid runner.

Owner:USG INTERIORS INC

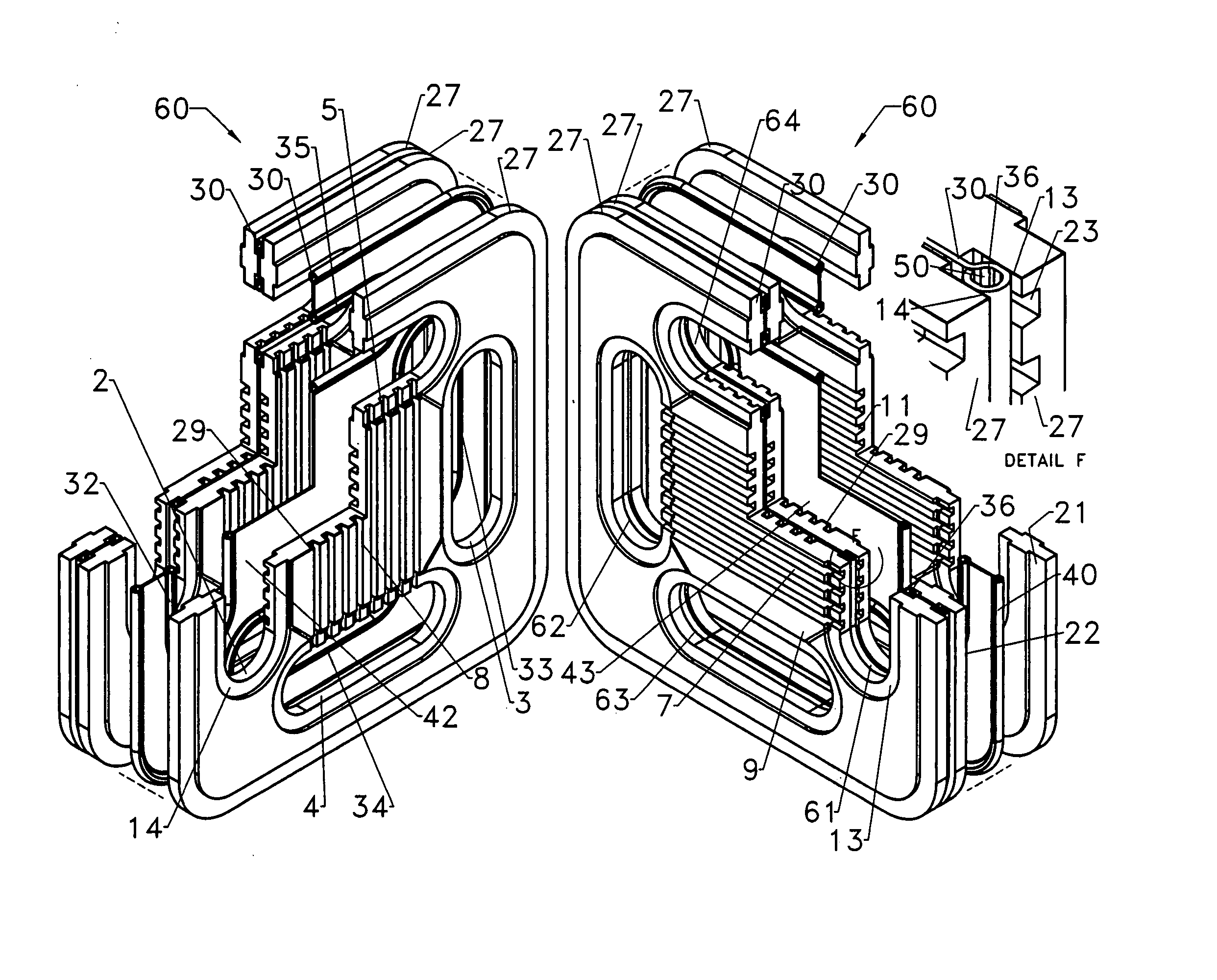

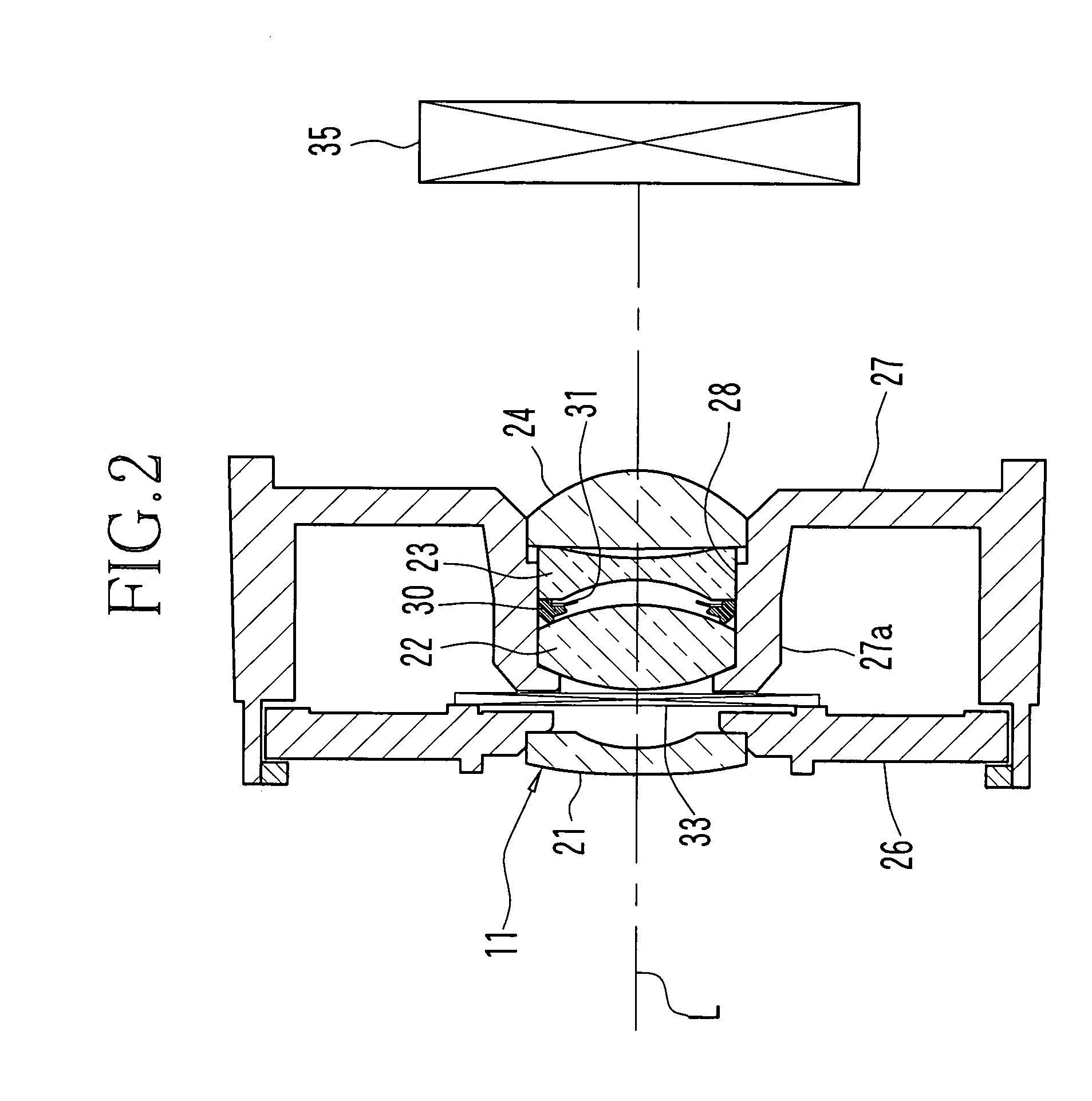

Fuel cell assemblies using metallic bipolar separators

InactiveUS20050249996A1Increased durabilityImprove performanceFuel cells groupingFuel cell auxillariesFuel cellsEngineering

High temperature solid oxide fuel cells (SOFC) and fuel cell stacks incorporating metallic bipolar separators with integral edge seals are provided. The electrochemical cells include reactant manifolds and flow passages, and may have either cathode or anode supported structures. The bipolar separators are thin metallic sheets that minimize thermal expansion stress in the electrochemical cells. The tubular bead edge seals are formed as an integral part of the bipolar separator by a low-cost sheet metal stamping process.

Owner:MEACHAM G B KIRBY

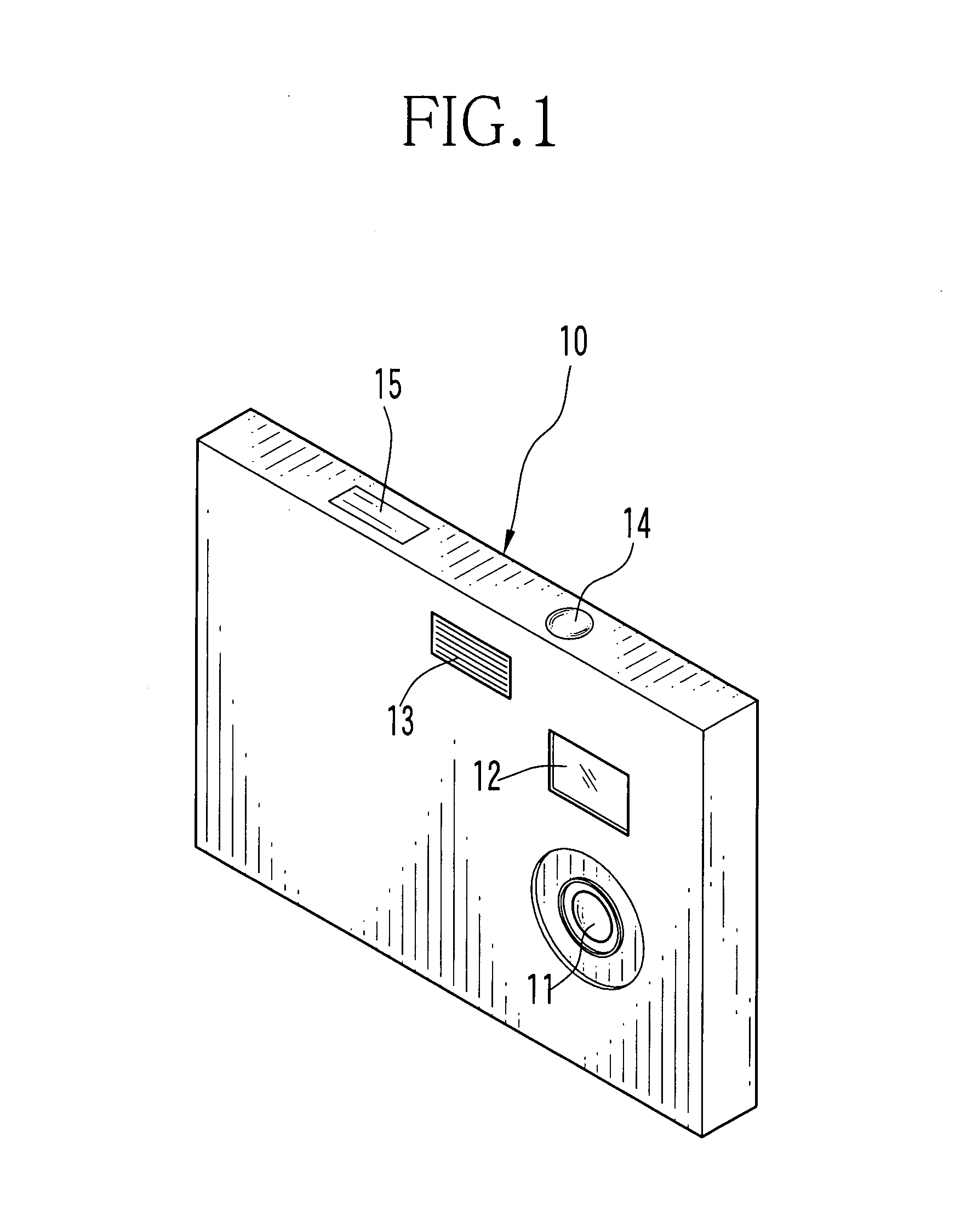

Flare stoppper and taking lens unit

InactiveUS7158318B2Reduce generationReduce occurrenceMicroscopesTelescopesCamera lensPhosphor bronze

A ring-shaped flare stopper is made of a phosphor bronze plate having a thickness of 0.03 mm by sheet metal stamping. An inner periphery for defining a circular opening is formed in the flare stopper. The inner periphery has the form of the side face of a circular truncated cone. The flare stopper is so installed in a lens barrel that the inner periphery is inclined with respect to an optical axis of a taking lens unit. Since incident light is not reflected by the inner periphery of the flare stopper, the occurrence of ghost and flare is prevented. To prevent the deformation and misalignment of the flare stopper, the flare stopper installed in the lens barrel is attached to a spacer.

Owner:FUJI PHOTO OPTICAL CO LTD

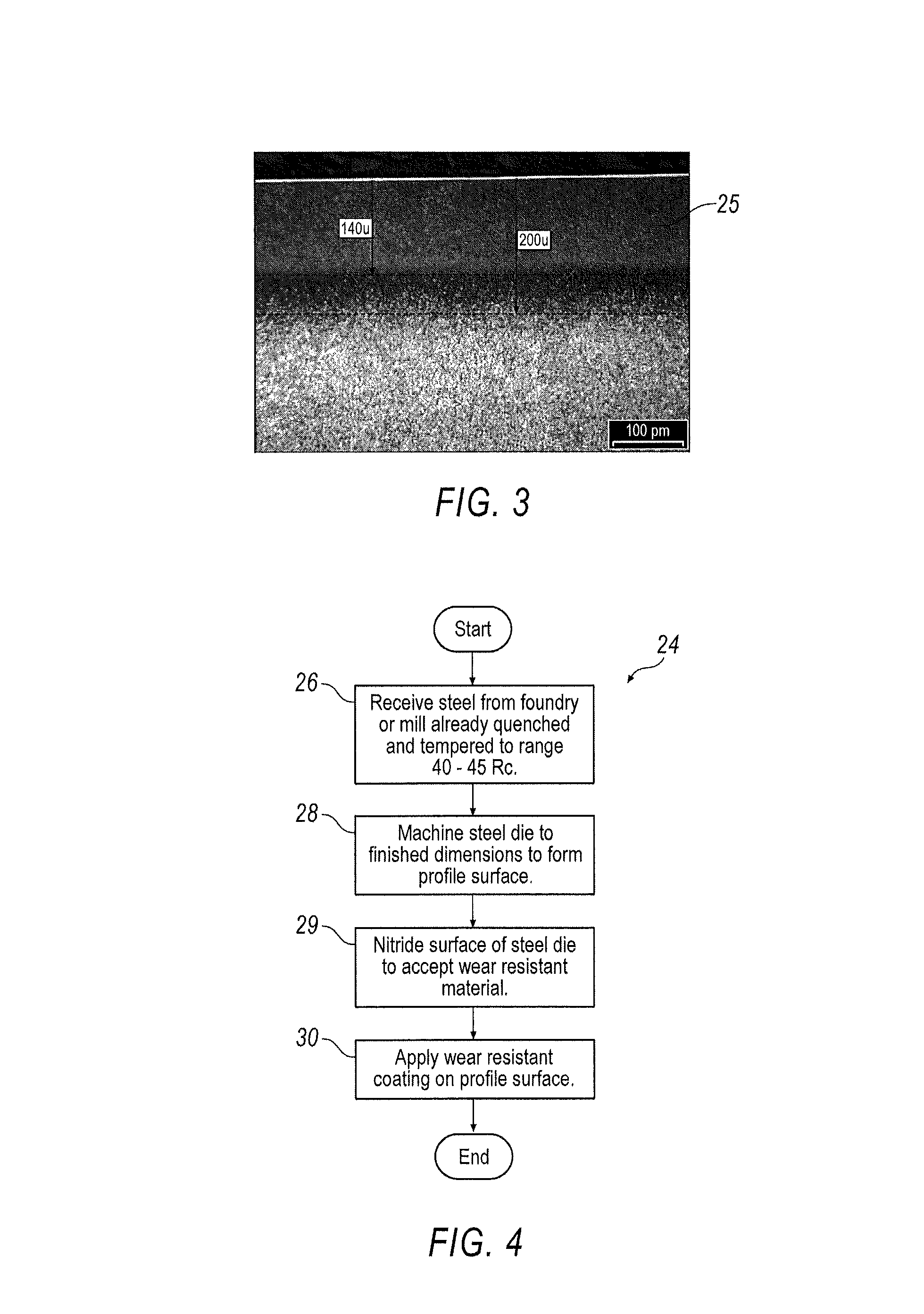

Wear resistant coated sheet metal die and method to manufacture a wear resistant coated sheet metal forming die

InactiveUS7587919B1Impart wear resistanceAvoid insufficient thicknessShaping toolsCutting toolsMetal formingGas phase

A method to manufacture a steel die having a Physical Vapor Deposition wear resistant coating on a profile surface and a steel die formed thereby is disclosed. The steel die is subjected to quenching and tempering to achieve a Rockwell hardness in the range of about 40-45 Rc and then subjected to machining to form a profile surface. The surface is then subjected to Physical Vapor Deposition of a wear resistant coating that may be multiple layers of CrN, AlCrN, TiCrN, TiN, TiCN or TiAlN, and preferably is alternating layers of TiN—TiCN—TiN. The coating is applied at a sufficient thickness to impart wear resistance to the steel die. The steel dies are useful in sheet metal stamping operations.

Owner:FORD MOTOR CO

Flare stopper and taking lens unit

A ring-shaped flare stopper is made of a phosphor bronze plate having a thickness of 0.03 mm by sheet metal stamping. An inner periphery for defining a circular opening is formed in the flare stopper. The inner periphery has the form of the side face of a circular truncated cone. The flare stopper is so installed in a lens barrel that the inner periphery is inclined with respect to an optical axis of a taking lens unit. Since incident light is not reflected by the inner periphery of the flare stopper, the occurrence of ghost and flare is prevented. To prevent the deformation and misalignment of the flare stopper, the flare stopper installed in the lens barrel is attached to a spacer.

Owner:FUJI PHOTO OPTICAL CO LTD

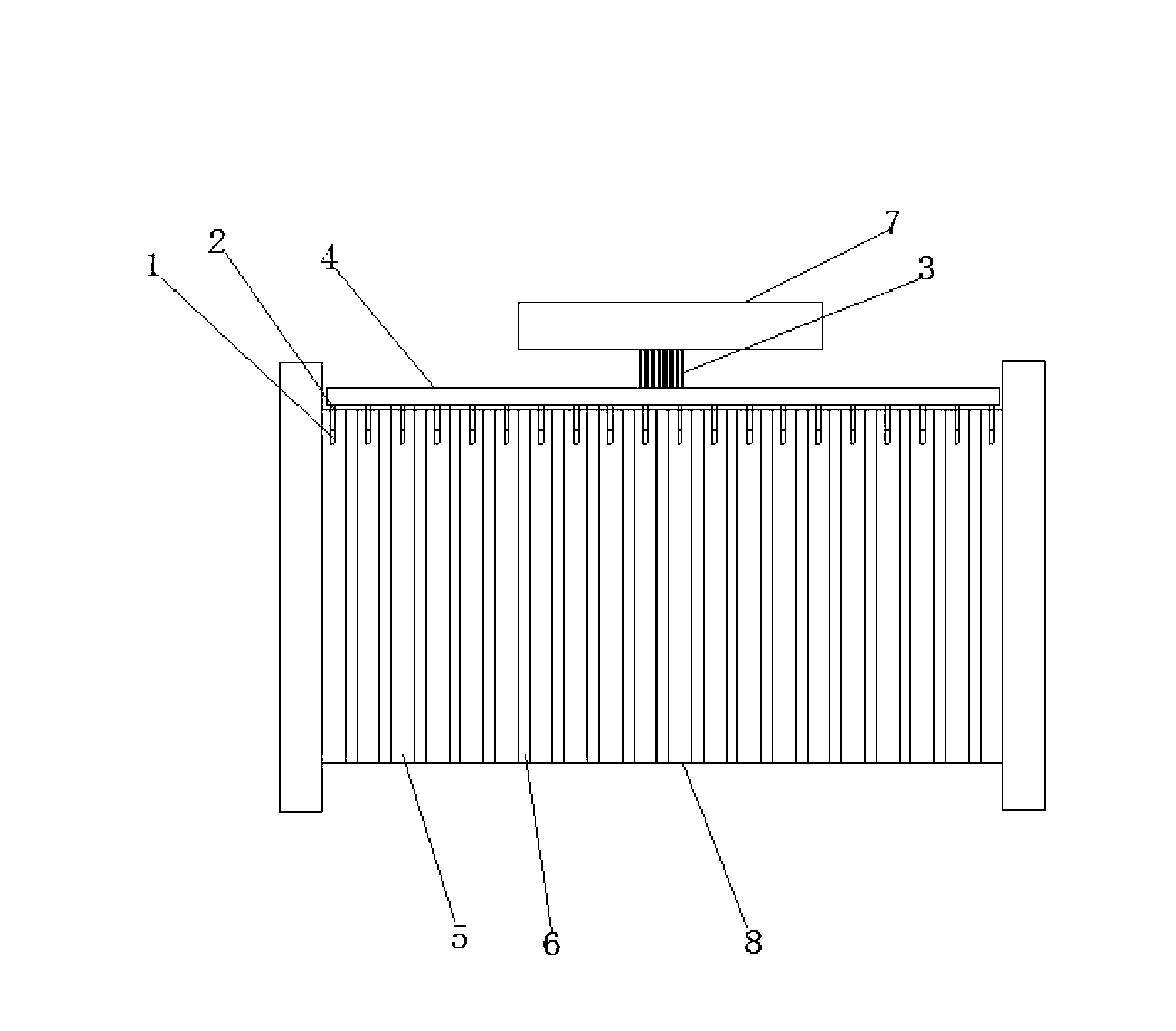

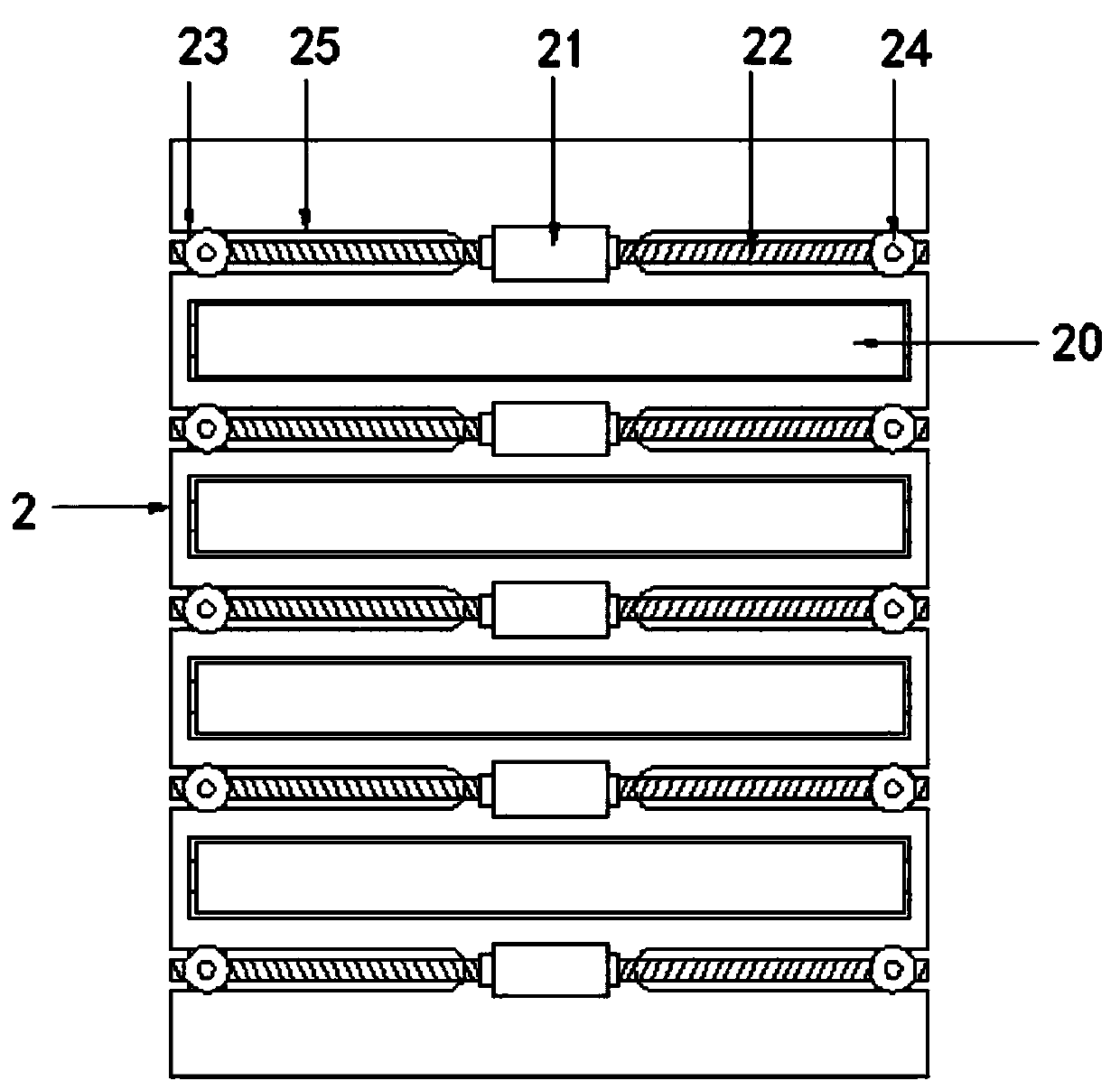

Connecting method of inspecting lines of metal bipolar plate fuel cell stack

ActiveCN102938470AEasy to assemble and disassembleImprove work efficiencyFuel cells groupingFuel cellsElectrical battery

The invention discloses a connecting method of inspecting lines of a metal bipolar plate fuel cell stack. The method includes the following steps that metal bipolar plates with inspection jacks are formed through sheet metal stamping, and the metal bipolar plates are used for assembling the fuel cell stack; the distance between adjacent inspection jacks is calculated according to the thicknesses of the metal bipolar plates; a flat cable connector is formed through press fit according to the distance between the adjacent inspection jacks, and pins of the flat cable connector are matched with the inspection jackets; the pins of the flat cable connector are inserted into the inspection jacks of the metal bipolar plates of the fuel cell stack; and flat cables of the flat cable connector are connected with a cell inspection system. According to the connecting method of the inspecting lines of the metal bipolar plate fuel cell stack, the connection mode is safe and reliable, the monitoring is accurate, and the cell stack can be conveniently and rapidly detached; and work efficiencies of voltage monitoring of a fuel cell are improved, and the problem brought by welding leads which are connected with the inspection system on the metal bipolar plates by means of traditional connecting methods of inspecting lines of metal bipolar plate fuel cell stacks is solved.

