Microhole mold for reducing burrs on punching portion

A technology for microporous molds and parts, which is applied in the direction of perforating tools, manufacturing tools, positioning devices, etc., can solve the problems of high requirements for microporous molds and affect product quality, and achieve the goal of reducing burrs, avoiding jumping and offsetting, and reducing burrs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

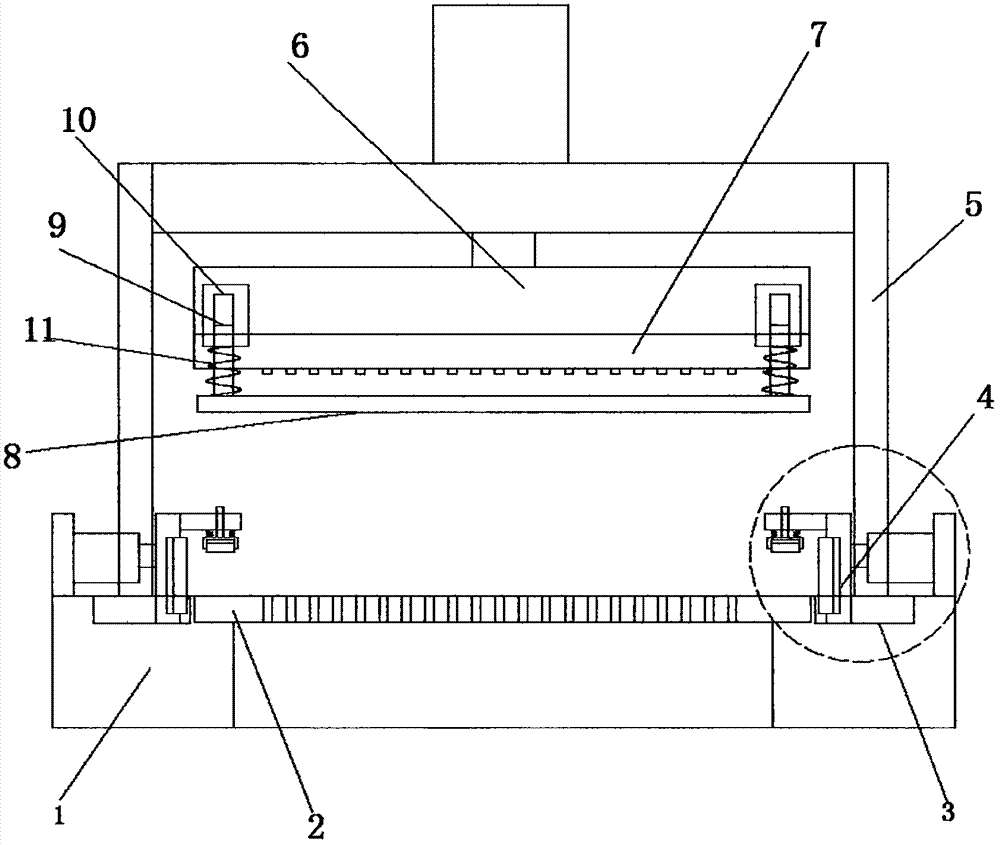

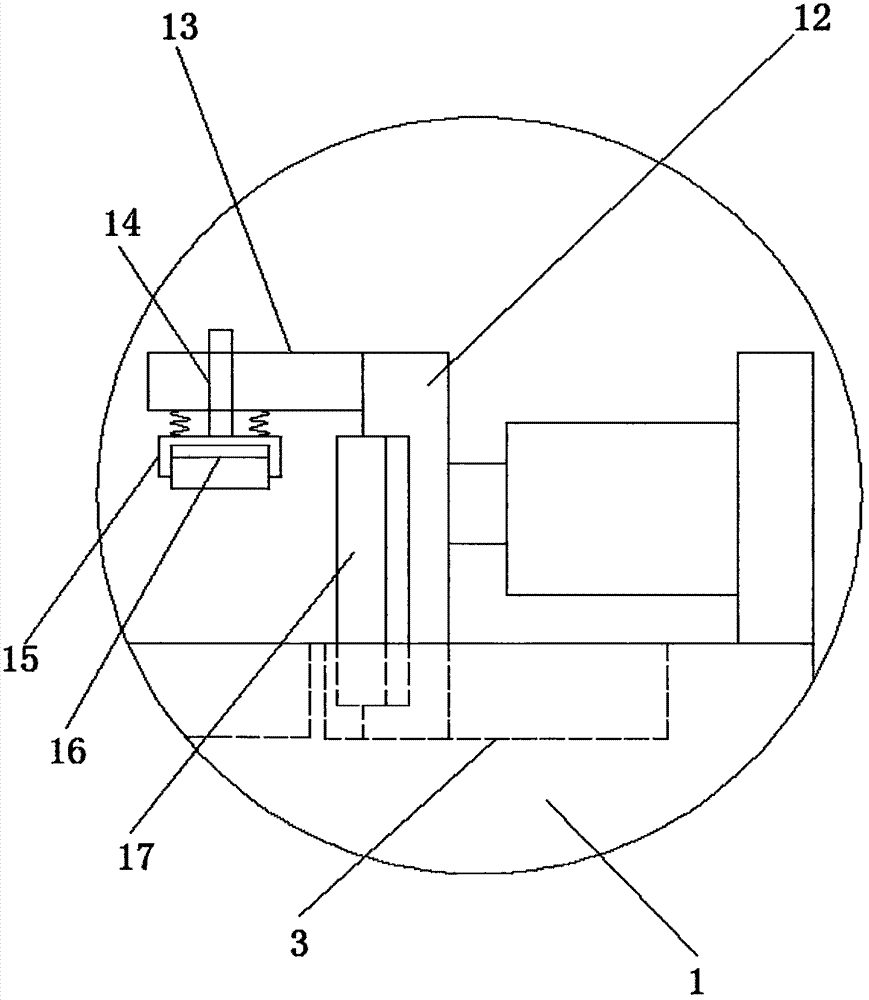

[0017] refer to Figure 1-2 , a microporous die for reducing burrs in punching parts, comprising a base 1, a stamping lower die 2 is installed on the top of the base 1, and both sides of the stamping lower die 2 are provided with elongated chutes 3 on the upper surface of the base 1, The chute 3 is slidingly installed with a pressing mechanism 4, the bottom of the base 1 is equipped with a bracket 5, and the side of the bracket 5 close to the base 1 is equipped with an upper mold mounting plate 6 parallel to the base 1, and the upper mold mounting plate 6 is close to the base 1. A stamping upper die 7 is installed on one side, and a pressing plate 8 arranged parallel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com