Sheet metal stamping device

A stamping device and sheet metal technology, applied in the field of mechanical processing equipment, can solve the problems of easy cracks, low reliability, lack of detection devices, etc., and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

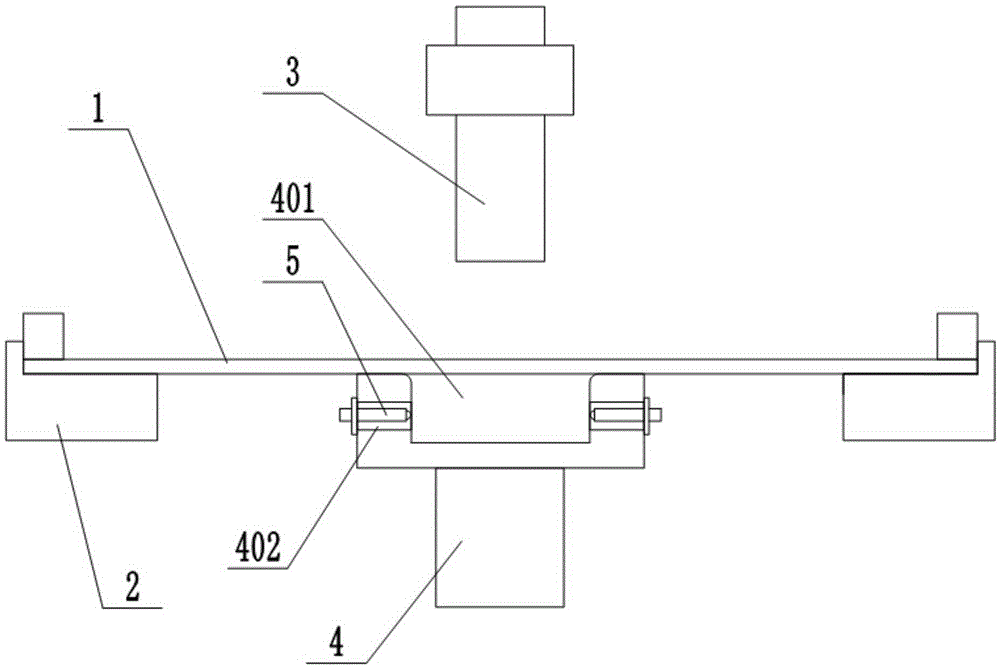

[0011] Such as figure 1 As shown, in the sheet metal stamping device of this embodiment, the sheet metal part 1 is horizontally mounted on the stamping support base 2, the upper part of which is the stamping head 3, the lower part of which is mounted the stamping die 4, and the stamping die 4 has a stamping cavity 401. The side of the punching die 4 is provided with an installation through hole 402 communicating with the punching cavity 401, and an ultrasonic crack detection head 5 is installed in the installation through hole 402.

[0012] The invention adopts the ultrasonic crack detection head to detect the sheet metal parts in the stamping process, without the need for later detection, and its reliability is greatly improved compared with the naked eye detection.

[0013] The above-mentioned embodiments are the preferred embodiments of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com