Owner:SUNRISE POWER CO LTD

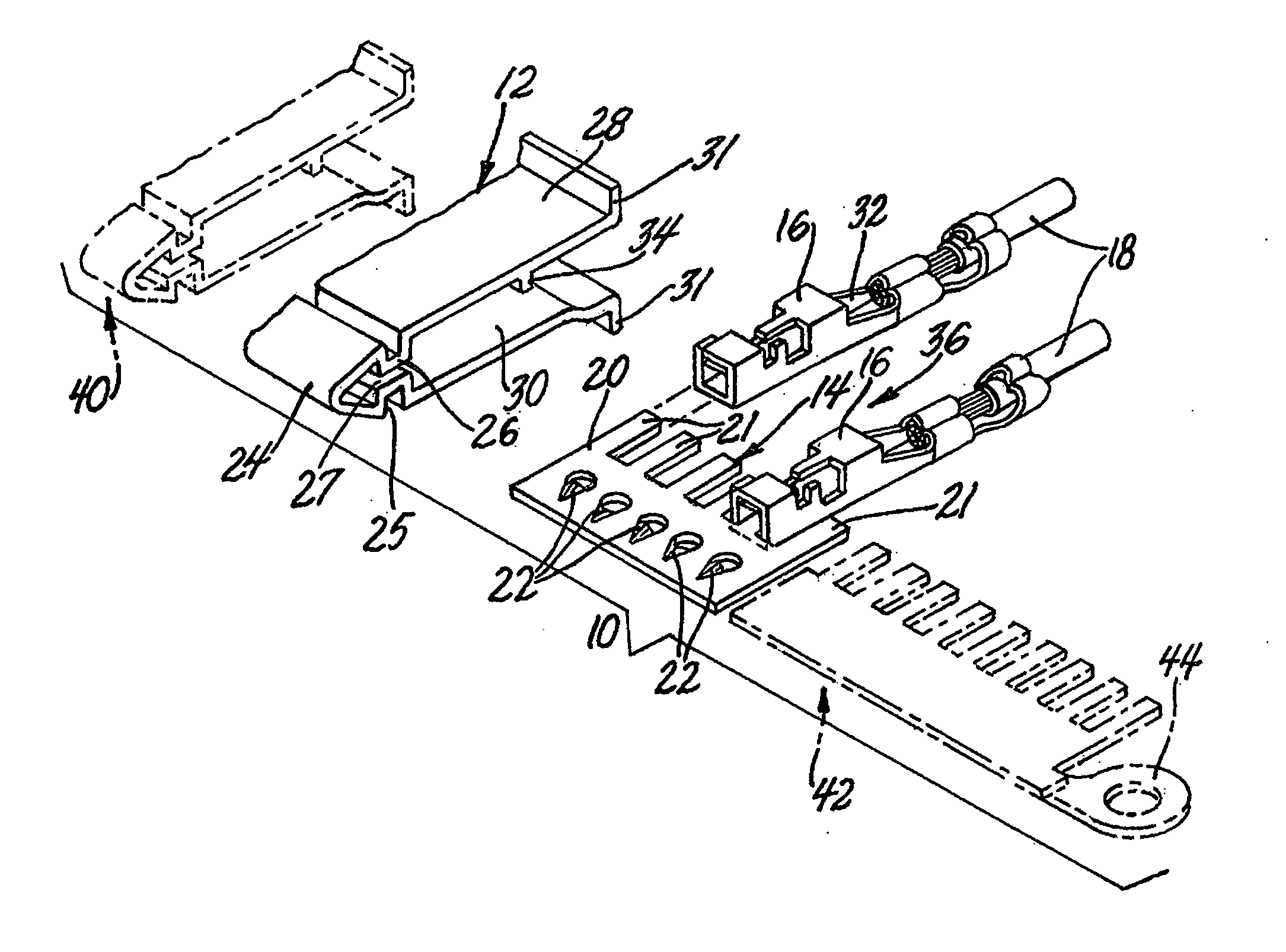

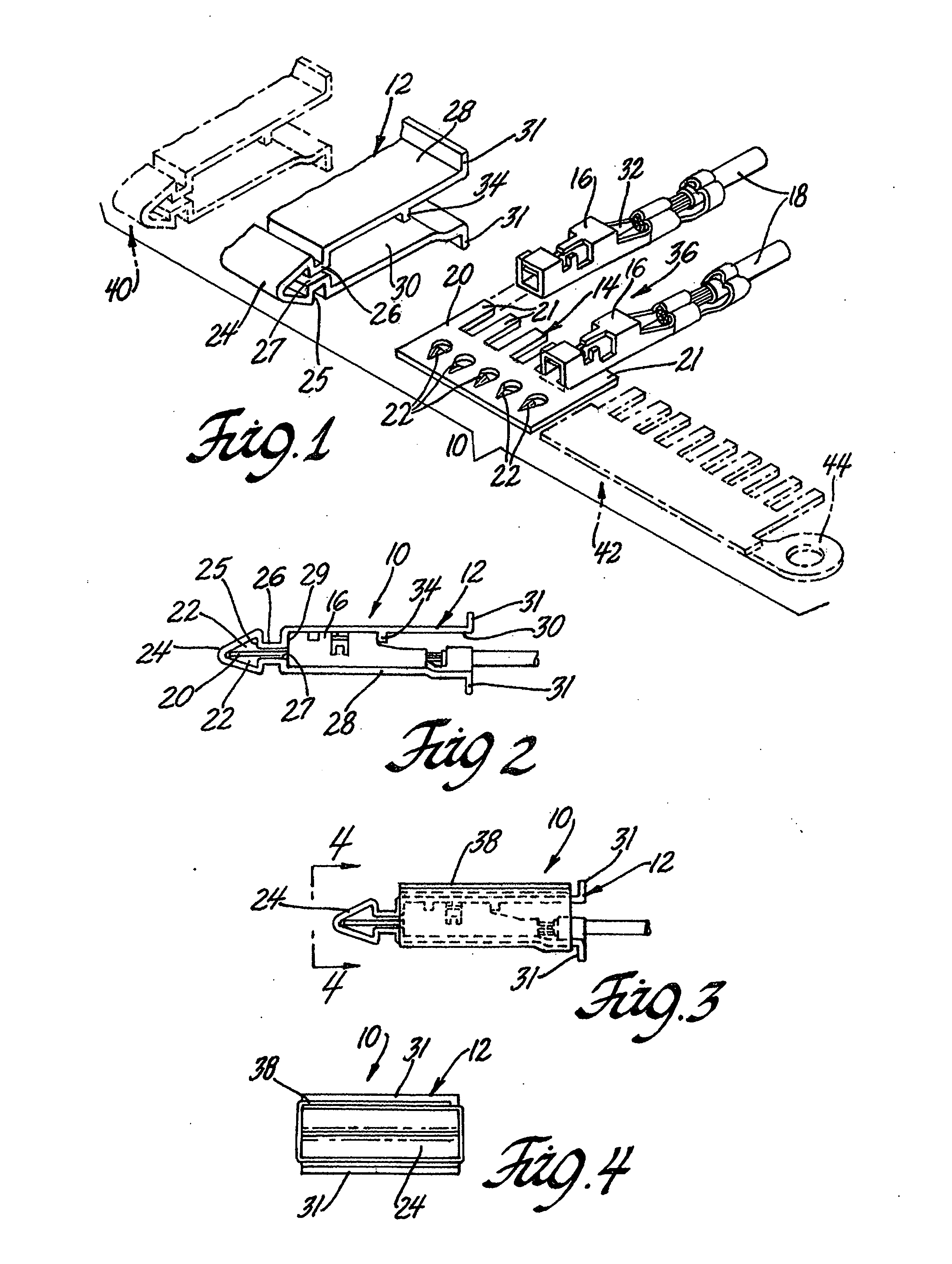

Electrical splice assembly

ActiveUS20070246241A1Low costLow profileContact member manufacturingElectrically conductive connectionsEngineeringSheet metal stamping

An electrical splice assembly includes a bus plate having a plurality of coplanar, spaced male blades extending from the bus plate in cantilever fashion, a plurality of female terminals attached to the male blades, and a generally U-shaped housing of extrudable shape. The housing has an elongate open end portion defining a terminal receiving cavity, a closed end portion and an intermediate portion defining a slot that communicates with the terminal receiving cavity. The bus plate is at least partially disposed in the slot and the spaced male blades are at least partially disposed in the terminal receiving cavity along with the female terminals attached to them. The bus plate is a sheet metal stamping and the housing is an extrusion. The female terminals are attached to selected ones of the male blades to form a sub-assembly that is inserted laterally into the housing so the bus plate is at least partially disposed in the slot and the female terminals are disposed in the terminal receiving cavity. During manufacture a bus plate of appropriate length may be severed from a long sheet metal bus plate precursor and a housing of appropriate length may be severed from a long extruded housing precursor.

Owner:APTIV TECH LTD

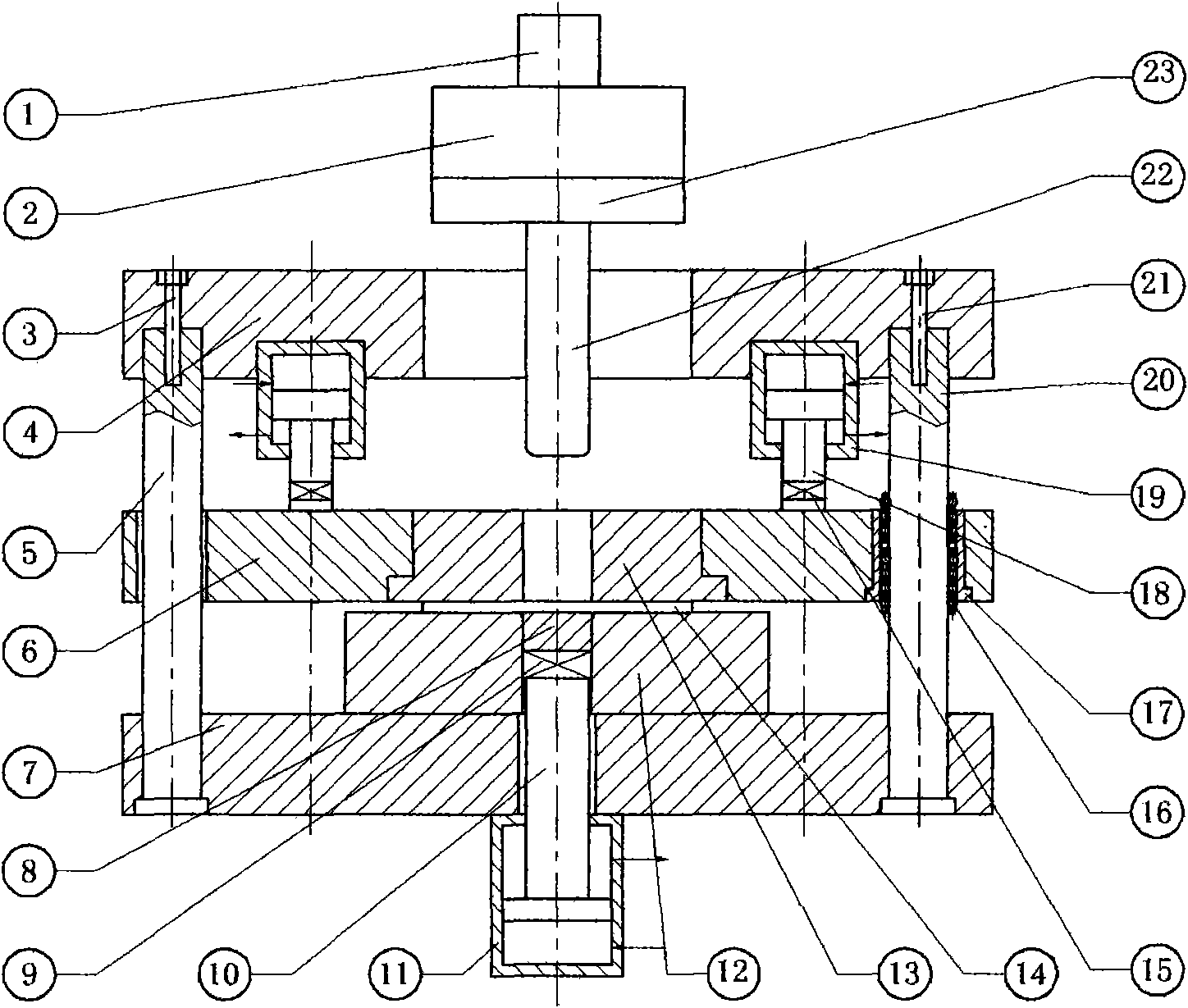

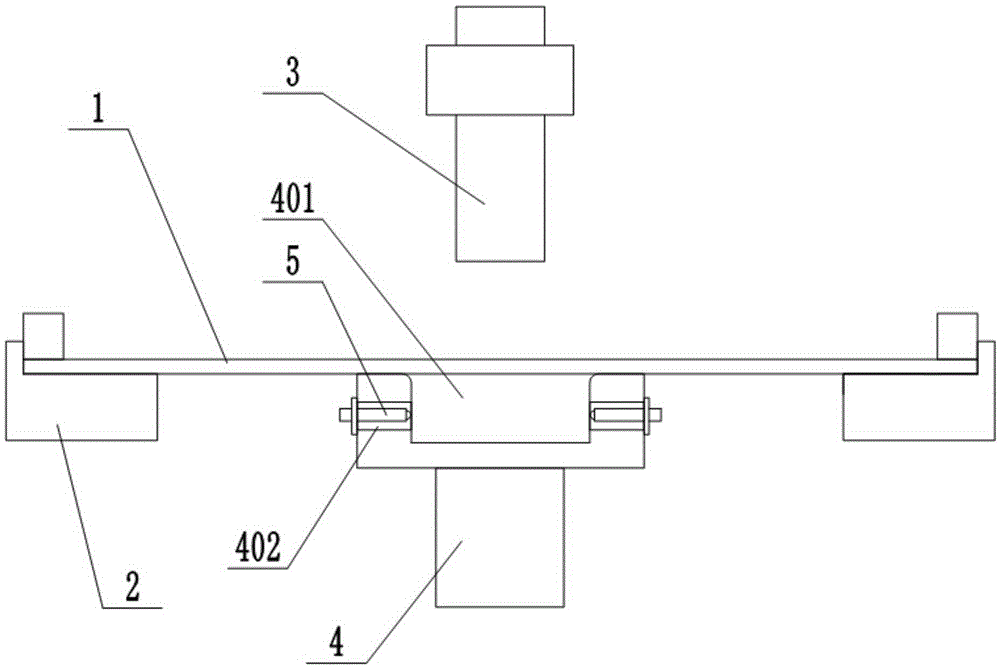

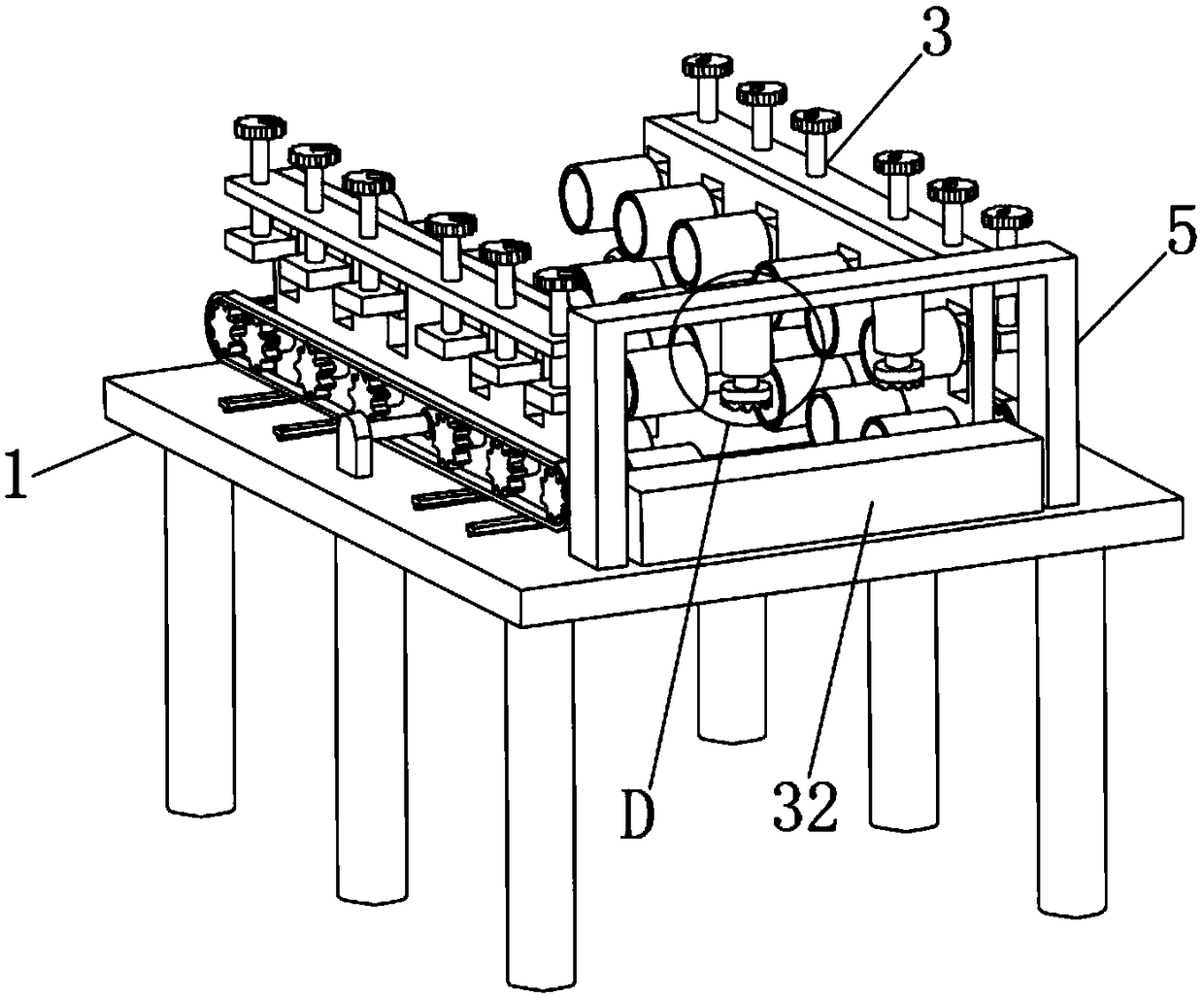

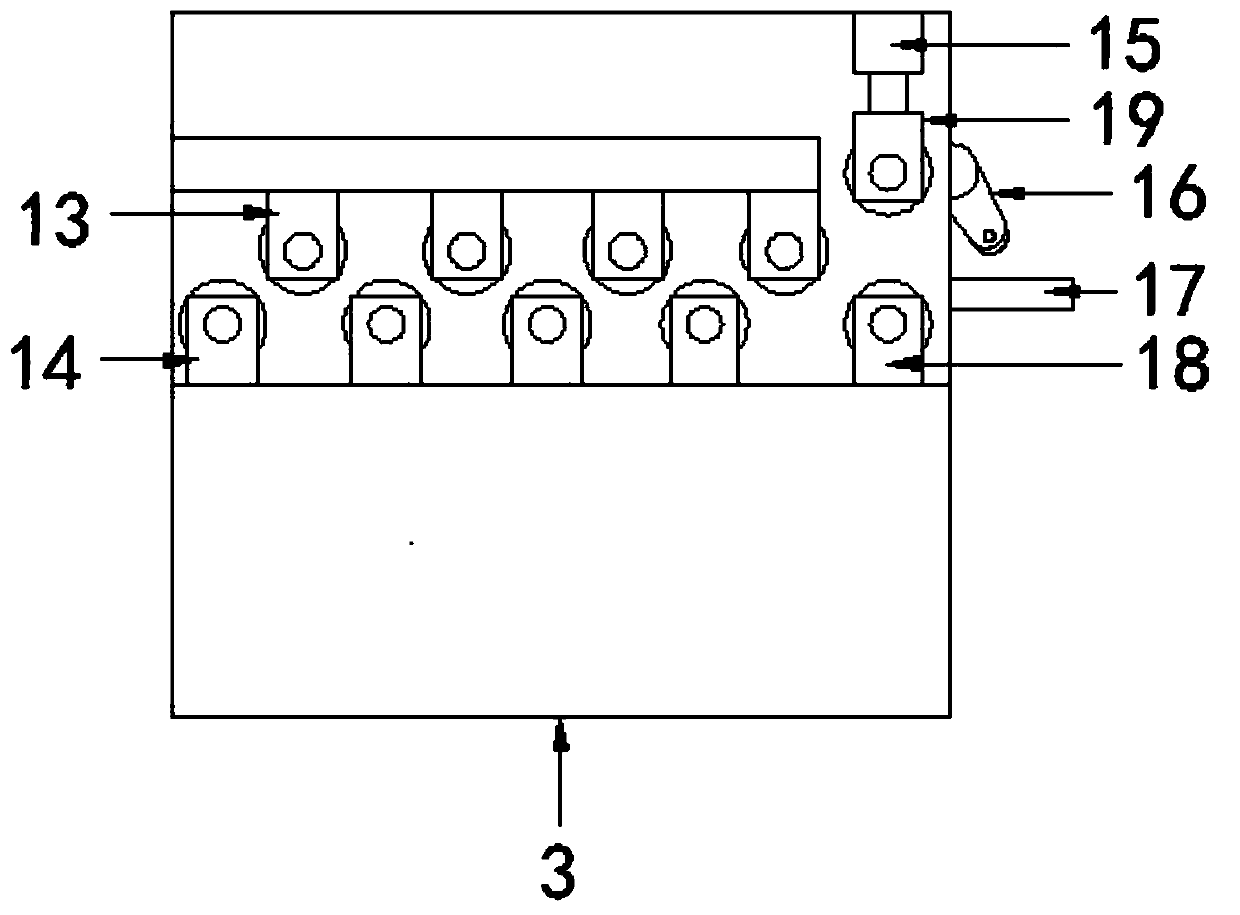

Multipurpose sheet metal stamping die-set for positive edge pressing

InactiveCN101912926AImprove performanceImprove work performanceShaping toolsMating connectionControl system

The invention relates to a multipurpose sheet metal stamping die-set for positive edge pressing. An edge pressing mechanism is arranged above a concave template, and comprises an edge pressing plate and a power driving device; the edge pressing plate is movably connected to a support post and a guide post; the upper end face of the edge pressing plate is in fit connection with the power driving device which is provided with an edge pressing force sensor; and electrical control parts of the edge pressing force sensor and the power driving device are connected with a PLC control system through circuits. The multipurpose sheet metal stamping die-set has the advantages that: the structure is novel and simple; the performance of the die is greatly improved; the edge pressing mechanism is arranged positively; an inverse jacking device is arranged; independent hydraulic power system and electrical control part are arranged and are used for controlling the strokes of the edge pressing plate and an inverse jacking plate and the magnitude of the edge pressing force and the inverse jacking force; the edge pressing force and the inverse jacking force required can be constantly generated at specific positions of the stamping stroke and high accuracy requirement can be met; and when the upper die part works, the upper die part is wrapped by the lower die part, and the safety of the stamping is greatly improved.

