Automobile sheet metal stamping die

A stamping die and sheet metal technology, which is applied in the field of molds, can solve the problems of easy shaking of automobile sheet metal, improper ejection of the ejector unit, etc., and achieve the effects of improving the stamping effect, simple structure, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

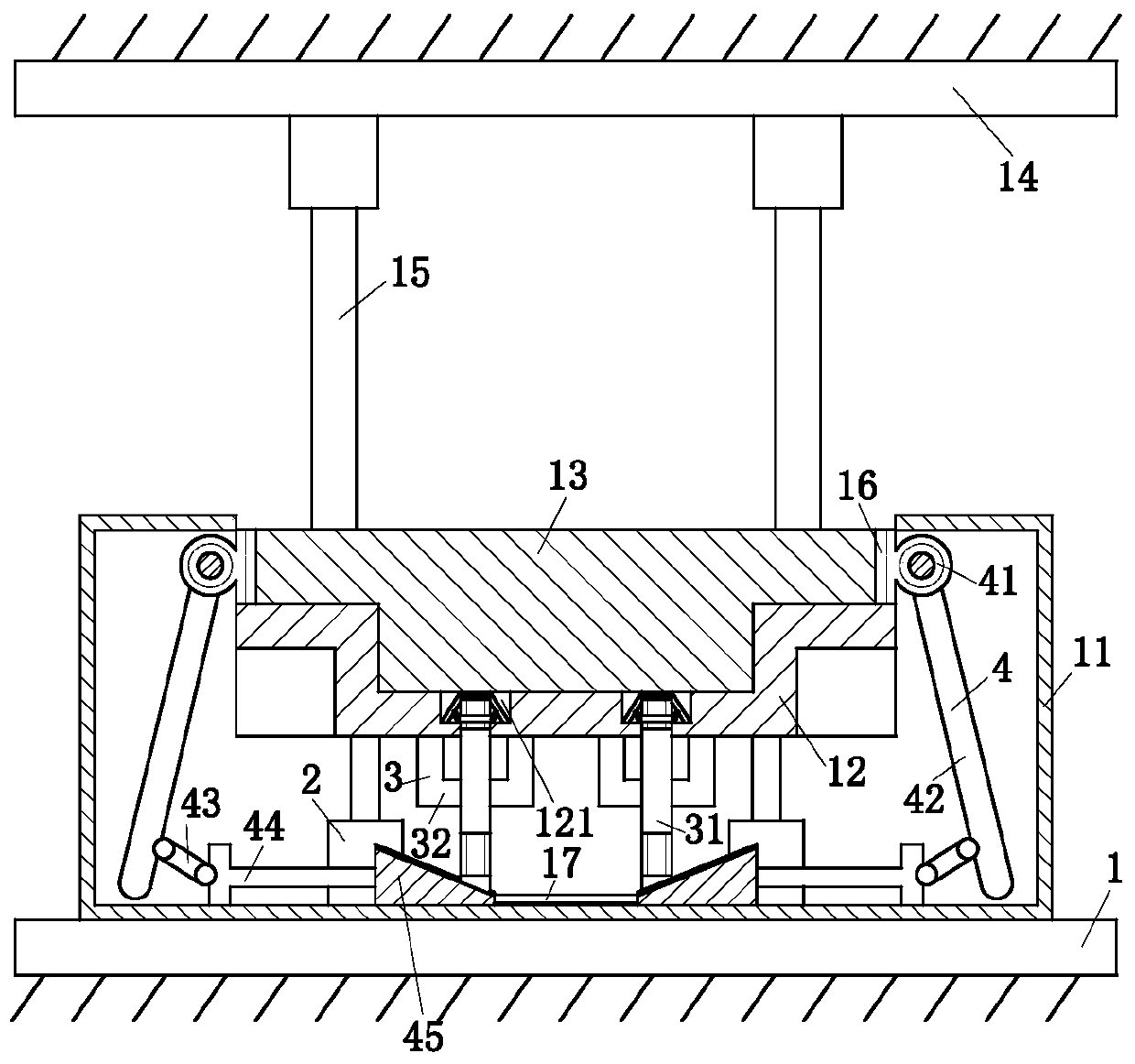

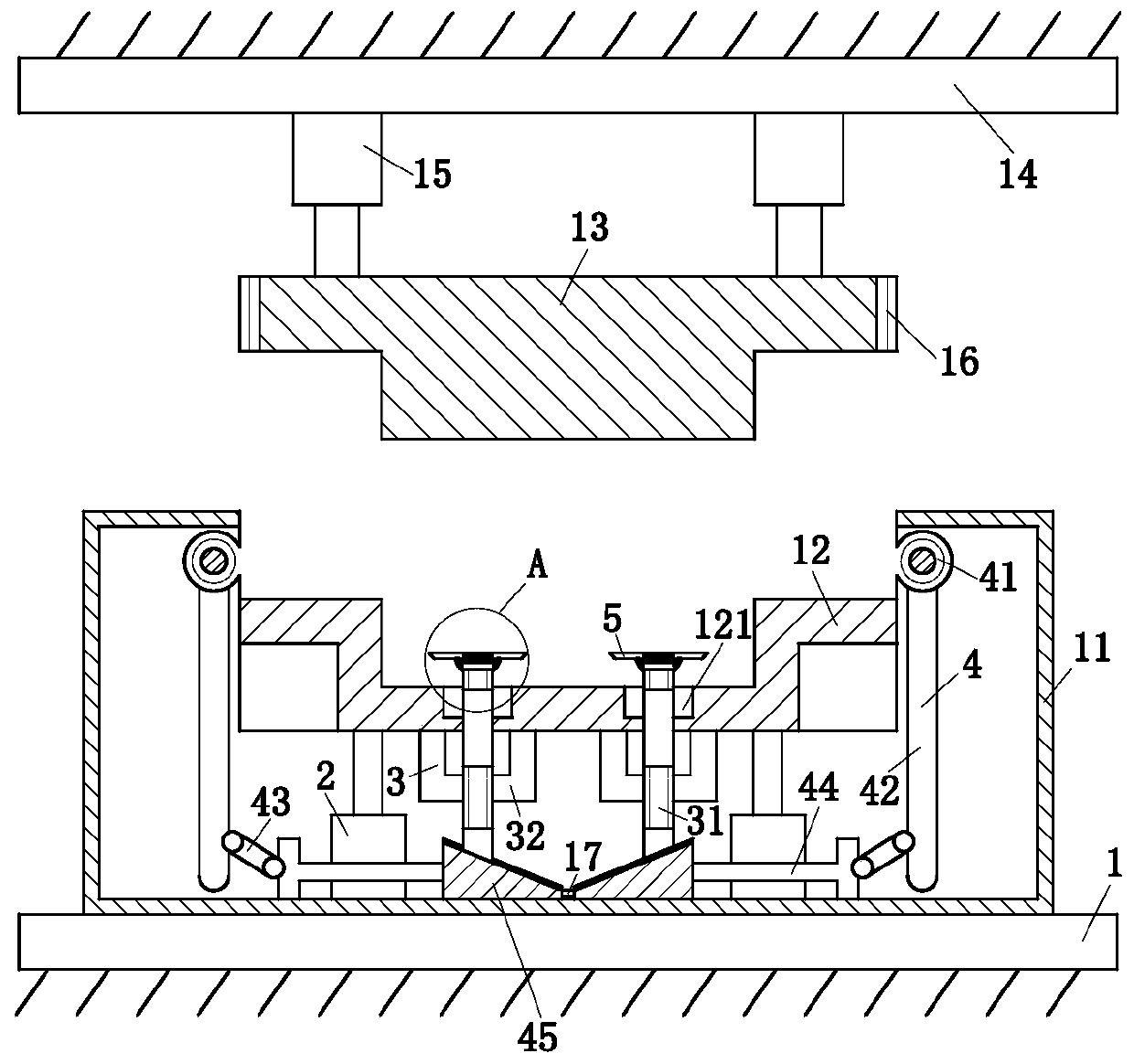

Method used

Image

Examples

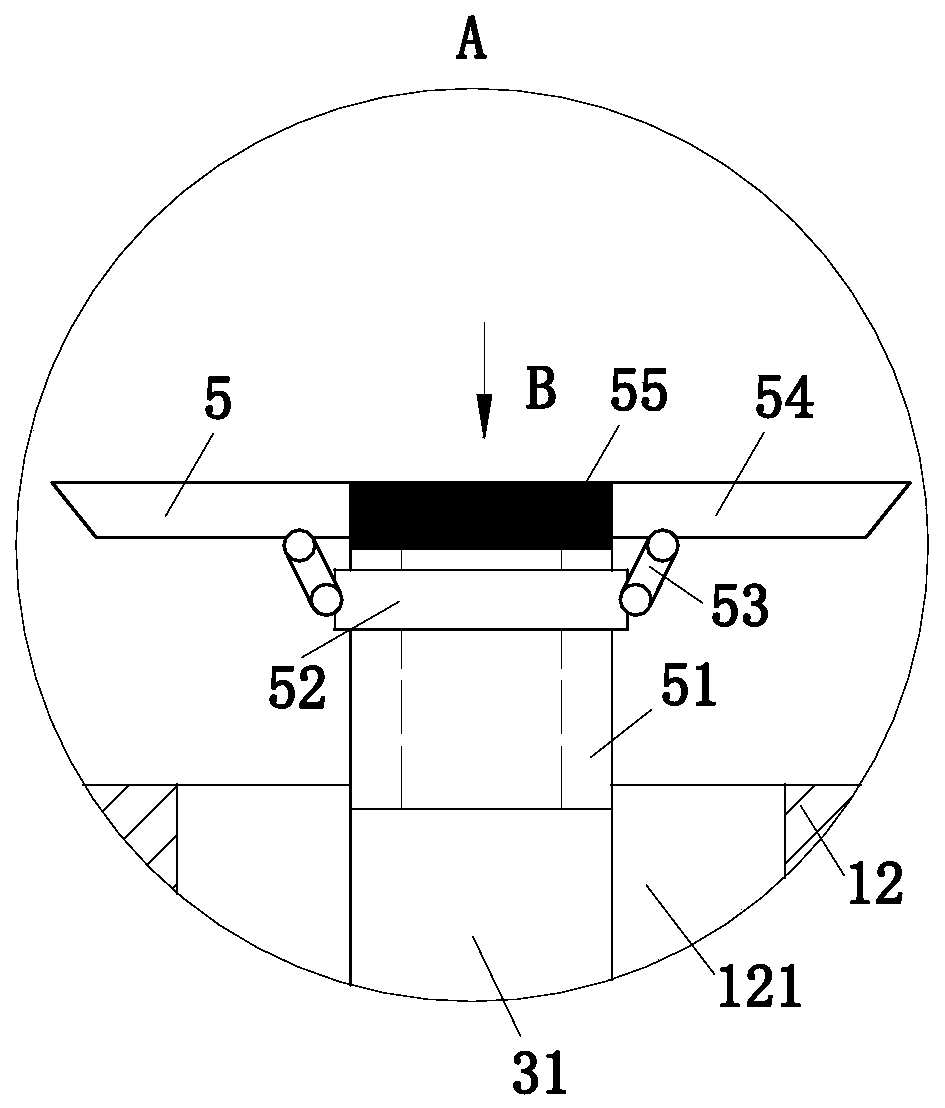

Embodiment approach

[0025] As an embodiment of the present invention, the support unit 2 includes a cylinder body 21, a movable plate 22 and a No. 1 column 23; the cylinder body 21 is fixedly installed on the base 11; the movable plate 22 is located in the cylinder body 21 , one end of the movable plate 22 is fixedly connected to the bottom of the cylinder body 21 through a spring, and the other end is fixedly connected to the No. 1 column 23; the No. 1 column 23 is fixedly connected to the bottom of the lower mold base 12; the middle part of the top column 31 has a No. 1 channel , and the No. 1 channel communicates with the cylinder body 21 through the hose; the gas in the movement of the movable plate 22 is blown from the No. 1 channel to the lower mold base 12, and the lower mold base 12 is cleaned; in the stamping of automobile sheet metal During the process, scraps left by stamping are often attached to the lower mold base 12. If these debris remain on the lower mold base 12, it will affect t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com