V-shaped part drilling tool with ultrasonic testing function

A drilling tool and ultrasonic technology, applied in the field of mechanical processing equipment, can solve the problems of low efficiency, low processing pass rate, and difficult drilling processing, etc., to facilitate drilling processing, processing management, improve drilling efficiency and The effect of pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

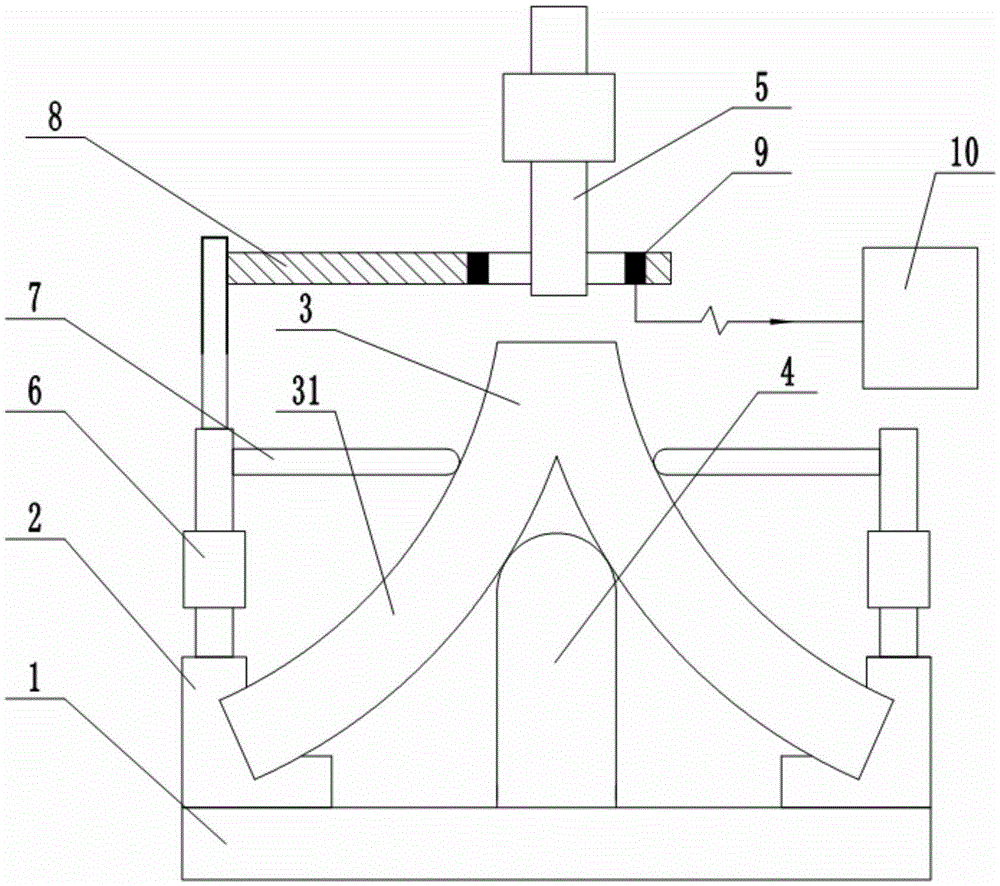

[0011] like figure 1 As shown, the V-shaped piece drilling tool with ultrasonic detection function in this embodiment includes a support base 1, and support bases 2 are symmetrically installed on both ends of the upper surface of the support base 1, and arc-shaped plates 31 at both ends of the V-shaped piece 3 Installed in the support base 2 respectively, the upper surface of the support base 1 has a support column 4 in the middle, and the upper end of the support column 4 abuts against the bifurcated root of the V-shaped piece 3; the upper end of the support base 2 is respectively equipped with a rotating lifting column 6 , the upper end of the rotating lifting column 6 is equipped with a horizontal clamping rod 7, and the end of the clamping rod 7 abuts against the outer surface of the arc plate 31; the upper end of the rotating lifting co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com