Owner:SHANGHAI UNIV OF ENG SCI

Method for determining plastic forming limit of sheet material based on finite element calculation analysis

ActiveCN109284515AShort cycleShorten the cycle of experimentsDesign optimisation/simulationSpecial data processing applicationsPost yieldEngineering

The invention provides a method for determining plastic forming limit of sheet material based on finite element calculation analysis. The method of the invention comprises the following steps: (1) obtaining the elastic modulus, Poisson's ratio, yield strength and post-yield stress of the sheet material Strain correspondence; (2) establishing the geometrical models of punch, concave die, blank holder and sample; (3) adding the corresponding material properties and setting the corresponding friction coefficient in the material model of the finite element software; 4) determining that applied load accord to the actual downward pressure amount and downward pressure of the blank holder ring; (5) controlling the downward pressing displacement of the punch, that is, the downward pressing amount;(6) meshing the sample; (7) defining the calculation time; (8) obtaining the results of stress-strain evolution in a sample forming experiment, and outputting the stress-strain nephogram of all the units; (9) using S-G filter to perform first and second order fitting on main strain. The invention provides reliable judging basis and criterion for obtaining accurate results of sheet metal stamping forming.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

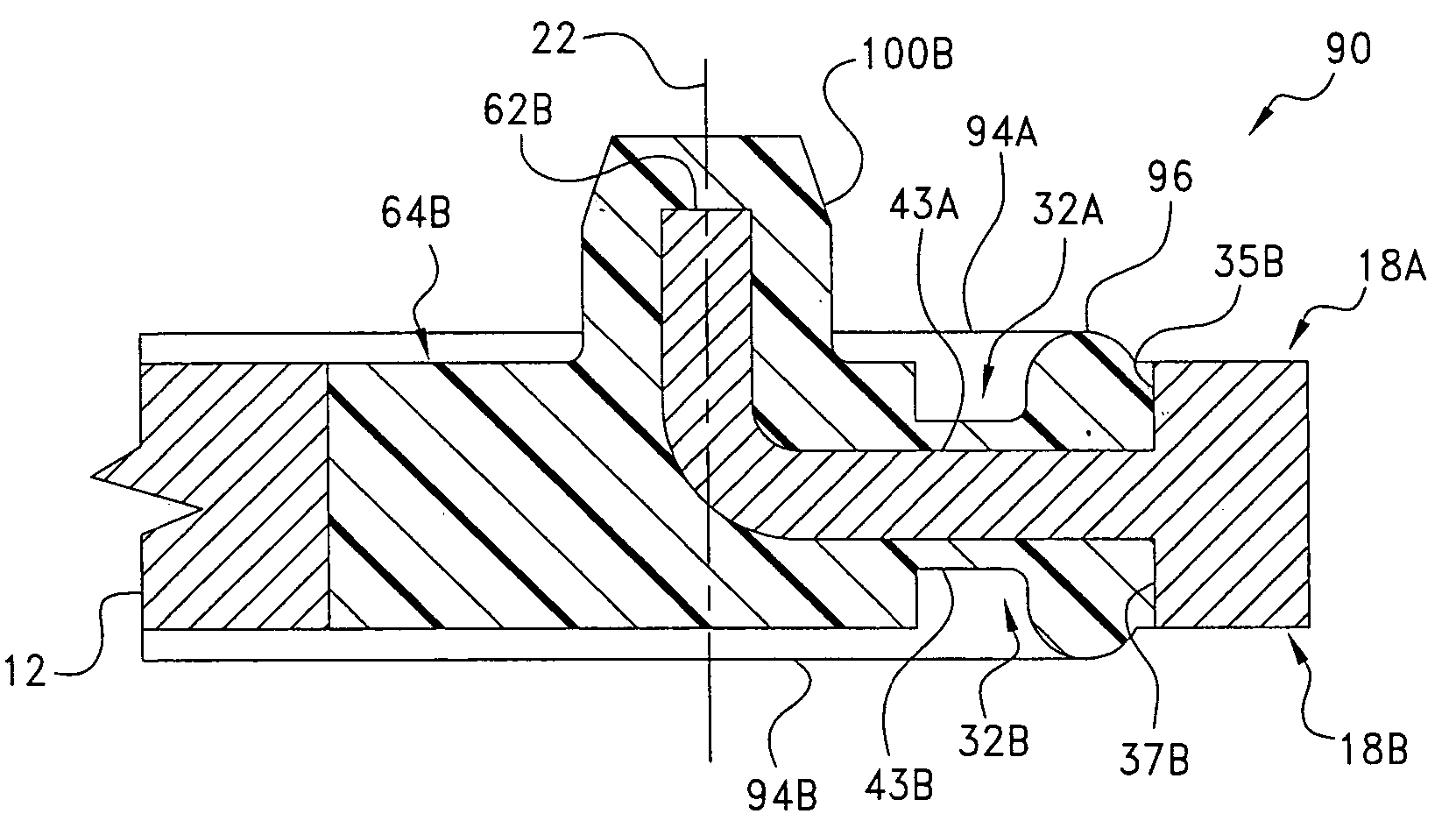

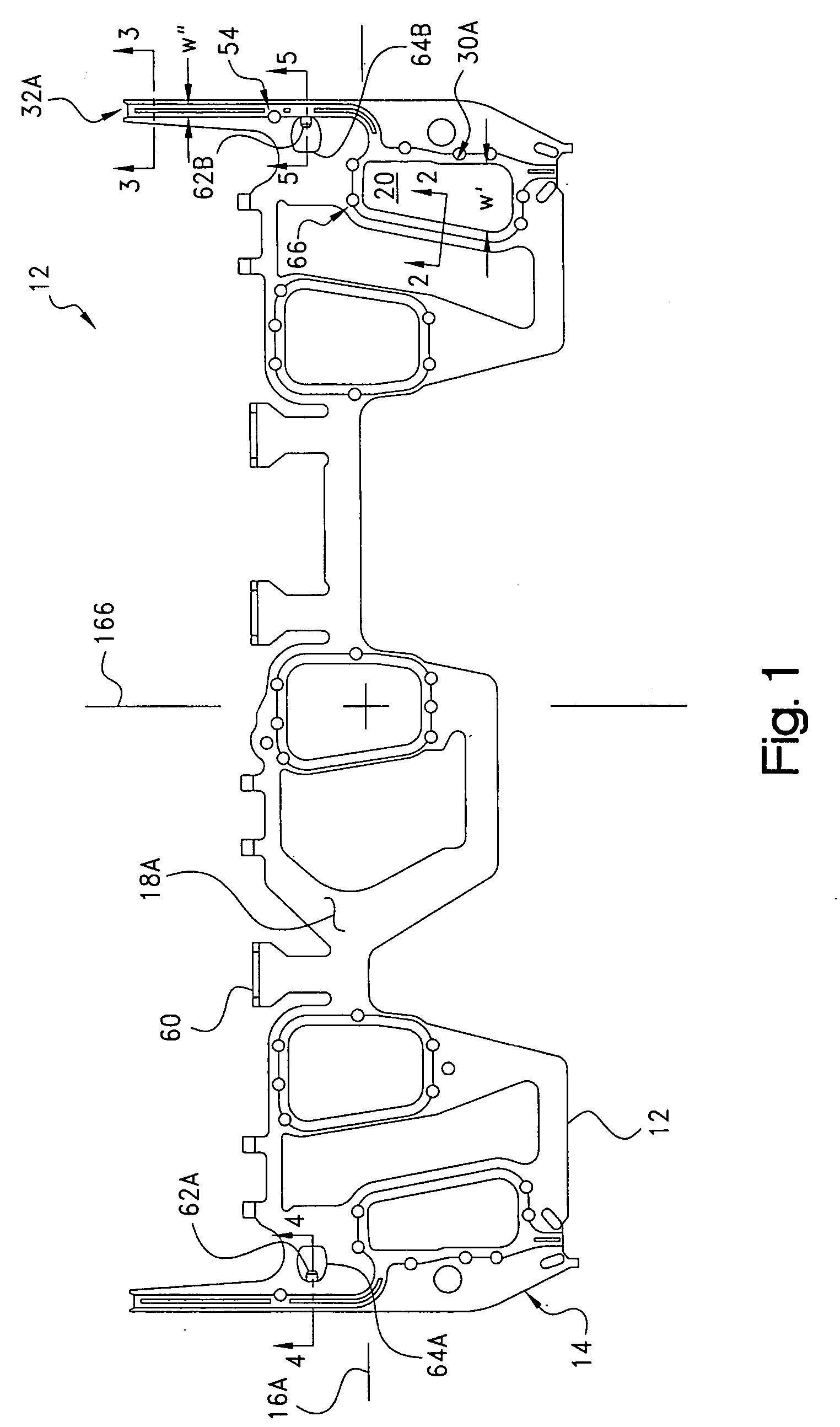

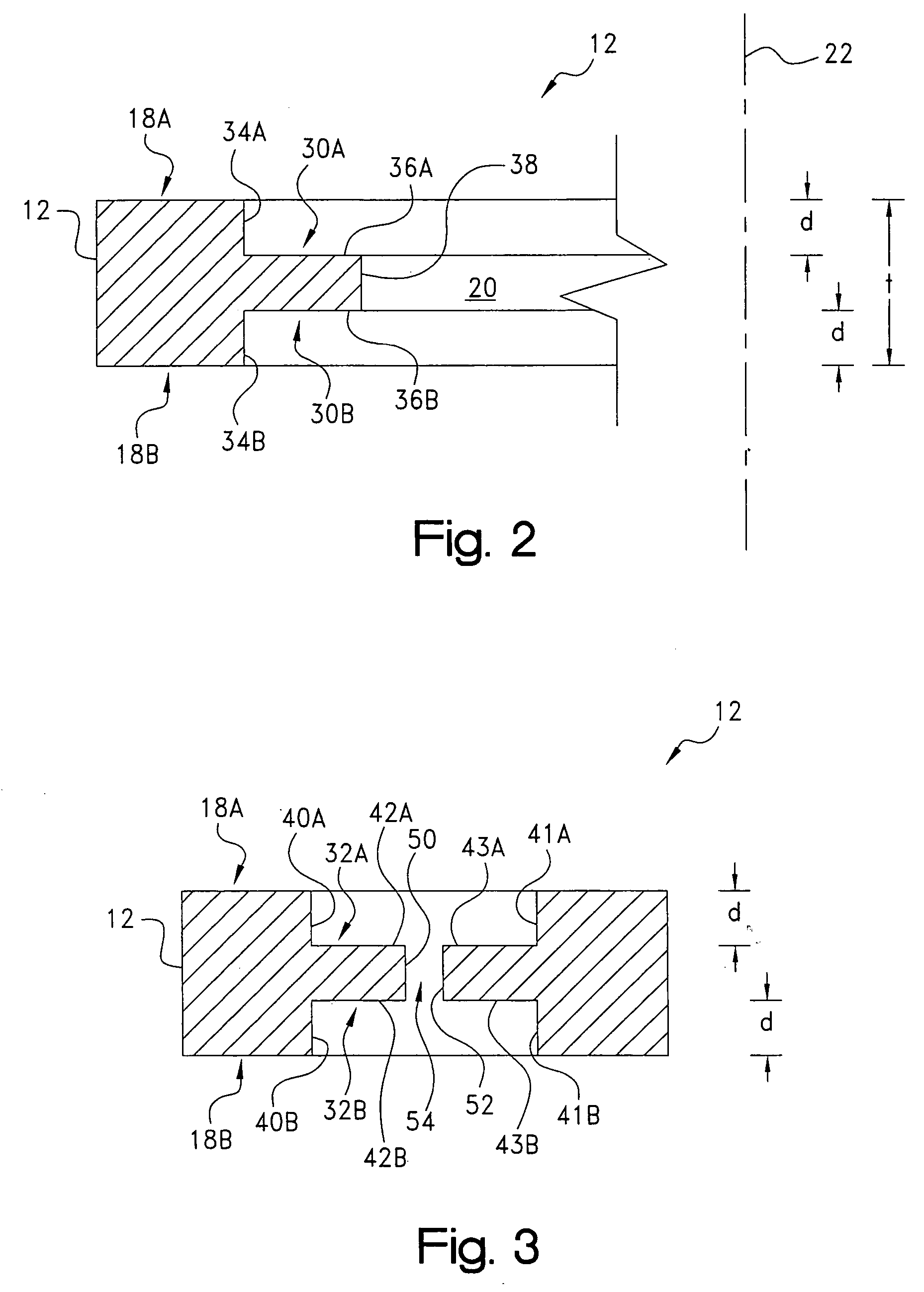

Retainer gasket construction

Sealing gasket construction for providing a fluid seal intermediate a pair of opposed, mating parts or structures. The gasket includes a metal retainer and a resilient seal element received in a groove formed into the retainer. Such groove is adapted to be fabricated by coining or a like sheet metal stamping or forming process.

Owner:PARKER INTANGIBLES LLC

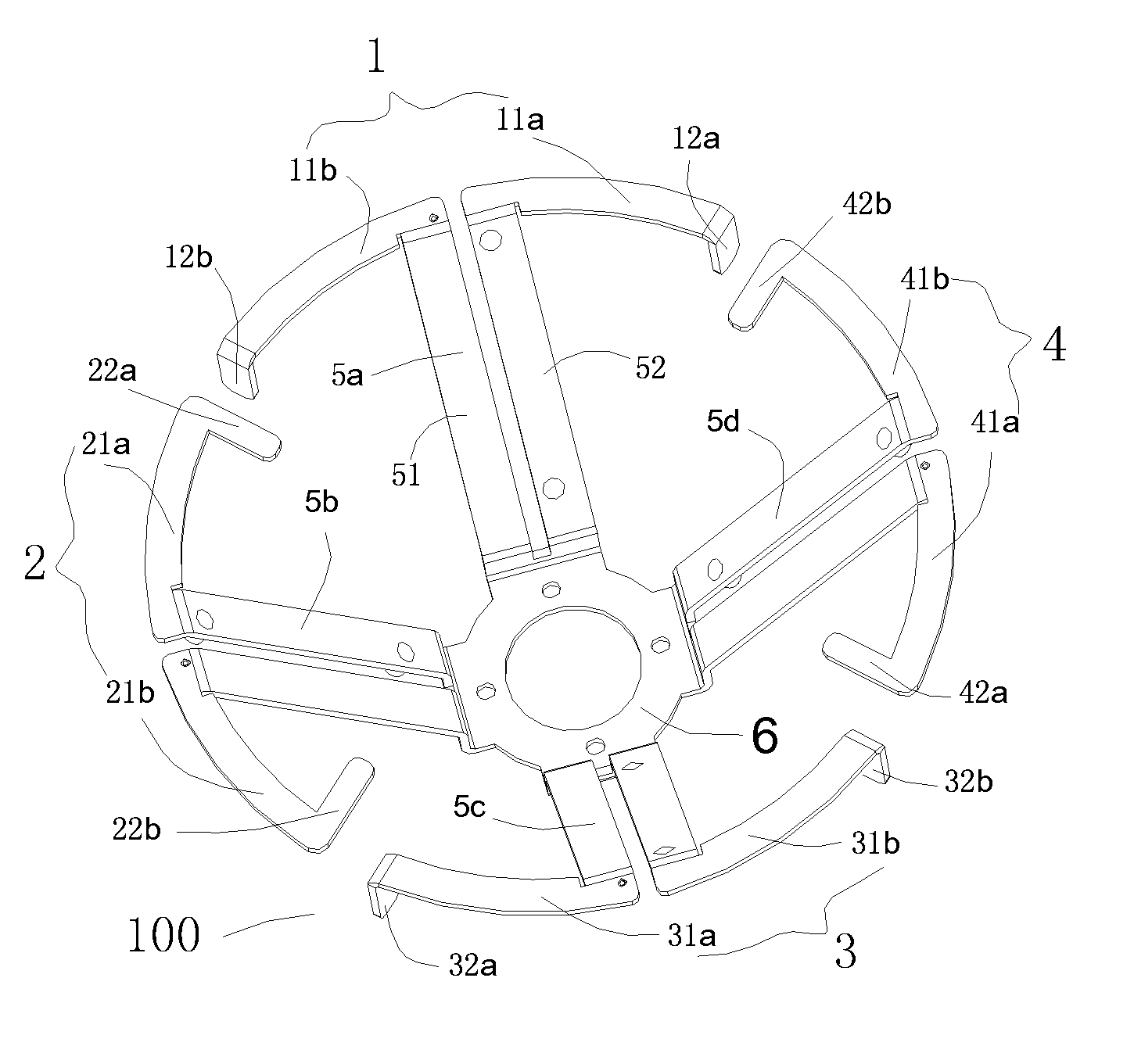

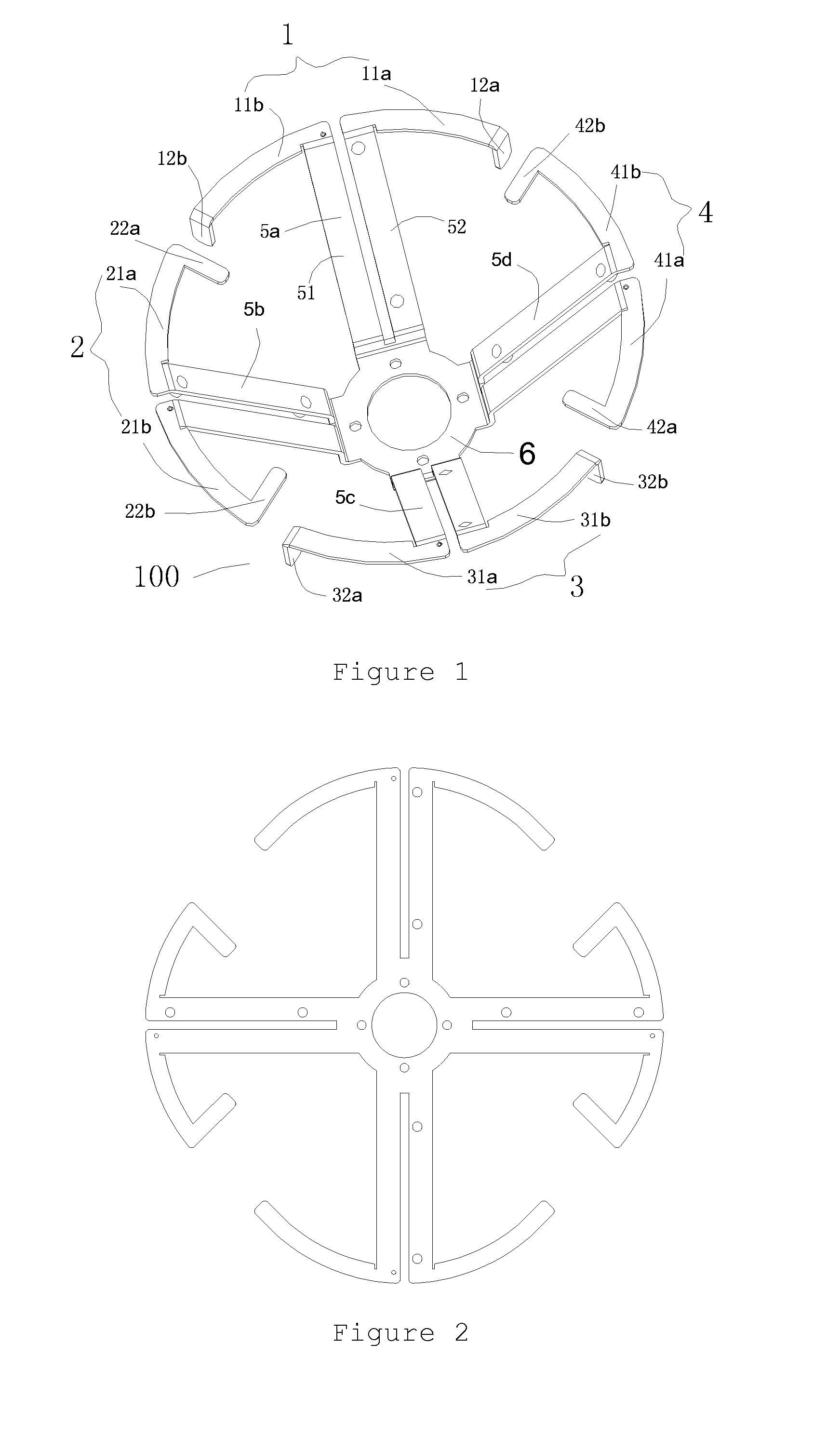

Bi-Polarized Broadband Annular Radiation Unit and Array Antenna

ActiveUS20150102971A1Simple structureImprove stabilitySimultaneous aerial operationsIndividually energised antenna arraysEngineeringSheet metal stamping

A bi-polarized broadband annular radiation unit, for being installed on a metal reflective plate thus constituting a communication antenna and defining an annular construction by two pairs of orthogonally polarized dipoles, includes two pairs of orthogonally polarized dipoles, each dipole comprising two symmetrical unit arms of a single line sheet shape, one end of a unit arm being facing to a corresponding end of the other unit arm, and a distal end of each unit arm of at least one pair of dipoles is provided with a loading line; and a plurality of balun arms feeding power to and supporting respective dipoles, each balun arm including two parallel balun lines, and the top ends of the two balun lines being connected with corresponding ends of the two unit arms of a corresponding dipole. Each unit arm and the balun line and / or loading line connected to the same unit arm are made by sheet metal stamping forming process or casting process.

Owner:ANHUI MOBILE COMM +1

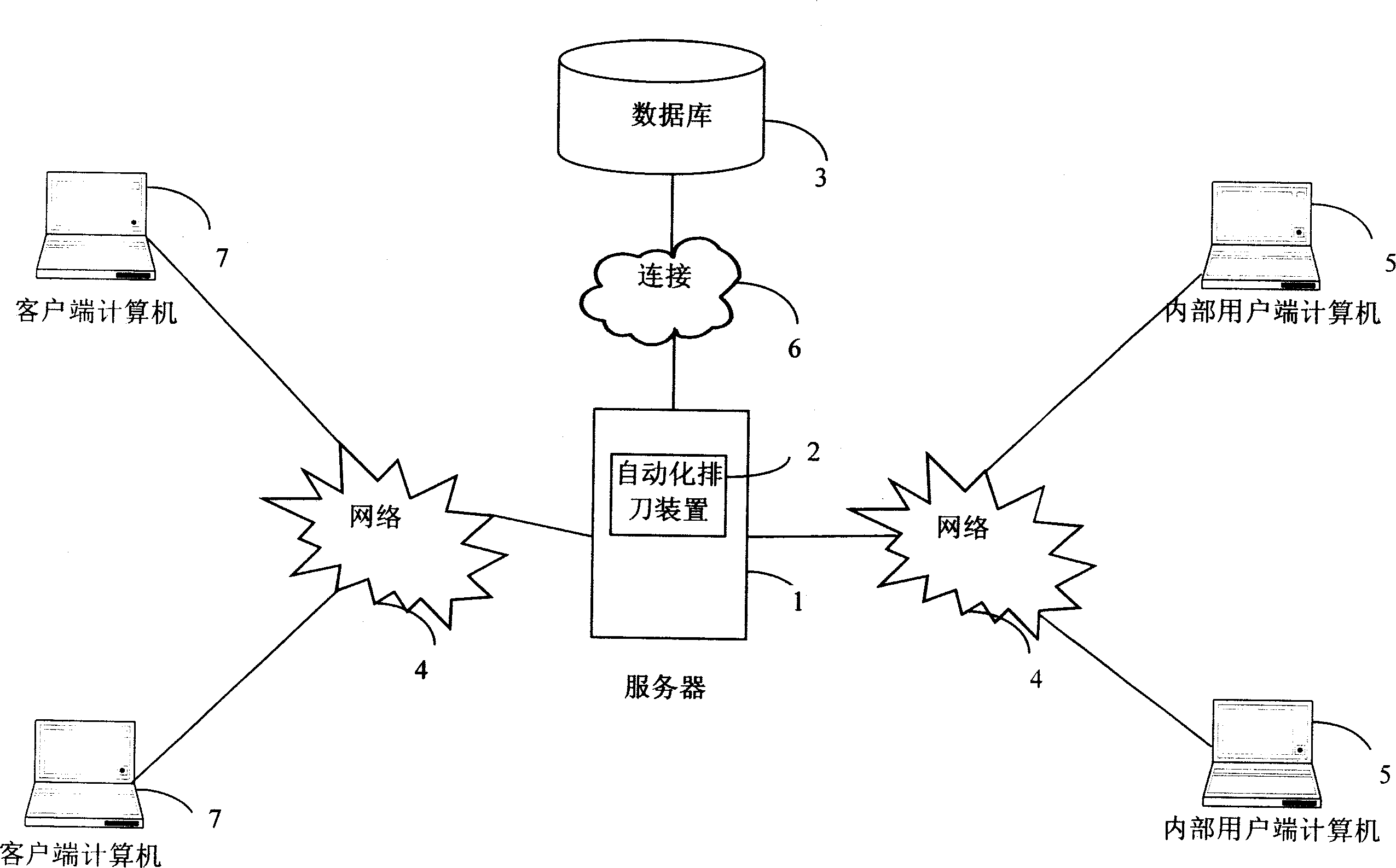

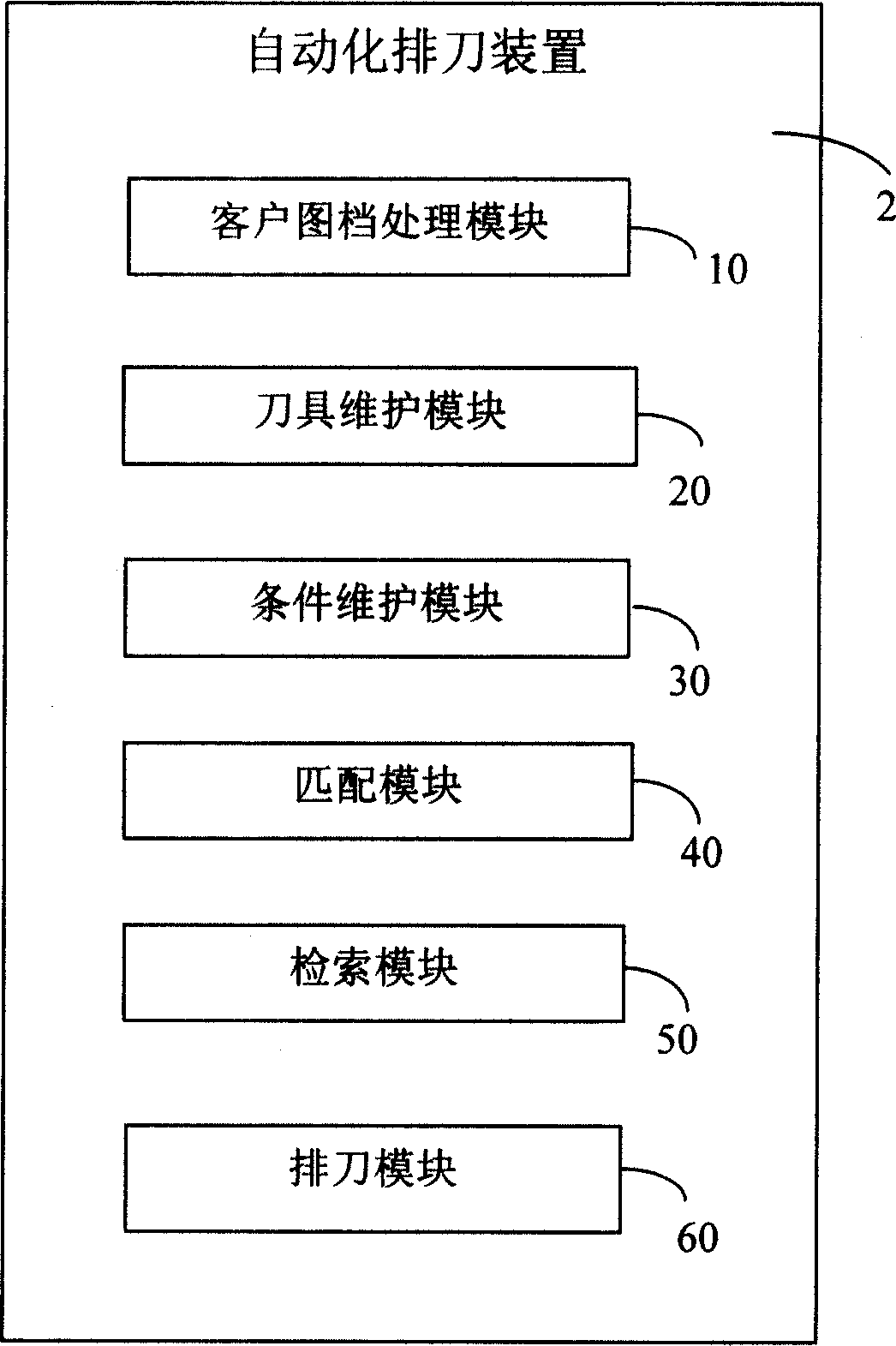

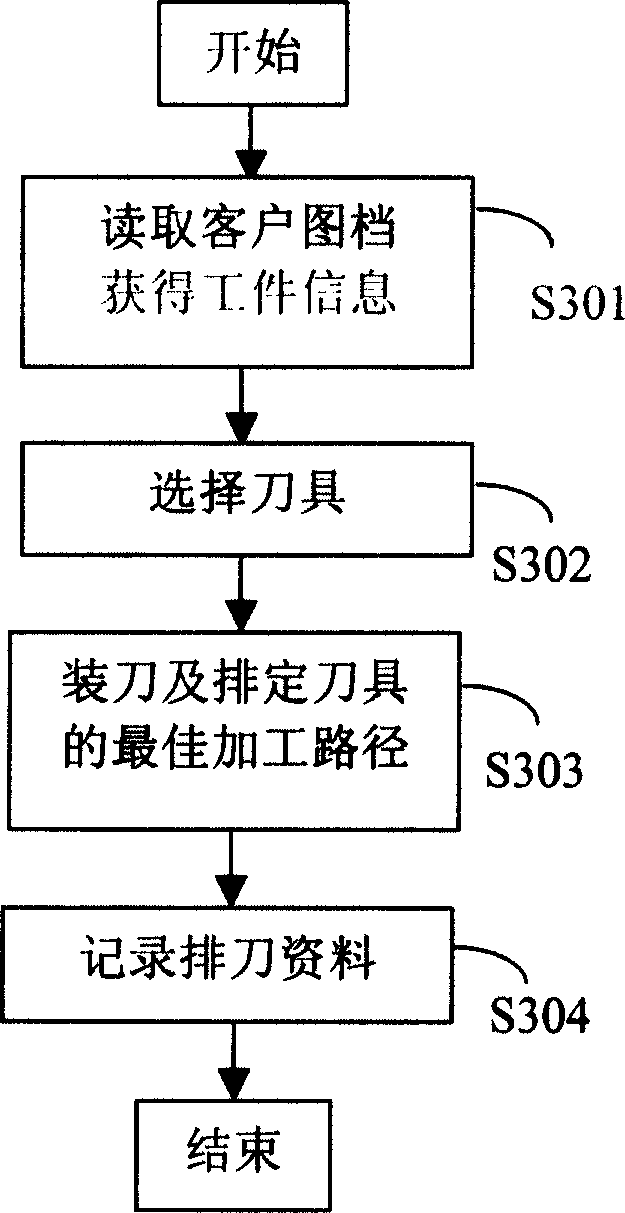

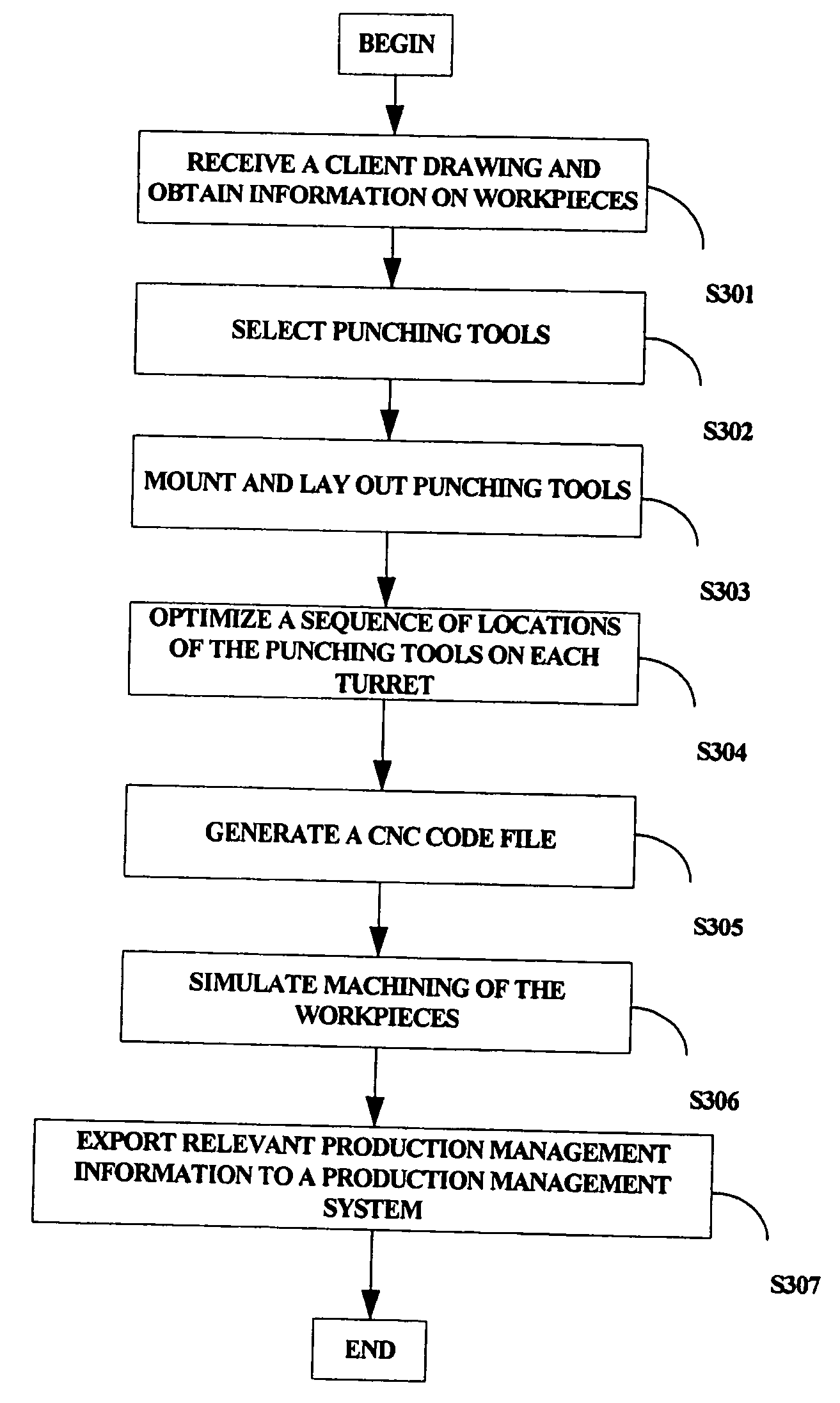

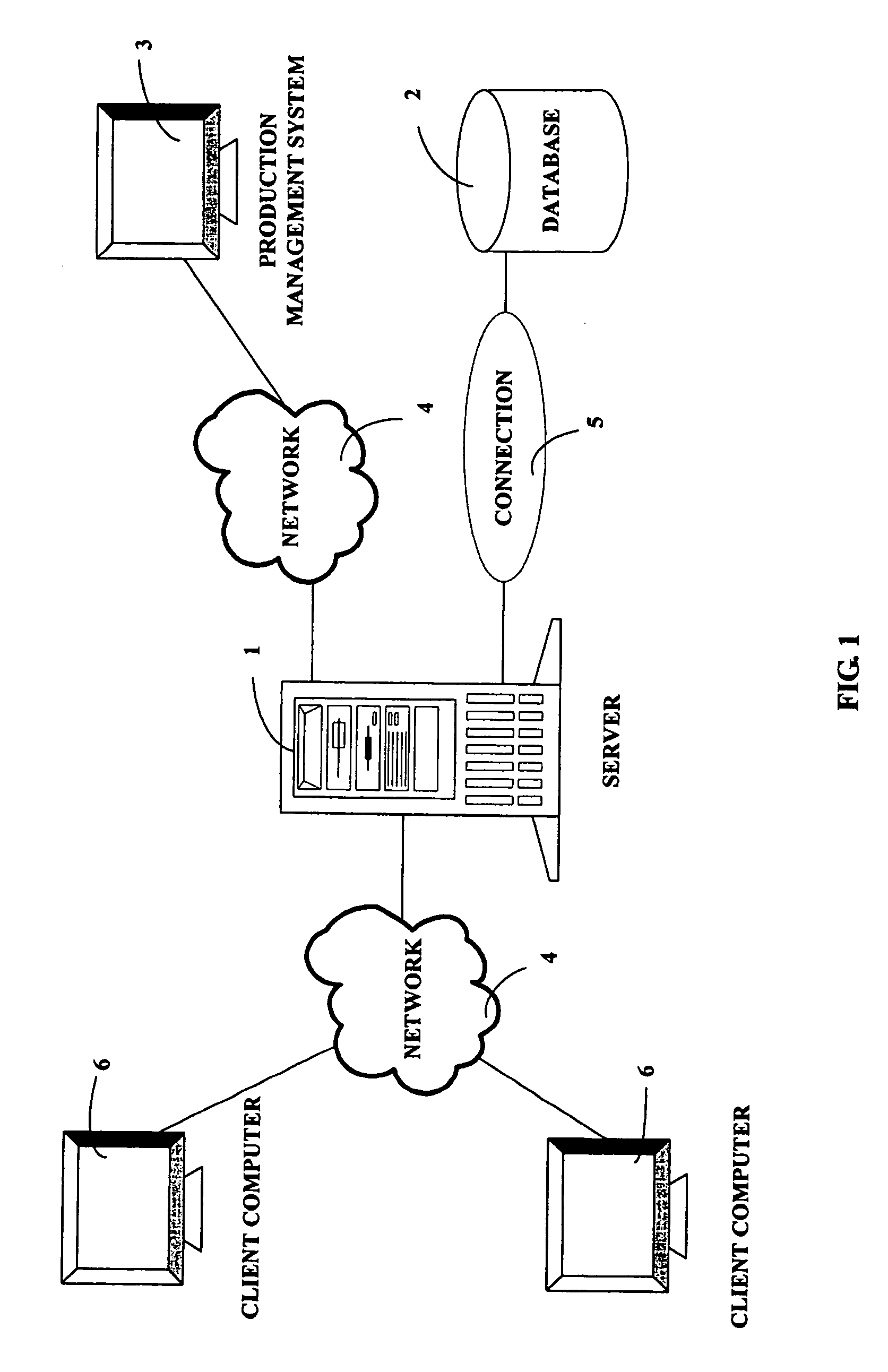

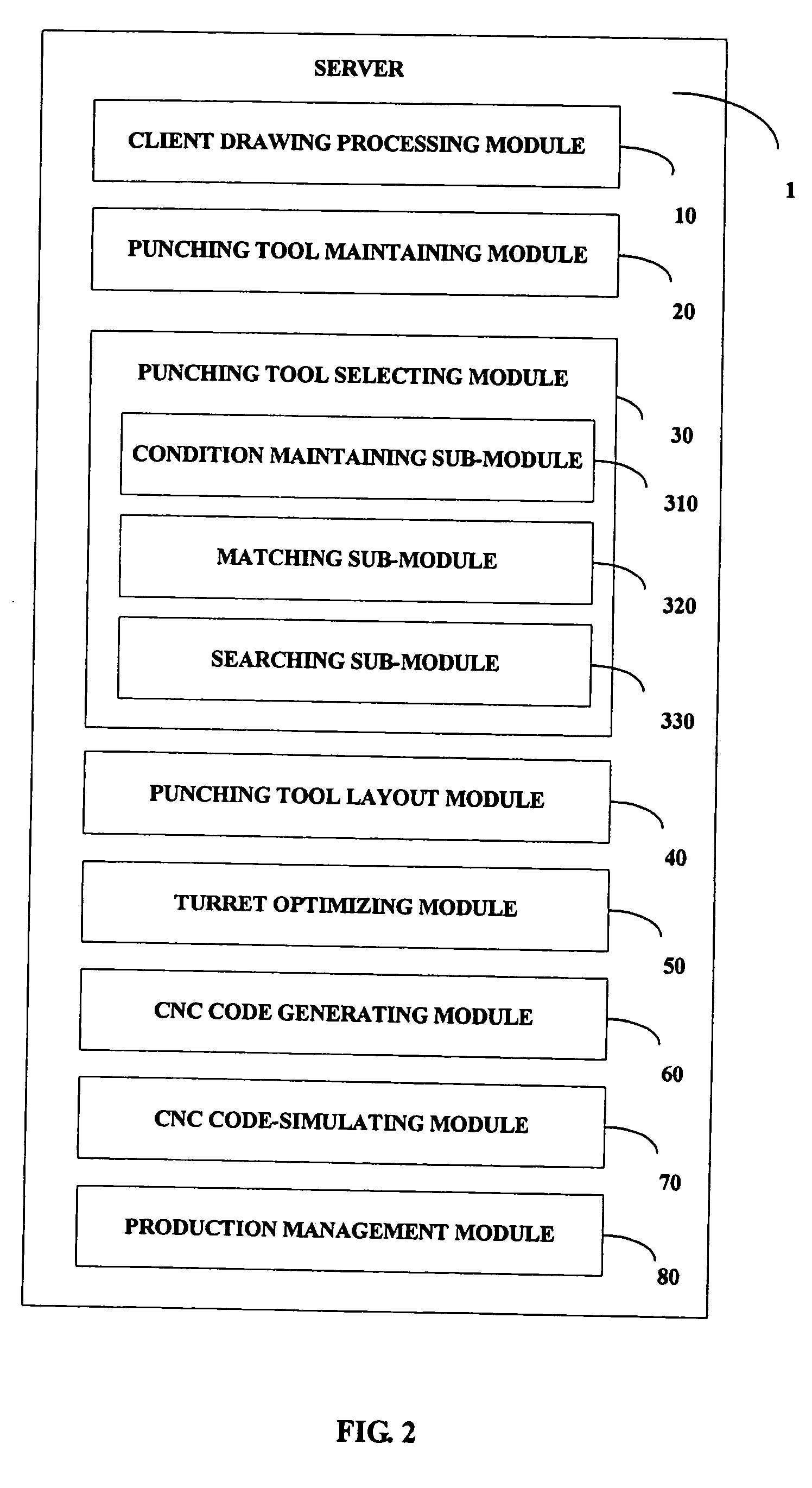

Automatic cutter-arranging device and method

InactiveCN1581175AMultiple digital computer combinationsSpecific program execution arrangementsSheet metal stampingModel Number

The present invention discloses an automatic cutters-arranging equipment and its method. Said equipment can be used in a computer-aided manufacturing system environment of sheet-metal stamping process. The computer-aided manufacturing system of sheet-metal stamping process includes a server, a database, several customer terminal computers, at the same time said system is connected with several internal user terminal computers by means of a network. Its automatic cutters-arranging equipment includes a customer drawing archive processing module, a cutter maintenance module, a condition maintenance module 1 a matching module, a searching module and a cutters-arranging module. Said invention also provides the functions of said system and said equipment, and provides its operation method and concrete steps.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Retainer gasket construction

Sealing gasket construction for providing a fluid seal intermediate a pair of opposed, mating parts or structures. The gasket includes a metal retainer and a resilient seal element received in a groove formed into the retainer. Such groove is adapted to be fabricated by coining or a like sheet metal stamping or forming process.

Owner:PARKER INTANGIBLES LLC

Composite disc brake backing plate

Owner:GRIPMETAL LTD

Computer-aided manufacturing system and method for sheet-metal punching

A computer-aided manufacturing system for sheet-metal punching includes client computers (6), a server (1), and a database (2). The client computers are used for transmitting client drawings to the server, and obtaining machining drawings from the server. The database is used for storing the client drawings, punching tool information, turret information, punching tool layout information, relevant production management information, machining drawings of workpieces, and statements for control of machining processes. The server is connected to a production management system (3) through a network (4), and is used for automatically selecting, mounting and laying out punching tools, optimizing turrets, simulating machining of workpieces, and exporting CNC (computer numerical control) code files, types of machines, machining information on workpieces and materials of the workpieces to the production management system in order to have statements for control of relevant machining processes generated. A related computer-aided manufacturing method for sheet-metal punching is also provided.

Owner:HON HAI PRECISION IND CO LTD

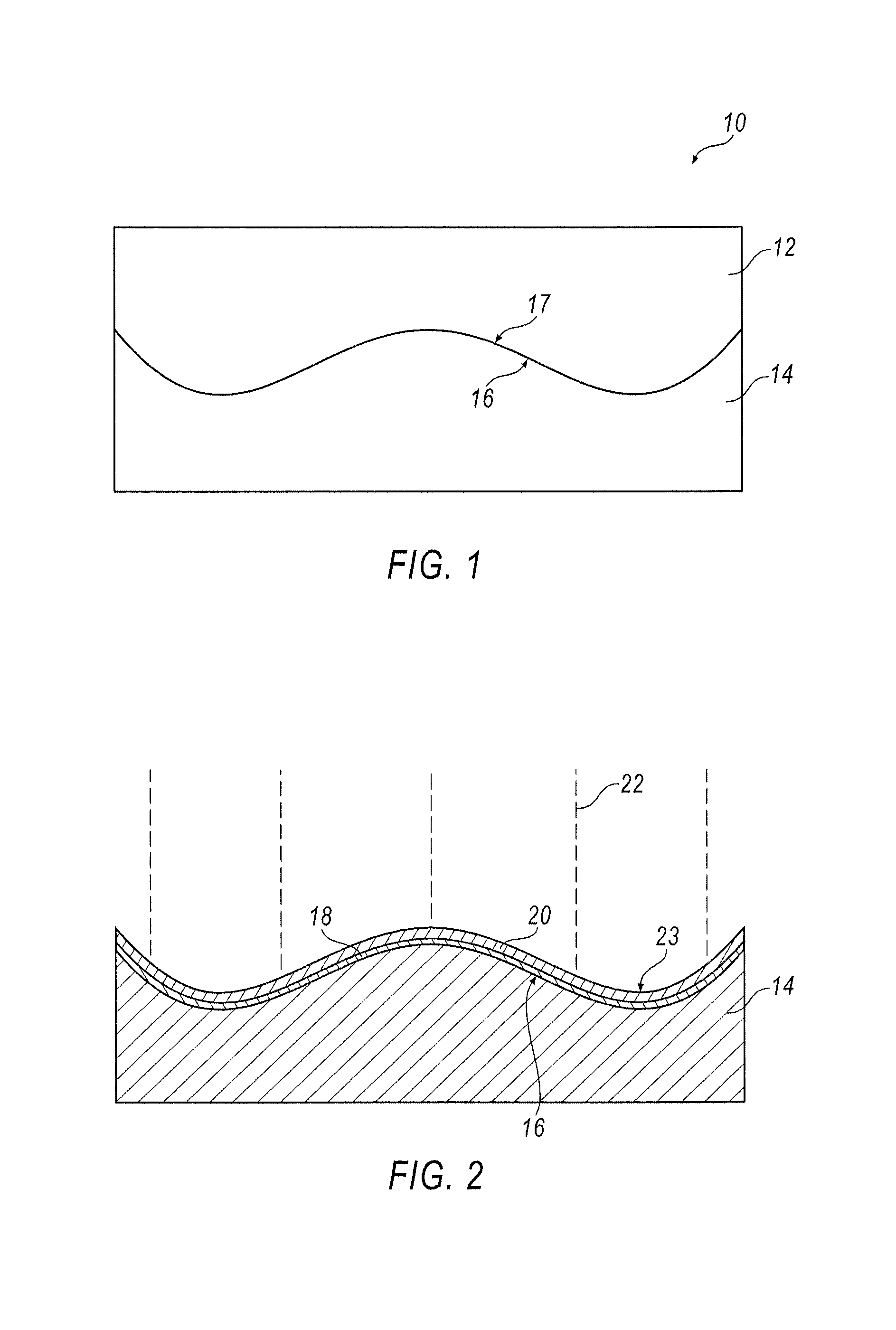

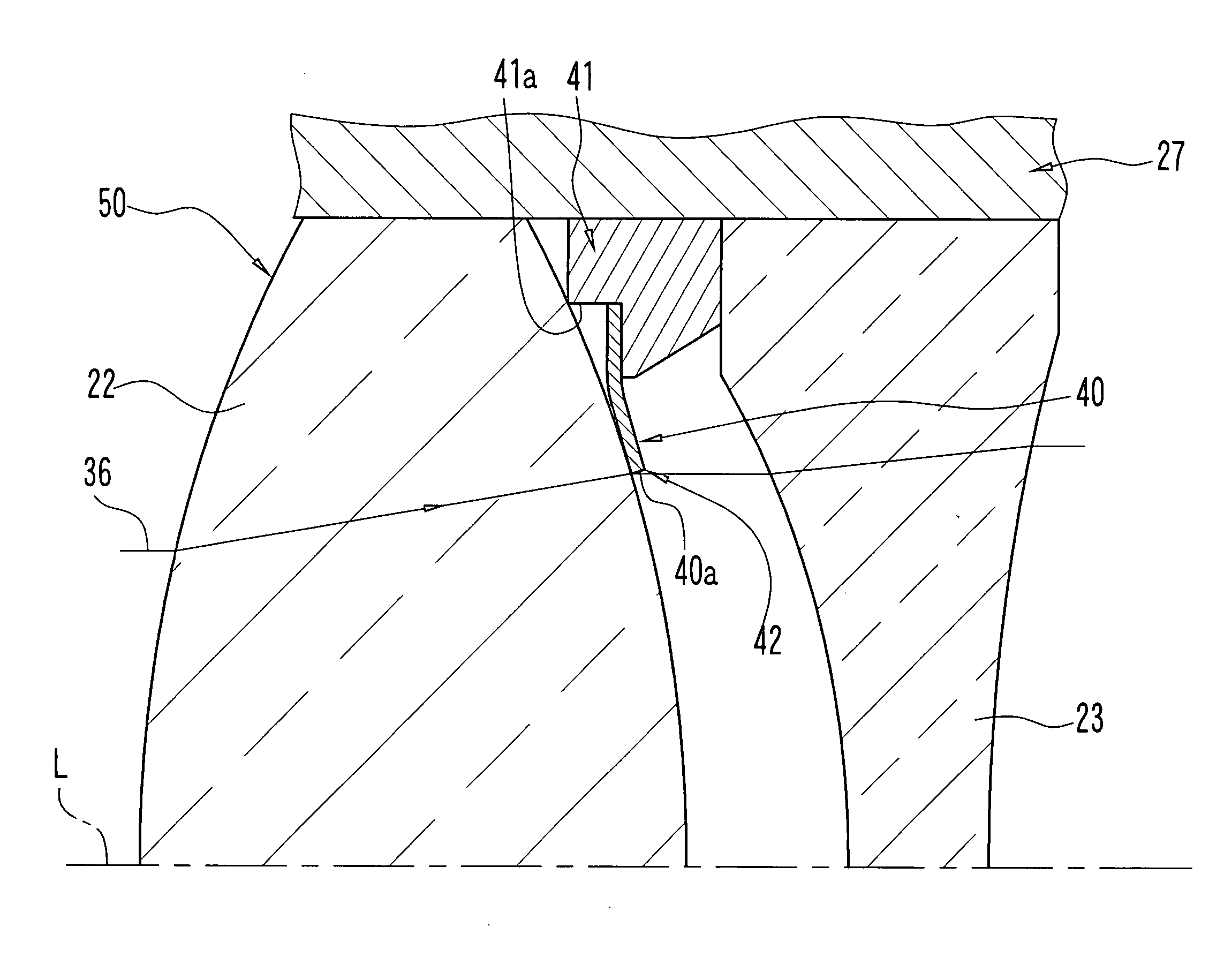

Reducing waste in metal stamping processes and systems therefor

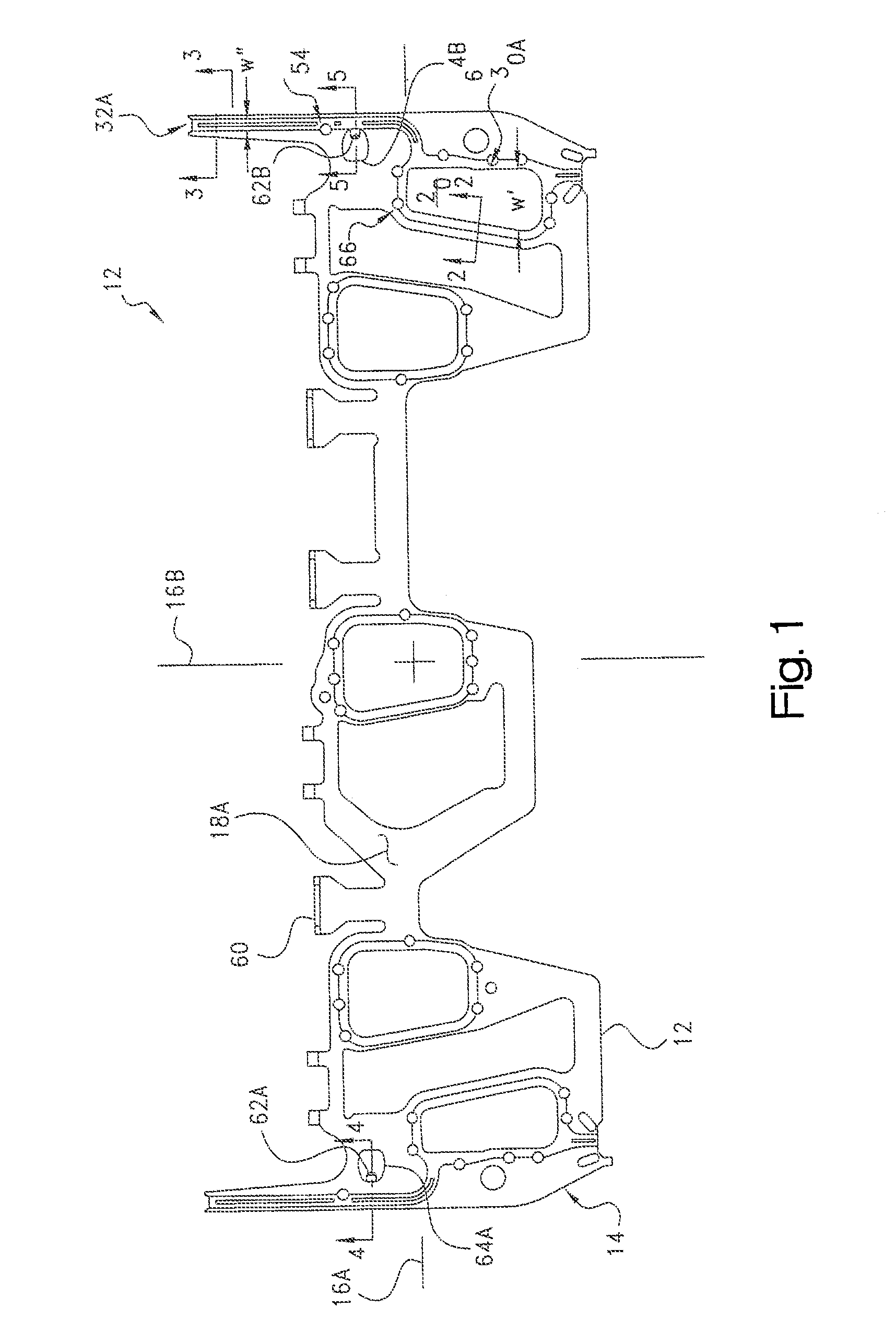

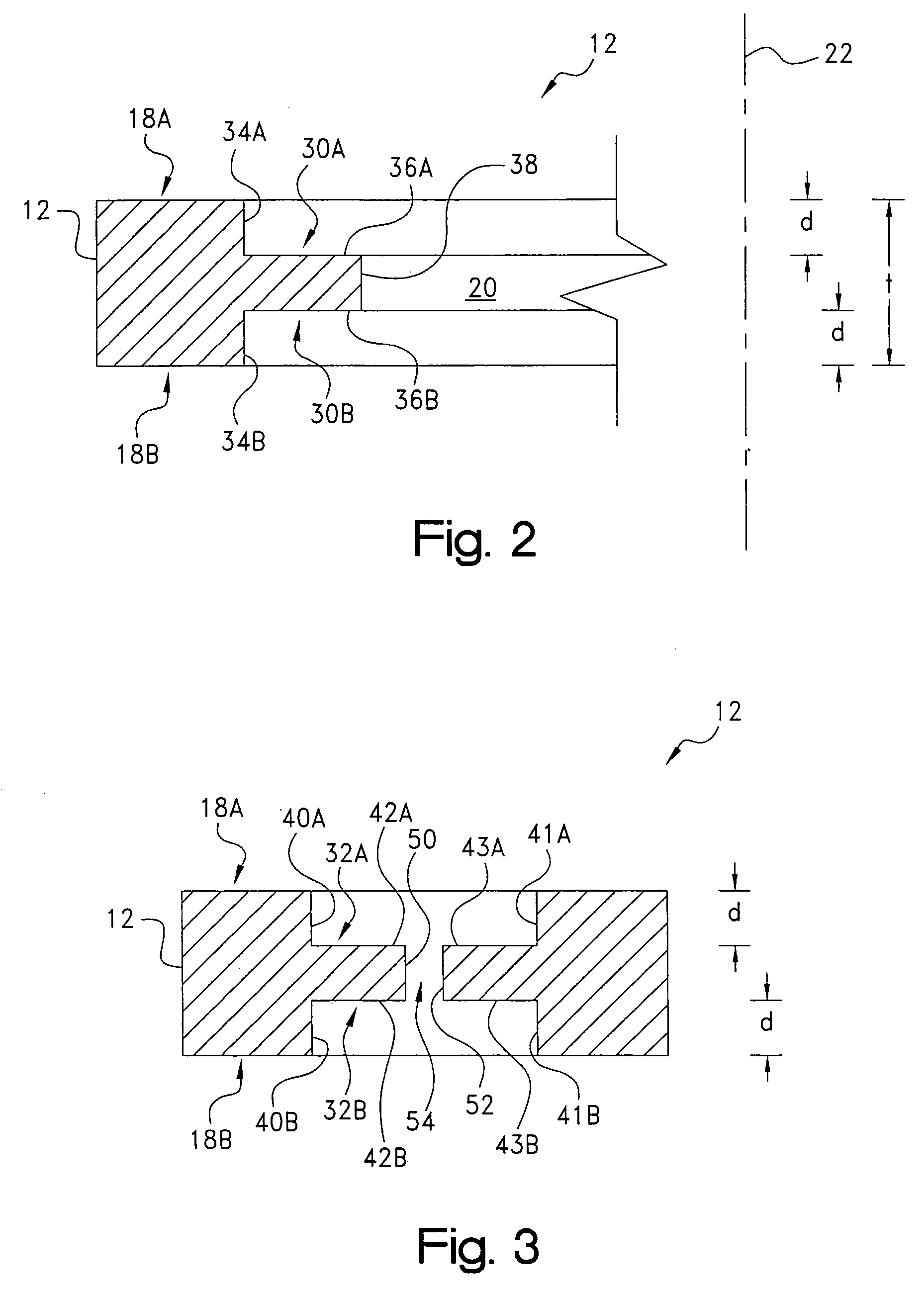

Disclosed herein is a sheet metal stamping device and methods for reducing the size of a blank required for producing a stamped part therefrom than is conventionally possible. The device utilizes an intermediate clamp section with projections having clamping formations located thereon which complement clamping formations located on a first die section. The intermediate clamp section projections allow for the use of a smaller blank size as less addendum material is required to secure the blank during the stamping process. The blank is secured using the intermediate clamp section and the first die section prior to the second die section engaging the blank to stamp the part. In some embodiments, retention beads resultant from the clamping process may remain in the stamped part, that being inside a trim line. Furthermore, in some embodiments, a blank shifter may be provided to locate the blank between the die sections prior to clamping. In other embodiments, more than one complementary pair of clamping formations may be provided. Furthermore, in some embodiments a trim line cutter may be provided.

Owner:HONDA MOTOR CO LTD

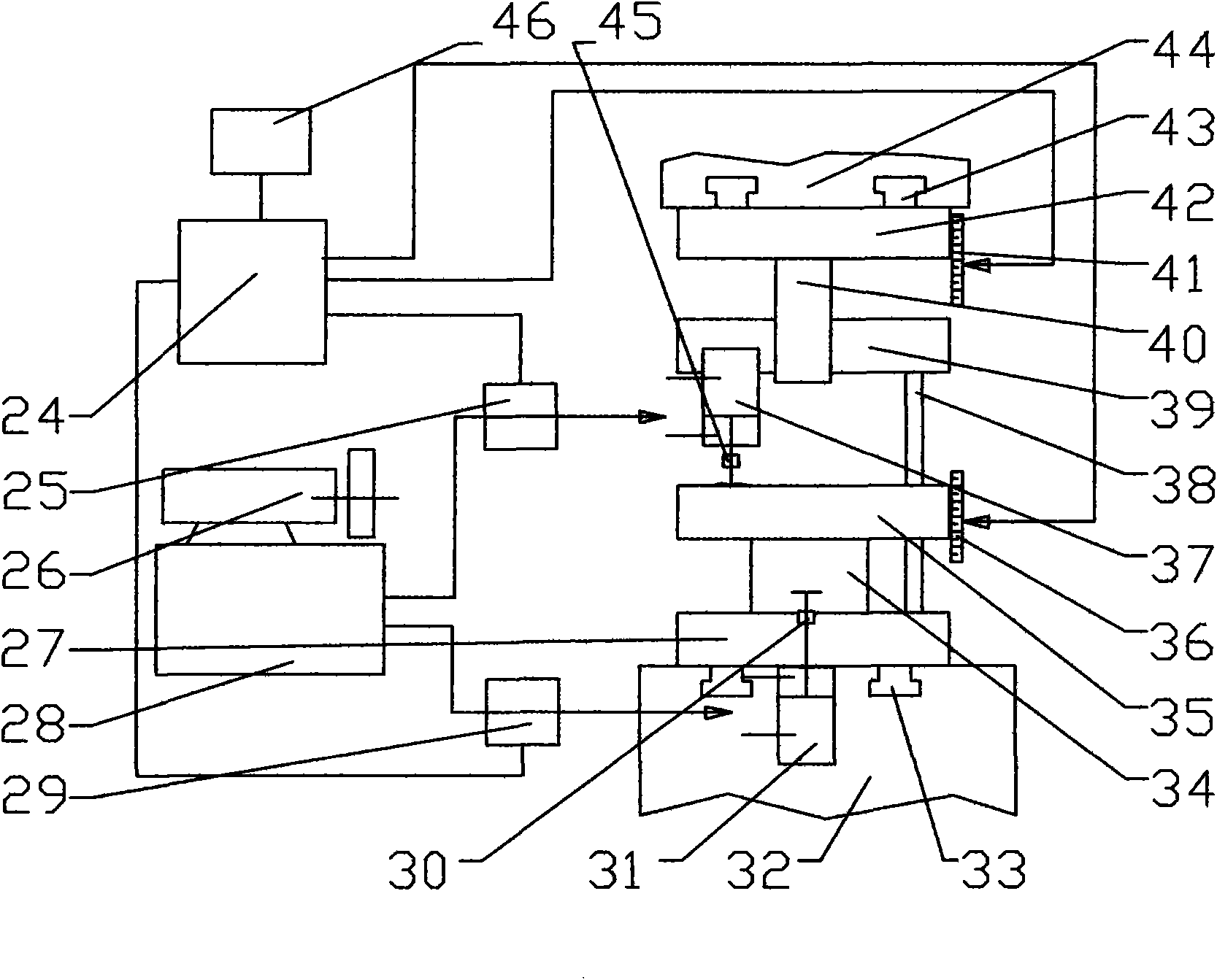

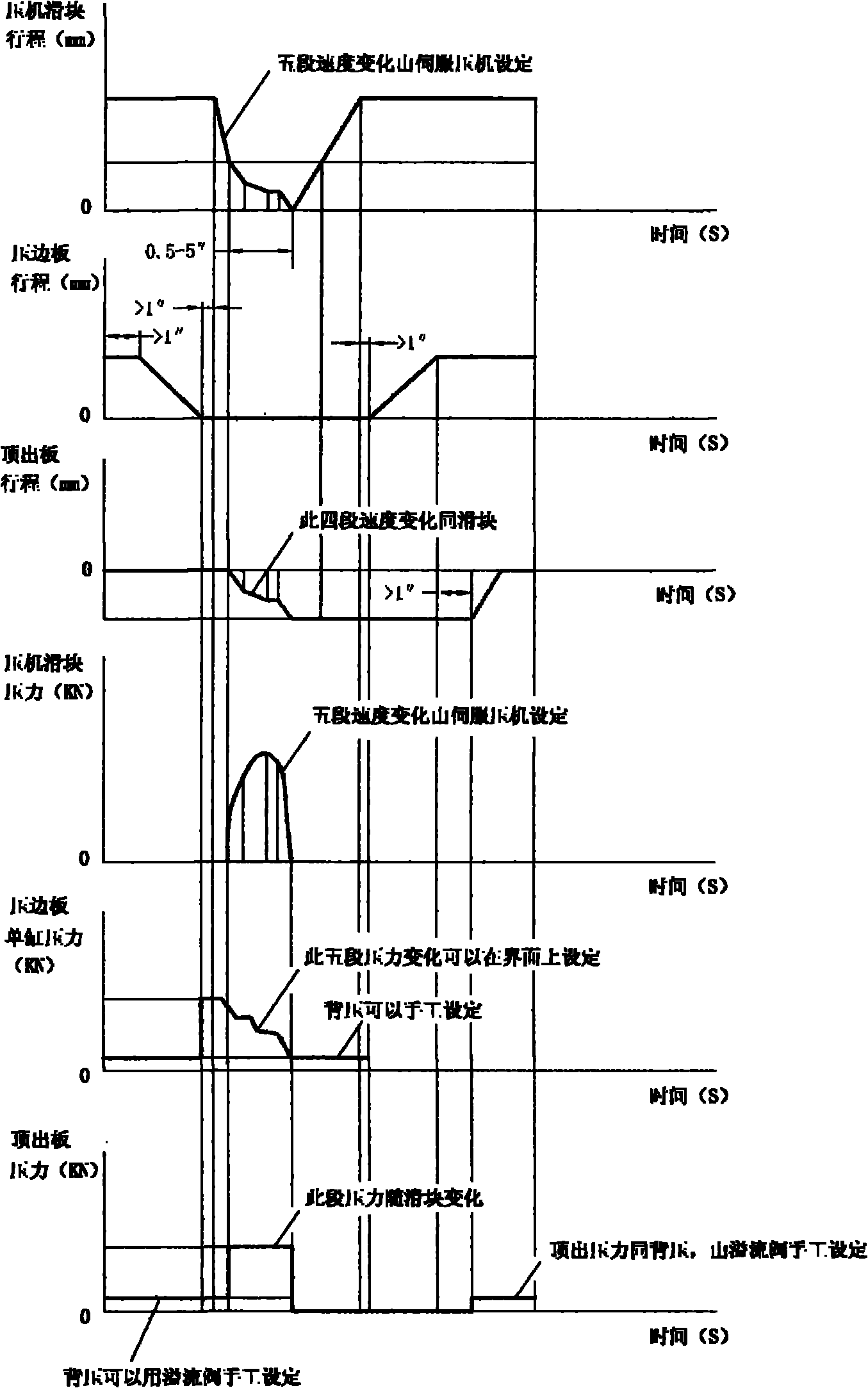

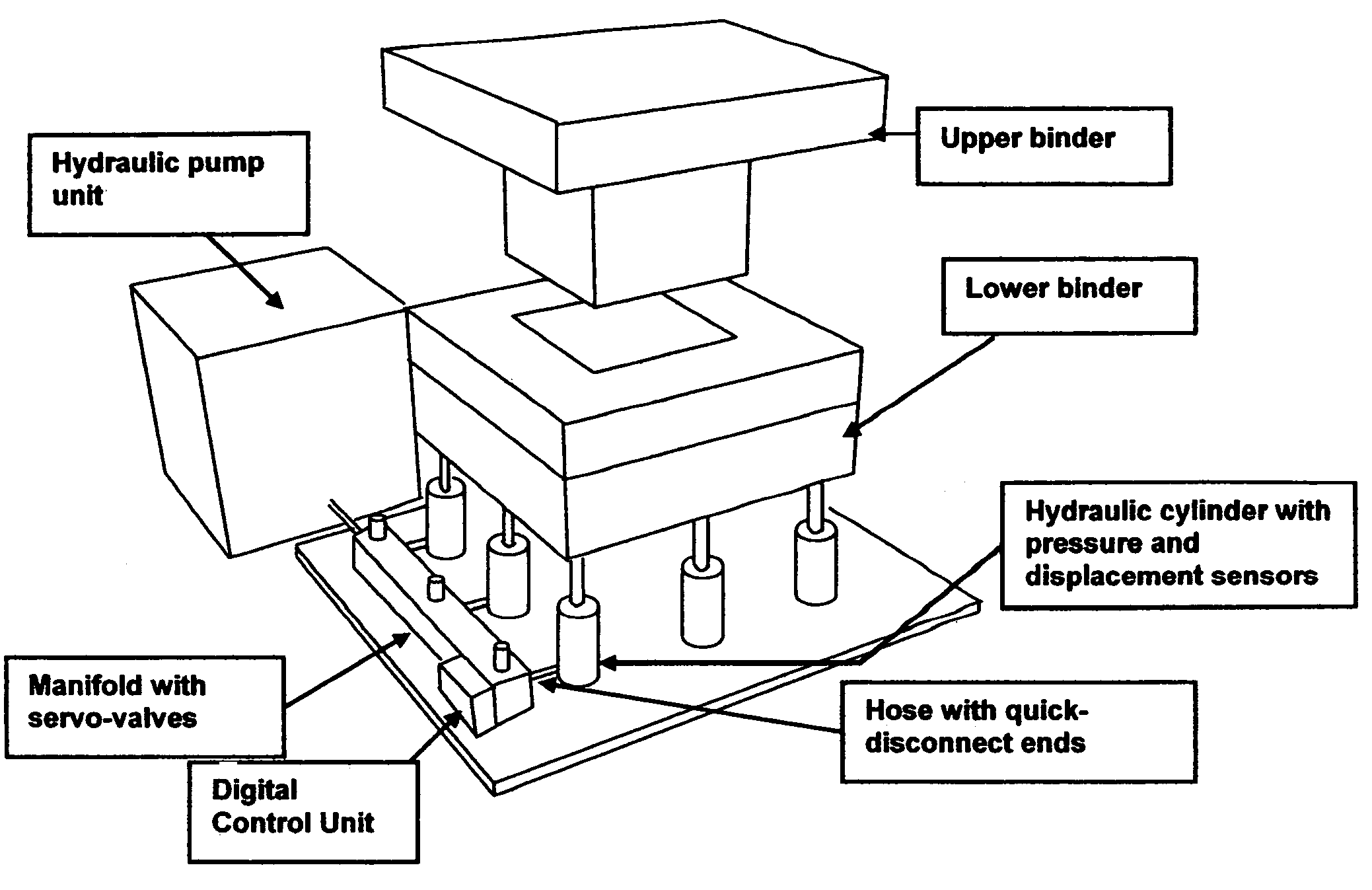

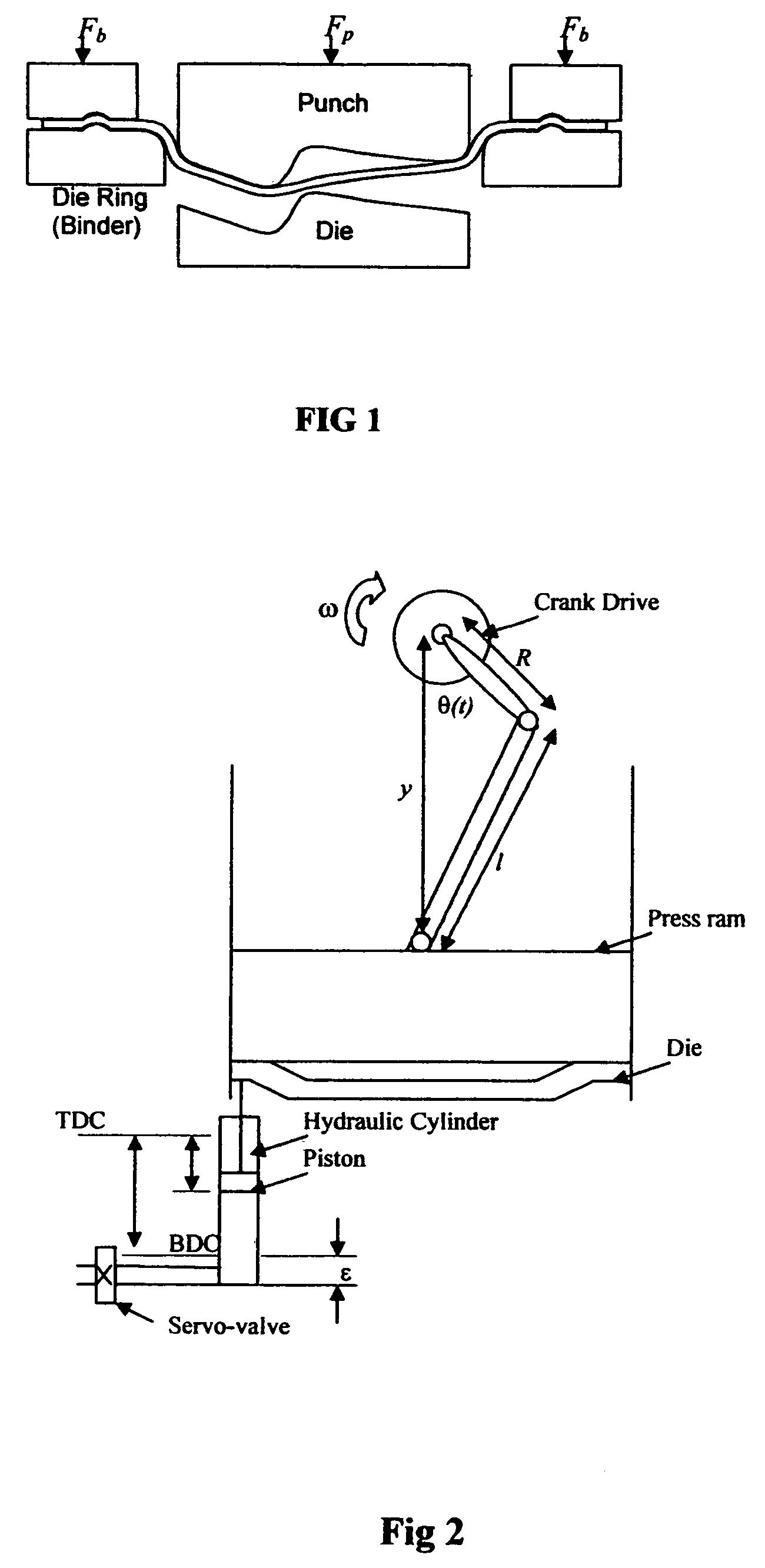

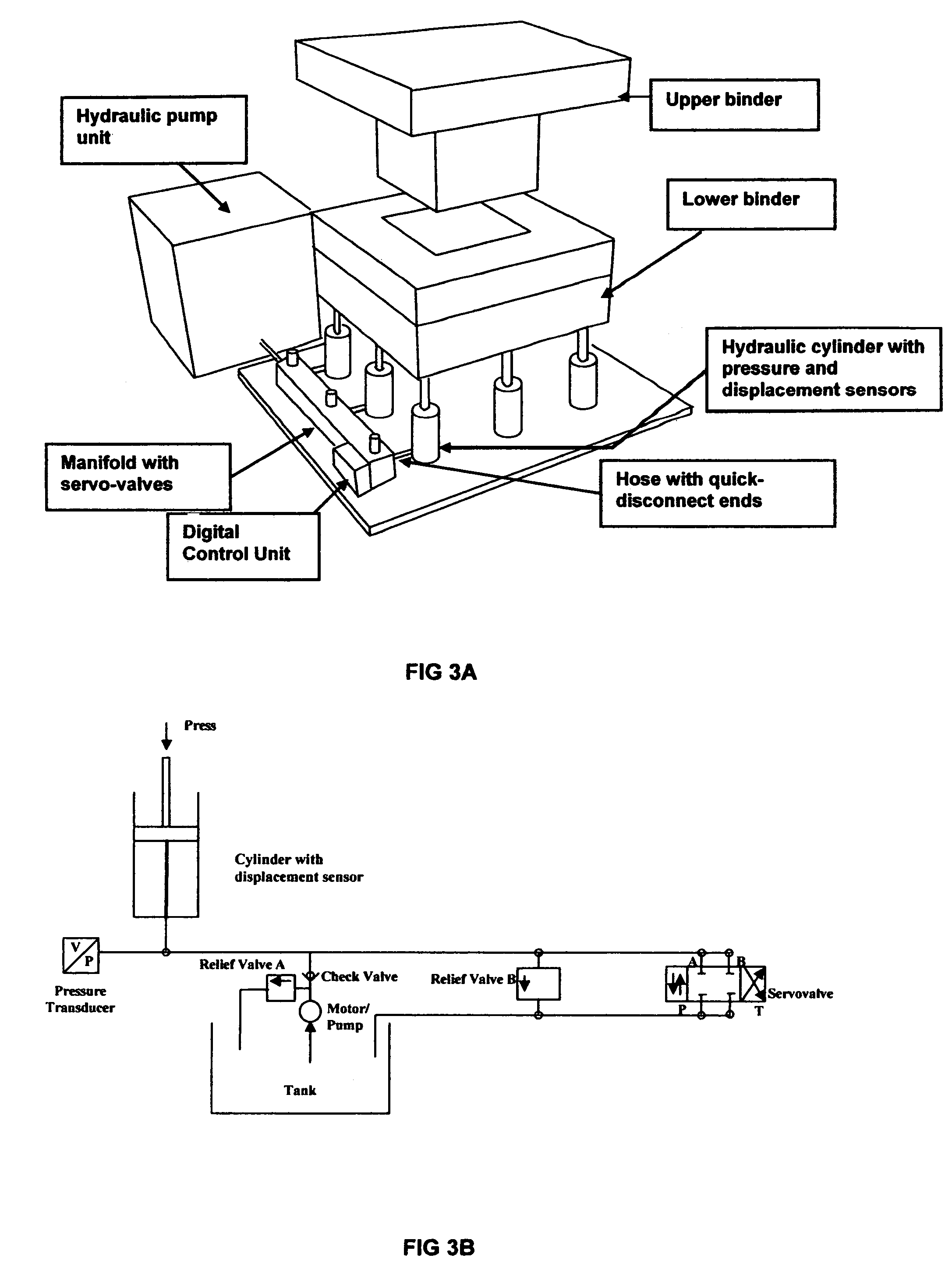

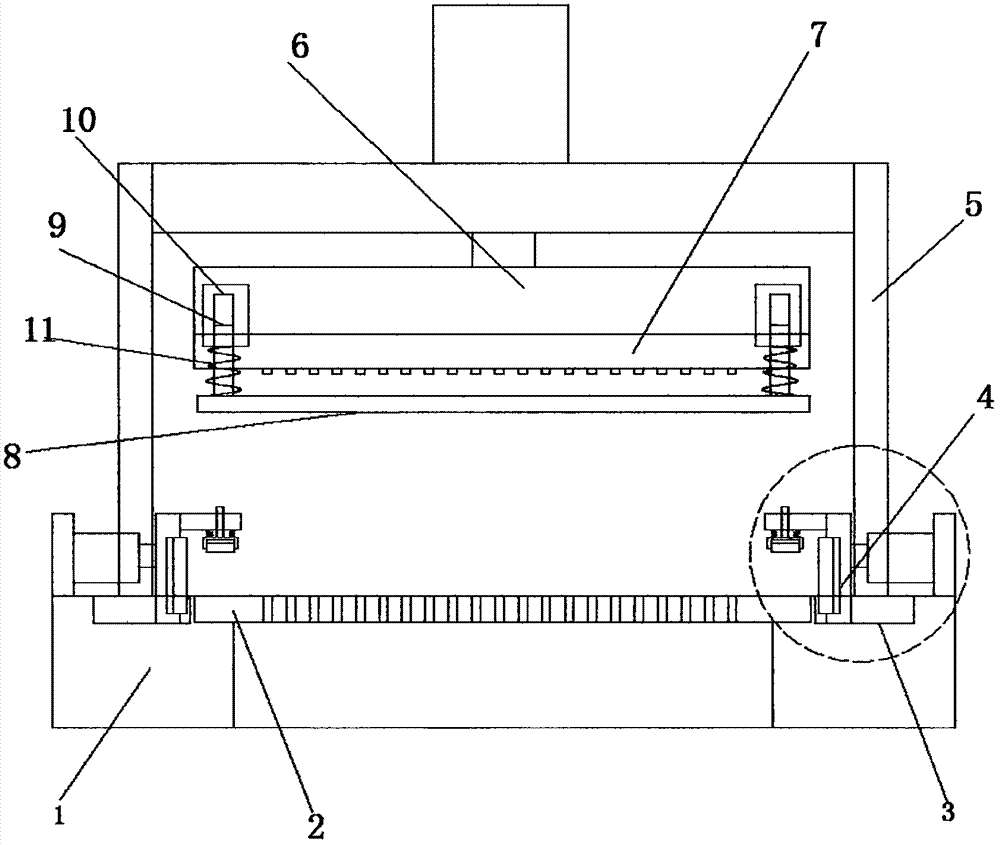

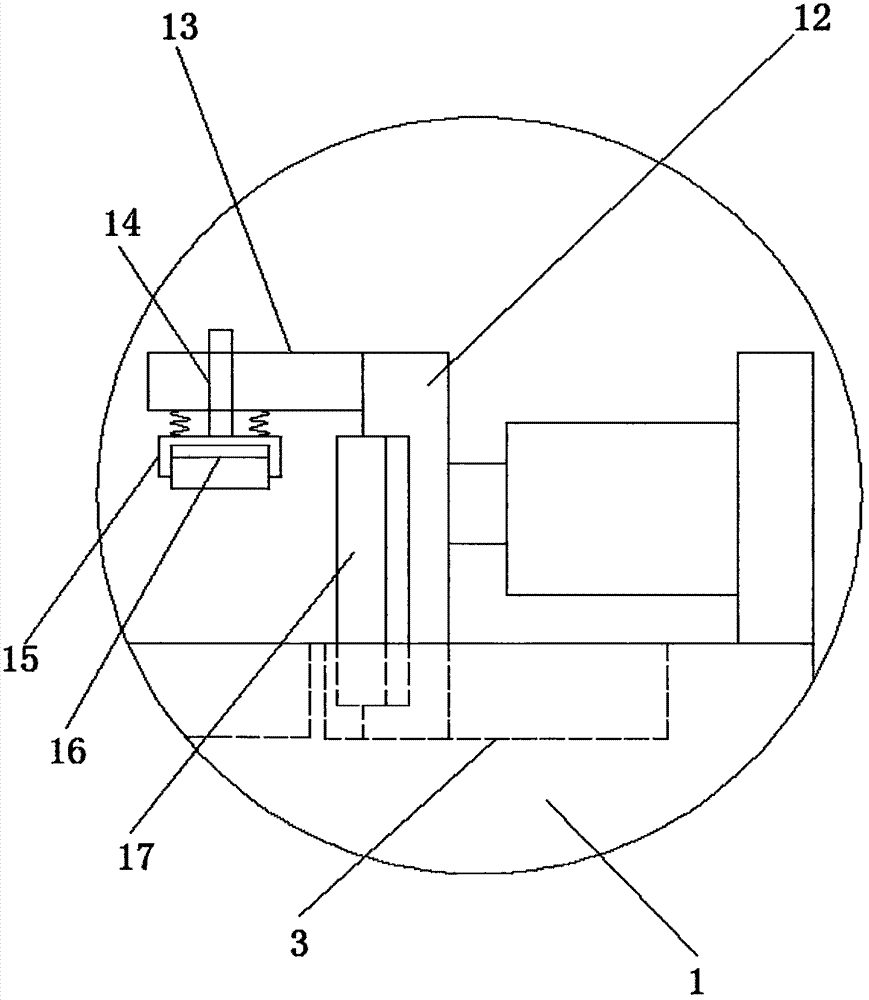

Reconfigurable variable blank-holder force system and method for sheet metal stamping

InactiveUS7257460B2Easy transitionImprove processing efficiencySpecial data processing applicationsPressesEngineeringActuator

A reconfigurable variable blank-holder force system (and method) for producing sheet metal stampings comprises a portable hydraulic unit, controlled by a digital control system and a knowledge-based expert system to enable reconfigurability and an easy transition from the try-out stage to production. The knowledge-base has a hierarchical structure and includes stored information about part geometry, material properties and press parameters. The expert system enables an operator to determine optimal blank-holder forces, and to fine-tune through a graphical interface unit. The optimal blank-holder forces are generated by hydraulic force actuators, using a controller running a nonlinear algorithm that accounts for valve nonlinearities, variable flow-rate and numbers of operational cylinders. The portable hydraulic unit preferably comprises hydraulic cylinders with quick disconnect hoses, a manifold, servo-valves and a pump unit. A structured method to utilize this system to produce sheet metal stampings is also described. An article embodying the method is included.

Owner:VENUGOPAL RAVINDER +2

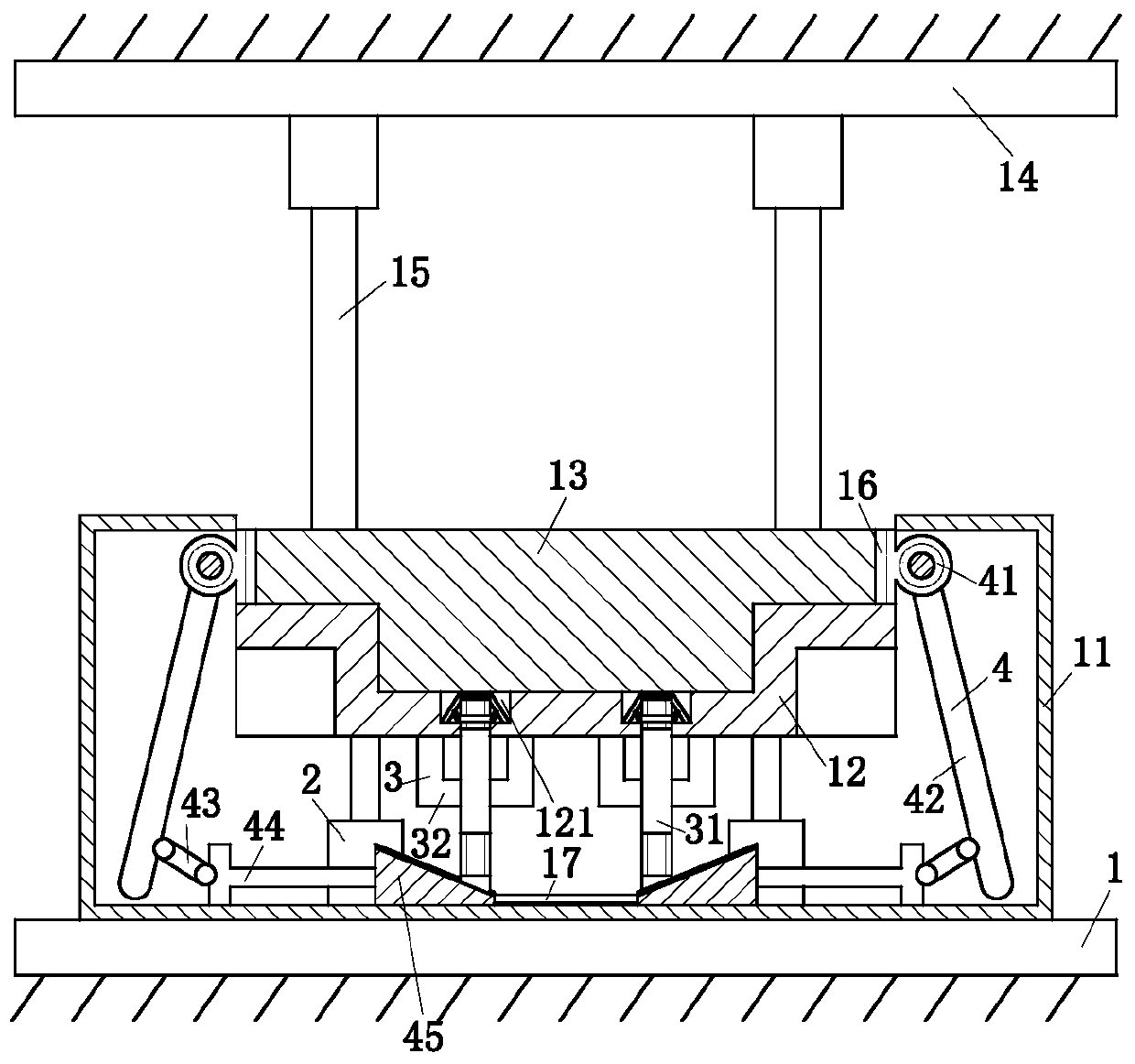

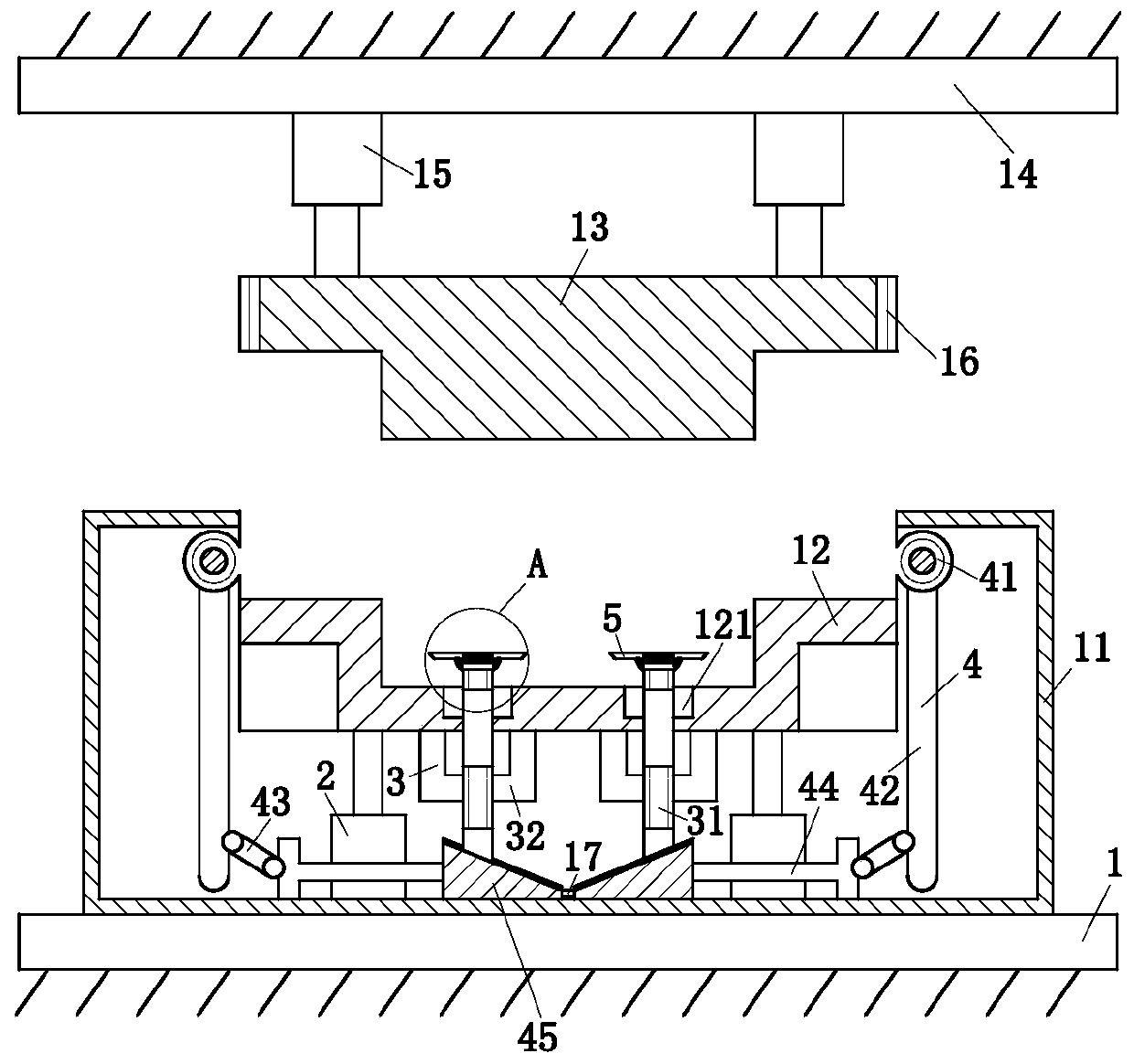

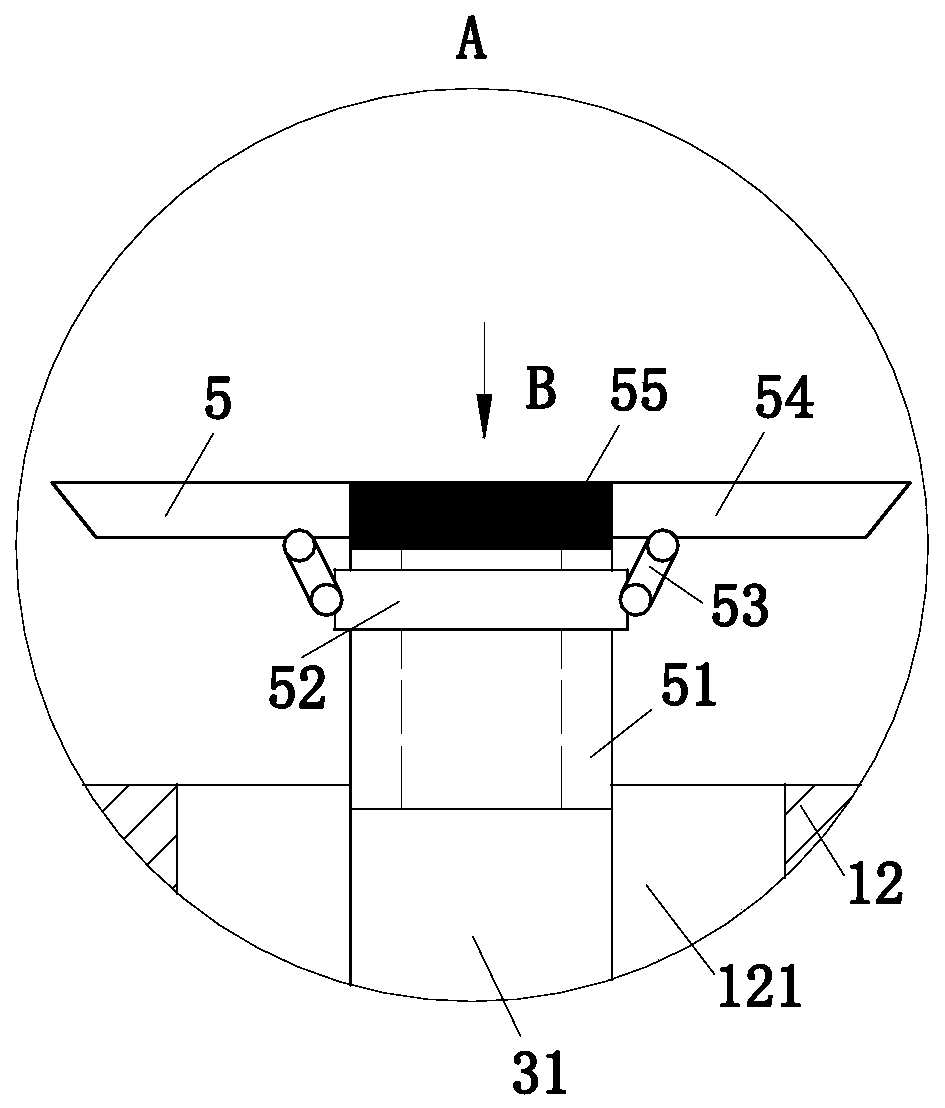

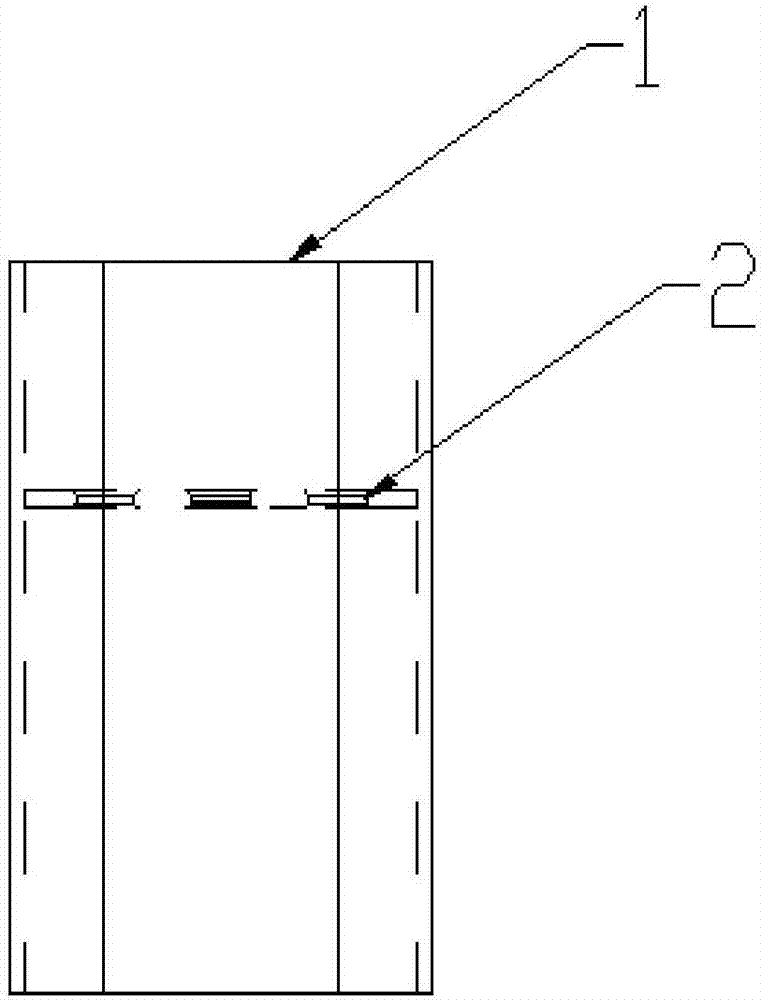

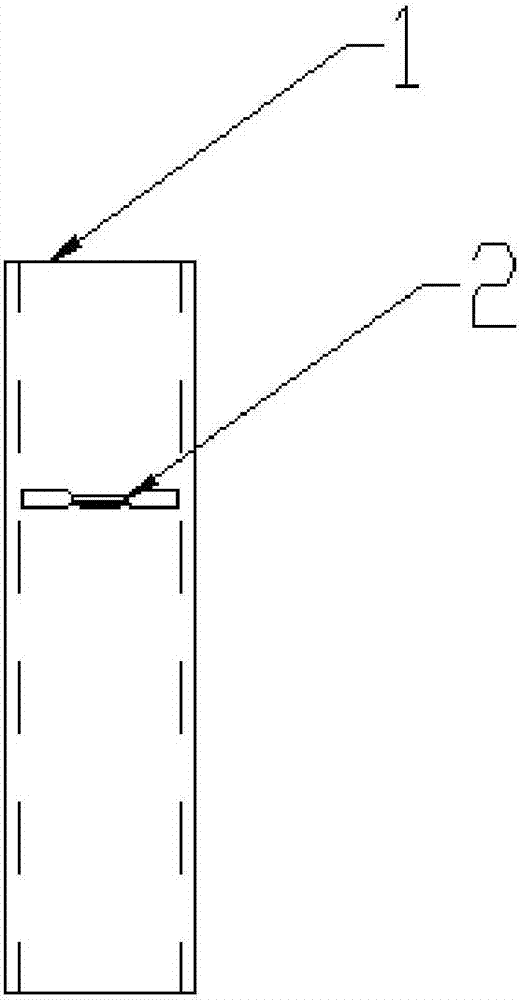

Automobile sheet metal stamping die

ActiveCN109759510ASimple structureReduce manufacturing costShaping toolsMetal-working feeding devicesGear wheelEngineering

The invention belongs to the technical field of dies, and particularly relates to an automobile sheet metal stamping die comprising a bottom plate, a base, a lower die holder, an upper stamping die, atop plate, first cylinders, supporting units, material ejecting units, pushing units and a controller. The upper stamping die is fixedly connected to the top plate through the first cylinders. Racksare arranged at the two ends of the upper stamping die. The base is fixedly installed on the bottom plate. The lower die holder is fixedly connected to the bottom of the base through the supporting units. T-shaped holes are formed in the lower die holder. The material ejecting units are located in the T-shaped holes correspondingly. Each material ejecting unit comprises an ejecting column and a U-shaped support. Each pushing unit comprises a first gear, a swinging rod, a first rod, a T-shaped rod and a wedge block. According to the automobile sheet metal stamping die, by means of the movement,in the vertical direction, of the upper stamping die, the ejecting columns can move in the vertical direction; by means of movement of the ejecting columns, automobile sheet metal where stamping is completed is ejected out of the lower die holder; it is avoided that when the lower die holder is ejected as a whole, high-power power devices are borrowed; and multiple purposes are achieved through one source, and the manufacture cost of the stamping die is reduced.

Owner:GUANGZHOU DONGRI METAL MOLD

Notebook computer hinge protection cover

PendingCN107193334AImprove protectionEasy to organizeDigital data processing detailsDie castingEngineering

The invention discloses a notebook computer hinge protection cover. The protection cover comprises a cylindrical suite and a bottom plate, wherein the bottom plate is fixedly inserted in the cylindrical suite; and the inner side wall of the cylindrical suite and one side of the bottom plate form a space for accommodating a hinge. The cylindrical suite is formed in an aluminum extrusion forming manner; the bottom plate is formed by sheet metal pressing; the cylindrical suite and the bottom plate are welded together by laser; the hinge accommodating space used for fixing and accommodating the hinge and a cable accommodating space for accommodating cables are formed between the cylindrical suite and the bottom plate; and foam is arranged in the spaces, so that the cables can be protected and arranged. The protection cover is simple in structure and convenient to process and form, sleeves the outer side of the die-cast hinge, keeps the surface of the outer side of the overall structure dense and bright, is diversified in color and low in manufacturing cost, and meets environmental protection requirements.

Owner:KUSN GUANGHE ELECTRONICS TECH

Sheet metal stamping device

InactiveCN105290184ANo post-testing requiredImprove reliabilityShaping toolsMetal working apparatusEngineeringSheet metal stamping

The present invention relates to a sheet metal stamping device. A sheet metal part is installed on a stamping support base horizontally, with a stamping head being located on the upper part and a stamping die being installed on the lower part. The stamping die has a stamping cavity. An installing through hole communicated with the stamping cavity is formed on the side of the stamping die. An ultrasonic crack detection head is installed in the installing through hole. The ultrasonic crack detection head of the present invention detects the sheet metal part in the stamping process without any subsequent detection and improves the reliability over visual detection.

Owner:谭华

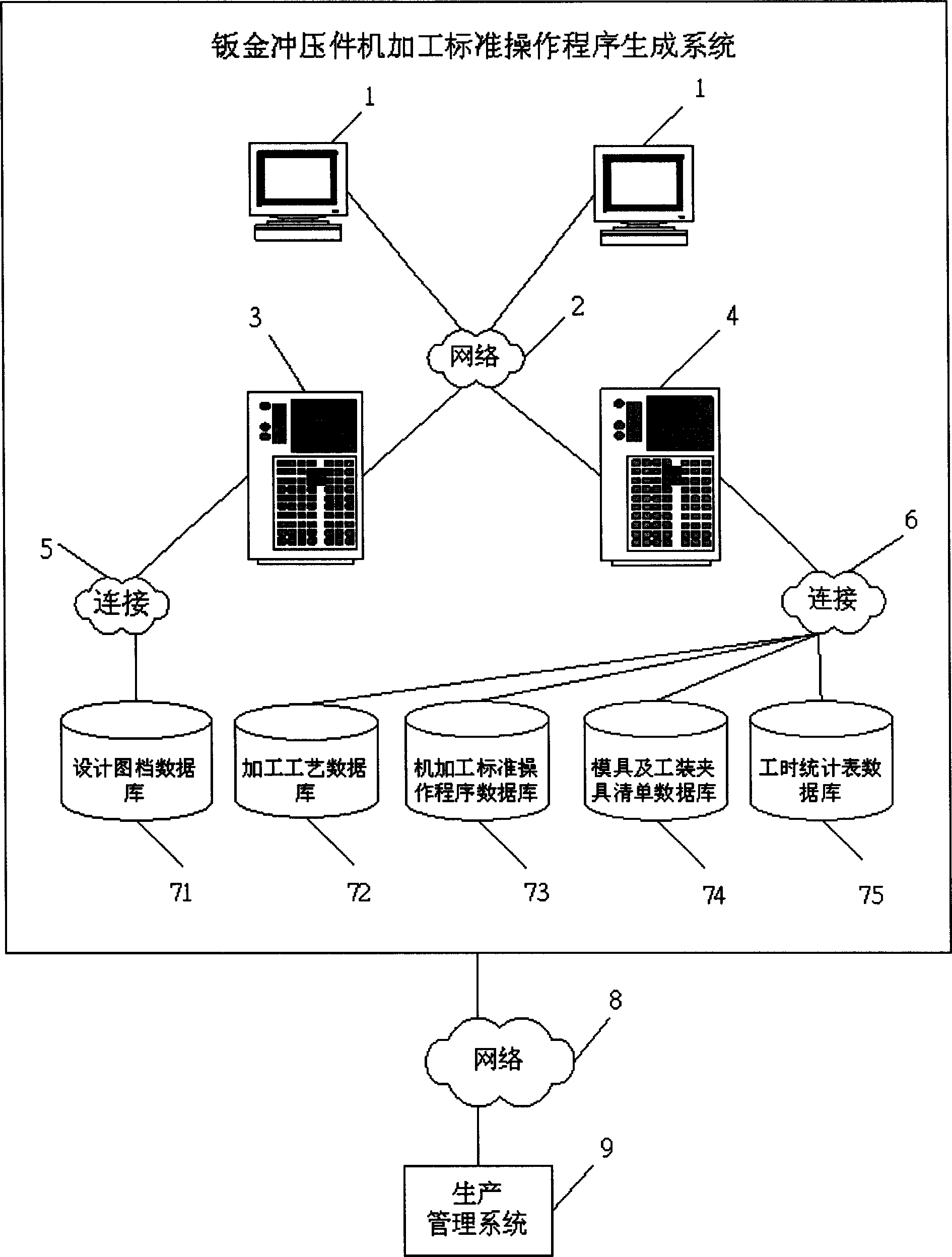

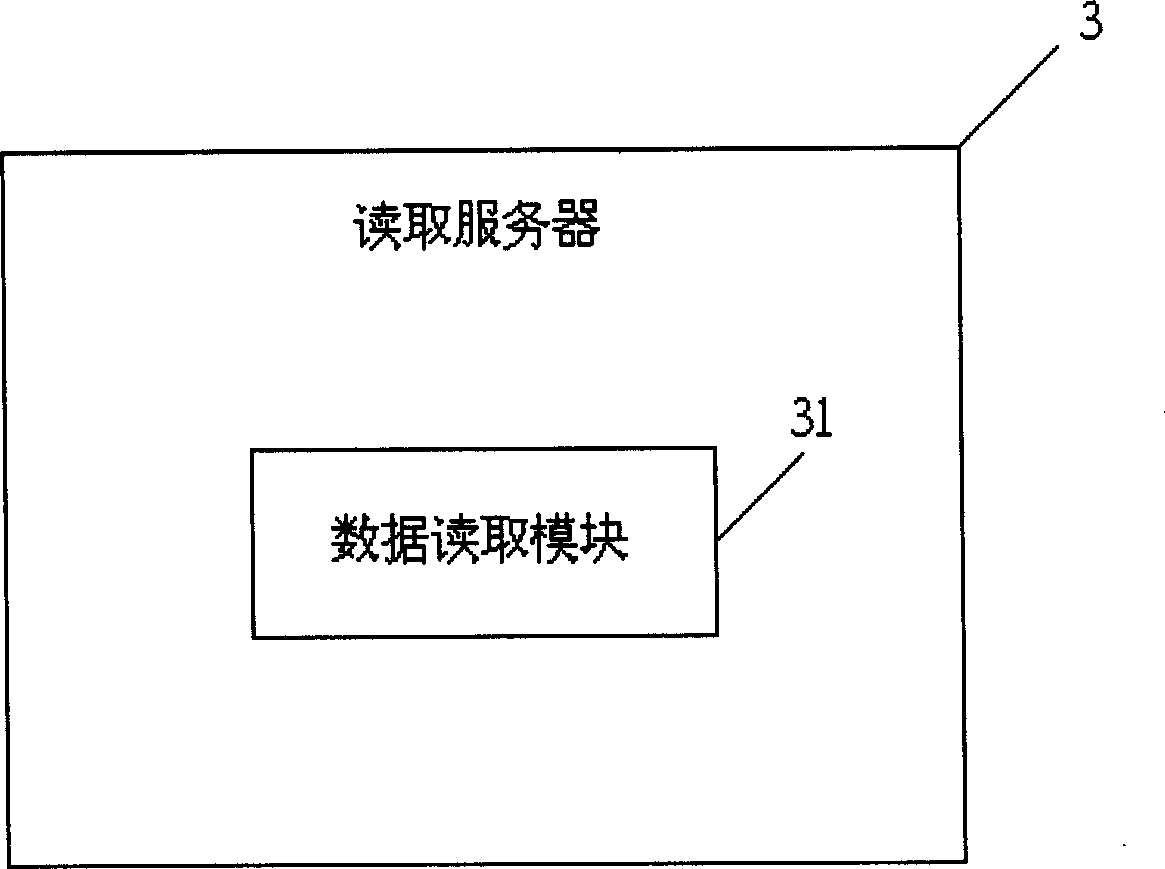

Standard operation program generation system and method for machining of sheet metal stamping

InactiveCN1734479AMade accuratelyIncrease productivitySpecial data processing applicationsComputer Aided DesignComputer-aided

The invention discloses a machined standard operating process formation system and method of sheet-metal punch element, which comprises the following parts: reading server, access server, pattern design file datum, crafting datum, SOP (Standard Operating Process) datum, at least one user side computer and the network connecting server, datum and user side. The CAD (Computer-aided designing) pattern files can judge and amend crafting questionable points and interventions by key field of machined standard operating process, which outputs machined standard operating program file. The method can utilize the CAD product to make SOP file quickly.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

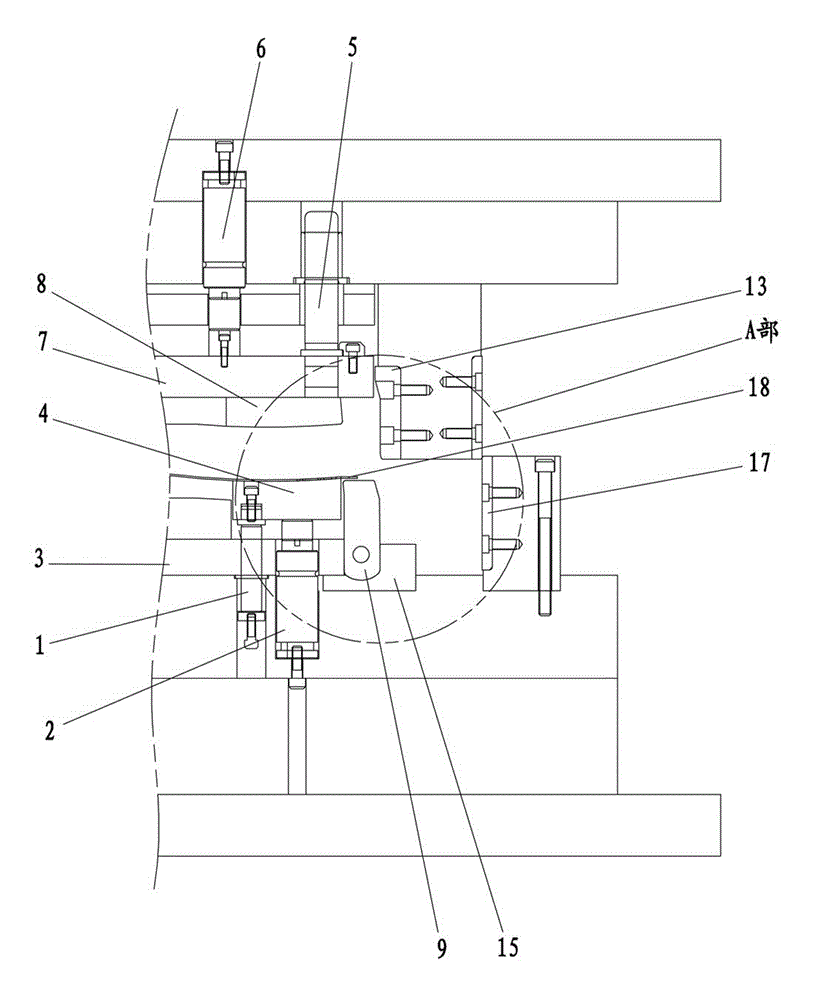

90-degree bending mechanism for sheet metal stamping die

The invention provides a 90-degree bending mechanism for a sheet metal stamping die; the 90-degree bending mechanism comprises a lower floating block, a pressing plate, and a male bending unit, wherein the lower floating block is connected with a lower die through a lower pull rod and a lower nitrogen spring; the pressing plate is connected with an upper die through an upper pull rod and an upper nitrogen spring, and the male bending unit is used for 90-degree bending; the male bending unit is arranged at the lower die and is located beside the lower floating block; the pressing plate corresponds to the lower floating block and is arranged above the lower floating block; the male bending unit is hinged at the lower die in a form of capable of rotating inwards the die; an outwards convex inner inclined surface is arranged at an inner side of the top part of the male bending unit; an inwards concave outer inclined surface is arranged at an outer surface of the top part of the male bending unit; an outer side surface of the pressing plate is of an inwards concave inclined surface shape, and specifically is of an avoiding inclined surface used for avoiding the male bending unit; the bending mechanism provided by the invention is novel in structure; when performing the 90-degrees bending to a sheet metal component by using the bending mechanism, negative angle bending used for compensating bending springback is achieved on the basis of the 90-degree bending is finished by using one set of stamping die via one stamping process, so that a 90-degree bending angle is ensured to be qualified, and die cost is saved, and meanwhile, a stamping process is reduced.

Owner:XIANGXIN AUTOMOTIVE COMPONENT TOOL & DIE

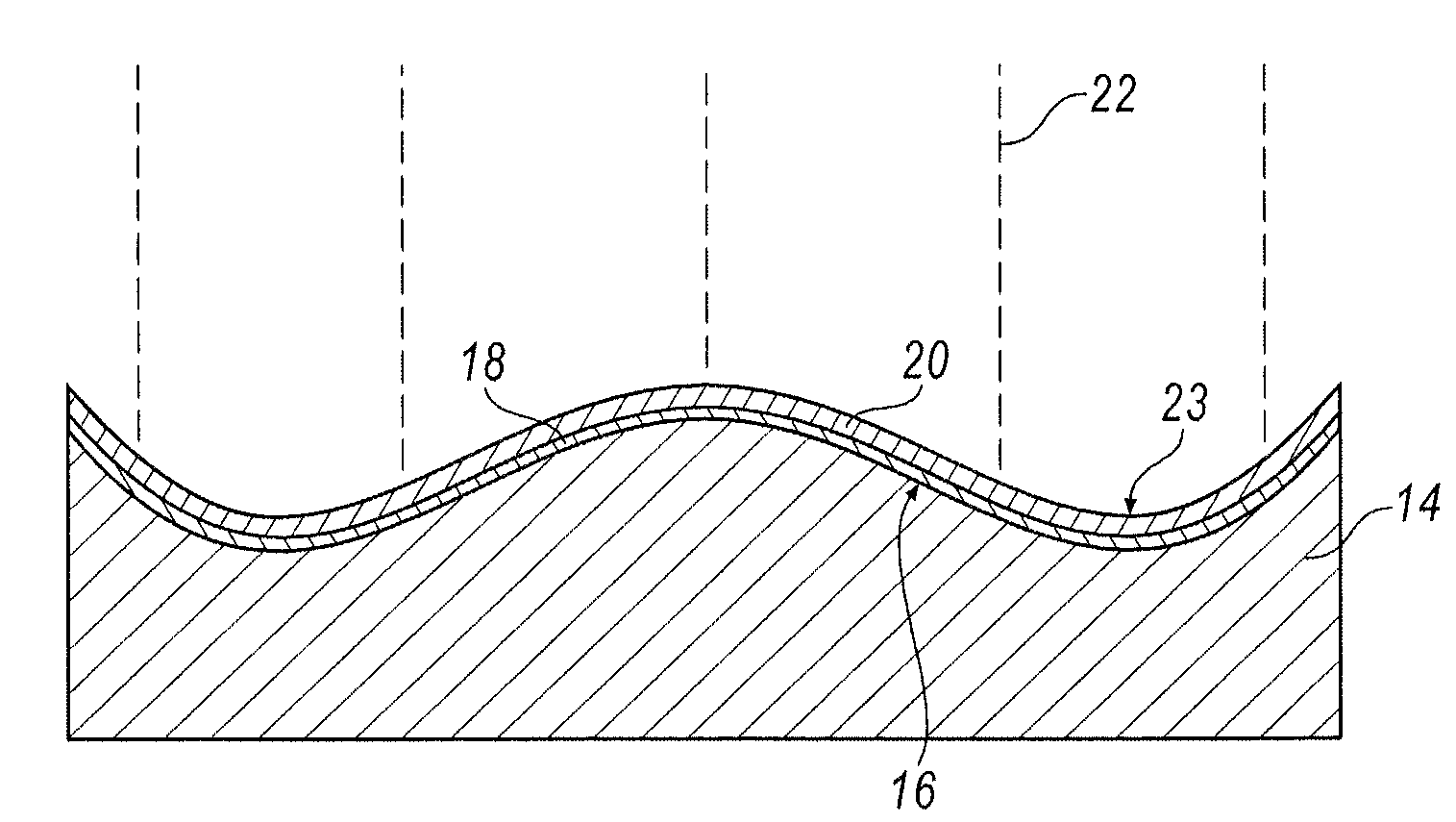

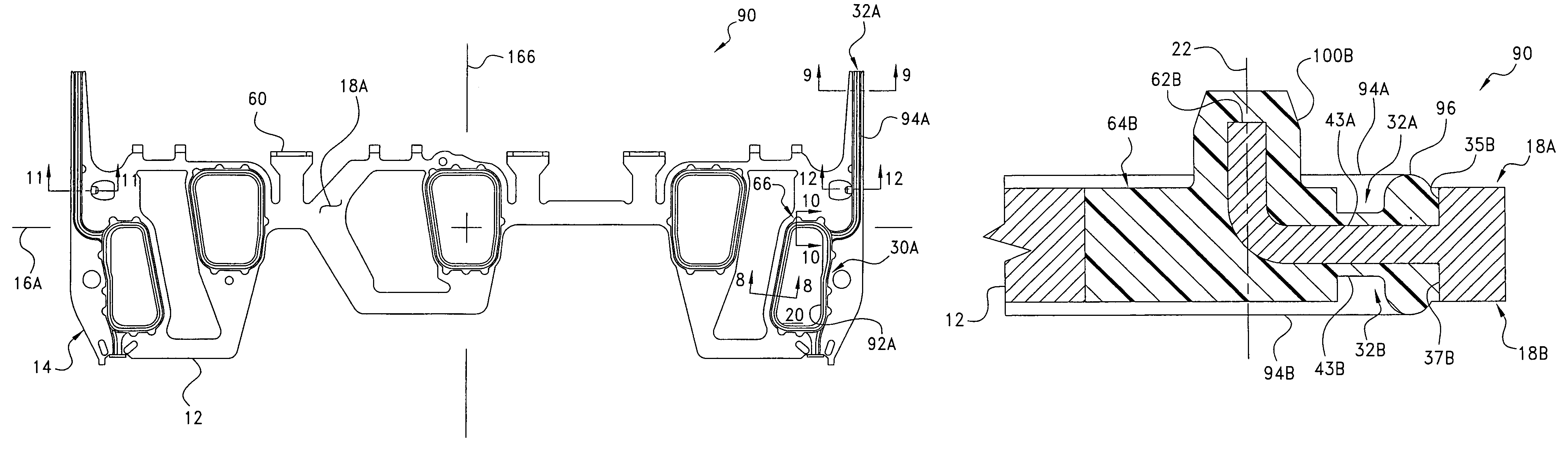

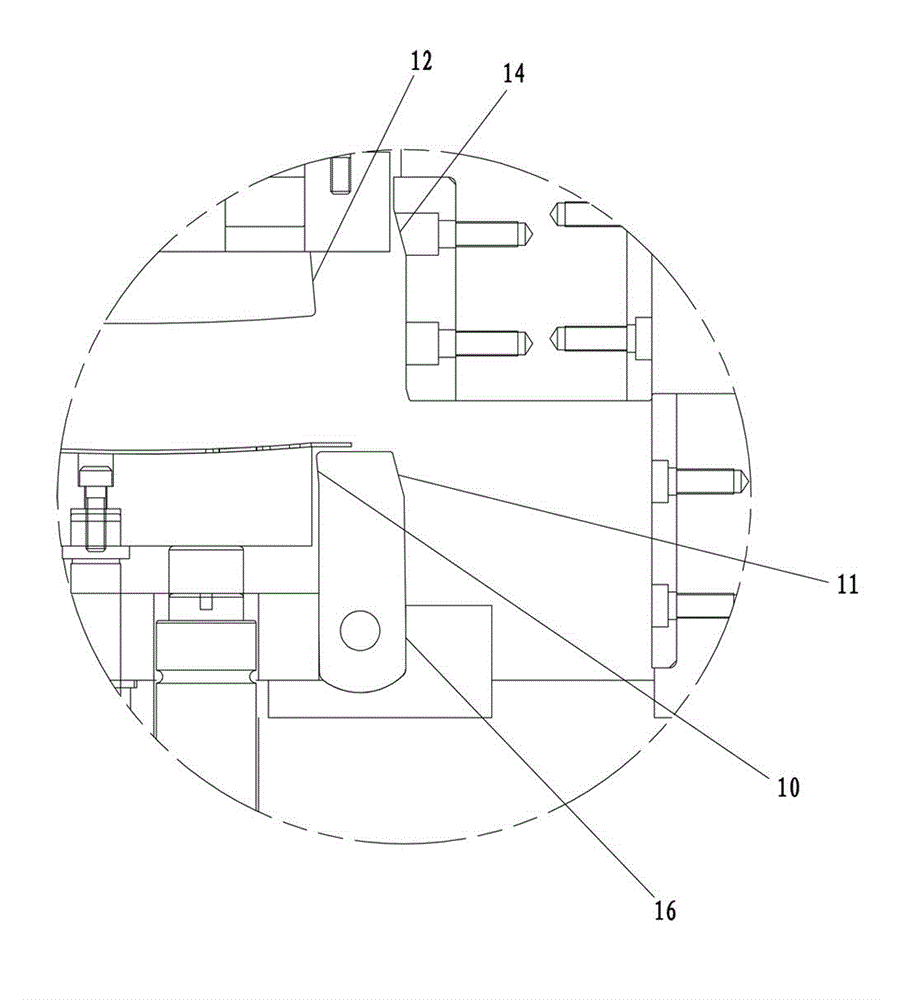

Scrap shape retention

ActiveUS20120210764A1Avoid recoilShaping toolsMetal-working feeding devicesSheet metal stampingMaterials science

Disclosed herein is a sheet metal stamping device and method for substantially inhibiting recoil from a neutral stamped position of a scrap part region. A sheet metal stamping device for stamping a sheet metal part comprising a first die body and a second is provided wherein the first die body and the second die body are in operable communication for forming the sheet metal part from a sheet metal blank. The sheet metal part includes at least one scrap region formed therein which is prone to recoil from a neutral stamped position. The first die body and the second die body have complementary elongate bead-forming regions located for forming an elongate bead region in the scrap region. And, the elongate bead-forming regions are configured such that the elongate bead substantially inhibits recoil or springback of the scrap region from the neutral stamped position when the scrap region is severed from the part. A method of stamping a sheet metal part having at least one scrap region prone to recoil formed therein utilizing the device and severing the scrap region is also disclosed.

Owner:HONDA MOTOR CO LTD

Microhole mold for reducing burrs on punching portion

PendingCN107234169AAvoid jerk offsetHigh precisionPerforating toolsMetal-working feeding devicesPunchingEngineering

The invention discloses a microhole mold for reducing burrs on a punching portion. The microhole mold comprises a base. A punching lower mold is mounted at the top of the base. Strip-shaped sliding grooves located on the upper surface of the base are formed in the two sides of the punching lower mold. A pressing mechanism is mounted in each sliding groove in a sliding manner. A support is mounted at the bottom of the base. An upper mold mounting plate parallel to the base is mounted on the side, close to the base, of the support. A punching upper mold is mounted on the side, close to the base, of the upper mold mounting plate. Press plates parallel to the base are mounted at the two ends of the side, close to the base, of the punching upper mold. Connecting rods are vertically mounted at the two ends of the side, away from the base, of each press plate. The end, away from the corresponding press plate, of each connecting rod is movably sleeved with a sleeve fixedly connected with the upper mold mounting plate. According to the microhole mold, bouncing deviation of a plate during punching is avoided, the plate is subjected to alignment and calibration, and therefore the burrs generated due to bouncing deviation of the plate during punching are reduced, the plate punching precision is improved, and product burrs are reduced.

Owner:昆山钣源冲压技术有限公司

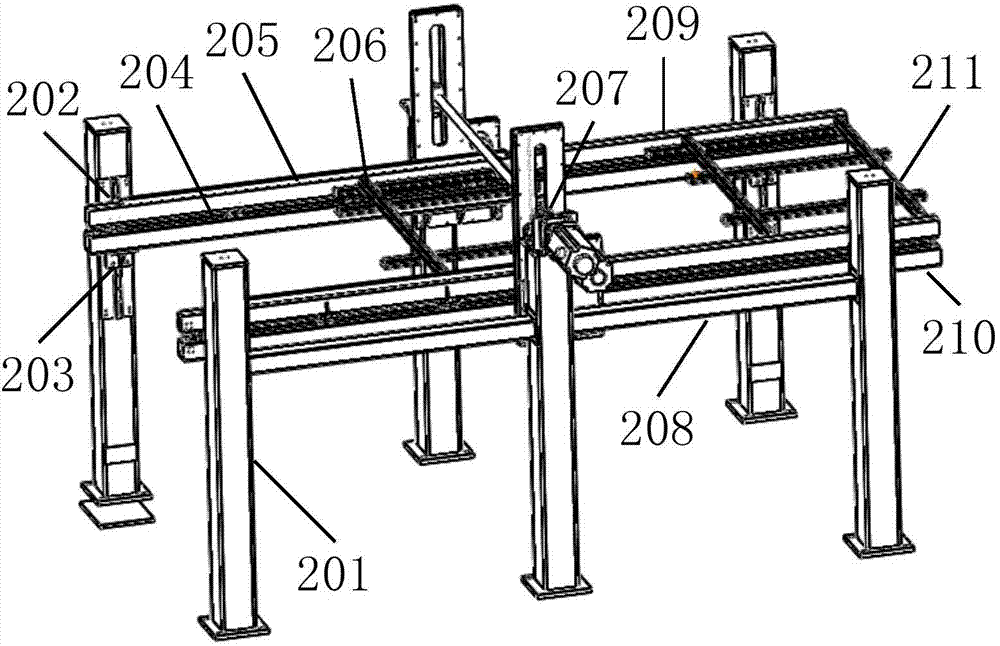

Feeding mechanism for sheet metal stamping based on Internet of Things

ActiveCN109482763AReduce usageImprove feeding efficiencyMetal-working feeding devicesMetal working apparatusProduction lineThe Internet

The invention discloses a feeding mechanism for sheet metal stamping based on Internet of Things. The feeding mechanism comprises a worktable and a feeding mechanism body. The feeding mechanism body includes two conveying devices, a width adjusting device and a fixing device. The two conveying devices are symmetrically distributed on the top of the worktable, wherein the conveying device comprisesa mounting plate, a driving roller, a passive gear, an executing device, a pressing roller and a thickness adjusting device; one end of the driving roller penetrates through the mounting plate to befixed to the passive gear, and the driving roller is rotatably connected with the mounting plate through a bearing; the passive gear is connected with the output end of the executing device; and the pressing roller is located above the driving roller, and one end of the pressing roller is connected with the output end of the thickness adjusting device. The feeding mechanism for sheet metal stamping can achieve a production line based on the Internet of Things, and is directly integrated into an intelligent manufacturing production line, and the integration and the reliability are high, so thatthe feeding efficiency of sheet metal is improved, and the mass production of the sheet metal is convenient.

Owner:XIAN SIYUAN UNIV

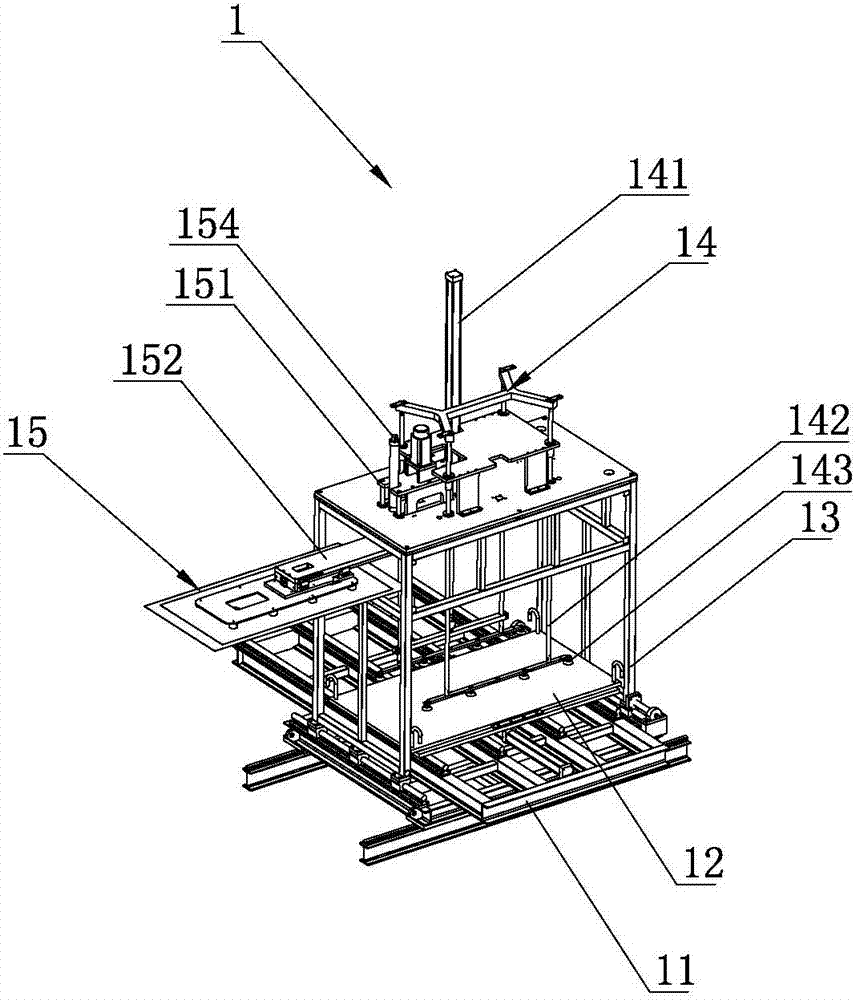

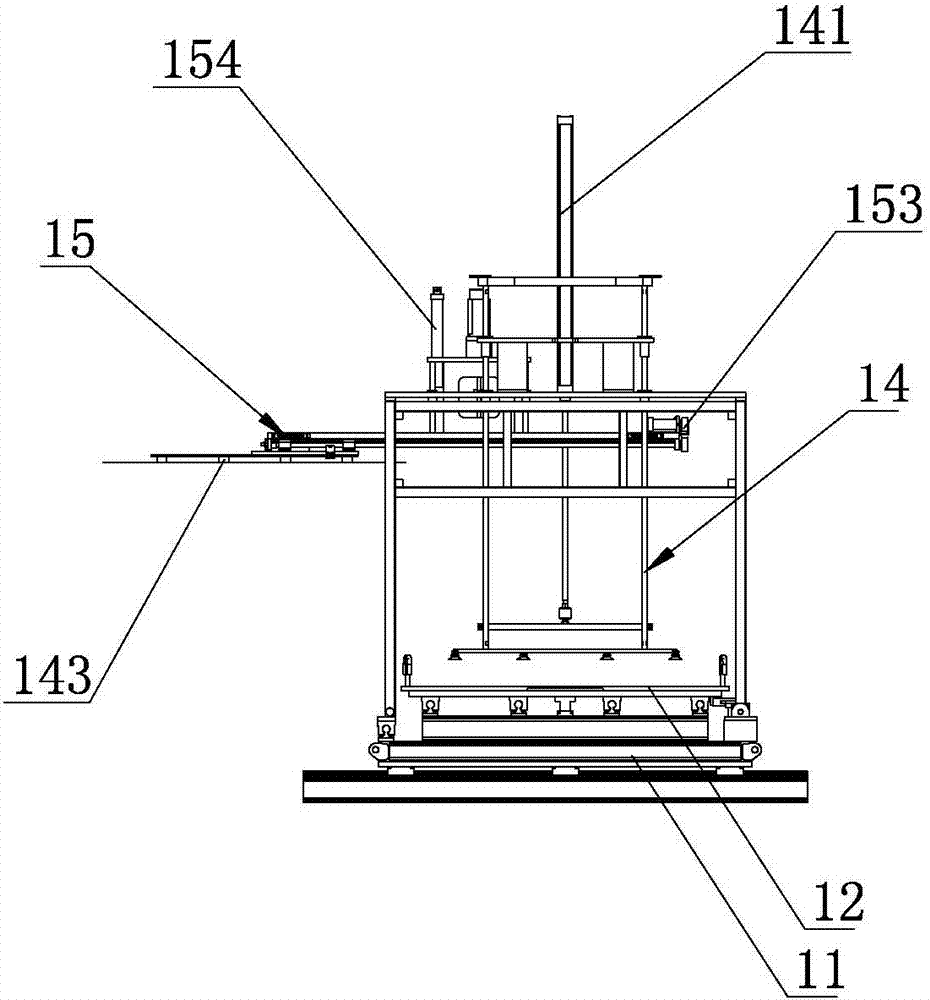

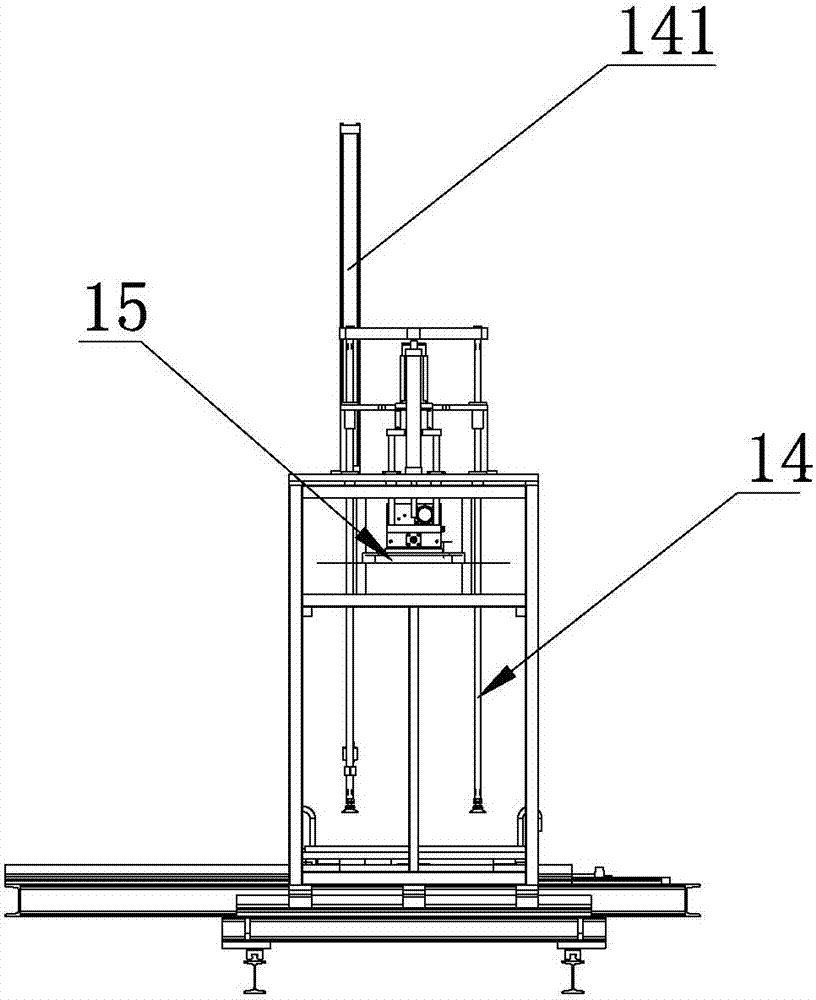

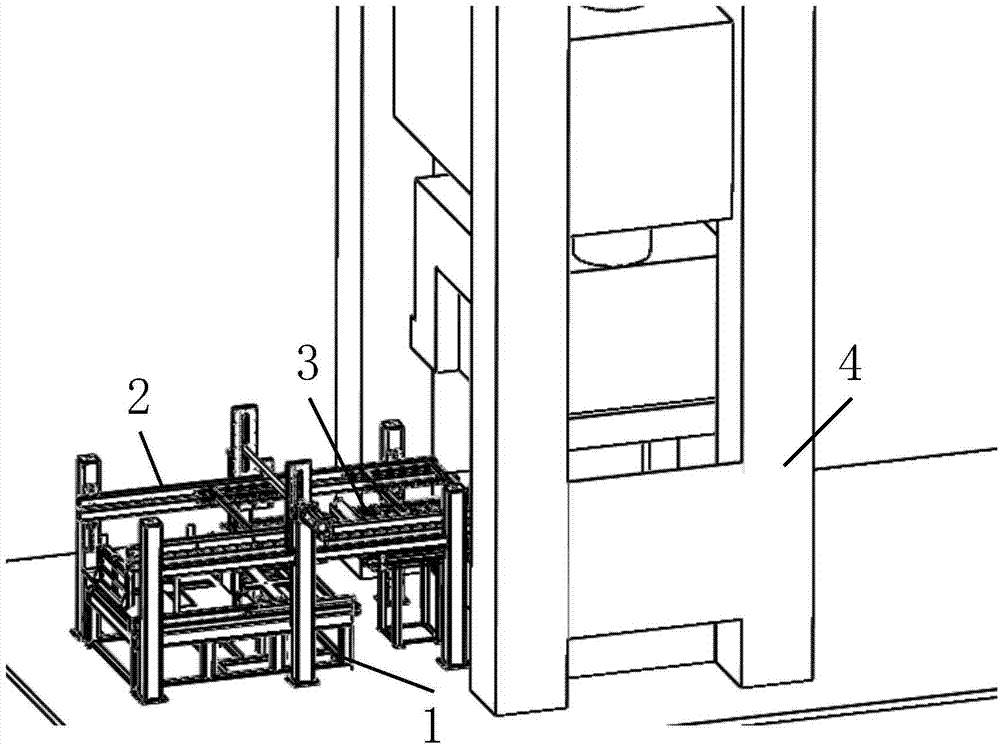

A plate automatic loading and unloading production line

InactiveCN105328064BRealize automated productionReduce safety incidentsMetal-working feeding devicesStripping-off devicesProduction lineEngineering

The invention relates to the technical field of automatic production equipment, in particular to an automatic plate loading and unloading production line, which includes a plate feeding mechanism, a plate receiving mechanism and a plate pulling mechanism. The plate feeding mechanism includes a feeding base, which is slidingly connected to a feeding platform, and The base is connected with a feeding bracket, and the feeding bracket is provided with a vertical feeding assembly, and the feeding bracket is provided with a horizontal feeding assembly; the plate receiving mechanism includes a receiving base, and the receiving base is slidingly connected with a rotary device for collecting product materials on the stamping equipment. The material receiving component; the plate material pulling mechanism includes a material pulling base, the material pulling base is slidably connected with a material pulling platform, the material pulling base is connected with a material pulling bracket, and the material pulling bracket is provided with a material pulling manipulator for pulling the plate material of the stamping equipment, pulling An automatic unloading door device is installed under the material manipulator. The automatic loading and unloading production line can complete the loading and unloading of the stamping die at high speed and efficiently, realize the automatic production of sheet metal stamping, and reduce the occurrence of safety accidents.

Owner:DONGGUAN DONGPING MACHINERY CO LTD

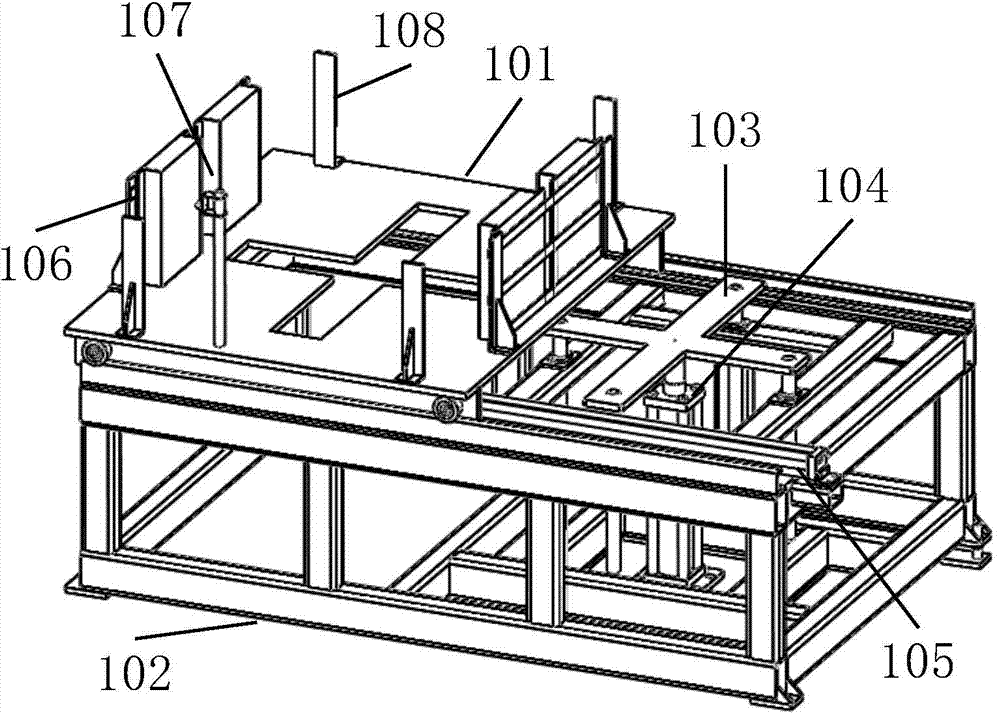

Sheet metal stamping automated production device

ActiveCN104741477ALow costReduce pollutionLiquid surface applicatorsMetal-working feeding devicesProduction lineSheet metal stamping

The invention discloses a sheet metal stamping automated production device which comprises a material stacking mechanism, a feeding mechanism, an oiling and locating mechanism and a press machine. The feeding mechanism is a gantry type feeding mechanism and is arranged on one side, close to a feed port, of the press machine. The material stacking mechanism and the oiling and locating mechanism are located below the feeding mechanism, the oiling and locating mechanism is located on the side close to the press machine, and the material stacking mechanism is located on the side far away from the press machine. The gantry type feeding mechanism can be horizontally and vertically adjusted according to positions of molds installed on the press machine. The sheet metal stamping automated production device is suitable for production lines for stamping large sheet metal, has the advantages of being reasonable in structure, high in accuracy, stable in operation, high in efficiency and the like, and can be applied to the car industry, the locomotive industry, the ship industry, the machine manufacturing industry and the like.

Owner:NANJING UNIV OF SCI & TECH

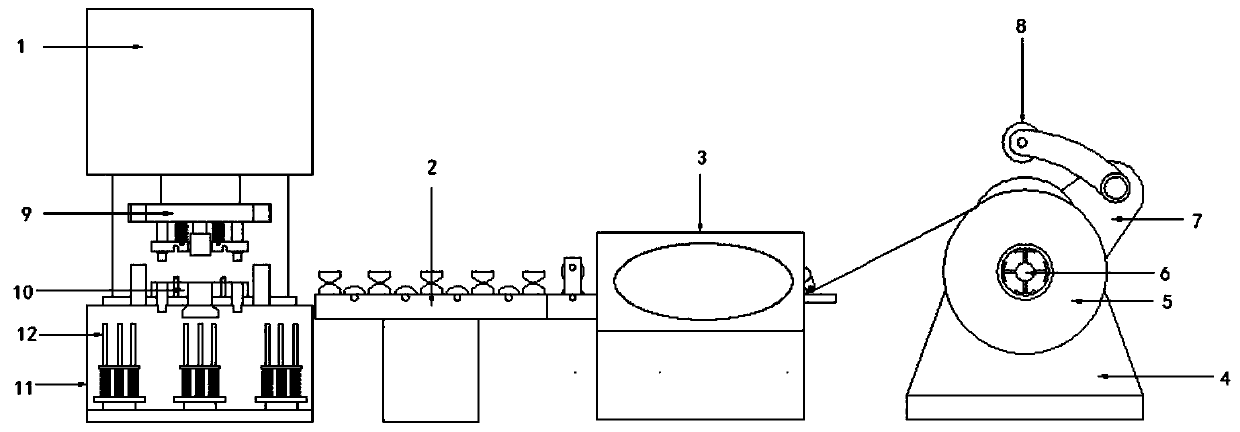

Automatic stamping equipment for sheet metal stamping

InactiveCN111151623AImprove work efficiencyReduce transshipment processShaping toolsMetal-working feeding devicesStructural engineeringSheet metal stamping

The invention discloses automatic stamping equipment for sheet metal stamping. The automatic stamping equipment includes a stamping mechanism, a guide transporting mechanism is arranged on the right side of the stamping mechanism, a flattening mechanism is arranged on the right side of the guide transporting mechanism, and a unwinding mechanism is arranged on the right side of the flattening mechanism; the unwinding mechanism includes an unwinding wheel and an unwinding shaft, the unwinding wheel is connected into the unwinding shaft in an inserted mode, a bracket is arranged on the right sideof a unwinding machine and a pressing wheel is arranged on the side surface of the bracket, the pressing wheel is in contact with the unwinding wheel, and the flattening mechanism is provided with aplurality of groups of first flattening wheels and second flattening wheels. According to the automatic stamping equipment, the stamping mechanism and the guide transporting mechanism, the flatteningmechanism and the unwinding mechanism are used in a matched mode and simultaneously work, the transfer process in the processing process is reduced, sheet metal can be automatically and continuously stamped, the working efficiency of stamping is greatly improved, three guide positioning mechanisms are arranged in the stamping mechanism, and the stamping accuracy and quality are greatly increased.

Owner:滁州市精美家电设备股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com